The Partially Drained Behaviour of Dense Fibre-Reinforced Sands

Abstract

:1. Introduction

2. Materials and Methods

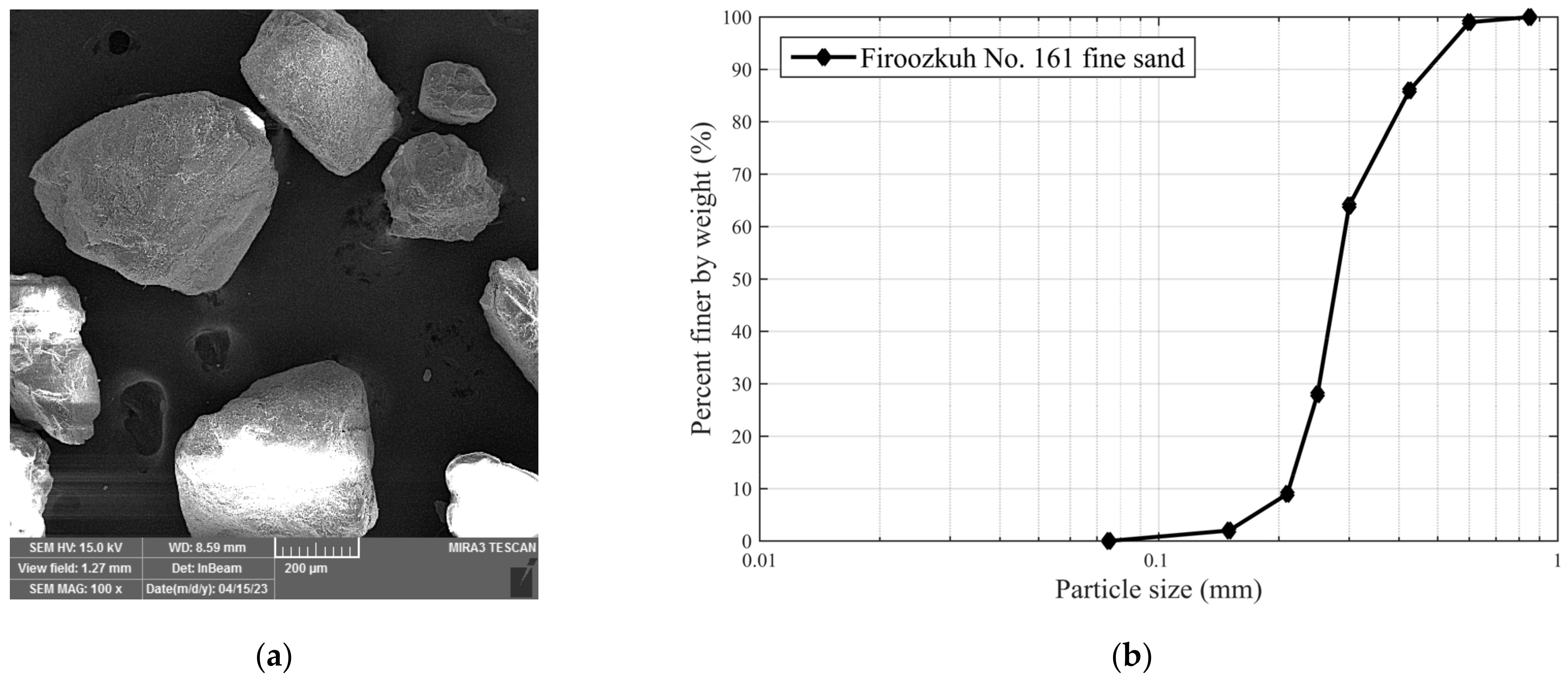

2.1. Sand and Employed Polypropylene Fibres

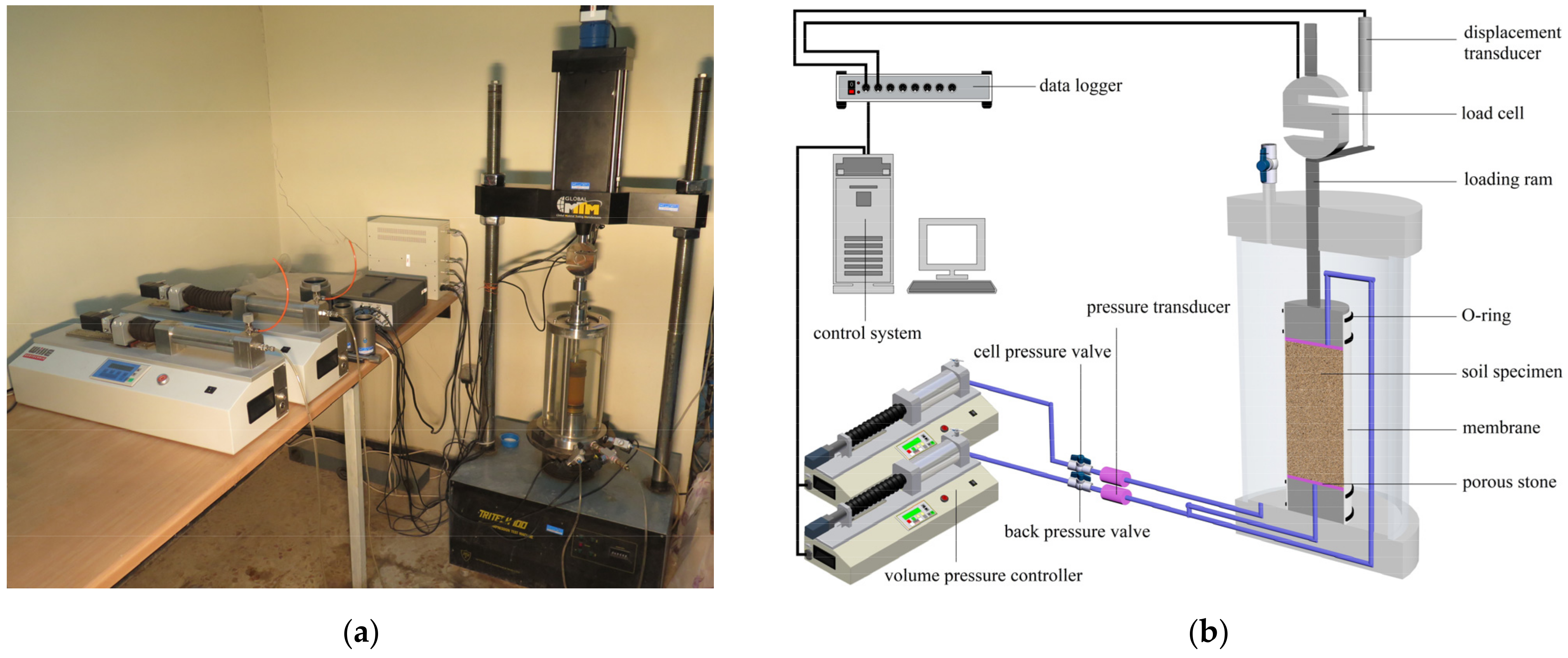

