Analyzing Physical-Mechanical and Hydrophysical Properties of Sandy Soils Exposed to Long-Term Hydrocarbon Contamination

Abstract

1. Introduction

2. Research Methods and Results

3. Discussion

4. Conclusions

- (1)

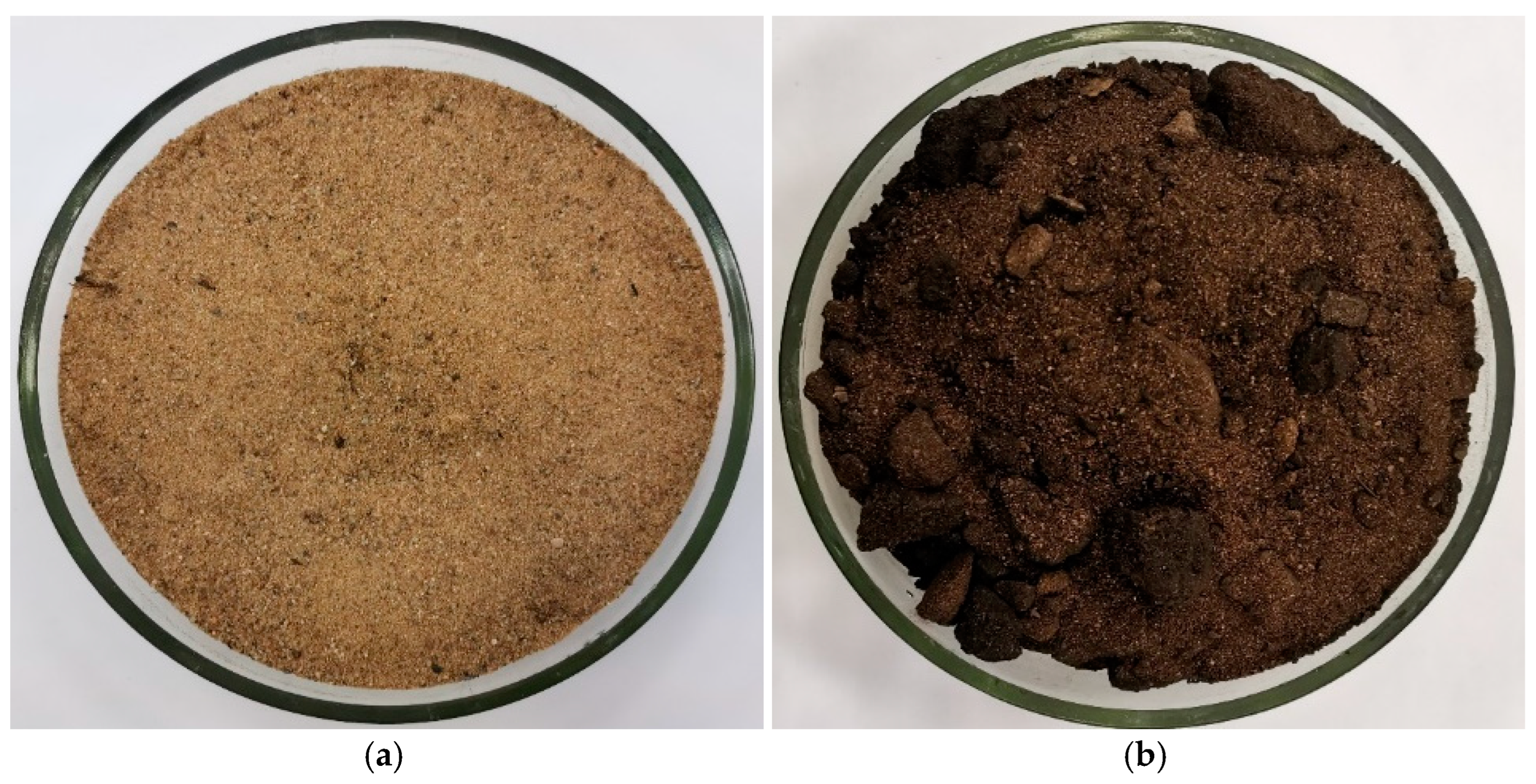

- Oil hydrocarbon sorption causes the formation of hydrocarbon films on the grain surface of sandy soils and promotes the development of microaggregates, ranging in size from 0.5 to 5.0 mm, which are cemented by detected films.

