Abstract

With the continuous growth in the use of home appliances and electronics, waste produced with obsolete material (e-waste) has an increasing environmental impact. Furthermore, the production of such devices leads to increased consumption of natural resources and produces a multitude of toxic and hazardous substances, which are normally not treated properly. One of the approaches that may be adopted to reduce such problems relies on the circularization of the current linear model, commonly adopted in the Electric and Electronic Equipment (EEE) value chain. This includes recovering End-of-Life products and reintroducing their parts, components, or raw materials into the value chain (e.g., semiconductors, circuit boards, raw metals, etc.), contributing to a more sustainable value chain. In this article, we present a state-of-the-art review that focuses on approaches and solutions for EEE value chain traceability and analyze the technologies that may be beneficial for promoting and implementing the Circular Economy model in this value chain.

1. Introduction

Climate change is a current concern for humanity, which is aggravated by deforestation, the enormous use/burning of fossil fuels, and other human activities with a considerable impact on the environment. Most industrial and transport activities have a direct impact on the environment, and are net contributors to the increase in the average temperature of the planet. The Electric and Electronic Equipment (EEE) sector is a major contributor to this increase due to the increasing exploitation of minerals and other raw materials, the subsequent transport and industrial transformation, and the massive production of waste (e-waste). The global production of e-waste was around 53.6 million metric tons in 2019, and is expected to be 74.7 million metric tons by 2030 [1].

In 2016, only 20% of the 44.7 million metric tons of generated e-waste found its way into recycling channels [2], with the rest ending up in dump sites and landfills. These numbers are growing worse; according to the UN’s Global e-waste Monitor 2020, in 2019 only 17.4% of the 53.6 million metric tons of generated e-waste was collected and recycled [3]. Moreover, inappropriate disposal of e-waste can lead to multiple social and environmental problems; these products can contain substances dangerous to humans and the environment, including lead, cadmium, mercury, chromium, and polyvinyl chloride, among others. In addition to environmental concerns, e-waste represents a significant economic loss, and leads to scarcity of raw materials. The transition to a Circular Economy (CE) can greatly help to improve and optimize the EEE sector due to the high environmental impact of its products, which typically use multiple raw materials and require a substantial amount of energy during the product production and use stages.

The EEE sector includes the manufacturing of all types of electric and electronic products: TVs, microwaves, cell phones, desktop and laptop computers, etc. An electronic product such as a smartphone may be composed of 500 to 1000 different parts, from extremely small microcomponents to larger macrocomponents [4]. The demand for thinner gadgets has increased the need for raw materials. From 2004 to 2014, the production of iron, cobalt, and lithium increased by between 125% and 180% [4]. Different raw materials and minerals are used to build different components. Of the 83 stable elements in the periodic table, more than half are found in a typical smartphone [5]. Most of these are easily available metals such as iron and aluminum; however, others are at risk of supply shortage. Sixteen of the seventeen rare earth elements are used in smartphones production [5,6]., and several of these materials are listed in the European Union (EU) list of critical raw materials (Raw Materials Resilience: Charting a Path towards greater Security and Sustainability, European Commission, Brussels, September 2020, https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474, accessed on 5 September 2022).

Furthermore, smartphone production requires conflict minerals (e.g., Tungsten, Tantalum, Tin, and Gold); this designation is related to their origin in areas where human rights are not respected, with such minerals sometimes being traded by armed groups. The EU has established new legal requirements in order to combat these issues (Conflict Minerals Regulation, European Commission, Brussels, January 2021, https://ec.europa.eu/trade/policy/in-focus/conflict-minerals-regulation/, accessed on 5 September 2022).

Finally, it is important to mention substances of concern which have significant social or environmental impacts. The use of these substances is restricted in the EU market through Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation (Regulation (EC) No 1907/2006 of the European Parliament and of the Council of 18 December 2006 concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), establishing a European Chemicals Agency, amending Directive 1999/45/EC and repealing Council Regulation (EEC) No 793/93 and Commission Regulation (EC) No 1488/94, as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC, https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02006R1907-20140410, accessed on 5 September 2022).

One approach to reducing the harms that the EEE industry causes to the environment is to explore Circular Economy (CE) applicability in this sector. CE is an economic model based on a business model that replaces the traditional linear “take-make-dispose” model by reducing, reusing, recycling, and recovering materials or components in the production and consumption processes [7].

In order to assess the environmental impact of an EEE product, it is important to know each activity involved in the value chain and to track all of its relevant constituent items, such as batches of raw materials, electronic components, electrical material, circuit boards, integrated circuits, etc.

To accomplish this goal, a traceability platform is needed. Blockchain technology (BCT) is already being used for traceability purposes in many areas [8]. In a blockchain, information is stored in blocks in chronological order, creating a permanent and immutable data record and providing transparency in the value chain [8].

A traceability platform allows information about every item to be stored at any step of the value chain, allowing a physical item to be associated with a digital representation (its digital twin). Traceability data can be collected through Internet of Things (IoT) devices, offering an easy, truthful and thoughtful way to handle data.

1.1. Objectives and Contributions

This article reviews the state-of-the-art of BCT to support CE in the EEE value chain, being used for storing data about important indicators needed to measure the sustainability of electrical and electronic equipment’s throughout the value chain. Moreover, the state-of-the-art regarding IoT technology is analyzed, as real-time data collection about every traceable item in the value chain is crucial for computing the relevant operational metrics and indicators. Such tools are relevant for assisting decision-making at the business management level.

This article’s main contributions are:

- Analysis of the EEE linear value chain and proposal of a CE business model for the circularization of this value chain.

- Review of the state-of-the-art around traceability in the EEE value chain.

- Review of the state-of-the-art for identification of technology enablers in traceability supporting CE in the EEE value chain.

The goal of our research is to answer the following research questions:

- 1.

- How can the EEE value chain’s business process be circularized in order to reduce its global environmental impact?

- 2.

- How can blockchain and IoT Technologies be used to further traceability in the EEE value chain and help in fostering the adoption of a circular economy?

1.2. Materials and Methods

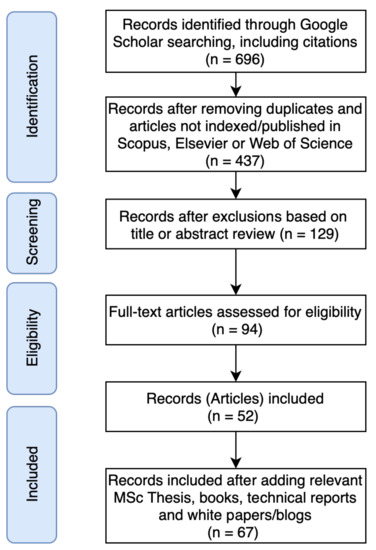

To answering the above research questions, we conducted a review of traceability systems and technologies used to promote the circularization of the EEE value chain in the EEE sector. Our research was conducted between 24 January and 31 March 2022. We used Google Scholar to search for results with a combination of the following terms: “Circular Economy”, “Electric and Electronic Equipment”, “Traceability System”, “Blockchain-based traceability”, “Blockchain”, and “IoT”. This process is depicted in the diagram in Figure 1.

Figure 1.

Screening process used in this review.

From the obtained results and their relevant citations, we selected those indexed/published in Scopus, Elsevier, or Web of Science from 2003 onwards for further analysis. To these papers, we added several MSc theses, technical reports, company white papers, and technical blogs.

These materials were individually analyzed based on the following steps:

- Manual screening of titles and abstracts was performed, with any manuscripts highly correlated with the topic under analysis being considered for review.

- With regard to blog opinions or other non-scientific items, they were only included if they presented a different or unique perspective on a certain topic.

- Ambiguous or duplicated articles were removed.

Finally, a total of 67 research items were selected, including 52 scientific papers, five books, three technical reports, two MSc theses, and five technical white papers or blog entries.

