Assessment of the Structural Integrity of a Laser Weld Joint of Inconel 718 and ASS 304L

Abstract

:1. Introduction

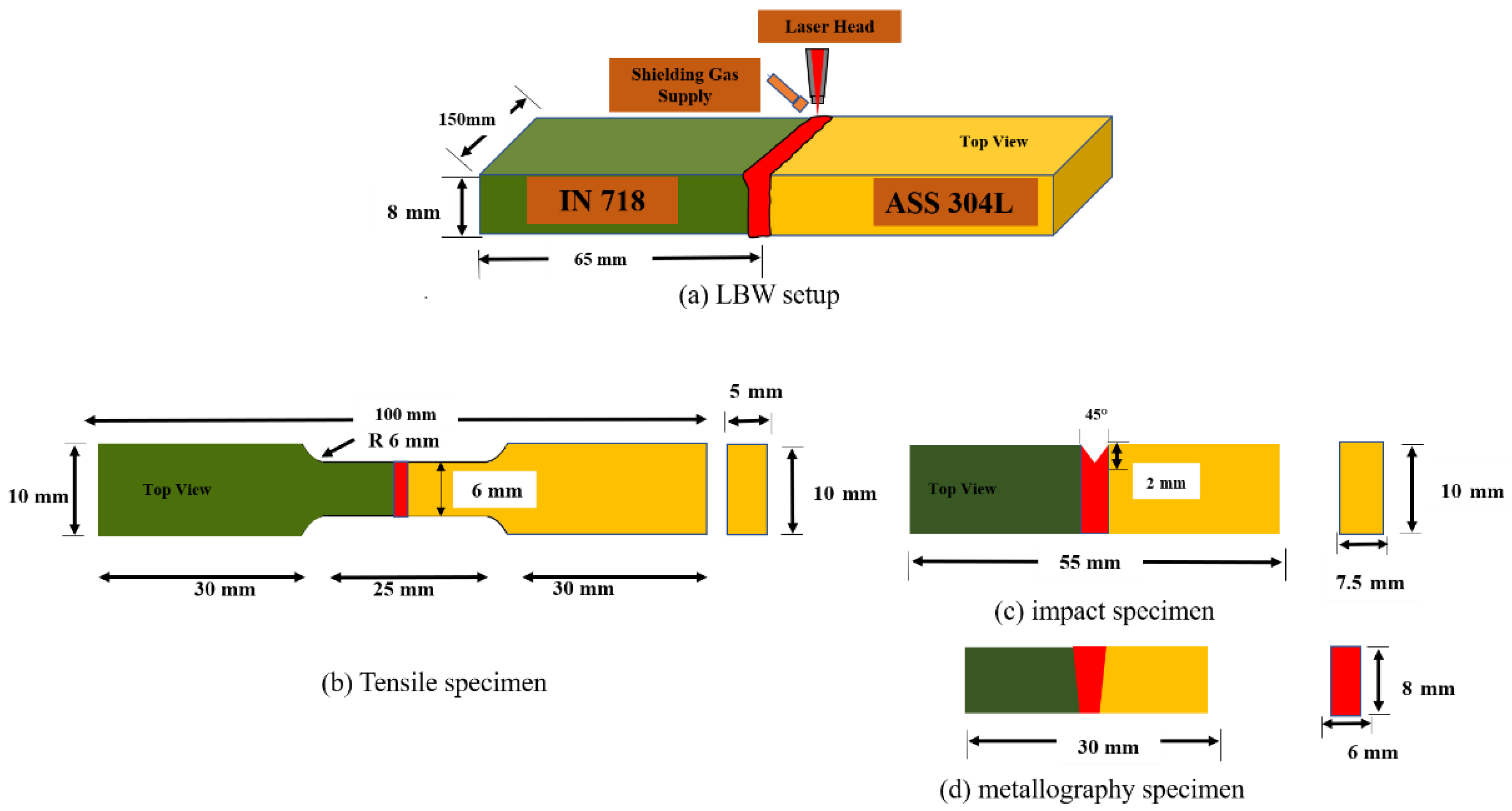

2. Materials and Method

3. Results and Discussion

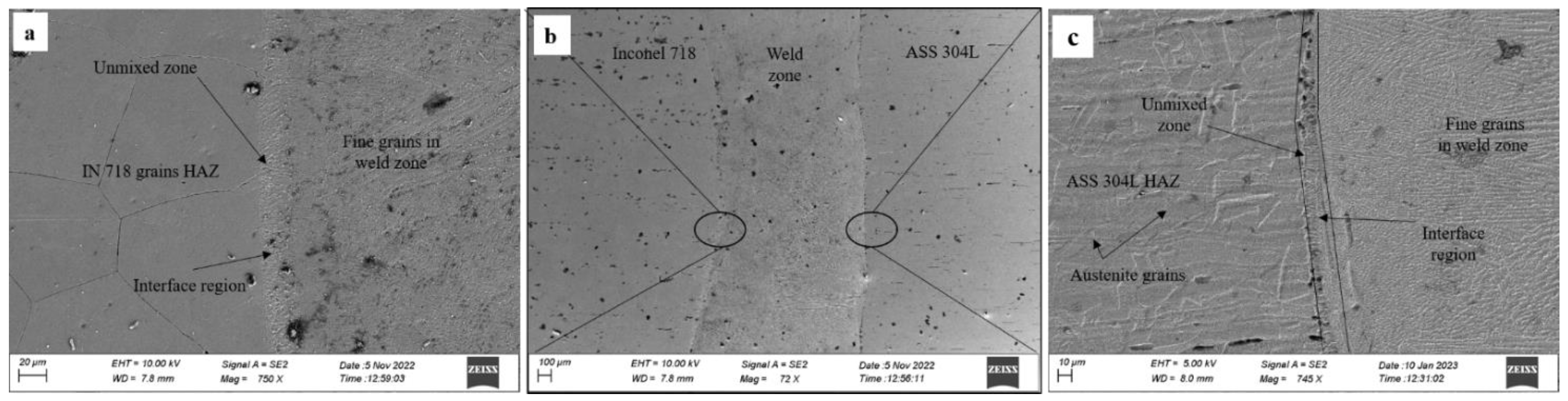

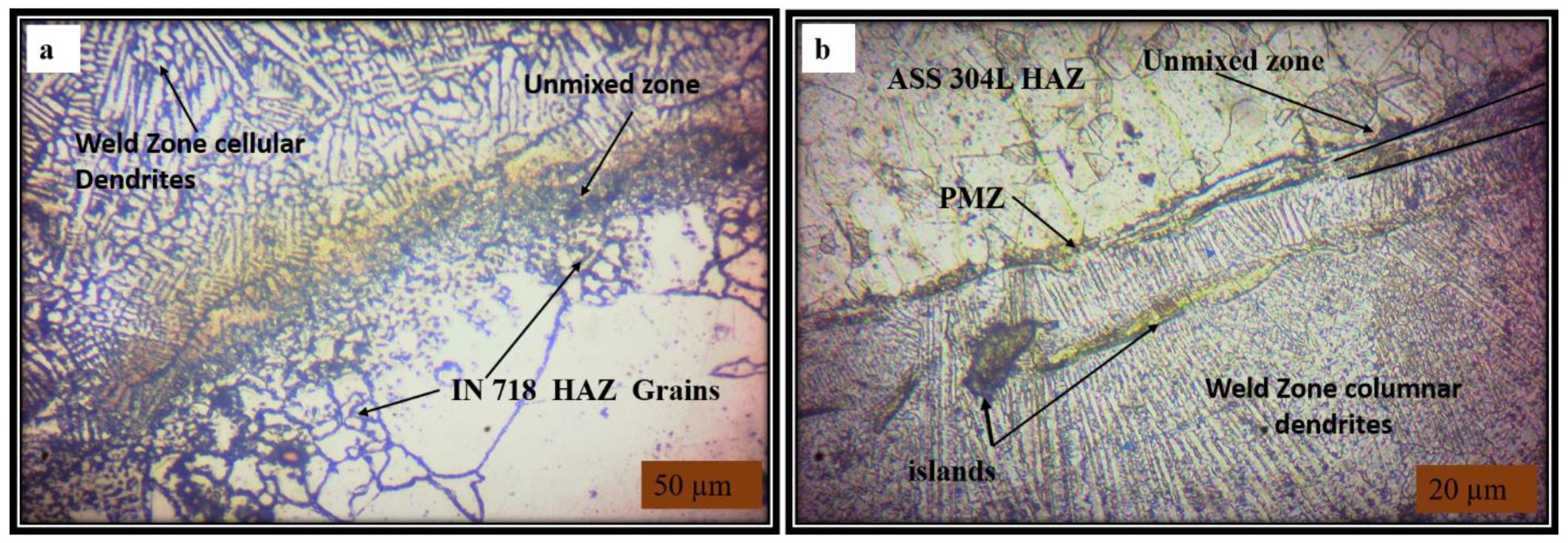

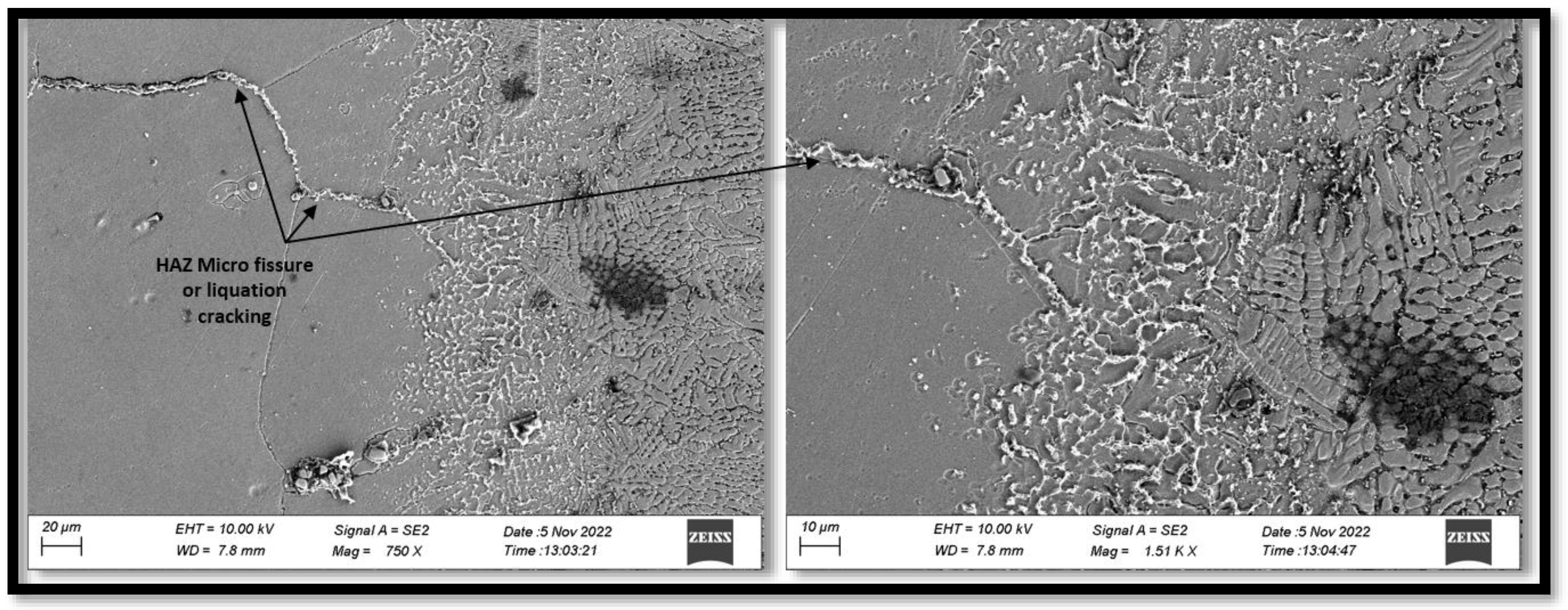

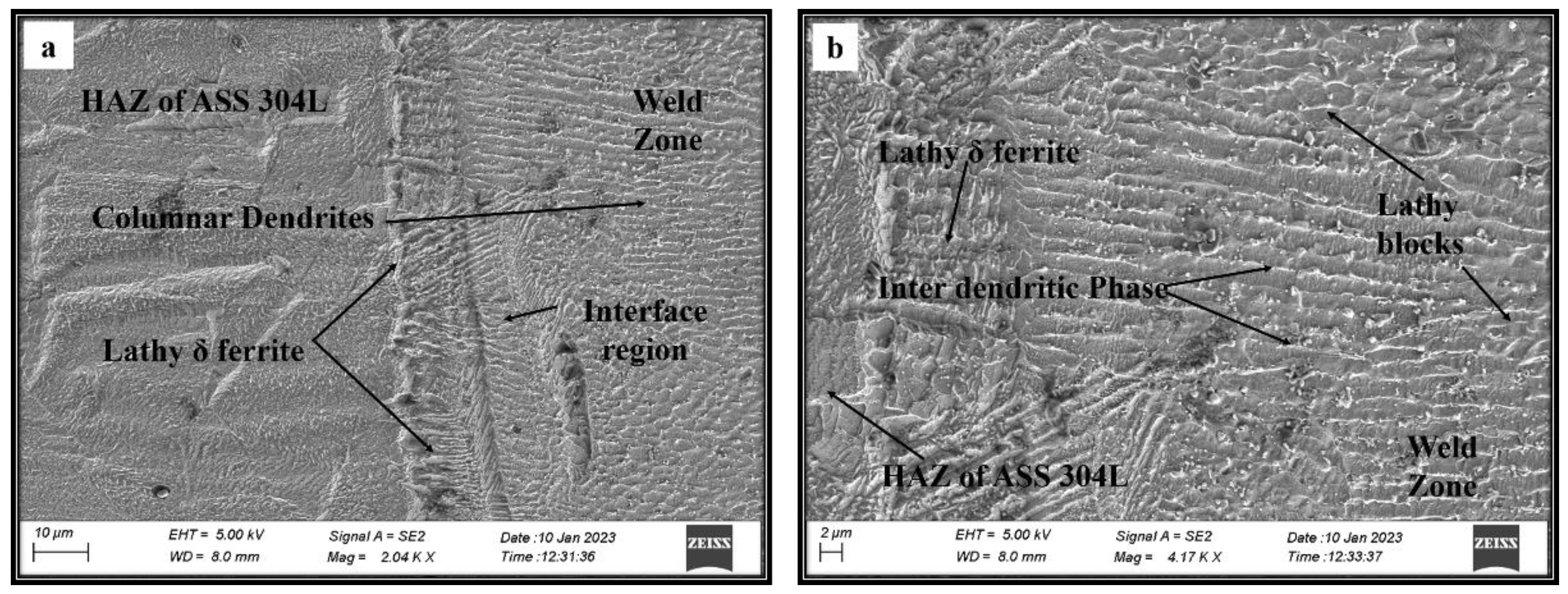

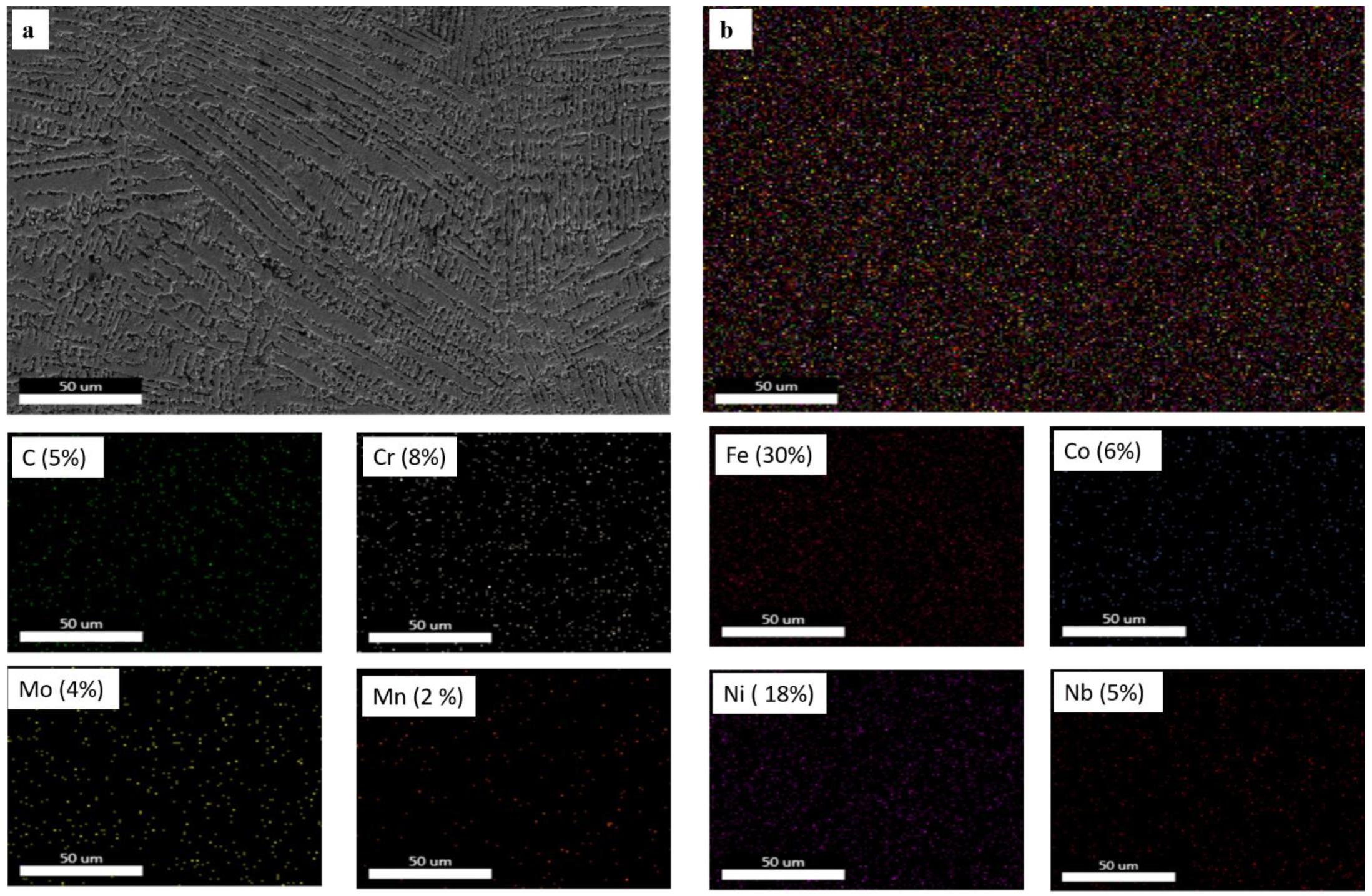

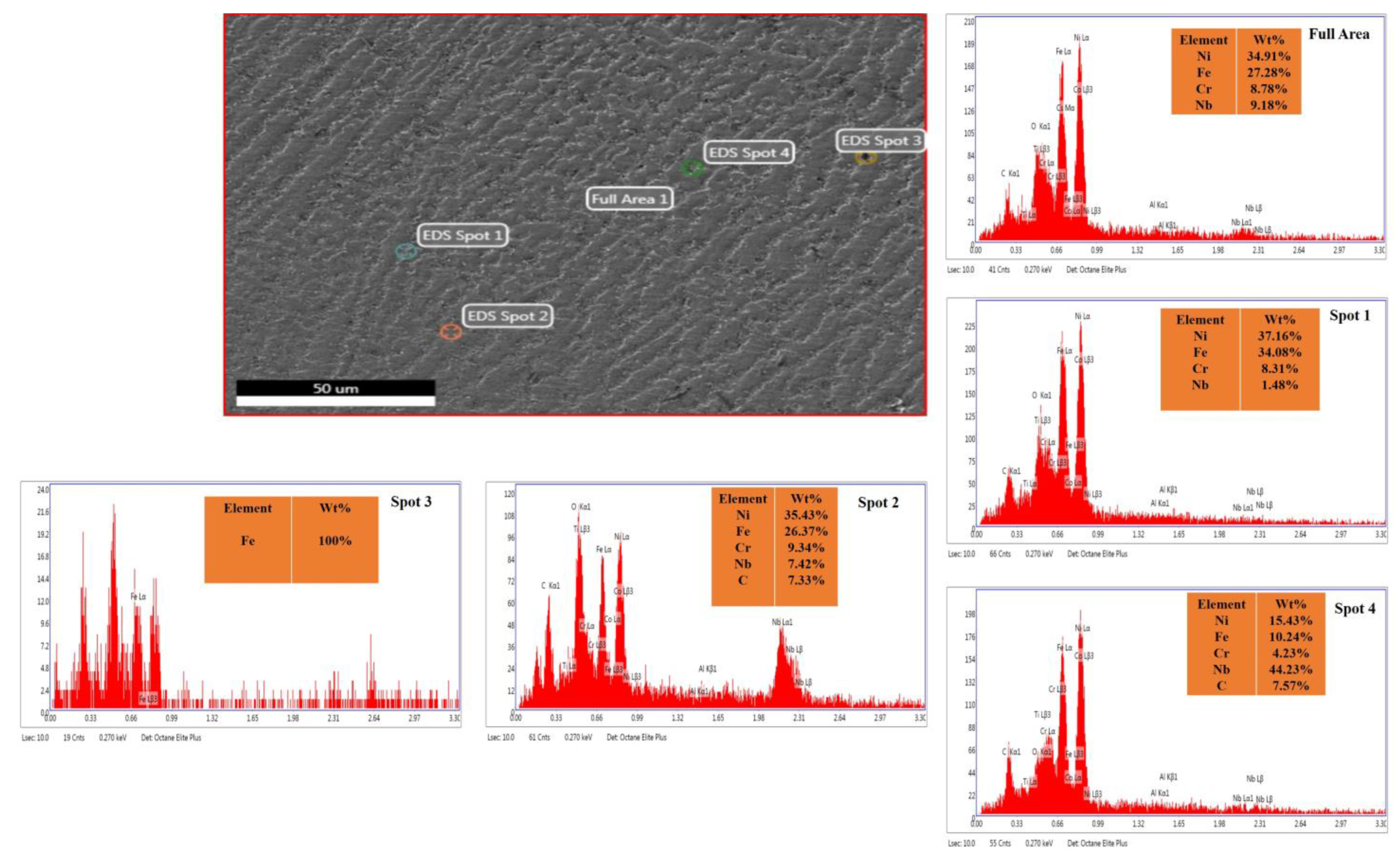

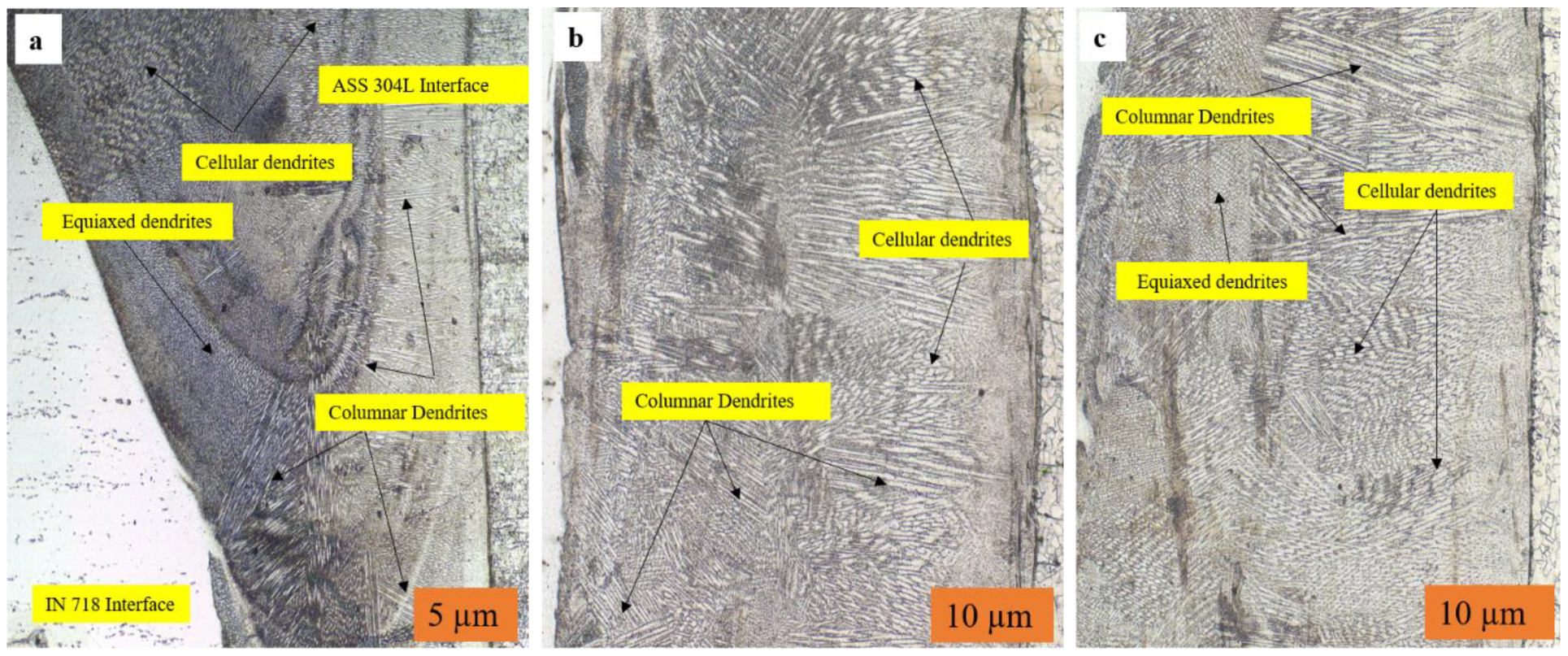

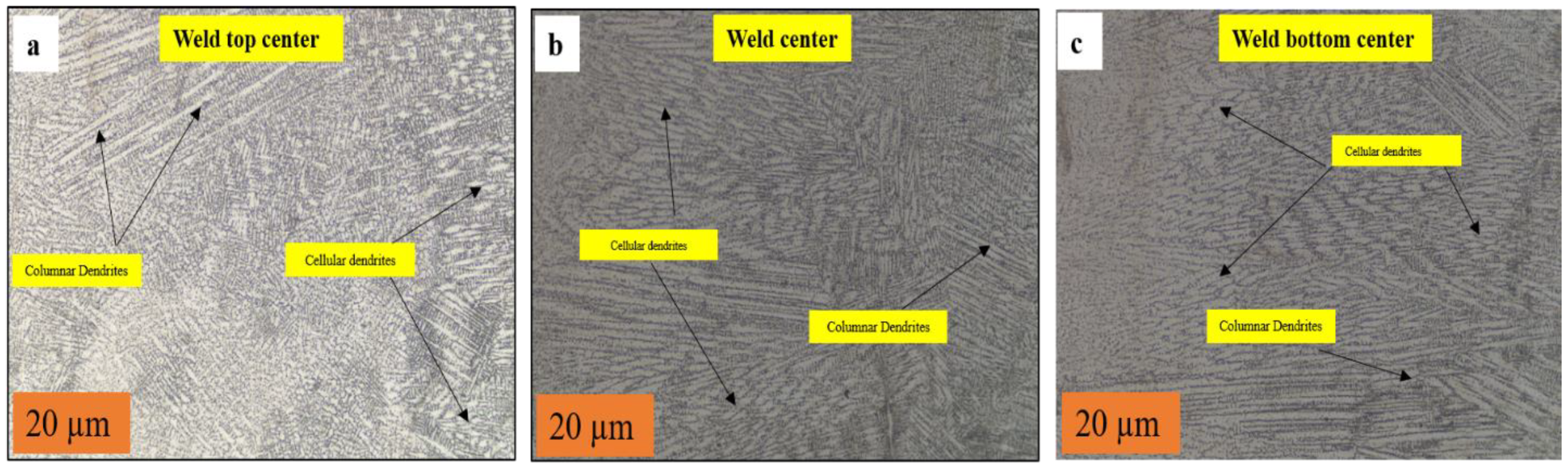

