Abstract

In order to cope with the current competitive scenario, more and more companies are increasingly challenged to redefine their current decision-making and control models in favour of lean, efficient and digitalised models. Recent advances in digital technologies offer new opportunities for management to digitise and automate decision-making and control processes, with numerous benefits, including in terms of sustainability. In many industries, especially in food and beverage sector, the implementation of smart technologies could play an important role and have a positive impact on business processes, making them sustainable. The literature on the use of smart technologies in food and beverage companies focuses on the impact that such technologies have on performance measurement and sustainability, but there is a lack of explanation of the impact of smart technologies on decision-making and control systems. This work aims to fill the gap in the literature by investigating, through a case study, the impact of smart technologies on the decision-making and control systems of food and beverage companies. The case study showed that the use of smart technologies in food and beverage companies has an impact both on control systems, which generate a range of information relevant to management control, and on decision-making systems, which support management in making optimal strategic decisions for the company.

1. Introduction

Food and beverage (F&B) companies are part of a dynamic environment, together with customers who have high expectations of food safety and who increasingly pay more attention to the products they consume by requesting information about their origin, the inputs used and the production standards [1]. The result is a controlled supply chain and clear and complete food labels. One of the challenges F&B companies are facing is to develop information systems that can help them respond consumers needs [2]. F&B companies are increasingly using information systems and technology, which is also used in relation to the concept of sustainability [3,4] to improve their performance and gain a competitive advantage. Companies use information systems to improve the management of their functions and apply these systems in human resources, finance and accounting, sales and marketing, operations and production [5]. Technologies that incorporate digital innovations (such as blockchain, artificial intelligence, the internet of things and big data analytics) play a major role in today’s competitive environments and can have a significant impact on a company’s sustainability [6]. This emphasis is pushing companies to make relevant investments to explore smart technologies and build or improve their sustainable business models [7,8]. Given the current competitive context, the priorities of the companies are therefore shifting significantly, and the management is called upon to manage change from various perspectives: the careful planning, the monitoring of the costs, value chain efficiency and measuring results. All these factors are forcing companies to change their decision-making and control systems: decision-making systems need to process huge amounts of data, while control systems follow an adaptive and incremental logic of the goal-setting process [9,10].

With the proliferation of smart technologies, the information system has become the ideal tool for processing a large amount of data from different sources and a suitable tool for developing enhanced analysis to support decision-making and control processes [11,12].

Studies on the use of smart technologies in companies operating in the F&B sector focus on the support that these technologies provide for performance measurement and for achieving sustainability, however, there is a lack of explanation of their impact on decision-making and control systems.

In light of these considerations, and given the novelty of the topic, both from a theoretical and practical point of view, the aim of this work is to investigate, through the analysis of a case study, the possible impacts of smart technologies on the decision-making and control systems of F&B companies.

Specifically, the research question that has been addressed is the following:

How do smart technologies affect the decision-making and control systems of F&B companies?

The paper is structured as follows. Section 2 reviews the literature on decision-making and control systems in the F&B industry highlighting the possible implications deriving from the use of smart technologies. Section 3 illustrates the research method employed. Section 4 reports the results drawn from the case study. Section 5 discusses these findings and conclusions, offers various implications for scholars and managers, and reports some limitations.

2. Literature Review

2.1. Decision-Making and Control Systems

The topic of control systems has been widely debated in the academic literature [13,14,15,16,17,18,19,20]. Over time, studies have attributed different meanings to the term “control” and proposed numerous methodologies and control. Scholars have attributed two different meanings to the term “control”: in a narrower sense, control is intended as an inspection activity aimed at verifying the compliance of behaviours with predefined procedures and standards; in a broader sense, control is intended as a guiding activity of the company towards the achievement of its objectives [13,15,16,21].

In the 1960s, a horizontal approach to the control system based on organisational levels began to be established, leading to a distinction between strategic planning, management control and operational control [14]. Anthony’s (1965) control system is inspired by the most common corporate decision-making processes, which lead to the identification of the objective, the execution of decisions to achieve the objective, the verification of the degree of achievement of the objectives and the evaluation of corrective actions [22]. An innovative aspect of control that emerges from the proposed approach is the emphasis on the systemic conception of control within the wider corporate system, expressed through the symbiosis between planning and control activities [15,17]. Planning emphasises the decision-making aspect of the three activities, i.e., the objectives to be pursued and the methods of action to be adopted to achieve them, while control mainly emphasises the observation and detection aspects of the implementation of decisions, ensuring their realization.

Starting from the North American studies, the attention of scholars has focused on the links between the control activity and the planning activities within a unitary management process, also aimed at recognizing the existence of organisational and behavioural implications of business management [23]. The management process, in a systemic logic, includes the interrelated moments of idea formulation, decision-making and their implementation [24]. The system of corporate ideas, through the decision-making process, is converted and materialised in the system of operations [25]. From this point of view, the system of decisions represents the link between the political moment of the formulation of ideas, and the moment of action, implementation and realisation of operations [26].

Therefore, the concept of a single management system is reaffirmed, which aims to overcome the rigid tripartition of the control system into the planning, programming and control phases, and in which strategic management and operational management are increasingly correlated, and the boundaries between strategy formulation and its implementation become steadily nuanced [15,27]. In this context, the control system, in addition to fulfilling the role of a tool for evaluating the strategy pursued and supporting decisions related to operational management, is interpreted as a set of principles aimed at supporting and directing decision-making processes towards the pursuit of the organization’s objectives [28]. According to this interpretation, the purpose of monitoring the performance achieved, by comparing the results with the objectives, becomes instrumental in the production of an information flow that is used to make the decision-making process more effective and thus ensure the pursuit of short and long-term objectives [29].

This concept of ex ante and in itinere control, aimed at detecting sudden deviations from predefined strategic lines by proposing timely corrective actions, effectively responds to the information needs posed by today’s competitive scenario, characterised by a high degree of instability and turbulence, the difficulty of predicting phenomena and the rapidity of their manifestation [29,30]. To cope with the growing complexity of the environment, top management is called upon to continually review and adapt strategies, management models and operational tools, and to increase the speed of the decision-making process. As a result, decision-making systems increasingly require the processing of large amounts of data to meet the growing information need. At the same time, control systems follow an adaptive and incremental logic of the goal formulation process, in which control itself must be re-proposed in ever shorter cycles [9,10].

The information system is configured as an essential tool for collecting the information that underpins the decision-making process and for controlling the degree of implementation of the decisions themselves [31].

Over time, information systems have evolved, on the one hand, to meet the growing information needs of corporates, and on the other, as a result of the impact of information and communication technologies (ICT). As part of the evolutionary path of information systems, management software has evolved into integrated modular systems, i.e., Enterprise Resource Planning (ERP), essentially aimed at the management and governance of transactional data and internal company information [32,33,34]. ERP systems, by integrating transaction-based corporate information into a central database to make it usable by different organisational units [35], have made relevant and real-time operational data accessible to management to support decision-making and control processes [36]. Subsequently, ERP systems were joined by Business Intelligence (BI) systems as tools to support the analysis of information about the market, competitors and their future evolution [37,38,39]. In recent times, the development and diffusion of new technologies have had an impact on the corporate information system, automating and integrating a large amount of data, both internal and external to the company, as well as developing enhanced and targeted analyses to support decision-making and control processes [11,12].

