Energy Potential of Urban Green Waste and the Possibility of Its Pelletization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Climatic Conditions

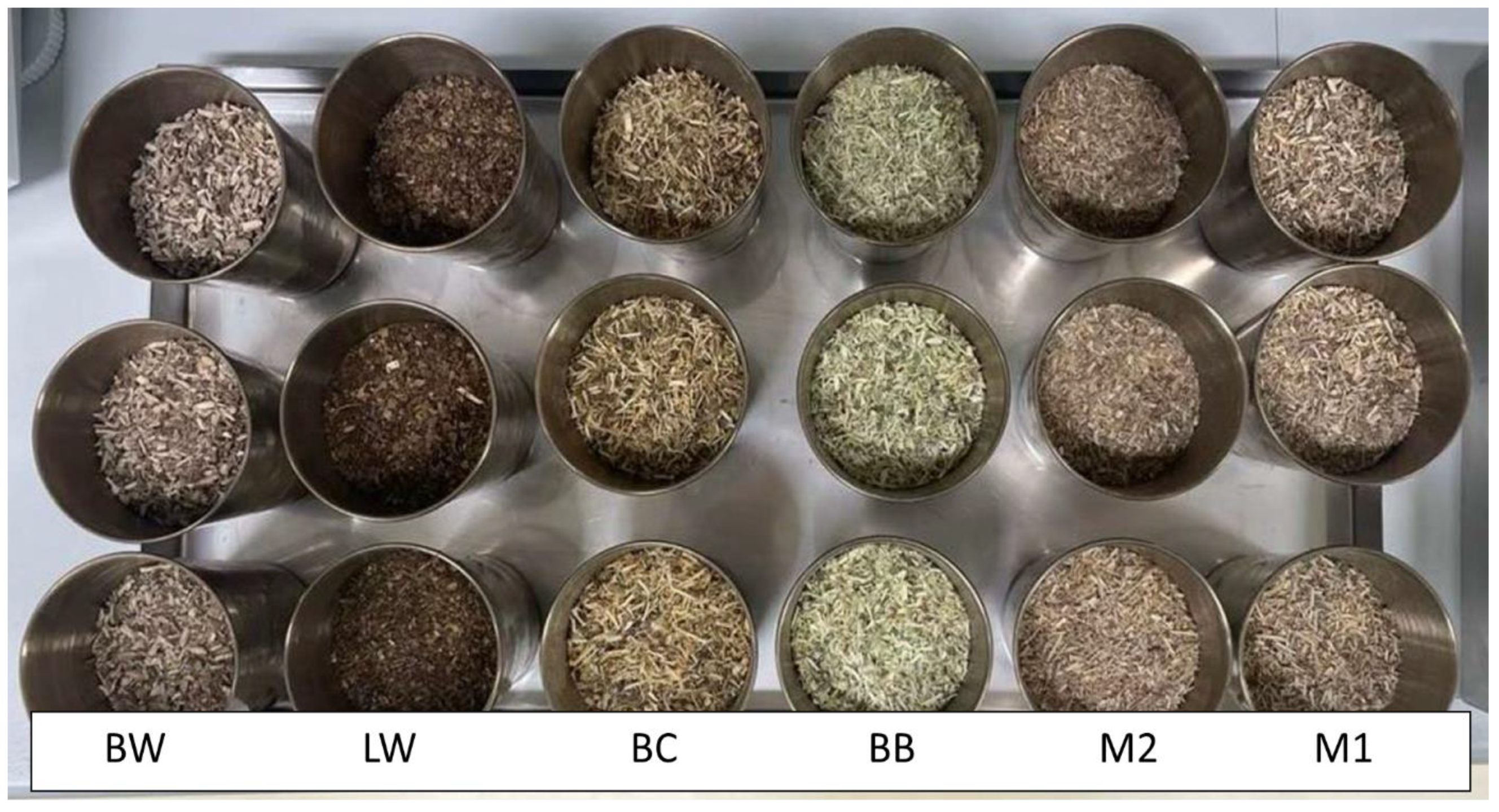

2.2. Samples

2.3. Physical and Chemical Properties

- —LHV of the evaluated sample, MJ·kg−1;

- —HHV of the original sample, MJ·kg−1;

- γ—ratio of evaporation of 1% H2O, MJ·kg−1, at temp. 25 °C, γ = 0.02442 MJ·kg−1;

- 8.94—hydrogen to water conversion ratio of, –;

- —total water content in the original sample, %;

- —total hydrogen content in the original sample, %.

