A Review of Electro-Mechanical Brake (EMB) System: Structure, Control and Application

Abstract

1. Introduction

- Reduced system volume and weight, convenient installation and maintenance;

- No brake fluid leakage and less environmental pollution;

- Zero residual drag torque, lower power consumption and longer brake service life;

- Easy to integrate with a parking brake;

- Faster braking response and higher control precision;

- Easy to match with composite braking systems and active safety control systems.

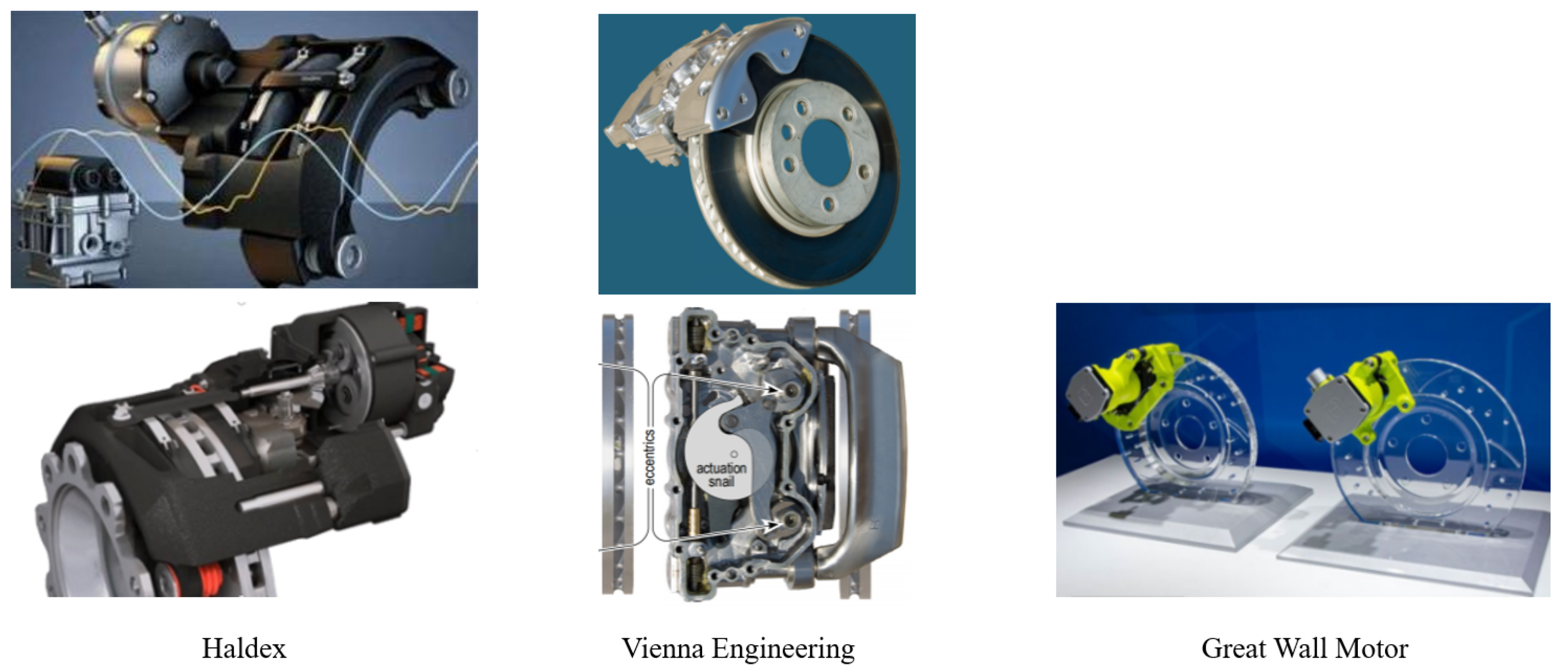

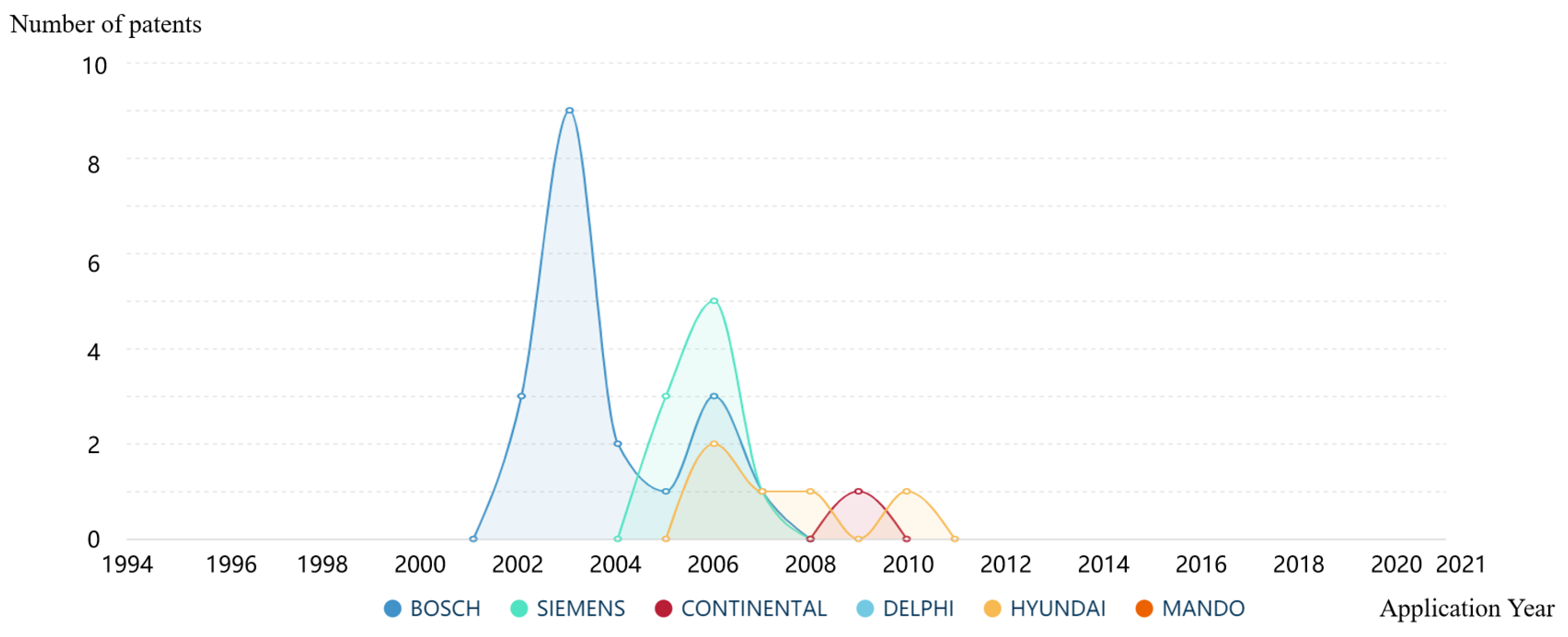

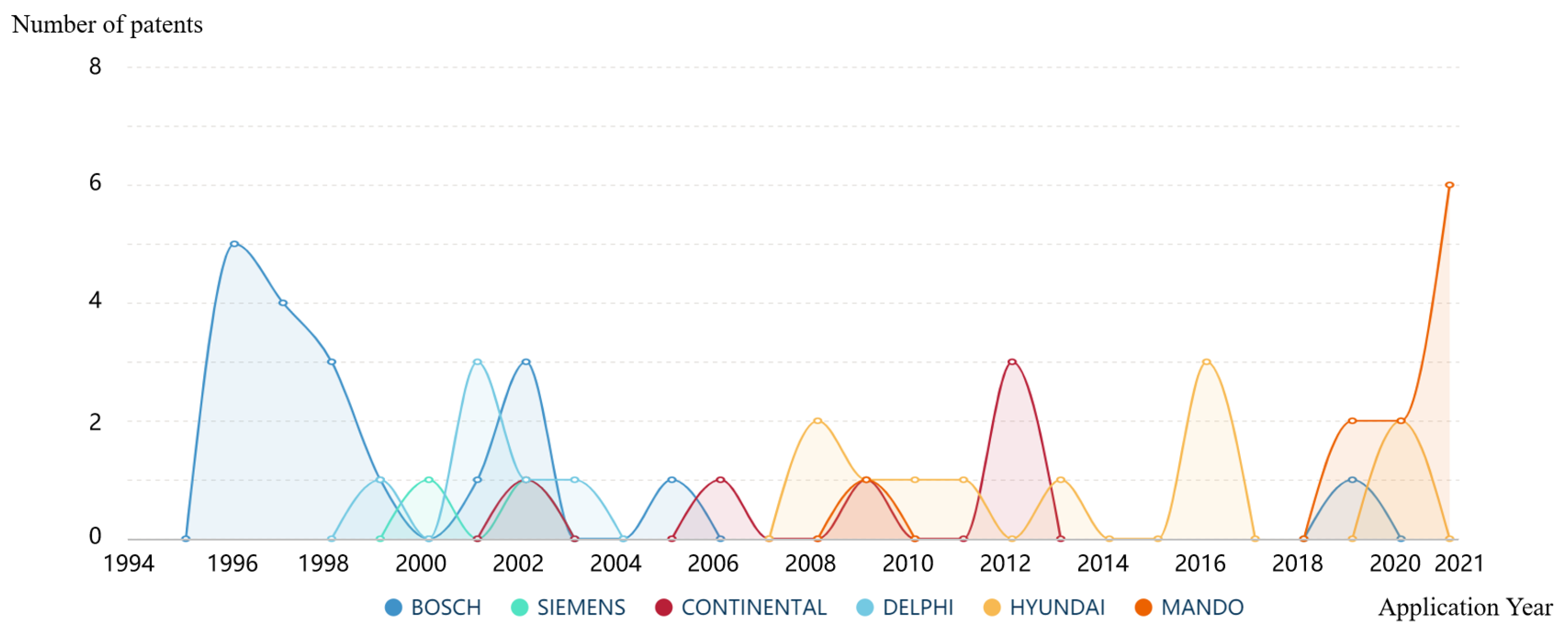

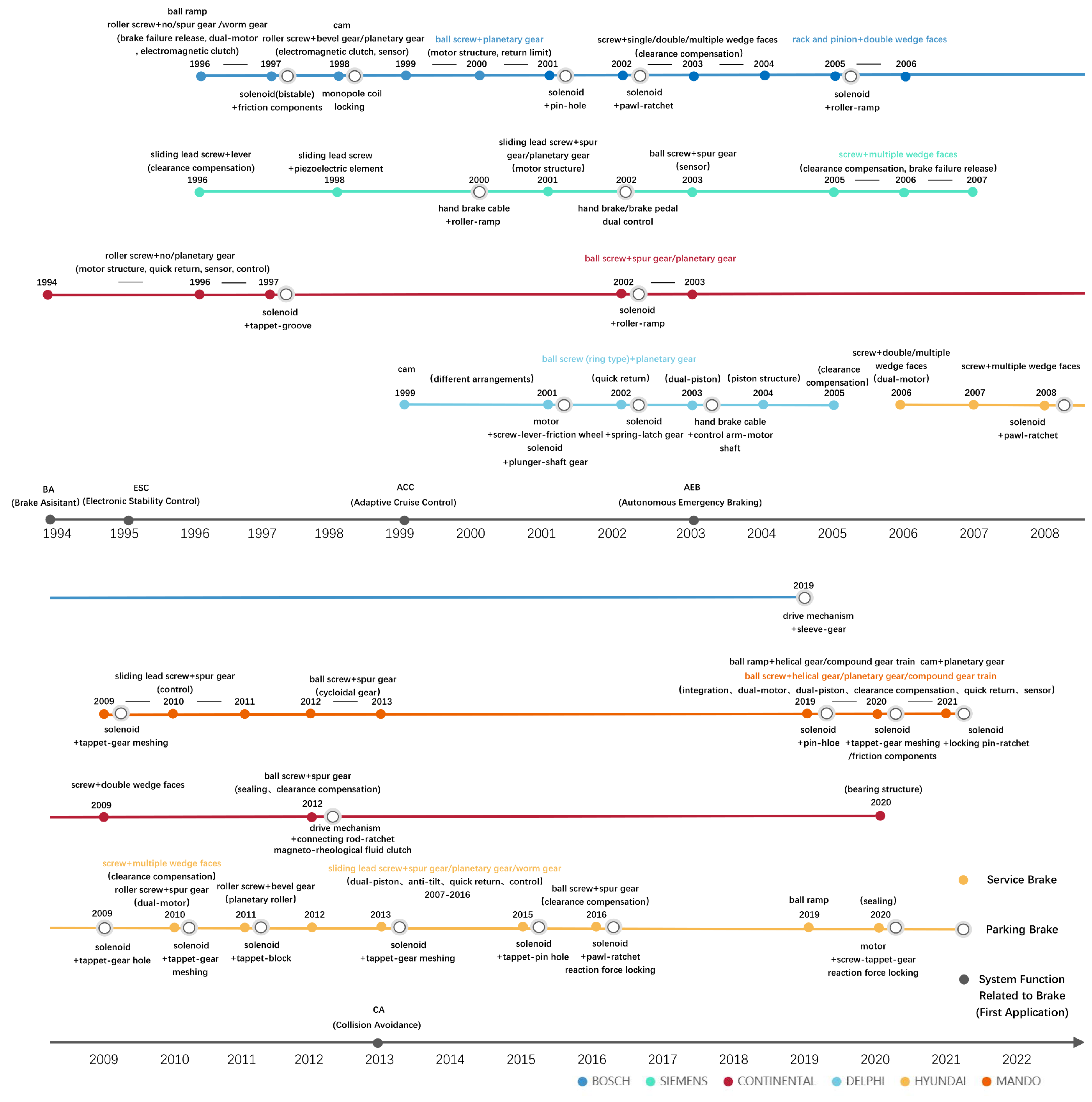

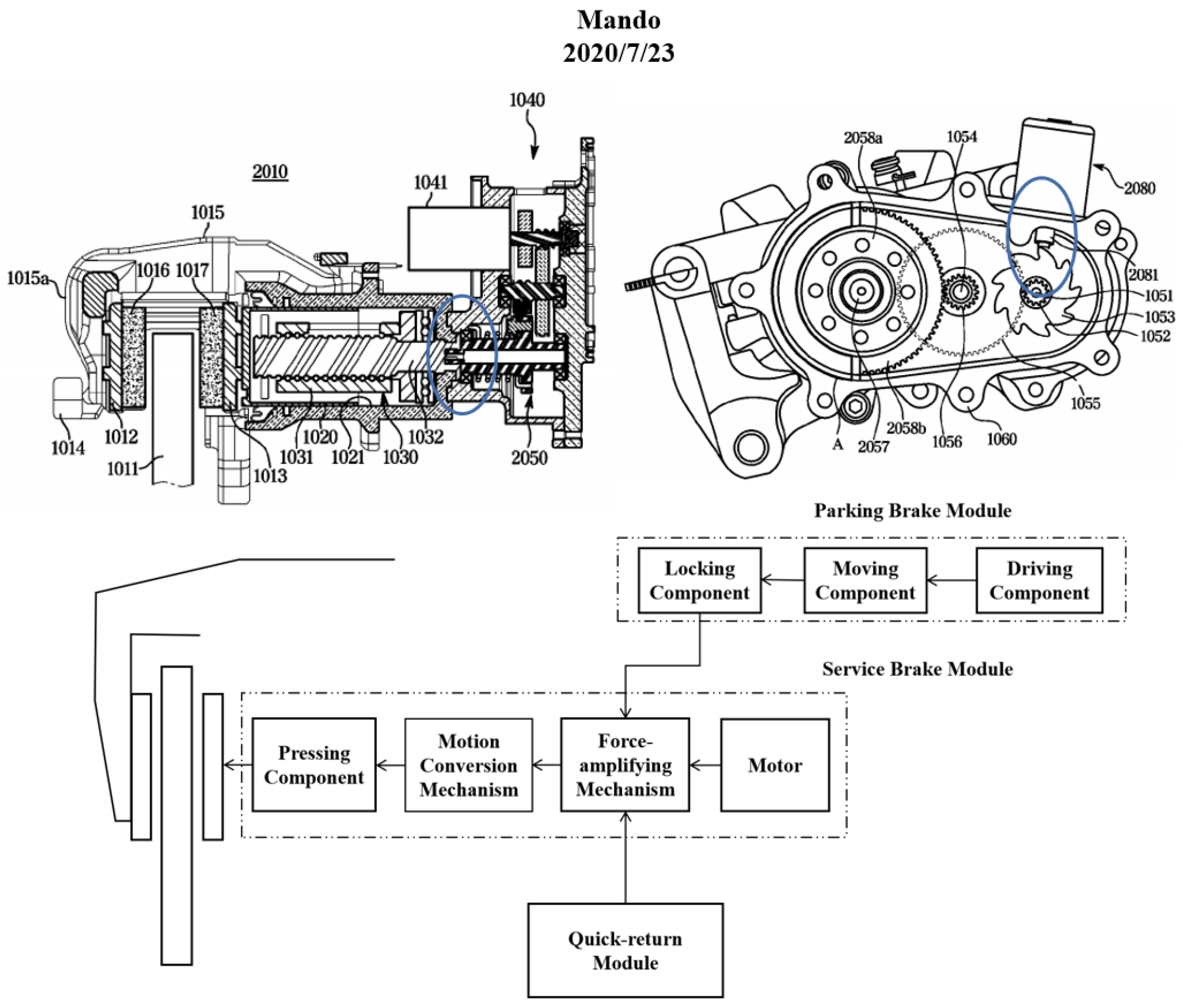

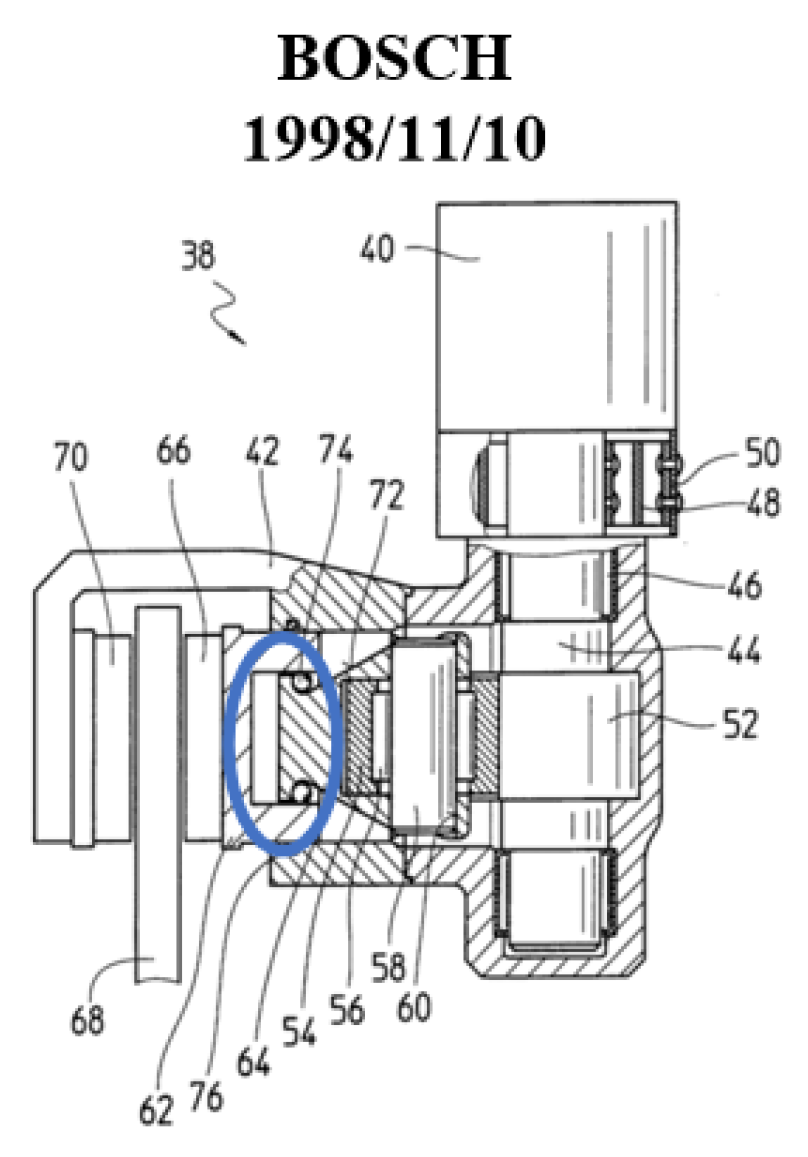

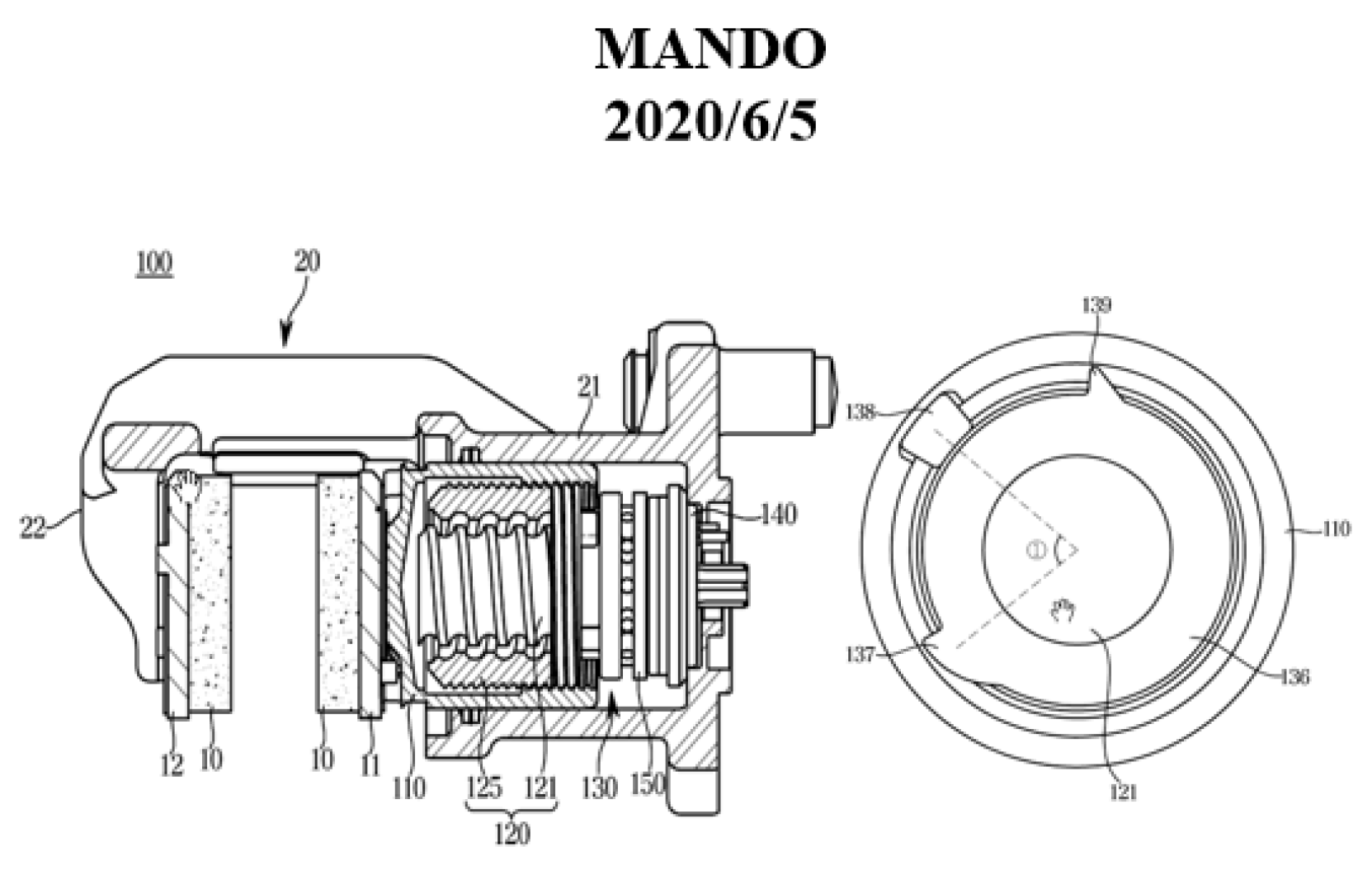

2. Development Status of the EMB Actuator

3. Basic Configuration of the EMB Actuator

3.1. Pressing Component

3.1.1. Basic Form

3.1.2. Dual Pressing Components

3.1.3. Point Contact Connection

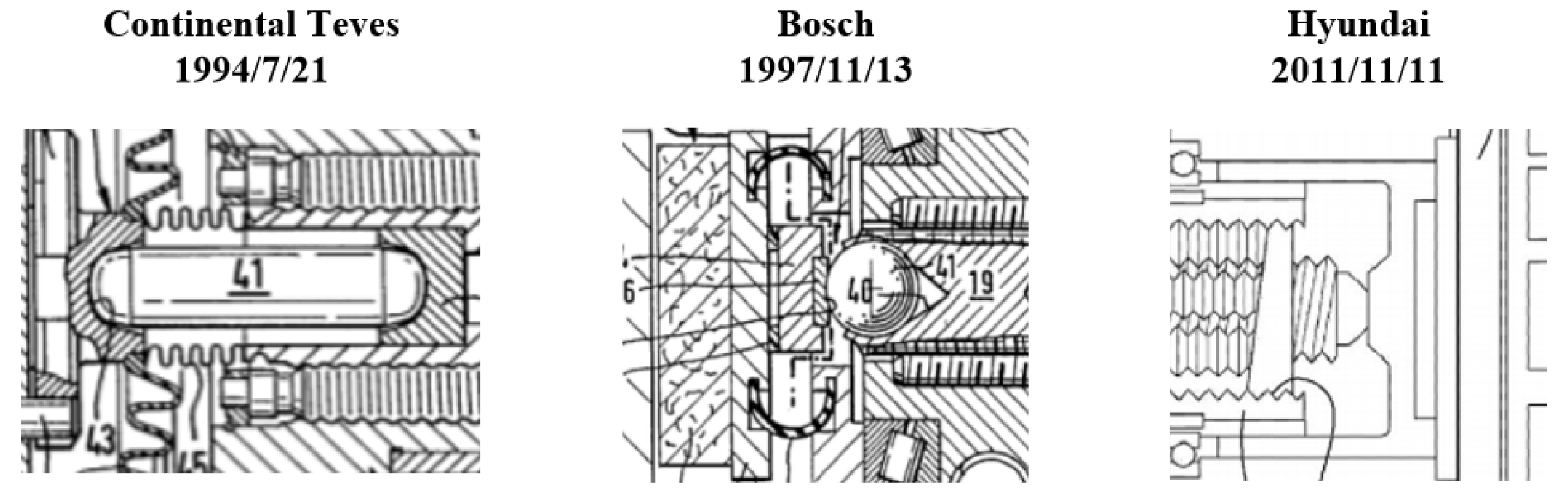