- (2)

- The content of microaggregates in contaminated sands increases their coarseness by over 51% up to coarse-grained and very coarse-grained types compared to conditionally pure sands, which are classified as medium-grained.

- (3)

- Aggregated state of mineral grains in contaminated sands affects their density. In loose and dense structures, it becomes lower by 0.10 and 0.21 g/cm3, respectively, in contrast to conditionally pure sands, which have densities of 1.42 g/cm3 and 1.72 g/cm3, respectively.

- (4)

- Changes in the density of contaminated sands have an impact on their permeability. In loose sands, the filtration coefficient is similar to that of conditionally pure samples, varying within the range of 18.7–20.0 m/day. The filtration coefficient of dense sands decreases to 5.1–6.5 m/day.

- (5)

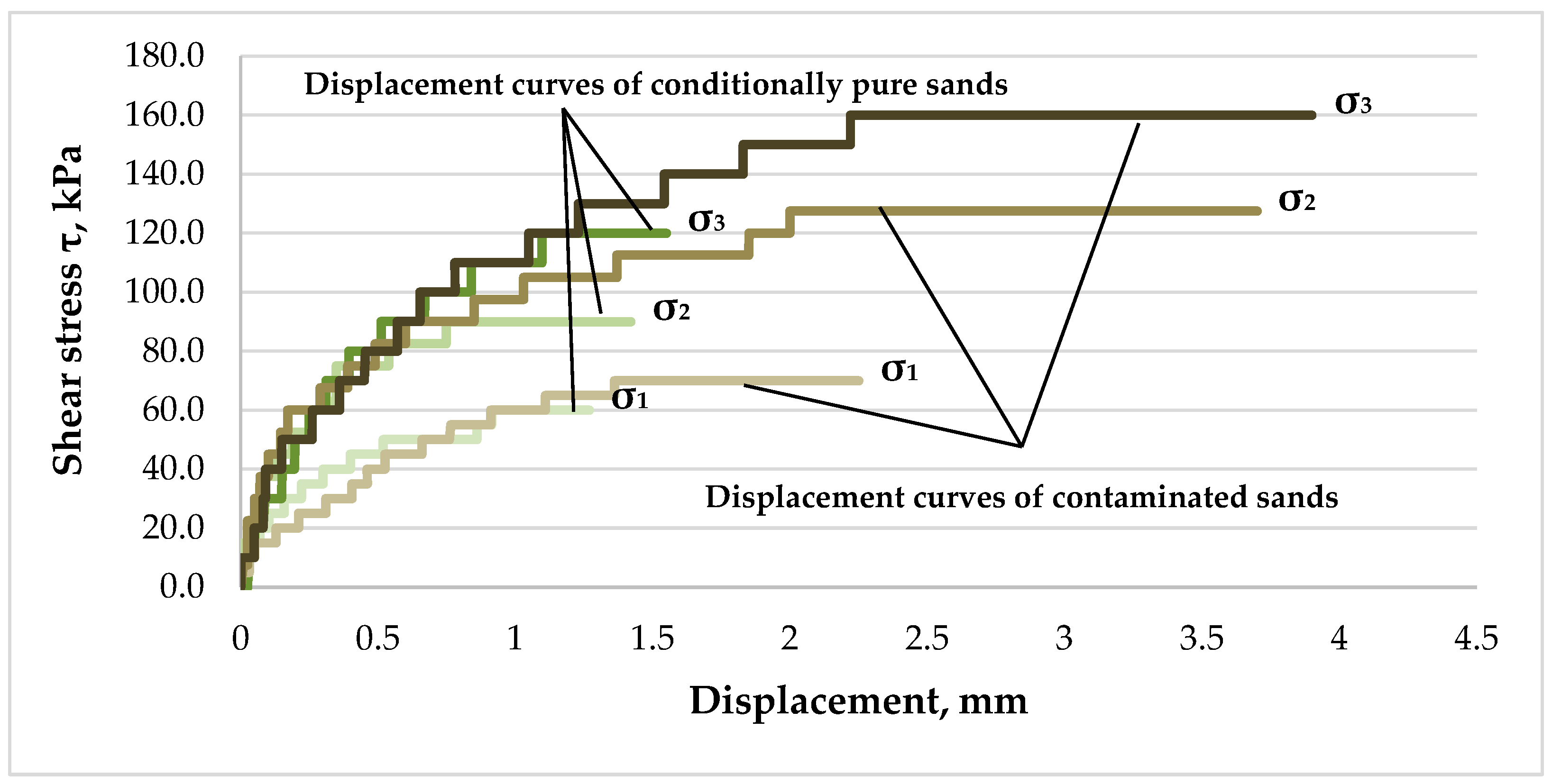

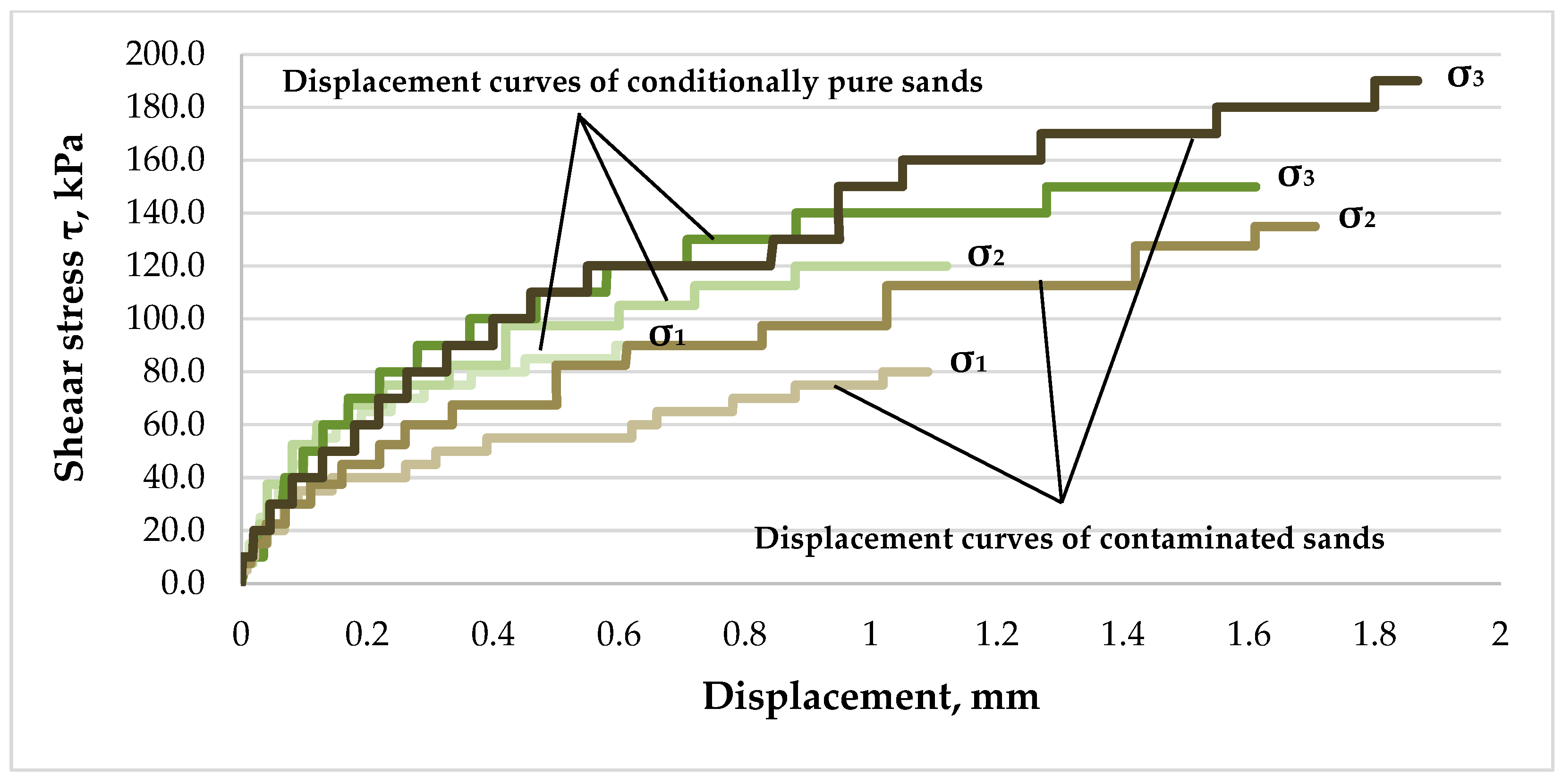

- Studying strength parameters of contaminated sands using the consolidated drain method of the direct shear test shows that, in comparison with conditionally pure sands, contaminated samples have higher internal friction angle ϕ (up to 39°) and display greater cohesion c (up to 5 kPa). Particular attention should be drawn to the duration of the contaminated sands’ shear deformations—depending on the applied normal stress and sample density, the experiment can last up to 10 h.