Abstract

Deep rock mass mechanics is a professional course which is offered to undergraduate and postgraduate students in some mining universities. This course mainly includes the following topics: the geological structure of deep rock mass, the mechanical properties of deep rocks, the strength theory of deep rock masses, stability analysis and control of deep surrounding rock classification of engineering rock masses, and the application of deep rock mechanics in underground mining engineering The purpose of this course is to present students with a basic theoretical knowledge of deep rock mass engineering. Analyzing the limitations of traditional deep rock mass mechanics teaching methods, here, we propose integrating a combined FEM/DEM (Finite Element Method/Discrete Element Method) approach into the teaching of a course on deep rock mass mechanics. The mechanical behaviors and failure instability process of rock at laboratory and engineering scales were analyzed using ELFEN software (a finite/discrete element code). The results show that a combined FEM/DEM approach as a deep rock mass mechanics teaching method is completely feasible and reasonable; this approach has the advantages of strong intuition, high reliability, time and labor savings, and low cost, which can offset the shortcomings of traditional teaching methods. Moreover, the proposed approach can stimulate students’ interests in a mining course on deep rock mass mechanics, deepen students’ understanding of the course curriculum, and cultivate students’ innovative abilities and subjective initiatives.

1. Introduction

The demand for deep-earth natural resources is expanding as a result of the rapidly growing global economy. Recently, many universities have developed courses on “deep rock mass mechanics” that are offered to college mining engineering students to further their understanding of the complex environmental and mining conditions. The main topics taught in this course are the concept of deep rock mass mechanics, the geological structure of deep rock mass, the stress field measurement of deep rock mass, the mechanical properties of deep rocks, the strength theory of deep rock masses, testing technology of deep rock mechanics, stability analysis and control of deep surrounding rock classification of engineering rock masses, and the application of deep rock mechanics in underground mining engineering. The aim of the course is to provide students who are engaged in deep mining engineering with a basic theoretical knowledge related to roadway exploitation, stoping, goaf treatment, and other operation activities. Through a systematic learning approach for a deeper understanding of the abovementioned concepts, students in this course should clarify the basic principles of deep rock mechanics and the ideas and methods for solving problems, master the mechanical properties of deep rock masses, and carry out quantitative analyses and evaluations of deformation, as well as the failure and stability of simple rock engineering. This course provides a solid foundation for solving practical rock mining engineering problems [1,2].

At present, most rock mechanics courses at universities in China have adopted the mode of combining classroom teaching and experimental mechanics teaching. Classroom teaching approaches mostly involve PowerPoint and board books, and they mainly rely on the presentation of concepts, mechanical derivation, and engineering examples, among which, mechanical deduction mainly involves the theory of rock mass strength, stress analysis of the surrounding rock of a chamber, and a rock media mechanics model [3,4,5]. These topics are the key points and challenges associated with deep rock mechanics, and they require students to have a deeper understanding of elasticity, fracture mechanics, and material mechanics. On the one hand, teachers spend significant time and energy on deduction and inversion during the teaching process. On the other hand, students are generally confused and bored while learning the abovementioned concepts; therefore, this teaching approach is ineffective. In addition, rock mass engineering exhibits different degrees of anisotropy and heterogeneity in actual underground mines, and the stress environment is extremely complex [6,7,8]. Therefore, there are obvious limitations and drawbacks associated with classroom teaching sessions that simply use mechanical deduction and existing theoretical results when analyzing the mechanical response and damage characteristics of rock masses.