2.2. Food and Beverage Industry

The F&B sector includes many different types of activities, such as restaurants, bars, catering and shopping centres. These are all examples of activities that offer food and drink for immediate consumption. In technical terms, however, the F&B industry is known as the Ho.Re.Ca. (Hotellerie, Restaurant, Café) and coincides with the sector encompassing the distribution of food products in hotels, restaurants and cafes (more commonly known as catering). The Ho.Re.Ca. is constantly evolving and represents an excellence of the Italian production system, consisting of about 330,000 companies of which bars and restaurants represent the most numerous categories (www.horeca.it; accessed on 12 September 2022).

Gomes (2017) [40] states that food and drink can be described as a management function, responsible for supply, reception, storage, distribution, production, service provision, etc.

The Ho.Re.Ca. includes the economic actors (industry, services, trade and reception) and the operations (production, distribution, trade and hospitality) that contribute to the formation and transfer of the product or service. The supply chain includes the entire chain of production, distribution and retail sale of F&B products, and can be more or less long depending on the number of actors intervening between the product and the consumer [41].

The F&B industry is characterised by a number of complexities.

The first complexity is inherent in the nature of the sector itself. Until a few years ago, the F&B sector was much less complex in terms of product supply and demand. Nowadays, even F&B companies are moving towards an economic model that is no longer based only on the supply of products, but also on services: production, service, gastronomy, safety and consumer expectations are sold along with meals [42]. In this context, particularly in the case of bars, restaurants and pastry shops, the ability of distributors to manage and provide ancillary services (i.e., maintenance services, timely restocking of raw materials) to subjects who are loaned the machinery to run their business (coffee machines being an example) is of great importance.

The second source of complexity in F&B is the coexistence of different functions such as production (of food and drink) and distribution (of food raw materials). In this context, the manager has to manage and coordinate functions with different needs in order to achieve the main objective: customer satisfaction, or more precisely, customer gratification.

Final products can be perishable and have a limited shelf life: the use of data on products and management processes is necessary, for example, for production planning, order management, purchasing and sales, warehouse management, and detailed production execution [43]. In this regard, consumers are increasingly interested in the products they consume and demand more and more information about their origin, the inputs used and the production standards [1]. During the COVID-19 pandemic crisis, consumers became more aware of the sustainability of not only food production but also packaging. Therefore, companies operating in the F&B industry have to ensure quality and safety in the production chain [44,45] and product traceability [46].

In the food sector, sustainability is synonymous with a controlled supply chain, local production linked to the territory, completeness and clarity of food labels (source: Nomisma Sustainability Observatory. (https://www.nomisma.it)) (accessed on 12 September 2022). The food sector faces specific challenges, of which product traceability is one of the most important. In this respect, the development and implementation of information systems capable of supporting food traceability is a source of competitive advantage for companies [2]. Previous studies have shown that there may be an information asymmetry between sellers and consumers and that some types of information systems can play an important role in reducing this asymmetry [47]. The development of internet-based information systems promises to overcome these shortcomings, but it is also widely recognised that such types of information systems face problems related to data processing, storage, transmission and control [48]. In this regard, new technologies are expected to overcome these limitations [49,50].

Innovation is not only important for reducing the information asymmetry between seller and consumer, but also for achieving sustainability and improving the environmental performance of companies and product quality. Indeed, in recent times, the concept of innovation has always been most studied in relation to the concept of sustainability [3,4]. Whereas in the past the food sector focused on minimising production line costs and paid little attention to consumer needs, today the food chain is reversed, with consumers telling producers what they want to eat [51,52]. As a result, the food sector is faced with an urgent need for innovation and consumer demands for health. The innovation capacity of the food sector is important in addressing sustainability challenges. Considering innovation and sustainability together, an innovation can take the form of traditional innovation, i.e., an innovation that contributes to an improvement in sustainability (such as process innovation), or a form that generates greater sustainability in itself (e.g., a new product that uses different raw materials) [53].

2.3. The Impact of Smart Technologies on Decision-Making and Control Systems in the F & B Industry: Some Speculations

Digital transformation has dramatically increased the amount of data available to companies. In this context, technological innovations, such as the Internet of Things (IoT), cyber-physical systems, and artificial intelligence integrate corporate information systems by enabling the collection and analysis of large volumes of data, both structured and unstructured, from various sources, both internal and external to the company, in order to convert them into information useful for the decision-making process [34,54,55]. Therefore, data and information acquired through traditional information systems and tools are combined with data and information acquired through smart technologies, offering new opportunities for using data in decision-making and control systems [11,56,57].

In this regard, several studies have highlighted the benefits and positive impacts on decision-making and control systems that result from the use of smart technologies [54,58,59,60].

In terms of the control system, the application of advanced analysis and forecasting models on databases from different sources, on the one hand, improves the reporting capability of performance measurement tools, and on the other hand increases the capacity and accuracy of management’s estimates of resource, utilization and customer requests, with a potential positive impact on the entire budgeting process [11,61,62,63]. Smart technologies can be implemented to automate repetitive accounting information processes characterised by large volumes of transactions, eliminating errors and making measurements more accurate [64,65,66]. Neural network-based technologies can be used in cost estimation to predict the attributes that influence, for example, the cost of production, thus allowing economic activities to be tracked and measured in advance and in detail [12,61]. Furthermore, big data could be useful for allocating indirect costs to the activities that drive most overheads [61]. The use of advanced analysis, forecasting and simulation models has an impact on the reporting system, offering increasingly complex, detailed and timely reports that can be consulted by management in real time [11]. Finally, these advanced analytics also have an impact on the feedback process, as through the comparison between actual results and feedforward data, they allow managers to predict possible deviations between results and targets, in order to better guide the behavior of operators to achieve the company’s objectives [65].

In terms of decision-making systems, smart technologies enhance business planning and scenario analysis, enabling management to make more rational and well-informed decisions [58,67,68,69,70]. Access to real-time data, the availability of population-level data, the increasing processing power of statistical analysis tools, and developments in visualisation methods allow managers to search for new patterns, correlations and links in data [69]. In particular, these tools facilitate knowledge of the essential interdependencies between inputs, processes, outputs and outcomes, and provide managers with valuable information on key aspects of performance, avoiding data overload and inefficient decisions, improving the objectivity of the decision-making process [58,71,72]. In addition, predictive analytics allows the management to predict future behaviours and scenarios, to immediately evaluate the different strategic alternatives and to test and compare them in parallel in order to choose the best one to achieve the company’s objectives [67]. Through the use of these tools, managers are able to continuously modify long-term planning by limiting the uncertainty in the forecasts. In this way, decision and action are closely integrated, reducing the time of the decision-making process [11].

Furthermore, several studies have shown how the adoption of smart technologies is an enabling factor for sustainability, supporting the company towards the achievement of sustainable goals [73,74,75,76,77].

As awareness of the importance of sustainability continues to increase, companies are integrating economic, environmental and social aspects into their business operations and decision-making processes. Therefore, in order to continuosly monitor the achievement of economic, social and environmental objectives, traditional control systems and tools are supported by systems and tools that are able to detect social and environmental impacts [78,79]. In this regard, smart technologies help companies to collect, integrate, automate and monitor information related to the dimensions of sustainability, helping managers to define measures that would otherwise be difficult to determine, such as the impact of organisations on the Sustainable Development Goals (SDGs) [63,80].

Despite the growing attention to these issues, scholars have only recently begun to focus their attention on the relationship between smart technologies and sustainability issues [73,75,77,81]. Morover, the literature still seems to be silent when it comes to linking aspects of sustainability/smart technologies with issues of decision-making and control systems.

The F&B industry represents a competitive context in which sustainability is a key element. Customers are increasingly demanding higher standards of sustainability and product quality [3,4]. In this context, the development of smart technologies, such as the IoT, big data analytics and the blockchain, could play an important role and have a positive impact on business processes by making them sustainable.