3.1. Microstructural Characterization

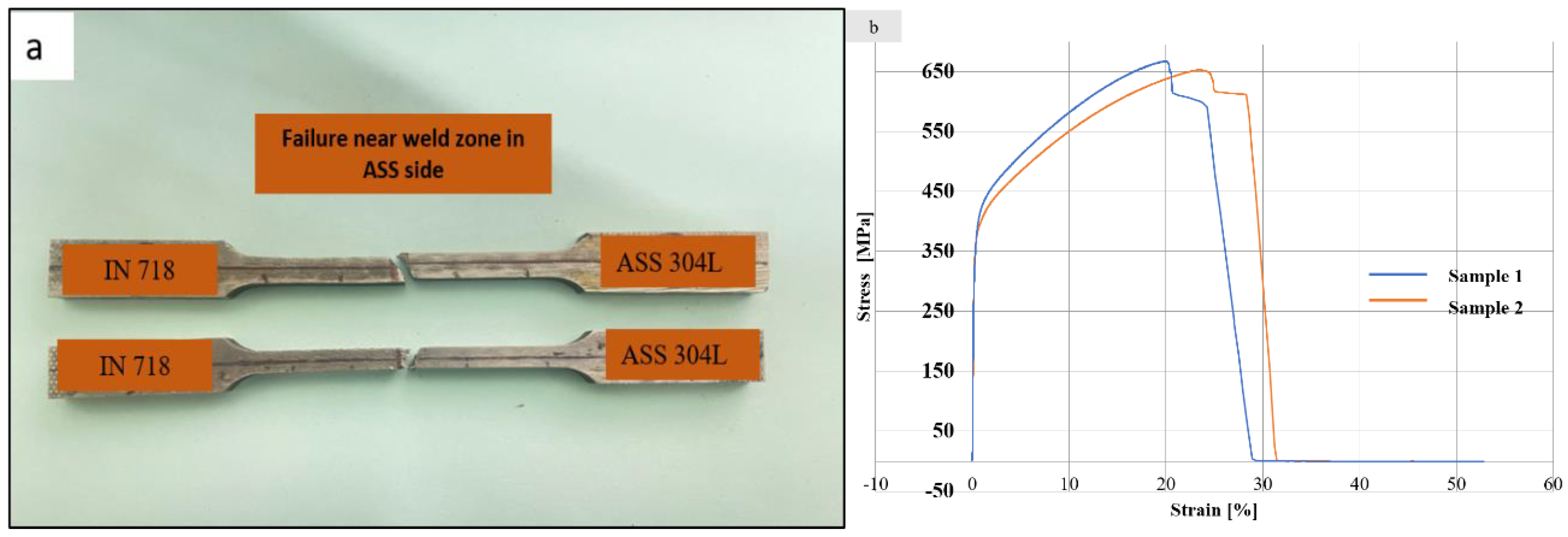

3.2. Tensile Testing

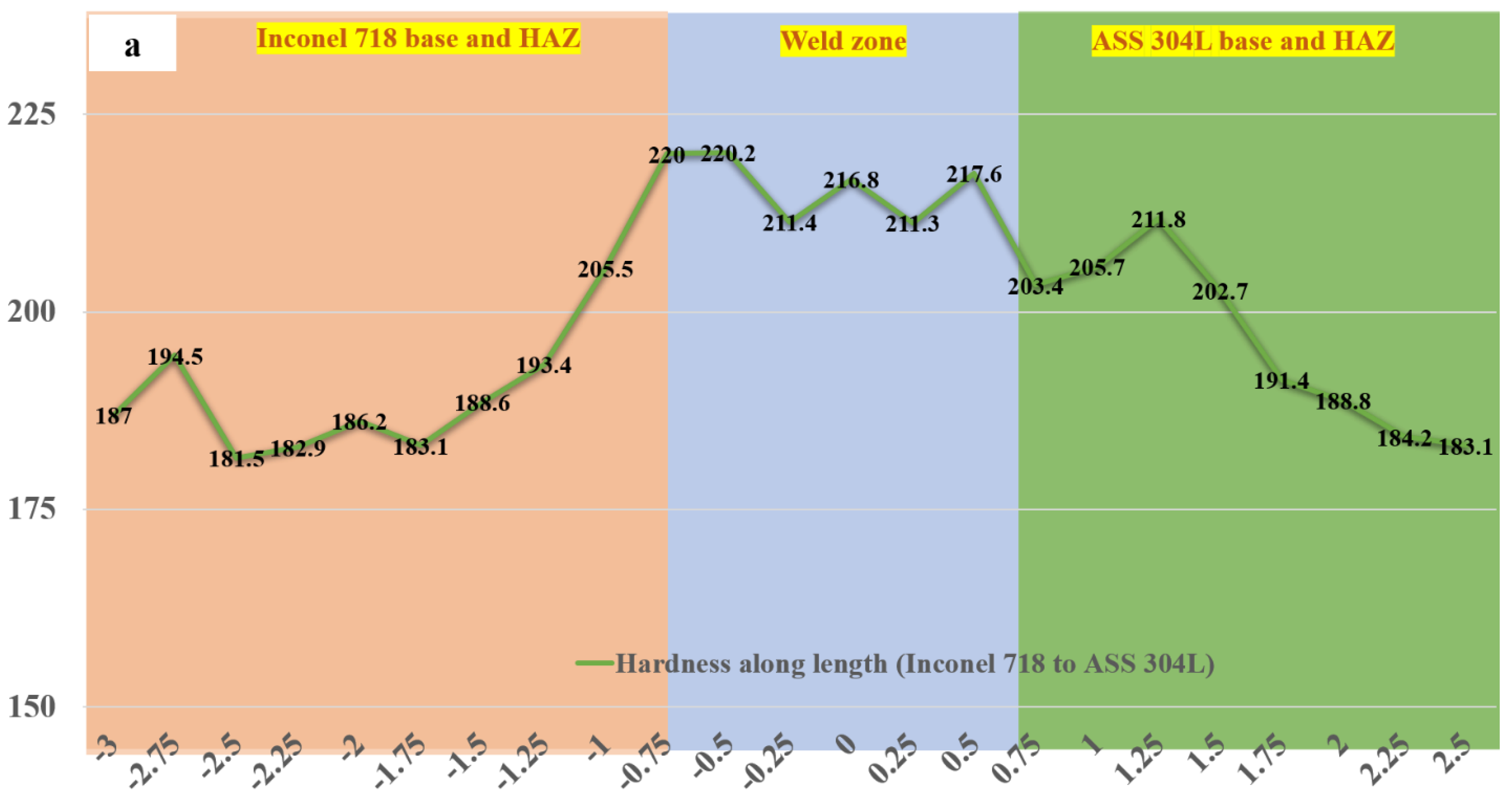

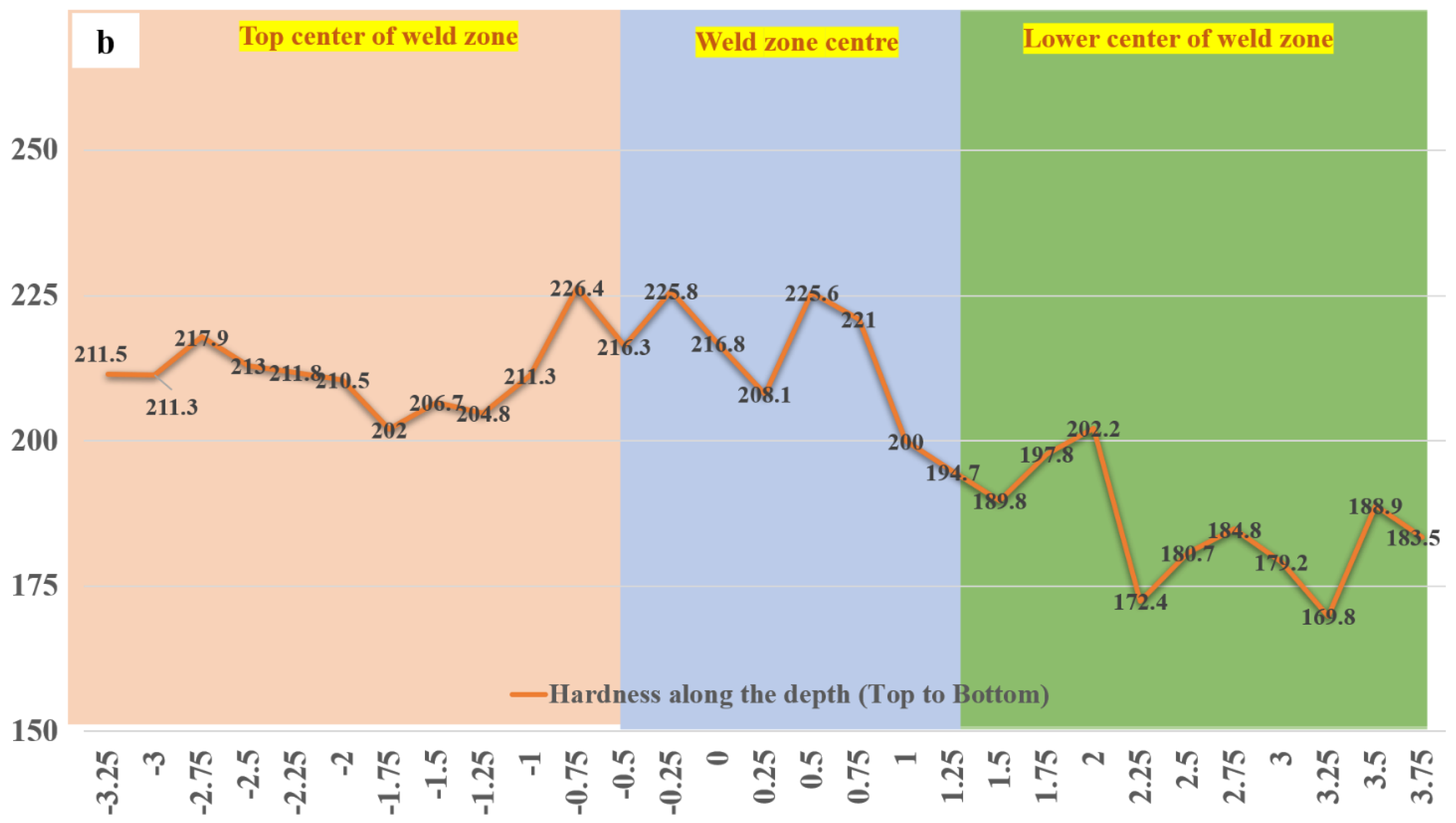

3.3. Microhardness Discussion

3.4. Impact Toughness

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sonar, T.; Balasubramanian, V.; Malarvizhi, S.; Venkateswaran, T.; Sivakumar, D. An overview on welding of Inconel 718 alloy—Effect of welding processes on microstructural evolution and mechanical properties of joints. Mater. Charact. 