Deep rock mechanics experiments are mainly carried out in a laboratory. Students can gain a better understanding of the basic mechanical properties and failure behaviors of rock masses by conducting laboratory tests (such as uniaxial compression, triaxial compression, Brazilian splitting, direct tension tests, etc.) [9]. However, there are still some shortcomings in the current experimental teaching sessions of deep rock mechanics. First, carrying out relevant experiments requires preparation of rock samples from mines or quarries and setting up of monitoring equipment in a laboratory, which should be performed in small groups if the number of students is large; this results in high testing costs and is time-consuming and laborious. Second, considering that most testing equipment consists of precision instruments, generally, teachers do not allow students to operate the testing equipment by themselves, but rather students only observe. Therefore, laboratory tests have been described as "take a quick look at the flowers". Third, the abovementioned traditional experimental teaching methods make it difficult for students to gain a comprehensive understanding of the process of rock deformation and failure. For example, it is difficult to clearly reproduce crack initiation, propagation, and coalescence in rock samples during the entire failure process in either of the abovementioned tests, and the internal stress field, displacement field, and plastic zone distribution characteristics of the rock also cannot be reflected intuitively. Students find it difficult to understand the failure behavior and mechanisms of rock masses, which leads to a significant lack of subjective motivation and creative thinking. Although many efforts have been dedicated to improving teaching effectiveness (e.g., textbook content updates, flipped classrooms, and video presentations), the results have always been unsatisfactory and inaccessible. In summary, there is an urgent need to improve and propose some new teaching approaches for mining engineering courses on deep rock mechanics, in order that students can have a clearer, more intuitive, and more accurate understanding of the mechanical behaviors and failure mechanisms of deep mine rock masses based on classroom teaching and experiments.

Recently, with the development and popularity of computer simulation technology, numerical simulation techniques have become an important aid in rock engineering applications and classroom teaching in higher education institutions [10,11,12,13]. In the field of deep rock mechanics, rock fractures actually undergo a transformation process from continuous to discontinuous media due to crack initiation, propagation, and coalescence behavior. A combined FEM/DEM approach integrates both the advantages of continuous and discontinuous numerical methods, and is capable of simulating the entire process of crack initiation and propagation of newly generated cracks in a complete rock mass after adopting fracture mechanics-related criteria [14,15]. Therefore, we propose to introduce a combined FEM/DEM approach as a method for teaching deep rock mass mechanics curriculum. This approach can result in saving significant human, material, and financial resources, and it also presents the entire process of rock deformation, failure, and the mechanical response characteristics in an intuitive and accurate way. This approach can stimulate students’ interest in mining courses on deep rock mechanics, can deepen their understanding of the course curriculum, and can cultivate their innovative abilities and subjective initiatives.

2. The Combined FEM/DEM Approach as an Improved Teaching Method

2.1. Brief Introduction of the Combined FEM/DEM Approach

The discrete element method (DEM) [16] and discontinuous deformation analysis (DDA) [17] comprise powerful functions for contact problems. However, conventional DEM and DDA methods cannot simulate the process of crack initiation and propagation. In other words, rock fragmentation cannot be achieved by newly generated cracks. Therefore, the abovementioned numerical simulation methods can only study the deformation and interaction between rock masses by defining existing cracks in advance.

The combined FEM/DEM approach integrates the principles of continuum mechanics with discontinuous algorithms to simulate interactions between deformable rock masses. The approach was first proposed by Munjiza et al. [18]. The basic idea is to divide the solution domain into discrete unitary bodies along the existing discontinuity surface. Each discrete cell is further divided into a finite cell mesh and the theory of damage mechanics. Thus, the theory of damage mechanics and fracture mechanics is introduced into the finite element method. The cracking of discrete elements occurs at the boundaries of finite elements. The discrete element method can be used to deal with the contact problem between cracked blocks. The motion and interaction of the blocks are treated in the same way as in the DEM. The motion of an individual rock mass is determined according to the unbalanced forces or unbalanced moments (according to Newton’s second law) applied to those blocks. No deformation coordination conditions need to be met between the blocks, and the blocks can be translated and rotated [19]. Notably, the combined FEM/DEM approach is different from the hybrid FEM/DEM method. According to the description by Cai [20], the discontinuous rock masses in a near field excavation are represented by the nonlinear plastic DEM and the far-field domain is represented by the linear elastic FEM in a typical hybrid model of an underground excavation problem. In contrast to the hybrid method where no new fractures are generated in the DEM domain or in the FEM domain, new fractures and the contact boundaries can be generated in the model of the combined FEM/DEM approach.