1.3. Structure of This Article

The remainder of this article is structured as follows. Section 2 analyzes the EEE linear value chain and presents its generic business process model. In Section 3, a CE business process model for the EEE value chain is proposed. The proposed model is presented at a high abstraction level, identifying the main value chain participants and activities. A model representing the CE of the EEE value chain is proposed as well. Section 4 reviews the existing traceability platforms in the EEE value chain and analyzes the main levers for CE in the EEE industrial sector. In Section 5, the technology enablers for CE in the EEE value chain are identified and analyzed. In Section 6, an analysis of the results is undertaken. Finally, in Section 7 our conclusions are drawn and we discuss ideas for future work on the traceability of CE in the EEE value chain.

2. The EEE Linear Value Chain

The EEE value chain is currently one of the largest in the world, involving many companies in various countries with different industrial processes, starting with mining and ending with consumer products and waste. While these manufacturing processes may assemble the final product, most of them produce intermediate parts such as transistors, chips, Central Processing Unit (CPUs), circuit boards, integrated circuits, and other electronic components.

EEE production activities result in significant use of natural resources, with consequent environmental damage from mining, transportation, and energy consumption during manufacturing [9]. These activities must be traceable in order for their environmental and social impacts to be measured.

According to [10], the currently predominant economic model is the Linear Economy (LE) model. Following the third industrial revolution, linear thinking has led to prosperity and economic growth in many parts of the world. Consequently, manufacturers have been oriented towards a business model that is based on substantial use of materials and minimizing of human labor costs. Automation, cheap materials, and the reduction of human labor costs are common reasons that recycling and reuse have been neglected. Moreover, the search for cheap labor has led to the transportation of goods over long distances.

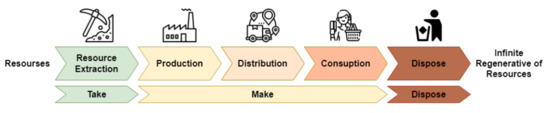

The “take-make-dispose” model, represented in Figure 2, is based on the assumptions of high availability of materials and the regenerative capacity of the earth.

Figure 2.

Linear Economy “take-make-dispose” model (adapted from [11]).

Although LE has shown great success over the last century, it has raised many concerns as well; this model uses resources in unsustainable ways, producing large amounts of waste and harming the environment [11]. Within LE, population growth requires more and more resources to keep up with the demand generated by this growth. In addition to environmental impacts, there is concern about non-renewable resources, including many metals, minerals, and fossil fuels, becoming scarce [11]. Furthermore, the price of these resources is rising and becoming unpredictable, leading to an increase in costs along the value chain and to higher prices for end consumers. At present, the “take-make-dispose” pattern is used by value chains in several different areas.

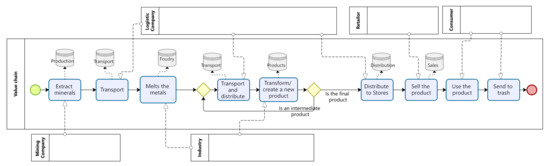

As mentioned before, the EEE value chain involves a huge number of participants that are spread all around the world. Figure 3, presents the inter-organizational business process model of the EEE value chain using the Business Process Model and Notation (BPMN) language. This model represents the generic linear EEE business process at a high level of abstraction. Thus, the main pool represents the main activities involved in the linear value chain, starting with the extraction of minerals and ending in waste. Following the ideas presented in [12], the value chain operators are represented as external participants. The participant responsible for carrying out an activity is represented by a message sent from the participant to the corresponding activity. At this inter-organizational level, an activity represents a process internal to the company responsible for its execution. The internal processes of each of these companies can be complex, and are often not very friendly to the environment.

Figure 3.

EEE Inter-organizational linear business process model.

As can be seen in Figure 3, the process begins with the extraction of different types of minerals by mining companies, such as tin, silicon, cobalt, iron, copper, etc.; this represents the first activity in the process. After mining, the minerals are transported for smelting, refining, or melting, as represented in the second and third activities in Figure 3. Minerals are sometimes mixed together, meaning that they receive raw materials from different mines. Next, the metals (refined metals) are transported to the companies that create diverse components such as chips, transistors, etc. (the fourth and fifth activities in Figure 3). Companies may create new products (final products or components) using other products (components). These components are used as inputs in the creation of new components. This is represented by the loop between the two gateways in the business process represented in Figure 3).

After the final product is finished, it is distributed by stores to be sold to the final consumers, who, after using the product, eventually dispose if it, producing e-waste.

In the inter-organizational business process model presented here, five main types of participants are identified:

- Mining companies—These participants represent the companies responsible for the exploration of mines from which minerals such as cobalt, tin, tantalum, silicon, and lithium, among many others, are extracted.

- Logistics companies—These participants represent the companies responsible for transporting materials, which may involve trucks, trains, boats, etc. The extraction of metals can be carried out in diverse parts of the world, and transportation time can be substantial.

- Industry—These participants represent the companies responsible for the fusion of materials (foundries), industries responsible for the creation of various types of components, such as chips, transistors, etc., and those responsible for the creation of new products, such as computers, mobile phones, etc. Usually, in the construction of an EEE product, many different industries of this type are involved, with each one being responsible for manufacturing a part or component and others responsible for assembling the resulting parts or components.

- Retailers—These participants represent the companies responsible for distributing the resulting products or components through stores and selling them to consumers.

- Consumers—These participants represent the final consumers; in the linear model, after purchasing a product and using it, the consumers throw it away (represented in Figure 3 by the “send to trash” activity).

As the EEE sector contributes heavily to climate change, a more sustainable approach is necessary to minimize the environmental and social impacts of such products. To accomplish a more sustainable approach, it is important to know the environmental impact of each stage of the value chain and the material composition of each product or component [13].

When the objective is to trace a product in the value chain, it is necessary to store information about what happens at each stage of activity. This data collection is represented in Figure 3 by writing to the data store at each stage of activity, which is the responsibility of the company that performs the particular activity.

3. EEE Circular Value Chain

Due to the scarcity of certain minerals and the increasing use of e-products, as well as population increase and ongoing technological advancements, society is face with End-of-Life (EoL) management challenges around reducing environmental impact and saving resources [14]. In a recent move towards a more circular process, there has been a widespread commitment to slowing and closing resource loops [15].

CE promotes the circularity of resources, materials, and product components for reuse instead of discarding them. To achieve the goals of this economic system, it is necessary, among other variables, to ensure the cooperation of all participants in the product value chain (producers and consumers) as well as proactive improvement from product designers. Product design must be considered in order to allow the easy replacement of a part or component of a product. Such initiatives are typically very challenging in light of the complexity of most e-products’ design and material composition [16].

The CE concept is a production and consumption model that contributes towards the transformation of industry towards a more sustainable and environmentally friendly approach. This means trying to reduce the waste of materials, recycling and reusing them throughout the value chain and production processes, aiming for innovation, economic growth, and reducing pressures on the environment [17].

The concept of CE as a regenerative system is generally viewed as a necessity for sustainability; it aims to reduce the waste of resources and maximize their efficiency and ecological sustainability by maintaining the value of products, materials, and resources in the CE as long as possible. This can be achieved through maintenance, repair, reuse, and recycling of products and materials [18].

3.1. EEE Circular Value Chain: Generic Business Process Model

CE is defined as a business model that can replace the linear economy or EoL concept by reducing, reusing, and recycling resources that can be used again in the production–consumption process. To achieve this, the alternative to the “take-make-dispose” pattern needs to operate at different levels, with products, companies, and consumers at a micro-level and cities, nations, and beyond at a macro-level [17].

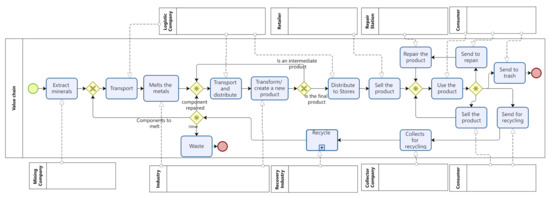

Figure 4, represents, at a high level of abstraction, the circularization of the EEE business process model presented previously in Figure 3. As shown in Figure 3, to circularize the business process it is necessary to involve new participants (or change the responsibilities of existing participants) in addition to those already in the value chain:

Figure 4.