2.4. Determination of Carbon, Hydrogen and Nitrogen

2.5. Determination of the Content of Major and Minor Elements, Total Sulphur, and Total Chlorine

2.6. Pellet Production

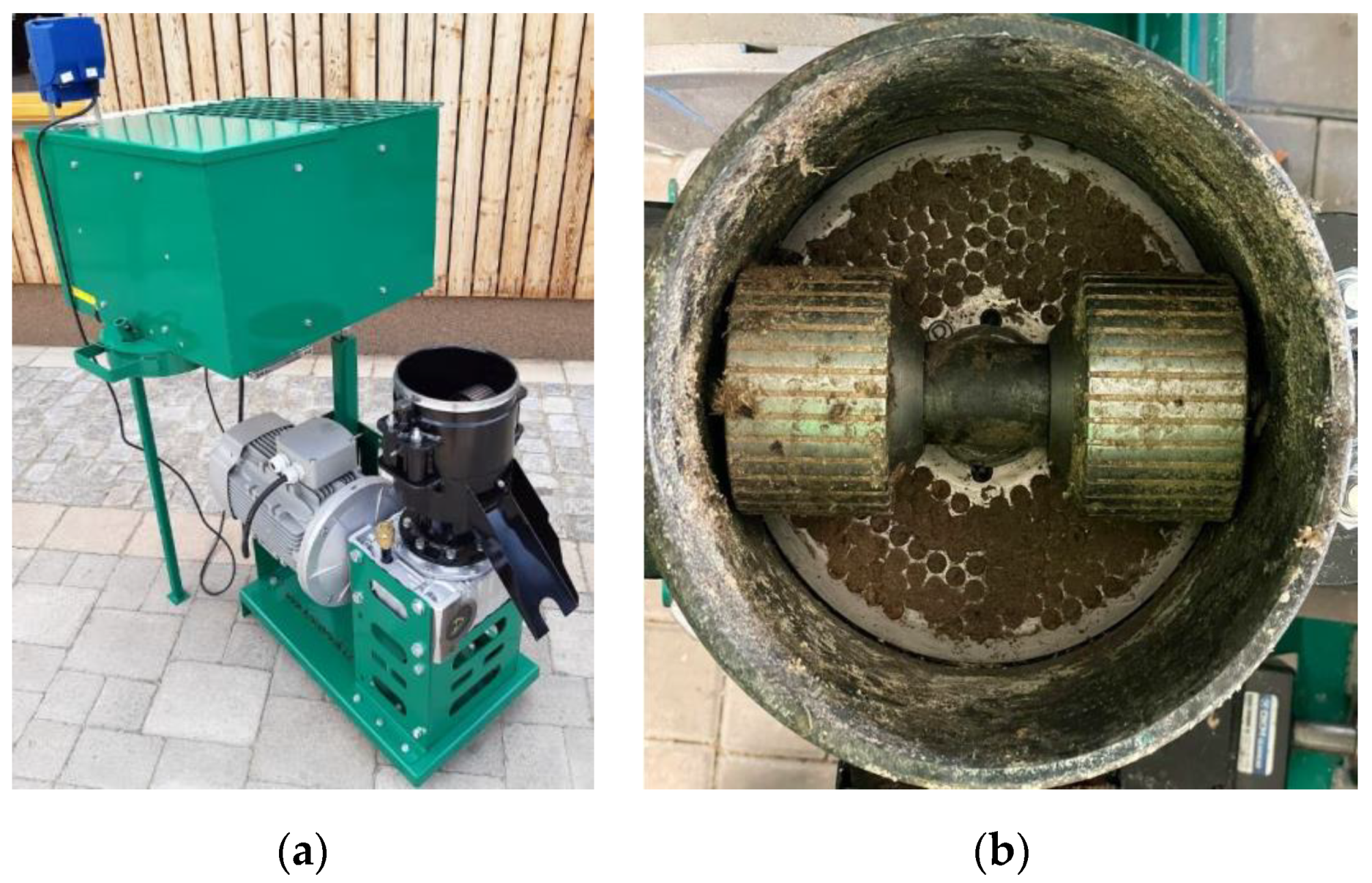

2.7. Evaluated of the Pellets Parameters

2.8. Methods of Statistical Analysis

3. Results and Discussion

3.1. Biomass Potential

3.1.1. Moisture

3.1.2. Bulk Density

3.1.3. Ash Content

3.1.4. Higher Heating Value

3.1.5. Chemical Composition

3.1.6. Heavy Metal Content

3.2. Pellet Production Process

3.2.1. Moisture and Pelletization

3.2.2. Mechanical Durability

3.2.3. Pellets Dimensions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The EU’s Energy Dependence: Facts and Figures. Available online: https://www.europarl.europa.eu/news/en/headlines/economy/20140718STO53032/the-eu-s-energy-dependence-facts-and-figures (accessed on 14 September 2023).

- Mandley, S.J.; Wicke, B.; Junginger, M.; van Vuuren, D.P.; Daioglou, V. The implications of geopolitical, socioeconomic, and regulatory constraints on European bioenergy imports and associated greenhouse gas emissions to 2050. Biofuels Bioprod. Biorefin. 2022, 16, 1551–1567. [Google Scholar] [CrossRef]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02018L2001-20220607 (accessed on 15 September 2023).

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021DC0550 (accessed on 14 September 2023).

- REPowerEU: Joint European Action for more Affordable, Secure and Sustainable Energy. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_22_1511 (accessed on 15 September 2023).

- Raj, T.; Sompura, S.; Chandrasekhar, K.; Singh, S.K.; Pandey, S.; Singh, L.K.; Rajput, M.S.; Kumar, D.; Bhatia, S.K.; Patel, A.K.; et al. Technology development and challenges for the transformation of municipal solid waste into sustainable energy production. Biomass Bioenerg. 2023, 178, 15. [Google Scholar] [CrossRef]

- Cesprini, E.; Resente, G.; Causin, V.; Urso, T.; Cavalli, R.; Zanetti, M. Energy recovery of glued wood waste—A review. Fuel 2020, 262, 116520. [Google Scholar] [CrossRef]