However, F&B companies are mostly Small and Medium-sized Enterprises (SMEs), which are characterised by limited availability of economic resources, difficulty in attracting capital and accessing credit, and underdeveloped and specialised entrepreneurial and managerial skills, which limit potential development. Due to the characteristics highlighted above, F&B companies may encounter difficulties in implementing new technologies [60].

Furthermore, studies on the use of smart technologies in F&B companies mainly focus on the support of these technologies in measuring performance and the role they play in achieving sustainability [2,82,83], while the literature is silent on the impact of smart technologies on decision-making and control systems.

3. Methods

In order to fill the gap in the literature, this study explores how smart technologies affect decision-making and control systems of F&B companies, using a qualitative case study methodology [84]. We have chosen a qualitative method, because qualitative research as a scientific investigation is often used for the inductive exploration of yet unknown phenomena [85]. This method is mainly used when the form of the research question is “How?” [84] and is indicated when the researcher’s intention is to investigate new topics in complex contexts.

From a methodological point of view, the case examined represents an exploratory case. This type of case study is appropriate when it is quite difficult to draw on empirical evidence from previous literature [84,86]. Exploratory case studies are characterised by the absence of hypotheses and less structuring of data collection instruments [86]; they offer the researcher the opportunity to gain a deep holistic view of the research problem and can facilitate the description, understanding and explanation of a research situation [87,88,89]. In particular, this type of case study aims to highlight what happens in the presence of a given phenomenon, which in our study is the implementation of a smart technology.

The qualitative approach used focuses on the case of Prodacta, an innovative start-up company specialising in the development of advanced technological solutions in the field of IoT for the various sectors of the manufacturing industry. Prodacta was born from a spin-off of the IoT for Industry 4.0 division of Software Business, an expert consultancy company in business processes, implementation of ERP systems, business intelligence and systems for integrating and collecting data from machines in the manufacturing industry. Prodacta specialises in three areas of intervention: the creation of industrial IoT projects to control and connect machines to other machines; the integration and interaction with all the company’s information systems, making them intelligent; and the development of web applications for the management of data flows and information on cloud platforms. Specifically, the object of analysis is a particular project developed by the company Prodacta: the Coffeehive project, an interconnection platform for the centralised and real-time data collection of post-production coffee machines. We were granted, through informed consent by the respondents, formal permission to show the name and information related to the company.

For the case study, it is important to develop a wide range of data collection procedures based on different sources of information [84,90]. The qualitative data to be analysed are divided into four main groups: interview (individual interview, face-to-face interaction in a group, web-based interaction), observation (participatory and non-participatory), documents (private and public) and audiovisual materials (artefacts in photographs).

A specific analysis protocol was followed for the case study object of our analysis [84]. After developing a basic knowledge of the issues under investigation through an in-depth analysis of the literature on the topic, we moved on to the collection of evidence. In order to ensure the triangulation of data [84], a process that supports researchers by limiting bias due to particular personal positions of the same or non-objective individual perspectives, data collection took place using the following sources: documents, company website and semi-structured interviews. We chose to conduct semi-structured interviews because this type of interview allows the researcher to refocus the questions or ask the interviewee for more information if something interesting or new emerges.

The sources of evidence were selected and used in a concatenated way [84], that is through an explicit correlation between the documents examined, the choice of the subjects to be interviewed and the questions put to them. In particular, the data and information obtained through the analysis of the documents and information on the company website were functional to structure the interviews, focusing on the aspects of interest. Therefore, before starting the interviews, a preliminary investigation was carried out to allow the research team to better understand the development and characteristics of the business, the context and the specifics of the Coffeehive project. This survey was mainly based on an in-depth analysis of the available data: internal documents, information available on the company’s website, and PowerPoint presentations or videos.

The case was developed on the basis of semi-structured interviews conducted between November 2020 and September 2022. The interviewees are part of both the management team of Prodacta and Software Business, as experts in the implementation of management systems of flows and processes in the company with experience in the F&B sector. Specifically, the Chief Executive Officer and Chief Marketing Officer of Prodacta; the Chief Technology Officer and the controller of Software Business were interviewed.

For each of them a focused interview was conducted [84], in which each subject was interviewed for about 90 min following a scheme of open questions. The questions were designed to allow the interviewee to answer the question spontaneously [91]. Due to the COVID-19 pandemic crisis, the interviews were conducted, on the Microsoft Teams communication platform. In particular, after contacting each manager, the research group was introduced, the main objectives of the study were explained, and all the issues related to the confidentiality of the information provided and the company data acquired were managed. The interviews were videotaped with the consent of the respondents and then transcribed following the “24 h rule” [92].

In order to study the impact of smart technologies in F&B companies, we adopted a qualitative approach based on a thematic analysis of the transcripts and documents related to our case study. The data were analysed using thematic qualitative coding techniques. The main goal of the data analysis is to find answers to the research question through categories or themes that are intended as results of the analysis [93]. Specifically, the transcriptions and documents were systematically analysed to identify categories and relationships of meanings [89,90].

Therefore, following the method of Gioia et al. (2013) [89], we linked first-order descriptive terms (e.g., quotations) and second-order themes (e.g., main that topics emerged) to the identified aggregate dimensions: (1) the information flows provided by smart technologies; (2) the impact of smart technologies on business processes; (3) and finally, the impact of smart technologies on decision-making and control processes.

In particular, the data analysis was conducted following an iterative process articulated in several steps [94,95]. First, we identified any units of data that could be relevant to our study and assigned codes to them. Then, we tried to group the codes that presented analogies and affinities of meaning within the same category. Finally, we grouped the categories into broader themes and then into the identified aggregate dimensions [94]. To ensure the validity and reliability of the analysis, the data were analysed and coded separately by each author. Subsequently, we shared and discussed the classification of key concepts, resolved any discrepancies, to arrive at a shared classification [93]. In this regard, we collaboratively reviewed the results to isolate any discrepancies in the identified aggregate dimensions until an acceptable level of reliability was achieved [93,95]. Through this rigorous data analysis process, the researchers maximised intercoder reliability and intercoder agreement [92].

4. Results

4.1. Case Description: The Coffeehive Project

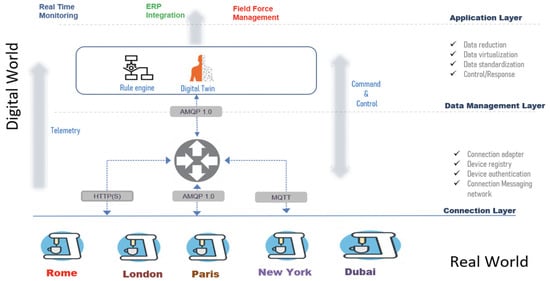

The Coffeehive project aims to develop an interconnection platform for centralized and real-time data collection from professional coffee machines used in the Ho.Re.Ca (Figure 1). The project provides all actors in the coffee supply chain with dashboards for real-time monitoring of volumes and revenues, as well as maintenance, in order to provide them with information on aspects related to the profitability of coffee machines.

Figure 1.

The Coffeehive project. Source: Prodacta website. https://www.prodacta.it/case_study/coffeehive-la-macchina-da-caffe-intelligente/ accessed on 14 September 2022.

The technological solution developed by the project consists of a hardware component (Plug&Play device) inserted in the professional coffee machines and a cloud platform for managing the data collected through the hardware component. By applying IoT real time data collection technologies, it provides real-time information on both the use and wear status of the machines and on the coffee consumption. The data collected and made available on the cloud platform is then processed by the analytics, providing analysis and useful information to the various stakeholders in the coffee supply chain connected through the technology.