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kazantsev, A.I.; Boikov, A.V.; Valkov, V.A. Monitoring the deformation of the earth's surface in the zone of influence construction. E3S Web Conf. 2020, 157, 02013. [Google Scholar] [CrossRef]

- Trushko, O.V.; Trushko, V.L.; Demenkov, P.A. Arrangement of multistory underground parking garages in complex engineering and geological environment. Int. J. Math. Eng. Manag. Sci. 2020, 5, 897–912. [Google Scholar] [CrossRef]

- Sarapulova, G.I. Geochemical approach in assessing the technogenic impact on soils. J. Min. Inst. 2020, 243, 388–392. [Google Scholar] [CrossRef]

- Iakovleva, E.V.; Belova, M.V.; Soares, A.O. Allocation of Potentially Environmentally Hazardous Sections on Pipelines. Geosciences 2021, 11, 3. [Google Scholar] [CrossRef]

- Iurchenko, V. Contamination and “Self-Cleaning” of soils, boarded on the objects of automobile and road complex, from petroleum products. Procedia Eng. 2017, 187, 783–789. [Google Scholar] [CrossRef]

- Shulaev, N.S.; Pryanichnikova, V.V.; Kadyrov, R.R. Regularities of electrochemical cleaning of oil-contaminated soils. J. Min. Inst. 2021, 252, 937–946. [Google Scholar] [CrossRef]

