Analysis of the Levelized Cost of Renewable Hydrogen in Austria

Abstract

1. Introduction

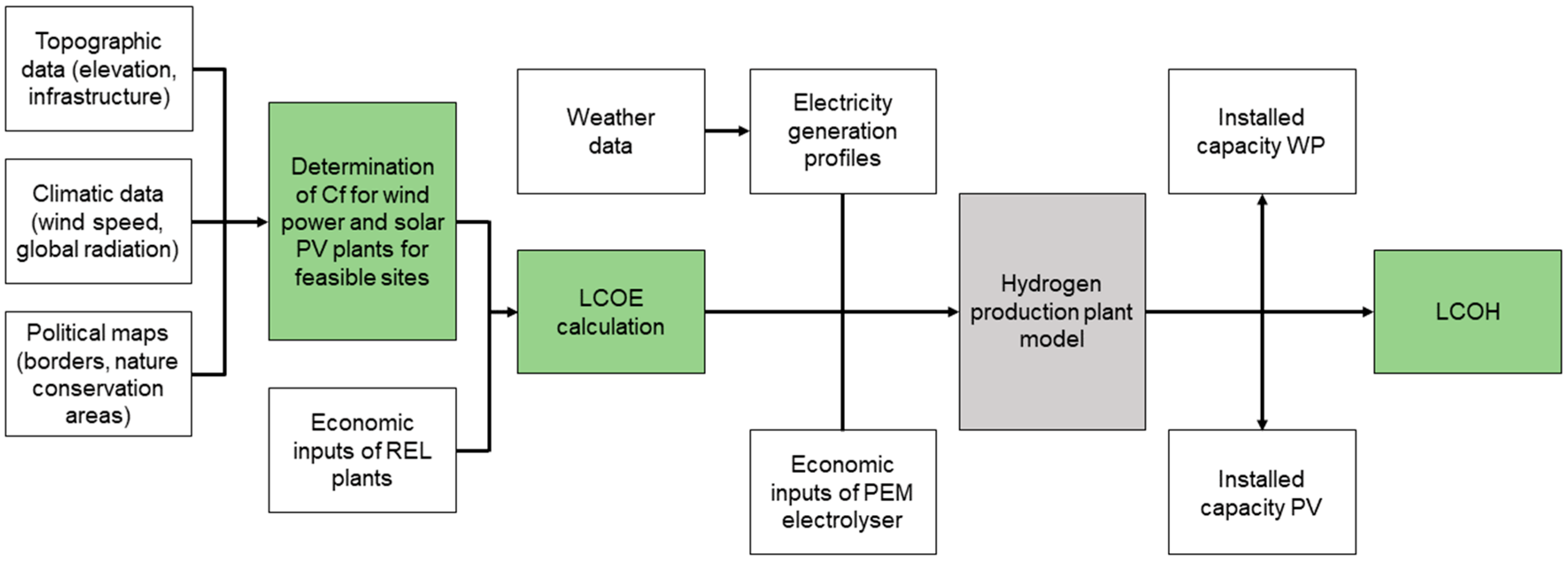

- The determination of the capacity factors (Cf) of WP (Cf-WP) and Cf of PV (Cf-PV) in Austria by conducting a geographic information system (GIS) analysis;

- The analysis of the levelized cost of electricity (LCOE) for these two renewable electricity (REL) sources;

- The analysis of the levelized cost of hydrogen (LCOH) for the predefined system design using electrical feed-in profiles based on real weather data;

- A sensitivity analysis of the techno-economic input parameters for the calculation of the LCOH.

- What is the levelized cost of renewable hydrogen in Austria given the proposed system design?

- What are the levelized costs of electricity for WP and PV in Austria and how are the qualities of sites distributed throughout the country?

- How do changes in techno-economic input parameters affect the cost for renewable hydrogen?

