Abstract

Renewable energy sources, particularly solar photovoltaic generation, now dominate generation options. Solar generation advancements have resulted in floating solar photovoltaics, also known as FSPV systems. FSPV systems are one of the fastest growing technologies today, providing a viable replacement for ground-mounted PV systems due to their flexibility and low land-space requirement. This paper presents a systematic approach for implementing a proposed FSPV–grid integrated system in Bhilai Steel Plant’s (BSP) subsections. BSP is a steel manufacturing plant located in Bhilai, Chhattisgarh, and the FSPV system has the potential to generate sufficient energy by accessing two of its reservoirs. The system was simulated in HOMER Pro software, which provided the FSPV system power estimations, area requirements, net present cost (NPC), levelized cost of energy (LCOE), production summary, grid purchasing/selling, IRR, ROI, paybacks and pollutant emissions. A sensitivity analysis for a hike in PV prices globally due to a shortage in poly silicone in international markets during the fiscal year 2021–2022 was undertaken for the proposed FSPV–grid system. Here, the authors considered hikes in the PV price of 1%, 9%and 18% respectively, since the maximum percentage increase in PV prices globally is 18%. The authors also compared the proposed FSPV–grid system to the existing grid-only system for two sections of the BSP and the results obtained showed that the NPC and LCOE would be much lower in the case of the FSPV–grid system than the grid-only system. However, with changes in the percentage hike in PV prices, the NPC and LCOE were found to increase due to changes in the proportion of FSPV–grid systems in production. The pollutant emissions were the minimum in the case of the FSPV–grid system, whereas they were the highest in the case of the existing grid-only system. Furthermore, the payback analysis indicated that the minimum ROI for the above-defined construction would be fully covered in 15.81 years with the nominal 1% pricing for FSPV–grid generation. Therefore, the overall results suggest that the FSPV–grid system has the potential to be a perfect alternative solar energy source that can meet the current electrical energy requirements of the steel manufacturing industry with nominal pricing better than the existing grid-only system, as well as addressing economic constraints and conferring environmental benefits.

Keywords:

BSP; Chhattisgarh; FSPV system; grid; India; LCOE; NPC; pollutants; production; purchase; sell; sensitivity analysis 1. Introduction

Solar energy is a time-honoured renewable source of energy due to its ubiquity and sustainability. Solar PV is an accepted and direct form of generation from solar energy in which the heat energy from the sun is directly converted into electrical energy through PV modules, which are made up of thin layers of semiconductor material called polysilicon [1]. Polysilicon exhibits free electrons upon gaining photonic energy from the sun. Based on the availability of space, solar PV mountings are categorized into roof and ground types. However, nowadays, power engineers are making solar PV systems that float on water bodies, which are called floating solar or flotovoltaics [2]. The FSPV system uses a concept that extends the theory of generation from solar energy through only slight modifications to the system’s structure to make it float on water bodies. It is a new method of solar power generation that utilizes the water surfaces of rivers, dams, reservoirs and other water bodies [3]. The efficiency of normal PV is restricted to up to 17–18%, whereas researchers have shown that an efficiency of 20% can be achieved using an FSPV system [4,5,6]. This system has proven to be more successful in recent years. However, the FSPV system has various additional issues that future researchers should address:

- ▪

- Birds are drawn to the projects because they are on water, and their nests, droppings and other debris cause problems;

- ▪

- There are important concerns in terms of freshwater’s difference from saltwater/seawater;

- ▪

- Power losses in PV modules may occur as a result of micro-cracks caused by motions triggered by wind, waves and other external forces;

- ▪

- Solar radiation, fog, the presence of shade and other factors can have a direct impact on generation;

- ▪

- Water level fluctuations, frozen regions, inflows of floating matter, accessibility, interference from dam facilities and so on are all factors that may affect installation and maintenance;

- ▪

- The power system connection, distance to distribution line, load, etc.

- ▪

- There are also legal constraints: water source protection zones, environmental protection, flora and fauna protection, marine activists, etc. [7].

India, which is a tropical country, and its state, such as Chhattisgarh, benefit from high and nearly constant solar radiation; the Tropic of Cancer passes through Ambikapur Chhattisgarh, thus offering a suitable condition for solar PV generation. This is a favourable condition for investment in solar PV power generation in Chhattisgarh. However, the PV selling price is the key feature allowing solar power to flourish around the world. Many countries, including India, have provided many rebates to consumers through subsidies to encourage people to adopt solar power. Thus, a slight increase in solar material prices can put energy engineers under great pressure. The Indian government has expressed clear intentions to develop 175 GW of clean, renewable energy by 2022, of which 100 GW would be from solar generation under its National Solar Mission (NSM). This has been possible for decades due to the plummeting trend in the prices of solar modules, which have dropped by up to 90%, a change which can be considered menacing [6].

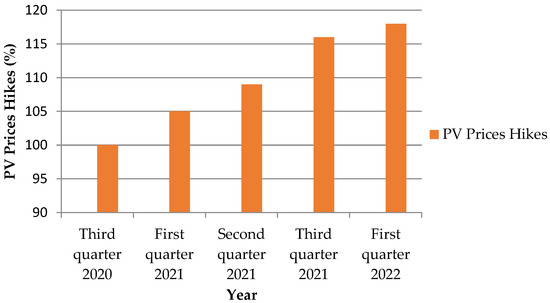

The hike in PV prices last year was a snag for the solar energy industry. The government has expressed a clear intention to impose a 40% basic customs duty (BCD) on modules. PV modules account for 52–56% of the total capital cost, which, in turn, increases the cost of energy. The module prices have increased by up to 18% over the past year and are expected to increase further if the conditions remain the same [8]. This is due to the increase in the price of polysilicon, which is the raw material for solar modules. China, as a primary supplier, has increased the metal price of polysilicon by one-fifth of the total cost, which, in turn, has increased the capital cost of solar PV. This will affect various nations, especially India, since all raw materials for solar power are imported from China. If this extravagant price continues to increase, then it will affect India in two ways: firstly, it will cause problems in meeting the deadlines of past projects; and, secondly, it will slow down the projects using solar power. The whole scenario will again have a cumulative effect on climate change [9]. Figure 1 shows the percentage increase in solar module pricing for the fiscal year 2021–2022. The trend shows a continuous hike in PV prices in 2021, which reached a maximum of 18% due to the shortage of polysilicon in the international market, and this hike is a bottleneck for solar engineers. The aforementioned problem will disrupt the plans of engineers and researchers to integrate FSPV systems as generation options. However, India is a country rich in resources and, its water bodies have the potential to generate 270 GW of power through FSPV systems [10]. FSPV has the advantage of reducing the cost of land, which is compensated for by its high capital cost, although this can be made to increase by rising PV prices. The International Energy Agency (IEA) has declared that, by 2050, 50% of the total power supply around the world will be generated by solar systems. The present research claimed to analyze the effects of rising PV prices on the overall production proportions of the system and the economic constraints.