3.2. Motion Conversion Mechanism

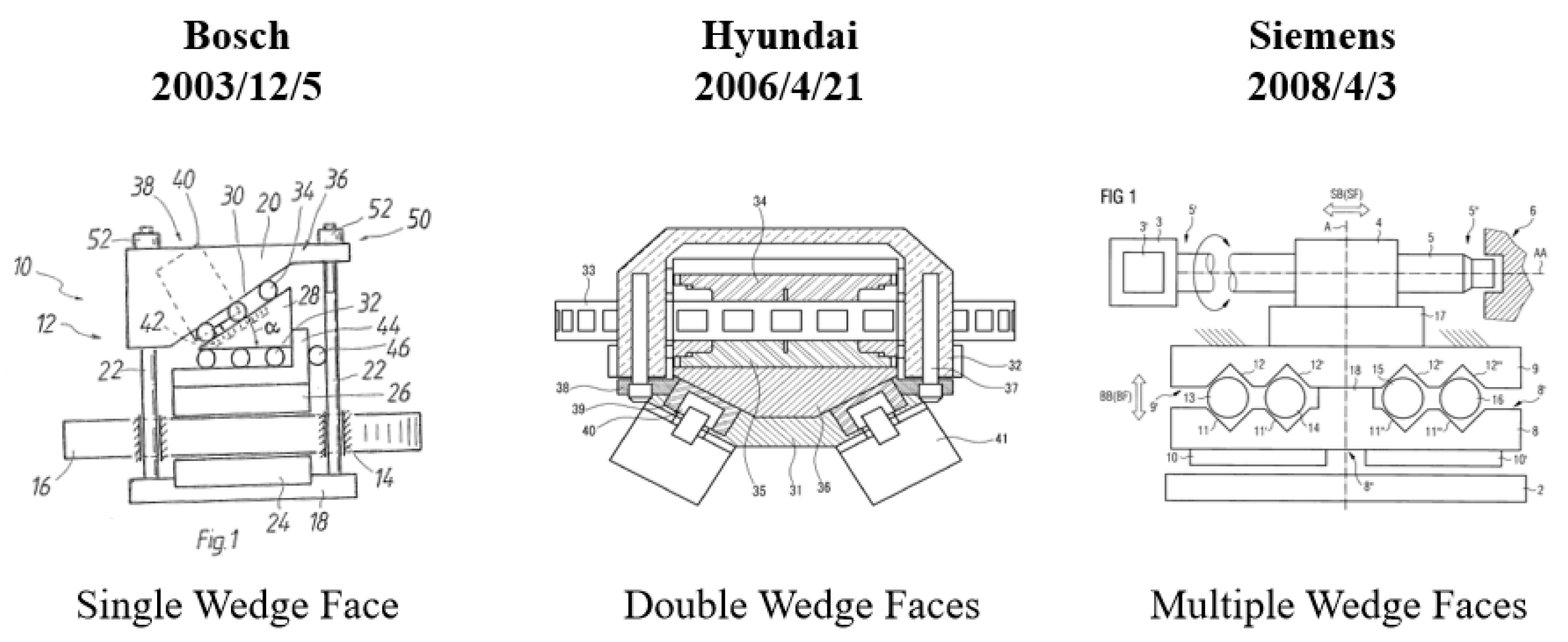

3.3. Force-Amplifying Mechanism

3.3.1. Reducing Mechanism

3.3.2. Self-Energizing Mechanism

3.4. Motor Type and Arrangement

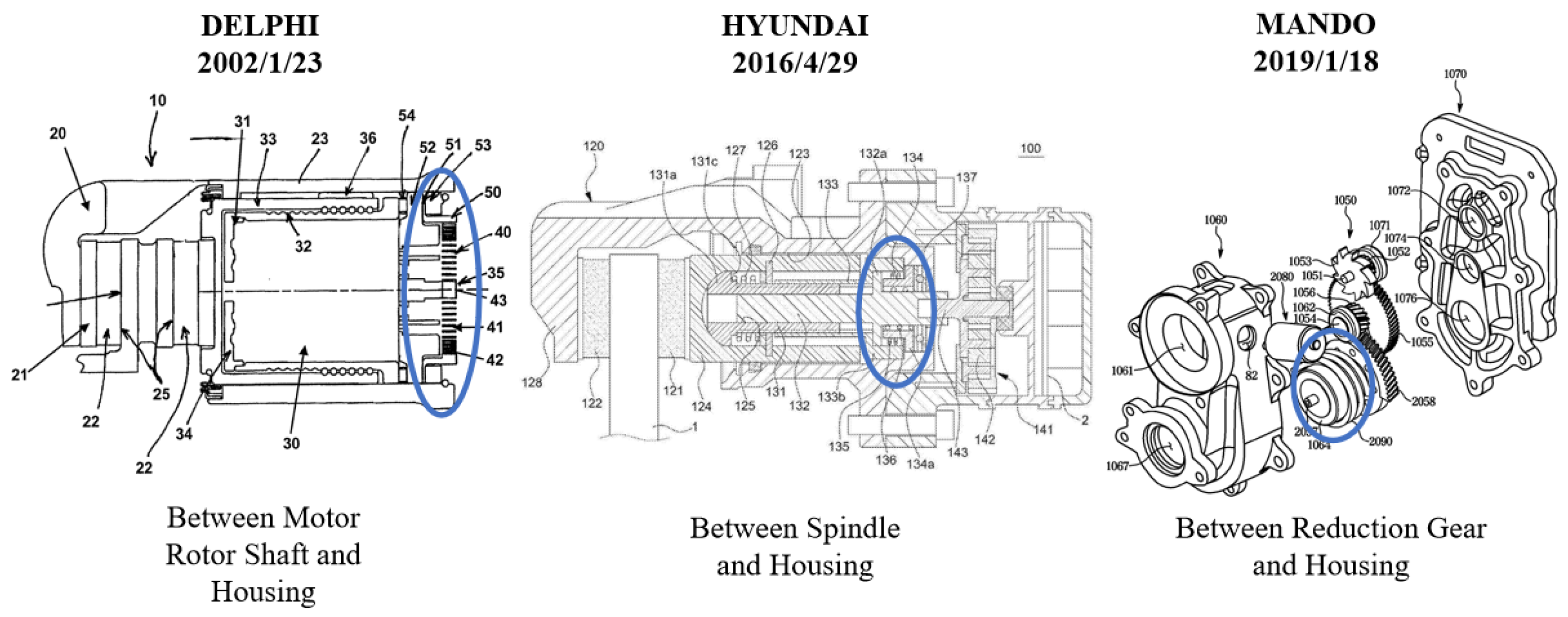

3.4.1. Motor Type

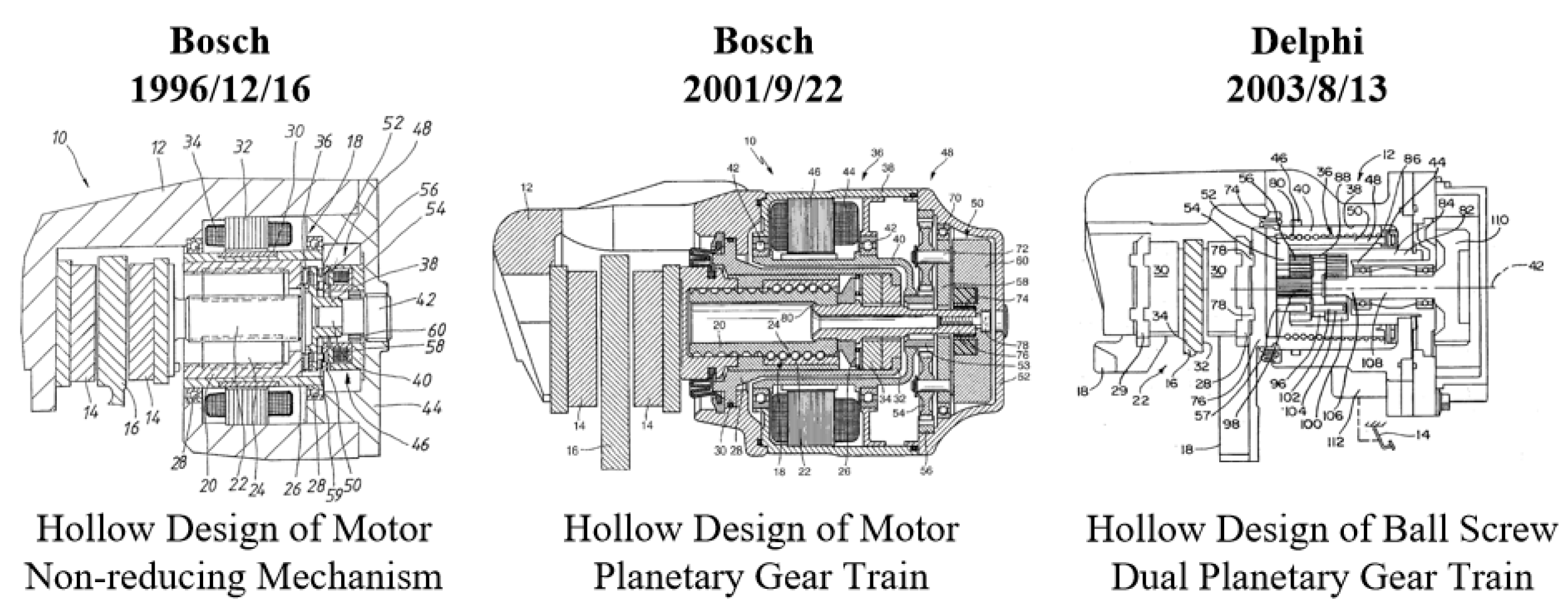

- Integral design, that is, a solid rotor is nested in the stator, and the end of the rotor is axially connected to other components to output power. As shown in Figure 13, this structure is simple but the axial or radial layout size is large;

- Hollow design, that is, a hollow rotor is nested in the stator, and the rotor is coaxially connected to other components to the output power. This structure has a high level of integration with reduced axial size, but is also complicated in design and the adaptability is relatively poor.

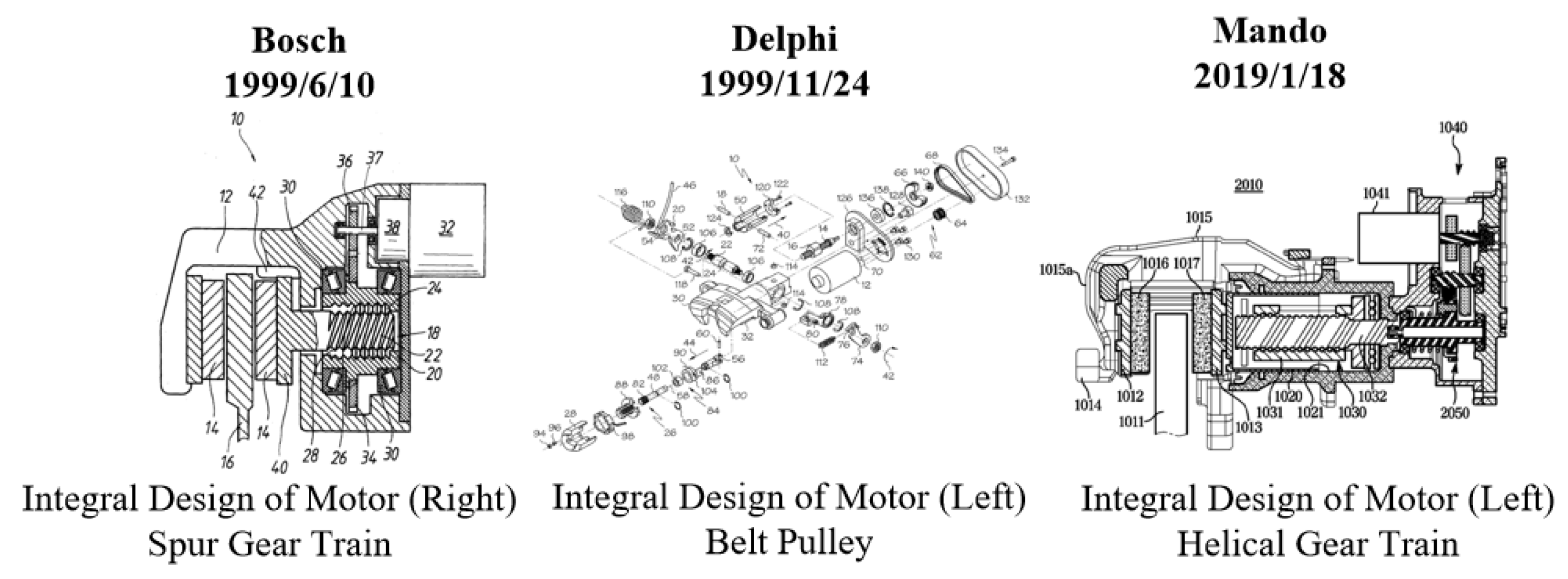

3.4.2. Motor Arrangement

3.4.3. Dual-Motor Design

- Brake clearance adjustment: the release motor 34 can be controlled by the angular displacement sensor at the output shaft to adjust the braking clearance to ensure that the braking clearance is constant.

- Brake failure release: the secondary motor 60 drives the trapezoidal nut 48 to rotate, so that the hollow shaft 46 with the entire supporting drive device moves axially, thereby releasing the brake in the event of a failure.

- Quick elimination of brake clearance: the secondary motor 50 drives the gear trains 52 and the spindle 56 to rotate, so that the nut 60 is axially displaced to quickly eliminate the brake clearance. Then, the secondary motor 50 is stopped and the main motor 22 is energized to generate a pressing force.

- Parking brake: the parking brake motor 30 drives the trapezoidal screw 34 to rotate, driving the trapezoidal nut 36 to move, so that the lever 40 is pressed on the friction disc 20, thereby preventing the rotation of the motor shaft 15 and achieving brake locking;

- Braking stability enhancement: two motors 41 directly drive the wedge 36 to press the disc, producing a self-energizing effect while maintaining a stable pressure.