Generic business process model for CE in the EEE value chain.

- Customers—Consumers play a very important role in circularizing the EEE business process, as they can (or should): (i) recover the product and use it again; (ii) sell it to another consumer, allowing the new consumer to use it again; or (iii) send it for recycling. In addition, consumers can choose to buy more sustainable products, thereby encouraging manufacturers to invest in the production of products with lower environmental impact. In this way, consumers can fuel the circular economy.

- Collector company—This is a new type of transport company responsible for collecting products sent for recycling and delivering these products to the recycling company.

- Recycling and Recovery company—This is a new kind of industry responsible for cleaning EEE residues, disassembly and componentization of products, and verification and promotion of new components that can be recovered, reused, or recycled. The recycling process of a EEE product can be very complex due to the high number of components and materials involved in creating theaw products. Recovered components that cannot be reused or recycled can be reconditioned to serve as raw materials for the creation of new components.

- Repair stations—Product repair shops that are prepared to receive and repair products from consumers. Repair shops can repair products or replace components that break down and need to be fixed. The ease of replacing a component (e.g., a battery) in a product depends on product design. Thus, to increase a product’s circularity it must be designed in such a way that if a component fails it is easy to replace without having to discard and replace the entire product.

The circular economy requires the active participation of governments to, among other things, provide collection points for this type of product in order to foster consumer participation in the CE by recycling of products. In addition, governments can create laws that prevent disposal of certain types of product, especially large electrical appliances.

3.2. End of Life Practices and Services

In Europe, the EoL of electronics should follow the Waste from Electrical and Electronic Equipment (WEEE) directive (Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE), https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02012L0019-20180704, accessed on 7 September 2022). This directive states that the EoL of these devices is the responsibility of producers and importers, and can be managed either individually or through a third party. The problem of insufficient collection of e-waste is caused by lack of data about the EoL of devices, the value of wasted devices, and especially in the case of smartphones and computers, data security issues [6].

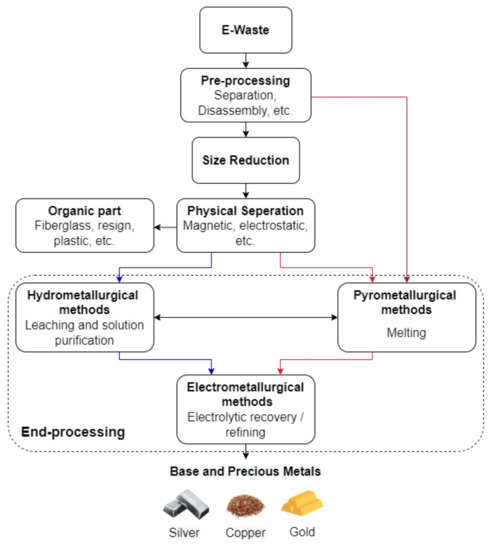

The process of creating a product is complex, involving the creation and assembling of many components, and the process of recycling it can be similarly complex. Akcil et al., presented a flowchart for the recovery of metal from e-waste (Figure 5). The presented scheme is divided into pre-processing and end processing [19]). Pre-processing refers to separating and sorting of parts and materials for safe disposal and recovery. end processing refers to all the steps needed to recover materials resulting from e-waste processing.

Figure 5.

Scheme for recovery of precious metals (adapted from [19]).

Pre-processing operations start with the removal of polluting substances. The goal of this step is to comply with pollution reduction requirements, as mentioned in Annex VII of the WEEE Directive. In the case of smartphones and other processing devices, selective treatment includes the removal of batteries, printed circuit boards and electric cables, and plastics containing brominated flame retardants. Design features allowing easy disassemble of a product, listed in annex VII of the WEEE Directive, are important to optimize this operation. Appropriate design principles allow for easy separation of parts, accurate labeling, and minimization of the amount of materials used, which can help in the process of recycling; an example is the case of Lithium-ion (Li-ion) recycling technologies.

After removing the most polluting materials, e-waste is separated into components and the generated scrap is separated into material outputs (e.g., gold, copper, printed circuit boards, plastics, etc.), which are then sent to end processing or to specialized companies that sort them (e.g., into various types of copper-based components).

Smartphones are mainly made from aluminum and plastics. However, the main residual value of an electronic product is from its precious metals. The recovery of these materials from e-waste is the main goal of the end Processing phase.

In [6], the authors provided an overview of different recycling options for smartphones. The most well known recycling route in the EU for the recovery of metals is based on pyro-metallurgical methods, illustrated in Figure 5. Several precious metals that have high recyclability rates can be recovered, as is the case for copper, gold, silver, palladium, and tin [6]. While other critical materials, such as tungsten, gallium, and indium, are relevant for recycling, they cannot be efficiently recovered with existing technologies.

Recycling and recovery of materials may be limited by the presence of certain substances. This may demand the development of advanced pre-treatment and recycling processes, which can increase efficiency. At the product design level, product design aspects such as ease of disassembly, separation of components, etc., are crucial for enabling subsequent repair, refurbishment. and recycling. Dedicated design approaches can make it easy to remove parts that can be reused and parts or that contain precious metals, provide documentation regarding the operations needed to access and remove such components, and provide information about metals from high-risk areas, should any exist. In Article 15, the WEEE Directive requires Member States to ensure that producers provide information free of charge about preparation for re-use and treatment in respect of each type of new EEE entering the European Union market for the first time.

3.3. Circular Economy Levers in EEE Industry

The main levers for CE in any area are product design, digitization, regulations and laws at the state level, and most importantly consumers. Many consumers have already become aware that sustainability and the fight against global warming are not in line with consumption without rules or with the linear economy responsible for throwing away end-of-life products instead of reusing or recycling them. Thus, consumers always have an active role to play in leveraging CE.

One important lever for CE is circular product design, which is a circular process for the design of a product. Product design is the phase where at least 70% of the total cost of a product is set, and is one of the most important stages where commitments to reduce the environmental impact can be made [20,21]. “Design for disassembly, reassembly, and recycling” aims to design EEE products that can be easily divided into components, enabling efficient repair of devices and recovery of the useful parts and materials within CE models [22]. Modular design consists of developing product architectures with separable modules, which can make the process of disassembly, reassembly, and recycling much easier considering that each module can be separated and attached as a group [23]. “Material selection” is a design option that incentivizes the use of secondary raw materials [24], eco-friendly materials, and materials with high recyclability rates.

Digitization through traceability systems is another important lever for implementing CE. At present, thanks to advances in technology, manufacturers have begun to automate processes through software and digital systems [25]. This automation enables the creation of bidirectional linkages between the physical and virtual worlds [26].

Governments may encourage companies to implement CE through new regulations [27] and other economic incentives [28]. As mentioned earlier, the European Union has published a list of critical raw materials and substances of concern, along with legislation to deal with these issues. These materials need to be managed carefully in order to prevent and avoid social or environmental impacts.

Other levers include the need for maintenance and repair services, which are essential means of extending the life span of EEE products [29]. Moreover, use-oriented Servitized Business Model (SBM) shifting from ‘product selling’ to ‘service provision’ may act as a means of moving from the current ‘replacement system’ to a new ‘optimal usage’ approach to products [20,30]. SBM levers focus on reverse logistics to close the value chain cycle. Reverse logistics is the process that deals with the return of products from consumers through the supply chain in a reverse direction until the product reaches the manufacturer or other business partners able to deal with reusing or recycling the product in order to recapture value [31]. Usually, a second-hand EEE product can be supplied for individuals, collection sites, or from retailers [32]. The implementation of a reverse logistics network poses a complex problem, from defining collection and inspection centers to the identification of optimal re-manufacturing and recycling facilities [33]. Recollection, whether from business or domestic customers, typically occurs at the end of a lease or at the EoL of the product, when the customer delivers it for asset recovery by municipal pick-up or retail take-back [33].