- Buzmakov, S.A.; Khotyanovskaya, Y.V. Degradation and pollution of lands under the influence of oil resources exploitation. Appl. Geochem. 2020, 113, 104–443. [Google Scholar] [CrossRef]

- Marinin, M.A.; Dolzhikov, V.V.; Isheyskiy, V.A. Improving the efficiency of drilling and blasting operations for high water cut conditions. Key Eng. Mater. 2020, 836, 124–130. [Google Scholar] [CrossRef]

- Wozney, A.; Clark, I.D.; Mayer, K.U. Quantifying natural source zone depletion at petroleum hydrocarbon contaminated sites: A comparison of 14C methods. J. Contam. Hydrol. 2021, 240, 103795. [Google Scholar] [CrossRef]

- Khaustov, A.P.; Redina, M.M. Hydrocarbon contamination of soils and soils: The practice of regulation, problems and trends. Geoecol. Eng. Geol. Hydrogeol. Geocryol. 2017, 1, 3–14. [Google Scholar]

- Golovina, E.I.; Karennik, K.S. Modern trends in the field of solving transboundary problems in groundwater extraction. Resources 2021, 10, 107. [Google Scholar] [CrossRef]

- Golovina, E.I.; Pasternak, S.N.; Tsiglianu, P.P.; Tselischev, N.A. Sustainable management of transboundary groundwater resources: Past and future. Sustainability 2021, 13, 12102. [Google Scholar] [CrossRef]