- Boldrin, A.; Christensen, T.H. Seasonal generation and composition of garden waste in Aarhus (Denmark). Waste Manag. 2010, 30, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Mahajani, S. Kinetic studies in pyrolysis of garden waste in the context of downdraft gasification: Experiments and modeling. Energy 2020, 208, 118427. [Google Scholar] [CrossRef]

- Petlickait, R.; Jasinskas, A.; Domeika, R.; Pedisius, N.; Lemanas, E.; Praspaliauskas, M.; Kukharets, S. Evaluation of the Processing of Multi-Crop Plants into Pelletized Biofuel and Its Use for Energy Conversion. Processes 2023, 11, 421. [Google Scholar] [CrossRef]

- Karkania, V.; Fanara, E.; Zabaniotou, A. Review of sustainable biomass pellets production–A study for agricultural residues pellets’ market in Greece. Renew. Sustain. Energy Rev. 2012, 16, 1426–1436. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory, 2nd ed.; Elsevier: London, UK, 2013; pp. 1–530. [Google Scholar]

- Kovacs, E.; Hoaghia, M.-A.; Senila, L.; Scurtu, D.A.; Varaticeanu, C.; Roman, C.; Dumitras, D.E. Life Cycle Assessment of Biofuels Production Processes in Viticulture in the Context of Circular Economy. Agronomy 2022, 12, 1320. [Google Scholar] [CrossRef]

- Flach, B.; Bolla, S. European Union: EU Wood Pellet Annual; E42022-0049; European Union: Maastricht, The Netherlands, 2022. [Google Scholar]

- Moreira, B.R.D.A.; Viana, R.D.S.; Cruz, V.H.; Magalhães, A.C.; Miasaki, C.T.; Figueiredo, P.A.M.D.; Lisboa, L.A.M.; Ramos, S.B.; Sánchez, D.E.J.; Teixeira Filho, M.C.M.; et al. Second-Generation Lignocellulosic Supportive Material Improves Atomic Ratios of C:O and H:O and Thermomechanical Behavior of Hybrid Non-Woody Pellets. Molecules 2020, 25, 4219. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. Factors affecting the quality of fuel pellets produced from waste biomass. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012013. [Google Scholar] [CrossRef]