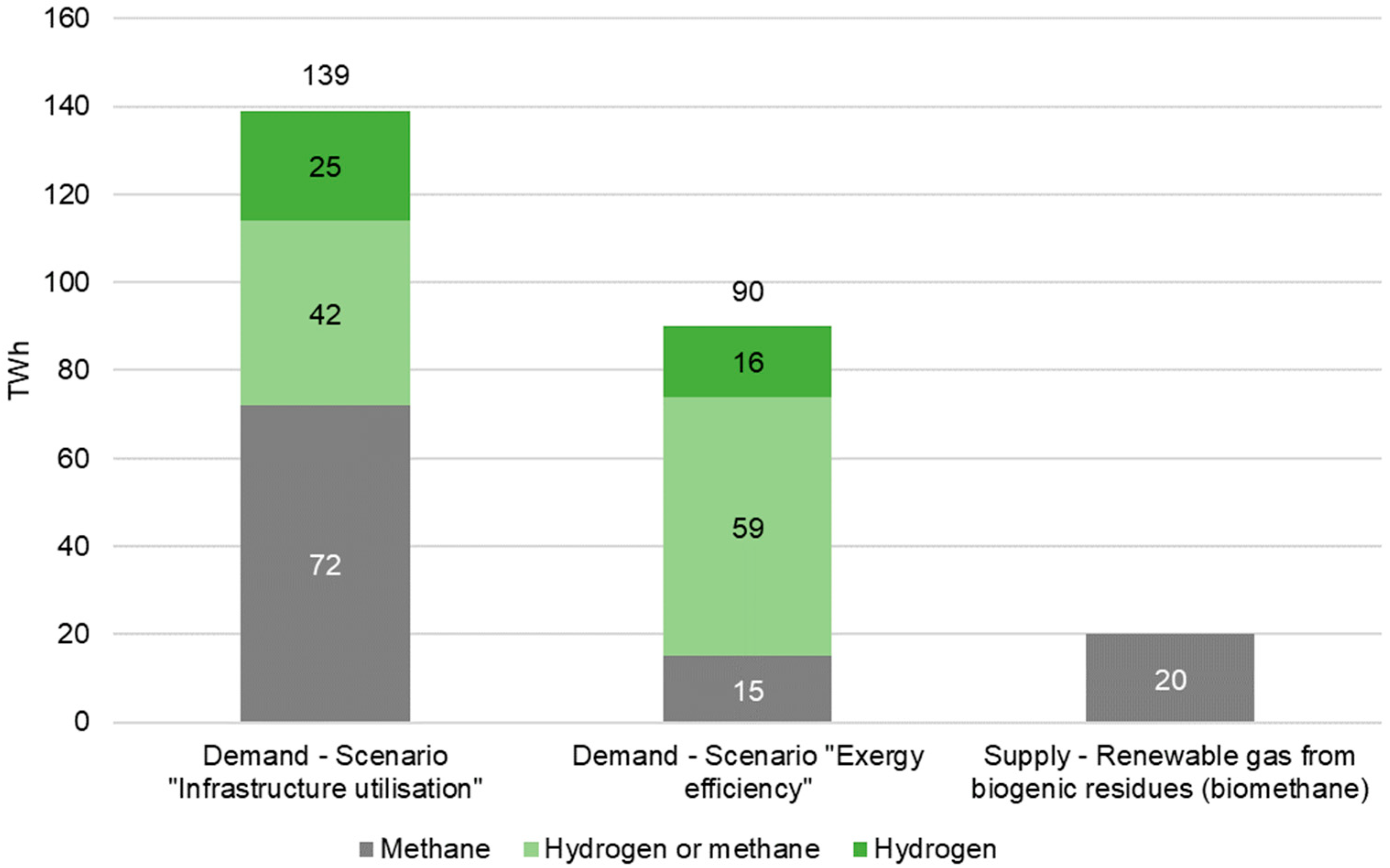

1.1. Hydrogen Prospects in Austria and the European Union

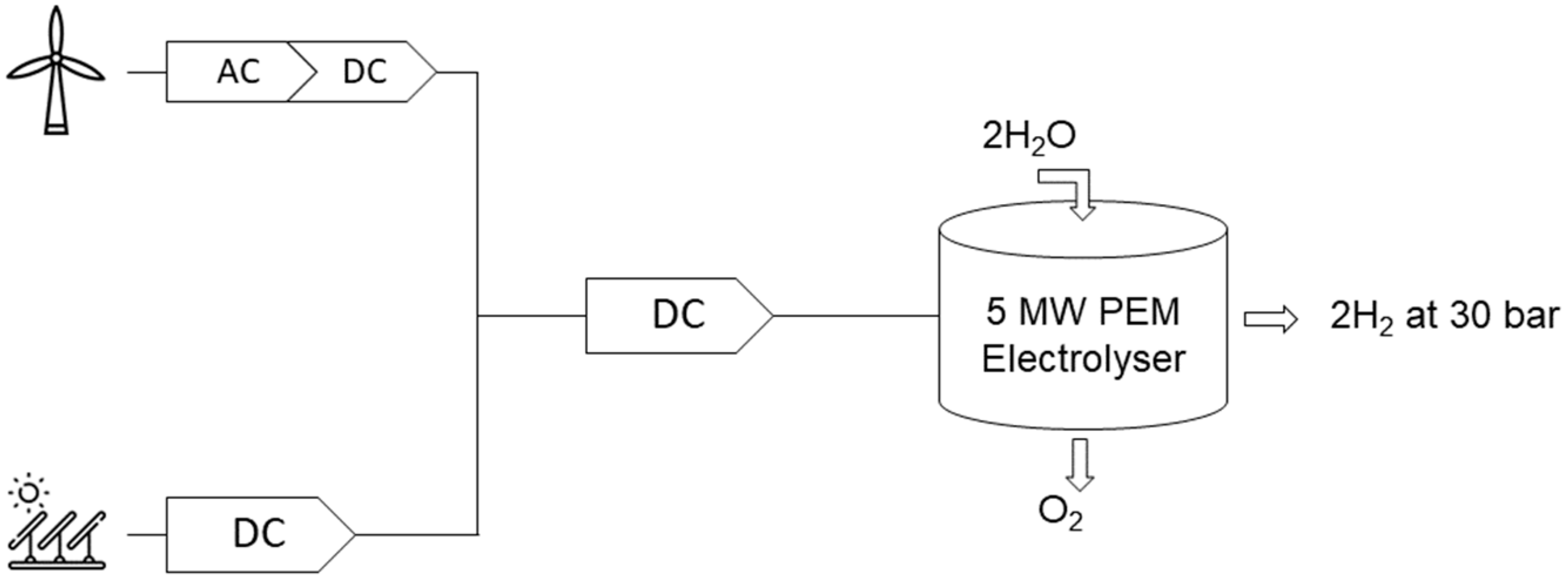

1.2. Definition of Renewable Hydrogen and the Followed System Design

- Direct coupling: “the installations generating renewable electricity are connected to the installation producing renewable liquid and gaseous transport fuel of non-biological origin via a direct line, or the renewable electricity production and production of renewable liquid and gaseous transport fuel of non-biological origin take place within the same installation” [22];

- Additionality: “the installations generating renewable electricity came into operation not earlier than 36 months before the installation producing renewable liquid and gaseous transport fuel of non-biological. Where additional production capacity is added to an existing installation producing renewable liquid and gaseous transport fuel of non-biological origin, the added capacity shall be considered to be part of the existing installation, provided that the capacity is added at the same site and the addition takes place no later than 24 months after the initial installation came into operation” [22];

- No grid connection: “the installation producing electricity is not connected to the grid, or the installation producing electricity is connected to the grid but a smart metering system that measures all electricity flows from the grid shows that no electricity has been taken from the grid to produce renewable liquid and gaseous transport fuel of nonbiological origin” [22].