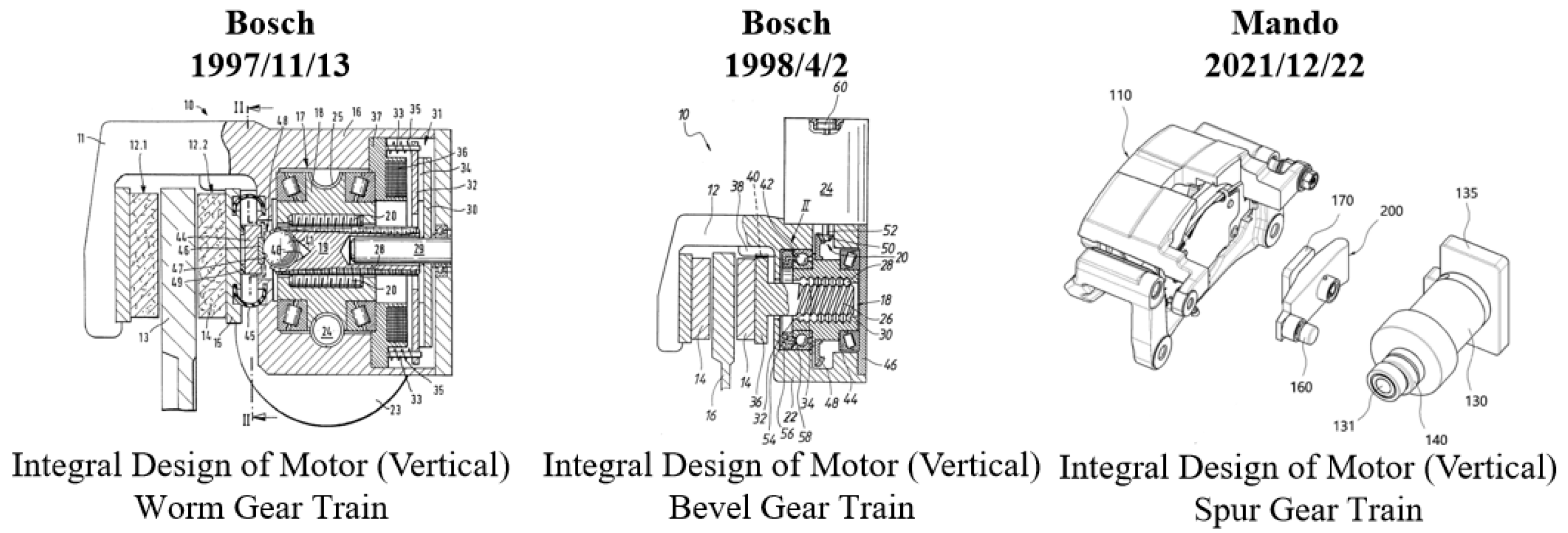

3.5. Parking Brake Module

3.5.1. Manual Parking Brake

3.5.2. Motor-Driven Parking Brake

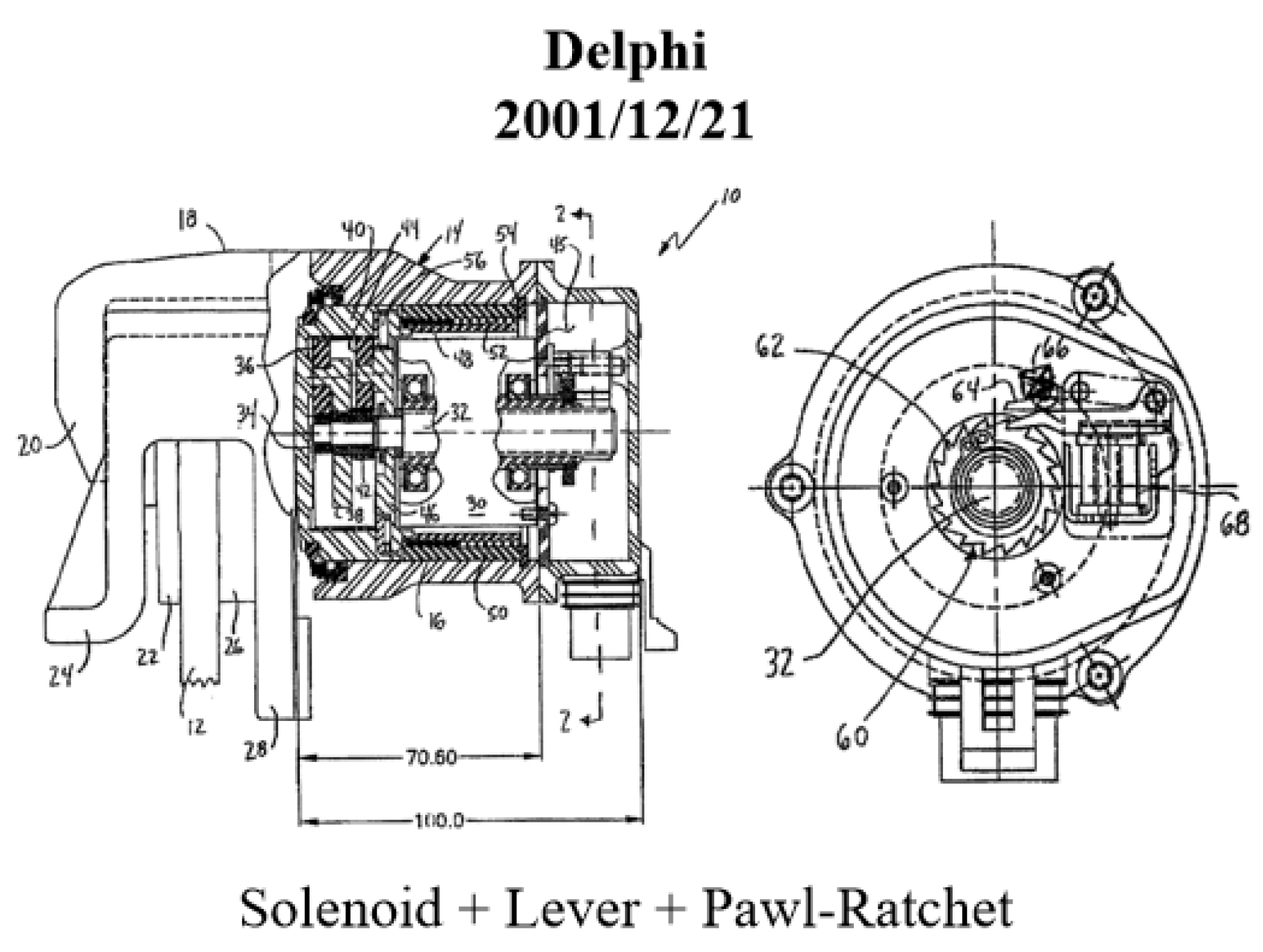

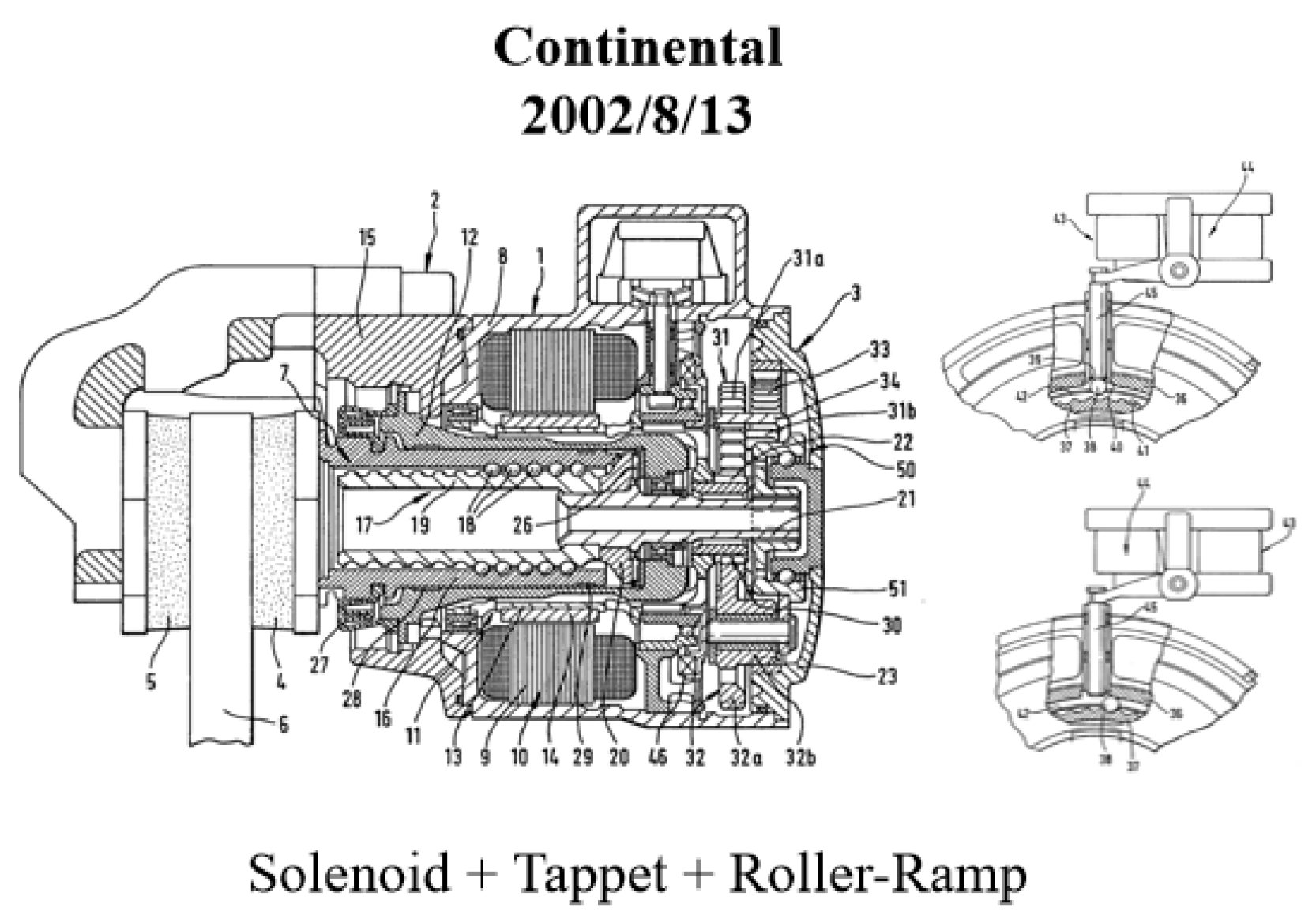

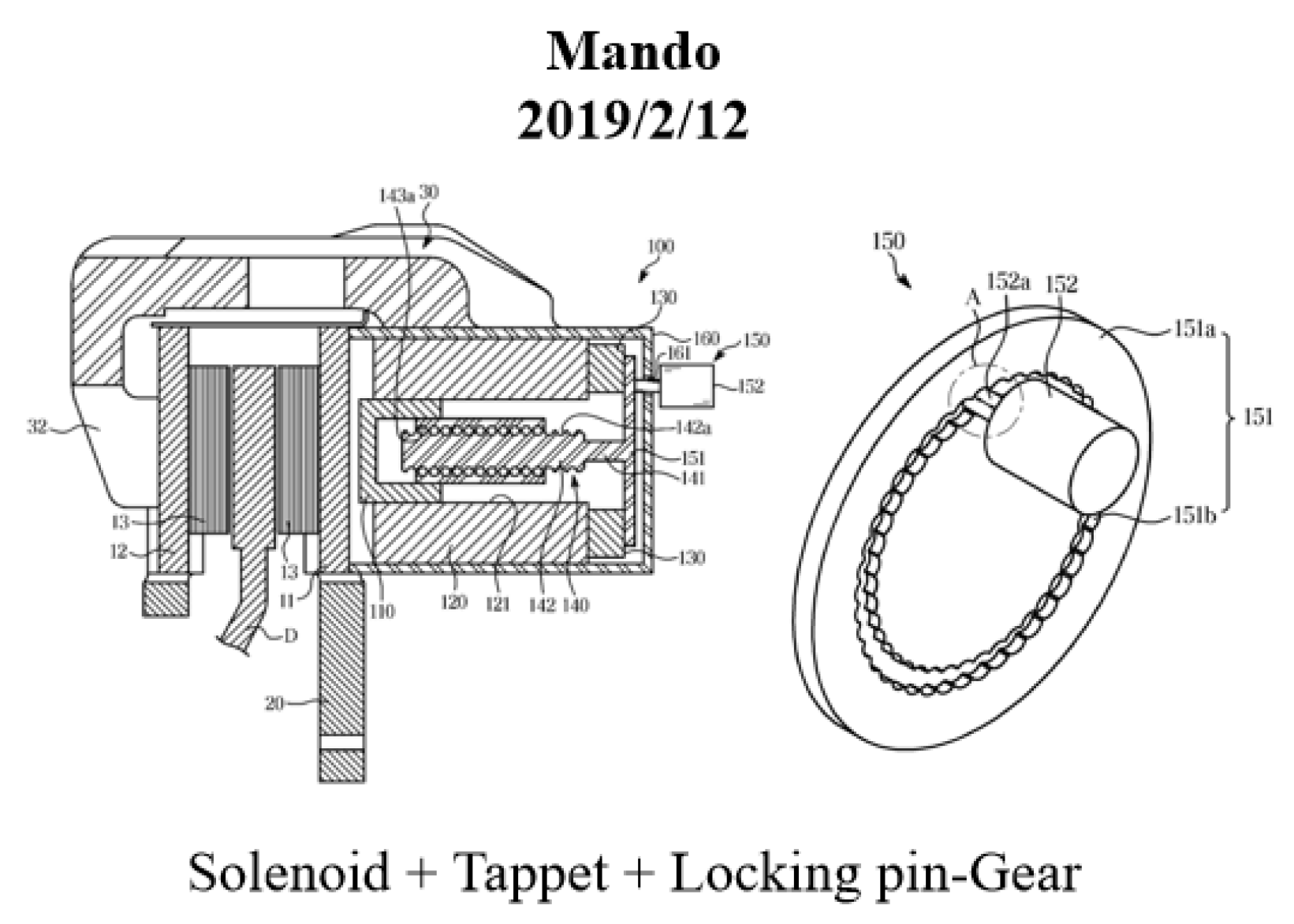

3.5.3. Solenoid-Driven Parking Brake

3.5.4. Summary

- Solenoid-driven schemes using the friction components can achieve flexible locking and braking force control, and the braking process is stable without large impacts, but the nature of friction leads to the problem of poor thermal stability and durability.

- Solenoid-driven schemes using the pawl and ratchet can maintain a relatively large braking force, but the pawl may advance excessively, causing a continuous impact on the ratchet, and further problems such as wear and deformation may occur, reducing the durability and reliability of the parking brake.

- Solenoid-driven schemes using the roller and ramp have a smooth locking process and can produce a certain force-amplifying effect. However, the ramp angle and locking position are difficult to design to ensure the locking effect.

- Solenoid-driven schemes using the pin and gear are simple in design, but when the locking pin is separated from the gear teeth, the gear may be stuck, which reduces the response speed and stability of the parking brake.