- Bailis, R.; Drigo, R.; Ghilardi, A.; Masera, O. The carbon footprint of traditional woodfuels. Nat. Clim. Change 2015, 5, 266–272. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew. Sustain. Energy Rev. 2015, 45, 359–378. [Google Scholar] [CrossRef]

- Chen, W.-H.; Peng, J.; Bi, X.T. A state-of-the-art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Zhai, M.; Li, X.; Yang, D.; Ma, Z.; Dong, P. Ash fusion characteristics of biomass pellets during combustion. J. Clean. Prod. 2022, 336, 130361. [Google Scholar] [CrossRef]

- García-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Holubcik, M.; Durcansky, P.; Jandacka, J.; Najser, J.; Klacko, A. Novel Design for Rotary Burner for Low-Quality Pellets. Appl. Sci. 2023, 13, 3053. [Google Scholar] [CrossRef]

- The Weather Pattern in Lednice-Online. Available online: http://a.la-a.la/chart/cl.php?probe=11359248 (accessed on 13 September 2023).

- Chaloupková, V.; Ivanova, T.; Havrland, B. Sieve analysis of biomass: Accurate method for determination of particle size distribution. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 25–27 May 2016; pp. 1012–1017. [Google Scholar]

- ISO 17828; Solid Biofuels—Determination of Bulk Density. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 18134-2; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 18122; Solid Biofuels—Determination of Ash Content. ISO (International Organization for Standardization): Geneva, Switzerland, 2022.

- ISO 18125; Solid Biofuels—Determination of Calorific Value. ISO (International Organization for Standardization): Geneva, Switzerland, 2017.

- ISO 1928; Coal and Coke—Determination of Gross Calorific Value. ISO (International Organization for Standardization): Geneva, Switzerland, 2020.

- ISO 16948; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 16967; Solid Biofuels—Determination of Major Elements—Al, Ca, Fe, Mg, P, K, Si, Na and Ti. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 16968; Solid Biofuels—Determination of Minor Elements. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- ISO 16994; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. ISO (International Organization for Standardization): Geneva, Switzerland, 2016.

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Younis, M.; Alnouri, S.Y.; Abu Tarboush, B.J.; Ahmad, M.N. Renewable biofuel production from biomass: A review for biomass pelletization, characterization, and thermal conversion techniques. Int. J. Green Energy 2018, 15, 837–863. [Google Scholar] [CrossRef]

- ISO 17831-1; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes—Part 1: Pellets. ISO (International Organization for Standardization): Geneva, Switzerland, 2015.

- Chaloupková, V.; Ivanova, T.; Krepl, V. Particle size and shape characterization of feedstock material for biofuel production. Agron. Res. 2019, 17, 1861–1873. [Google Scholar] [CrossRef]

- Tanoh, T.S.; Ait Oumeziane, A.; Lemonon, J.; Escudero Sanz, F.J.; Salvador, S. Green Waste/Wood Pellet Pyrolysis in a Pilot-Scale Rotary Kiln: Effect of Temperature on Product Distribution and Characteristics. Energy Fuels 2020, 34, 3336–3345. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. Pilot scale evaluation of fuel pellets production from garden waste biomass. Energy Sustain. Dev. 2018, 43, 1–14. [Google Scholar] [CrossRef]

- Poddar, S.; Kamruzzaman, M.; Sujan, S.M.A.; Hossain, M.; Jamal, M.S.; Gafur, M.A.; Khanam, M. Effect of compression pressure on lignocellulosic biomass pellet to improve fuel properties: Higher heating value. Fuel 2014, 131, 43–48. [Google Scholar] [CrossRef]

- Eisenbies, M.H.; Volk, T.A.; Therasme, O.; Hallen, K. Three bulk density measurement methods provide different results for commercial scale harvests of willow biomass chips. Biomass Bioenergy 2019, 124, 64–73. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Chwedoruk, K. Bulk density of forest energy chips. Ann. Wars. Univ. Life Sci. SGGW Agricult. 2016, 67, 101–111. [Google Scholar]

- Cousin, B.; Lekounougou, S.-T. Initial moisture content, bulk density, bulk porosity and desorption isotherm of wood chips from five species of the boreal forest. Wood Mater. Sci. Eng. 2021, 16, 229–236. [Google Scholar] [CrossRef]

