1. Introduction

Hybrid electric vehicles (HEVs), as a sustainable transportation option [

1,

2], offer improved fuel economy and reduced emissions compared to traditional internal combustion engine (ICE) vehicles [

3]. However, tip-in or back-out maneuvers of HEV drivelines can result in a prevalent and troublesome oscillation problem, especially in vehicles with long drive shafts [

4,

5]. This driveline oscillation reduces the sustainability of HEVs because it not only shortens component life due to the high mechanical contact stress, but also reduces customer acceptance due to poor driving comfort [

6]. Therefore, driveline oscillation damping has garnered considerable attention from researchers as a means to improve the sustainability of HEVs [

7,

8,

9].

Driveline oscillation damping methods can be broadly divided into two categories [

10]: passive devices, such as torsional vibration dampers, which reduce the transmission of vibrations from the driveline to the vehicle body [

11]; and advanced active damping techniques, which suppress the vibrations generated by the driveline. Although passive devices are effective, they introduce additional hardware that increases the overall cost of the driveline system [

12]. Furthermore, active damping techniques are more desirable because they act as software control systems and do not require additional hardware costs [

13]. HEVs enable the active torque control of the traction motor to facilitate the implementation of the active damping technique.

Active damping techniques have mainly been focused on designing algorithms for the control system. Some controllers have been designed to alleviate torsional vibration by generating compensation torque based on the linear dynamic model of the driveline [

14,

15]. Linear matrix inequalities have been used to design a linear parameter-varying dynamic-output feedback controller that compensates for the torque ripples in HEVs [

16]. A linear-quadratic-Gaussian controller was designed to actively dampen the oscillations of heavy-duty trucks in Reference [

17]. However, the linear dynamic model is insufficient to represent the nonlinear behavior of backlash, resulting in inconsistencies between the real system and the model. Other controllers have been designed using the nonlinear dynamic model. For example, Yonezawa et al. presented a fuzzy-reasoning-based compensation algorithm in Reference [

18] in order to enhance the robustness of the oscillation damping controller. Chen et al. proposed a pulse cancellation algorithm for by dual-mode hybrid vehicles to suppress torque fluctuation [

19]. These methods require a high-fidelity model of the driveline in order to achieve effective control. However, the high-fidelity model of the driveline system is supported by the high-order nonlinear model, which is too complicated for the design of the controller and observer. In addition, the torque load of the driveline cannot be measured, making it extremely challenging to build a high-fidelity model.

In order to suppress driveline oscillation in HEVs effectively, two critical issues, namely time-varying torque load and nonlinear driveline backlash, must be addressed. While addressing these issues, the introduction of high-order models must be avoided. To achieve this objective, this study proposes an extended-state-observer-based compensator to actively suppress the driveline oscillation of HEVs. The procedure for damping driveline oscillation can be summarized as follows. First, a control-oriented model, which which is comprised of a second-order system with a dead zone to facilitate the control algorithm design, is selected. Second, a torque feedback compensator is designed using the pole placement method. This method is simple yet effective. Third, an extended state observer is designed to estimate system states and the unmeasurable load torque. The observer’s stability is guaranteed by using a Lyapunov function. By implementing these steps, the driveline oscillation can be significantly dampened.

The remainder of this paper is organized as follows. In the Modeling section, we establish a model for the gearbox with backlash; the dynamic model for the drive shaft, tire, and vehicle; and a control-oriented model. The Controller Design section outlines the design of the torque compensator and an extended state observer. In the Results section, we verify the effectiveness of the control strategy through simulations and experiments. Finally, the Conclusion section provides a summary of the study’s findings.

3. Controller Design

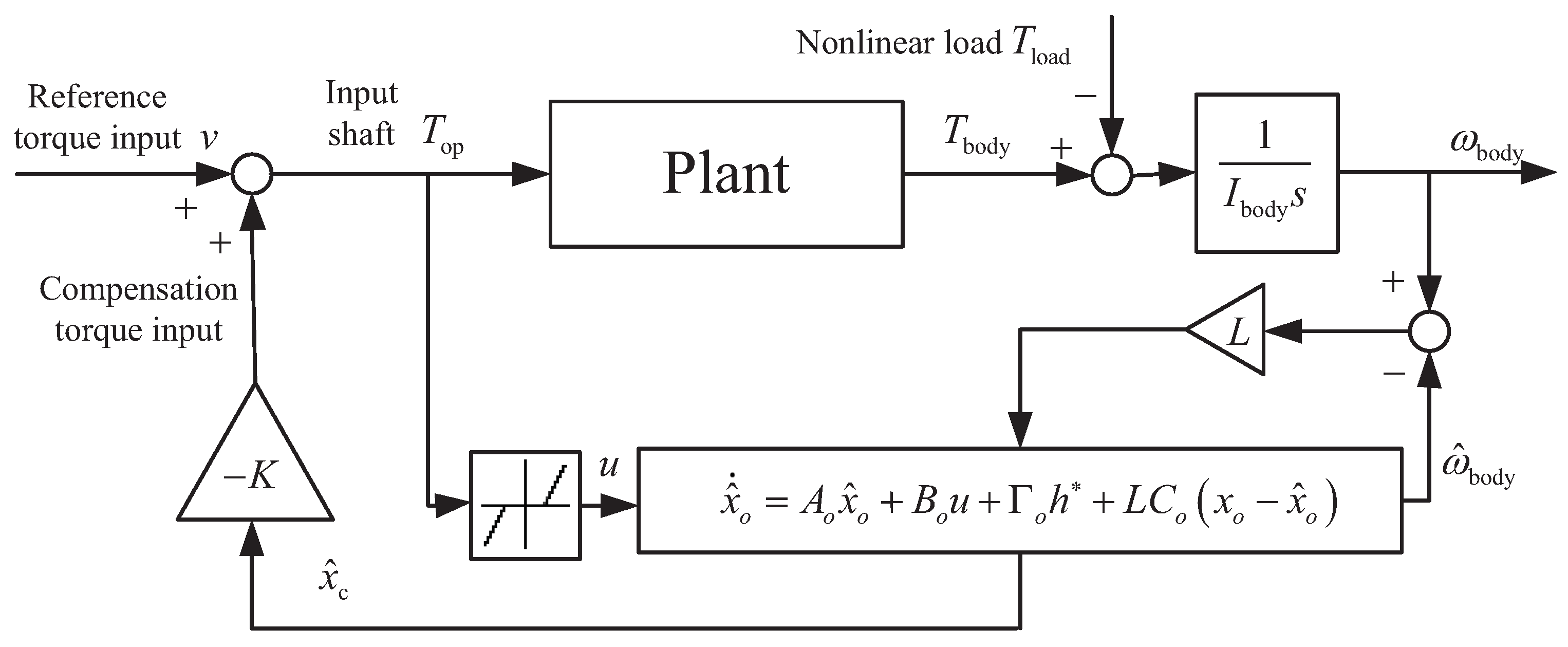

This section presents the design of a compensator for damping driveline oscillations. The control scheme of the proposed extended-state-observer-based compensator is depicted in