Figure 1.

Percentage increase in PV prices for the fiscal year 2021–2022 (PV Magazine).

Solar generation is attracting remarkable attention among power engineers for use in industrial applications due to its intermittent and sustainable nature. Solar power can be employed in a variety of industrial applications, such as chemical processes, electrical processes, space heating, cooling of buildings, etc. [11]. Studies have proved that solar power is even applicable in industries such as telecommunications, the textiles industry, agriculture, water desalination, etc. Solar energy, when implemented for industrial applications in the form of FSPV systems, can provide a variety of energy demand solutions and will cumulatively improve the reliability of industries [12,13]. When integrated with grid systems, they modify the proportion of energy demand, improving the system sustainability, stability and conversion reduction and, often, enhancing the overall system efficacy [14]. The present research aimed to analyse the compatibility of FSPV–grid systems with industrial applications as compared to existing grid-only systems.

2. Development of the FSPV System and Related Work

This section provides a survey of various research papers that have contributed to the development of FSPV in one way or another throughout their evolution. There is a growing demand for generation in different areas, and solar PV has provided a major contribution for a long time [15]. The following literature review discusses FSPV generation across a wide range.

Trapani et al. stated that the FSPV system was first proposed in Aichi, Japan, in 2007 with a capacity of 20 kW, soon after which many systems were built around the world. The authors provide a historical review of the FSPV system [16].

Sahu et al. presented an extended review of FSPV systems around the world, describing the evolution of FSPV techniques and their modelling and implementation. FSPV systems emerged in early 2007 and were built with fixed angles and simple designs, but they were precisely moored to avoid panel movements. The use of high-density polyethylene (HDPE) as a floating structure with galvanized steel supporting it has recently gained popularity due to its low manufacturing cost [17].

Oliveria et al. observed that HDPE meets the criteria of modularity, flexibility, robustness and safety, and it has become widely popular and currently has the greatest installed capacity; thus, this floating structure was adopted for the study. Due to the improved performance of FSPV systems and the availability of scalable supporting structures, the emphasis has shifted to accurately estimating the solar energy at a given site [18].

Rosa et al. described how pontoons were used to mount FSPV systems in the beginning. Although the structure was strong, it was expensive and not specifically designed for the FSPV systems [19].

Choi et al. stated that reduced weight rather than a strong mechanical structure is the key advantage of FSPV systems [20].

Rosa et al. estimated the cost of 1 MW in an FSPV system to be USD 1,081,398. The authors used the enhanced FSPV system and focused on optimizing it [21].

Choi et al. presented the performances of two FSPV systems of 100 and 500 kW compared to that of a 1 MW PV plant located in Hapcheon, China. The site had the same amount of GHI and temperature. The efficiency obtained for the FSPV system was approximately 4% greater than that of the overland PV system [22].

Liu et al. explained that the increased efficiency of FSPV systems is possible due to their self-cooling effect, since the efficiency depends upon the cell temperature. FSPV systems maintain an ambient temperature due to their positioning on water bodies. The authors observed a temperature difference of 3.5 °C between FSPV and overland PV systems [23].

Gisbert et al. observed that the cost of installing an FSPV system is nearly 30% higher than for a conventional overland PV system. This is due to additional components, such as mooring systems, floaters and supporting platforms. Furthermore, the type of material greatly affects the structures, since they have to robustly withstand the environmental conditions. The authors carried out the study at an agriculture reservoir in Spain and utilized only 7%of its area for FSPV generation [24].

Green et al. explained that the lifetime of PV systems is currently 25 years and it may be extended to 30 years in the near future. Furthermore, the power duration will reach 90% after 12 years and up to 80% after 25 years [25].

Aryani et al. analyzed the system performance of a stand-alone FSPV system supplying power to loads with a battery for energy storage. The simulation was accomplished by using small values for the PV module, battery and load, with all the components being integrated, and safe operation was maintained using a solar charge controller. The FSPV system was compared to ground PV in terms of efficiency and higher efficiencies were achieved in the case of the FSPV system, as the cell temperature was maintained in an optimum condition [26].

Rizvi et al. proposed a system architecture for the steel industry with economic benefits and reduced pollutant emissions. The authors simulated the systems with the lowest cost of energy and capital costs and reduced pollutant emissions for various proposed applications in the steel industry [27].

Yanlai et al. proposed an artificial intelligence-based system driven by FSPV and used the grasshopper algorithm optimization technique to maximize the FSPV output with the aim of promoting this energy scenario in Taiwan. Sufficiently improved benefits were observed in water storage, food production and FSPV output, respectively, with varying tilt angles during summer and winter. FSPV provides a feasible scheme thanks to its sustainability and ubiquity [28].

Lee et al. presented a decision-making review of hybrid floating PV systems and their technical potential using publicly available data. The authors identified significant potential for FSPV system operational benefits in existing and planned systems [29].