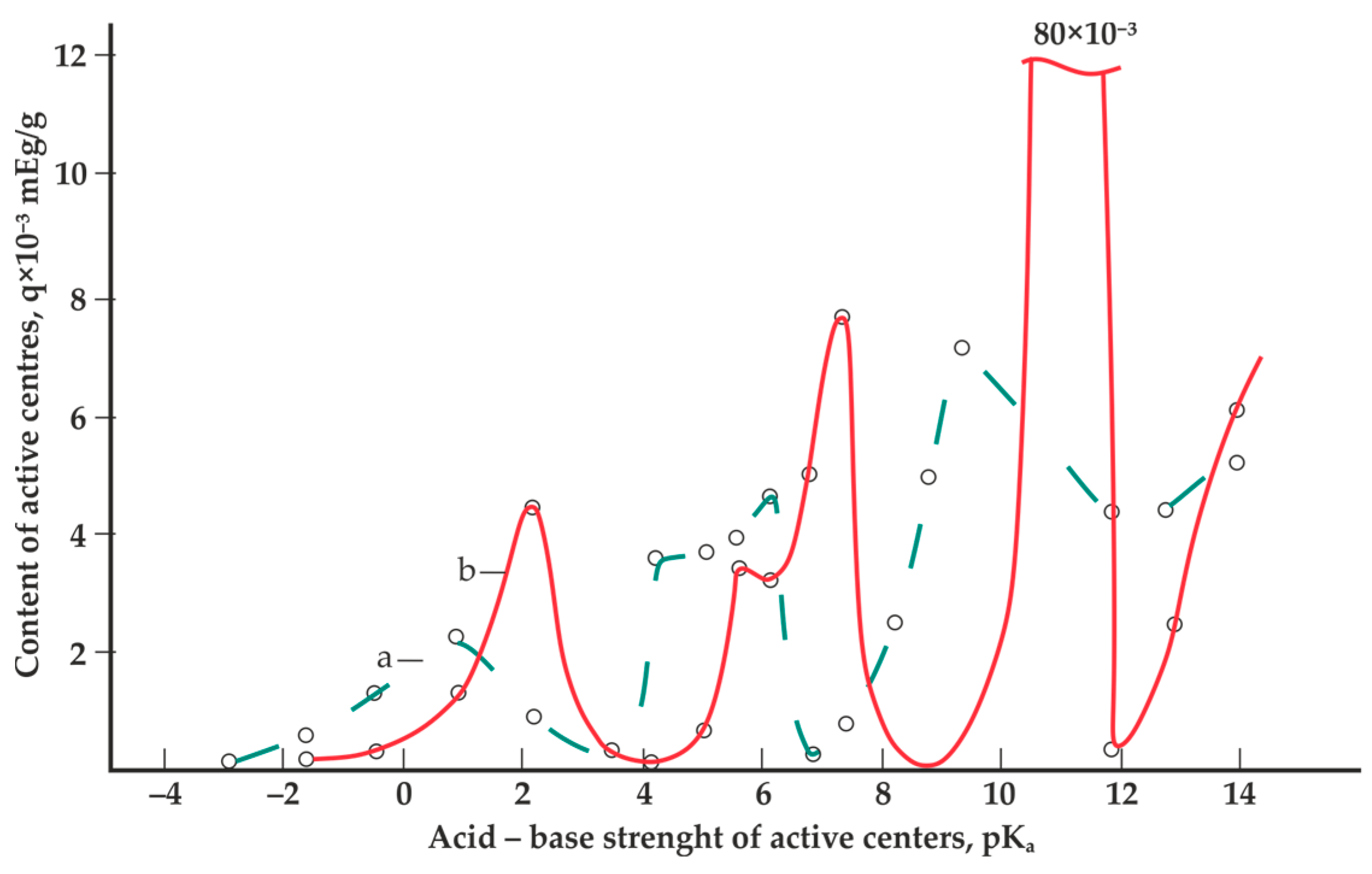

- Baranova, N.V.; Pashina, L.A.; Kostochko, S.V. Comparative analysis of some methods for determining the acid-base properties of the surface of solids from the point of view of studying the adhesive interaction. Her. Technol. Univ. 2014, 19, 19–36. [Google Scholar]

- Dashko, R.E.; Lokhmatikov, G.A. The Upper Kotlin clays of the Saint Petersburg region as a foundation and medium for unique facilities: An engineering-geological and geotechnical analysis. J. Min. Inst. 2022, 254, 180–190. [Google Scholar] [CrossRef]

- Kondrasheva, N.K.; Baitalov, F.D.; Boitsova, A.A. Comparative assessment of structural-mechanical properties of heavy oils of timano-pechorskaya province. J. Min. Inst. 2017, 225, 320. [Google Scholar] [CrossRef]

- Estabragh, A.R. Consolidation behavior of two fine-grained soils contaminated by glycerol and ethanol. Eng. Geol. 2014, 178, 102–108. [Google Scholar] [CrossRef]

- Haghsheno, H.; Arabani, M. Geotechnical properties of oil-polluted soil: A review. Environ. Sci. Pollut. Res. 2022, 29, 32670–32701. [Google Scholar] [CrossRef]