2021, 174, 110997. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Newman, S.T.; Jawahir, I.S.; Biermann, D.; Shokrani, A. Future research directions in the machining of Inconel 718. J. Mater. Process. Technol. 2021, 297, 117260. [Google Scholar] [CrossRef]

- Kumar, N.; Pandey, C.; Kumar, P. Dissimilar Welding of Inconel Alloys with Austenitic Stainless-Steel: A Review. J. Press. Vessel Technol. 2023, 145, 011506. [Google Scholar] [CrossRef]

- Kumar, A.; Pandey, C. Development and Evaluation of Dissimilar Gas Tungsten Arc-Welded Joint of P92 Steel/Inconel 617 Alloy for Advanced Ultra-Supercritical Boiler Applications. Metall. Mater. Trans. A 2022, 53, 3245–3273. [Google Scholar] [CrossRef]

- Sirohi, S.; Gupta, A.; Pandey, C.; Vidyarthy, R.S.; Guguloth, K.; Natu, H. Investigation of the microstructure and mechanical properties of the laser welded joint of P22 and P91 steel. Opt. Laser Technol. 2022, 147, 107610. [Google Scholar] [CrossRef]

- Ardakani, H.A.; Naffakh-Moosavy, H. The effect of pulsed Nd:YAG laser welding parameters on defects of Kovar to AISI 304L dissimilar joint. Opt. Laser Technol. 