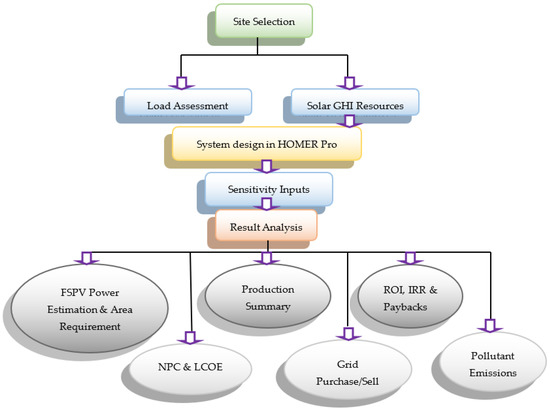

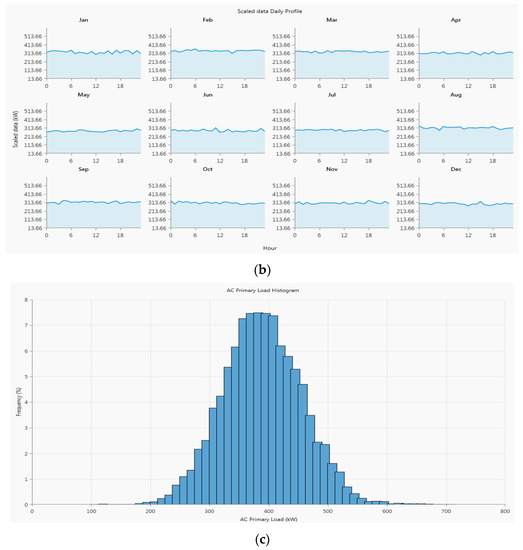

3. Site Selection, Resources and System Modelling

This section deals with the site selection (BSP), the availability of solar global horizontal index (GHI) resources at the site and the system modelling. BSP is located at 21°10.7 N latitude and 81°23.4 E longitude 319 m above sea level. BSP, headquartered in Bhilai, Chhattisgarh, is the country’s first and largest producer of steel rails, as well as a major producer of wide steel plates and other steel products. It also manufactures steel and sells various chemicals by-products produced by its various sections. It was founded in 1959 with the assistance of the Soviet Union [30,31,32,33]. It has various sections, such as a blast furnace, steel melting shop, coke oven and rail mill, among which two—namely, the BSP oxygen plant (BSP Oxy Plant) and BSP plant operations (BSP Plant Operat)—were selected for simulation and analysis. BSP currently operates with a grid-only system, purchasing power at USD 0.100/kWh. BSP has two main reservoirs named Maroda Reservoir-1 and Maroda Reservoir-2 within its plant area, as shown in Figure 2. Maroda Reservoir-1 is not used by BSP, whereas Maroda Reservoir-2 water is used for the treatment processes in some plant operations. Presently, there is no generation system installed in either of these two reservoirs. The data for the two reservoirs were obtained from BSP for further research evaluation and demonstrated that they have a high potential for the generation of power with an FSPV system. As a result, the authors of this study proposed an FSPV–grid system for these two reservoirs. Figure 3 shows the step-wise methodological flow chart adopted for the research.

Figure 2.

(a) Satellite view of Maroda Reservoir-1 and Maroda Reservoir-2, (b) Rear view of BSP and its reservoir captured by authors.

Figure 3.

Flow chart of methodological approach.

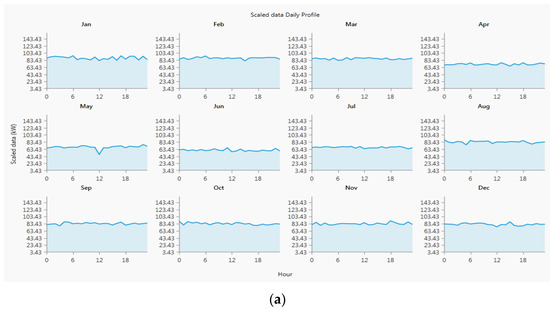

3.1. Load/Demand Assessment

The load profile included two plant loads; the first load was the BSP oxygen plant, which is capable of supplying 265 litres of medical oxygen per day in Chhattisgarh and eight other states in India [34]. This plant has acted as a lifeline during pandemics in previous years. The second load was BSP plant operations, which include the lighting, fans, air conditioning and various mechanical loads involved in steel production. The hourly load profiles for both loads for the months of the fiscal year 2021–2022 are shown in Figure 4a,b, whereas Figure 4c shows the histogram profile for both loads.

Figure 4.

(a) Load profile of BSP oxygen plant for the fiscal year 2021–2022, (b) Load profile of BSP plant operations for the fiscal year 2021–2022, (c) Yearly histogram load profile of the two sections for the fiscal year 2021–2022.

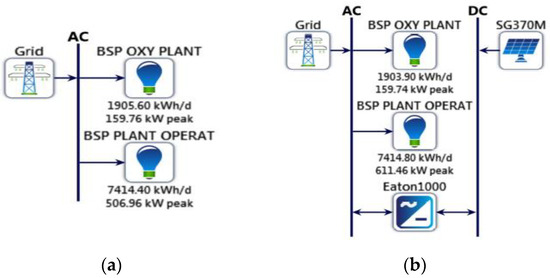

For the BSP oxygen plant and BSP plant operations loads, the energy demand was 1903.90 kWh/day and 7414.80 kWh/day, with a peak demand of 159.74 kW and 611.46 kW in March 2021 and load factors of 0.5 and 0.51, respectively.

3.2. Availability of Solar GHI Resources

The solar global horizontal index (GHI) resources at the selected location were collected from the United States National Aeronautics and Space Administration (NASA) Prediction of Worldwide Energy Resource (POWER) database. The annual average temperature is 26.16 °C and the scaled annual average value for solar radiation is 5.08 kWh/m2/day. The highest daily solar radiation values obtained were 6.710 kWh/m2/day and 6.580 kWh/m2/day in the peak summer months of April and May 2021 and the clearness index values were 0.639 and 0.601, respectively, as shown in Figure 5a,b. Figure 5c shows the monthly global solar daily profile.

Figure 5.

(a) Monthly average temperature data, (b) Monthly average solar GHI data and (c) Monthly global solar daily profiles.

3.3. Input Data for Homer Pro and System Modelling

The system configurations of the grid-only and FSPV–grid systems with sensitivity inputs are shown in Figure 6a,b, respectively.

Figure 6.