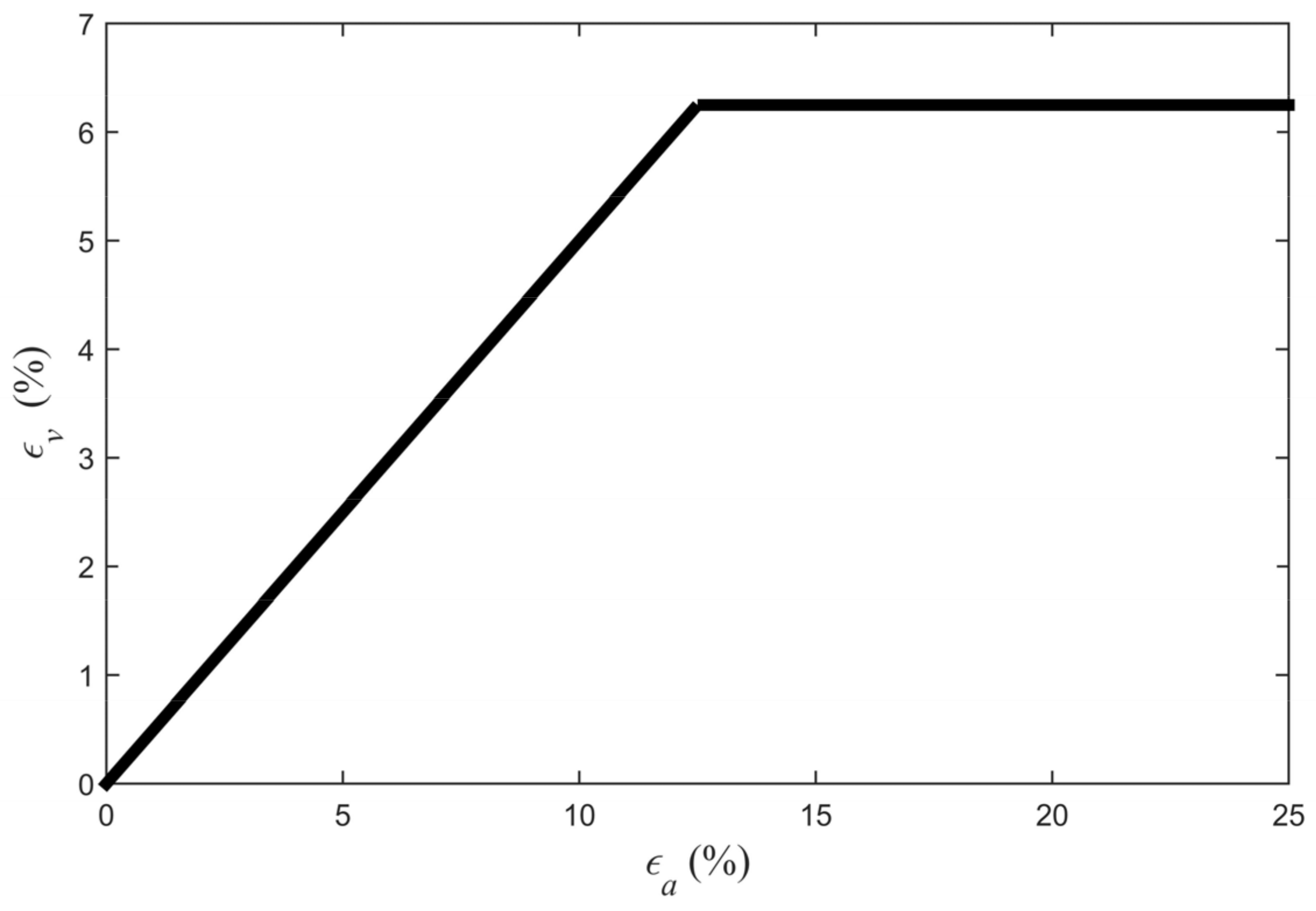

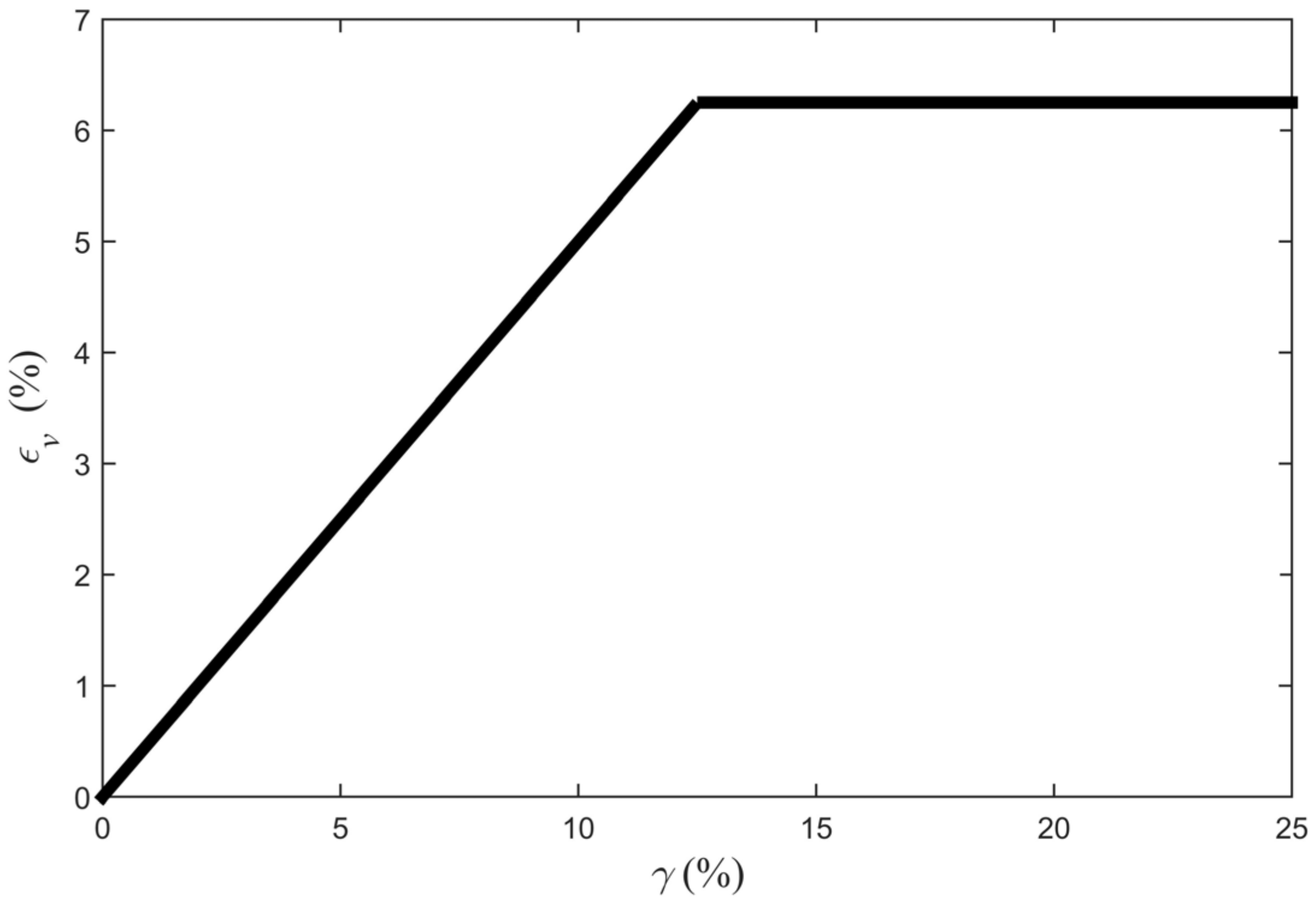

2.2. The Triaxial Shear Test Apparatus and Applied Paths

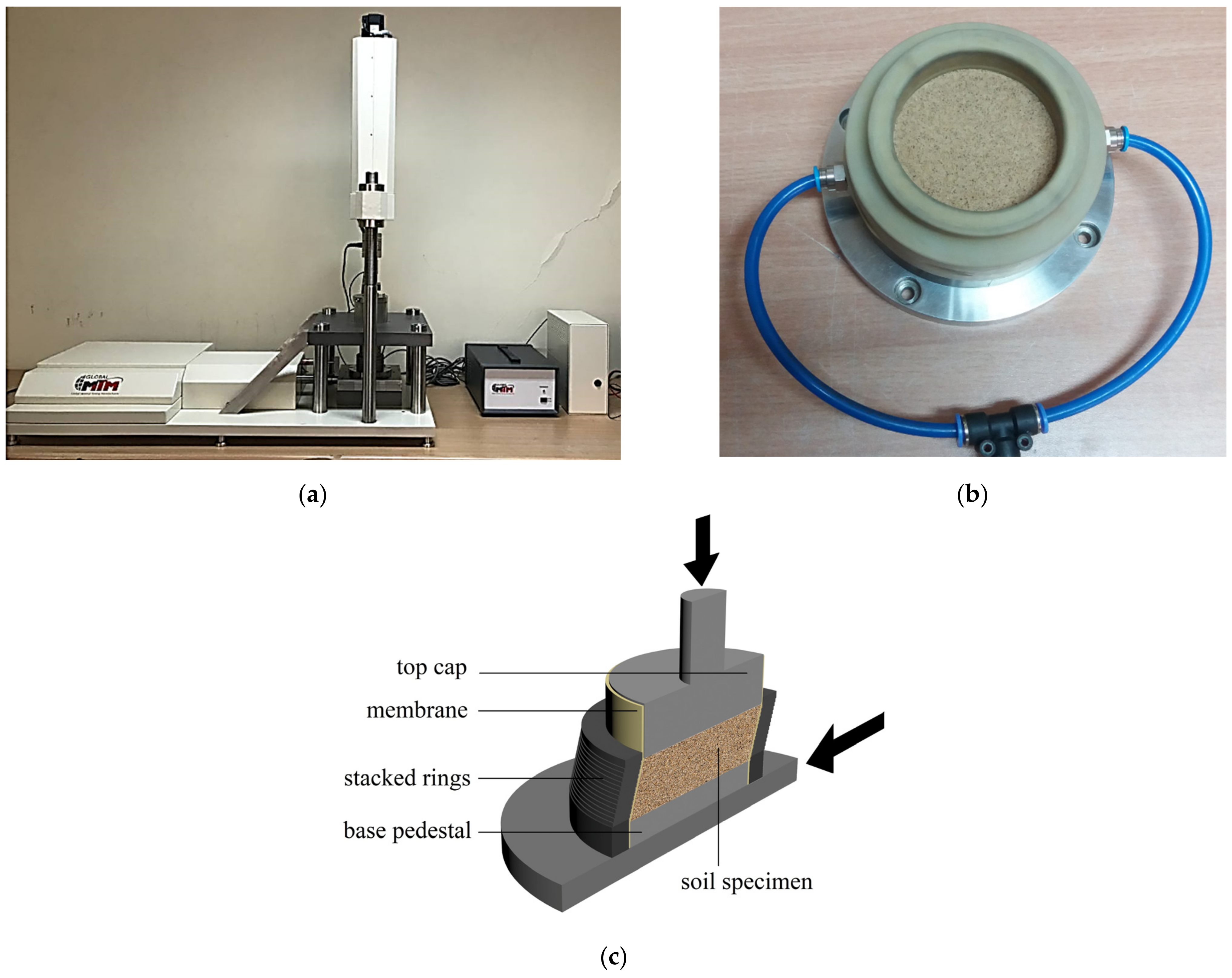

2.3. The Direct Simple Shear Test Apparatus and Applied Paths