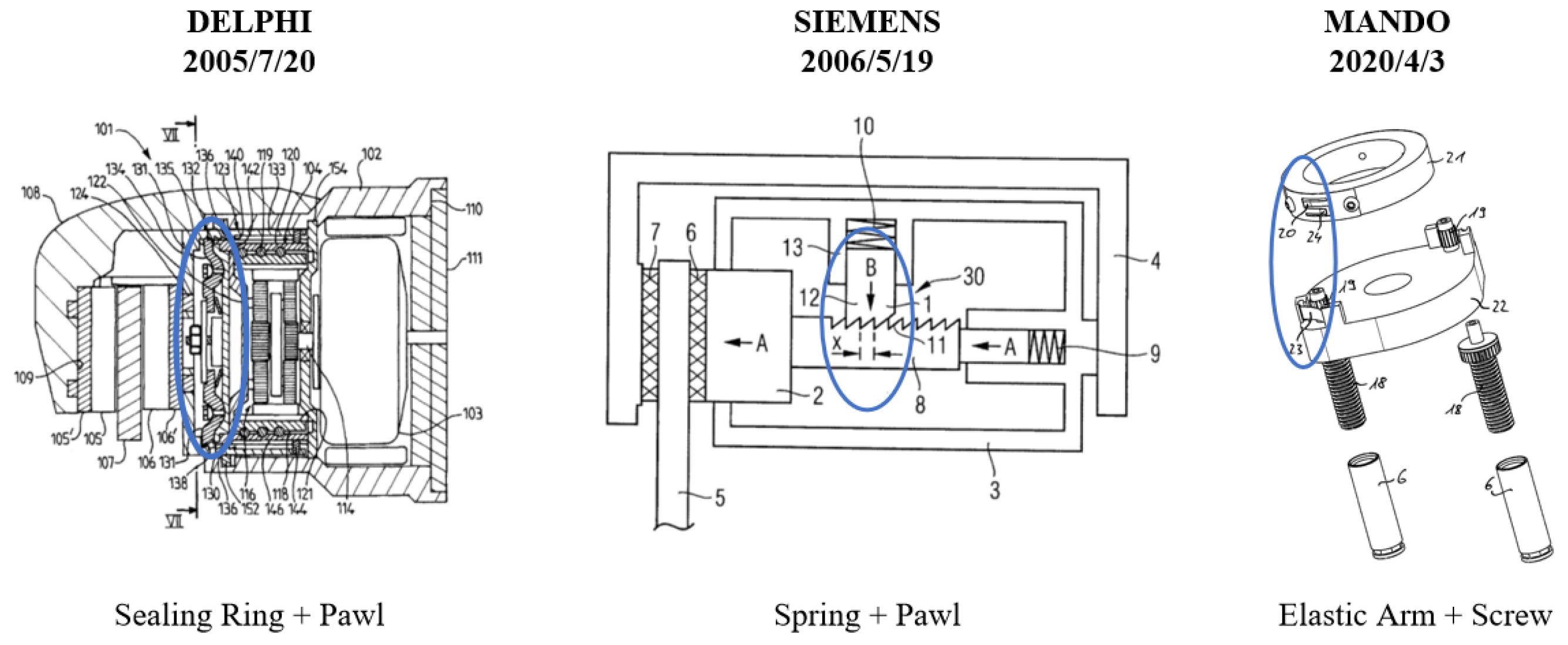

3.6. Brake Clearance Compensation Module

3.6.1. Flexible Compensation Mechanism

3.6.2. Rigid Compensation Mechanism

3.6.3. Flexible and Rigid Compensation Mechanism

3.7. Quick-Return Module

3.7.1. Torsion Spring

3.7.2. Compression Spring

3.7.3. Other Elastic Components

3.8. Sensor Type and Arrangement

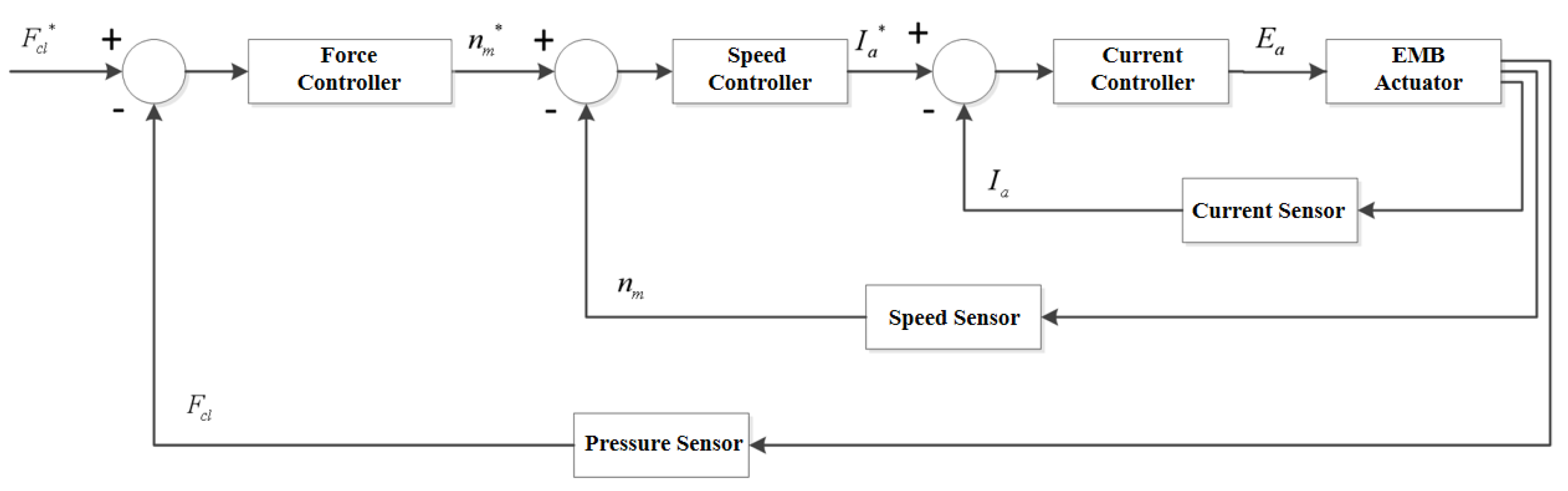

4. Research on Control of the EMB Actuator

4.1. Estimation Method for Indirect Clamping Force Control

4.2. Direct Clamping Force Control

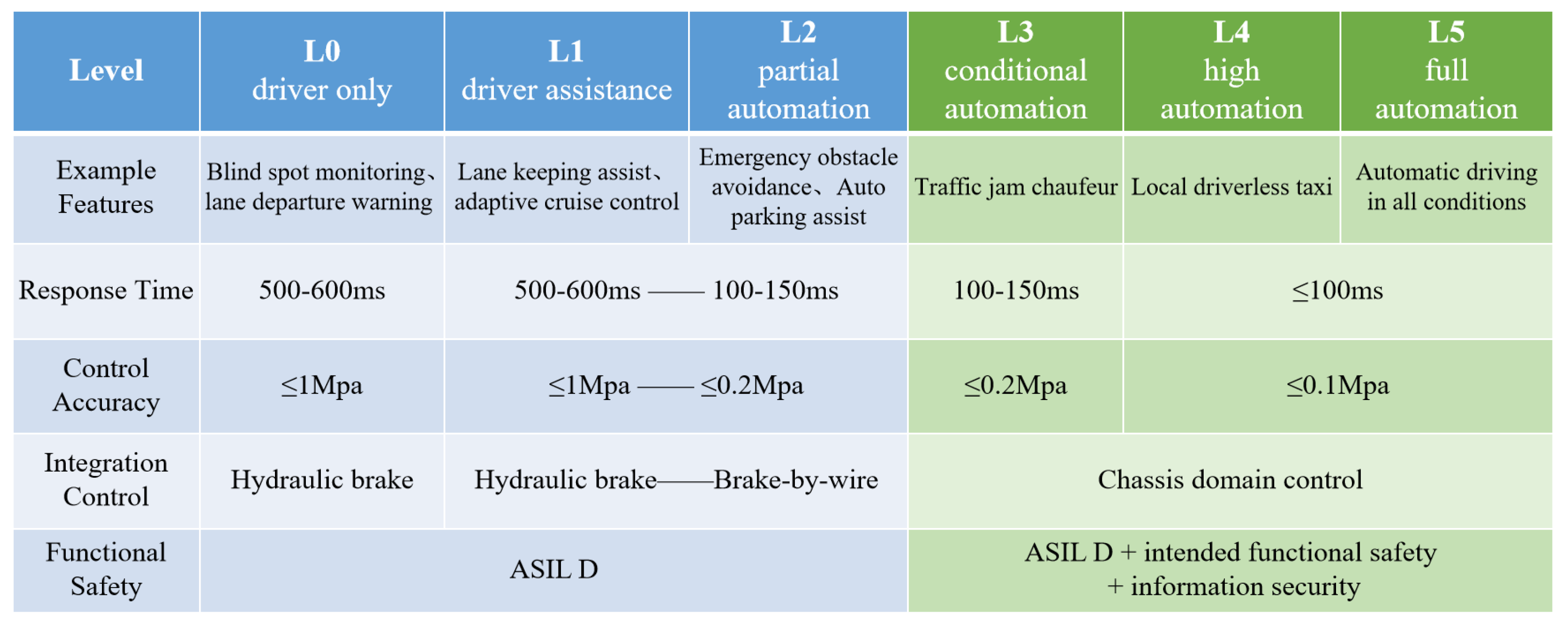

5. System Architecture and Intelligent Driving Application of EMB

- Fast response and precise control: automated driving above L4 level puts forward higher requirements on the response speed and control accuracy of active braking in terms of vehicle dynamic control. For EMB systems, the braking response time should be within 100ms, and the steady-state control accuracy should reach 0.1MPa;

- Highly integrated control: the coordinated control of driving, braking and steering requires the control of each subsystem to be centralized in the chassis domain controller. Under the framework of the chassis domain controller, the EMB system needs to have a high degree of control freedom for integrated control;

- Good redundant safety: From assisted driving (L1 and L2 levels) to automatic driving (above L3 level), the functional safety of the intelligent driving system is a key issue, and it is necessary to ensure that the system can still take over in the event of a single failure. Brake redundancy is an important part of functional safety. For EMB systems, ASIL-D level functional safety must be met through the redundant design of actuators (dual-motor design), control algorithms (indirect control based on clamping force estimation) and system architecture. In addition, it is also necessary to meet the requirements of the intended functional safety and information security.

5.1. System Architecture

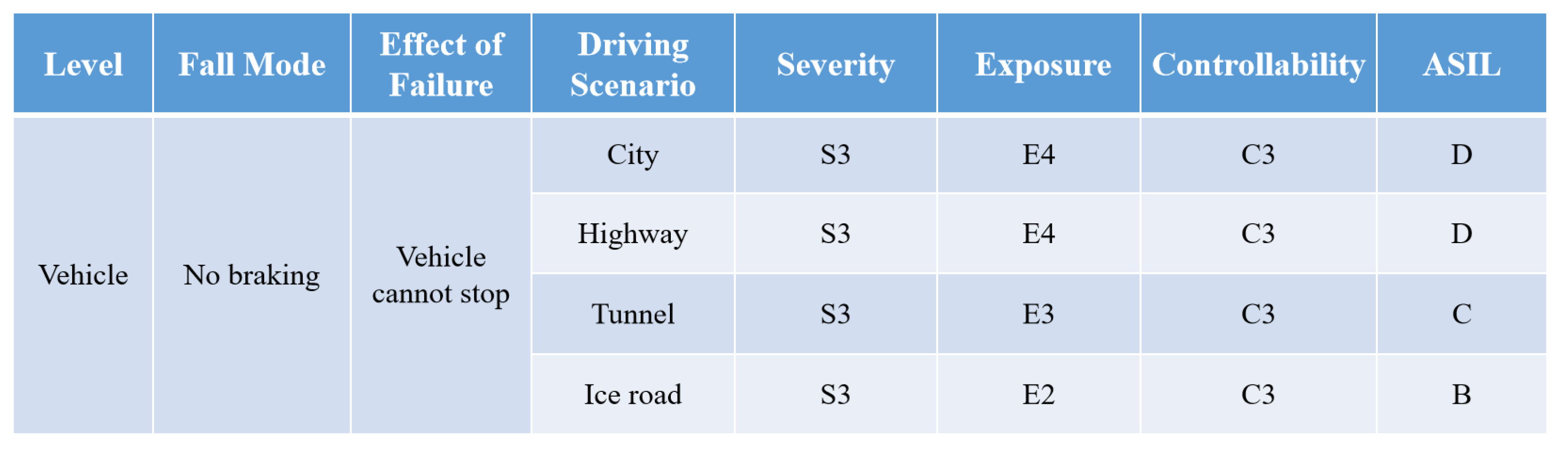

- Hazard analysis: the Automotive Safety Integrity Level (ASIL) is first assigned by systematically assessing the hazard at the vehicle and subsystem levels based on three factors: severity, exposure and controllability. As shown in Figure 36, the fall mode of “no braking” for various driving scenarios is analyzed as an example [88]; the braking system should meet the highest safety level, ASIL-D.

- Safety function requirements: based on the hazard analysis, the overall safety goal is set as reducing the possibility of losing the braking ability. Specifically, it includes three different modes: (1) Full function mode: the system can tolerate at least one arbitrary fault and guarantee full braking capacity; (2) partial function mode: partial loss of braking capacity caused by a single failure should not affect the stability of the vehicle. (3) Emergency mode: the system must ensure that the vehicle can stop completely after the occurrence of a second arbitrary fault.

- System architecture design principles: based on the safety function requirements, the main design principles are set as follows: (1) Avoid single point failure; (2) minimal dependency of the system on any condition that can suddenly become false; (3) conservative design with minimal dependencies and adequate fault tolerance.