- Nasrin, A.B.; Loh, S.K.; Sukiran, M.A.; Bukhari, N.A.; Aziz, A.A.; Lim, J.; Lim, S.; Chin, E. Production and Characterization of Low-Ash Empty Fruit Bunches Pellets as a Solid Biofuel. BioEnergy Res. 2022, 15, 517–529. [Google Scholar] [CrossRef]

- Kongprasert, N.; Wangphanich, P.; Jutilarptavorn, A. Charcoal Briquettes from Madan Wood Waste as an Alternative Energy in Thailand. Procedia Manuf. 2019, 30, 128–135. [Google Scholar] [CrossRef]

- Nasrin, A.B.; Vijaya, S.; Loh, S.K.; Astimar, A.A.; Lim, W.S. Quality compliance and environmental impact assessment of commercial empty fruit bunch (EFB) pellet fuel in Malaysia. J. Oil Palm Res. 2017, 29, 570–578. [Google Scholar] [CrossRef]

- ISO 17225-2; Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets. ISO (International Organization for Standardization): Geneva, Switzerland, 2021.

- ISO 17225-6; Solid Biofuels—Fuel Specifications and Classes—Part 6: Graded Non-Woody Pellets. ISO (International Organization for Standardization): Geneva, Switzerland, 2021.

- Hays, M.D.; Geron, C.D.; Linna, K.J.; Smith, N.D.; Schauer, J.J. Speciation of Gas-Phase and Fine Particle Emissions from Burning of Foliar Fuels. Environ. Sci. Technol. 2002, 36, 2281–2295. [Google Scholar] [CrossRef]

- Volpe, M.; Messineo, A.; Mäkelä, M.; Barr, M.R.; Volpe, R.; Corrado, C.; Fiori, L. Reactivity of cellulose during hydrothermal carbonization of lignocellulosic biomass. Fuel Process. Technol. 2020, 206, 106456. [Google Scholar] [CrossRef]

- Ipiales, R.P.; Mohedano, A.F.; Diaz, E.; de la Rubia, M.A. Energy recovery from garden and park waste by hydrothermal carbonisation and anaerobic digestion. Waste Manag. 2022, 140, 100–109. [Google Scholar] [CrossRef]

- Bassam, N.E. Handbook of Bioenergy Crops: A Complete Reference to Species, Development and Application; International Institute for Environment and Development: London, UK, 2010; Volume 47, p. 516. [Google Scholar]

- Liu, Z.; Quek, A.; Kent Hoekman, S.; Balasubramanian, R. Production of solid biochar fuel from waste biomass by hydrothermal carbonization. Fuel 2013, 103, 943–949. [Google Scholar] [CrossRef]

- Raveendran, K.; Ganesh, A.; Khilar, K.C. Influence of mineral matter on biomass pyrolysis characteristics. Fuel 1995, 74, 1812–1822. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y.; Zhi, D.; Lin, Y.; He, K.; Liu, B.; Mao, H. Assessment of combustion and emission behavior of corn straw biochar briquette fuels under different temperatures. J. Environ. Manag. 2019, 250, 109399. [Google Scholar] [CrossRef] [PubMed]

- Niemiec, M. The Content of Lead, Cadmium and Mercury in Sediments from Rainwater Reservoirs Situated Along the National Road 4. Chem. Didact. Ecol. Metrol. 2016, 20, 75–83. [Google Scholar] [CrossRef]

- Terzopoulou, P.; Kamperidou, V.; Lykidis, C. Cypress Wood and Bark Residues Chemical Characterization and Utilization as Fuel Pellets Feedstock. Forests 2022, 13, 1303. [Google Scholar] [CrossRef]

- Hussein, A.O.; Nozdrovicky, L.; Macak, M.; Maga, J. Effect of die diameter and pressure force on the characteristics of pellets. In Proceedings of the 5th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 3–6 September 2013; pp. 228–233. [Google Scholar]

- Pawłowska, M.; Bielińska, E.J.; Kasprzycka, A. Influence of Storage Conditions on a Quality of Pelletized Waste-Derived Fertilizer. J. Ecol. Eng. 2019, 20, 226–233. [Google Scholar] [CrossRef]