(a) Schematic of the grid-only simulation model, (b) Schematic of FSPV–grid simulation model.

The above-mentioned data for the systems were entered into HOMER Pro. The technical inputs provided in HOMER Pro for the installation of an FSPV–grid system based on load demand and the availability of solar GHI resources are described below.

3.3.1. FSPV Module Input

Peimar SG370M PV panels with parameters changed to suit an FSPV system were selected. The array sizes considered for the search space in kW were 0, 200, 400, 600, 1000, 2000, 3000, 4000 and 5000. The capital cost, replacement cost and operation and maintenance cost of the FSPV array were considered in all simulations with HOMER Pro. The expected lifetime of the FSPV system was 30 years.

3.3.2. Converter Inputs

An Eaton1000 was selected as the power converter with sizes of 0, 200, 400, 600, 800, 1000, 2000 and 3000 kW. The capital cost, replacement cost and operation and maintenance cost of the converter were considered in all simulations with HOMER Pro, with an expected An Was with an expected lifetime of 15 years and 98% efficiency.

3.3.3. Grid Inputs

A national grid with scheduled rates and net purchases calculated monthly was selected. The grid supplies power to fulfil the load demand and absorbs power when excessive power is available. It was set to provide power at USD 0.1000/kWh and the FSPV–grid system sell back power was set at USD 0.0500/kWh. The grid system was included in all of the simulation optimizing systems. The rates of pollutant emission from the grid were set to 632 g/kWh of carbon dioxide, 274 g/kWh of sulphur dioxide and 134 g/kWh of nitrogen oxides.

3.3.4. Controlling Inputs

The simulation approach applied was the HOMER cycle charging process and HOMER load-following was used for the control. The load following always followed the complete load with minimum supply from the grid and the maximum from the FSPV system to achieve the optimal cost for the system design. The excess power generated was supplied back to the grid to make the overall FSPV–grid system more economical as compared to the existing grid-only system.

3.3.5. Economic Inputs

The defined inputs for simulation were the variables for project lifetime, which was 30 years with an interest rate of 6% and inflation growth of 2% annually. The costs of various constructions, the cost of administration and the charges set by license authorities were together considered system fixed costs in HOMER Pro.

3.3.6. System Constraints

The loads need a continuous power supply without a break; thus, to achieve a 100% reliable system, the parameter known as the capacity shortage was set to zero for the production of excess electricity that occurs in some cases with FSPV–grids systems.

3.3.7. Sensitivity Parameters

To analyze the effect of PV price hikes on the design of the FSPV–grid system, different percentage increases in PV prices were input into HOMER Pro as sensitivity cases. Considering the PV price percentage increases, the sensitivity cases were 1% (nominal), 9% and 18%.

4. Results and Sensitivity Analysis

HOMER Pro was used to perform various technical and economic simulations based on the grid-only and proposed FSPV–grid systems for BSP and its inputs. The FSPV nominal value (1%) and price hikes of 9% and 18% were considered for the simulation process since the maximum percentage increase up to the first quarter of 2022 was 18%. For each percentage increase in the sensitivity inputs, many solutions were obtained by HOMER Pro, out of which several were feasible. The criteria selected for defining the results were:

- ▪

- FSPV system power estimations and area requirement;

- ▪

- NPC and LCOE;

- ▪

- Production summary;

- ▪

- Grid purchase/sell;

- ▪

- IRR, ROI and paybacks;

- ▪

- Pollutant emissions.

4.1. FSPV System Power Estimations and Area Requirements

Based on experience with FSPV installations and indications by various installers, a conservative estimate of 40 MW capacities FSPV per square km of reservoir surface area covered was used [35]. Table 1 shows the data for the two reservoirs of BSP and Table 2 shows theoretical calculations for the FSPV system installation for different percentages of the area covered. Table 2 shows the total area requirements for the proposed FSPV–grid system installation on Maroda Reservoirs-1 and -2 based on the optimized FSPV rating results from HOMER Pro.

Table 1.

Reservoir data for BSP.

Table 2.

FSPV installation calculations.

- ▪

- According to estimates, Maroda Reservoir-1 and Maroda Reservoir-2 have the potential to generate 20 MW and 65 MW, respectively, with a minimum of 20% area coverage. For a maximum of 100% coverage, generation increases to 100 MW and 325 MW, respectively;

- ▪

- According to a conservative estimate of 40 MW capacity FSPV per square km of reservoir surface area covered, as shown in Table 3, a minimum area of 0.083 km2 was calculated for a rating of 4185 kW as selected for FSPV–grid generation with a 1% PV price increase;

- ▪

- Similarly, an area of 0.041 km2 was calculated for a rating of 2097 kW as selected for FSPV–grid generation with the maximum 18% PV price increase;

- ▪

- The above three results were theoretically calculated to be consistent with the optimized HOMER Pro results. Furthermore, the calculated area required for the FSPV installation could come from either Maroda Reservoir-1 or Maroda Reservoir-2.

Table 3.

Effects of PV price hikes on the sizes of the grid and FSPV systems for the fiscal year 2020–2021.

Table 3.

Effects of PV price hikes on the sizes of the grid and FSPV systems for the fiscal year 2020–2021.

| System | FSPV Price Hike (%) | FSPV (kW) | Area Required for FSPV Installation (km2) |

|---|---|---|---|

| Grid-only | NA | NA | NA |

| FSPV–grid | 1 | 4185 | 0.083 |

| FSPV–grid | 1.09 | 3930 | 0.078 |

| FSPV–grid | 1.18 | 2097 | 0.041 |

4.2. NPC and LCOE

The NPC is defined as the present value of all installation and operation costs for the component over the project lifespan, less the present value of all revenues earned over the project lifetime. The LCOE is defined as the system’s average cost per kWh of useful electrical energy produced and is represented in form of Equation (1) below:

where:

= total annualized cost of system (USD/year);

= marginal cost (INR/kWh);

= total thermal load;

= total served electric load.