Figure 3. The torque compensator is designed using pole placement. An extended state observer is used to estimate unmeasurable states and load torque.

3.1. Torque Compensator

Given that the oscillations in the driveline are caused by under-damping, the pole placement method [

21] is used to place the closed-loop poles of the driveline at a predetermined location in the s-plane. By doing so, the under-damping of the driveline can be compensated for.

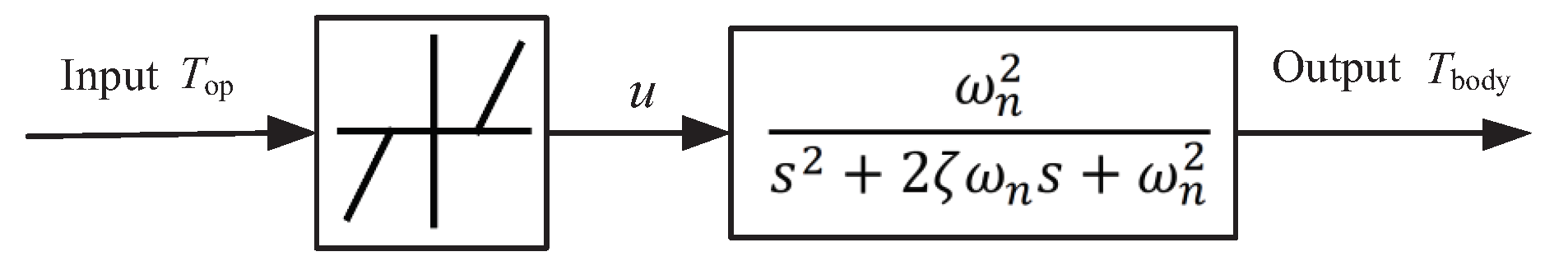

Based on the simplified model shown in

Figure 2, the driveline dynamics can be described by the state–space equation:

where

,

, and

. The driveline dynamics (

13) represent the reduced-order form of the system (

12).

A control input proportional to the state vector is selected as

where

v is the reference torque input provided by the driver and

is the compensation torque input provided by the compensator. Given that the state vector

is unmeasurable, it is replaced by its estimated value

in practical applications. Substituting Equation (

15) into system (

13), the state–space equation becomes

The poles of the closed-loop feedback system are determined by the characteristic equation of the matrix

. A robust pole placement method proposed by Reference [

22] is used to determine the feedback gain K in Equation (

15) as part of the proposed state compensation strategy. The practical implementation of the robust pole placement method consists of three fundamental steps: Step A, Step X, and Step F. In Step A, the matrix

is decomposed. In Step X, gradient iterative methods are used to select vectors that ensure the system is well conditioned. Step F involves solving linear equations to compute the feedback gain

K. Steps A and F are consistent across all methods, whereas Step X is the critical step that employs an iterative process to minimize the measures of robustness.

Although the pole placement method itself is not new, the application of robust pole placement in the context of the proposed extended-state-observer-based compensator is innovative and unique. Specifically, the method was used to place the closed-loop poles of the system in a desired location, thereby ensuring good oscillation-damping performance. The proposed state compensation strategy differs from existing methods in the literature by incorporating an extended state observer to estimate the unmeasurable load torque and compensate for the nonlinear driveline backlash. This combination of state compensation and disturbance compensation is novel and has the potential to improve the control performance of HEVs.

3.2. Extended State Observer

The extended state observer is a tool used in control engineering for estimating the state variables of a system, especially when some of these variables cannot be directly measured or are affected by disturbances. The basic concept behind the extended state observer involves developing an additional dynamic system that models the uncertainties and disturbances that affect the main system and then utilizing this model to estimate the unknown variables. Specifically, the extended state observer includes a state observer for the main system and an extended state term for the disturbance. The load torque of a moving vehicle, which is influenced by the road slope and cannot be measured directly, can be regarded as a disturbance. Additionally, the system state vector is unmeasurable. Therefore, this study developed an extended state observer in order to estimate the load torque and system states.

Considering that no prior information is available regarding the derivative of the load torque, a bounded variable

has been introduced to represent it as

. Assuming that the load torque remains constant or slowly varies during vehicle acceleration, the variable

remains small. By treating the load torque

as a system state, system (

12) is extended as an augmented system:

First, we verify whether the augmented system is observable when the system output is the rotation speed of the vehicle wheel. The system is observable if the matrix has a full rank. It is evident that the rank of the matrix is four, indicating that the augmented system is indeed observable.

Next, the correction term for the extended state observer is selected as the difference between the rotation speed of the vehicle wheel

and its estimated value

. Using this, the extended state observer is designed as follows:

where

is the observer gain and

is the nominal value of the derivative of the load torque.

Let

, then the error dynamics of the extended state observer are obtained by subtracting (

17) from (

16):

where

represents the model deviation of the derivative of the load torque. The extended state observer is asymptotically stable when the matrix

is Hurwitz and the derivative of the load torque

h is known accurately, that is,

.

However, if

due to inaccurate knowledge of

h, then we define a Lyapunov function as

, where

, and differentiate it along the error dynamics (

18). We obtain

The application of Young’s inequality to the last term of the aforementioned equality leads to

with

. The derivative of the Lyapunov function

V becomes

where

I is the unit matrix.