ELFEN is a combined FEM/DEM analysis software product developed by the Rockfield Software Company in the United Kingdom [21]. ELFEN is powerful enough to perform implicit and explicit dynamic solutions for 2D and 3D models, as well as to simulate the rock failure process under static and dynamic loads. ELFEN can accurately simulate the whole process of rock transition from continuum medium to discontinuous medium. When the failure criterion of the intact rock (when the unit mesh is represented by the FEM domain) meets the requirements, cracks begin to initiate and propagate [20]. In addition, ELFEN has a large selection of intrinsic models that can be used in conjunction with each other to create material models for different types of rock mechanics problems. ELFEN numerical simulation software adopts a graphical user interface (GUI), and the image processing window is easy to operate (as shown in Figure 1). It is especially suitable for beginners of numerical simulation software who only have a basic knowledge of rock mechanics theory. ELFEN has been widely employed in analyzing the rock failure process, which embodies its powerful advantages in aspects at laboratory or engineering scales [22,23]. It should be noted that ELFEN was selected as a typical tool in the present study. It is also feasible that other combined FEM/DEM codes could be used for teaching a deep rock mass mechanics course.

Figure 1.

ELFEN’s graphical user interface window.

2.2. Improvement of the Combined FEM/DEM Approach for Teaching Deep Rock Mechanics

In summary, the combined FEM/DEM approach can be fully applied in the classroom and experimental teaching of research on discontinuous media such as rock masses at engineering and laboratory scales. As compared with mechanical derivation, conceptual narration, and laboratory testing, this approach can accurately describe the inherent anisotropy and non-homogeneous structure within a rock mass. It can clearly visualize crack propagation, stress and displacement distribution, as well as energy evolution laws during the destruction of rock masses subjected to complex stress environments [24,25]. By supplementing classroom and laboratory teaching with this approach, students’ initiative and interest in research can be significantly increased, and it can stimulate their creative energy. For example, the combined FEM/DEM approach can effectively reproduce the whole process of crack initiation, propagation, and coalescence of a rock specimen, and can obtain the full stress–strain curve of the rock mass at a laboratory scale [26]. For rock masses containing geological structures and faults, this can be achieved by means of prefabricated fractures and holes; for non-homogeneous rock masses, this can be achieved by setting material parameters (Young’s modulus, Poisson’s ratio, density, tensile strength, fracture energy, etc.) and specific commands (setting upper and lower limits for a given percentage on the average value of each parameter and applying a random generator to create values for each property for each element). The random number generator can create three different distribution types: uniform (default), logarithmic (exponential), and Gaussian (normal). Users can choose one distribution type according to specific conditions. In addition, different stress paths and stress states can be achieved by adjusting the boundary conditions of the model. For engineering-scale rock mass, the finite element/discrete element methods coupled with numerical simulation technology can accurately describe the mechanical response and instability failure process of rock mass engineering in deep underground engineering. For example, for the course section on "Application of Rock Mass Engineering in Underground Cavern Engineering", traditional classroom teaching often introduces the elastic-plastic solution of surrounding rock stress of a deep cavern, the loose circle of surrounding rock, and related knowledge points through mechanical derivation, which is difficult for students to understand. In addition, most existing textbooks only contain circular chambers with a simple stress regime (horizontal stress equals vertical stress). However, the mechanical response characteristics of chambers with other cross-sectional shapes and complex stress environments are barely presented and mentioned. The combined FEM/DEM approach can realistically reproduce the stress, displacement, plastic zone, and energy evolution law of the surrounding rock after excavation unloading of the deep buried chamber, and it can fully consider the influence of geological structure, excavation method, initial in situ stresses, and non-homogeneous rock mass [26]. The simulation results are intuitive and comprehensible, and also broaden students’ scientific research horizons, create a positive learning atmosphere, and achieve twice the result with half the effort.