1.3. Current Research Status

2. Materials and Methods

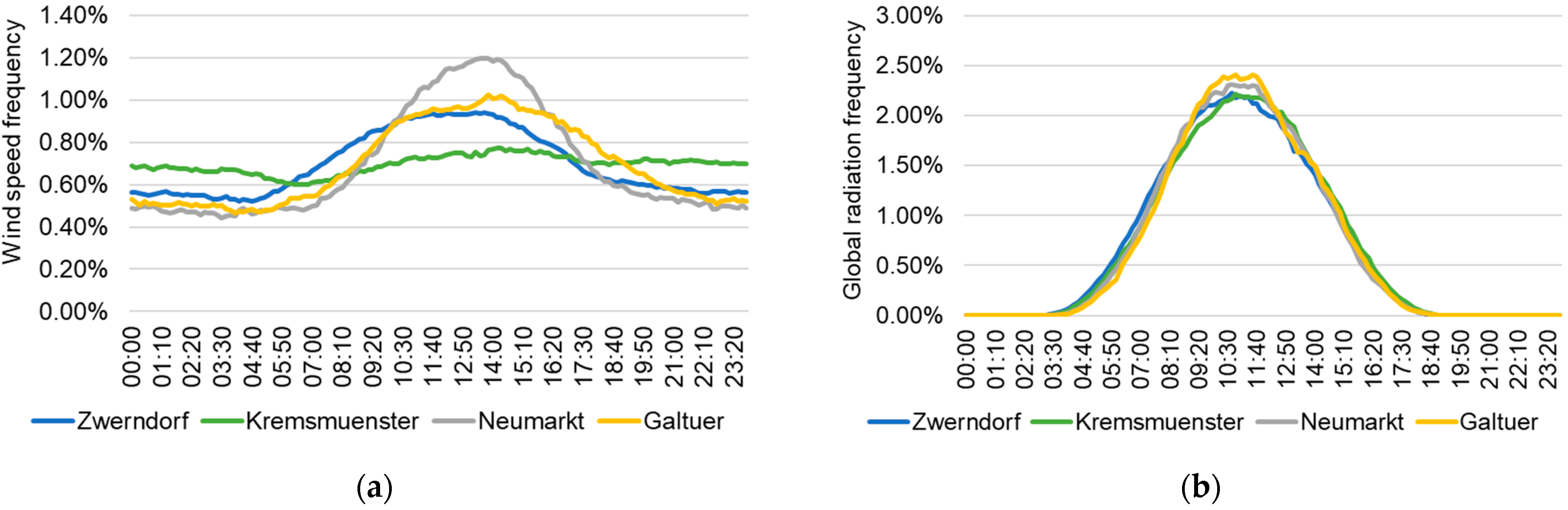

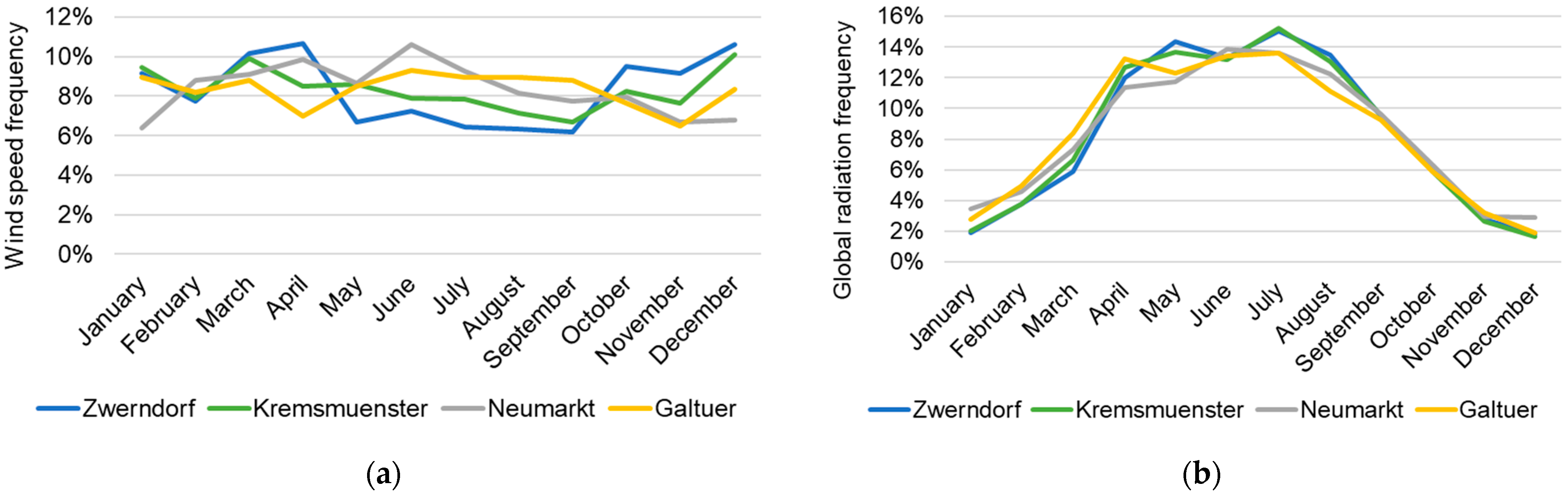

2.1. Cf-WP for Selected Sites

2.2. Cf-PV for Selected Sites

2.3. LCOE for WP and PV in Austria

2.4. Generation Profiles of WP and PV

2.5. Calculation of the LCOH

3. Results & Discussion

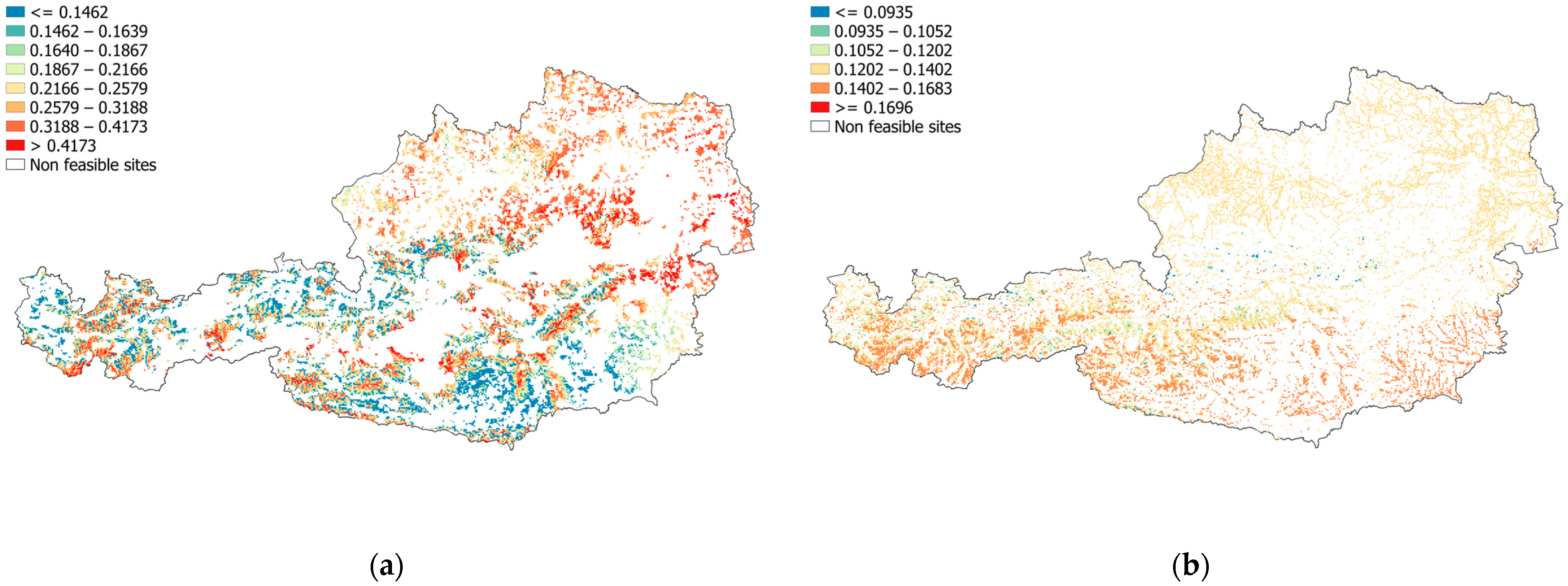

3.1. Spatial Distribution of the REL-Cf

- White: non-feasible sites according to applied criteria

- Colored (blue to red): lowest to highest Cf-estimates

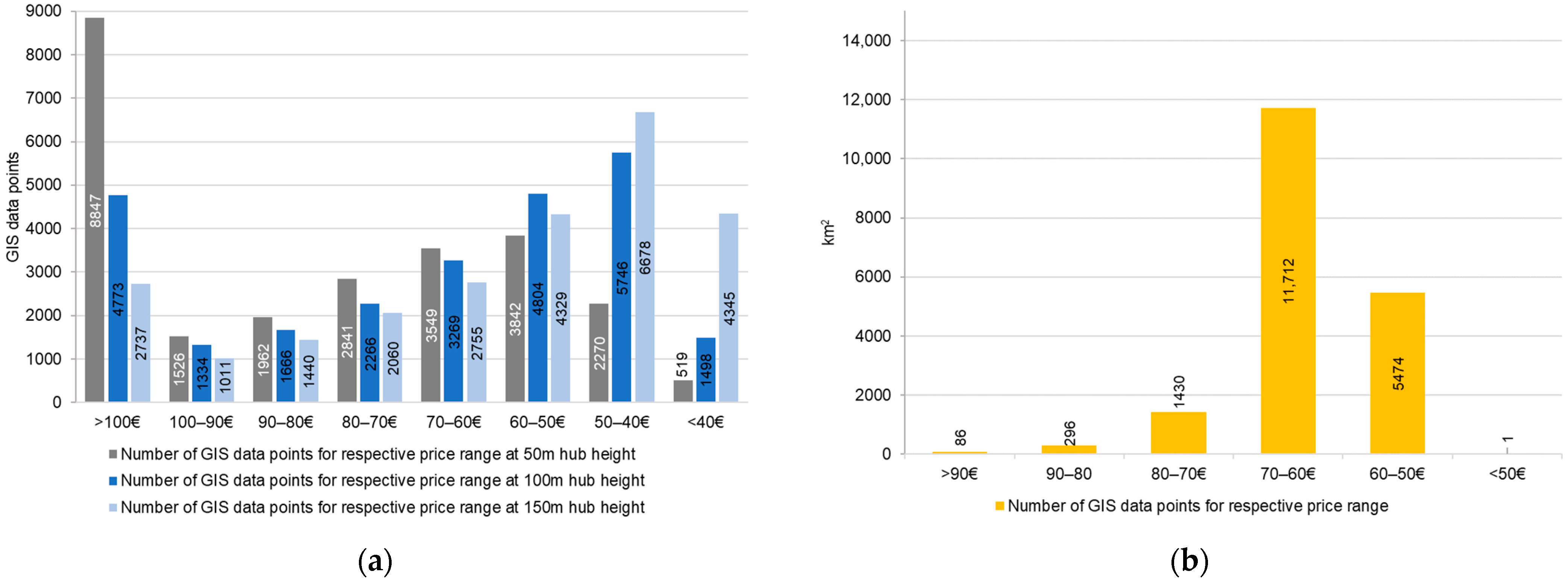

3.2. Analysis of the LCOE for WP and PV in Austria

3.2.1. LCOE for WP in Austria

3.2.2. LCOE for PV in Austria

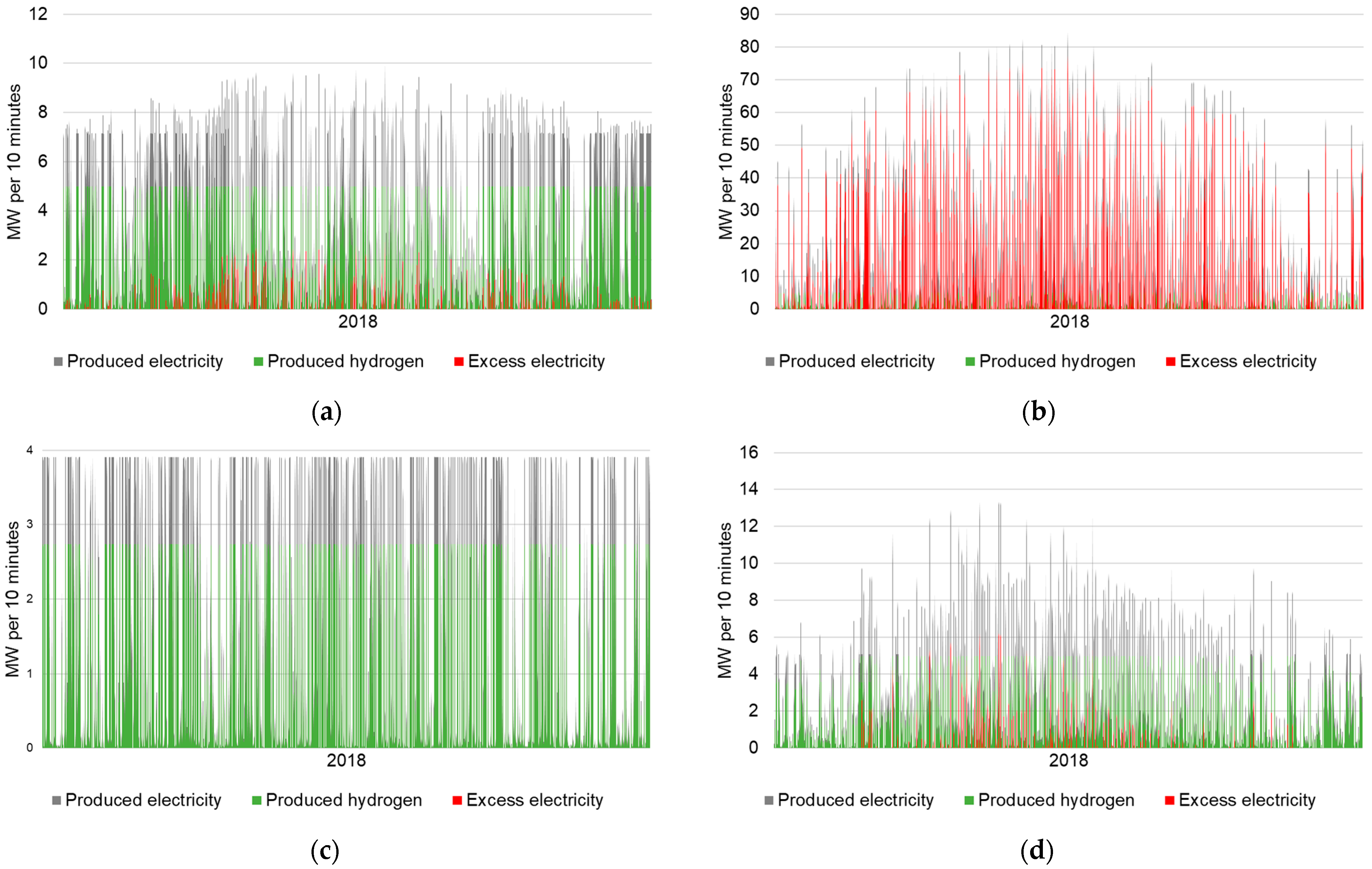

3.3. Analysis of the LCOH

3.3.1. Impact of the EGP, the REL-CF and the PEM-FLH on the LCOH

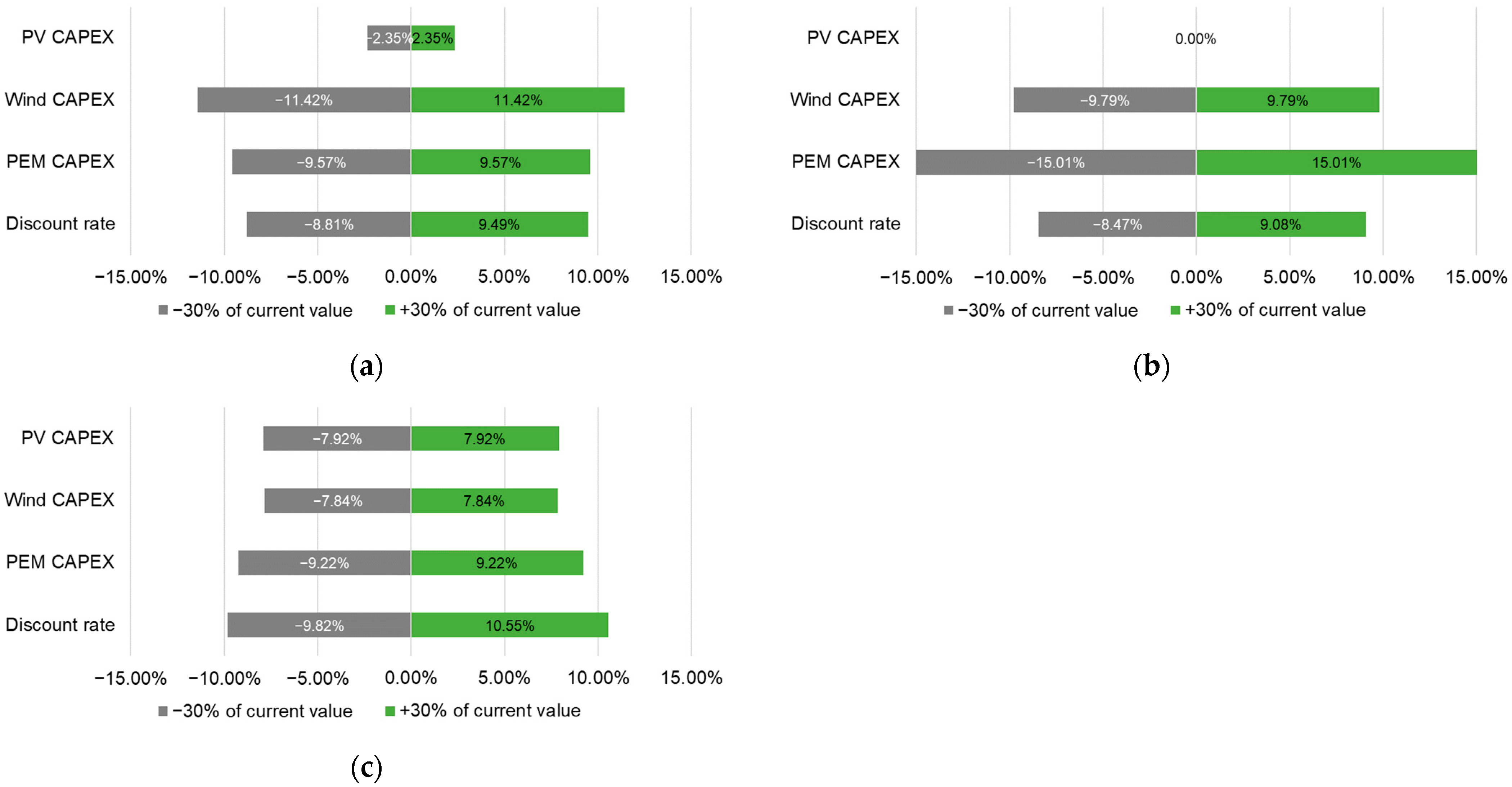

3.3.2. Sensitivities of the Economic Input Parameters

4. Conclusions

5. Need for Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Cf | capacity factor |

| Cf-PV | capacity factor of solar photovoltaics |

| Cf-WP | capacity factor of wind power |

| EAG | Renewable Energy Expansion Act of Austria |

| EC | European Commission |

| EGP | electricity generation profile |

| EU | European Union |

| GIS | geographic information system |

| LCOE | levelized cost of electricity |

| LCOH | levelized cost of hydrogen |

| PEM | proton exchange membrane |

| PEM-FLH | full load hours of the proton exchange membrane electrolyzer |

| PV | solar photovoltaics |

| REL | renewable electricity |

| REL-Cf | capacity factors of the renewable electricity sources |

| WP | wind power |

References

- Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie. Wasserstoffstrategie für Österreich; Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Vienna, Austria, 2022; p. 60. [Google Scholar]

- European Commission. A Hydrogen Strategy for a Climate-Neutral Europe; European Commission: Brussels, Belgium, 2020.

- Baumann, M.; Fazeni-Fraisl, K.; Kienberger, T.; Nagovnak, P.; Pauritsch, G.; Rosenfeld, D.; Sejkora, C.; Tichler, R. Erneuerbares Gas in Österreich 2040; Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Vienna, Austria, 2021; p. 94. [Google Scholar]