3. Results and Discussion

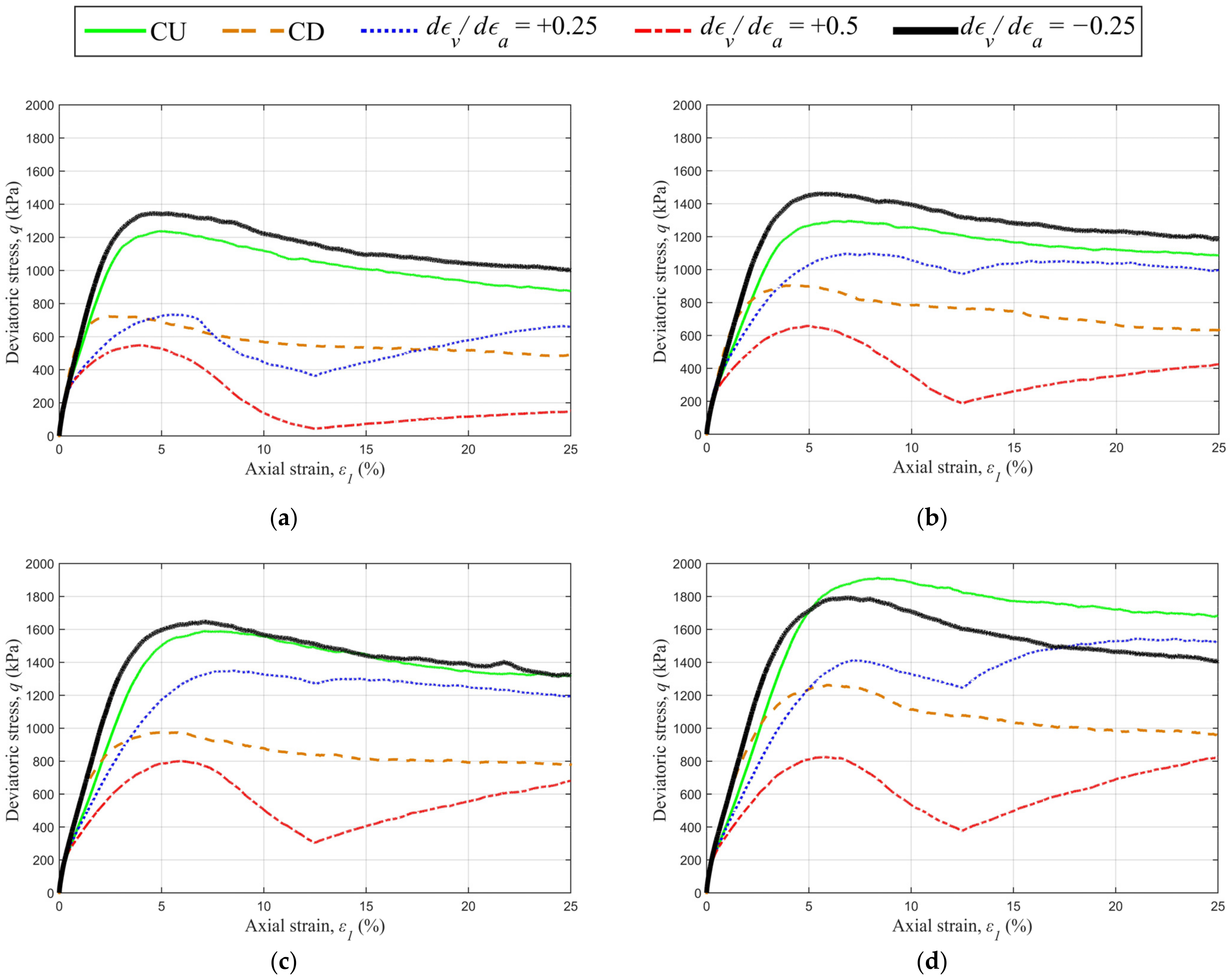

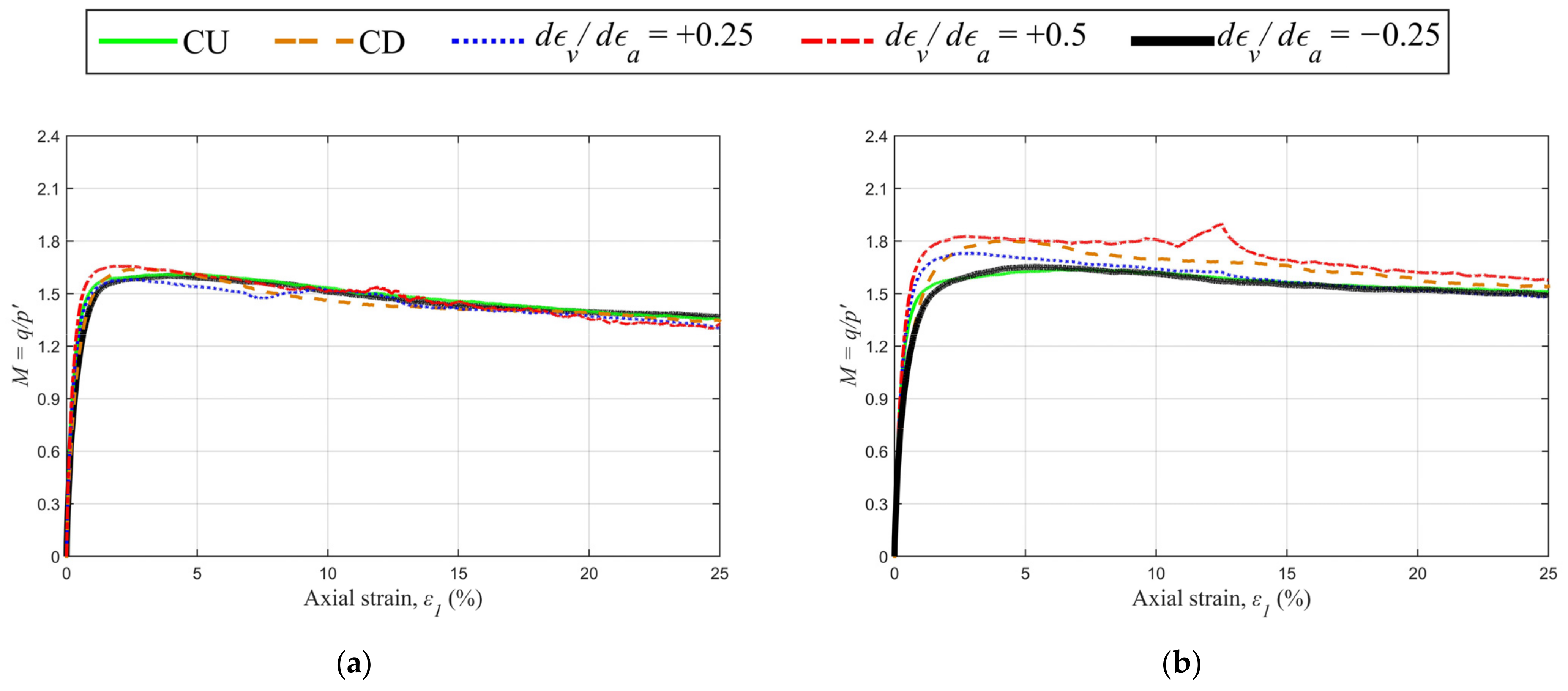

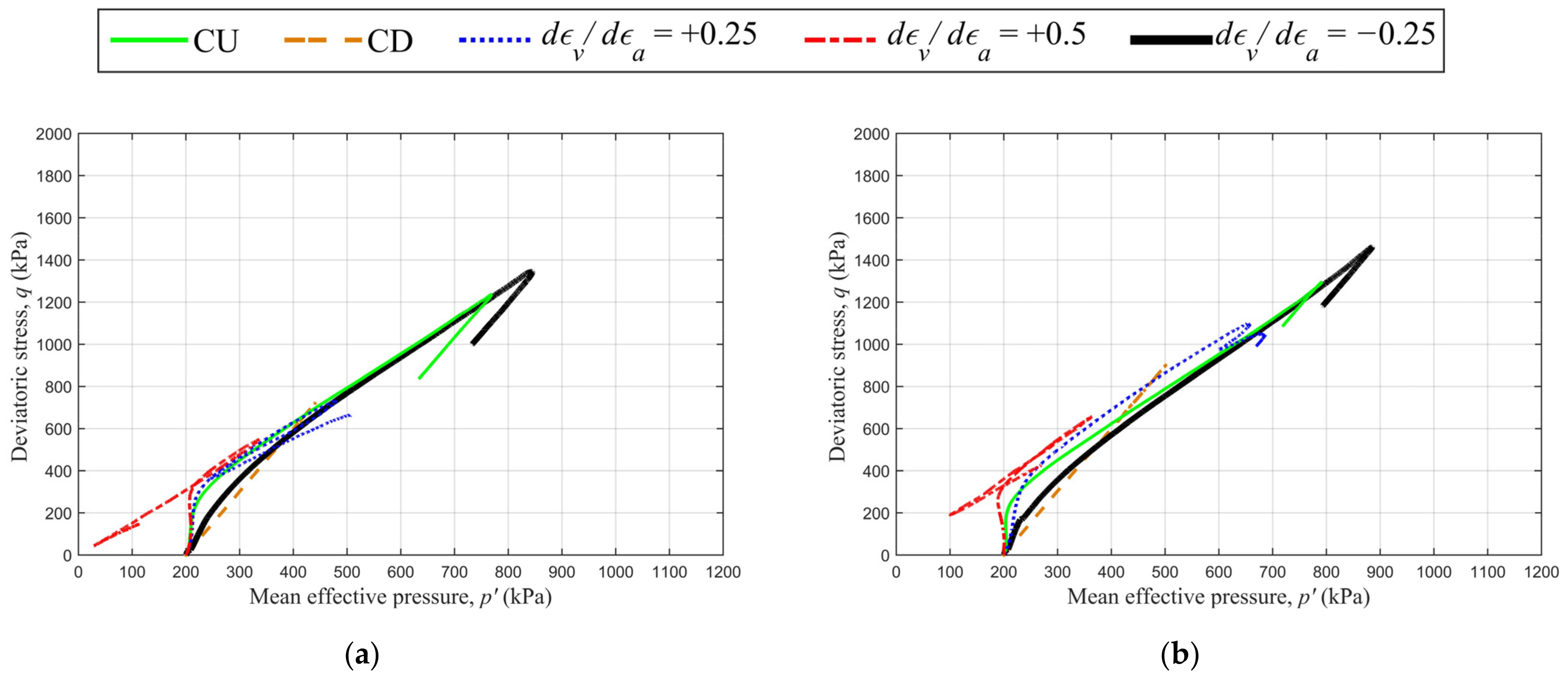

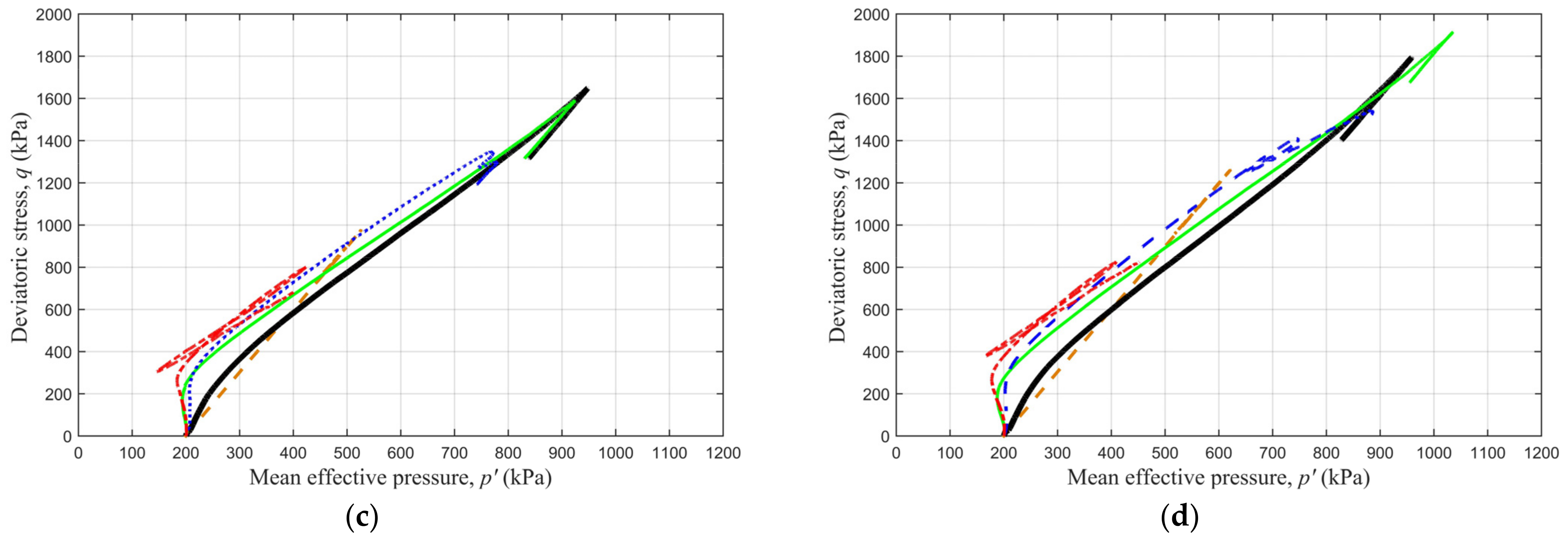

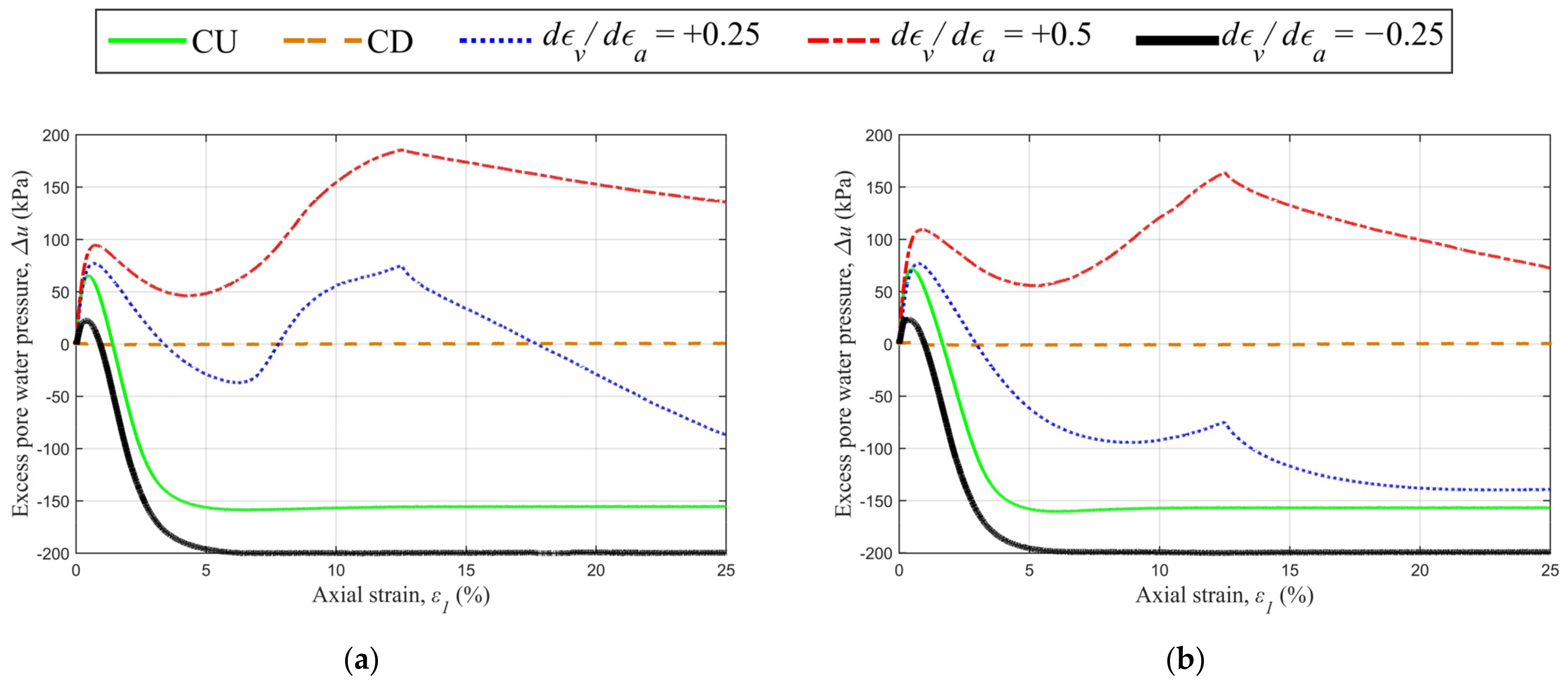