3. Application of the Combined FEM/DEM Approach for Teaching Deep Rock Mechanics

3.1. Application of Deep Rock Mass Mechanics Teaching at a Laboratory Scale

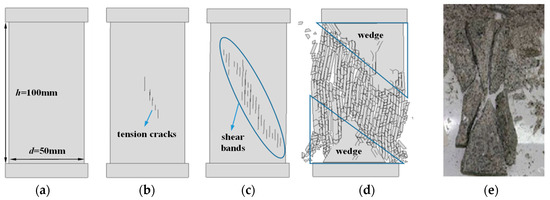

In this paper, the ELFEN numerical simulation software was used to analyze the failure process and mechanical behavior of granite samples under uniaxial compression. The simulation results and figures have been cited from a previously published academic paper by authors [27]. The purpose is to illustrate the applicability and advancement of this numerical simulation technique for teaching deep rock mechanics. The numerical model created is a two-dimensional numerical model with a specimen width of 50 mm and a height of 100 mm. Unstructured triangular mesh is adopted for model mesh, and the number of meshes is 55,188. A static displacement control mode is adopted for the loading mode, namely, x-direction and y-direction constraints at the bottom. The displacement is gradually applied on top of the rock specimen. The whole process is linearly loaded and the Mohr–Coulomb, with rotating crack, constitutive model is adopted because it is able to simulate rock fracturing due to both tension and compression (It is essentially assumed that in heterogeneous rocks, the fracturing process is an extensional process. Therefore, the failure of a rock in a compressive environment is a result of inelastic extensional strain associated with dilation of rock [26]). The simulation results are shown in Figure 2.

Figure 2.

The whole process of crack evolution and damage pattern of granite specimens in indoor tests [27]. Note that (a)–(d) corresponds to those key points in Figure 3.

Figure 2a–d represent the typical transition stages of the rock from the intact state to the fractured state, corresponding to those key points in Figure 3. Analysis of Figure 2a shows that there is no crack during this stage. This stage should be the elastic stage during the compression deformation process of the specimen. Figure 2b represents the crack initiation corresponding to the yield stage close to the peak strength. Figure 2c,d both occur in the post-peak phase of the rock specimen and represent the crack propagation and coalescence, respectively. In addition, it can be seen that the newly generated cracks produced within the specimen are mostly parallel to the direction of loading. These meso-cracks actually belong to tensile cracks. As the load is gradually increased, the initial crack starts to expand towards the diagonal direction of the specimen. As can be seen from Figure 2c, these cracks (tension cracks) gradually penetrate and eventually form macroscopic shear bands. Macroscopic shear cracks divide the specimen into two distinct wedge-shaped regions, resulting in complete destruction of the hard rock specimen (Figure 2d). It is worth noting that, although some slender rock slabs are observed in the middle of the sample, the main failure mode of the specimen is still manifested as shear failure at a macroscopic scale. The comparison of final failure modes between laboratory testing (see Figure 2e) and numerical simulation shows good agreement, which validates the practicability and advancement of the combined FEM/DEM approach.

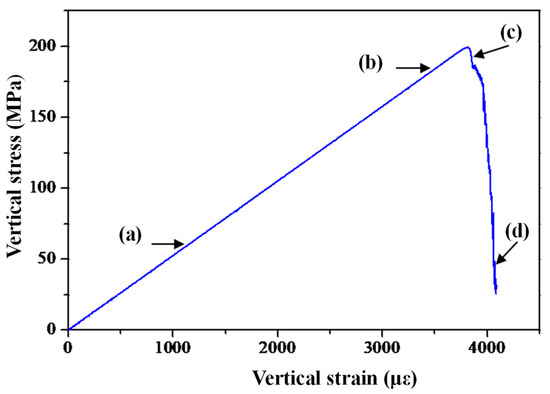

Figure 3.

Typical stress–strain curve for a granite specimen [27].

Figure 3 is a typical stress–strain curve of a rock specimen. It can be seen from the figure that the stress–strain curve in the pre-peak stage shows linear characteristics, and the yield stage is not obvious. In the post-peak phase, the uniaxial compressive strength falls and decreases rapidly, and the residual strength remains at a low level. This reflects the obvious hard and brittle properties of the selected rock specimen. The combined FEM/DEM approach demonstrates the development and change of cracks at any point in the rock failure process; therefore, students can visualize the dynamic rock failure process and can establish the corresponding relationships at different crack stages and stress characteristic points.