4. Traceability in the EEE Value Chain

Traceability mechanisms provide the possibility of following and understanding the step-by-step history of a product. Through a IoT tag, e.g., an RFID, QR Code, or Bar code, it is possible to track a product along its value chain [34]. Traceability brings transparency and is a risk management tool; its benefits include [34,35]:

- Allowing companies to follow each component at every stage of the value chain, as well as to identify these components and the locations associated with their movements;

- Providing real-time tracing information of all activities, from raw materials extraction to the final consumer;

- Providing a historical record by tracing components throughout the value chain;

- The capacity to respond quickly to potential supply chain risks, thereby minimizing losses and maximizing product returns;

- Improving the transparency of processes throughout the value chain by detecting any problems with a product, thereby protecting the brand from faulty or counterfeit products.

- The information gathered can be used in control and management of different production stages;

- Enabling dynamic lot allocation as well as other optimization and control processes along the supply/value chain.

A traceability system can help to improve the relationship between business partners as well as that between manufacturers and clients by offering greater transparency about the product. Product authenticity is another benefit of traceability systems; counterfeit products lead to huge economic losses to the companies, and may place the overall value chain at risk [36].

In order to comply with regulations, particularly warranties, returns, and costs, it is beneficial for EEE producers to rely on manufacturing traceability solutions.

The authors of [37] discuss an Industry 4.0 Smart Factory in which systems are interconnected and able to receive and send data from/to other systems. They note that there are systems/machines that can help to implement traceability at each stage of production, from labeling incoming goods (e.g., Bar codes), to monitoring production runs, to determining which components are needed in order to assemble a product. The authors point out that there are machines capable of storing data on test results, movement of units throughout the production phase, and other important processes.

Today, with the globalization of value chains, the need for traceability is becoming more and more important, particularly the ability to track a product all along its value chain [38]. In the EEE value chain, it is necessary to track both completed products and their components, as this can ensure authenticity and avoid forgeries. Traceability can be seen as a step towards greater transparency in the product value chain [8].

A number of traceability platforms have been proposed for the EEE value chain, of which several are listed in Table 1 and briefly described below.

Table 1.

Summary of solutions for traceability and CE in the EEE value chain.

The authors of [39] presented a case study on LCD TV e-waste to support more sustainable e-waste management, proposing a generic global EEE information model and other EEE services [39]. The proposed conceptual information model supports gathering information about the product, including traceability data and technological information for product recovery/re-manufacturing, among other information.

The authors of [40] suggested a cloud-based system for e-waste using web application based on an Relational DataBase Management System (RDBMS) that can be used to track EEE products throughout the product life cycle. Their platform supports several features, such as adding new products, managing, disassembling, and searching for products, etc. Relevant data are registered in the database at each step of the product life cycle. This system allows additional information to be stored within the product itself (e.g., in its internal memory or an Radio-Frequency Identification (RFID) tag with memory) and sent to the cloud when the product changes its stage in the life cycle, for which it relies on IoT capabilities.

In [41], the authors proposed a platform for traceability and auditing for reverse logistics activities in the EEE value chain, with a special focus on mobile phones. Their platform, based on a private blockchain, provides functional implementation of several smart contracts. As it is based on smart contracts, the presented solution offers automated collecting, handling, and traceability of information in the reverse logistics processes. As the BCT is not suitable for storing larges amounts of data, the authors used off-chain storage, namely, InterPlanetary File System (IPFS), to ensure scalability and integrity when storing critical records of reverse logistics events. In the IPFS, each stakeholder stores all the important data of the reverse logistics operations in a Table of Contents (TOC); afterwards, the hashes of all individual records are stored on the blockchain. Therefore, instead of saving all the data directly on the blockchain, the system only saves the hashes of reverse logistics data on the blockchain [41].

The authors of [42] suggested a blockchain-based traceability solution for several value chains, including the EEE value chain. Their solution, which demonstrated the potential of BCT in traceability and value chain transparency, was developed using the Microsoft Blockchain Workbench Platform (MBWP). The authors explored several applications in different value chains, and described several IoT tools used for traceability, such as RFID tags, QR Codes, Bar codes, Near Field Communications (NFC) tags, Global Positioning System (GPS), etc.

The authors of [43] proposed a combination of IoT and BCT for improved circularity of EEE. The authors used a permissioned blockchain called Hyperledger Fabric that allows the introduction of access control mechanisms, which is important for filtering the users that are authorized to initiate transactions. The use of IoT devices can help in traceability, as it is possible to retrieve data from materials in terms of their, availability, geolocation, etc. [43].

The authors of [44] presented a traceability solution for automotive electrical system manufacturing through BCT and IoT technology. The process of manufacturing these systems involves thousands of parts, which are managed by systems such as Enterprise Resource Planning (ERP), Manufacturing Resource Planning (MRP), specific centralized applications, etc. The importance of traceability in this sector is growing with the advent of Autonomous Driving (AD), especially for products that are safety-critical. Traceability can help to identify product components involved failure or production problems. The authors developed a blockchain-based traceability system using an Ethereum-based blockchain. Instead of using a conventional blockchain solution, such as integrating product data as primary transaction data and events, they proposed a different approach using ERC 1155 (https://eips.ethereum.org/EIPS/eip-1155, accessed on 20 September 2022) blockchain tokens. The ERC 1155 standard defines a smart contract interface that enables representation and management of different types of virtual objects (token types), each having its own metadata and other attributes. Several components in this industry are unique, requiring separate tokens in order to link a component’s unique Identifier (ID), status, and production history. The application of ERC 1155 to this use case permits the use of multiple tokens, which are needed to represent different products, and allows tokens to be linked with a Uniform Resource Identifier (URI) that can contain further product information [44].

There is ongoing concern within the EEE industry regarding the introduction of counterfeit electronic parts. In [45], the authors noted that, regardless of the effectiveness and procedures used, traceability cannot assure quality and performance after the component leaves the authorized value chain. Despite it being almost impossible to completely prevent counterfeit components from entering a supply chain, it is possible to reduce their occurrence by implementing “risk-based policies”, as specified in the regulations, by focusing on buying materials only from authorized suppliers.

5. Technology Enablers for CE Traceability in the EEE Value Chain

Traceability systems, together with IoT, allow the EEE value chain to be smart and connected. These technologies can help in improving the EoL activities before disassembly by permanently disclosing information about the product regarding its general condition as well as information about the components used in the product [46]. Traceability and IoT can play an important role in supply chain management, helping to improve the quality and integrity of data and enabling reverse logistics activities for faster EoL item recovery and more sustainable treatment of e-waste. Furthermore, traceability systems and IoT can improve circular product design, as all the data collected throughout the EEE lifecycle can be used to trace both products and their components [47,48].

5.1. Blockchain Technology

With regard to traceability systems, blockchain technology is one of the best alternatives, and is increasingly used to face the challenges posed by global value chains [49]. Following the introduction of Bitcoin in 2008 [50], blockchains have been applied in several different scenarios involving value and supply chains [51,52,53,54].

Blockchains can be applied in many contexts, providing compliance, transparency, tracking, error reduction, payment processing, and other applications [55].

A blockchain is a distributed database that allows its participants to store information securely and in real-time. Distributed Ledger Technology (DLT) is the base layer of a blockchain. This technology offers a consensus mechanism that allows peer-to-peer transactions without the need for an intermediary to process and maintain the data generated by transactions. When a group of transactions is validated, a new ‘block’ can be created and added to the existing chain of blocks [56].

Distributed ledger technology is often misunderstood as a synonym for blockchain; more specifically, it refers to the distributed and decentralized ledger of BCT. With DLT, a ledger can be maintained, authenticated, and secured without recourse to any central authority. Instead, copies of the ledger are distributed and maintained by the participants in the network [56].