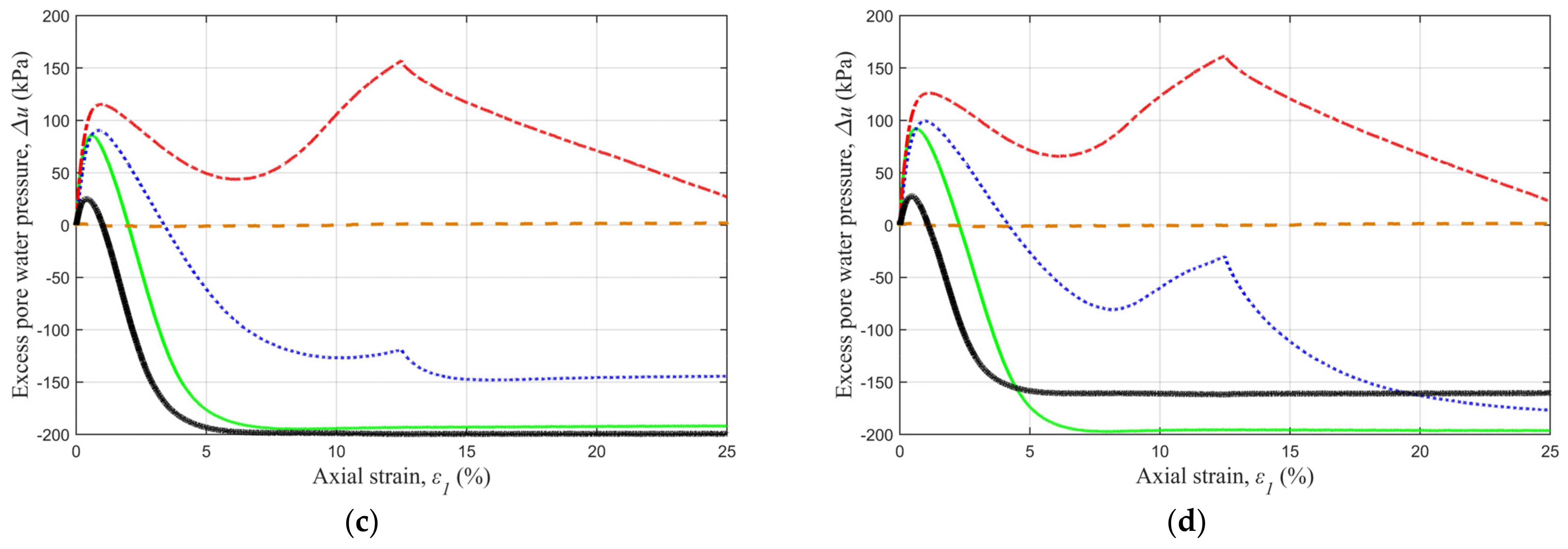

3.1. Findings from the Triaxial Shear (TX) Tests

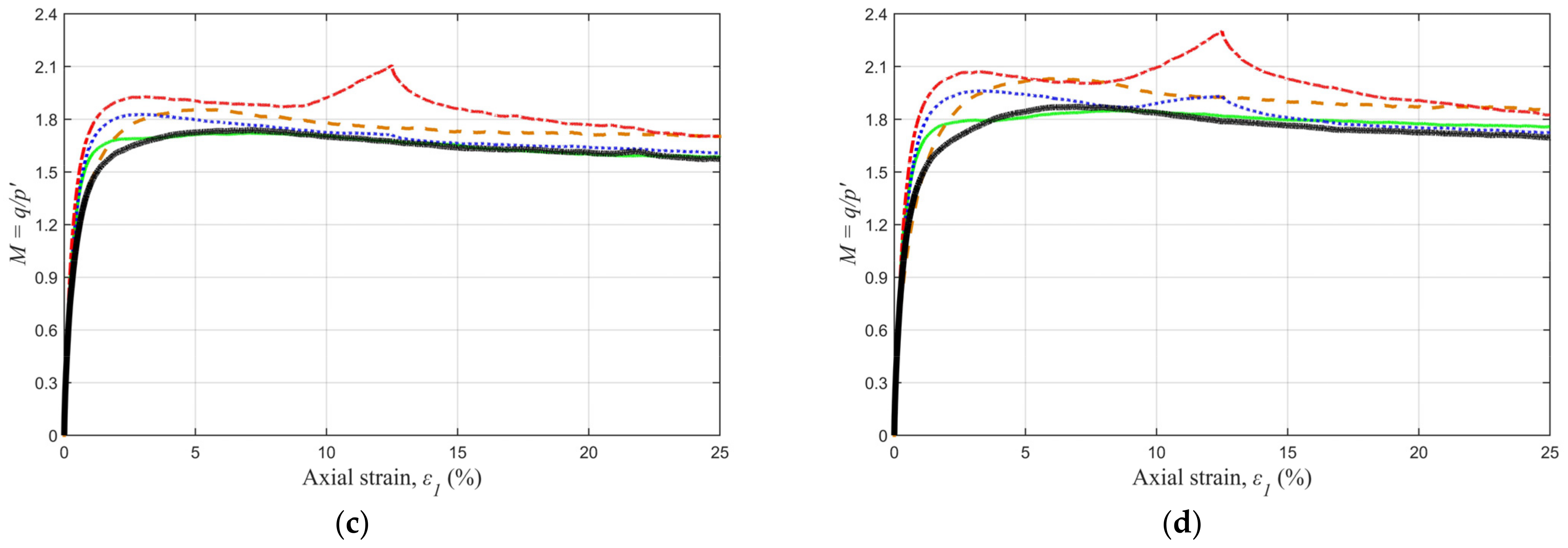

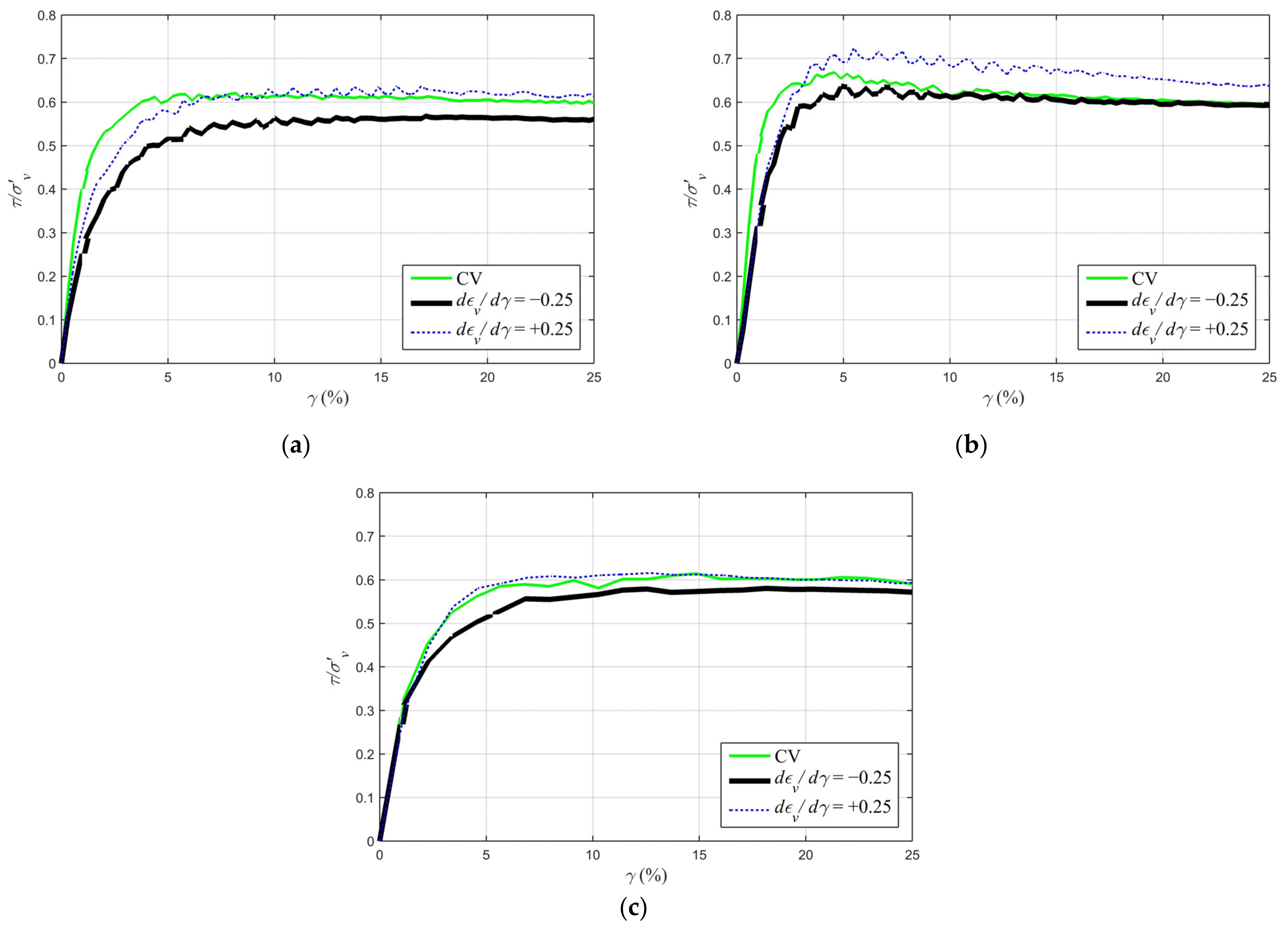

3.2. Findings from the Direct Simple Shear Tests (DSS)

4. Conclusions

- The experienced strain path significantly influences the ultimate and peak stress states of both clean and fibre-reinforced sands. Contractive strain paths result in higher peak deviatoric stress (dεv/dεa = −0.25% strain path led to 13.6% larger peak deviatoric stress in clean sand), while expansive strain paths yield lower peak deviatoric stress (dεv/dεa = +0.25% led to 82.72% lower peak deviatoric stress) compared to conventional CD tests.