3.2. Application of Deep Rock Mass Mechanics Teaching at an Engineering Scale

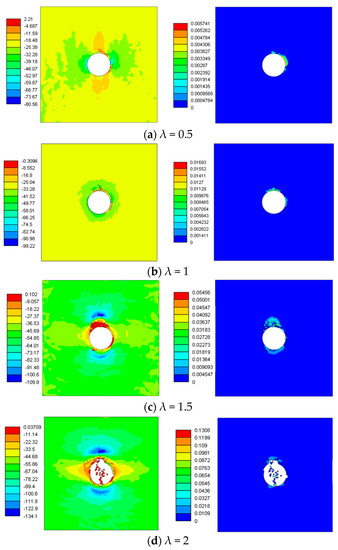

In order to demonstrate the applicability of deep rock mass mechanics teaching at an engineering scale, we adopt the ELFEN numerical simulation software to analyze the mechanical behavior and rupture characteristics of the surrounding rock after excavation of a deep circular tunnel. The simulation results and figures are also selected from a previously published academic paper by [28]. A circular hole is considered in the center of the model to simulate the excavation unloading of a circular tunnel. The size of the model is 20 m × 20 m, and the diameter of the tunnel is 4 m. Monitoring points (numbered 5–8) are set on the roof, floor, and both sides of the tunnel boundaries, respectively, for the purpose of monitoring the variation trend of effective plastic strain and tangential stress in the corresponding areas. In order to reveal the mechanical and failure characteristics of the hard rock subjected to high in situ stresses at great depth, a lead-zinc mine in Inner-Mongolia, China is selected as the engineering background, and deep marble is taken as the research object. The non-homogeneity of the rock mass is also taken into account simultaneously during the simulation. The non-homogeneous nature of the material applied to the base unit allows each unit to have an independent Young’s modulus, Poisson’s ratio, density, tensile strength, and fracture energy. According to the different initial in situ stresses, the lateral pressure coefficients λ (horizontal-to-vertical stress ratio) are divided into four types: 0.5, 1, 1.5, and 2. In ELFEN, upper and lower bounds (given as a percentage) are first set on an average value, and a random generator is applied to create a value for each attribute for each element. The numbers in the legend represent the ratio of the assigned value to the mean value of the corresponding unit in the model. The model mesh is an unstructured triangular mesh with 4568 meshes (including circular lanes). Initial in situ stresses are applied to the model boundaries using surface forces. This means that vertical stresses are applied to the top of the model and horizontal stresses are applied to the sides of the model, and the bottom y-direction is constrained. The loading method is linear displacement control with a duration of 0.01 s. After 0.01 s, the stresses in the x and y directions remain constant. Excavation unloading starts after 0.01 s and the whole unloading process takes 0.005 s. A linear relaxation curve was assigned to the circular tunnel representing the excavated material. When 0.015 s is reached, it means that the circular tunnel has been fully excavated.

Figure 4 is the contour of maximum principal stress (tangential stress) and the effective plastic strain of the numerical model under different lateral pressure coefficients. After excavation and unloading activities, the stresses around the tunnel begin to redistribute. It means that the radial stresses gradually decrease, and the tangential stresses gradually increase. By observing the contour of the maximum principal stress, it can be seen that when λ = 0.5, the stress concentration mainly occurs on both sides of the tunnel. When λ = 1, the stress concentration around the roadway begins to decrease, and the stress distribution is relatively uniform. As λ increases to 1.5 and 2, more pronounced stress concentrations begin to occur near the top and bottom plates, especially when λ = 2. The analysis shows that both sides of the tunnel will be subjected to higher compressive stress when λ < 1, resulting in higher strain energy near the side wall. The strain energy mainly starts to accumulate at the roof and floor when λ > 1. The initiation, propagation, and coalescence of cracks are closely related to the effective plastic strain. As can be seen from Figure 4, the effective plastic strain values around the circular tunnel exhibit a non-uniform distribution, regardless of the value of the lateral pressure coefficient (even when λ = 1). This might be attributed to the non-homogeneous property of rock mass engineering. Due to the strength non-homogeneity exhibited by rock mass, plastic strain may also be observed when the maximum principal stress in some area is less than the average uniaxial compressive strength. This depends on whether the strength value of the grid element is greater than its maximum principal stress value (tangential stress value around the tunnel). If the strength value is less than the maximum principal stress value, newly generated cracks may appear.