- Nasehi, S.A. Influence of gas oil contamination on geotechnical properties of fine and coarse-grained soils. Geotech. Geol. Eng. 2016, 34, 333–345. [Google Scholar] [CrossRef]

- Dashko, R.E.; Lange, I.Y. Engineering-geological aspects of negative consequences of contamination of dispersive soils by petroleum products. J. Min. Inst. 2017, 228, 624–630. [Google Scholar] [CrossRef]

- Chen, C.S.; Tien, C.J. Factors affecting in situ analysis of total petroleum hydrocarbons in contaminated soils by using a mid-infrared diffuse reflectance spectroscopy. Chemosphere 2020, 261, 127751. [Google Scholar] [CrossRef]

- Gordon, G. Oil spill effects on soil hydrophobicity and related properties in a hyper-arid region. Geoderma 2018, 312, 114–120. [Google Scholar] [CrossRef]

- Abdelhalim, R.A.; Selamat, M.R.; Ramli, H. Evaluation of strength properties of oil-contaminated sands upon stabilisation with laterite soil. Int. J. Pavement Eng. 2021, 23, 2981–2997. [Google Scholar] [CrossRef]

- Abousnina, R.M. Effects of light crude oil contamination on the physical and mechanical properties of fine sand. Soil Sediment Contam. Int. J. 2015, 24, 833–845. [Google Scholar] [CrossRef]

- Al-Adili, A.; Alsoudany, K.Y.; Shakir, A. Investigation of crude oil pollution effect on stiffness characteristics of sandy and gypseous soil. Soil Mech. Found. Eng. 2017, 54, 276–282. [Google Scholar] [CrossRef]

- Askarbioki, M.H. Impact of gasoline contamination on mechanical behavior of sandy clay soil. J. Min. Environ. 2019, 10, 389–399. [Google Scholar] [CrossRef]

- Kererat, C. Effect of oil-contamination and water saturation on the bearing capacity and shear strength parameters of silty sandy soil. Eng. Geol. 2019, 257, 105–138. [Google Scholar] [CrossRef]

- Chen, Y.A. Effect of soil organic matter on petroleum hydrocarbon degradation in diesel/fuel oil-contaminated soil. J. Biosci. Bioeng. 2020, 129, 603–612. [Google Scholar] [CrossRef]

- Gharedaghloo, B.; Price, J.S. Characterizing the immiscible transport properties of diesel and water in peat soil. J. Contam. Hydrol. 2019, 221, 11–25. [Google Scholar] [CrossRef]

- Quiñones-Bolaños, E.; Bustillo-Lecompte, C. Geotechnical Properties and Stabilization of Well-graded Sand with Clay and Gravel Soils Contaminated with Gasoline. Water Air Soil Pollut. 2020, 231, 1–13. [Google Scholar] [CrossRef]

- Liu, H. Hydrocarbon transformation pathways and soil organic carbon stability in the biostimulation of oil-contaminated soil: Implications of 13C natural abundance. Sci. Total Environ. 2021, 788, 147–580. [Google Scholar] [CrossRef]

- Olatunde, K.A. Determination of petroleum hydrocarbon contamination in soil using VNIR DRS and PLSR modeling. Heliyon 2021, 7, e06794. [Google Scholar] [CrossRef] [PubMed]

- Rajabi, H.; Sharifipour, M. Geotechnical properties of hydrocarbon-contaminated soils: A comprehensive review. Bull. Eng. Geol. Environ. 2019, 78, 3685–3717. [Google Scholar] [CrossRef]

- Salimnezhad, A.; Soltani-Jigheh, H.; Soorki, A.A. Effects of oil contamination and bioremediation on geotechnical properties of highly plastic clayey soil. J. Rock Mech. Geotech. Eng. 2021, 13, 653–670. [Google Scholar] [CrossRef]

- Goldberg, V.M.; Zverev, V.P.; Arbuzov, A.I.; Kazennov, S.M.; Kovalevsky, Y.V.; Putilin, V.S. Technogenic Pollution of Natural Waters by Hydrocarbons and Its Environmental Consequences; Nauka: Moscow, Russia, 2001; p. 125. [Google Scholar]

- Mousavi, S.E. Shear strength behavior in the interface of contaminated soil with bio-diesel oil and geosynthetics. Transp. Geotech. 2017, 10, 62–72. [Google Scholar] [CrossRef]