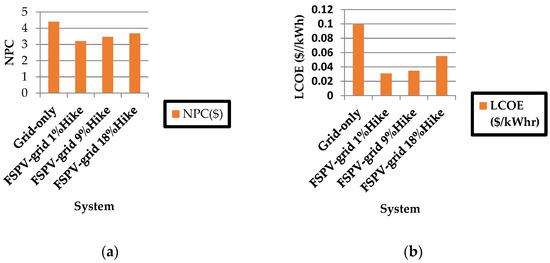

The systems with the lowest NPC and LCOE obtained from HOMER Pro results are tabulated in Table 4. Figure 7 shows a graphical representation of the same. In the case of increasing percentage prices, the following conclusions can be drawn:

- ▪

- The NPC and LCOE varied in direct proportion to the percentage PV price increases;

- ▪

- Hikes in PV prices affected the NPC and LCOE of the proposed FSPV–grid system directly, due to which the initial capital cost and other operating costs changed, reflecting the change in NPC and LCOE;

- ▪

- In comparison to the grid-only system, the NPC dropped to 27% with the FSPV–grid system for the nominal price (1%), 21.1% with the FSPV–grid system for the 9% hike and 16.36% with the FSPV–grid system for an 18% price increase;

- ▪

- The LCOE fell to 69% with the FSPV–grid system for the nominal price (1%), 65.3% with the FSPV–grid system for the 9% hike and 45% with the FSPV–grid system for an 18% price increase.

Table 4.

Effects of PV price hike on size of grid-only and FSPV-grid systems, along with NPC and LCOE, for the fiscal year 2020–2021.

Table 4.

Effects of PV price hike on size of grid-only and FSPV-grid systems, along with NPC and LCOE, for the fiscal year 2020–2021.

| System | FSPV Price Hike (%) | Initial Capital (USD) | Total NPC (USD) | Decrease in NPC (%) | LCOE (USD/kWh) | Decrease in LCOE (%) |

|---|---|---|---|---|---|---|

| Grid-only | NA | NA | 4.40 M | 0 | 0.1000 | 0 |

| FSPV–grid | 1 | 3.87 M | 3.21 M | 27 | 0.0310 | 69 |

| FSPV–grid | 1.09 | 3.94 M | 3.47 M | 21.1 | 0.0347 | 65.3 |

| FSPV–grid | 1.18 | 2.25 M | 3.68 M | 16.36 | 0.0550 | 45 |

Figure 7.

(a) NPC of grid-only and FSPV–grid systems with various price hikes, (b) LCOE of grid-only and FSPV–grid systems with various price hikes.

4.3. Production Summary

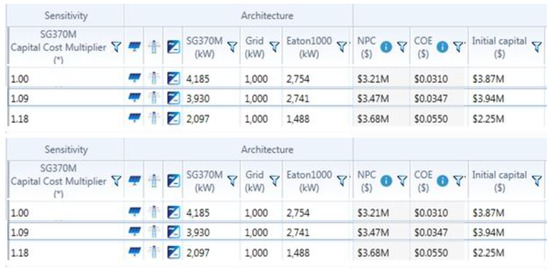

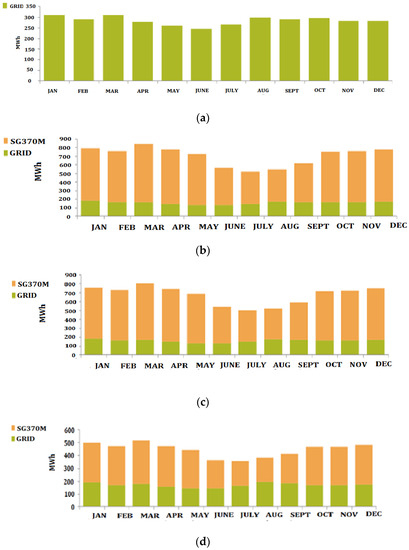

Table 5 shows system configuration and the size optimized by HOMER Pro. Figure 8 shows a screenshot of the same. Figure 9 indicates the proportions of the contributions of the renewable FSPV and grid for the grid-only and proposed FSPV–grid systems.

Table 5.

Effects of PV price hike on the size of the grid and FSPV systems for the fiscal year 2020–2021.

Figure 8.

Screenshot of the results obtained in HOMER Pro.

Figure 9.

(a) Grid-only monthly proportions and (b) FSPV–grid monthly proportions for 1% PV price hike. (c) FSPV–grid monthly proportions for a 9% PV price hike and (d) An 18% PV price hike.

As can be seen, the following conclusions can be drawn:

- ▪

- The most feasible combination of plant loads was the FSPV–grid system with nominal 1% pricing, for which 76.6% was contributed by the FSPV and 22.3% by the grid;

- ▪

- As the percentage price increases, production proportions also change: 75.6% FSPV + 23.5% grid for the 9% price hike and 60.7% + 38.2% grid for the 18% PV price hike;

- ▪

- As optimized by HOMER Pro, the proportions of the FSPV and grid generation systems varied directly with the kW rating of the FSPV and converter system used;

- ▪

- The FSPV rating was reduced to 2097 kW from 4185 kW to obtain a feasible solution with increasing PV prices and, similarly, the converter ratings were also reduced to 1488 kW from 2754 KW, respectively, to support the FSPV ratings.

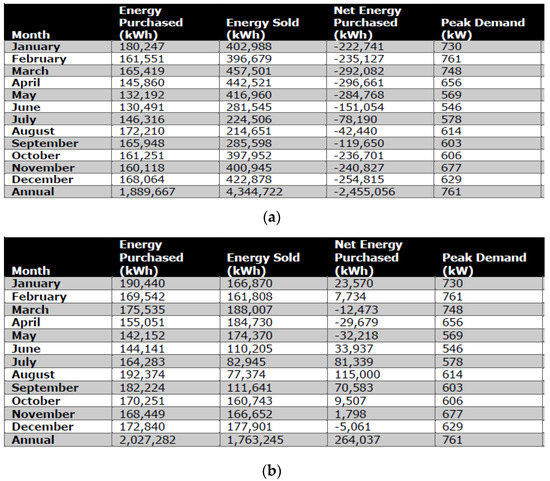

4.4. Grid Purchase/Sell

Table 6 indicates that the amount of energy purchased from the grid and sold back changes in proportions of FSPV–grid contributions, which, again, resulted from PV price hikes. The amount of energy purchased from the grid was 2,102,061 kWh in the case of an 18% hike, while it was 1,642,883 kWh for a nominal 1% price increase. The system relies more on the grid than FSPV for a PV price hike. Figure 10a,b show the monthly purchase/selling data for 9% and 18% price hikes.