Figure 4.

Clouds of maximum principal stress and effective plastic strain for different lateral pressure coefficients [28].

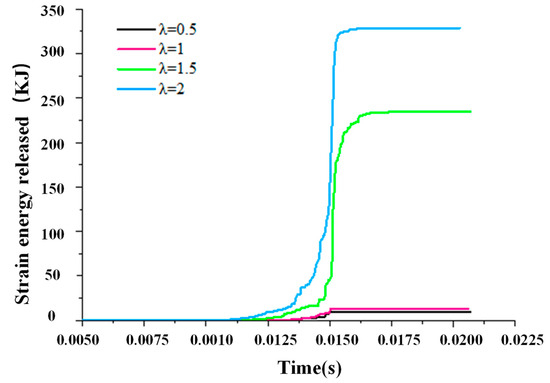

Figure 5 shows the time history curve of released strain energy of the model for different lateral pressure coefficients. When λ = 0.5 and 1, the released strain energy is maintained at a very low level (about 11 KJ). Tangential stresses are difficult to concentrate at low initial stresses and the elastic strain energy stored within the model is inherently low; therefore, the strain energy released is very limited. With an increase in the lateral pressure coefficient, a large amount of elastic energy is accumulated in rock masses. Under the action of excavation and unloading activities, the stress around the tunnel is redistributed. The formation of the free surface is bound to release a large amount of elastic energy in the rock masses. In this case, the failure intensity and damage degree of the surrounding rock of the tunnel will increase, and the dynamic disasters of rock mass is more prone to be induced at this time.

Figure 5.

Time history curve of released strain energy with different lateral pressure coefficients [28].

4. Discussion

By applying the combined FEM/DEM approach to deep rock mass mechanics teaching at a laboratory scale, students can clearly observe the entire failure process (from crack initiation to propagation, and then to coalescence) from the beginning to the end of the testing. This is barely reproduced in actual laboratory tests because the fracturing is always instantaneous and the micro-cracks within rock specimens are too tiny to be observed. If college students are equipped with the ability to establish a numerical model, they can perform an in-depth analysis. The application of a numerical simulation requires fewer human, physical, and financial resources [29]; therefore, it is completely feasible that it can be applied to teaching a deep rock mass mechanics course. Notably, although the proposed teaching approach shows significant advantages, the authors do not suggest canceling the laboratory testing procedure. The proposed approach is an auxiliary for indoor tests, at least for now.

By applying the combined FEM/DEM approach to deep rock mass mechanics teaching at a laboratory scale, the excavation unloading effect can be fully considered, and the stress and displacement distribution law of the deep circular tunnel can be intuitively presented. Moreover, when using mechanical derivation and existing theoretical results to teach the course section on "Application of Rock Mass Engineering in Underground Cavern Engineering", students can merely obtain the analytical solution of stress and displacement of surrounding rock around the tunnel when the lateral pressure coefficient is one, through theoretical calculation. However, the proposed numerical simulation technology can obtain the stress field, displacement field, plastic zone, and energy distribution characteristics of the surrounding rock of the tunnel corresponding to various lateral pressure coefficients. Therefore, students can intuitively and comprehensively grasp the mechanical response characteristics and failure mechanism of the surrounding rock of the deep tunnel or chamber. In addition, the model schemes can be designed according to students’ own ideas, which can stimulate students’ innovative thinking and learning interests, which greatly offset the shortcomings of traditional teaching methods.