By selecting the observer gain

L to satisfy the following equality:

with

, we arrive at the relationship

This relationship implies that the extended state observer is input-to-state stable in the presence of bounded model deviation

[

23]. Specifically, the derivative of the Lyapunov function

V is bounded by a negative semi-definite matrix

, multiplied by the squared norm of the error

, and a term proportional to the squared norm of the model deviation

.

4. Simulation Results

Simulations were carried out in MATLAB/Simulink, in order to evaluate the effectiveness of the designed control algorithm, using the plant model of the HEV driveline and the proposed control scheme. This section presents the results of these simulations, which include an assessment of the performance of the designed controller and the extended state observer as well as an analysis of the observer results with different initial state values.

The proposed control scheme involves determining the observer and feedback gains. The observer gain is first adjusted based on the stability condition (

23). The appropriate order of magnitude of the observer gain can be determined by observing the observation error. Subsequently, the gain is fine-tuned to ensure optimal performance. After the tuning process, the observer gain is set to L = [4,156,000, 2,508,900, 300, −963,400]

. The chosen damping value is set to eight times that of the original damper after evaluating the oscillation-damping effectiveness. The feedback gain of

is attained by using the desired damping value and the robust pole placement approach.

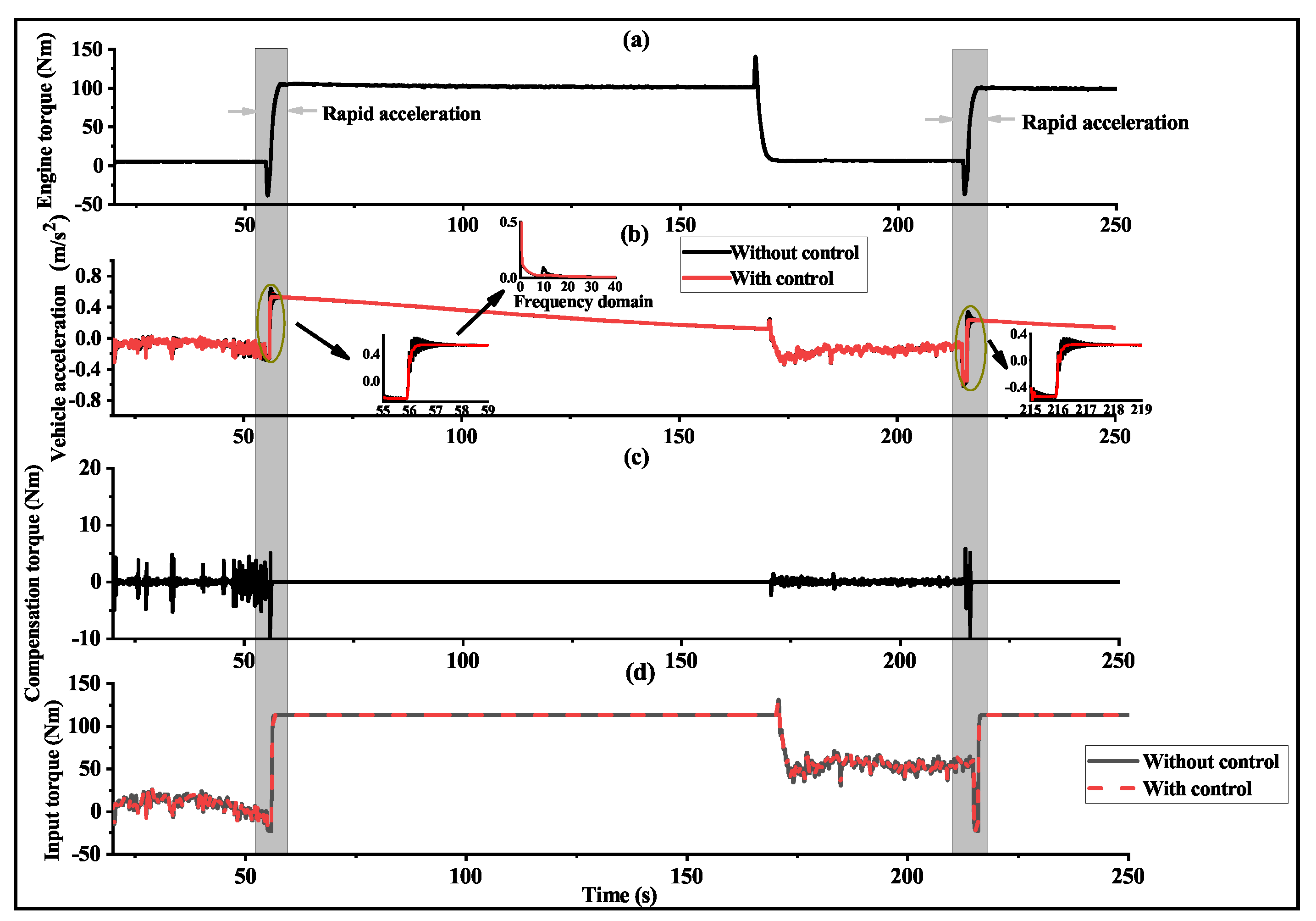

4.1. Control Performance of the Designed Controller

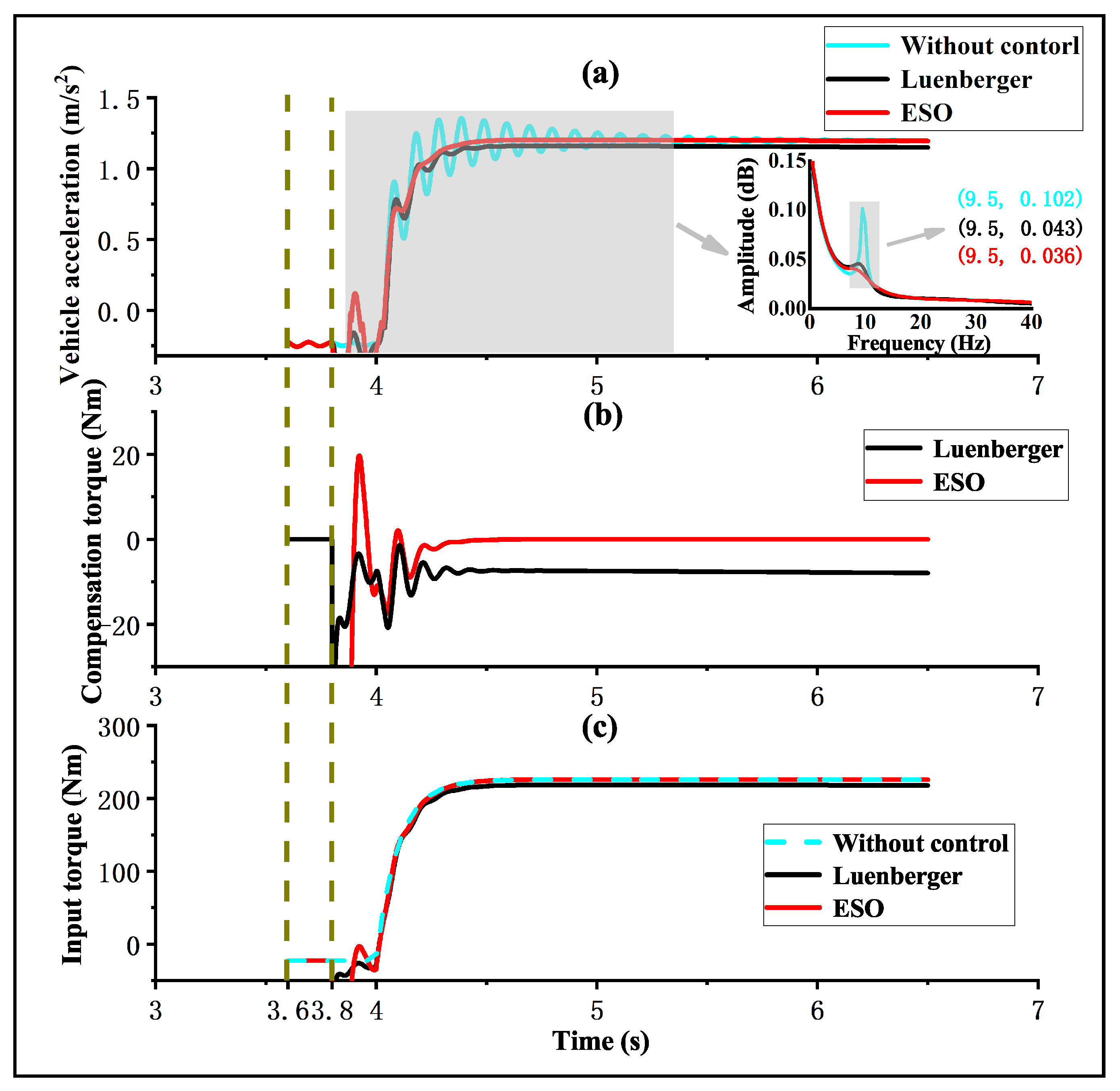

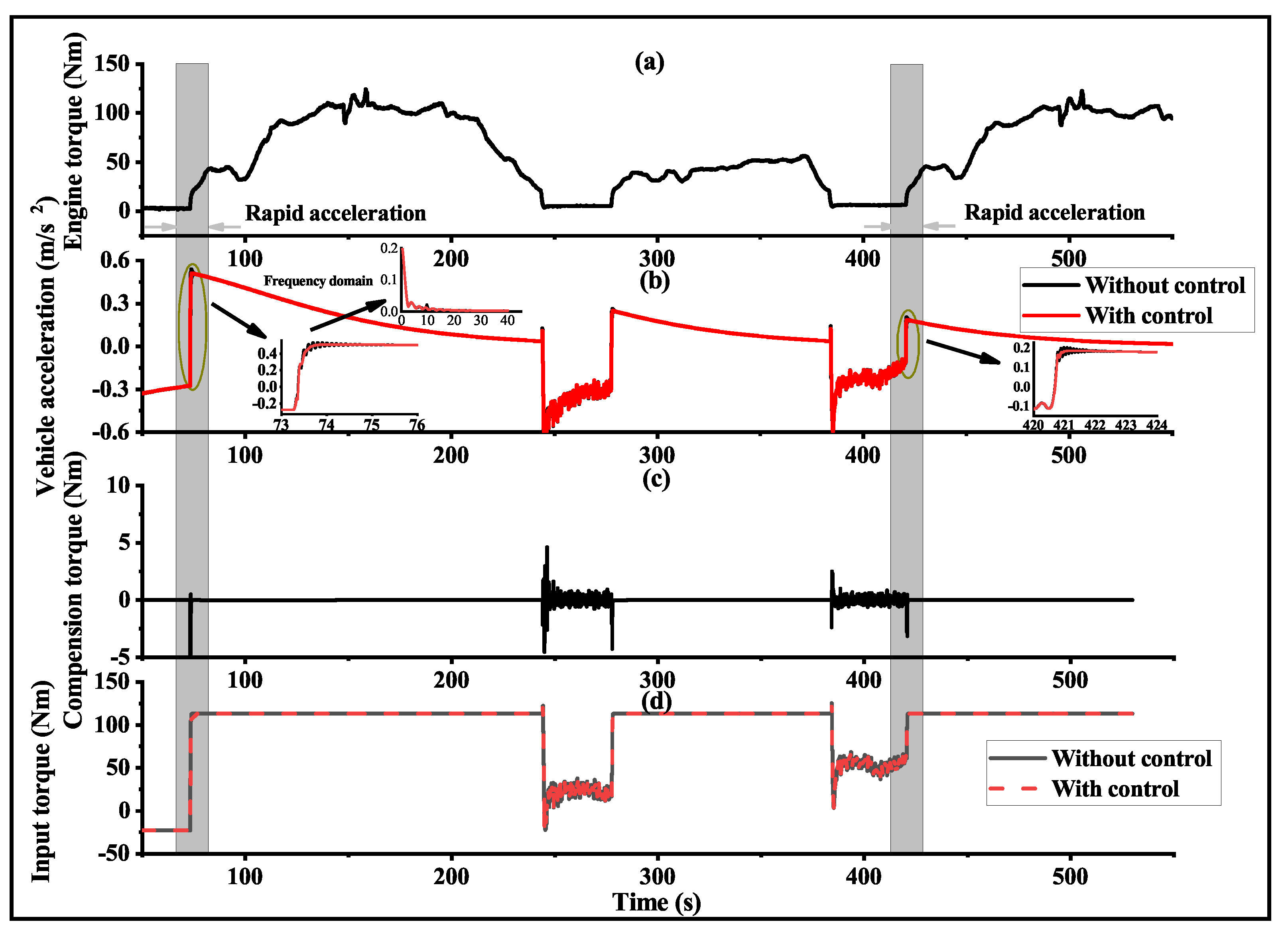

In the simulation, a tip-in operation is utilized as the driveline oscillation scenario. The control performance of the observer-based controller is illustrated for the test scenario in