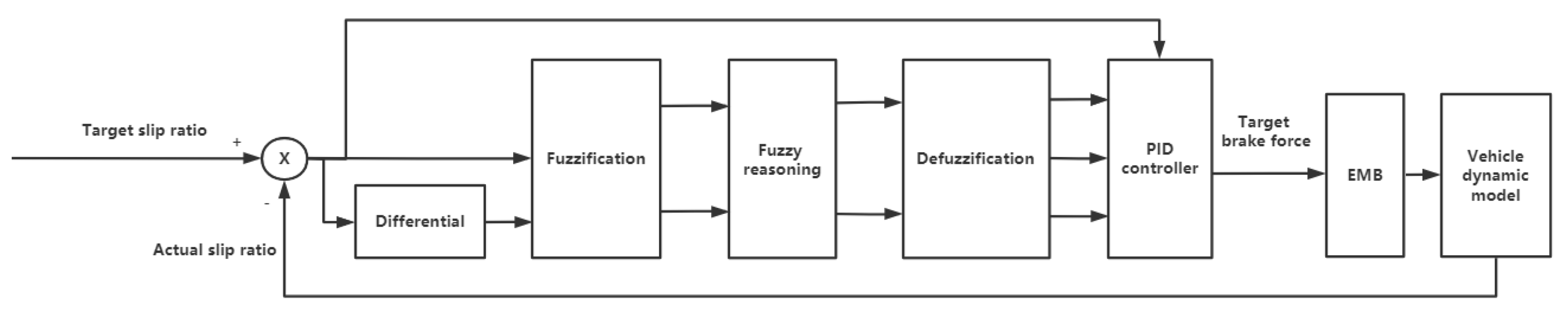

5.2. Vehicle Stability Control Based on the EMB System

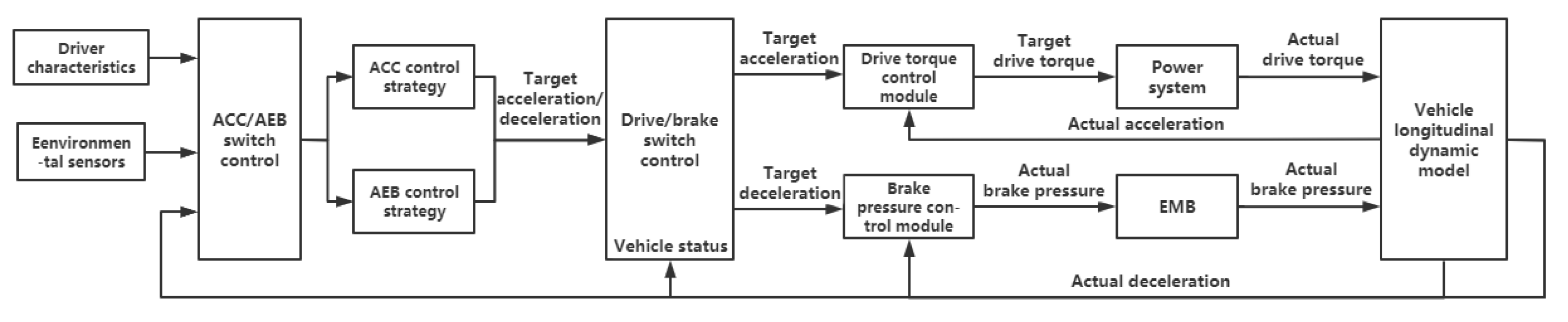

5.3. Advanced Driver Assistance Based on the EMB System

6. Conclusions

- For the service brake module, the motion conversion is generally realized in the form of screw transmission (especially ball screw and roller screw). Moreover, the reducing mechanism (represented by the planetary gear train) or force increasing mechanism (represented by the wedge-type self-energizing mechanism) are mainly used to solve the problem of the insufficient driving force of the motor.

- For the parking brake module, according to the different driving components commonly used, it can be divided into three types: manual type, motor-driven type and solenoid-driven type. Among them, the solenoid-driven scheme has become the mainstream scheme, since its structure is simple and compact.

- For the brake clearance compensation module, according to the material properties of the components used, it can be divided into three types: flexible type, rigid type, flexible and rigid type. Among them, the flexible and rigid compensation mechanism combines the characteristics of the former two schemes, so that the control of the brake clearance is more accurate and reliable, and the compensation process is smoother.

- For the quick-return module, torsion springs, compression springs or other elastic elements are generally used to store the elastic energy and realize the quick release of the braking force.

- For the estimation of the clamping force, there are three methods, respectively, based on the angular displacement of the motor, the motor current, and the fusion of the angular displacement and current. Most of them still use the approximate model for fitting, which is not robust in interference factors such as temperature and friction. A strong robust state estimation algorithm needs to be further developed.

- For the control of the clamping force, the cascaded PID control algorithm is mainly used at present, and other algorithms such as robust control, model predictive control, and sliding mode control are also included. Given the nonlinear time-varying characteristics of the EMB system, the use of adaptive intelligent control algorithms to achieve a precise adjustment of the braking force is a major trend in the current research.

- The research on the application of the EMB system in intelligent driving is currently mainly focused on vehicle stability control, and there are few studies on the application of the EMB system in advanced driver assistance. The application of the EMB system in the lateral and longitudinal dynamics control of the vehicle for L3-L5 automatic driving will be the focus of future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, L. The Study on Distributed Hybrid Braking System Based on EMB. Ph.D. Thesis, Chongqing University, Chongqing, China, 2019. [Google Scholar]

- Zong, C.; Li, G.; Zheng, H.; Zhang, Z. Study Progress and Outlook of Chassis Control Technology for X-by-Wire Automobile. China J. Highw. Transp. 2013, 26, 160–176. [Google Scholar]

- Mou, X. Research on Control Strategy of Electromechanical Brake System for Dynamic Control. Master’s Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

- Xiong, L.; Yu, Z.; Zhang, L. Present Situation and Prospect of Automotive Electric Braking System (BBW). Shanghai Auto. 2002, 6, 1–4. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?FileName=SHQC200206000&DbName=CJFQ2002 (accessed on 15 June 2002).

- Zhang, M.; Song, J. A Review of Electromechanical Brake (EMB) System. Mech. Sci. Technol. Aerosp. Eng. 2005, 24, 208–211. [Google Scholar]

- Zhao, Y. Research and Development of Electromechanical Brake System Actuator. Master’s Thesis, Tsinghua University, Beijing, China, 2010. [Google Scholar]

- Basu, B.; Bursi, O.S.; Casciati, F.; Casciati, S.; Del Grosso, A.E.; Domaneschi, M.; Faravelli, L.; Holnicki-Szulc, J.; Irschik, H.; Krommer, M.; et al. A European Association for the Control of Structures joint perspective. Recent studies in civil structural control across Europe. Struct. Control. Health Monit. 2014, 21, 1414–1436. [Google Scholar] [CrossRef]

- Schrade, S.; Nowak, X.; Verhagen, A.; Schramm, D. Short Review of EMB Systems Related to Safety Concepts. Actuators 2022, 11, 214. [Google Scholar] [CrossRef]

- Waknin, D.; Eng, J.; Surcel, M. Electromechanical Braking Systems Review; Technical Report; PIT Group: Atlanta, GA, USA, 2020. [Google Scholar]

- Zhang, Q.; Jin, L.; Jin, B.; Zhang, Y.; Chen, P.; Liu, Y.; Li, J. Research Progress of EMB Clamping Force Control and Sensor Fault Diagnosis. Automot. Eng. 2022, 44, 736–755. [Google Scholar]

- Gong, X.; Ge, W.; Yan, J.; Zhang, Y.; Gongye, X. Review on the development, control method and application prospect of brake-by-wire actuator. Actuators 2020, 9, 15. [Google Scholar] [CrossRef]

- Li, D.; Tan, C.; Ge, W.; Cui, J.; Gu, C.; Chi, X. Review of brake-by-wire system and control technology. Actuators 2022, 11, 80. [Google Scholar] [CrossRef]

- Analysis on the Application and Key Technologies of Electro-Mechanical Braking System. Available online: https://auto.vogel.com.cn/c/2020-07-28/1050084.shtml (accessed on 1 February 2023).

- Bosch IBooster Is No Longer a Monopoly, BYD and Other Domestic Line Control Only Half a Body! Available online: https://new.qq.com/rain/a/20220715A07YT600 (accessed on 1 February 2023).

- Electro-Mechanical Disc Brake. Available online: http://www.vienna-engineering.com/images/stories/dokumente/FolderAnhangRA.pdf (accessed on 1 February 2023).

- Great Wall By-Wire Chassis: What’s It Like to Move a Simulator Into a Car? Available online: https://auto.ifeng.com/c/8AiJLBHovvS (accessed on 1 February 2023).

- Man, S.J.; Ho, J.K.; Joon-Kyu, S. Electromechanical Brake System. WO Patent 2,020,149,695A1, 17 January 2020. [Google Scholar]

- Chang, H.T.; Padiolleau, E. Dual Bore Electric Caliper with Taper Wear Adjustment. US Patent 2,004,159,509A1, 14 February 2004. [Google Scholar]

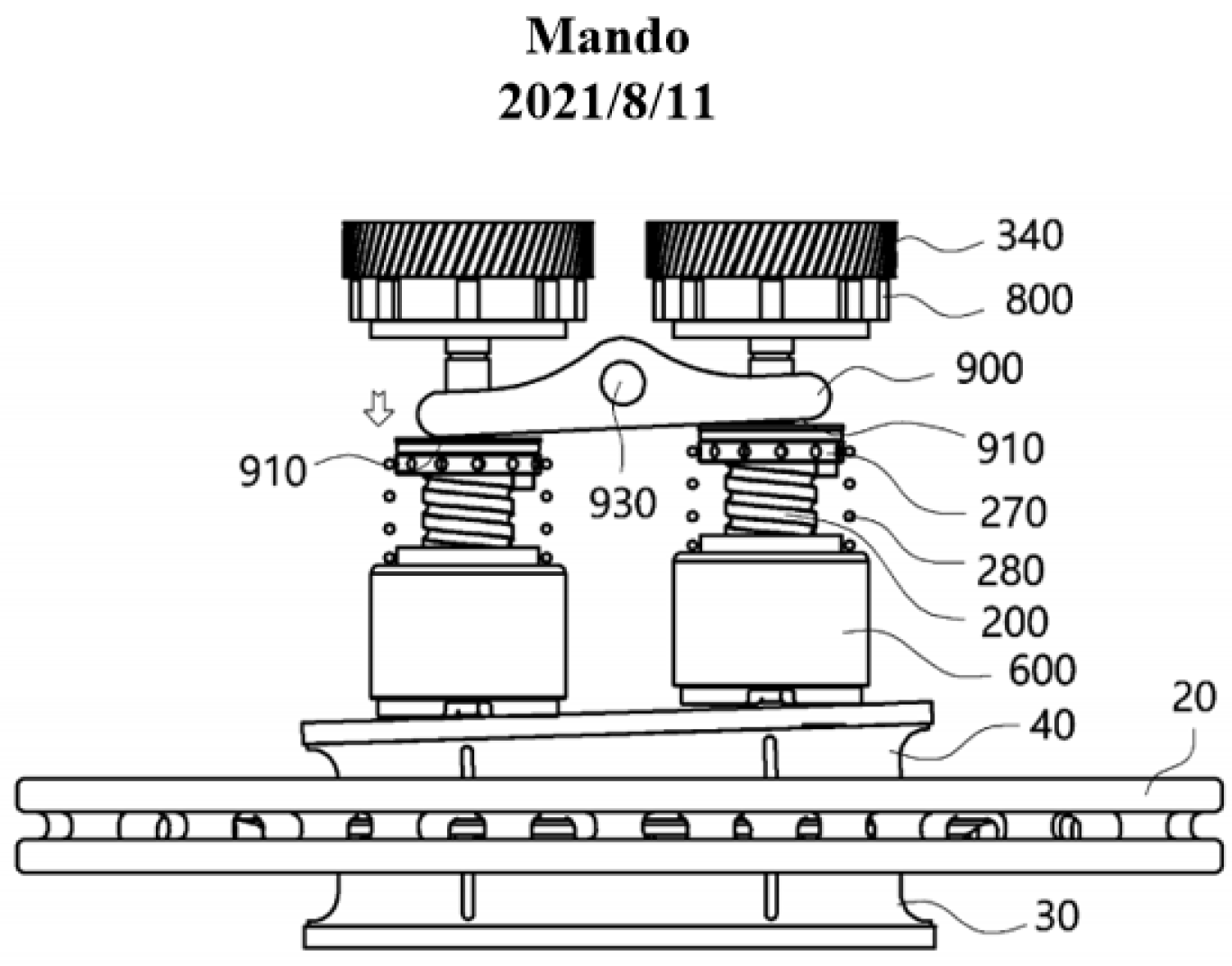

- Song, J.K.; Son, P.K.; Kim, J.S.; Lim, W.; Daejune, J. Electro-Mechanical Brake. KR Patent 102,401,765B1, 11 August 2021. [Google Scholar]

- Georg, H.W.; Dr, B.K.; Juergen, B.; Lothar, K.; Stefan, S. Elektromechanische Betätigbare Scheibenbremse. DE Patent 19,511,287A1, 21 July 1994. [Google Scholar]

- Wolfram, S. Electromechanical Brake for Motor Vehicles. DE Patent 19,750,274A1, 23 April 1999. [Google Scholar]

- Sung, K.J. Roller Screw of Electro-Mechanical Brake in Vehicle. KR Patent 20,130,052,446A, 11 November 2011. [Google Scholar]

- Hur, J.J. Actuator and Electromechanical Disc Brake Having the Same. KR Patent 20,200,094,377A, 30 January 2019. [Google Scholar]

- Dietmar, B.; Dirk, H.; Herbert, V.; Willi, N.; Andreas, H.; Bertram, F.; Bernd, G. Self-boosting Electromechanical Vehicle Brake. DE Patent 10,356,936A1, 15 September 2005. [Google Scholar]

- Bae, J.K.; Hwan, H.I.; Mok, S.J. Electric Mechanical Disk Brake Device For Vehicle. KR Patent 20,070,104,058A, 21 April 2006. [Google Scholar]

- Hendrik, P. Electromechanical Wedge Brake for Use in Braking System of Vehicle. DE Patent 102,006,038,824A1, 18 August 2006. [Google Scholar]

- Huang, Y. Research on the Actuator and Control Algorithm of Light Vehicle Electromechanical Brake. Master’s Thesis, Xihua University, Chengdu, China, 2019. [Google Scholar]

- Qu, W. Research on Hardware System of Automobile Brake-by-Wire. Ph.D. Thesis, Wuhan University of Technology, Wuhan, China, 2006. [Google Scholar]

- Dragos, M. Electromechanical Brake of Wire Brake System for Vehicle, Has Nut Whose Gear is Provided with Spindle such that Rotational Movement of Spindle is Converted into Translational Movement of Another Nut Connected with Brake Piston. DE Patent 102,011,080,714A1, 20 September 2012. [Google Scholar]

- Frank, S. Electromechanically Actuatable Brake. US Patent 6,257,377B1, 10 July 2001. [Google Scholar]

- Frank, S. Electromechanical Brake. WO Patent 03,027,528A1, 3 April 2003. [Google Scholar]

- Drennen, D.B.; Siler, E.R.; Waag, J.R.; Osterday, C.A.; Smith, R.G.; Holmes, D.E. Electric Brake Caliper Having a Ballscrew with Integral Gear Carrier. US Patent 2,005,034,936A1, 17 February 2005. [Google Scholar]

- Klaus, L.; Frank, S. Elektromechanische Radbremsvorrichtung und Verfahren zum Betrieb derselben. DE Patent 19,926,432A1, 29 April 2000. [Google Scholar]