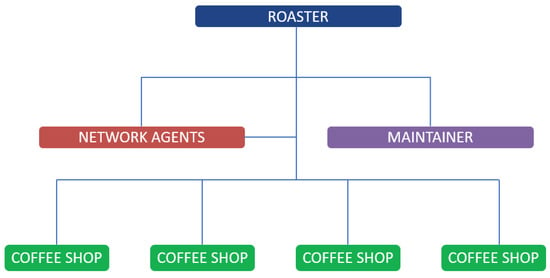

In this regard, the technological solution proposed by the Coffeehive Project connects the following actors in the coffee supply chain: roasting companies; coffee agents and retailers; professional coffee machine maintenance service companies; and coffee shop/point of sale (Figure 2).

Figure 2.

The main actors of the coffee supply chain. Source: Prodacta.

In essence, the technological solution aims to make every espresso coffee machine smart, allowing it to be monitored via a cloud platform.

4.2. Main Findings of the Case

The aim of this paper is to understand how the implementation of smart technologies affects the decision-making and control processes of companies operating in the F&B industry. In line with the research objective, the case of the Coffeehive project analyses how the implementation of an intelligent technological solution, significantly expanding the amount of data and information, affects both the business processes of the various players in the coffee supply chain and their decision-making and control processes. Therefore, we have reported the results of the multiple sources of evidence under three aggregate dimensions: (1) the information flows provided by smart technologies; (2) the impact of smart technologies on business processes; (3) and, finally, the impact of smart technologies on decision-making and control processes.

4.2.1. The Information Flows Provided by Smart Technologies

The Cloud platform developed by the Coffeehive project is multi-tenant and provides information at different levels by creating dedicated dashboards for different types of stakeholders. Therefore, the technological solution provides the various actors in the coffee supply chain with structured and unstructured data and information from external sources. These data and information are then integrated into the company’s information systems and combined with data from internal company sources, to provide useful information for the decision-making process.

The Information provided by the t”chno’ogical solution is presented below for each stakeholder in the coffee supply chain.

The roasting company, which is the main player in the coffee supply chain, has management data on the number of coffee machines allocated to customers, the geolocation of the machines and their operation. IoT technology provides a wealth of real-time information on the coffee consumption of the machine fleet. This information is integrated with the roasters’ ERP systems, allowing them to obtain information in terms of sales volumes and revenues updated in real time. The technological solution also provides inventory data on the quantity of coffee delivered and the quantity of coffee in stock. This data can be analysed by business intelligence systems through an algorithm that defines the scheduled reordering time of the stores built on out-of-stock predictions based on consumption (Table 1).

Table 1.

The roaster’s dashboard.

“The roaster has a complete overview of what the fleet of machines is on loan for use, has real-time information on the coffee consumption of the machine park and on the consumption of the machines”.(Chief Technology Officer)

The agent is another important player in the coffee supply chain, as he manages the relationship between the roaster and the selling points. For the agent, the dashboard is limited to the store he manages.

“Out of 1000 points of sale of the roaster, the agent manages 30. Compared to those 30 points of sale managed, the agent has an overview of the data and information held by the roaster. This way, he can manage his store fleet more effectively”.(Chief Marketing Officer)

Therefore, limited to managed the points of sale, the agent has information on the number of machines and their operation; on the consumption of coffee by the machine park and on the inventory in terms of coffee delivered and coffee in stock (Table 2).

Table 2.

The agent’s dashboard.

The coffee shop has limited data access to its point of sale. IoT technology provides the coffee shop with real-time information on coffee consumption. This data can then be processed to create correlations between coffee consumption and certain days and/or time slots; between the consumption of coffee and the number of customers in relation to specific time intervals. Coffee consumption data is also used to determine the need for scheduled reordering. Furthermore, the technological solution provides the bar with a wide range of data relating to the quality of the coffee dispensed, such as the number of daily cleanings, and data on extraction time, temperature or delivery pressure (Table 3).

Table 3.

The coffee shop’s dashboard.

Finally, the maintenance company has access to data relating to the use and operation of the coffee machine. IoT technology provides the maintenance company with a series of information relating to the number of interventions, monitoring of energy consumption, and signs of components replacement. In addition to information on routine maintenance operations, the technological solution offers the maintenance company real-time monitoring of the machines and the processing of information for predictive maintenance interventions (Table 4).

Table 4.

The maintainer’s dashboard.

Through this data and information, the maintenance company is able to detect the intervention in real time and optimize the maintenance performance.

“The information is also provided to the maintenance company which in this way is able to understand and intercept any machine interruptions/breakages in advance”.(Controller)

4.2.2. The Impact of Smart Technologies on Business Processes

The technological solution provided by the Coffeehive project has a different impact on the business processes and on service offerings of the various stakeholders in the coffee supply chain.

Traditionally, the coffee sector is characterised by the loan for use contract. The coffee roaster/distributor provides a Ho.Re.Ca. operator (e.g., the coffee shop) with the coffee machine on loan for use. The Ho.Re.Ca. operator, in turn, undertakes to the exclusive purchase of coffee and commits to display the distributor’s coffee brand/sign inside its premises. The distributor/roaster bears all the costs and obligations for the periodic maintenance of the machine as well as the management of any repairs in the event of breakdowns.

The Coffeehive project aims to satisfy different types of latent needs of the various players in the coffee supply chain. In this context, the risk for the roaster is to lose control over the actual consumption of coffee and the use of the machine by the coffee shop, and to lose part of its revenue due to the customer’s unfaithful behaviour. The coffee shop, on the other hand, relies on the sale for a large part of its revenue. Therefore, the coffee shop cannot risk suffering a machine downtime due to poor maintenance.

The technological solution developed by the Coffeehive project mainly impacts on the business processes of the roasting company.

As explained in the previous paragraph, by implementing the technological solution, the roaster has punctual and precise information on the actual consumption of coffee at a given point of sale, avoiding the risk of unfaithful behaviour by the coffee shop and exercising greater control over it. The technological solution ensures a closer link between the roaster (supplier/lender) and the coffee shop (customer/borrower), fostering customer loyalty.

“The roaster sees in his customers as a kind of affiliate, since the coffee shop buys exclusively from a single supplier”.(Chief Marketing Officer)

The quality of the coffee served is a determining factor in the loyalty of the final customer to a brand and its points of sale. In this sense, the IoT can be used to have better control over the quality of coffee. The main service that is usually offered by the roaster to the coffee shop is to guarantee the quality of the blending and grinding of the coffee dispensed. However, the quality of the coffee depends on many factors, such as the blend, the quality of the water used and the pressure exerted by the barista on the machine. The implementation of the technological solution allows the roasting company to have access to a huge amount of data that would otherwise be difficult to obtain, such as data on water quality and coffee brewing pressure. In this way, the roaster is able to exercise effective control over the quality of the coffee dispensed, proposing ad hoc corrective actions to improve coffee quality.

Furthermore, by obtaining information on the actual consumption of coffee, the roaster is able to automatically replenish its customers. The technological solution entails the efficiency of the logistical processes of attempted sales, i.e., all those organized processes of means and people able to periodically check the stock of a specific product at a point of sale and therefore its replenishment. Thanks to real-time data on actual consumption and product stock at the point of sale, the technological solution makes it possible to develop a replenishment model that will lead to rationalisation and cost savings associated with stock levels and a reduction in logistics costs.

Changing in the business model from attempted sale to pay-per-use has an impact in environmental terms. Timely information on restocking requests from the points of sale reduces the number of trips to the store, which in turn results in lower costs and reduced CO2 emissions. An efficient vehicle fleet has a positive impact on the environment.