Table 6.

Effects of PV price hike on grid purchasing and selling for the fiscal year 2020–2021.

Figure 10.

(a) Screenshot of HOMER Pro results for energy purchased and sold in FSPV–grid system for 9% PV price hike. (b) Screenshot of HOMER Pro results for energy purchased and sold in FSPV–grid system for 18% PV price hike.

4.5. ROI, IRR and Paybacks

The ROI is an important parameter defined as the annual cost savings in comparison to the initial investment. ROI can be calculated using Equation (2):

where:

= annual nominal cash flow for the base system;

= annual cash flow for the proposed system;

= capital cost of the proposed system;

= capital cost of the base system;

= lifetime of the project in years.

The obtained results, as shown in Table 7, for ROI, IRR and paybacks for the grid-only system and proposed FSPV–grid system with increases in PV prices were as follows:

- ▪

- The ROI ultimately remained the same;

- ▪

- The IRR reached 9.0% from 8.8%;

- ▪

- The discounted payback time increased from 15.81 years to 17.37 years and then decreased to 15.44 years due to a change in the production proportions in the FSPV and grid system;

- ▪

- The simple payback time increased from 10.11 years to 10.70 years and then decreased to 9.77 years due to a change in the production proportions in the FSPV and grid system.

Table 7.

Effects of PV price hikes on other economic parameters.

Table 7.

Effects of PV price hikes on other economic parameters.

| System | FSPV Price Hike (%) | IRR (%) | ROI (%) | Simple Payback (year) | Discounted Payback (year) |

|---|---|---|---|---|---|

| Grid-only | Not Applicable | Not Applicable | Not Applicable | Not Applicable | Not Applicable |

| FSPV–grid | 1 | 8.8 | 6.4 | 10.11 | 15.81 |

| FSPV–grid | 1.09 | 8.2 | 5.8 | 10.70 | 17.37 |

| FSPV–grid | 1.18 | 9.0 | 6.4 | 9.97 | 15.44 |

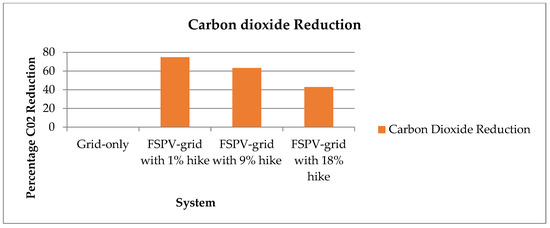

4.6. Pollutant Emissions

Table 8 shows the results for the reduction in pollutant emissions, which can be summarized as follows:

- ▪

- Pollutant emissions, such as carbon dioxide, sulphur dioxide and nitrogen dioxide, were high in the case of the grid-only system;

- ▪

- In the case of the FSPV–grid system:

- Carbon dioxide was reduced by 74.8% for 1%, 63.4% for 9% and 42.9% for 18% increases in PV prices, as shown in Figure 11;

- Sulphur dioxide was reduced by 44.76% for 1%, 42.4% for 9% and 33.3% for 18% increases in PV prices;

- Nitrogen oxides were reduced by 54.3% for 1%, 51.9% for 9% and 38.3% for 18% increases in PV prices.

Table 8.

Effects of PV price hikes on pollutant emissions with the size of the system.

Table 8.

Effects of PV price hikes on pollutant emissions with the size of the system.

| System | FSPV Price Hike (%) | Carbon Dioxide (kg/year) | Sulphur Dioxides (kg/year) | Nitrogen Oxides (kg/year) | Decrease in Carbon Dioxide (%) | Decrease in Sulphur Dioxide (%) | Decrease in Nitrogen Oxides (%) |

|---|---|---|---|---|---|---|---|

| Grid-only | Not Applicable | 2,149,681 | 9320 | 4558 | 0 | 0 | 0 |

| FSPV–grid | 1 | 1,187,451 | 5148 | 2518 | 74.8 | 44.76 | 54.3 |

| FSPV–grid | 1.09 | 1,194,269 | 5178 | 2532 | 63.4 | 42.4 | 51.9 |

| FSPV–grid | 1.18 | 1,281,242 | 5555 | 2717 | 41.9 | 33.3 | 38.3 |

Figure 11.

Reductions in carbon dioxide percentages for grid-only and FSPV—grid systems.

5. Conclusions

This study sought to propose an FSPV–grid system for the electrification of two sections of the BSP—namely, the BSP oxygen plant and BSP plant operations—that could be employed in the two reservoirs (Maroda Reservoir-1 and Maroda Reservoir-2) while accounting for a PV price increase as a sensitivity analysis parameter. The obtained results were then compared with the grid-only system used in the BSP. Global PV price increases are impeding many of the ongoing solar projects proposed by the Government of India under its National Solar Mission in 2022 and will have an impact on global solar production options. The current study aimed to provide better solutions for increasing energy demand with rising PV prices through an FSPV–grid system for BSP. HOMER Pro identified various sizes for the FSPV–grid system with increasing PV prices of 1%, 9% and 18% to make it more economical and feasible.