Figure 4. “Without control” refers to the case where no compensation torque is applied. The term “Luenberger” denotes the compensation torque obtained via state feedback, with the state observed using a Luenberger state observer. “ESO” refers to the compensation torque obtained by the state feedback process, where the state is observed using an extended state observer. The observer begins working at 3.6 s, and the observer-based compensator starts working at 3.8 s. As shown in

Figure 4, at 4 s, the input torque sharply increases, resulting in rapid vehicle acceleration. When no controller is applied, this acceleration produces a significant chattering vibration. Compared with the non-observer-based controller, the controllers using the Luenberger state observer and extended state observer significantly reduce chattering during the acceleration process. Specifically, the extended-state-observer-based controller achieves better control performance that result in almost no chattering. The magnified graph in

Figure 4a displays the amplitude spectrum of the corresponding vehicle acceleration, showing that the main frequency of the vehicle acceleration chattering is 9.5 Hz. The amplitudes generated by no control, Luenberger observer, and extended state observer at this frequency are 0.102, 0.043, and 0.036, respectively. The proposed extended-state-observer-based controller reduces chattering during acceleration from the perspective of the amplitude spectrum. Therefore, the proposed controller substantially dampens driveline oscillations.

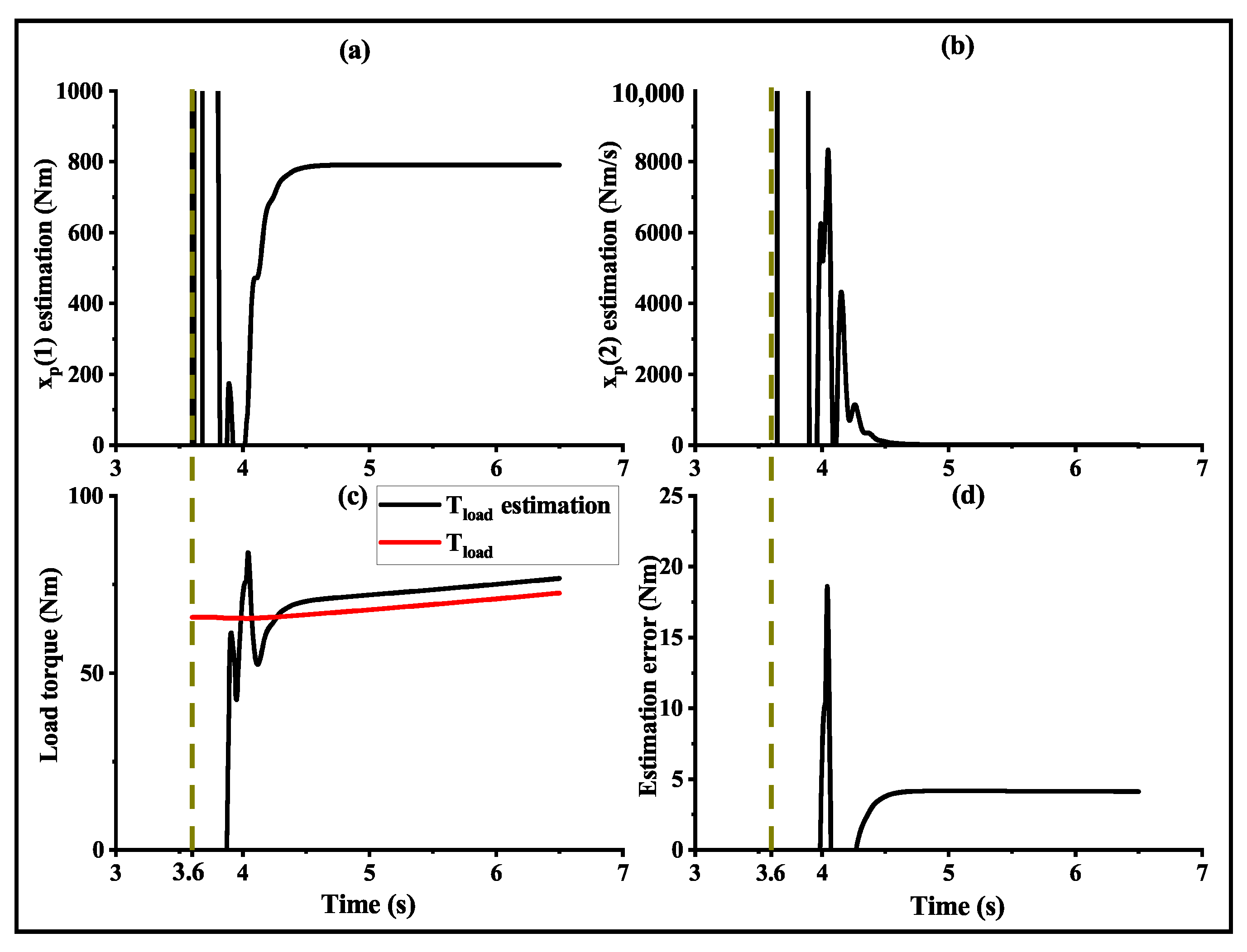

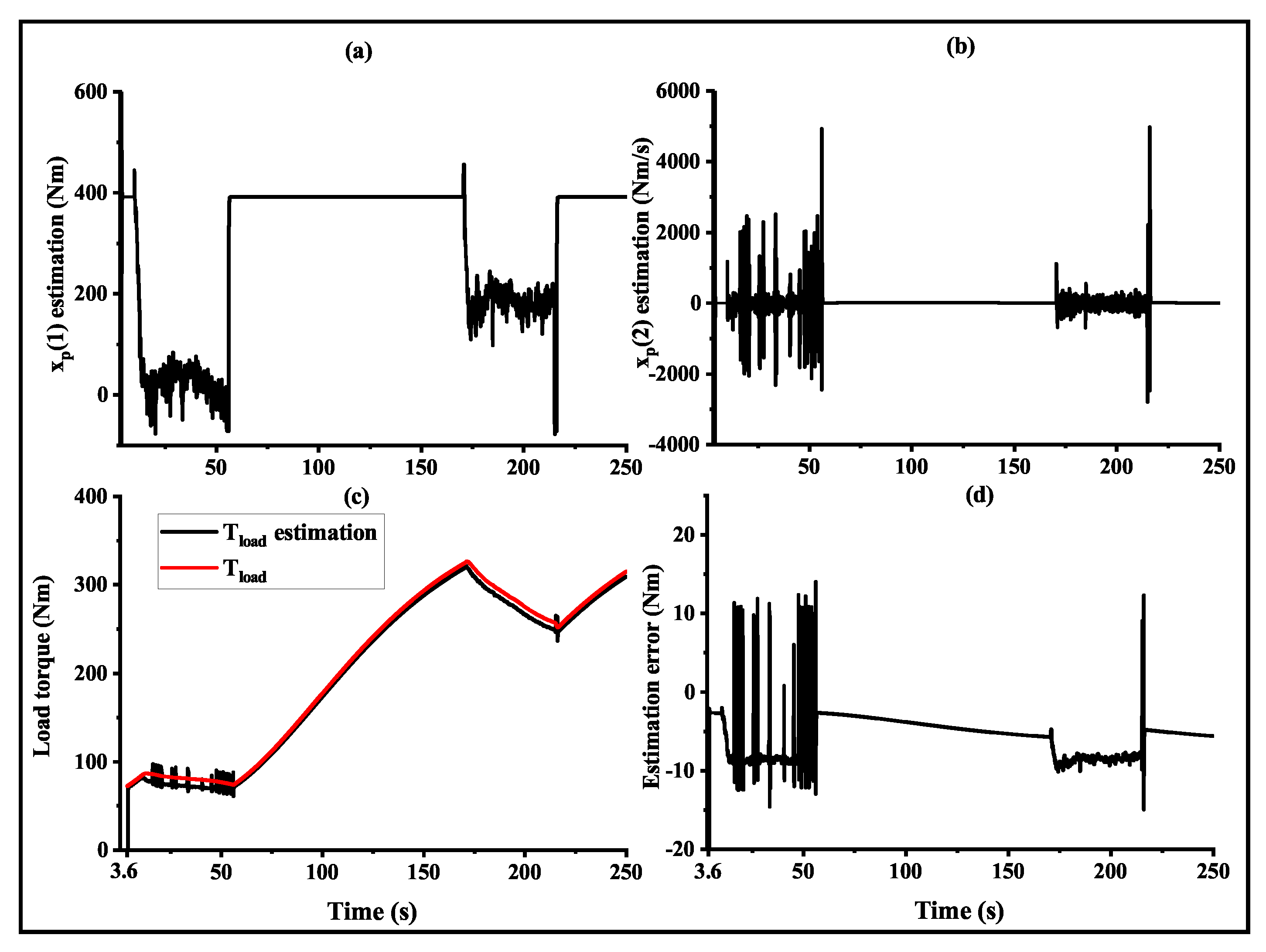

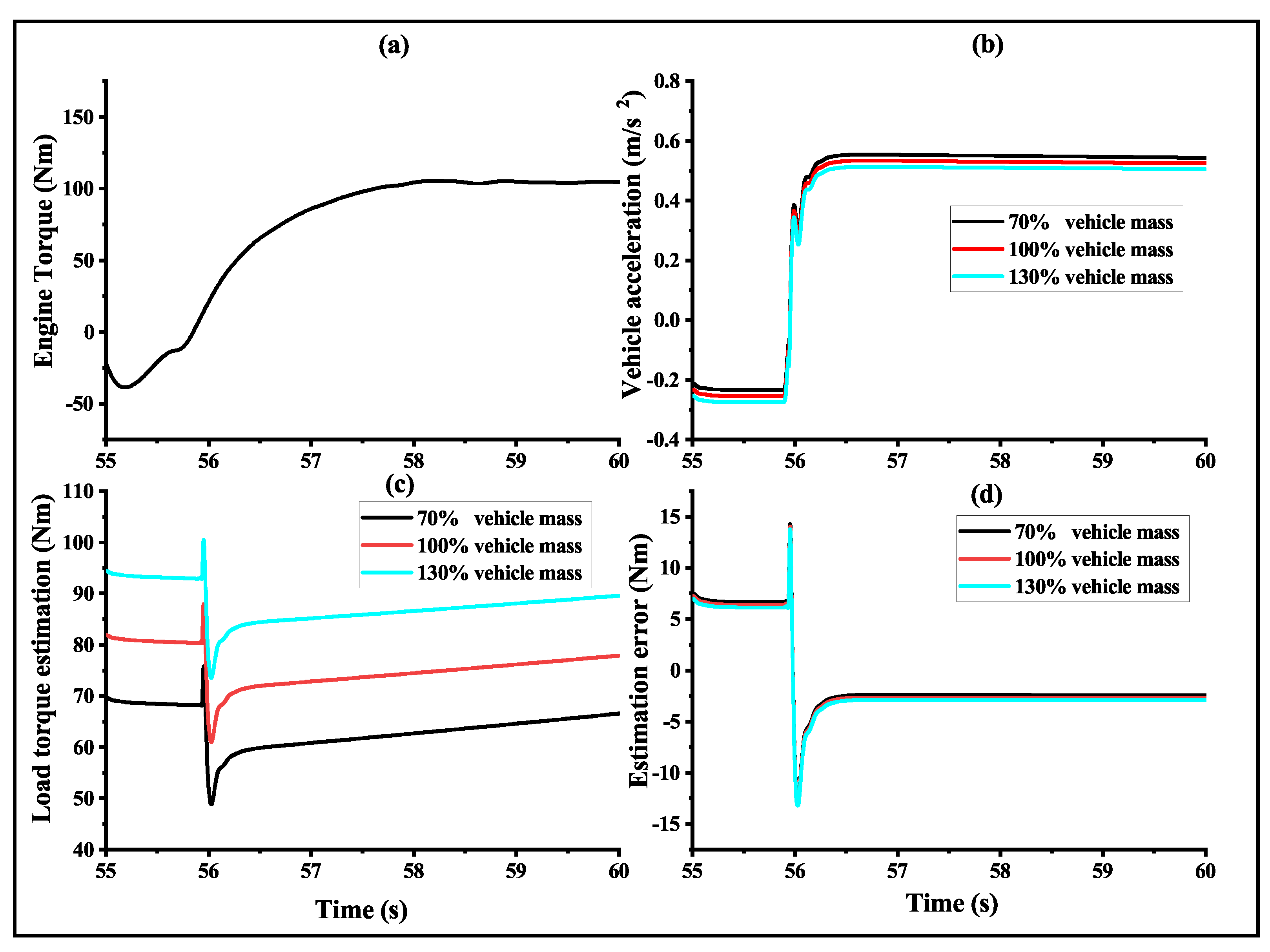

The performance of the extended state observer in the tip-in operation is illustrated in

Figure 5. Additionally, the estimation error of the load torque is presented in order to evaluate the observer’s design. At approximately 3.6 s, the observer is activated, and at around 4 s, the observed values gradually converge. The results demonstrate that the estimated value from the observer is in good agreement with the actual value, with a steady-state error deviation of less than 5 Nm after convergence.