Blockchains can have different types of permissions (see Table 2), and are mainly characterized by their consensus protocols [57]. As there is no central authority that validates transactions, in order to ensuring that all network nodes are synchronized and have the same ledger it is necessary to use a consensus protocol. A consensus protocol is an algorithm that allows all blockchain nodes to reach agreement on committing information on a new block, ensuring that new blocks are been added to the chain correctly, i.e., that the same block is added to all the blockchain nodes [57]. The different blockchain consensus protocols include Proof-of-Work (PoW), Proof-of-Stake (PoS), Proof-of-Authority (PoA), and Practical Byzantine Fault Tolerance (pBFT), among others [58].

Table 2.

Blockchain permission types.

One of the most widely known public blockchains is the Bitcoin network, which is used for the cryptocurrency of the same name. Bitcoin uses the PoW consensus mechanism, which is known to waste energy [59]. There are several other consensus mechanisms applied in other blockchains, a number of which try to address energy efficiency and other concerns [60].

Smart contracts are simple programs stored on a blockchain that run when certain conditions are met. Normally, these are used to execute agreements about which the participants can be certain of the outcome without any third-party involvement [57]. Smart contracts can be seen as “if–then” statements written in code and stored on a blockchain. The network executes the action defined by the smart contract when the conditions are met. Such actions could include registering a product, transferring ownership, etc. When the transaction processing is completed, the blockchain ledger is updated, and from this point on the transaction cannot be changed [58].

5.2. Blockchain-Based Solutions for Traceability and CE

It is essential that traceability systems have accurate information, and that this traceability information is both easy to collect from sources and easy to retrieve by business partners. Ultimately, connectivity between all the machines and processes used in the production phase is desirable, in order to automatically obtain and record every data element that is relevant for traceability, as these data influence future decisions. The EEE value chain involves several players around the world, and a data storage network technology that is secure and solves trustability issues among the stakeholders is mandatory.

A Digital Twin is a digital representation of a physical object that provides all of the relevant information about that object. While the real EEE product passes through the different stages of the value chain, the activities in these different stages and processes should leave a trail within the traceability system. To accomplish this, a digital twin of the real product can be created to facilitate the tracking and tracing of the product throughout its lifecycle, providing easy access to its registered information (product identification, measurements with an environmental impact, etc.) [61,62]. According to [63], IoT can help record information from any product at any life cycle stage through devices, ensuring seamless tracking of the product. When this technology is combined with a blockchain, the information can be made unalterable and fully transparent.

BCT is currently used in different commercial scenarios, including traceability in value chains [43], where it can aid in tracing the origins of products [64], monitoring product quality [12,65,66], monitoring environmental impacts [53,54], and supporting reverse logistics [42], among other contexts. However, we were able to find very few studies on the use of BCT in EEE value chains. These studies have been presented in Section 4. The adoption of BCT would be useful and bring many benefits, such as compliance, transparency, tracing, tracking, immutability, and more [55]. In addition, blockchain-based systems provide real-time data and smart contract technology to suit the needs of their users, and can be integrated with other technologies such as Big Data, Artificial Intelligence (AI), and IoT.

The characteristics of BCT have motivated the development of blockchain-based platforms dedicated to the logistics sector, such as TradeLens (https://www.tradelens.com/, accessed on 21 September 2022), DataPorts (https://dataports-project.eu/, accessed on 21 September 2022), and LACChain (https://www.lacchain.net/home, accessed on 21 September 2022).

Alves et al. have referred to alternative blockchain-based solutions for CE in the textile and clothing value chain [62], for example, Circularise, Vechain, and Waltonchain, which use public blockchains with permissionless user profiles, and Everledger and Ambrosus, which use private/consortium blockchains with permissioned user profiles.

Hyperledger (https://www.hyperledger.org/, accessed on 20 September 2022) is an open source multi-project collaborative effort that pursues the development of stable frameworks, tools, and libraries for enterprise blockchain deployments. One such tool is Hyperledger Fabric. With this private blockchain technology, the confidentiality of the data stored on the ledger is assured. One noteworthy feature is the “channels” functionality, by which nodes can only share and access information in channels for which they have permission [62]. This architecture allows information to be shared between nodes connected to a given channel, thereby protecting private data from other nodes outside the channel.

The Hyperledger Fabric, here used as an example of a private/consortium permissioned blockchain framework, provides a number of advantages, such as:

- Permissioned network—Hyperledger Fabric allows the deployment of blockchain-based solutions that are not publicly accessible. Different permissions may be assigned to different users, and only registered users may access the blockchain and act within the assigned permissions.

- Confidential transactions—The data handled in a transaction are shared and viewable only among the users/organizations involved in the transaction.

- Pluggable architecture—Hyperledger Fabric’s consensus protocols are pluggable, meaning that it is possible to modify/configure different consensus protocol implementations. Hyperledger Fabric supports several different consensus protocols, such as CFT (crash fault-tolerant) and BFT (byzantine fault-tolerant), among others.

- Easy to start—Instead of a custom language, as is the case with Ethereum, Hyperledger Fabric supports several different existing smart contract programming languages.

The use of BCT provides several features and characteristics that can be seen as advantages/benefits when used in value chains comprising several participants spread around the world [57,60]. Decentralization is one of these features; it means that the blockchain does not rely on a central authority and that data are stored in a distributed/decentralized way without being controlled by a third party. Immutability is an intrinsic feature of BCT, and is related to the fact that it is nearly impossible to change previously registered data. Pseudonymity is another advantage; it avoids identity exposure in the network through encrypted addresses. Autonomy refers to the fact that nodes in the system can safely manage data, with the purpose being that trust is included in the system itself instead of an outside entity. Finally, Transparency is one of the key characteristics of distributed ledger systems, as any node can consult the data records.

In a blockchain, the data manipulated in transactions are stored in blocks that are chained together in a distributed and immutable ledger. The data are transparently available to the participants. This information sharing can improve product tracing and tracking in value chain scenarios [67]. Through DLT, it is possible to trace and track a product throughout its life cycle, transfer its ownership, etc. In the case of an emergency, it is easy to identify and trace the history of all events that may have caused a problem and take immediate action. BCT can store data about the origin of a product, its components, processes, and entities, and all related transactions. These data are traceable and verifiable by other participants in the network. This could lead to the application of verifiable sustainability criteria for materials, products, suppliers, and more, as well as the design of more sustainable logistics and internal networks [43].

5.3. IoT Technologies

Many industrial sectors, including logistics and manufacturing, place a high priority on traceability. This is because it allows for effective tracking along with safe and transparent item recall when necessary. Numerous examples in the literature demonstrate the implementation of traceability in various application domains, including food value chains [68], the pharmaceutical industry [69,70], agriculture [71], and fisheries [8]. Furthermore, the integration of IoT and BCT technologies can improve the productivity of the value chain [71].

Traceability technologies enable the identification and tracking of items throughout their value chain, from the manufacturer to the customer. The IoT offers technological tools that bridge the gap between the physical and digital worlds. These tools consist of web-enabled smart devices that can gather data from their surroundings using embedded systems and provide easy access to information about the device or materials. By connecting to an IoT gateway or other edge devices, IoT devices can share the data they collect with the cloud. Today, IoT technologies are not only about connectivity; they are part of a larger ecosystem, with platforms such as Microsoft Azure, IBM Bluemix, and AWS Cloud offering a variety of services that encourage interaction with IoT technologies.

The use of low-cost IoT devices for tracking and tracing is a common approach in different IoT-based applications, and value chain traceability is no exception [72]. In the case of food [68] and pharmaceutical [70] value chains, extra attention regarding product traceability is needed. In these contexts, it is important to increase safety and quality control, including the acquisition of distinct environmental parameters such as temperature and relative humidity both during the production stage and during distribution. This can add value to the products, as these environmental parameters can be consulted at any stage of the value chain prior to sale/purchase.