- Lundblad, T.; Taljegard, M.; Johnsson, F. Centralized and decentralized electrolysis-based hydrogen supply systems for road transportation—A modeling study of current and future costs. Int. J. Hydrog. Energy 2023, 48, 4830–4844. [Google Scholar] [CrossRef]

- Hydrogen Council. Path to Hydrogen Competitiveness—A Cost Perspective; Hydrogen Council: Brussels, Belgium, 2020; p. 88. [Google Scholar]

- Bundesministerium für Wirtschaft und Energie (BMWi). Die Nationale Wasserstoffstrategie; Bundesministerium für Wirtschaft und Energie (BMWi): Berlin, Germany, 2020.

- Ministère de la Transition écologique. Stratégie Nationale Pour le Développement de l’hydrogène Décarboné en France; Ministère de la Transition écologique: Paris, France, 2020.

- Government of the Netherlands. Government Strategy on Hydrogen; Government of the Netherlands: Amsterdam, The Netherlands, 2020.

- Ministero dello sviluppo economico. Strategia Nazionale Idrogeno Linee Guida Preliminari; Ministero dello sviluppo economico: Rome, Italy, 2020. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions—A Green Deal Industrial Plan for the Net-Zero Age; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- Weltenergierat. International Hydrogen Strategies. Available online: https://www.weltenergierat.de/publikationen/studien/international-hydrogen-strategies/ (accessed on 7 September 2022).

- Ewa, M. Polish Hydrogen Strategy until 2030 with a Perspective until 2040—Project. 2021. Available online: https://www.gov.pl/web/klimat/rozpoczely-sie-konsultacje-publiczne-projektu-polskiej-strategiiwodorowej (accessed on 15 February 2021).

- Gawlik, L.; Mokrzycki, E. Analysis of the Polish Hydrogen Strategy in the Context of the EU’s Strategic Documents on Hydrogen. Energies 2021, 14, 6382. [Google Scholar] [CrossRef]

- Westphal, K.; Dröge, S.; Geden, O.; Stiftung Wissenschaft Und Politik. The International Dimensions of Germany’s Hydrogen Policy. SWP Comment. 2020. Available online: https://www.swp-berlin.org/10.18449/2020C32/ (accessed on 20 March 2022).

- Department for Business, Energy & Industrial Strategy. UK Hydrogen Strategy; Dandy Booksellers Ltd.: London, UK, 2021; ISBN 978-1-5286-2670-5. [Google Scholar]

- Pastore, L.M.; Lo Basso, G.; Sforzini, M.; de Santoli, L. Technical, economic and environmental issues related to electrolysers capacity targets according to the Italian Hydrogen Strategy: A critical analysis. Renew. Sustain. Energy Rev. 2022, 166, 112685. [Google Scholar] [CrossRef]