- Gilvari, H.; De Jong, W.; Schott, D.L. The Effect of Biomass Pellet Length, Test Conditions and Torrefaction on Mechanical Durability Characteristics According to ISO Standard 17831-1. Energies 2020, 13, 3000. [Google Scholar] [CrossRef]

| ID | LW | BW | BB | BC | M1 | M2 |

|---|---|---|---|---|---|---|

| Sample/ Parameter (Unit) | Walnut Leaves | Walnut Branches | Black Locust Branches | Common Apricot Branches | Mixture 1 Branches | Mixture 2 Perennials |

| Moisture at collection (%) | 27.83 ± 1.75 d | 10.86 ± 0.26 a | 13.47 ± 0.09 b | 16.06 ± 0.22 c | 9.21 ± 0.06 a | 10.00 ± 0.39 a |

| HHV (MJ·kg−1) * moisture at 10% | 12.49 ± 0.74 c | 17.67 ± 0.11 a | 17.12 ± 0.09 ab | 16.35 ± 0.08 b | 17.4 ± 0.07 a | 17.09 ± 0.16 ab |

| LHV (MJ·kg−1) | 11.32 ± 0.69 c | 16.15 ± 0.09 a | 15.61 ± 0.07 ab | 14.85 ± 0.06 b | 15.97 ± 0.05 a | 15.60 ± 0.13 ab |

| Bulk density (kg·m−3 wt) | 140.31 ± 11.78 a | 242.82 ± 3.14 d | 173.97 ± 3.68 c | 196.61 ± 7.22 b | 201.57 ± 9.93 b | 131.45 ± 4.46 a |

| Ash (wt%) | 28.05 ± 1.32 c | 5.41 ± 2.40 ab | 3.02 ± 0.23 a | 7.2 ± 1.79 ab | 5.96 ± 1.49 ab | 9.49 ± 1.33 b |

| C (wt%, dry matter) | 37.49 | 49.02 | 48.01 | 47.73 | 46.81 | 47.98 |

| H (wt%, dry matter) | 4.23 | 5.88 | 5.79 | 5.73 | 5.43 | 5.67 |

| O (wt%, dry matter) | 28.56 | 38.55 | 41.76 | 37.40 | 40.69 | 35.62 |

| N (wt%, dry matter) | 1.34 | 0.94 | 1.21 | 1.72 | 0.80 | 0.91 |

| O:C | 0.76 | 0.79 | 0.87 | 0.78 | 0.87 | 0.74 |

| ID | LW | BW | BB | BC | M1 | M2 |

|---|---|---|---|---|---|---|

| Sample /Elements (mg·kg−1) | Walnut Leaves | Walnut Branches | Black Locust Branches | Common Apricot Branches | Mixture 1 Branches | Mixture 2 Perennials |

| Cd | 10.61 ± 0.92 | 12.39 ± 3.27 | 17.16 ± 2.25 | 16.96 ± 2.51 | 13.06 ± 1.63 | 12.23 ± 2.50 |

| Pd | nd | 5.33 ± 0.55 | nd | nd | 4.77 ± 0.57 | 5.18 ± 0.82 |

| Mo | 4.23 ± 0.22 | 5.53 ± 0.75 | 7.12 ± 0.05 | 6.28 ± 0.77 | 6.03 ± 0.30 | 6.41 ± 0.43 |

| Nb | 6.93 ± 0.36 | 6.6 ± 0.55 | 8.07 ± 1.19 | 8.87 ± 0.34 | 7.45 ± 0.96 | 7.5 ± 1.48 |

| Zr | 34.76 ± 0.85 | 5.47 ± 0.47 | 7.06 ± 1.69 | 6.68 ± 0.83 | 8.59 ± 0.51 | 15.87 ± 0.70 |

| Sr | 106.53 ± 1.05 | 45.48 ± 0.19 | 64.74 ± 1.42 | 47.58 ± 1.30 | 29.7 ± 0.81 | 35.64 ± 0.49 |

| Rb | 8.7 ± 0.29 | 2.84 ± 0.17 | 2.35 ± 0.47 | 7.57 ± 0.09 | 4.41 ± 0.37 | 2.93 ± 0.13 |