5. Conclusions

In this paper, we have proposed applying a combined FEM/DEM approach for teaching a course on deep rock mass mechanics. A typical combined FEM/DEM analysis software, namely, ELFEN, is introduced in this study, and two cases including the mechanical response, crack evolution process, and failure mechanism of deep rock mass at laboratory and engineering scales, respectively, are briefly presented. The study shows that applying a combined FEM/DEM approach for teaching deep rock mass mechanics is completely feasible and meaningful. The advantages of the proposed teaching approach are illustrated by comparing the approach with traditional teaching methods. The approach can intuitively and accurately show the laws of crack propagation, stress, and displacement distribution, as well as energy evolution laws during the process of rock failure under deep stress environment, and can overcome the difficulties of single means, obscurity, abstraction, and vagueness in traditional deep rock mechanics teaching methods. At the same time, it has the advantages of time and labor savings and low cost. The proposed approach can significantly mobilize students’ subjective initiatives in learning, deepen students’ understanding of the rock mechanics course curriculum, stimulate their interest in scientific research in this field, and cultivate their abilities to find and solve practical engineering problems in mines through advanced scientific and technological means such as numerical simulation. It is expected to play important roles in establishing confidence in the mining engineering and enriching the connotation construction of the mining engineering subject.

Author Contributions

Conceptualization, F.F. and X.L.; methodology, F.F.; investigation, T.X., E.W. and R.H.; resources, F.F.; writing—original draft preparation, Z.X.; writing—review and editing, X.L and S.G.; All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (No. 52004143, No. 52104204), the open fund for Laboratory of Mining Response and Disaster Prevention and Control in Deep Coal Mines (No. SKLMRDPC21KF06), and the Taishan Scholars Project.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request due to privacy restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bieniawski, Z.-T. Reviving The Mission Of Rock Mechanics Teaching In Mining And Civil Engineering. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 135–142. [Google Scholar] [CrossRef]

- Tomás, R.; Cano, M.; Santamarta, J.-C.; Hernández-Gutiérrezc, L.-E. New Approaches For Teaching Soil And Rock Mechanics Using Information And Communication Technologieses. Procedia Soc. Behav. Sci. 2015, 191, 1644–1649. [Google Scholar] [CrossRef]

- Brady, B.-H.-G.; Brown, E.-T. Rock Mechanics for Underground Mining, 3rd ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 1–567. [Google Scholar]

- Mogi, K. Experimental Rock Mechanics, 1st ed.; Taylor & Francis/Balkema: Leiden, The Netherlands, 2007; pp. 1–357. [Google Scholar]

- Shen, M.-R.; Chen, J.-F. Rock Mass Mechanics, 2nd ed.; Tongji University Press: Shanghai, China, 2015; pp. 1–262. [Google Scholar]

- Cui, Z.; Sheng, Q.; Luo, Q.-Z.; Zhang, G.-M. Investigating The Anisotropy Of Mechanical Parameters Of Schist Rock With Practical Numerical Methods. Sustainability 2021, 13, 725. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Zhang, W.-L.; Ma, N.-J.; Guo, S.-Y. Study On Shape Characteristics Of Plastic Zone In Heterogeneous Roadway-Surrounding Rock. Sustainability 2022, 14, 9480. [Google Scholar] [CrossRef]

- Sonmez, H.; Ercanoglu, M.; Dagdelender, G. A Novel Approach To Structural Anisotropy Classification For Jointed Rock Masses Using Theoretical Rock Quality Designation Formulation Qdjusted To Joint Spacing. J. Rock Mech. Geotech. Eng. 2022, 14, 329–345. [Google Scholar] [CrossRef]

- Paterson, M.-S.; Wong, T.-F. Experimental Rock Deformation—The Brittle Field, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–80. [Google Scholar]

- Feng, F.; Zhang, J.-Q.; Yan, Z.-K.; Wu, Y.-D.; Song, Y.-M.; Xie, Z.-W.; Cheng, X. Safe And Efficient Recovery Technique Of Horizontal Isolated Pillar Under Loose Tailings Backfill; A Case Study in a Zinc-Lead Mine. Minerals 2022, 12, 1066. [Google Scholar] [CrossRef]

- Liu, H.; Lin, Z.; Liu, C.; Zhang, B.; Wang, C.; Liu, J.; Liang, H. Stability Analysis Of Karst Tunnels Based On A Strain Hardening–Softening Model And Seepage Characteristics. Sustainability 2022, 14, 9589. [Google Scholar] [CrossRef]