- In clean sand, experienced strain paths have no impact on the ultimate stress ratio. However, an increase in fibre content in samples undergoing expansive strain paths leads to an elevated ultimate stress ratio. Clean sand exhibits an average ultimate stress ratio of 1.33, but as the fibre content increases to 0.25%, 0.5%, and 1%, the average ultimate stress ratio also rises to 1.53, 1.64, and 1.75, respectively.

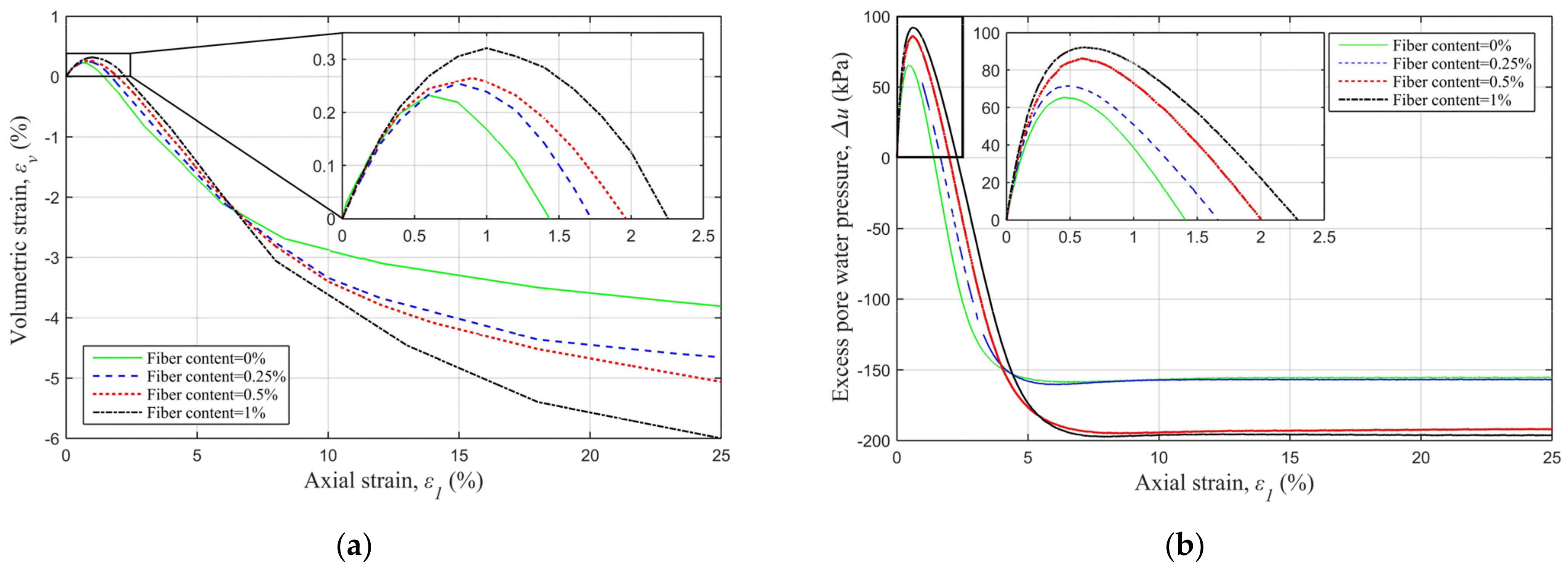

- With an elevated fibre content, samples display a more pronounced volume reduction at initial axial strains and a more significant increase in volume at larger strains. Moreover, the increased fibre content results in a phase transition occurring at a greater axial strain.

- In dense sands, the ultimate stress ratios under the TX shear mode exhibit limited sensitivity to the applied strain path. However, under the DSS path, greater sensitivity becomes apparent. Under the TX shear mode, the stress paths, pore water pressure generation pattern, peak shear strength, and hardening or softening behaviour of dense FRS samples are sensitive to the experienced strain paths.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Macedo, J.; Vergaray, L. Properties of mine tailings for static liquefaction assessment. Can. Geotech. J. 2022, 59, 667–687. [Google Scholar] [CrossRef]

- Wang, R.; Fu, P.; Zhang, J.-M.; Dafalias, Y.F. Fabric characteristics and processes influencing the liquefaction and re-liquefaction of sand. Soil Dyn. Earthq. Eng. 2019, 125, 105720. [Google Scholar] [CrossRef]

- Adhikari, S.; Bhattacharya, S. Vibrations of wind-turbines considering soil-structure interaction. Wind. Struct. 2011, 14, 85–112. [Google Scholar] [CrossRef]

- Amini, P.F.; Wang, G. Integrated effects of inherent and induced anisotropy on reliquefaction resistance of Toyoura sand with different strain histories. Géotechnique 2023, 1–15. [Google Scholar] [CrossRef]

- Oda, M.; Koishikawa, I.; Higuchi, T. Experimental Study of Anisotropic Shear Strength of Sand by Plane Strain Test. Soils Found. 1978, 18, 25–38. [Google Scholar] [CrossRef]

- Arthur, J.R.F.; Chua, K.S.; Dunstan, T. Principal Stress Rotation: A Missing Parameter. J. Geotech. Eng. Div. 1980, 106, 419–433. [Google Scholar] [CrossRef]

- Triantafyllos, P.K.; Georgiannou, V.N.; Dafalias, Y.F.; Georgopoulos, I.-O. Novel findings on the dilatancy and non-coaxiality of sand under generalised loading. Acta Geotech. 2021, 16, 1699–1734. [Google Scholar] [CrossRef]

- Cho, G.-C.; Dodds, J.; Santamarina, J.C. Particle Shape Effects on Packing Density, Stiffness, and Strength: Natural and Crushed Sands. J. Geotech. Geoenviron. Eng. 2006, 132, 591–602. [Google Scholar] [CrossRef]

- Yamamuro, J.A.; Covert, K.M. Monotonic and Cyclic Liquefaction of Very Loose Sands with High Silt Content. J. Geotech. Geoenviron. Eng. 2001, 127, 314–324. [Google Scholar] [CrossRef]

- Alarcon-Guzman, A.; Leonards, G.A.; Chameau, J.L. Undrained Monotonic and Cyclic Strength of Sands. J. Geotech. Eng. 1988, 114, 1089–1109. [Google Scholar] [CrossRef]

- Sladen, J.A.; D’Hollander, R.D.; Krahn, J. The liquefaction of sands, a collapse surface approach. Can. Geotech. J. 1985, 22, 564–578. [Google Scholar] [CrossRef]

- Lade, P.V. Static Instability and Liquefaction of Loose Fine Sandy Slopes. J. Geotech. Eng. 1992, 118, 51–71. [Google Scholar] [CrossRef]

- Goren, L.; Aharonov, E.; Sparks, D.; Toussaint, R. Pore pressure evolution in deforming granular material: A general formulation and the infinitely stiff approximation. J. Geophys. Res. Solid Earth 2010, 115. [Google Scholar] [CrossRef]

- Seed, H.B. Design Problems in Soil Liquefaction. J. Geotech. Eng. 1987, 113, 827–845. [Google Scholar] [CrossRef]

- Boulanger, R.W.; Truman, S.P. Void redistribution in sand under post-earthquake loading. Can. Geotech. J. 1996, 33, 829–834. [Google Scholar] [CrossRef]

- Umehara, Y.; Zen, K.; Hamada, K. Evaluation of Soil Liquefaction Potentials in Partially Drained Conditions. Soils Found. 1985, 25, 57–72. [Google Scholar] [CrossRef]