- Department of the Environment, Climate and Communications. Consultation on Developing a Hydrogen Strategy for Ireland; Department of the Environment, Climate and Communications: Cavan, UK, 2022.

- De Tommasi, L.; Lyons, P. Towards the Integration of Flexible Green Hydrogen Demand and Production in Ireland: Opportunities, Barriers, and Recommendations. Energies 2022, 16, 352. [Google Scholar] [CrossRef]

- van Rossum, R.; Jens, J.; La Guardia, G.; Wang, A.; Kühnen, L.; Overgaag, M. European Hydrogen Backbone—A European Hydrogen Infrastructure Vision Covering 28 Countries. Tech. Rep. 2022. Available online: https://gasforclimate2050.eu/wp-content/uploads/2022/04/EHB-A-European-hydrogen-infrastructure-vision-covering-28-countries.pdf (accessed on 20 March 2022).

- Hebling, C.; Ragwitz, M.; Fleiter, T.; Groos, U.; Härle, D.; Held, A.; Jahn, M.; Müller, N.; Pfeifer, T.; Plötz, P.; et al. Eine Wasserstoff-Roadmap für Deutschland; Fraunhofer-Institut für System-und Innovationsforschung ISI: Karlsruhe, Germany, 2019; p. 51. [Google Scholar]

- Frontier Economics. Grundlage für die Positionierung zu Wasserstoff—Bericht für OesterreichsEnergie; OesterreichsEnergie: Wien, Vienna, 2021. [Google Scholar]

- European Commission. Production of Renewable Transport Fuels—Share of Renewable Electricity (Requirements); European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Bundesgesetz über den Ausbau von Energie aus Erneuerbaren Quellen (Erneuerbaren-Ausbau-Gesetz—EAG). 2022. Available online: https://www.ris.bka.gv.at/GeltendeFassung.wxe?Abfrage=Bundesnormen&Gesetzesnummer=20011619 (accessed on 4 September 2022).

- Fuchs, M. Wasserkraftpotenzialstudie Österreich Aktualisierung 2018; Pöyry: Helsinki, Finland, 2018. [Google Scholar]

- Tremel, A. Electricity-Based Fuels; SpringerBriefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-72458-4. [Google Scholar]

- Department for Business, Energy & Industrial Strategy. Hydrogen Production Costs 2021; GOV.UK: London, UK, 2021; p. 36.

- Zhou, Y.; Searle, S. Cost of Renewable Hydrogen Produced Onsite at Hydrogen Refueling Stations in Europe. 2022. Available online: https://theicct.org/wp-content/uploads/2022/02/fuels-eu-cost-renew-H-produced-onsite-H-refueling-stations-europe-feb22.pdf (accessed on 1 September 2022).