2019, 118, 62–68. [Google Scholar] [CrossRef]

- Devendranath Ramkumar, K.; Jagat Sai, R.; Santhosh Reddy, V.; Gundla, S.; Harsha Mohan, T.; Saxena, V.; Arivazhagan, N. Effect of filler wires and direct ageing on the microstructure and mechanical properties in the multi-pass welding of Inconel 718. J. Manuf. Process. 2015, 18, 23–45. [Google Scholar] [CrossRef]

- Radhakrishna, C.; Prasad Rao, K. The formation and control of Laves phase in superalloy 718 welds. J. Mater. Sci. 1997, 32, 1977–1984. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, C.; Goyal, A. A microstructural and mechanical behavior study of heterogeneous P91 welded joint. Int. J. Press. Vessel. Pip. 2020, 185, 104128. [Google Scholar] [CrossRef]

- Aghayar, Y.; Naghashzadeh, A.R.; Atapour, M. An assessment of microstructure and mechanical properties of inconel 601/304 stainless steel dissimilar weld. Vacuum 2021, 184, 109970. [Google Scholar] [CrossRef]

- Devendranath Ramkumar, K.; Patel, S.D.; Sri Praveen, S.; Choudhury, D.J.; Prabaharan, P.; Arivazhagan, N.; Xavior, M.A. Influence of filler metals and welding techniques on the structure-property relationships of Inconel 718 and AISI 316L dissimilar weldments. Mater. Des. 2014, 62, 175–188. [Google Scholar] [CrossRef]

- Prabu, S.S.; Ramkumar, K.D.; Arivazhagan, N. Microstructural evolution and precipitation behavior in heat affected zone of Inconel 625 and AISI 904L dissimilar welds. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2017; Volume 263. [Google Scholar]