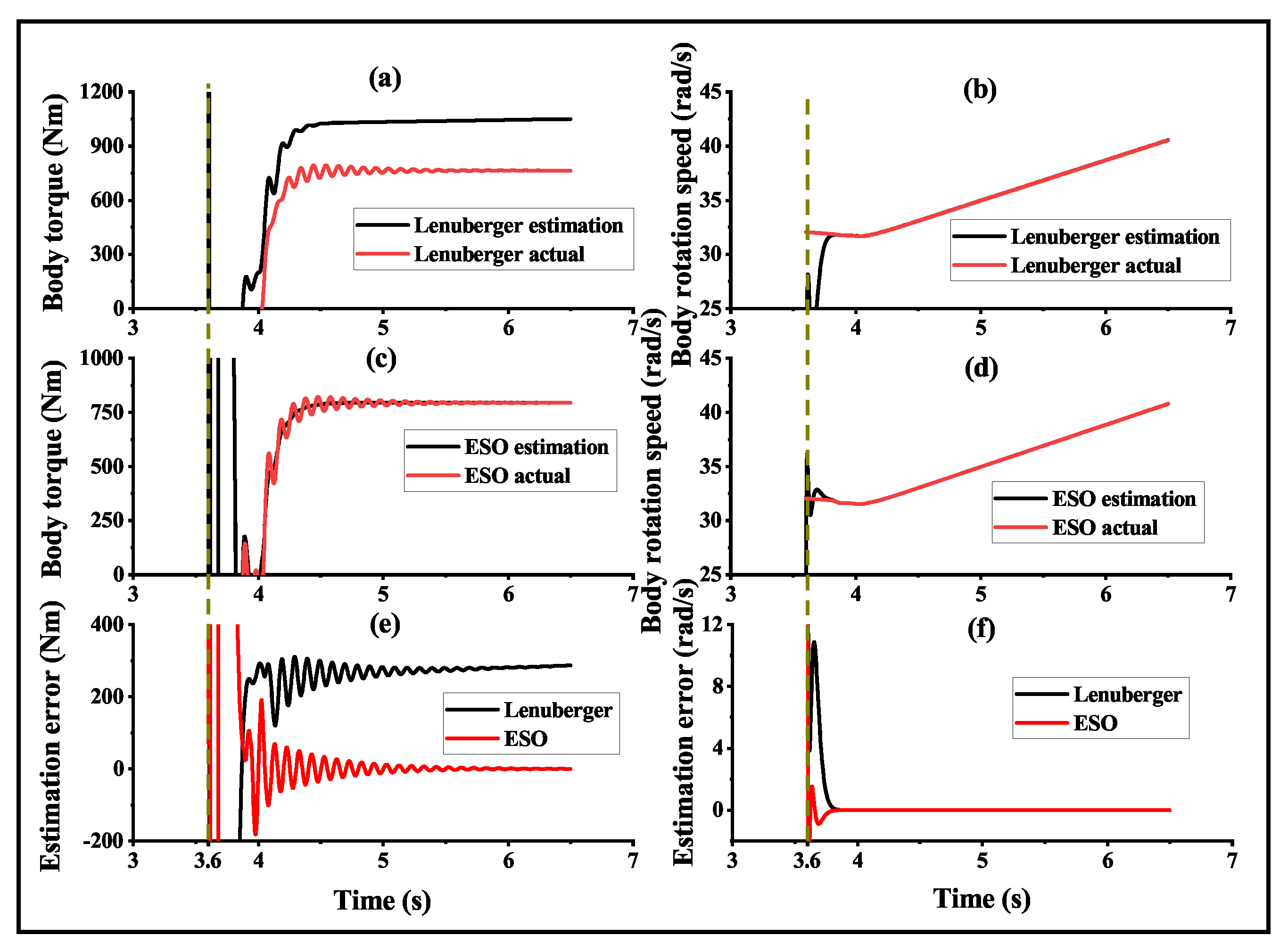

In order To highlight the advantages of the designed extended state observer, a comparison was made between the extended state observer and the Luenberger state observer, as shown in

Figure 6.

Figure 6a,b show the body torque and body rotation speed as estimated by the Luenberger state observer, whereas

Figure 6c,d show the observation results for the extended state observer.

Figure 6e,f depict the observation errors between the estimated values and the actual values for the two observers. From the estimation error of

Figure 6, the extended state observer outperforms the Luenberger state observer in terms of estimation accuracy. Specifically, the extended state observer achieves near-zero error in its estimation of the body torque, whereas the Luenberger state observer’s error remains around 300 Nm. Similarly, the extended state observer’s estimation error for body rotation speed converges faster towards zero compared to the Luenberger state observer.