- Alvim, G.M.; Pontes, P.P. Aeration and sawdust application effects as structural material in the bioremediation of clayey acid soils contaminated with diesel oil. Int. Soil Water Conserv. Res. 2018, 6, 253–260. [Google Scholar] [CrossRef]

- Wei, K.H. Recent progress on in-situ chemical oxidation for the remediation of petroleum contaminated soil and groundwater. J. Hazard. Mater. 2022, 432, 128738. [Google Scholar] [CrossRef]

- Yao, Y. Modeling capillary fringe effect on petroleum vapor intrusion from groundwater contamination. Water Res. 2019, 150, 111–119. [Google Scholar] [CrossRef]

- Safehian, H.; Rajabi, A.M.; Ghasemzadeh, H. Effect of diesel-contamination on geotechnical properties of illite soil. Eng. Geol. 2018, 241, 55–63. [Google Scholar] [CrossRef]

- Bykova, M.V.; Alekseenko, A.V.; Pashkevich, M.A.; Drebenstedt, C. Thermal desorption treatment of petroleum hydrocarbon-contaminated soils of tundra, taiga, and forest steppe landscapes. Environ. Geochem. Health 2021, 43, 2331–2346. [Google Scholar] [CrossRef]

- Meng, L.; Bao, M.; Sun, P. A new perspective of particle adsorption: Dispersed oil and granular materials interactions in simulated coastal environment. Mar. Pollut. Bull. 2017, 122, 100–109. [Google Scholar] [CrossRef]

| Laboratory Sample | Loose Structure | Dense Structure | ||||

|---|---|---|---|---|---|---|

| Density, g/cm3 | Average Value 1, g/cm3 | Density, g/cm3 | Average Value 1, g/cm3 | |||

| from | to | From | To | |||

| Conditionally pure sand | ||||||

| 1–6 | 1.41 | 1.43 | 1.42 | 1.71 | 1.72 | 1.72 |

| Contaminated sand | ||||||

| 7–12 | 1.31 | 1.34 | 1.32 | 1.51 | 1.52 | 1.51 |

| Laboratory Sample | Conditionally Pure Sand | Laboratory Sample | Contaminated Sand | ||

| Stress, kPa | Stress, kPa | ||||

| Normal (Confining), σ | Shear (Tangential), τ | Normal (Confining), σ | Shear (Tangential), τ | ||

| Loose structure | |||||

| 1 | 100 | 65 | 7 | 100 | 75 |

| 2 | 150 | 99 | 8 | 150 | 119 |

| 3 | 200 | 130 | 9 | 200 | 170 |

| Laboratory sample | Conditionally Pure Sand | Laboratory sample | Contaminated Sand | ||

| Stress, kPa | Stress, kPa | ||||

| Normal (Confining), σ | Shear (Tangential), τ | Normal (Confining), σ | Shear (Tangential), τ | ||

| Dense structure | |||||

| 4 | 100 | 95 | 10 | 100 | 85 |

| 5 | 150 | 126 | 11 | 150 | 126 |

| 6 | 200 | 160 | 12 | 200 | 190 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lange, I.; Kotiukov, P.; Lebedeva, Y. Analyzing Physical-Mechanical and Hydrophysical Properties of Sandy Soils Exposed to Long-Term Hydrocarbon Contamination. Sustainability 2023, 15, 3599. https://doi.org/10.3390/su15043599

Lange I, Kotiukov P, Lebedeva Y. Analyzing Physical-Mechanical and Hydrophysical Properties of Sandy Soils Exposed to Long-Term Hydrocarbon Contamination. Sustainability. 2023; 15(4):3599. https://doi.org/10.3390/su15043599

Chicago/Turabian StyleLange, Ivan, Pavel Kotiukov, and Yana Lebedeva. 2023. "Analyzing Physical-Mechanical and Hydrophysical Properties of Sandy Soils Exposed to Long-Term Hydrocarbon Contamination" Sustainability 15, no. 4: 3599. https://doi.org/10.3390/su15043599

APA StyleLange, I., Kotiukov, P., & Lebedeva, Y. (2023). Analyzing Physical-Mechanical and Hydrophysical Properties of Sandy Soils Exposed to Long-Term Hydrocarbon Contamination. Sustainability, 15(4), 3599. https://doi.org/10.3390/su15043599