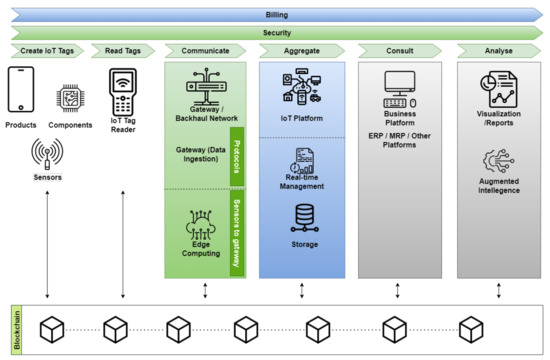

Figure 6 presents a general IoT traceability model showing all the operations and logistics stages, including the production stage. Taking into consideration the EEE value chain presented above, the proposed model consists of the following six steps:

- Create: Production of EEE goods or components integrating IoT-readable tags during the manufacturing process;

- Read: Reading the identification tag at any stage of the value chain;

- Communicate: Data communication from IoT devices in the assembly line must guarantee high interoperability;

- Aggregate: Through reorganization of data with multiple formats, aggregating data items, and ensuring data consistency, this stage verifies that the dataset is complete and disseminates to the relevant places;

- Consult: Platform management for businesses, supply chains, manufacturing, and other related services;

- Analyze (Visualization): Business operation management that integrates traceability systems, reporting, manufacturing, and other related activities (e.g., ERP and MRP);

- Analyze (Augmented Intelligence): Enhances human interaction through augmented intelligence, which involves people and machines working together and using their strengths to significantly improve business value.

Figure 6.

Generic IoT traceability model for the EEE value chain.

The introduction of information technologies has revolutionized the way companies manage their manufacturing processes. Digital traceability offers numerous benefits, such as accuracy, security, and efficiency, among others [73]. The technology of Automatic Identification (auto-ID) facilitates the tracking and tracing of objects throughout the supply chain by automatically reading and transferring data with minimal or no human intervention [73]. While auto-ID technologies enable automatic tracking, the most commonly used technologies in supply chains include Bar codes, RFID, Real-time Locating System (RTLS), and GPS. These technologies have unique features and can be utilized for different purposes:

- Bar codes consists of a printed image tag with black lines and white spaces that can be read by an optical scanner. Bar codes are typically applied to products to speed up their identification. Today, QR-Codes and Datamatrix are commonly used, offering increased data capacity. However, Bar codes have poor data security, deteriorate over time, and are read-only tags, making them less reliable.

- RFID: Radio Frequency IDentification uses radio waves to energize a chip-based tag and communicate a unique serial number attached to an item, possibly along with additional information. Multiple tags can be read simultaneously, and they can usually be rewritten and encrypted for added security.

- RTLS: provides real-time location information about items or people. In addition to location, this type of device can provide data on speed, temperature, and other variables. This technology has many applications, including tracking vehicles and other assets.

- GPS: provides the ability to remotely track any object in the world in real time. This technology is beneficial during shipping and logistics activities, especially for tracking vehicles.

There are other IoT communication technologies that can be adopted for traceability, such as NFC, Low Power Wide Area Network (LPWAN), SigFox, NB-IoT, and Bluetooth, which are discussed and compared in detail in [62]. The smart tags market has experienced significant growth, largely due to the implementation of technologies such as RFID, NFC, and Bluetooth Low Energy (BLE).

Usually, these tags generate supplementary data such as the environmental temperature/humidity, speed, location, etc., which can be utilized to improve the traceability of specific value chains. Additionally, the use of smartphones as mobile readers has made this method more cost-effective, as most of the effort is on the design and development of software applications that guarantee the integration of traceability services and mobile devices through a Service Oriented Architecture (SOA) or Microservices Architecture.

The value chain of a product is comprised of interconnected activities and sub-processes that require tracing to prevent potential problems, such as operational issues, transport delays, and product quality issues. The failure of any of these activities may significantly impact the value chain and increase costs. To address this complexity, IoT technologies are considered vital technological enablers that can accelerate value chain management in real-time and promote circularity in the product lifecycle. By utilizing IoT devices as tracing elements in conjunction with traceability platforms, continuous improvements can be achieved in the value chain, thereby reducing operational inefficiencies. The adoption of IoT traceability in the EEE value chain offers several major benefits, including: (i) Transparency, enabling real-time problem identification; (ii) Transportation optimization, improving transportation leading to reduced time and cost (e.g., by delivery route optimization); and (iii) Operational efficiency, as IoT technologies are less susceptible to errors than humans, resulting in reduced operational costs in inventory, transportation, and other areas.

6. Discussion

This review has aimed at examining the adoption of Blockchain and IoT technologies for pushing the implementation of a Circular Economy in the EEE value chain. The first of the two research questions that we have sought to answer is:

- (1)

- How can the EEE value chain’s business process be circularized in order to reduce its global environmental impact?

The current LE model in the EEE industry needs to move towards a more sustainable and environmentally friendly paradigm that reduces the intensive use of natural resources, energy consumption, and the production of waste. The CE model tackles these issues by circularizing the value chain, maintaining the resources in the value chain as long as possible through continuous CE process loops. The proposed CE business model for the EEE value chain, depicted in Figure 4 (Section 3.1), provides insight into how the EEE industry can be moved towards a CE model. The proposed process model contains new activities in the value chain, such as activities that enable recycling and reusing EoL products, providing the ability to prolong the use of raw materials and electronic components in the value chain by re-introducing them again in the production of new products. The proposed CE model provides the advantages of reusing natural resources by recycling components of older products, as well as other benefits. Moreover, the model poses a number of new challenges to be overcome, as the involvement of the stakeholders in the traceability platform demands tactics to avoid the introduction of counterfeit products into the value chain. Similarly, certain materials have low recyclability rates, as addressed in Section 3.2, and the recovery phase of certain materials can be challenging when dealing with e-waste from different types of EEE [6].

Traceability platforms are an essential requirement of CE, as they allow a product to be traced back to its constituent components and materials and to the activities used to build each of them. This provides the final consumer with information about the social and environmental impact of producing a product, enabling them to choose products with less impact. Section 4 identifies several platforms for traceability in the EEE value chain have been, which are presented in Table 1. This leads to the second research question we sought to answer in this study:

- (2)

- How can Blockchain and IoT Technologies be used for Traceability in the EEE value chain and help to foster the adoption of a Circular Economy?

Blockchain and IoT technologies can change the way companies operate throughout value chain activities/sub-processes by providing the ability to trace and track an object along the chain. Blockchain, in this context, refers solely to a distributed way of registering and sharing information. As mentioned in Section 5.1, a blockchain is a distributed ledger; while the technology can and has been used in cryptocurrencies, it does not necessarily involve the ethical, financial, and other problems that they raise.

Blockchain and IoT technologies in combination can provide automated registration of traceable data and identification of products, components, and materials. They offer easy traceability of products and materials, data immutability, and transparency in both value chain activities and product use along the value chain. This enables the development of risk management tools that can be used to identify production failures or logistics risks in supply chains, and could be used in environmental and social impact traceability tools as well. While these technologies provide several benefits, such as those mentioned in Section 5, their use poses a number of challenges.The main technical challenges raised by BCT are [74,75]:

- Security: Public blockchains, such as the ones used in cryptocurrencies, do not allow users to have different permissions, and private transactions are not supported. Furthermore, public blockchains, typically based on PoS or PoW consensus protocols, can suffer a 51% attack, which is when more than half of the nodes coordinate their efforts to attack the rest of the network. Normally, private and consortium blockchains support private channels and permissioned users, enabling them to play different roles in the system. While this provides better security mechanisms and private transactions, the associated consensus mechanisms may have a lower tolerance to attacks.

- Scalability: Particularly in public blockchains, scalability can be problematic. While more miners generally result in better security and more decentralization, an increase in the number of transactions can mean that each transaction takes longer to complete, reducing transaction throughput and threatening scalability.

- Transaction cost: Public blockchains rely on rewarding miners for their staking power in participating in the consensus mechanism and committing distributed transactions. Public networks are typically associated with cryptocurrencies, which are utilized in this reward process, which increases transaction costs. In private blockchains, this cost can be negligible.