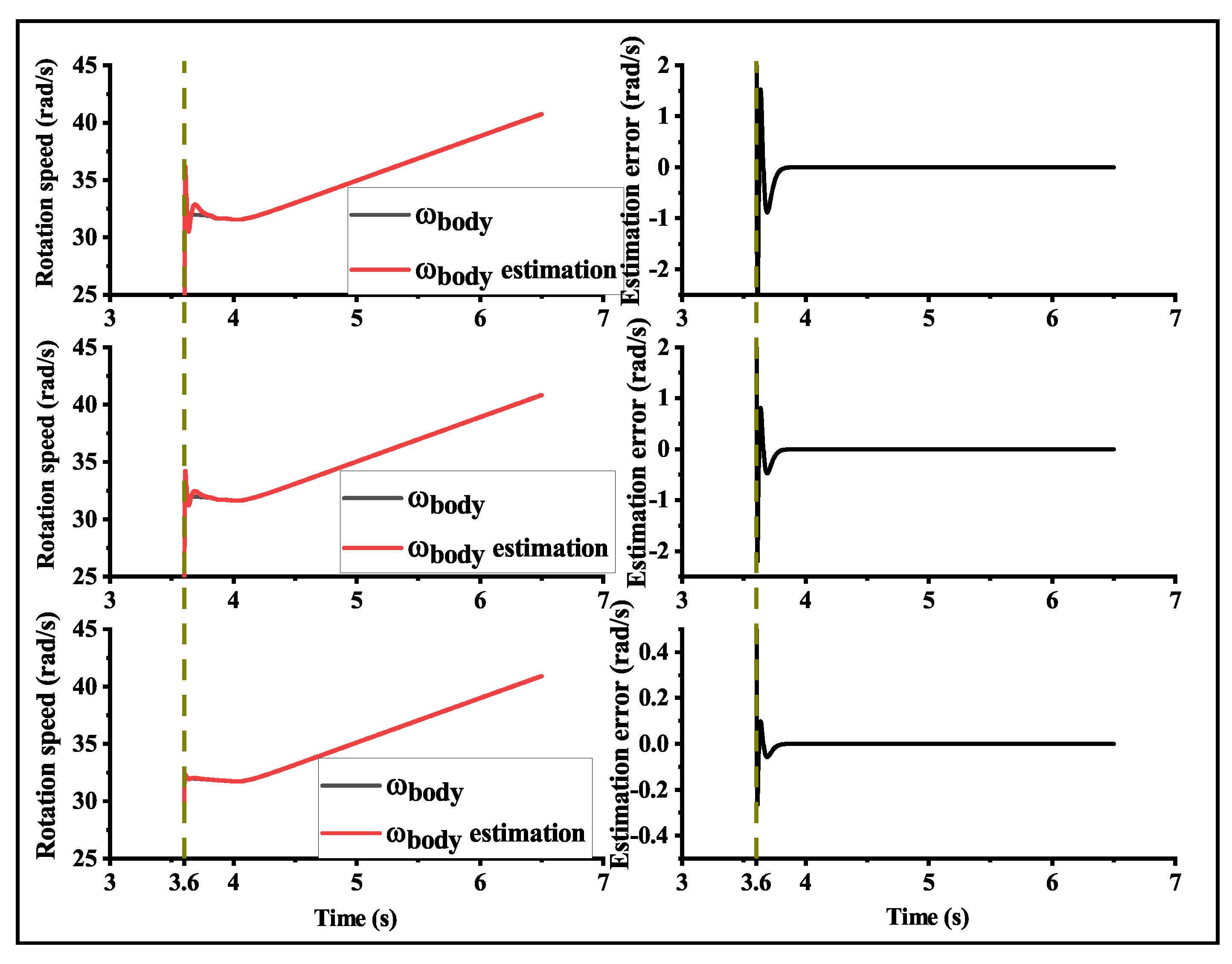

4.2. Observation Results for Different Initial State Values

In order to investigate the impact of different initial values on the convergence of the observer, we tested the designed observer with various initial state values. As depicted in

Figure 7, “

” is the actual value of the rotation speed of the vehicle body, “

estimation” is the estimated value of the rotation speed of the vehicle body, we selected initial state values of

,

, and

from top to bottom. These values represent different rotational speeds of the vehicle body. As the initial value of the rotation speed of the vehicle body increases, the estimated results of the observer become increasingly closer to the true values, and for an initial value of 30, almost no estimation error was observed throughout the entire simulation process. However, regardless of the initial value, the estimation error of the observer can converge within 0.2 s after the controller is activated, indicating that different initial values do not have a significant impact on the observer’s estimation accuracy.

6. Conclusions

Ensuring the effective suppression of driveline oscillation is crucial for promoting the sustainability of HEVs. The two primary challenges to address when damping driveline oscillation are the presence of time-varying torque load and nonlinear driveline backlash. Despite the fact that several active control methods have been proposed to address these challenges, certain issues, such as the requirement of a high-order model and the assumption of a known torque load, remain unresolved. In response to these challenges, the present study proposed an extended-state-observer-based compensator to actively suppress driveline oscillation in HEVs. The driveline model was simplified, for ease of controller design, as a second-order system with a dead zone. Subsequently, the compensator was designed using the method of pole allocation. An extended state observer was designed in order to estimate the state variables and load torque, and the input-to-state stability with respect to bounded model deviation was analyzed for the observer. Finally, simulation and engine-in-loop experiments were conducted in order to evaluate the control and observation performance of the proposed control scheme. The designed observer exhibited fast convergence performance and robustness against the considered model uncertainties, whereas the proposed control scheme significantly reduced driveline oscillation.

In our study, a fixed feedback gain was selected for the damping system and operating conditions. Nevertheless, investigating how the performance of the system would be affected if the feedback gain varied for different damping systems and operating conditions would be valuable. To this end, future research could focus on exploring the potential of adaptive control strategies that can adjust the feedback gain in real-time based on the performance of the system. Furthermore, additional research on the option value of electrified transportation is necessary in order to enhance its sustainability.