- Prognos; Öko-Institut; Wuppertal Institut. Klimaneutrales Deutschland 2045—Wie Deutschland seine Klimaziele schon vor 2050 erreichen kann—Langfassung im Auftrag von Stiftung Klimaneutralität, Agora Energiewende und Agora Verkehrswende. p. 120. Available online: https://www.agora-verkehrswende.de/veroeffentlichungen/klimaneutrales-deutschland-2045-langfassung/#:~:text=Ein%20klimaneutral-es%20Deutschland%20ist%20bereits,Leitmarkt%20und%20Leitanbieter%20f%C3%BCr%20Klimaschutztechnologien (accessed on 2 September 2022).

- Prognos, A.G. Kosten und Transformationspfade für strombasierte Energieträger; Bundesministeriums für Wirtschaft und Energie: Berlin, Germany, 2020; p. 107. [Google Scholar]

- IEA. The Future of Hydrogen—Seizing Today’s Opportunities. Rep. Prep. Int. Energy Agency G20 Jpn. 2019. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 22 August 2022).

- Schoehuijs, T. Direct Coupling Feasibility Evaluation—Predicting the Price of Hydrogen Produced by Solar Energy; Delft University of Technology: Delft, The Netherlands, 2018. [Google Scholar]

- Tang, O.; Rehme, J.; Cerin, P. Levelized cost of hydrogen for refueling stations with solar PV and wind in Sweden: On-grid or off-grid? Energy 2022, 241, 122906. [Google Scholar] [CrossRef]

- Bhandari, R.; Shah, R.R. Hydrogen as energy carrier: Techno-economic assessment of decentralized hydrogen production in Germany. Renew. Energy 2021, 177, 915–931. [Google Scholar] [CrossRef]

- Janssen, J.L.L.C.C.; Weeda, M.; Detz, R.J.; van der Zwaan, B. Country-specific cost projections for renewable hydrogen production through off-grid electricity systems. Appl. Energy 2022, 309, 118398. [Google Scholar] [CrossRef]

- Bundesministerium für Finanzen. Digitales Geländemodell (DGM) Österreich. Available online: https://www.data.gv.at/katalog/dataset/dgm (accessed on 13 March 2022).

- European Environment Agency. Copernicus Land Monitoring Service—EU-DEM—European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/data/copernicus-land-monitoring-service-eu-dem (accessed on 13 March 2022).

- Geofabrik GMBh. OpenStreetMap Data for Austria. Available online: https://download.geofabrik.de/europe/austria.html (accessed on 13 March 2022).

- Copernicus. CORINE Land Cover—Copernicus Land Monitoring Service. Available online: https://land.copernicus.eu/pan-european/corine-land-cover (accessed on 10 August 2022).

- Technical University of Denmark (DTU). Global Wind Atlas 3.0, a Free, Web-Based Application Developed, Owned and Operated by the Technical University of Denmark (DTU). The Global Wind Atlas 3.0 Is Released in Partnership with the World Bank Group, Utilizing Data Provided by Vortex, Using Funding Provided by the Energy Sector Management Assistance Program (ESMAP). Available online: https://globalwindatlas.info (accessed on 3 August 2021).

- Global Solar Atlas. Available online: https://globalsolaratlas.info (accessed on 20 March 2022).

- Copernicus. CLC 2018—Copernicus Land Monitoring Service. Available online: https://land.copernicus.eu/pan-european/corine-land-cover/clc2018 (accessed on 13 March 2022).

- European Environment Agency. Natura 2000 End 2020—Shapefile—European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/data/natura-12/natura-2000-spatial-data/natura-2000-shapefile-1 (accessed on 13 March 2022).

- European Environment Agency. Nationally Designated Areas (CDDA)—European Environment Agency. Available online: https://www.eea.europa.eu/data-and-maps/data/nationally-designated-areas-national-cdda-16 (accessed on 13 March 2022).

- Kost, C.; Shammugam, S.; Fluri, V.; Peper, D.; Memar, A.D.; Schlegl, T. Stromgestehungskosten Erneuerbare Energien; Fraunhofer-Institute for Solar Energy Systems ISE: Freiburg, Germany, 2021; p. 49. [Google Scholar]

- Cost of Capital Study 2021—Sustainability vs. Return ESG as a Key Driver for Long-Term Performance? KPMG AG Wirtschaftsprüfungsgesellschaft: Amstelveen, The Netherlands, 2021; p. 56.

- IRENA. Renewable Power Generation Costs in 2020; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021; p. 180. [Google Scholar]

- Chan, A.; Hart, D.; Lehner, F.; Madden, B.; Standen, E.; Bertuccioli, L. Development of Water Electrolysis in the European Union. 2014. Available online: https://www.h2knowledgecentre.com/content/researchpaper1120 (accessed on 13 July 2022).

- Glenk, G.; Reichelstein, S. Economics of converting renewable power to hydrogen. Nat. Energy 2019, 4, 216–222. [Google Scholar] [CrossRef]

- Smolinka, T.; Aschbrenner, S.; Marius, H.; Voglstätter, C.; Grimm, G. Cost Forecast for Low-Temperature Electrolysis—Technology Driven Bottom-Up Prognosis for PEM and Alkaline Water Electrolysis Systems. 2021. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/cost-forecast-for-low-temperature-electrolysis.pdf (accessed on 28 June 2022).

- Bareiß, K.; de la Rua, C.; Möckl, M.; Hamacher, T. Life cycle assessment of hydrogen from proton exchange membrane water electrolysis in future energy systems. Appl. Energy 2019, 237, 862–872. [Google Scholar] [CrossRef]

- Zentralanstalt für Meteorologie und Geodynamik (ZAMG). ZAMG Data Hub. Available online: https://data.hub.zamg.ac.at/ (accessed on 21 July 2022).

- IG Windkraft—Austrian Wind Energy Association. Windfakten—Abstandsregelung. Available online: https://windfakten.at/?xmlval_ID_KEY[0]=1240 (accessed on 13 March 2022).

- ENERCON GmbH. ENERCON Product Overview. 2015. Available online: https://www.wind-turbine-models.com/turbines/832-enercon-e-115-3.000 (accessed on 13 March 2022).

- International Electrotechnical Commission. IEC 61400-12-1:2017—Wind Energy Generation Systems—Part 12-1: Power Performance Measurements of Electricity Producing Wind Turbines; International Electrotechnical Commission: Geneva, Switzerland, 2017. [Google Scholar]

- Fechner, H. Ermittlung des Flächenpotentials für den Photovoltaik-Ausbau in Österreich: Welche Flächenkategorien sind für die Erschließung von besonderer Bedeutung, um das Ökostromziel realisieren zu können. ÖsterreichsEnergie. 2020. Available online: https://oesterreichsenergie.at/fileadmin/user_upload/Oesterreichs_Energie/Publikationsdatenbank/Studien/2020/PV-Studie_2020.pdf (accessed on 20 March 2022).

- Konstantin, P. Praxisbuch Energiewirtschaft; Springer: Berlin/Heidelberg, Gernamy, 2017; ISBN 978-3-662-49822-4. [Google Scholar]

- Hau, E.; von Renouard, H. (Eds.) The Wind Resource. In Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer: Berlin/Heidelberg, Gernamy, 2006; pp. 451–483. ISBN 978-3-540-29284-5. [Google Scholar]

- Hau, E.; von Renouard, H. (Eds.) Power Output and Energy Yield. In Wind Turbines: Fundamentals, Technologies, Application, Economics; Springer: Berlin/Heidelberg, Gernamy, 2006; pp. 485–532. ISBN 978-3-540-29284-5. [Google Scholar]

- Fuernsinn, B.; Wonisch, P.; Krenn, A. IEA Wind TCP 2020 Annual Report. 2022. Available online: https://www.seai.ie/publications/IEA_Wind_Annual_Report_2020.pdf (accessed on 30 August 2022).