“The fundamental aspect is the change of the business model from attempted sale to pay per use, so as to avoid going to the point of sale to offer the coffee with the risk that it will not be purchased, making empty trips. Without the technology, the vehicle fleet consumes unnecessarily fuel. With Coffeehive, the fleet moves in a targeted way, optimizing the supply chain and making sales more efficient”.(Chief Executive Officer)

On the one hand, the adoption of IoT technology and the Cloud platform has an impact on the roaster’s business processes making them more sustainable; on the other hand, it improves the efficiency of the supply chain management process, in terms of all aspects related to logistics and warehousing, and then improves consumption and deliveries to the point of sale.

Therefore, the technological solution implemented in the coffee machines allows roasters to expand the range of services offered to their customers. In addition to supplying their own product, the coffee machine, they can provide data collection services to their users. These services translate into advantages for both the customer and the roaster, such as: control of unfaithful operations, reduction of maintenance costs, automatic reordering, optimization of attempted sales processes.

Within the coffee supply chain, customer trust and loyalty are important aspects. The relationship of trust between the roaster and the coffee shop is managed by the agents present in the area, who in fact represent the roasting company.

In general, one of the impacts of digital transformation is the phenomenon of disintermediation. With reference to the analysed case, the technological solution provides for the planning of warehouse interruptions and the scheduled reordering of goods. Therefore, by adopting IoT technology, the roaster has precise information on the coffee consumption of the shop and is able to automatically reorder the goods. In this sense, the role of the agent who goes to the point of sale to acquire orders for the goods or to sell the product could be bypassed, leading to disintermediation.

In reality, since customer relationships are an important aspect in the context of the coffee supply chain, the intent of Coffeehive is to ensure that the agent, who maintains a loyal relationship with the roaster at the point of sale, becomes a business consultant. The agent has at his disposal data and information on the points of sale he manages. Thus, his role becomes that of interpreting the data and information obtained through the technology and analysing it together with the coffee shop in order to adopt the most appropriate strategic solutions and business changes.

Therefore, the adoption of technology has an impact on the agent, who offers the point of sale the additional service of consultancy.

“Our intention is to turn the agent into a business consultant: through the management of dashboards and data that will be available for the analysis, for example, of the turnover rather than coffee consumption at that point of sale, the agent could understand what kind of blend to supply, what kind of time slots to favor for promotions or to boost coffee consumption. All this information, both qualitative and relative to profitability, facilitates the business process of the point of sale”.(Chief Executive Officer)

“The agent is no longer a salesperson but an all-round business consultant in terms of both quality and profitability and volume analysis. […]. Coffeehive ensures that the relationship with the agent is precisely one of high added value because the agent has to interpret the data and information provided to him”.(Chief Marketing Officer)

Finally, the technological solution developed by the Coffeehive project has a minor impact on the business processes of the coffee shop and the maintenance company. With reference to these two actors, the technological solution developed by the Coffeehive project has a minor impact on their business processes.

The coffee shop/point of sale, as mentioned above, has limited access to data; for example, it can have information relating to coffee consumption in terms of coffee consumed on certain days or at certain times, or of coffee consumed in relation to the number of customers who have accessed the point of sale. The advantage offered by the technological solution is the optimisation of the store management. The solution offered by Coffeehive, in addition to the number of coffees dispensed in a given period of time, provides customer-related information (for example, information on aspects related to the quality of coffee extraction), with the aim of offering added value in the management of the store. Furthermore, through the technological solution, coffee shops can exercise greater control over their point of sale.

The maintainer is usually an actor appointed by the roaster. The maintenance technician has access to the data relating to the operation of the machines. The technological solution offers the service of the real-time monitoring of the machine, enabling the maintenance technician to carry out routine maintenance and predictive maintenance, thus partially expanding his range of services.

4.2.3. The Impact of Smart Technologies on Decision-Making and Control Processes

The data collected by the centralised platform are integrated into the information systems to support the decision-making and control processes of the roaster. Depending on the characteristics and type of the information system and the team of control systems adopted by the roaster, the integration can take place through analytics and concern the analysis of unstructured data and the extraction of information used for decision-making and control processes, or through ERP with reference to a single company function, for example, to make the supply chain more efficient.

Furthermore, the data and information made available by the solution can be integrated into the information systems of maintainers and roasters, connecting them in machine-to-machine mode.

“In a use case that we have implemented, the integration takes place in the following way: the system reports an anomaly, for example the excessive temperature of the coffee machine in a store, directly to the maintenance technician, who goes to the shop to carry out the intervention. At the same time, a report is also opened in the roaster’s systems, so that they are aware of the interventions that have to be carried out or have been carried out by the maintenance technician”.(Chief Technology Officer)

This integration has an impact on the control systems of the roasting company, which not only controls the sales of a specific point of sale through real-time monitoring of volumes and revenues, but also the maintenance carried out, which is reflected in more information on maintenance costs. These are significant costs in the context of the store margin analysis, and information about them is usually difficult to find.

“Often the maintenance costs are watered-down and it is difficult to retrieve information on them. Furthermore, the maintainers are often small, unstructured companies, and have great difficulty in intercepting the interventions and, the activities carried out”.(Chief Executive Officer)

Therefore, the use of IoT technology and the cloud platform provides information that helps to perceive costs that are not always directly quantifiable or difficult to capture, which has an impact on cost accounting systems. In addition, the information provided by the technological solution facilitates the process of allocating indirect costs to individual cost objects, as it enables the precise identification of cost drivers.

“The IoT solution, for example, makes it possible to allocate the depreciation costs of individual hardware items. At a management level, it is known that a machine lasts four years, but by having evidence of its actual use, you are able to attribute costs in a more reliable and real way and you are better able to create the famous point of sale income statement”.(Chief Technology Officer)

Furthermore, real-time knowledge of actual consumption and the level of the product in stock at the point of sale allows the roaster to carry out a supply planning and avoid stock outages, leading to rationalisation and cost savings in terms of stock levels, reduced logistics costs, and lower environmental impact. The supply planning resulting from the analysis of coffee consumption would involve different strategic choices of the roaster related to changes in the partnership with the point of sale.

“Trivially, if the roaster sees that a store does not have a high turnover, he can also decide not to invest in it anymore. The roasters make investments related to hardware, personnel, training, advertising, based on estimated analysis of the market potential of the points of sale. On the basis of the data obtained through the platform for each store, they can decide whether or not to invest in a particular point of sale”.(Controller)

Therefore, as highlighted by the interviewees, the data and information obtained through the proposed technological solution are used for current day-to-day operations and thus provide an important support to the control systems. At the same time, such data and information support strategic decisions, influencing decision-making systems and processes.

“IoT technology in the coffee shop allows us to have an indication of how many people frequent that coffee shop. For example, if I compare the number of people who frequent that coffee shop and the number of coffees dispensed, I start to understand the trends. If I see that some trends are not consistent, I think about the reason why and what corrective action I need to take”.(Chief Marketing Officer)

The increased availability of data not only feeds the ex-post analysis for monitoring the results achieved, but also provides useful information support for the ex-ante analysis in the budgeting and strategic planning phase.

5. Discussion and Conclusions

This study deepens the understanding of the impact of smart technologies on the decision-making and control systems of companies operating in the F&B industry by investigating a specific case study.