- Bernard, D.D. Electric Caliper with Eccentric Lever Drive. US Patent 6,390,247B1, 24 November 1999. [Google Scholar]

- Wolfram, S. Electromechanical Wheel Brake System. US Patent 6,340,077B1, 22 January 2002. [Google Scholar]

- Frank, S. Electro-mechanical Wheel Brake Device. DE Patent 19,814,787A1, 27 May 1999. [Google Scholar]

- Song, J.K.; Lim, W. Electro-mechanical Brake and Vehicle Having the Same. KR Patent 102,401,771B1, 22 December 2021. [Google Scholar]

- Frank, S. Braking Device for Vehicles. US Patent 6,179,097B1, 26 March 1996. [Google Scholar]

- Wolfram, S. Electromechanical Brake. US Patent 6,189,661B1, 5 August 1996. [Google Scholar]

- Georg, B.; Frieder, K. Electric Motor-driven Braking Apparatus. US Patent 6,012,556A, 30 December 1996. [Google Scholar]

- Drennen, D.B.; Mescher, P.A.; Longuemare, P.C.; Klode, H. Electric Park Brake Actuator (Electric Caliper). US Patent 6,401,879B1, 11 June 2002. [Google Scholar]

- Michael, D.; Volker, M.; Rainer, S.; Anita, S. Electromechanical Brake Device for a Vehicle. EP Patent 1,138,971A2, 10 April 2001. [Google Scholar]

- Xavier, D.; Jacques, L. Caliper of an Electromechanical Disc Brake. EP Patent 05,291,550A, 21 January 2007. [Google Scholar]

- Othmar, B.; Georg, K. Magnetic Brake and Electromechanical Braking Device with a Magnetic Brake. US Patent 6,471,017B1, 29 October 2002. [Google Scholar]

- Drennen, D.B.; Siler, E.R.; Fulks, G.C.; Poole, D.E. Caliper with Internal Motor. US Patent 2,003,116,388A1, 30 September 2003. [Google Scholar]

- Maron, C.; Georg, R. Method for Actuating an Electromechanical Parking Brake Device. US Patent 2,006,131,113A1, 13 August 2002. [Google Scholar]

- Seo, J. Electro-mechanical Brake System. KR Patent 20,200,098,219A, 12 February 2019. [Google Scholar]

- Bernd, K.; Matthias, S. Wheel Brake Arrangement for Motor Vehicle Has Electric Motor, Spring Storage Device Acting upon Non-linear Gear Set Containing Cam Drive in Direction of Brake Application. DE Patent 19,851,668A1, 11 May 2000. [Google Scholar]

- Kim, J.S. Electro Wedge Brake Device for Vehicle. KR Patent 20,110,114,901A, 10 July 2005. [Google Scholar]

- Seungtae, B.; Joon-Kyu, S.; Kyungho, J. Electromechanical Brake and Operating Method Therefore. WO Patent 2,021,246,828A1, 4 June 2021. [Google Scholar]

- Xavier, D.; Jacques, L. Caliper of an electromechanical disc brake. EP Patent 17,463,01A1, 20 July 2005. [Google Scholar]

- Christian, B.W.; Monika, B.; Lars, E.; Stefan, P.; Hendrik, P.; Marcel, R.; Mathias, W.; Heinrich, Z. Electromechanical Disc Brake for Motor Vehicle, Has Rubbing Unit Pressed Against Friction Surface of Brake Caliper, Which Is to Be Braked, by Actuator, and Wear Adjusting Device with Gear Rod That Is Operated on Rubbing Unit. DE Patent 102,006,023,612A1, 19 May 2006. [Google Scholar]

- Kristijan, T.; Hans-Jörg, F.; I-Che, C. Elektromechanische Bremse. DE Patent 102,021,203,135A1, 29 March 2021. [Google Scholar]

- Hageman, J.B.; Klode, H.; Rymoff, P., Jr. Brake Caliper Backdrive Apparatus and Method. US Patent 2,003,136,616A1, 24 July 2003. [Google Scholar]

- Yoon, H.D.; Yun, J.J.; Hee, L.J. Electromechanical Brake. KR Patent 101,786,337B1, 29 April 2016. [Google Scholar]

- Jang, J.H.; Jung, K.; Kang, G. Electro-mechanical Brake System. KR Patent 20,210,002,280A, 28 June 2019. [Google Scholar]

- Jung, K.; Song, J.K. Electro-mechanical Brake. KR Patent 20,210,007,762A, 12 July 2019. [Google Scholar]

- Schwarz, R.; Isermann, R.; Böhm, J.; Nell, J.; Rieth, P. Clamping Force Estimation for a Brake-by-Wire Actuator; Technical Report, SAE Technical Paper; SAE: Vienna, Austria, 1999. [Google Scholar]

- Saric, S.; Bab-Hadiashar, A.; van der Walt, J. Estimating Clamp Force for Brake-by-Wire systems: Thermal Considerations. Mechatronics 2009, 19, 886–895. [Google Scholar] [CrossRef]

- Park, G.; Choi, S.; Hyun, D. Clamping Force Estimation Based on Hysteresis Modeling for Electro-mechanical Brakes. Int. J. Automot. Technol. 2017, 18, 883–890. [Google Scholar] [CrossRef]

- Wang, J. Research on Electromechanical Brake Control System. Master’s Thesis, Zhejiang University, Hangzhou, China, 2016. [Google Scholar]

- Sung, K.J. Electro-mechanical Brake. KR Patent 20,220,086,144A, 16 December 2020. [Google Scholar]

- Wei, Z.; Xu, J.; Halim, D. Clamping Force Control of Sensor-Less Electro-mechanical Brake Actuator. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; pp. 764–769. [Google Scholar]

- Saric, S.; Bab-Hadiashar, A.; Hoseinnezhad, R. Clamp-Force Estimation for a Brake-by-Wire System: A Sensor-Fusion Approach. IEEE Trans. Veh. Technol. 2008, 57, 778–786. [Google Scholar] [CrossRef]

- Bae, J.; Eum, S.; Lee, S. Hybrid Genetic Algorithm and Kalman Filter Approach to Estimate the Clamping Force of Electro-mechanical Brake. Int. Res. J. Electron. Comput. Eng. 2017, 3. [Google Scholar] [CrossRef]

- Maron, C.; Dieckmann, T.; Hauck, S.; Prinzler, H. Electromechanical Brake System: Actuator Control Development System; Technical Report, SAE Technical Paper; SAE: Vienna, Austria, 1997. [Google Scholar]

- Schwarz, R.; Isermann, R.; Böhm, J.; Nell, J.; Rieth, P. Modeling and Control of an Electromechanical Disk Brake; Technical Report, SAE Technical Paper; SAE: Vienna, Austria, 1998. [Google Scholar]

- Fox, J.; Roberts, R.; Baier-Welt, C.; Ho, L.M.; Lacraru, L.; Gombert, B. Modeling and Control of a Single Motor Electronic Wedge Brake. SAE Int. 2007, 116, 321–331. [Google Scholar]

- Yang, K. Research of Electromechanical Brake and VehicleStability Control System for Light Vehicle. Ph.D. Thesis, Jilin University, Changchun, China, 2009. [Google Scholar]

- Zhang, L. The Clamping Force Control Strategy Research for Electro-mechanical Braking System. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2012. [Google Scholar]

- Li, C. Research on Vehicle Brake Control of the Electromechanical Brake Actuator. Master’s Thesis, Chongqing University, Chongqing, China, 2015. [Google Scholar]

- Li, J.; Mengchun, W.; He, R.; Zhang, J. A Design of Electromechanical Brake System Triple-loop Controllers Using Frequency Domain Method Based on Bode Plote. In Proceedings of the 2011 International Conference on Transportation, Mechanical, and Electrical Engineering (TMEE), Changchun, China, 16–18 December 2011; pp. 795–798. [Google Scholar]

- Jo, C.; Hwang, S.; Kim, H. Clamping-force control for electromechanical brake. IEEE Trans. Veh. Technol. 2010, 59, 3205–3212. [Google Scholar] [CrossRef]

- Line, C.; Manzie, C.; Good, M. Control of an Electromechanical Brake for Automotive Brake-by-Wire Systems with an Adapted Motion Control Architecture. In SAE Transactions; SAE: Vienna, Austria, 2004; pp. 1047–1056. [Google Scholar]

- Ki, Y.; Lee, K.; Cheon, J.; Ahn, H. Design and Implementation of a New Clamping Force Estimator in Electro-mechanical Brake Systems. Int. J. Automot. Technol. 2013, 14, 739–745. [Google Scholar] [CrossRef]

- Zhang, J. Research on Accurate Control Algorithm for Electromechanical Brake Actuator. Master’s Thesis, Jilin University, Changchun, China, 2011. [Google Scholar]

- Zhang, R. Research on EMB Clamping Force Control Strategy and Development of Experimental Platform. Master’s Thesis, Hunan University, Changsha, China, 2018. [Google Scholar]

- Line, C.; Manzie, C.; Good, M. Robust Control of an Automotive Electromechanical Brake. IFAC Proc. Vol. 2007, 40, 579–586. [Google Scholar] [CrossRef]

- Krishnamurthy, P.; Lu, W.; Khorrami, F.; Keyhani, A. Robust Force Control of an SRM-based Electromechanical Brake and Experimental Results. IEEE Trans. Control. Syst. Technol. 2009, 17, 1306–1317. [Google Scholar] [CrossRef]

- Eum, S.; Choi, J.; Park, S.S.; Yoo, C.; Nam, K. Robust Clamping Force Control of an Electro-mechanical Brake System for Application to Commercial City Buses. Energies 2017, 10, 220. [Google Scholar] [CrossRef]

- Line, C.; Manzie, C.; Good, M.C. Electromechanical Brake Modeling and Control: From PI to MPC. IEEE Trans. Control. Syst. Technol. 2008, 16, 446–457. [Google Scholar] [CrossRef]

- Lee, C.F.; Line, C.M.C. Explicit Nonlinear MPC of an Automotive Electromechanical Brake. IFAC Proc. Vol. 2008, 41, 10758–10763. [Google Scholar] [CrossRef]

- Lindvai-Soos, D.; Horn, M. Modelling, Control & Implementation of an Electro-mechanic Braking Force Actuator for HEV and EV. IFAC Proc. Vol. 2013, 46, 620–625. [Google Scholar]

- Han, K.; Kim, M.; Huh, K. Modeling and Control of an Electronic Wedge Brake. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 2440–2455. [Google Scholar] [CrossRef]

- Park, G.; Choi, S.B. Clamping Force Control Based on Dynamic Model Estimation for Electromechanical Brakes. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 232, 2000–2013. [Google Scholar] [CrossRef]

- Lee, C.F.; Manzie, C. Near-Time-Optimal Tracking Controller Design for an Automotive Electromechanical Brake. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2012, 226, 537–549. [Google Scholar] [CrossRef]

- Kim, C.; Kim, Y.; Kwon, O.; Seo, J.; Lee, D.; Yi, H. An Application of the Brain Limbic System–Based Control to the Electromechanical Brake System. Adv. Mech. Eng. 2018, 10, 1687814018755215. [Google Scholar] [CrossRef]

- Sinha, P. Architectural Design and Reliability Analysis of a Fail-Operational Brake-by-Wire System from Iso 26262 Perspectives. Reliab. Eng. Syst. Saf. 2011, 96, 1349–1359. [Google Scholar] [CrossRef]

- Lee, K.J.; Ki, Y.H.; Ahn, H.S.; Hwang, G.; Cheon, J.S. Functional Safety Compliant ECU Design for Electro-mechanical Brake (EMB) System. SAE Int. J. Passeng. Cars Mech. Syst. 2013, 6, 1476–1483. [Google Scholar] [CrossRef]

- Xu, H. Braking Force Distribution Control Strategy of Electromechanical Braking System. Master’s Thesis, Yanshan University, Qinhuangdao, China, 2018. [Google Scholar]

- Lee, J.; Choi, S. Braking Control for Improving Ride Comfort. In Proceedings of the 2nd International Conference on Mechanical, Aeronautical and Automotive Engineering, Singapore, 24–26 February 2018; Volume 166, p. 02002. [Google Scholar]

- Dong, X. Research on Anti Lock Brake Controller of Vehicle Electromechanical Braking System. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2009. [Google Scholar]

- Tian, H. Research on Automobile Electromechanical Brake Control System Based on FPGA/SOPC Technology. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2010. [Google Scholar]

- Han, P. Research on Anti Lock Braking System of Light Electromechanical Braking Vehicle. Master’s Thesis, Jilin University, Changchun, China, 2011. [Google Scholar]

- Yang, K.; Li, J.; Li, Y.; Tan, S.; Wei, Q.; Tang, L. EBD/ABS Research Based on Automotive Electromechanical Brake System. J. Syst. Simul. 2009, 21, 1785–1788. [Google Scholar]

- Tang, L. Research on Control Strategy and Algorithm of Light Vehicle Electromechanical Braking System. Master’s Thesis, Jilin University, Changchun, China, 2008. [Google Scholar]

- Rao, Z. Research on Electronic Mechanical Braking and Driving Anti slip Control System of Light Vehicle. Master’s Thesis, Jilin University, Changchun, China, 2009. [Google Scholar]

- Wang, K.Y.; Liu, C.Y.; Tang, J.H. Research on Control Strategy of Anti-lock Brake System in Cornering with Braking Based on Electromechanical Brake System. In Proceedings of the 2010 IEEE International Conference on Mechatronics and Automation, Xi’an, China, 4–7 August 2010; pp. 45–48. [Google Scholar]

- Shen, Y.; Mao, J.; Wu, A.; Liu, R.; Zhang, K. Optimal Slip Ratio Tracking Integral Sliding Mode Control for an EMB System Based on Convolutional Neural Network Online Road Surface Identification. Electronics 2022, 11, 1826. [Google Scholar] [CrossRef]

- Zhang, S. Research on Control Strategy of Electronic Mechanical Brake (EMB). Master’s Thesis, Changan University, Xi’an, China, 2021. [Google Scholar]

- Liang, B.; Zhu, Y.; Li, Y.; He, P.; Li, W. Adaptive Nonsingular Fast Terminal Sliding Mode Control for Braking Systems with Electro-mechanical Actuators Based on Radial Basis Function. Energies 2017, 10, 1637. [Google Scholar] [CrossRef]