- Sens, L.; Neuling, U.; Kaltschmitt, M. Capital expenditure and levelized cost of electricity of photovoltaic plants and wind turbines—Development by 2050. Renew. Energy 2022, 185, 525–537. [Google Scholar] [CrossRef]

- Fuel Cells and Hydrogen Observatory Levelised Cost of Hydrogen|FCHObservatory. Available online: https://www.fchobservatory.eu/observatory/technology-and-market/levelised-cost-of-hydrogen-green-hydrogen-costs (accessed on 1 September 2022).

- AIT Austrian Institute of Technology GmbH. Gutachten—Referenzkosten Photovoltaik—Gemäß Verordnung EU Nr. 651/2014; OeMAG Abwicklungsstelle für Ökostrom AG: Vienna, Austria, 2021; p. 12. [Google Scholar]

- Hinkley, J.; Hayward, J.; McNaughton, R.; Gillespie, R.; Matsumoto, A.; Watt, M.; Lovegrove, K. Cost Assessment of Hydrogen Production from PV and Electrolysis; CSIRO: Canberra, Australia, 2016; p. 44. [Google Scholar]

| Author | System Design/ Assumptions | Economic Input Parameters | Region/Year | LCOH in EUR/kg | Source |

|---|---|---|---|---|---|

| UK.GOV BEIS (2021) | Lifetime 30 years; electrolyzer capacity 10 MW; off-grid; REL-source wind offshore with Cf of 51% 2025; compression and storage cost excluded | Costs for electrolyzer for offshore system not specified | UK/2025 | 5.13 | [26] |

| ICCT (2022) | Lifetime 60,000 h; electrolyzer capacity 1 MW; grid-connected, Cf-PEM of 95%; 30 bar at nozzle; electrolyzer efficiency 56% | Electricity cost country specific; electrolyzer CAPEX 1005 EUR/kW; WACC country specific; electrolyzer efficiency 56% | EU average/2020 | 5–6 | [27] |

| Prognos et al. (2021) | Lifetime 25 years; FLH electrolyzer 3500 h; grid-connected; electrolyzer efficiency 72% | Electricity cost 62 EUR/MWh; electrolyzer CAPEX 500 EUR/kW; WACC 6%; stack replacement after 12.5 years with costs of 35% of CAPEX | Germany/2020 | 5 | [28] |

| Frontier economics (2021) | Lifetime 20 years; off-grid; Cf-W 26.25% and Cf-PV 10.73%; electrolyzer efficiency 70% | Electrolyzer CAPEX 700 EUR/kW; electrolyzer OPEX fix 1.5% of CAPEX/year; | Austria/2030 | 3.57–6.57 | [21] |

| Prognos (2019) | FLH electrolyzer 5000 h; grid-connected; REL-source WP and PV 54 to 75 EUR/MWh; including transport and storage | WACC 10%; 48% of LCOH is electricity, 27% of LCOH is CAPEX, 8% of LCOH is OPEX; minor share of LCOH are water costs | Germany/2020 | 7 | [29] |

| IEA (2019) 1 | FLH electrolyzer 4000 h; grid-connected | Electricity cost 35.71 EUR/MWh | EU average/2030 | 1.8–3.6 | [30] |

| Schoehuijs (2020) | Lifetime 20 years; off-grid; REL-source PV with Cf of 26.26%; storage included | Electrolyzer CAPEX 700 EUR/kW, OPEX fix 4% of initial CAPEX/year; WACC 4% | Netherlands/2018 | 3.35 | [31] |

| Tang et al. (2022) | Lifetime 20 years; PEM electrolyzer with installed capacity 270 kW; off-grid REL-system with PV and WP each 250 kW directly coupled; Cf-PV 10.51% to 11.24%; Cf-WP 11.57% to 50.71%; hydrogen production is 47,000 kg/year; storage unit with 1900 kg H2 capacity; including storage | PEM CAPEX 2518 EUR/kW, OPEX 1% of CAPEX/year; Compressor CAPEX 250,000 EUR; CAPEX PV 700 EUR/kW; CAPEX WP 2000 EUR/kW; Storage unit CAPEX 195,000 EUR; WACC 6% | SWE/2020 | 7–15.08 | [32] |

| Bhandari and Shah (2021) | Lifetime 20 years; PEM electrolyzer with capacity of 10 Nm3/h; off-grid PV system with 3.3 MW directly coupled including battery with a size of 9125 kWh; PEM-FLH 8760 h; surplus energy by the PV feeds the batteries; deficit of PV for PEM electrolyzer is supplied by battery | PEM CAPEX 1000 EUR/kW, OPEX 2% of CAPEX/year; stack replacement 420 EUR/kW; stack lifetime 5 years; water cost 3 EUR/m3; PV CAPEX 800 EUR/kWp; PV OPEX 1% of PV CAPEX/year | Germany/2020 | 57.61 | [33] |

| Lundblad et al. (2023) 2 | Lifetime 25 years; off-grid system directly coupled; FLH of the electrolyzer are set to roughly 4000; hydrogen production and storage modelled to meet demand of a hydrogen refueling station; including storage and/or transportation | Electrolyzer efficiency of 65%, CAPEX 900,000 EUR/MW, annual O&M of $% of CAPEX of electrolyzer; CAPEX, annual fixed and variable OPEX of 1,120,000 EUR/MW, 14,000 EUR/MW and 1.5 EUR/MWh for WP; CAPEX and annual fixed O&M of 560,000 EUR/MW and 11,300 EUR/MW for PV; WACC 5% | Sweden/2022 | 6.7 | [4] |

| Janssen et al. (2022) | Lifetime 30 years; off-grid system directly coupled; electrolyzer capacity equals peak output capacity of either WP or PV; FLH of electrolyzer depend on REL-Cf; installed capacity of WP and PV are equal in hybrid system; Cf-WP 28%; Cf-PV 13.04% | Electrolyzer efficiency of 70%, CAPEX 700,000 EUR/MW, OPEX 30,000 EUR/MW; loan depreciation of 10 years; WACC 5%; CAPEX WP 1,040,000 EUR/MW, OPEX 3%; CAPEX PV 690,000 EUR/MW, OPEX 2% | Austria/2020 | 3.01 | [34] |

| Data Component | Data Usage | Data Source |

|---|---|---|

| Topographic data | Topographic data is used in raster as well as shape format. With its use technically feasible, socially accepted sites for WP and PV, respectively, are determined. The spatial resolution is scaled to 1 km2. | [35,36,37,38] |

| Climatic data | Climatic data is used in raster format. It forms the basis for the calculation of the REL-Cf. The spatial resolution is scaled to 1 km2. | [39,40] |

| Political maps | Political maps are used in shape format. With its use technically feasible, socially accepted sites for WP and PV, respectively, are determined. The resolution is vectorized. | [38,41,42,43] |

| Economic input data | Economic input parameters are used to determine the CAPEX as well as variable and fixed OPEX of the hydrogen production system components. The selection followed by a thorough literature research focused on parameters specifically referring to Austria and, if not available, Western Europe. | [28,44,45,46,47,48,49,50] |