To cope with the current unstable and turbulent competitive scenario, characterised by a high degree of uncertainty that makes forecasting phenomena extremely difficult, companies are increasingly challenged to redefine the current decision-making and control models in favour of lean, efficient and digitised ones. At the same time, the growing demand for information and the need to make predictions about the future, as well as the growing stakeholders demand for sustainability, are forcing companies to embark on paths of revision and optimisation of key company processes in order to steer them towards sustainable goals.

The F&B industry is a particular study context, as it is characterised by a number of elements of complexity. In a rapidly changing context such as the current one, in order to adapt their offer to the real needs of the market, F&B companies have felt the need to rethink their business models, transforming the way in which value is created: from an approach focused on product sales to one that mixes additional products and services, aimed at offering the end customer an added value perceived as strategic [42]. The high perishability and limited shelf life of the products offered by F&B companies fuel the complexity in the management of orders, purchases, sales, warehouses and, in general, production planning [43]. Therefore, management has to manage the coexistence of various functions with different needs. Moreover, nowadays, the final consumer pays more attention to the provenance and origin of products, asking companies for increasingly detailed information on all stages of the production chain [1]. Therefore, in this competitive context, sustainability is a key element in meeting customers’ needs in terms of product quality and compliance with high standards [45].

The complexity inherent in the sector and the growing amount of information to be managed generate the need for tools and technologies to digitise and automate decision-making and control processes. In this context, smart technologies represent a useful tool for company management to support the decision-making and control system, with numerous advantages also in terms of sustainability [54,58,59,60].

Despite their potential, smart technologies have so far played a minimal role in improving the decision-making and control systems of F&B companies. F&B companies, being mainly small and medium-sized enterprises, are struggling to modernise their production and operational processes by introducing smart technologies pervasively. This results in lower levels of adoption and less sophisticated digital technologies. Thus far, there are still few F&B companies that have decided to focus on IoT projects and applications rather than on Cloud Computing to store company information.

Furthermore, the literature seems to be silent on the impact of smart technologies on the decision-making and control systems of companies operating in the F&B industry. In light of the above considerations, we conducted an exploratory case study aimed at providing clarifications on the issues investigated. Therefore, the paper analyses the topic of smart technologies in the F&B industry, which has not yet been well researched. With regard to the role of smart technologies in decision-making and control systems, the case study is characterised by the use of smart technologies which represent an indispensable need within the business activities of the stakeholders in the coffee supply chain.

Our findings support the idea that smart technologies can play a key role in improving the decision-making and control systems of F&B companies. In particular, the results of the case study show how the access to data offered by smart technologies represents a source of competitive advantage and has a particular impact on both business processes and decision-making and control systems.

The information flows provided by the technological solution make a significant contribution to both operational and strategic management. In fact, the case study analysed highlighted how the application of IoT solutions in the coffee supply chain greatly favours and develops information flows that go from retail to the parent company, i.e., from the coffee shop to the roaster, which were previously much less relevant [51,52]. This information is useful throughout the coffee supply chain, as it affects different business processes of the various stakeholders. Furthermore, the results show how the data generated by the IoT solution enables effective management of the coffee supply chain and operations within the organisation, especially with regard to the main actor in the supply chain, i.e., the roaster. These information flows help to improve the efficiency and effectiveness of supply chain management (cost, time and resource savings, high quality and on-time delivery). Moreover, the information flows obtained become relevant in the management of the various corporate functions, overcoming the element of complexity that characterises F&B companies [43]. Referring to the roaster, the information flows obtained is relevant in the perspective of the different business functions, such as the sales manager, the production manager and the logistics manager. The information flows provided by the technological solution also reduce the information asymmetry between the various stakeholders in the coffee supply chain that often characterises F&B companies [47].

An innovative aspect that emerged from the analysed case is the change in the role played by the agent who becomes a business consultant. While in other sectors, digital transformation usually leads to disintermediation, in the F&B industry, where customer loyalty is the qualifying element of the business, digital transformation has an impact by changing the role of agents in the supply chain.

The case analysed shows how the adoption of smart technologies, such as IoT and the cloud platform, has a direct impact on the decision-making and control system of the roaster, which is the central actor in the coffee supply chain. Therefore, by implementing the technological solution proposed by the project, the data and information acquired through traditional information systems and tools are combined with those obtained through the IoT, offering new opportunities for using data in decision-making and control systems.

In particular, the increased flow of information resulting from the application of IoT solutions in the F&B industry has been shown to have an impact on control systems, as it generates a large amount of mainly non-accounting information that is relevant for management control purposes. In this sense, the results of the interviews showed how the technological solution offers access to an enormous amount of data that would otherwise be difficult to obtain (such as data on water quality and coffee brewing pressure), providing the opportunity to effectively control the quality of the product supplied and to propose ad hoc corrective actions to improve the quality of the product. Furthermore, the IoT solution also provides information to support sustainability, with a positive impact on the environment. However, the technological solution allows management to obtain data to be integrated into decision-making and control processes only on ecological and economic aspects.

At the same time, our findings show how the technological solution also impacts on decision-making systems, as it supports an information flow that enables management to make optimised strategic decisions, as in the case of supply planning. In essence, the new technology implemented by the project offers not only final data but also real-time data. Whereas previously, to support the decision-making process, the practice of controllers was limited to the analysis of historical, aggregated and accounting data, with the adoption of the technology much of the change is related to the fact that the range of data acquired and available for companies has increased significantly and data is provided in real time.

Specifically, the results show how real-time collection and analysis of data related to actual consumption and machine operation improves performance measurement systems, facilitating the calculation of non-financial indicators and offering management the opportunity to conduct more accurate profitability analysis along new dimensions of analysis [64,65,66]. In this regard, the use of smart technologies could play an important role in the design and implementation of performance measurement systems and their use in the formulation of strategies as it would improve the understanding of business dynamics and support decision-making systems. The availability of real-time data on the actual use of resources and customer demands has a positive impact on the budgeting process, as it improves the accuracy of estimates made by management [11,61,62,63]. Furthermore, the results of the interviews show how the technological solution also has a positive impact on analytical accounting systems, allowing for a more accurate cost estimation through the identification of costs that would otherwise be difficult to determine (as in the case of maintenance costs) and a more efficient allocation of indirect costs to cost centres [12,61]. Through the dashboards made available by the technological solution, management is able to consult increasingly articulated, detailed and timely data in real time, which can have a positive impact on the reporting system [11]. Finally, by comparing the actual results with the feedforward data, managers are able to foresee possible deviations between results and objectives and implement corrective actions [67].

In essence, the technological solution has provided some tools capable of processing information to assist managers in decision-making, and it is also capable of matching information for management and monitoring objectives.

With reference to decision-making systems, the results of the analysis highlighted how the availability of data and information on stock and consumption levels allows the company to make more informed decisions. The application of IoT solutions facilitates and develops information that flows both upstream and downstream of the supply chain, thus helping management to make smarter, faster and more effective decisions, reducing the time between decision and action and increasing the accuracy of planning. Through the use of these tools, managers are able to continuously modify long-term planning by limiting forecast uncertainty, as in the case of planned reordering [11]. The technologies used in this case show how the analysis of structured and unstructured data gives companies an advantage by creating correlations and patterns between the different sources to provide alerts that minimise the costs and risks of disruptions or malfunctions, and allowing management to make optimal decisions. In addition, analysing and accessing customer data allows the company to better predict future demand, decide which products can be reduced when they become less profitable, which products to focus on and make promotions instead, and what the customer’s needs are. This aspect is very relevant in the decision-making and control system of F&B companies given the need to meet customer expectations.

In conclusion, the implementation of the solution has represented an opportunity for the roasting company to activate several changes in internal processes and to implement a more effective realisation of the integration of decision-making and control processes, information flows and management accounting.