- Power consumption: Certain blockchains, such as those using PoW consensus mechanisms, are compute-intensive and often have a large carbon footprint due to the energy consumed when attempting to commit transactions. While PoW suffers from this issue, several other options for consensus algorithms that do not rely on power consumption, such as PoS and pBFT, are available today, as well as others, e.g., those available for Hyperledger Fabric.

When implementing an EEE value chain, certain specifications or properties are better suited than others. Because all value chain participants can create a consortium, the optimal choice is a private blockchain [43]. Furthermore, despite the advantages they offer, implementation of IoT technologies in a value chain to ensure traceability can encounter a number of difficulties. There are various challenges associated with deployment, including both technical and non-technical aspects. Non-technical challenges mostly comprise factors that hinder the adoption of these technologies [76]:

- Business owners often lack an understanding of new technologies, and may be hesitant to adopt new solutions due to the absence of industry standards and practices or to market uncertainties, which typically have a huge impact on early adopters.

- Legacy ERP tools that are widely used do not support the integration of new technologies, which increases the cost of adapting new tools and restricts their functionality.

- The integration of new technologies requires the operators of the value chain to acquire new technical skills and an understanding of business-related activities at the macro-level, which can only be achieved through training.

On the other hand, there are technical challenges associated with the adoption of IoT technologies as well, including:

- Maintaining scalability, which is is a major challenge when adopting IoT technologies with BCT for traceability. This is because a product value chain must remain responsive to changes and be subject to continuous improvement in order to meet evolving business needs.

- Achieving interoperability among heterogeneous devices within the network and the federated computing environment; it is a significant technical challenge to promote integration among diverse IoT networks. To enable a more efficient federated computing paradigm, it is essential to consider standardization practices.

7. Conclusions

Due to its size, the EEE industry urgently needs to adopt CE practices within its value chain. The CE model is one of the most promising approaches for promoting sustainable development in the value chain, as it enables the continuous reuse of materials and resources, reducing the production of e-waste and natural resources consumption. Adopting a CE business model requires the development of applications for data collection and tracing products and for measuring their social and environmental impact. Combining blockchain and IoT technologies appears to be a promising solution for addressing the needs of traceability and CE, as described in this article. However, the use of IoT and BCT poses challenges that require further research. One of these challenges is related to the collection of data such as temperature and humidity readings from IoT devices, which generates large quantities of data that cannot all be stored in a blockchain [77]. In this case, high-performance databases such as time-series databases are needed to pre-process and filter the data before selecting the relevant information to be stored in the blockchain. Another challenge concerns the implementation of digital twins.

A traceable item can either be a single product (with a serial number) or a product lot (e.g., semiconductors). This poses additional challenges when implementing traceability solutions, as not all items in a lot may be involved in the production of an EEE. Here, the utilization of blockchain technology for traceability and CE in the EEE value chain has several advantages over other solutions. As there are many participants involved in the value chain, having traceability information on a decentralized network that provides immutability of data is of great significance. Transparency is another major benefit of BCT, as all participants can access the data recorded in the ledger, enabling traceability audits. However, certain blockchains, particularly those utilized for cryptocurrencies, come with their own set of issues, including high energy consumption and transaction fees. Nevertheless, other blockchain technologies that do not present these problems exist to support traceability and CE models. For instance, Hyperledger Fabric is a BCT that uses a fast and non-energy-intensive consensus protocol, and provides several tools for implementing access control, security policies, and private channels [74].

In a CE model, the final consumer is responsible for delivering the EoL of EEE equipment for recycling, thereby closing the loop. However, to ensure the success of the CE model, it may be necessary to incentivize or gamify the participation of final consumers in this process.

As a result of these findings, several notable future work directions have emerged:

- The use of IoT devices results in the generation of large quantities of data which cannot be directly registered on a blockchain. It is necessary to develop middleware for storing these data, for instance in a time-series database, and for pre-processing or filtering the data before disclosing the selected or processed data items for storage on the blockchain.

- To register the environmental and social impact of a value chain into a traceability platform, the adoption of a blockchain-based solution is advantageous, as it will not be owned by any one value chain business partner, instead being distributed among all participants. However, the selected blockchain technology should not have any significant environmental impact, as those based on the proof of work consensus protocol do. Hyperledger Fabric is an existing example of a blockchain technology with low environmental impact.

- To encourage the final consumers to participate in the recycling process, an end user application with gamification features could be developed.

Author Contributions

Conceptualization: E.F.C., A.M.R.d.C., S.I.L. and L.F.; Data curation: E.F.C., S.I.L. and A.M.R.d.C.; Formal analysis: E.F.C., A.M.R.d.C. and S.I.L.; Funding acquisition: A.M.R.d.C.; Investigation: L.F., S.I.L. and E.F.C.; Methodology: E.F.C., A.M.R.d.C. and S.I.L.; Project administration: S.I.L. and A.M.R.d.C.; Resources: L.F., E.F.C., A.M.R.d.C. and S.I.L.; Software: L.F.; Supervision: E.F.C., S.I.L. and A.M.R.d.C.; Validation: E.F.C., S.I.L. and A.M.R.d.C.; Visualization: L.F.; Writing—original draft: L.F., E.F.C., S.I.L. and A.M.R.d.C.; Writing—review and editing: E.F.C., S.I.L. and A.M.R.d.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by FEDER through the Operational Programme for Competitiveness and Internationalization (POCI)—Project “STVgoDigital: Digitalização da Cadeia de Valor do Setor Têxtil e Vestuário”—PPS1 (reference POCI-01-0247-FEDER-046086).

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AD | Autonomous Driving |

| AI | Artificial Intelligence |

| auto-ID | Automatic Identification |

| BPMN | Business Process Model and Notation |

| CE | Circular Economy |

| CPU | Central Processing Unit |

| BCT | Blockchain Technology |

| DLT | Distributed Ledger Technology |

| EEE | Electric and Electronic Equipment |

| EoL | End-of-Life |

| ERP | Enterprise Resource Planning |

| EU | European Union |

| e-waste | Electrical and Electronic Equipment Waste |

| GPS | Global Positioning System |

| IoT | Internet of Things |

| LE | Linear Economy |

| Li-ion | Lithium-ion |

| Li-poly | Lithium polymer |

| LPWAN | Low Power Wide Area Network |

| MRP | Manufacturing Resource Planning |

| NFC | Near Field Communications |

| PoW | Proof of Work |

| PoS | Proof of Stake |

| pBFT | practical Byzantine Fault Tolerance |

| RDBMS | Relational DataBase Management System |

| REST | Representational State Transfer |

| RFID | Radio Frequency IDentification |

| RL | Reverse Logistics |

| RTLS | Real-Time Locating System |

| SBM | Servitized Business Model |

| SC | Smart Contract |

| SCM | Supply Chain Management |

| SOA | Service Oriented Architecture |

| VM | Virtual Machine |

| WEEE | Waste from Electrical and Electronic Equipment |

References

- Rajesh, R.; Kanakadhurga, D.; Prabaharan, N. Electronic waste: A critical assessment on the unimaginable growing pollutant, legislations and environmental impacts. Environ. Challenges 2022, 7, 100507. [Google Scholar] [CrossRef]

- Baldé, C.P.; Forti, V.; Gray, V.; Kuehr, R.; Stegmann, P. The Global e-Waste Monitor 2017: Quantities, Flows and Resources; United Nations University, International Telecommunication Union, and International Solid Waste Association: Hamburg, Germany, 2017. [Google Scholar]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Garam, B. The Global E-Waste Monitor 2020—Quantities, Flows, and the Circular Economy Potential; United Nations University/United Nations Institute for Training and Research, International Telecommunication Union, and International Solid Waste Association: Hamburg, Germany, 2020. [Google Scholar]

- Wiens, K. Smartphone Repairs You Can Do on Earth Day; iFixit: San Luis Obispo, CA, USA, 2014. [Google Scholar]