FSPV system power estimations and area requirements; the NPC and LCOE; the production summary; grid purchasing/selling; IRR, ROI and paybacks; and, last but not least, pollutant emissions were the major categories for the evaluation of the results. The following are the major findings:

- ▪

- Maroda Reservoir-1 and Maroda Reservoir-2, with areas of 2 km2 and 6.5 km2, respectively, have sufficient potential to meet the power requirements of the abovementioned BSP industrial sections;

- ▪

- Theoretically, 100 MW and 325 MW of maximum power could be drawn using an FSPV installation with 100% coverage. However, when the optimized results of HOMER Pro were evaluated, they showed that for an FSPV–grid system with a rating of 4185 kW and a 1% PV price increase, an area of 83 km2 would be required, while an area of 78 km2 would be required for an FSPV–grid system with a rating of 3930 kW and a9% PV price increase and an area of 41 km2 area would be required for an FSPV–grid system with a rating of 2097 kW and an 18% PV price increase;

- ▪

- The above areas for the FSPV installation calculated based on HOMER Pro results could be taken from either reservoir;

- ▪

- The NPC and LCOE were found to be proportional to the percentage increase in the PV price;

- ▪

- The proportion of FSPV and grid generation, as optimized by HOMER Pro, varied directly with the kW rating of the FSPV and converter system used;

- ▪

- The amount of energy purchased from the grid and sold back to it varied with the proportions of the FSPV–grid contributions, which changed as a result of PV price increases;

- ▪

- The ROI ultimately remained constant, while the IRR rose due to changes in the production proportions of the FSPV and grid systems. The discounted payback time and simple payback time rose with PV price increases;

- ▪

- Pollutant emissions, such as carbon dioxide, sulphur dioxide and nitrogen dioxide, were high with the grid-only system, whereas they were significantly reduced in the case of the FSPV–grid system.

Finally, it is possible to conclude that moving toward FSPV–grid integration may bring a variety of benefits, including faster development of solar projects due to reduced land requirements. Despite the many benefits, there is still a need for scientific research on the long-term effects of FSPV systems on marine ecosystems, since these systems can disrupt their biological activities. Reservoir coverage should also be explored in order to achieve a perfect balance between electricity production and nature conservation.

Author Contributions

Conceptualization, T.R.; Software, T.R.; Validation, T.R., S.P.D. and N.T.; Formal analysis, T.R.; Investigation, T.R.; Resources, T.R.; Data curation, T.R., S.P.D. and S.P.M.; Writing—original draft, T.R. and S.P.M.; Writing—review & editing, T.R., G.S., S.P.M. and M.K.M.; Visualization, S.P.D.; Supervision, S.P.D. and N.T.; Funding acquisition, G.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Campana, P.E.; Wasthage, L.; Nookuea, W.; Tan, Y.; Yan, J. Optimization and Assessment of Floating and Floating-Tracking PV Systems Integrated in On- and Off-Grid Hybrid Energy Systems. Sol. Energy 2019, 177, 782–795. [Google Scholar] [CrossRef]

- Mayville, P.; Patil, N.V.; Pearce, J.M. Distributed Manufacturing of After Market Flexible Floating Photovoltaic Modules. Sustain. Energy Technol. Assess. 2020, 42, 100830. [Google Scholar] [CrossRef]

- Junianto, B.; Dewi, T.; Carlos, R.; Sitompul, C.R. Development and Feasibility Analysis of Floating Solar Panel Application in Palembang, South Sumatra. J. Phys. Conf. Ser. 2020, 1500, 012016. [Google Scholar] [CrossRef]

- Sheikh, Y.A.; Butt, A.D.; Paracha, K.N.; Awan, A.B.; Bhatti, A.R.; Zubair, M. An Improved Cooling System Design to Enhance Energy Efficiency of Floating Photovoltaic Systems. J. Renew. Sustain. Energy 2020, 12, 053502. [Google Scholar] [CrossRef]

- Belhadi, A.; Djenouri, Y.; Srivastava, G.; Jolfaei, A.; Lin, J.C. Privacy reinforcement learning for faults detection in the smart grid. Ad Hoc Netw. 2021, 119, 122. [Google Scholar] [CrossRef]

- Tariq, M.; Adnan, M.; Srivastava, G.; Poor, H.V. Instability detection and prevention in smart grids under asymmetric faults. IEEE Trans. Ind. Appl. 2020, 56, 4510–4520. [Google Scholar] [CrossRef]

- Choi. Y., K. Empirical Research on the efficiency of Floating PV systems compared with Overland PV System. In Proceedings of the 3rd International Conference on Circuits, Control, Communication, Electricity, Electronics, Energy, System, Signal and Simulation (CES-CUBE 2013), Guam, USA, 18–20 July 2013. [Google Scholar]

- Available online: https://www.google.co.in/search?q=Solar+Energy+Industries+Association+and+Wood+Mackenzie&sxsrf=ALiCzsZQi-LxeNa7rccx3Oxk0poszByvKw%3A1667400496859&source=hp&ei=MINiY5ujMcOB2roP67-2As&iflsig=AJiK0e8AAAAAY2KRQM1uKLJCDrqg7QnaWg7LkIEQ-tDr&ved=0ahUKEwib-73y3o_7AhXDgFYBHeufCbsQ4dUDCAg&uact=5&oq=Solar+Energy+Industries+Association+and+Wood+Mackenzie&gs_lp=Egdnd3Mtd2l6uAED-AEC-AEBMgUQABiABDIFEAAYgAQyBRAAGIYDMgUQABiGA0jfCVAAWABwAHgAyAEAkAEAmAHAAaABwAGqAQMwLjE&sclient=gws-wiz (accessed on 15 January 2023).

- Farfan, J.; Breyer, C. Combining Floating Solar Photovoltaic Power Plants and Hydropower Reservoirs a Virtual Battery of Great Global Potential. Energy Procedia 2018, 155, 403–411. [Google Scholar] [CrossRef]

- Mohiddin, M.K.; Dutt, V.B.S.S.I. Routing Path Estimation Based on RWS Method for Competent Energy Dissipation Employing X-Layer Network. Int. J. Recent Technol. Eng. 2019, 8, 6296–6303. [Google Scholar] [CrossRef]

- Makhija, S.P.; Dubey, S.P. Optimally Sized Hybrid Energy System for Auxiliaries of a Cement Manufacturing Unit with Diesel Fuel Price Sensitivity Analysis. Int. J. Ambient. Energy 2016, 38, 267–272. [Google Scholar] [CrossRef]

- Ryu, J.H.; Lee, S.B.; Hodge, B.M.; Lee, I.B. Techno-Economic Simulation Approach in Preparation of Employing Renewable Energies for Process Industry. In Proceedings of the IEEE 43rd Conference on Photovoltaic Specialist, Portland, OR, USA, 5–10 June 2016; pp. 1862–1864. [Google Scholar]