- Benine-Neto, A.; Moreau, X.; Lanusse, P. Robust Control for an Electro-mechanical Anti-lock Braking System: The CRONE Approach. IFAC PapersOnLine 2017, 50, 12575–12581. [Google Scholar] [CrossRef]

- Dinçmen, E.; Altınel, T. An Emergency Braking Controller Based on Extremum Seeking with Experimental Implementation. Int. J. Dyn. Control. 2018, 6, 270–283. [Google Scholar] [CrossRef]

- Xiang, W.; Richardson, P.C.; Zhao, C.; Mohammad, S. Automobile Brake-by-Wire Control System Design and Analysis. IEEE Trans. Veh. Technol. 2008, 57, 138–145. [Google Scholar] [CrossRef]

- Wang, K. Research on Yaw and Lateral Control of Light Electronic Mechanical Brake Vehicle. Master’s Thesis, Jilin University, Changchun, China, 2009. [Google Scholar]

- Zhou, L. Research on Control Algorithm of Automobile ESP Based on Electromechanical Braking. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2015. [Google Scholar]

- Yin, W.; Li, J.; Li, Y.; Wang, K. Research on Yaw Moment Control for Light Vehicle Electromechanical Brake System. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, Hohhot, China, 15–17 July 2011; pp. 6059–6063. [Google Scholar]

- Fergani, S.; Menhour, L.; Sename, O.; Dugard, L.; Novel, B. Study and Comparison of Non Linear and LPV Control Approaches for Vehicle Stability Control. In Proceedings of the 21st Mediterranean Conference on Control and Automation, Platanias, Greece, 25–28 June 2013; pp. 303–310. [Google Scholar]

- Yang, K.; Li, J.; Li, Y.; Rong, R.; Tan, S.; Guo, L. The Application of Electromechanical Braking System in Automobile Adaptive Cruise Control. J. Agric. Mach. 2008, 39, 34–38. [Google Scholar]

- Xu, B. Research on Key Technologies of Mechanical Line Control System. Master’s Thesis, Shandong Jiao Tong University, Jinan, China, 2021. [Google Scholar]

- Miu, J. Research on Design and Control of Electromagnetic-Motor Wedge Brake-by-Wire System for Passenger Cars. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2020. [Google Scholar]

| Works | Summary | Actuator Structure | Control Algorithm | System Architecture | Application |

|---|---|---|---|---|---|

| [8] | EMB systems related to safety concepts | Brief summary | / | Detailed analysis of system architectures | / |

| [9] | Market review of EMBs for commercial vehicles | 2 typical structures | / | Detailed information about EMB systems of 5 contacted manufacturers | Brief overview |

| [10] | EMB clamping force control and sensor fault diagnosis | 4 typical structures | Comprehensive review of direct clamping force control (without force estimation) | Brief description | / |

| [4,5] | Brake-by-wire (BBW) or EMB system review | 1–3 typical structures | / | 1 typical structure | Brief overview |

| [11,12] | Brake-by-wire (BBW) system and control technology | 1 typical structure | Comprehensive review of force control for BBW actuators | Brief description | Comprehensive review of BBW system application |

| No. | Manufacturer | Nation | Applicable Vehicle Type |

|---|---|---|---|

| 1 | Bosch | Germany | Automotive and Commercial |

| 2 | Continental Teves | Germany | / |

| 3 | Siemens | Germany | / |

| 4 | Bendix | U.S. | Commercial |

| 5 | Chassis | U.S. | Automotive |

| 6 | Delphi | U.S. | Automotive |

| 7 | TRW | U.S. | Automotive |

| 8 | Brembo | Italy | Automotive |

| 9 | Vienna Engineering | Austria | Automotive and Commercial |

| 10 | Haldex | Sweden | Commercial |

| 11 | SKF | Sweden | / |

| 12 | Hyundai | South Korea | Automotive |

| 13 | Mando | South Korea | Automotive |

| 14 | Akebono | Japan | Automotive |

| 15 | Hitachi | Japan | / |

| 16 | NTN | Japan | Automotive |

| 17 | Great Wall Motor | China | Automotive |

| 18 | VIE | China | Commercial |

| 19 | Jiong Yi Electronic Technology | China | / |

| 20 | Figge Technology | China | / |

| 21 | FinDreams Technology | China | / |

| No. | Manufacturer | Period | Reducing Mechanism | Number of Patents Self-Energizing Mechanism | Integrated with Parking Brake |

|---|---|---|---|---|---|

| 1 | Bosch | 1996–2019 | 29 | 19 | 19 |

| 2 | Siemens | 1996–2007 | 9 | 9 | 2 |

| 3 | Continental Teves | 1994–2020 | 15 | 1 | 6 |

| 4 | Delphi | 1999–2005 | 14 | 0 | 6 |

| 5 | Hyundai | 2006–2020 | 35 | 5 | 11 |

| 6 | Mando | 2009–2021 | 33 | 0 | 11 |

| Total | 1994–2021 | 135 | 34 | 55 |

| Manufacturer | Structure Schemes | |

|---|---|---|

| Motion Conversion Mechanism | Reducing Mechanism/ Self-Energizing Mechanism | |

| Bosch | Ball screw | Planetary gear train |

| Rack and pinion | Double wedge face self-energizing mechanism | |

| Siemens | Screw | Multiple wedge face self-energizing mechanism |

| Continental Teves | Ball screw | Spur gear/planetary gear train |

| Delphi | Ball screw (ring type) | Planetary gear train |

| Hyundai | Sliding lead screw | Spur gear/planetary gear/worm gear train |

| Screw | Multiple wedge face self-energizing mechanism | |

| Mando | Ball screw | Helical gear/planetary gear /compound gear train |

| Manufacturer | Bendix | Haldex | VE |

|---|---|---|---|

| Brake Type | Disc | Disc | Disc |

| Applicable Vehicle Type | Trucks | Trucks, trailers and buses | Trucks, trailers and on-road vehicles in general |

| EMB Prototypes Developed | Yes | 100 | More than 20 |

| EMB Prototypes Technology Readiness Level (TRL) | Pre-production | TRL 7 | TRL 5 |

| Prototype Phase Completion Estimate | Undefined | 2020 | Mid 2020 |

| Expected Start of Production (SOP) | Undefined | 2021 | 2025 |

| Most Challenging Factors | Cost constraints | Regulation and testing requirements | Safety concerns and redundancies |

| Power Circuit Redundancy | 1 for standard architecture + at least 2 for braking system | Each axle can power another, n−1 redundancies | Each EMB has 1 main and 1 redundant |

| Energy Storage System Redundancy | 1 for standard architecture + at least 2 for braking system | Each axle can power another, n−1 redundancies | 1 main and 1 redundant |

| Communication Networks redundancy | 1 main and at least 1 redundant | 2 in a 2-axle vehicle (1 redundancy per axle) | 1 main and 1 redundant |

| Failure | Requirement | EU + UK | U.S. | China | India | Canada |

|---|---|---|---|---|---|---|

| 1st Circuit | Provide more than 2.6 m/s2 deceleration | A3.2 | 14.14 | 5.2.1 | 4.1.2 | 5.1.2.1 |

| ASS | Provide more than 5.15 m/s2 deceleration | A6.4 | 14.12 | - | 9.5.4 | 5.5.2 |

| Brake Distr. | Provide more than 3.86 m/s2 deceleration with the engine disconnected | A5.4 | 14.13 14.17 | A6 | - | - |

| Power Brake Unit | Provide more than 2.6 m/s2 deceleration | - | 14.18 | - | - | 5.1.3.1 |

| Any 1st E/E | Provide more than 6.43 m/s2 deceleration with the engine disconnected | - | - | - | - | 5.1.3.5 |

| Any | No unintended application | 5.2.9 | - | - | - | - |

| E-Supply | E-reserves must tolerate it | 5.2.15 | - | - | - | - |

| Transmission | No unintended application of parking brake | 5.2.19 | - | - | - | - |

| Motor Type | Advantages | Shortcomings |

|---|---|---|

| Brushed DC Motor | Large starting torque, good controllability and overload capability, and excellent speed regulation performance. | The mechanical commutation device is used, has a short life and high noise, generates sparks easily and has low efficiency. |

| Brushless DC Motor | No spark interference, large starting torque, excellent overload capacity, high efficiency and relatively simple control method. | There is a certain torque ripple that causes vibration noise and has a risk of demagnetization. |

| Permanent Magnet Synchronous Motor | Small torque ripple, low noise and high control precision. | The control method is more complicated: an encoder is required and the price is higher. |

| Switched Reluctance Motor | Simple and reliable, large starting torque, good low-speed performance, wide speed range and high efficiency. | Large torque fluctuations and high noise; a position detector is required. |

| Types | Characteristics | Commonly Used Reducing Mechanism |

|---|---|---|

| Coaxial | Large axial size and small radial size | Planetary gear train |

| Parallel | Middle axial size and middle radial size | Spur gear train, helical gear train, compound gear train and pulley |

| Angled | Small axial size and large radial size | Bevel gear train and worm gear train |

| Manufacturer | Driving Component | Moving Component | Locking Component |

|---|---|---|---|

| Bosch | Solenoid | Armature disc/tappet | Friction components/pawl-ratchet/roller-ramp/self-locking |

| Continental Teves | Solenoid | Tappet/towing link | Locking pin-gear/roller-ramp/pawl-ratchet |

| Delphi | Motor/solenoid /manual | Threaded screw/lever/spring/plunger | Handbrake lock/protrusion-tooth/pawl-ratchet/tooth seat-gear |

| Hyundai | Motor/solenoid | Threaded screw/tappet/baffle/elastic plate | Locking pin-gear/baffle-gear/pawl-ratchet |

| Mando | Solenoid | Tappet | Pawl-ratchet/friction components/rotary pin-gear |

| Siemens | Manual | Cable | Roller-ramp/handbrake lock |

| Manufacturer | Sensor Type |

|---|---|

| Bosch | Angular displacement and pressure |

| Continental Teves | Angular displacement, pressure and contact |

| Delphi | Angular displacement and pressure |

| Hyundai | Angular displacement, axial displacement, pressure, torque, current and pad wear |

| Mando | Angular displacement, pressure and pad wear |

| Siemens | Angular displacement and pressure |

| Estimation Method | Advantages | Disadvantages | Classification |

|---|---|---|---|

| Based on angular displacement | Simple | Requires contact point identification, affected by factors such as temperature | Average stiffness characteristic Thermal effect modified stiffness characteristic Hysteresis effect modified stiffness characteristic |

| Based on current | Simple and convenient current detection | Difficult in identifying model parameters | Simplified torque balance Fitting modified torque balance |

| Fusion estimation based on angular displacement and current | Good accuracy and robustness | Complex | Maximum likelihood estimation Genetic algorithm + Kalman filter |

| Control Algorithm | Advantages | Disadvantages | Classification |

|---|---|---|---|

| PID control | Simple structure, easy application and good adaptability | Difficult in parameter tuning and difficult to handle time-varying nonlinear problems | Cascaded PID control Adaptive PID control Feedforward compensation PID control Fuzzy PID control Compound PID control |

| Robust control | Good robustness | Conservative | Linear robust optimal control Nonlinear robust control Disturbance observation robust control |

| Model predictive control | Explicitly deal with the constraint problem and good dynamic control performance | Large calculation | Model predictive control + PID control Explicit nonlinear model predictive control |

| Sliding mode control | Fast response, fewer tuning parameters and good robustness | Chattering problem | Sliding mode control Adaptive sliding mode control |

| Other algorithms | Near-time-optimal control Brain limbic system-based control |

| 1 | Scheme 1 | Scheme 2 | Scheme 3 | Other Schemes |

|---|---|---|---|---|

| ECU Redundancy | Main ECU + 2 axis ECUs + 4 actuator ECUs | Main ECU + 4 actuator ECUs | Main ECU + auxiliary ECU + 4 actuator ECUs | 2/3 main ECUs + 4 actuator ECUs |

| Power redundancy | 2 power supplies (H-arrangement) | 2 power supplies (full redundancy) | 2 power supplies (X-arrangement) | 2 power supplies (X/H-arrangement) + backup power supply (full redundancy) |

| Communication redundancy | 4 communication lines | 2 communication lines | 2 communication lines | |

| Wheel speed sensor | Wheel speed sensor-axis ECU | Wheel speed sensor-actuator ECU | Wheel speed sensor-auxiliary ECU | |

| Voltage | 12 V/24 V/48 V | |||

| Communication bus | CAN FD/FlexRay/Ethernet | |||

| Vehicle Stability Control | System Function | Control Methods |

|---|---|---|

| Longitudinal stability control | ABS/EBD | Optimized logic threshold control Integral sliding mode control Terminal sliding mode control Fuzzy Sliding Mode Control Fuzzy PI/PID control CNN neural network PI/PID control Non-integer order robust control (CRONE) Self-optimizing algorithm |

| TCS | BP Neural network PI/PID control | |

| Lateral Stability control | ESC | Fuzzy logic control Fuzzy PI/PID control PID+logic threshold value control LPV Control |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Zhuo, G.; Tang, C.; Xiong, L.; Tian, W.; Qiao, L.; Cheng, Y.; Duan, Y. A Review of Electro-Mechanical Brake (EMB) System: Structure, Control and Application. Sustainability 2023, 15, 4514. https://doi.org/10.3390/su15054514

Li C, Zhuo G, Tang C, Xiong L, Tian W, Qiao L, Cheng Y, Duan Y. A Review of Electro-Mechanical Brake (EMB) System: Structure, Control and Application. Sustainability. 2023; 15(5):4514. https://doi.org/10.3390/su15054514

Chicago/Turabian StyleLi, Congcong, Guirong Zhuo, Chen Tang, Lu Xiong, Wei Tian, Le Qiao, Yulin Cheng, and Yanlong Duan. 2023. "A Review of Electro-Mechanical Brake (EMB) System: Structure, Control and Application" Sustainability 15, no. 5: 4514. https://doi.org/10.3390/su15054514

APA StyleLi, C., Zhuo, G., Tang, C., Xiong, L., Tian, W., Qiao, L., Cheng, Y., & Duan, Y. (2023). A Review of Electro-Mechanical Brake (EMB) System: Structure, Control and Application. Sustainability, 15(5), 4514. https://doi.org/10.3390/su15054514