This study offers important implications from both a theoretical and a practical point of view. From a theoretical point of view, the study enriches the literature on decision-making and control systems of F&B companies and aims to partially fill the gap found in the literature. In particular, this research advances our understanding of the role of smart technologies in decision-making and control systems, contributing to the growing but still inchoate studies on smart technologies and clarifying their role in improving decision-making and control processes. Specifically, we provide empirical evidence to academic research investigating the support of new technologies for the management of organizations.

From a practical point of view, the research work offers important managerial implications. By providing evidence of the effectiveness of smart technologies in supporting decision-making and control systems, it can serve as an example for those who intend to approach the introduction of such technologies in their business, with specific reference to the F&B industry. Managers of companies operating in the analysed sector can take advantage of our study by analysing the successful practice of such entrepreneurial initiatives. By analysing this case, we sought to better understand how F&B companies, characterised by elements of complexity, can exploit the value created and provided by new technologies to improve their decision-making and control processes. The implementation of smart technologies represents an interesting business opportunity for the entire supply chain. The technology offers both benefits at the individual level in terms of greater efficiency and lower costs, and benefits at the supply chain level by making it more efficient. With specific regard to the sector analysed, this study shows how the use of smart technologies is relevant and indispensable to achieve better effectiveness in managing individual organisations and the entire supply chain.

Our research has provided a better understanding of how digital technologies affect decision-making and control systems. However, like any other study, ours has several limitations. The main one relates to the context of the case study. More precisely, this paper sheds light on the case of a project developed for F&B companies. The specific characteristics of the industrial sector may have introduced a bias, making the results at least partially unsuitable for application in other industrial contexts. Furthermore, since the analysis is based on a single case study, the results obtained cannot be generalised to all companies operating in the reference sector. Further studies will have to validate our results in other contexts and derive the conditions for the generalisability of the implications. The second limitation of this study concerns the small number and type of actors involved in the analysis. The interviews were conducted with members of the top management of Prodacta and Software Business, thus only taking into account the point of view of the developers of the technological solution and not that of the users, such as roasters. This limitation could lead to a limited view of the phenomenon under investigation. Given the elements of subjectivity that inevitably characterise the use of decision-making and control systems, the present work paves the way for future case studies that can confirm, integrate or contrast the empirical evidence presented.

Author Contributions

Conceptualization, D.L.; methodology, D.L. and P.P.; validation, D.L. and P.P.; formal analysis, D.L. and P.P.; investigation, D.L. and P.P.; data curation, D.L. and P.P.; writing—original draft preparation, D.L. and P.P.; writing—review and editing, D.L. and P.P.; visualization, D.L. and P.P.; supervision, D.L. and P.P.; project administration, D.L. and P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The authors represent that their manuscript is ethically sound and meets industry-recognized standards as reflected in the MDPI policies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Beske, P.; Land, A.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Engelseth, P. Multiplex uses of food-product standards. Int. Food Agribus. Manag. Rev. 2013, 16, 75–94. [Google Scholar]

- Caiazza, R.; Bigliardi, B. Web marketing in agri-food industry: Challenges and opportunities. Trends Food Sci. Technol. 2020, 103, 12–19. [Google Scholar] [CrossRef]

- Caiazza, R.; Chaudhuri, S. Explaining emerging-market firms’ acquisitions of developed-market firms: A resource based perspective. Trends Food Sci. Technol. 2019, 91, 662–669. [Google Scholar] [CrossRef]

- Mitsos, B.; Kontogeorgos, A.; Beligiannis, G.N. Information systems and software used by food businesses in Western Greece. Int. J. Bus. Cont. Risk Manag. 2019, 9, 153–170. [Google Scholar] [CrossRef]

- Lee, H.J. A Review of Value Creating Motive and Business Model in Smart Technology. In Human Centric Technology and Service in Smart Space; Park, J., Jin, Q., Sang-soo Yeo, M., Hu, B., Eds.; Lecture Notes in Electrical Engineering, Springer: Dordrecht, The Netherlands, 2012; Volume 182. [Google Scholar]

- Fiorentino, R.; Garzella, S. The Disclosure of Synergy Value in Mergers and Acquisitions. Eur. J. Sci. Res. 2014, 120, 504–524. [Google Scholar]

- Pan, L.; Xu, Z.; Skare, M. Sustainable business model innovation literature: A bibliometrics analysis. Rev. Manag. Sci. 2022, 4, 1–29. [Google Scholar] [CrossRef]

- De Santis, F. ERP e Strumenti di Business Intelligence. Supporto Gestionale e Impatto Organizzativo; Giappichelli: Torino, Italy, 2017. [Google Scholar]

- Marchi, L. L’evoluzione del controllo di gestione nella prospettiva informativa e gestionale esterna. Manag. Control 2011, 3, 5–16. [Google Scholar] [CrossRef]

- Marchi, L.; De Santis, F. Il processo e la struttura tecnico-informativa del controllo. In Controllo di Gestione. Pianificazione, Programmazione e Reporting; Giappichelli Editore: Torino, Italy, 2020; pp. 33–71. [Google Scholar]

- Vasarhelyi, M.A.; Kogan, A.; Tuttle, B.M. Big data in accounting: An overview. Account. Horiz. 2015, 29, 381–396. [Google Scholar] [CrossRef]

- Amigoni, F. I Sistemi di Controllo Direzionale: Criteri di Progettazione e di Impiego; Giuffrè: Milano, Italy, 1979. [Google Scholar]

- Anthony, R.N. Planning and Control Systems: A Framework for Analysis; Division of Research, Graduate School of Business Administration, Harvard University: Boston, MA, USA, 1965. [Google Scholar]

- Barbato, M.B. Programmazione e Controllo in Un’ottica Strategica; Utet: Torino, Italy, 1997. [Google Scholar]

- Brunetti, G. Il Controllo di Gestione in Condizioni Ambientali Perturbate; FrancoAngeli: Milano, Italy, 1979. [Google Scholar]

- Flamholtz, E.G.; Das, T.K.; Tsui, A.S. Toward an integrative framework of organizational control. Account. Organ. Soc. 1985, 10, 35–50. [Google Scholar] [CrossRef]

- Merchant, K.A. Control in Business Organizations; Harpercollins College Division: New York, NY, USA, 1985. [Google Scholar]

- Ouchi, W.G. A conceptual framework for the design of organizational control mechanisms. Manag. Sci. 1979, 25, 833–848. [Google Scholar] [CrossRef]

- Simons, R. Levers of Control: How Managers Use Innovative Control Systems to Drive Strategic Renewal; Harvard Business Press: Brighton, MA, USA, 1994. [Google Scholar]

- Marchi, L. I Sistemi Informativi Aziendali; A. Giuffrè Editore: Milano, Italy, 2003. [Google Scholar]

- Marasca, S. Il Controllo di Gestione Nelle Aziende Commerciali Complesse; Giappichelli: Torino, Italy, 1989. [Google Scholar]

- Corsi, K. Il Controllo Organizzativo: Una Prospettiva Transnazionale; Giuffrè: Milano, Italy, 2003. [Google Scholar]

- Bertini, U. Scritti di Politica Aziendale; Giappichelli: Torino, Italy, 1995. [Google Scholar]

- Vitali, P.M. Il Sistema Delle Decisioni Aziendali: Analisi Introduttiva; G. Giapichelli Editore: Torino, Italy, 1993. [Google Scholar]

- Mancini, D. Le Condizioni di Efficacia del Sistema di Controllo Aziendale: Qualità e Sicurezza nel Governo Delle Aziende; G. Giappichelli: Torino, Italy, 2005. [Google Scholar]