- Jardim, E. From Smart to Senseless: The Global Impact of 10 Years of Smartphones; Greenpeace Inc.: Washington, DC, USA, 2017. [Google Scholar]

- Manhart, A.; Blepp, M.; Fischer, C.; Graulich, K.; Prakash, S.; Priess, R.; Schleicher, T.; Tür, M. Resource Efficiency in the ICT Sector; Greenpeace eV: Tokyo, Japan, 2016. [Google Scholar]

- Limata, P. Speculating on the Application of Blockchains in the Circular Economy; CERBE Working Papers wpC32; CERBE Center for Relationship Banking and Economics: St. Louis, MO, USA, 2019. [Google Scholar]

- Da Cruz, A.M.R.; Cruz, E.F. Blockchain-based Traceability Platforms as a Tool for Sustainability. In Proceedings of the 22st International Conference on Enterprise Information Systems (ICEIS 2020), Prague, Czech Republic, 5–7 May 2020; SciTePress: Setubal, Portugal, 2020; Volume 2, pp. 330–337. [Google Scholar]

- Gu, Y.; Wu, Y.; Xu, M.; Mu, X.; Zuo, T. Waste electrical and electronic equipment (WEEE) recycling for a sustainable resource supply in the electronics industry in China. J. Clean. Prod. 2016, 127, 331–338. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards the Circular Economy; Ellen MacArthur Foundation: Geneva, Switzerland, 2015. [Google Scholar]

- Wautelet, T. Exploring the Role of Independent Retailers in the Circular Economy: A Case Study Approach. Master’s Thesis, eufom European University for Economics & Management, Luxembourg, 2018. [Google Scholar] [CrossRef]

- Cruz, E.F.; da Cruz, A.M.R.; Gomes, R. Analysis of a traceability and quality monitoring platform for the fishery and aquaculture value chain. In Proceedings of the 2019 14th Iberian Conference on Information Systems and Technologies (CISTI), Coimbra, Portugal, 19–22 June 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Ongondo, F.; Williams, I.; Cherrett, T. How are WEEE doing? A global review of the management of electrical and electronic wastes. Waste Manag. 2011, 31, 714–730. [Google Scholar] [CrossRef] [PubMed]

- González, X.M.; Rodríguez, M.; Pena-Boquete, Y. The social benefits of WEEE re-use schemes. A cost benefit analysis for PCs in Spain. Waste Manag. 2017, 64, 202–213. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Atlason, R.; Giacalone, D.; Parajuly, K. Product design in the circular economy: Users’ perception of end-of-life scenarios for electrical and electronic appliances. J. Clean. Prod. 2017, 168, 1059–1069. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Akcil, A.; Erust, C.; Gahan, C.S.; Ozgun, M.; Sahin, M.; Tuncuk, A. Precious metal recovery from waste printed circuit boards using cyanide and non-cyanide lixiviants—A review. Waste Manag. 2015, 45, 258–271. [Google Scholar] [CrossRef]

- Bressanelli, G.; Pigosso, D.C.; Saccani, N.; Perona, M. Enablers, levers and benefits of Circular Economy in the Electrical and Electronic Equipment supply chain: A literature review. J. Clean. Prod. 2021, 298, 126819. [Google Scholar] [CrossRef]

- Kumar, S.; Putnam, V. Cradle to cradle: Reverse logistics strategies and opportunities across three industry sectors. Int. J. Prod. Econ. 2008, 115, 305–315. [Google Scholar] [CrossRef]

- Mandolini, M.; Favi, C.; Germani, M.; Marconi, M. Time-based disassembly method: How to assess the best disassembly sequence and time of target components in complex products. Int. J. Adv. Manuf. Technol. 2018, 95, 409–430. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, S.; Sekhari, A. A modular eco-design method for life cycle engineering based on redesign risk control. Int. J. Adv. Manuf. Technol. 2011, 56, 1215. [Google Scholar] [CrossRef]

- Kim, J.; Hwang, Y.; Park, K. An assessment of the recycling potential of materials basedon environmental and economic factors; case study in South Korea. J. Clean. Prod. 2009, 17, 1264–1271. [Google Scholar] [CrossRef]

- Nistor, S.; Wu, J.; Sooriyabandara, M.; Ekanayake, J. Capability of smart appliances to provide reserve services. Appl. Energy 2015, 138, 590–597. [Google Scholar] [CrossRef]

- Batty, M. Digital twins. Environ. Plan. B Urban Anal. City Sci. 2018, 45, 817–820. [Google Scholar] [CrossRef]

- Favot, M.; Veit, R.; Massarutto, A. The ratio of EPR compliance fees on sales revenues of electrical and electronic equipment in Italy. A circular economy perspective. Resour. Conserv. Recycl. 2018, 135, 34–37. [Google Scholar] [CrossRef]

- Gnoni, M.G.; Mossa, G.; Mummolo, G.; Tornese, F.; Verriello, R. Circular economy strategies for electric and electronic equipment: A fuzzy cognitive map. Environ. Eng. Manag. J. EEMJ 2017, 16, 1807–1817. [Google Scholar]

- Intlekofer, K.; Bras, B.; Ferguson, M. Energy Implications of Product Leasing. Environ. Sci. Technol. 2010, 44, 4409–4415. [Google Scholar] [CrossRef]

- Tasaki, T.; Hashimoto, S.; Moriguchi, Y. A quantitative method to evaluate the level of material use in lease/reuse systems of electrical and electronic equipment. J. Clean. Prod. 2006, 14, 1519–1528. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Thürer, M.; Qu, T.; Huisingh, D. Circular supply chain management: A definition and structured literature review. J. Clean. Prod. 2019, 228, 882–900. [Google Scholar] [CrossRef]

- Kissling, R.; Fitzpatrick, C.; Boeni, H.; Luepschen, C.; Andrew, S.; Dickenson, J. Definition of generic re-use operating models for electrical and electronic equipment. Resour. Conserv. Recycl. 2012, 65, 85–99. [Google Scholar] [CrossRef]

- Alumur, S.A.; Nickel, S.; da Gama, F.S.; Verter, V. Multi-period reverse logistics network design. Eur. J. Oper. Res. 2012, 220, 67–78. [Google Scholar] [CrossRef]

- Zhang, T.; Kraisintu, K. The Role of Traceability in Sustainable Supply Chain Management. Master’s Thesis, Chalmers University of Technology, Göteborg, Sweden, 2011. [Google Scholar]

- Traceability in the Production of Electronics. 2017. Available online: https://en.elhurt.com/traceability-in-the-production-of-electronics/ (accessed on 8 September 2022).

- Giannakis, M.; Papadopoulos, T. Supply chain sustainability: A risk management approach. Int. J. Prod. Econ. 2016, 171, 455–470. [Google Scholar] [CrossRef]

- Richardson, H. Traceability for Electronics Manufacturing; Siemens PLM: Plano, TX, USA, 2020. [Google Scholar]

- Oliveira, J.; Lima, J.E.; da Silva, D.; Kuprych, V.; Faria, P.M.; Teixeira, C.; Ferreira Cruz, E.; Rosado da Cruz, A.M. Traceability system for quality monitoring in the fishery and aquaculture value chain. J. Agric. Food Res. 2021, 5, 100169. [Google Scholar] [CrossRef]

- Li, W.; Chao, K.M.; Jin, G.; Xia, K.; Gao, L. Sustainable information management for Waste Electrical and Eletronic Equipment. In Proceedings of the 2012 IEEE 16th International Conference on Computer Supported Cooperative Work in Design (CSCWD), Wuhan, China, 23–25 May 2012; pp. 875–881. [Google Scholar] [CrossRef]

- Capecci, S.; Cassisi, E.; Granatiero, G.; Scavongelli, C.; Orcioni, S.; Conti, M. Cloud-based system for waste electrical and electronic equipment. In Proceedings of the 2017 13th Workshop on Intelligent Solutions in Embedded Systems (WISES), Hamburg, Germany, 12–13 June 2017; pp. 41–46. [Google Scholar] [CrossRef]