- Vaid, Y.P.; Eliadorani, A. Instability and liquefaction of granular soils under undrained and partially drained states. Can. Geotech. J. 1998, 35, 1053–1062. [Google Scholar] [CrossRef]

- Eckersley, J. Flowslides in stockpiled coal. Eng. Geol. 1985, 22, 13–22. [Google Scholar] [CrossRef]

- Wanatowski, D.; Chu, J.; Lo, R.S.-C. Strain-softening behaviour of sand in strain path testing under plane-strain conditions. Acta Geotech. 2008, 3, 99–114. [Google Scholar] [CrossRef]

- Chu, J.; Lo, S.C.R.; Lee, I.K. Instability of Granular Soils under Strain Path Testing. J. Geotech. Eng. 1993, 119, 874–892. [Google Scholar] [CrossRef]

- Adamidis, O.; Madabhushi, S.P.G. Experimental investigation of drainage during earthquake-induced liquefaction. Géotechnique 2018, 68, 655–665. [Google Scholar] [CrossRef]

- Tohidvand, H.R.; Hajialilue-Bonab, M.; Katebi, H.; Nikvand, V.; Ebrahimi-Asl, M. Monotonic and post cyclic behavior of sands under different strain paths in direct simple shear tests. Eng. Geol. 2022, 302, 106639. [Google Scholar] [CrossRef]

- Logeswaran, P.; Sivathayalan, S. A New Hollow Cylinder Torsional Shear Device for Stress/Strain Path Controlled Loading. Geotech. Test. J. 2014, 37. [Google Scholar] [CrossRef]

- Gray, D.H.; Ohashi, H. Mechanics of Fiber Reinforcement in Sand. J. Geotech. Eng. 1983, 109, 335–353. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E. Fibre-reinforced sand: Interaction at the fibre and grain scale. Géotechnique 2015, 65, 296–308. [Google Scholar] [CrossRef]

- Consoli, N.C.; Casagrande, M.D.T.; Prietto, P.D.M.; Thomé, A. Plate Load Test on Fiber-Reinforced Soil. J. Geotech. Geoenviron. Eng. 2003, 129, 951–955. [Google Scholar] [CrossRef]

- Pincus, H.; Maher, M.; Ho, Y. Behavior of Fiber-Reinforced Cemented Sand Under Static and Cyclic Loads. Geotech. Test. J. 1993, 16, 330. [Google Scholar] [CrossRef]

- Zhang, X.; Russell, A.R.; Dong, X. Liquefaction responses of fibre reinforced sand in shaking table tests with a laminated shear stack. Soil Dyn. Earthq. Eng. 2022, 162, 107466. [Google Scholar] [CrossRef]

- Noorany, I.; Uzdavines, M. Dynamic behavior of saturated sand reinforced with geosynthetic fabrics. Geosynthetics 1989, 2, 385–396. [Google Scholar]

- Consoli, N.C.; Casagrande, M.D.T.; Coop, M.R. Performance of a fibre-reinforced sand at large shear strains. Géotechnique 2007, 57, 751–756. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E.; Russell, A.R.; Wood, D.M. Fibre reinforced sands: From experiments to modelling and beyond. Int. J. Numer. Anal. Methods Géoméch. 2013, 37, 2427–2455. [Google Scholar] [CrossRef]

- Tohidvand, H.R.; Tabrizi, E.M.; Irani, A.E.; Hajialilue-Bonab, M.; Farrin, M. Effects of the Fiber Reinforcement on the Monotonic Behavior of Sands Considering Coupled Volumetric–Shear Strain Paths. Int. J. Geosynth. Ground Eng. 2023, 9, 1–15. [Google Scholar] [CrossRef]

- ASTM D 6913-04(2009)e1; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM Standards: West Conshohocken, PA, USA, 2014. [CrossRef]

- ASTM D5550-14; Standard Test Method for Specific Gravity of Soil Solids by Gas Pycnometer. ASTM Standards: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM D4253-16e1; Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table. ASTM Standards: West Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D4254-16; Standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density. ASTM Standards: West Conshohocken, PA, USA, 2016. [CrossRef]

| ) | Tension Strength, ) | Mean Thickness, ) | Elastic Modulus ) | Mean Length ) |

|---|---|---|---|---|

| 91 | 350 | 0.025 | 6200 | 5 |

| Consolidation Stress (kPa) | Initial Relative Density (%) | Type of the Test | (%) | Fibre Content, FC (%) |

|---|---|---|---|---|

| 200 | 72.59 | CU | 0 | 0 |

| 200 | 70.79 | CD | - | 0 |

| 200 | 72.73 | PD | −0.25 | 0 |

| 200 | 71.86 | PD | 0.25 | 0 |

| 200 | 72.2 | PD | 0.5 | 0 |

| 200 | 72.22 | CU | 0 | 0.25 |

| 200 | 72.78 | CD | - | 0.25 |

| 200 | 70.69 | PD | −0.25 | 0.25 |

| 200 | 71.69 | PD | 0.25 | 0.25 |

| 200 | 72.63 | PD | 0.5 | 0.25 |

| 200 | 72.84 | CU | 0 | 0.5 |

| 200 | 73.59 | CD | - | 0.5 |

| 200 | 72.8 | PD | −0.25 | 0.5 |

| 200 | 72.45 | PD | 0.25 | 0.5 |

| 200 | 71.07 | PD | 0.5 | 0.5 |

| 200 | 70.36 | CU | 0 | 1 |

| 200 | 71.31 | CD | - | 1 |

| 200 | 72.43 | PD | −0.25 | 1 |

| 200 | 71.46 | PD | 0.25 | 1 |

| 200 | 72.74 | PD | 0.5 | 1 |

| Consolidation Stress (kPa) | Initial Relative Density (%) | Type of the Test | (%) | Fibre Content, FC (%) |

|---|---|---|---|---|

| 200 | 71.2 | CV | 0 | 0 |

| 200 | 70.6 | PD | −0.25 | 0 |

| 200 | 71.5 | PD | 0.25 | 0 |

| 200 | 71.3 | CV | 0 | 0.25 |

| 200 | 72.1 | PD | −0.25 | 0.25 |

| 200 | 72.3 | PD | 0.25 | 0.25 |

| 200 | 72.5 | CV | 0 | 0.5 |

| 200 | 72.8 | PD | −0.25 | 0.5 |

| 200 | 72.1 | PD | 0.25 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maleki Tabrizi, E.; Dibazar, A.A.; Hajialilue-Bonab, M.; Esmatkhah Irani, A.; Assadi-Langroudi, A. The Partially Drained Behaviour of Dense Fibre-Reinforced Sands. Sustainability 2023, 15, 16286. https://doi.org/10.3390/su152316286

Maleki Tabrizi E, Dibazar AA, Hajialilue-Bonab M, Esmatkhah Irani A, Assadi-Langroudi A. The Partially Drained Behaviour of Dense Fibre-Reinforced Sands. Sustainability. 2023; 15(23):16286. https://doi.org/10.3390/su152316286

Chicago/Turabian StyleMaleki Tabrizi, Emad, Amir Abbas Dibazar, Masoud Hajialilue-Bonab, Arash Esmatkhah Irani, and Arya Assadi-Langroudi. 2023. "The Partially Drained Behaviour of Dense Fibre-Reinforced Sands" Sustainability 15, no. 23: 16286. https://doi.org/10.3390/su152316286

APA StyleMaleki Tabrizi, E., Dibazar, A. A., Hajialilue-Bonab, M., Esmatkhah Irani, A., & Assadi-Langroudi, A. (2023). The Partially Drained Behaviour of Dense Fibre-Reinforced Sands. Sustainability, 15(23), 16286. https://doi.org/10.3390/su152316286