- D’Onza, G. Il Sistema di Controllo Interno Nella Prospettiva del Risk Management; Giuffrè editore: Milano, Italy, 2008; Volume 81. [Google Scholar]

- Chiucchi, M.S.; Gatti, M. L’evoluzione degli studi di management control: Un percorso nel segno della varietà. Manag. Control 2015, 1, 5–8. [Google Scholar] [CrossRef]

- Paolini, A.; Chiucchi, M.S.; Gatti, M. I sistemi di pianificazione e controllo della gestione. In Controllo di Gestione. Pianificazione, Programmazione e Reporting; Giappichelli Editore: Torino, Italy, 2020; pp. 3–29. [Google Scholar]

- Mancini, D.; De Nicola, M.; Iacoviello, G. L’impatto della crisi pandemica sui sistemi di controllo di gestione: Un’analisi empirica. Manag. Control 2021, 1, 105–127. [Google Scholar] [CrossRef]

- Mancini, D.; Vaassen, E.H.J.; Dameri, R.P. (Eds.) Accounting Information Systems for Decision Making; Springer: Heidelberg, Germany, 2013. [Google Scholar]

- LaValle, S.; Lesser, E.; Shockley, R.; Hopkins, M.S.; Kruschwitz, N. Big data, analytics and the path from insights to value. MIT Sloan Manag. Rev. 2011, 52, 21–32. [Google Scholar]

- Petrosino, A.; Mancini, D.; Garzella, S.; Lamboglia, R. La Business Intelligence e la Business Analytics nell’era dei Big Data: Una analisi della letteratura. Manag. Control 2018, 3, 31–58. [Google Scholar] [CrossRef]

- Shao, B.B.; Lin, W.T. Assessing output performance of information technology service industries: Productivity, innovation and catch-up. Int. J. Prod. Econ. 2016, 172, 43–53. [Google Scholar] [CrossRef]

- Dechow, N.; Mouritsen, J. Enterprise resource planning systems, management control and the quest for integration. Account. Organ. Soc. 2005, 30, 691–733. [Google Scholar] [CrossRef]

- Appelbaum, D.; Kogan, A.; Vasarhelyi, M.; Yan, Z. Impact of business analytics and enterprise systems on managerial accounting. Int. J. Account. Inf. Syst. 2017, 25, 29–44. [Google Scholar] [CrossRef]

- Hawking, P.; Sellitto, C. Business Intelligence (BI) critical success factors. In Proceedings of the 21st Australasian Conference on Information Systems Business Intelligence (BI) Success Factors, Brisbane, Australia, 1–3 December 2010. [Google Scholar]

- Negash, S. Communication of The Association for Information Systems. Bus. Intell. 2004, 13, 177–195. [Google Scholar]

- Olson, D.L. Managerial Issues of Enterprise Resource Planning Systems; McGraw-Hill: New York, NY, USA, 2004; pp. 2–78. [Google Scholar]

- Gomes, V. Introdução à Gestão de Alimentação e Bebidas; Lidel–Edições TécniCaS: Lisboa, Portugal, 2017. [Google Scholar]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Phil. Trans. Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef]

- Daly, P.; Dias, A.L.; Patuleia, M. The impacts of tourism on cultural identity on Lisbon historic neighbourhoods. J. Ethn. Cult. Stud. 2021, 8, 1–25. [Google Scholar] [CrossRef]

- Trienekens, J.H. Management of Processes in Chains: A Research Framework. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 1999. [Google Scholar]

- Grunert, K.G. Food quality and safety: Consumer perception and demand. Eur. Rev, Agric. Econ. 2005, 32, 369–391. [Google Scholar] [CrossRef]

- Henson, S.; Caswell, J. Food safety regulation: An overview of contemporary issues. Food Policy 1999, 24, 589–603. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- Pavlou, P.A.; Liang, H.; Xue, Y. Understanding and mitigating uncertainty in online exchange relationships: A principal-agent perspective. MIS Q. 2007, 31, 105–136. [Google Scholar] [CrossRef]

- Zahariadis, T.; Papadimitriou, D.; Tschofenig, H.; Haller, S.; Daras, P.; Stamoulis, G.D.; Hauswirth, M. Towards a Future Internet Architecture. In The Future Internet Assembly; Springer: Berlin/Heidelberg, Germany, 2011; pp. 7–18. [Google Scholar]

- Lehmann, R.J.; Reiche, R.; Schiefer, G. Future internet and the agri-food sector: State-of-the-art in literature and research. Comput. Electron. Agric. 2012, 89, 158–174. [Google Scholar] [CrossRef]

- Paul, S.; Pan, J.; Jain, R. Architectures for the future networks and the next generation Internet: A survey. Comput. Commun. 2011, 34, 2–42. [Google Scholar] [CrossRef]

- Bigliardi, B.; Filippelli, S. Open innovation and incorporation between academia and the food industry. In Innovation Strategies in the Food Industry; Academic Press: Cambridge, MA, USA, 2022; pp. 17–37. [Google Scholar]

- Volpentesta, A.P.; Felicetti, A.M.; Frega, N. Organizational and technological aspects of a platform for collective food awareness. Adv. Hum. Comput. Interact. 2018, 2018, 8608407. [Google Scholar] [CrossRef]

- Steiner, G. Supporting sustainable innovation through stakeholder management: A systems view. Int. J. Innov. Learn. 2008, 5, 595–616. [Google Scholar] [CrossRef]

- Arnaboldi, M.; Busco, C.; Cuganesan, S. Accounting, accountability, social media and big data: Revolution or hype? Account. Audit. Account. J. 2017, 30, 762–776. [Google Scholar] [CrossRef]

- Nielsen, C.; Montemari, M. Big data for business modeling: Towards the next generation of performance measurement systems? Manag. Control 2021, 1, 5–10. [Google Scholar] [CrossRef]

- Garzella, S.; Capurro, R.; Galeotti, M. Mondo reale-tradizionale e mondo digitale, strategie aziendali e web intelligence: Il futuro del controllo e della gestione delle informazioni. Manag. Control 2018, 2, 83–111. [Google Scholar] [CrossRef]

- Mancini, D. Evoluzione e prospettive dei sistemi di informazione e di controllo. Manag. Control 2018, 2, 5–14. [Google Scholar] [CrossRef]

- Lombardi, R.; Cano-Rubio, M.; Schimperna, F.; Trequattrini, R. The impact of smart technologies on the management and strategic control: A structured literature review. Manag. Control 2021, 1, 11–30. [Google Scholar] [CrossRef]

- Paolini, A. Integrated data management: New perspectives for management control. Manag. Control 2022, 2, 5–14. [Google Scholar] [CrossRef]

- Vitale, G.; Riccaboni, A.; Cupertino, S. L’impatto dei Big Data sulle attività di pianificazione & controllo aziendali: In caso di studio di una PMI agricola Italiana. Manag. Control 2018, 3, 59–86. [Google Scholar] [CrossRef]

- Pérez, L.F.R.; Blasco, Á.R. A Data Science Approach to Cost Estimation Decision Making-Big Data and Machine Learning: Un enfoque de ciencia de datos para la toma de decisiones en la estimación de costes-Big Data y aprendizaje automático. Rev. Contab.-Span. Account. Rev. 2022, 25, 45–57. [Google Scholar] [CrossRef]

- Vitale, G.; Cupertino, S.; Riccaboni, A. Big data and management control systems change: The case of an agricultural SME. J. Manag. Control 2020, 31, 123–152. [Google Scholar] [CrossRef]