| Ti | 873.47 ± 21.37 | 44.92 ± 1.09 | 84.12 ± 3.55 | 84.4 ± 4.95 | 95.51 ± 16.89 | 249.77 ± 12.93 |

| Al | 1313.48 ± 286.71 | nd | nd | nd | nd | 523.28 ± 175.98 |

| Si | 17,613.75 ± 301.2 | 1813.69 ± 31.8 | 3754.1 ± 134.1 | 2848.18 ± 91.0 | 18,888.11 ± 244.4 | 31,076.83 ± 505.1 |

| K | 29,526.37 ± 433.3 | 11,776.67 ± 89.6 | 17,264.06 ± 254.5 | 25,069.97 ± 507.4 | 19,498.66 ± 165.0 | 26,804.84 ± 133.1 |

| P | 1137.55 ± 152.6 | 1220.13 ± 86.3 | 2243.13 ± 169.3 | 2344.26 ± 140.1 | 2431.09 ± 113.2 | 3542.42 ± 118.0 |

| Ca | 87,665.85 ± 1051.0 | 36,475.24 ± 147.4 | 40,163.07 ± 244.3 | 45,371.12 ± 710.7 | 20,635.21 ± 69.7 | 37,377.25 ± 267.3 |

| S | 4341.74 ± 75.33 | 1587.02 ± 15.64 | 3690.75 ± 39.90 | 3119.35 ± 49.08 | 3504.57 ± 60.99 | 4361.53 ± 54.27 |

| Cl | 5863.12 ± 53.14 | 371.34 ± 2.22 | 1221.23 ± 21.88 | 378.5 ± 20.99 | 3308.04 ± 30.19 | 5680.75 ± 88.63 |

| Fe | 9483.38 ± 47.55 | nd | 266.75 ± 30.33 | 91.57 ± 22.96 | 537.45 ± 21.29 | 1717.2 ± 46.76 |

| Zn | 92.02 ± 3.33 | nd | 22.78 ± 1.08 | 19.2 ± 0.39 | 14.17 ± 0.49 | 35.94 ± 4.65 |

| Ag | 6.61 ± 0.46 | 5.08 ± 0.06 | 6.03 ± 0.08 | 5.39 ± 1.28 | 4.85 ± 1.47 | 5.77 ± 1.05 |

| ID | LW | BW | BB | BC | M1 | M2 |

|---|---|---|---|---|---|---|

| Sample | Walnut Leaves | Walnut Branches | Black Locust Branches | Common Apricot Branches | Mixture 1 Branches | Mixture 2 Perennials |

| Moisture after pelletization (%) | 11.54 ± 0.73 c | 8.34 ± 0.37 ab | 7.74 ± 0.2 a | 7.53 ± 0.5 a | 9.55 ± 0.16 b | 11.13 ± 0.68 c |

| Mechanical durability (%) | 96.26 ± 0.37 b | 98.64 ± 0.09 a | 98.80 ± 0.14 a | 98.49 ± 0.14 a | 98.02 ± 0.29 a | 96.99 ± 0.48 b |

| Diameter (mm) | 6.16 ± 0.2 b | 6.57 ± 0.18 a | 6.55 ± 0.21 a | 6.68 ± 0.22 a | 6.61 ± 0.15 a | 6.13 ± 0.17 b |

| Length (mm) | 10.02 ± 2.87 d | 17.58 ± 2.7 ab | 17.01 ± 3.12 ab | 15.64 ± 3.42 a | 20.29 ± 2.12 c | 19.26 ± 1.77 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mašán, V.; Burg, P.; Souček, J.; Slaný, V.; Vaštík, L. Energy Potential of Urban Green Waste and the Possibility of Its Pelletization. Sustainability 2023, 15, 16489. https://doi.org/10.3390/su152316489

Mašán V, Burg P, Souček J, Slaný V, Vaštík L. Energy Potential of Urban Green Waste and the Possibility of Its Pelletization. Sustainability. 2023; 15(23):16489. https://doi.org/10.3390/su152316489

Chicago/Turabian StyleMašán, Vladimír, Patrik Burg, Jiří Souček, Vlastimil Slaný, and Lukáš Vaštík. 2023. "Energy Potential of Urban Green Waste and the Possibility of Its Pelletization" Sustainability 15, no. 23: 16489. https://doi.org/10.3390/su152316489