- Siddiquee, S.M.S.; Alam, M.S.; Mortuza, M.K.I.; Reza, H.; Arafat, M.A. Optimized Hybrid Renewable Energy System for Efficient Industrial Electrification. In Proceedings of the IEEE 2nd International Conference on Electrical Engineering and Information & Communication Technology, Dhaka, Bangladesh, 21–23 May 2015; pp. 1–5. [Google Scholar]

- Mishra, R.; Ralhan, S.; Mohiddin, M.K. A Review on Frequency Stability Enhancement and Effective Energy Storage through Various Optimization Techniques. Mob. Inf. Syst. 2022, 2022, 4170938. [Google Scholar] [CrossRef]

- Trapani, K.; Santafe, M.R. A Review of Floating Photovoltaic Installations: 2007–2013. Prog. Photovolt. Res. Appl. 2015, 23, 524–532. [Google Scholar] [CrossRef]

- Sahu, A.; Yadav, N.; Sudhakar, K. Floating Photovoltaic Power Plant: A Review. Renew. Sustain. Energy Rev. 2016, 66, 815–824. [Google Scholar] [CrossRef]

- Pinto, O.S.; Stokkermans, J. Assessment of the potential of different floating solar technologies—Overview and analysis of different case studies. Energy Convers. Manag. 2020, 211, 112747. [Google Scholar] [CrossRef]

- Rosa, C.M.; Tina, G.M. Submerged and Floating Photovoltaic Systems; Academic Press: Boston, MA, USA, 2018; pp. 89–136. [Google Scholar]

- Choi, Y.K. A study on power generation analysis of floating PV system considering environmental impact. Int. J. Softw. Eng. Its Appl. 2014, 8, 75–84. [Google Scholar] [CrossRef]

- Shukla, A.; Shukla, S.P.; Chacko, S.T.; Mohiddin, M.; Fante, K.A. Monitoring of Single-Phase Induction Motor through IoT Using ESP32 Module. J. Sens. 2022, 2022, 8933442. [Google Scholar] [CrossRef]

- Rosa, C.M.; Tina, G.M.; Nizetic, S. Floating photovoltaic plants and wastewater basins: An Australian project. Energy Procedia 2017, 134, 664–674. [Google Scholar] [CrossRef]

- Choi, J.S. Analysis of the Potential for Use of Floating Photovoltaic Systems on Mine Pit Lakes: Case Study at the Ssangyong Open-Pit Limestone Mine in Korea. Energies 2016, 9, 102. [Google Scholar]

- Liu, L.; Wanga, Q.; Lina, H.; Lib, H.; Suna, Q.; Wennerstena, R. Power Generation Efficiency and Prospects of Floating Photovoltaic Systems. In Proceedings of the 8th International Conference on Applied Energy (ICAE2016), Beijing, China, 8–11 October 2016; pp. 1136–1142. [Google Scholar]

- Gisbert, F.C.; Gozalvez, J.J.F.; Santafe, R.M. A new photovoltaic floating cover system for water reservoirs. Renew. Energy 2013, 60, 63–70. [Google Scholar] [CrossRef]

- Green, M.; Emery, K.; Hishikawa, Y. Solar cell efficiency tables (version 40). IEEE Trans. Fuzzy Syst. 2012, 20, 1114–1129. [Google Scholar] [CrossRef]

- Aryani, D.R.; Khairurraziq, T.A.; Ramadhan, G.R.; Wardana, N.S.; Husnayain, F.; Garniwa, I. Simulation of Stand-Alone Floating Photovoltaic and Battery Systems. IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012059. [Google Scholar] [CrossRef]

- Rizvi, T.; Dubey, S.P.; Tripathi, N. Designing of a Feasible Low Pollutant Grid Integrated System for Steel Plant. CSVTU Res. J. 2022, 10, 144–154. [Google Scholar] [CrossRef]

- Zhou, Y.; Chang, F.J.; Chang, L.C.; Lee, W.D.; Huang, A.; Xu, C.Y.; Guo, S. An Advanced Complementary Scheme of Floating Photovoltaic and Hydropower Generation Flourishing Water-Food-Energy Nexus Synergies. Appl. Energy 2020, 275, 115389. [Google Scholar] [CrossRef]

- Lee, N.; Grunwald, U.; Rosenlieb, E.; Mirletz, H.; Aznar, A.; Spencer, R.; Cox, S. Hybrid Floating Solar Photovoltaics-Hydropower Systems Benefits and Global Assessment of Technical Potential. Renew. Energy 2020, 162, 1415–1427. [Google Scholar] [CrossRef]

- Verma, S.; Verma, H.K.; Mohiddin, M.K. Modeling & Analysis of Standalone Photovoltaic System. Int. J. Res. Eng. Technol. 2013, 2, 259–265. [Google Scholar]

- Rizvi, T.; Dubey, S.P.; Tripathi, N. A Comparative Analysis of FSPV-Grid and Grid-Only Systems for an Industrial Subsection. In Proceedings of the IEEE Sponsored Second International Conference on Advances in Electrical, Computing, Communications and Sustainable Technologies (ICAECT 2022), Bhilai, India, 21–22 April 2022. [Google Scholar]

- Rizvi, T.; Dubey, S.P.; Tripathi, N. Reconceptualizing the Application of Renewable Energy Sources in Industry: A Review. Int. Res. J. Eng. Technol. 2022, 9, 514–518. [Google Scholar]

- Nirmal, S.; Rizvi, T. A Review of Renewable Energy Systems for Industrial Applications. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 1740–1745. [Google Scholar] [CrossRef]

- Available online: https://www.psuconnect.in/news/sail-bsp-producing-265-tonnes-of-medcal-oxygen-per-day-24-supply-of-2410-metric-tons-to-chhattisgarh/27461 (accessed on 11 April 2022).

- Sharma, A.K.; Kothari, D.P. Floating Solar Pv Potential In Large Reservoirs In India. Int. J. Innov. Res. Sci. Technol. 2016, 2, 5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).