- Mortezaie, A.; Shamanian, M. An assessment of microstructure, mechanical properties and corrosion resistance of dissimilar welds between Inconel 718 and 310S austenitic stainless steel. Int. J. Press. Vessel. Pip. 2014, 116, 37–46. [Google Scholar] [CrossRef]

- Prabaharan, P.; Ramkumar, K.D.; Arivazhagan, N. Characterization of microstructure and mechanical properties of Super Ni 718 alloy and AISI 316L dissimilar weldments. J. Mater. Res. 2014, 29, 3011–3023. [Google Scholar] [CrossRef]

- Adomako, N.K.; Park, H.J.; Cha, S.C.; Lee, M.; Kim, J.H. Microstructure evolution and mechanical properties of the dissimilar joint between IN718 and STS304. Mater. Sci. Eng. A 2021, 799, 140262. [Google Scholar] [CrossRef]

- Shakil, M.; Ahmad, M.; Tariq, N.H.; Hasan, B.A.; Akhter, J.I.; Ahmed, E.; Mehmood, M.; Choudhry, M.A.; Iqbal, M. Microstructure and hardness studies of electron beam welded Inconel 625 and stainless steel 304L. Vacuum 2014, 110, 121–126. [Google Scholar] [CrossRef]

- Li, G.; Huang, J.; Wu, Y. An investigation on microstructure and properties of dissimilar welded Inconel 625 and SUS 304 using high-power CO2 laser. Int. J. Adv. Manuf. Technol. 2015, 76, 1203–1214. [Google Scholar] [CrossRef]

- Jaypuria, S.; Kumar Gupta, S.; Suresh-Fazeela, S.; Kumar Pratihar, D.; Chakrabarti, D.; Jha, M.N. Study of metallurgical and mechanical behavior of laser butt-welded dissimilar joint of inconel and stainless steel. In ASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2019; Volume 59384, p. V02BT02A036. [Google Scholar] [CrossRef]

- Sirohi, S.; Pandey, S.M.; Tiwari, V.; Bhatt, D.; Fydrych, D.; Pandey, C. Impact of laser beam welding on mechanical behaviour of 2.25Cr–1Mo (P22) steel. Int. J. Press. Vessel. Pip. 2023, 201, 104867. [Google Scholar] [CrossRef]

- Dak, G.; Sirohi, S.; Pandey, C. Study on microstructure and mechanical behavior relationship for laser-welded dissimilar joint of P92 martensitic and 304L austenitic steel. Int. J. Press. Vessel. Pip. 2022, 196, 104629. [Google Scholar] [CrossRef]

- Hong, J.K.; Park, J.H.; Park, N.K.; Eom, I.S.; Kim, M.B.; Kang, C.Y. Microstructures and mechanical properties of Inconel 718 welds by CO2 laser welding. J. Mater. Process. Technol. 2008, 201, 515–520. [Google Scholar] [CrossRef]

- Richards, N.L.; Nakkalil, R.; Chaturvedi, M.C. The influence of electron-beam welding parameters on heat-affected-zone microfissuring in INCOLOY 903. Metall. Mater. Trans. A 1994, 25, 1733–1745. [Google Scholar] [CrossRef]

- Idowu, O.A.; Ojo, O.A.; Chaturvedi, M.C. Effect of heat input on heat affected zone cracking in laser welded ATI Allvac 718Plus superalloy. Mater. Sci. Eng. A 2007, 454–455, 389–397. [Google Scholar] [CrossRef]

- Lippold, J.C. Welding Metallurgy and Weldability; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; ISBN 9781118230701. [Google Scholar]

- Lippold, J.C.; Kiser, S.D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Banovic, S.W.; DuPont, J.N.; Marder, A.R. Dilution and microsegregation in dissimilar metal welds between super austenitic stainless steel and nickel base alloys. Sci. Technol. Weld. Join. 2002, 7, 374–383. [Google Scholar] [CrossRef]

- Naffakh, H.; Shamanian, M.; Ashrafizadeh, F. Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J. Mater. Process. Technol. 2009, 209, 3628–3639. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2003; ISBN 0471434914. [Google Scholar]

- Pavan, A.H.V.; Vikrant, K.S.N.; Ravibharath, R.; Singh, K. Development and evaluation of SUS 304H—IN 617 welds for advanced ultra supercritical boiler applications. Mater. Sci. Eng. A 2015, 642, 32–41. [Google Scholar] [CrossRef]

- YIlmaz, R.; Tümer, M. Microstructural studies and impact toughness of dissimilar weldments between AISI 316 L and AH36 steels by FCAW. Int. J. Adv. Manuf. Technol. 2013, 67, 1433–1447. [Google Scholar] [CrossRef]

| Elements (%) | C | Cr | Co | Mo | Al | Ti | Fe | Ni | Si | Mn | Nb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ASS 304L | 0.11 | 0.92 | 0.46 | 0.92 | - | - | Bal | 0.28 | 2 | 8.08 | - |

| IN 718 | - | 19.3 | - | 2.9 | 0.6 | 0.9 | Bal | 53.2 | 0.1 | - | 5.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, N.; Kumar, P.; Upadhyaya, R.; Kumar, S.; Panday, C. Assessment of the Structural Integrity of a Laser Weld Joint of Inconel 718 and ASS 304L. Sustainability 2023, 15, 3903. https://doi.org/10.3390/su15053903

Kumar N, Kumar P, Upadhyaya R, Kumar S, Panday C. Assessment of the Structural Integrity of a Laser Weld Joint of Inconel 718 and ASS 304L. Sustainability. 2023; 15(5):3903. https://doi.org/10.3390/su15053903

Chicago/Turabian StyleKumar, Niraj, Prakash Kumar, Rajat Upadhyaya, Sanjeev Kumar, and Chandan Panday. 2023. "Assessment of the Structural Integrity of a Laser Weld Joint of Inconel 718 and ASS 304L" Sustainability 15, no. 5: 3903. https://doi.org/10.3390/su15053903

APA StyleKumar, N., Kumar, P., Upadhyaya, R., Kumar, S., & Panday, C. (2023). Assessment of the Structural Integrity of a Laser Weld Joint of Inconel 718 and ASS 304L. Sustainability, 15(5), 3903. https://doi.org/10.3390/su15053903