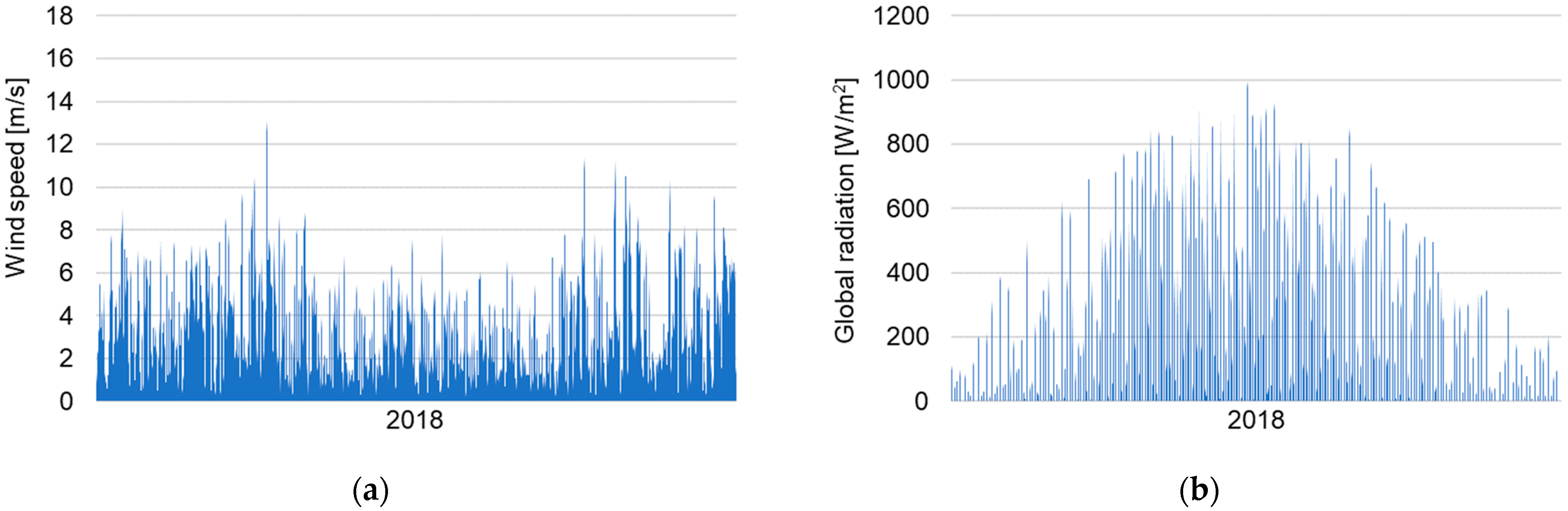

| Weather data | The weather data from real weather stations in Austria forms the basis for the EGP of WP and PV. It has a 10-min granularity. 2018 is chosen as a representative weather year. | [51] |

| Category | Description | GIS Data Source |

|---|---|---|

| Elevation | Areas with a sea level above 2000 m are excluded | [35] |

| Slope | Areas with a slope exceeding 15° are excluded | [36] |

| Infrastructure | Infrastructural networks, including roads, railways and the electrical grid, with a buffer of 200 m along the lines are excluded | [37] |

| Rivers | Areas covered by rivers including a buffer of 200 m are excluded | [37] |

| Settlement areas | Settlement areas with a buffer of 1200 m are excluded | [41] |

| Nature conservation areas | Nature conservation areas, including Natura 2000 and nationally designated areas are excluded | [42,43] |

| Category 1 Areas | Category 2 Areas |

|---|---|

| Industrial or commercial units | Non-irrigated arable land |

| Dump sites | Pastures |

| Natural grasslands | Land principally occupied by agriculture, with significant areas of natural vegetation |

| Parameter | Value | Unit | Source |

|---|---|---|---|

| Nominal investment | 1,400,000 | [EUR/MW] | [44] |

| Fixed O&M | 20,000 | [EUR/MW/a] | [44] |

| Variable O&M | 8 | [EUR/MWh] | [44] |

| Discount rate | 4.9 | [%] | [45] |

| Parameter | Value | Unit | Source |

|---|---|---|---|

| Nominal investment | 804,954 | [EUR/MW] | [46] |

| Fixed O&M | 13,300 | [EUR/MW/a] | [46] |

| Variable O&M | 0 | [EUR/MWh] | |

| Discount rate | 4.9 | [%] | [45] |

| Degradation rate | 0.5 | [%/a] | [56] |

| Name of Weather Station | Longitude [°E] | Latitude [°N] | Weather Station’s Sea Level [m] | Federal State |

|---|---|---|---|---|

| Zwerndorf | 16.83 | 48.34 | 144 | Lower Austria |

| Kremsmuenster | 14.13 | 48.06 | 382 | Upper Austria |

| Neumarkt | 14.42 | 47.07 | 869 | Styria |

| Galtuer | 10.19 | 46.97 | 1587 | Tirol |

| Component | 2020 [EUR/kW] |

|---|---|

| Electrolysis stacks | 294 |

| Power electronics | 195 |

| BoP Cathode + H2 Purification | 76 |

| BoP Anode | 26 |

| H2O Purification | 9 |

| System Cooling | 12 |

| Compression | 0 |

| Piping | 98 |

| Instrumentation | 122 |

| Housing | 19 |

| Engineering | 128 |

| Sum | 978 |

| Parameter | Value | Source |

|---|---|---|

| OPEX fix | 2.2% of initial PEM CAPEX | [47] |

| Costs for water | 0.09 EUR/kg of H2 | [48] |

| Discount rate | 4.9% | [45] |

| Stack lifetime 1 | 8.3 years | [50] |

| Stack replacement cost | 35% of initial PEM CAPEX | [28] |

| Class [EUR/MWh] | Cf-WP [%] |

|---|---|

| >100 | <14.62 |

| 100–90 | 14.62–16.40 |

| 90–80 | 16.40–18.67 |

| 80–70 | 18.67–21.66 |

| 70–60 | 21.66–25.79 |

| 60–50 | 25.79–31.88 |

| 50–40 | 31.88–41.73 |

| <40 | >41.73 |

| Class [EUR/MWh] | Cf-PV [%] |

|---|---|

| >90 | <9.35 |

| 90–80 | 9.35–10.52 |

| 80–70 | 10.52–12.03 |

| 70–60 | 12.03–14.03 |

| 60–50 | 14.03–16.84 |

| <50 | >16.84 |

| REL-Technology | Cf—Lower Step Limit | Cf—Upper Step Limit |

|---|---|---|

| WP | 21.658% | 41.728% |

| REL-Technology | Cf—Lower Step Limit | Cf—Upper Step Limit |

|---|---|---|

| PV | 12.025% | 16.835% |

| Parameter | Lower Step Limit | Upper Step Limit | Unit |

|---|---|---|---|

| PV CAPEX | 563,468 | 1,046,440 | [EUR/MW] |

| Wind CAPEX | 980,000 | 1,820,000 | [EUR/MW] |

| PEM CAPEX 1 | 684,600 | 1,271,400 | [EUR/MW] |

| Discount rate | 3.43 | 6.37 | [%] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Povacz, L.; Bhandari, R. Analysis of the Levelized Cost of Renewable Hydrogen in Austria. Sustainability 2023, 15, 4575. https://doi.org/10.3390/su15054575

Povacz L, Bhandari R. Analysis of the Levelized Cost of Renewable Hydrogen in Austria. Sustainability. 2023; 15(5):4575. https://doi.org/10.3390/su15054575

Chicago/Turabian StylePovacz, Leonhard, and Ramchandra Bhandari. 2023. "Analysis of the Levelized Cost of Renewable Hydrogen in Austria" Sustainability 15, no. 5: 4575. https://doi.org/10.3390/su15054575

APA StylePovacz, L., & Bhandari, R. (2023). Analysis of the Levelized Cost of Renewable Hydrogen in Austria. Sustainability, 15(5), 4575. https://doi.org/10.3390/su15054575