- Miao, L.-T.; Duan, Z.-H.; Xia, Y.-C.; Du, R.-J.; Lv, T.-T.; Sun, X.-Y. Analysis Of Factors Influencing Mining Damage Based on Engineering Detection And Machine Learning. Sustainability 2022, 14, 9622. [Google Scholar] [CrossRef]

- Wang, E.-Y.; Dai, Y.-Y.; Wang, W.-C.; Lv, P.-F.; Chen, G.-B. Application Of UDEC Numerical Simulation Nethod In Experimental Teaching Of Mine Rock Mass Mechanics. Exp. Technol. Manag. 2021, 38, 220–223. (In Chinese) [Google Scholar]

- Trivino, L.-F.; Mohanty, B. Assessment Of Crack Initiation And Propagation In Rock From Explosion-Induced Stress Waves And Gas Expansion By Cross-Hole Seismometry And FEM–DEM Method. Int. J. Rock Mech. Min. Sci. 2015, 77, 287–299. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.-J.; Wang, Y.-J.; Huang, W.-P.; Han, Z.-Y. Cracking Mechanism And Strength Criteria Evaluation Of Granite Affected By Intermediate Principal Stresses Subjected To Unloading Stress State. Int. J. Rock Mech. Min. Sci. 2021, 143, 104783. [Google Scholar] [CrossRef]

- Li, M.-L.; Wu, J.-F.; Li, J.-F.; Zhang, L.; Wang, S.-Y.; Zhang, F.-S. Modeling Of Hydraulic Fracturing In Polymineralic Rock With A Grain-Based DEM Coupled With A Pore Network Model. Eng. Fract. Mech. 2022, 275, 108801. [Google Scholar] [CrossRef]

- Zhang, F.; Zhuang, X.-Y.; Zheng, H.; Jiao, Y.-Y.; Rabczuk, T. Discontinuous Deformation Analysis With Distributed Bond For The Modelling Of Rock Deformation And Failure. Comput. Geotech. 2021, 139, 104413. [Google Scholar] [CrossRef]

- Munjiza, A. The Combined Finite-Discrete Element Method, 1st ed.; John Wiley & Sons: Chichester, UK, 2004; pp. 1–318. [Google Scholar]

- Munjiza, A.; Owen, D.-R.-J.; Bicanic, N. A Combined Finite-Discrete Element Method In Transient Dynamics Of Fracturing Solids. Eng. Comp. 1995, 12, 145–174. [Google Scholar] [CrossRef]

- Cai, M. Fracture Initiation And Propagation In A Brazilian Disc With A Plane Interface: A Numerical Study. Rock Mech. Rock Eng. 2013, 46, 289–302. [Google Scholar] [CrossRef]

- Rockfield. ELFEN Explicit/Implicit Manual, version 4.7.1; Rockfield Software Limited: West Glamorgan, UK, 2013. [Google Scholar]

- Hamdi, P.; Stead, D.; Elmo, D. Damage Characterization During Laboratory Strength Testing: A 3D-Finite-Discrete Element Approach. Comput. Geotech. 2014, 60, 33–46. [Google Scholar] [CrossRef]

- Chen, S.-J.; Feng, F.; Wang, Y.-J.; Li, D.-Y.; Huang, W.-P.; Zhao, X.-D.; Jiang, N. Tunnel Failure In Hard Rock With Multiple Weak Planes Due To Excavation Unloading Of In-Situ Stress. J. Cent. South Univ. 2020, 27, 2864–2882. [Google Scholar] [CrossRef]

- Feng, F.; Chen, S.-J.; Zhao, X.-D.; Li, D.-Y.; Wang, X.-L.; Cui, J.-Q. Effects Of External Dynamic Disturbances And Structural Plane On Rock Fracturing Around Deep Underground Cavern. Int. J. Coal. Sci. Techn. 2022, 9, 15. [Google Scholar] [CrossRef]

- Tang, W.; Zhai, C.; Xu, J.-Z.; Yu, X.; Sun, Y.; Cong, Y.-Z.; Zheng, Y.-F.; Zhu, X.-Y. Numerical Simulation Of Expansion Process Of Soundless Cracking Demolition Agents By Coupling Finite Difference And Discrete Element Methods. Comput. Geotech. 2022, 146, 104699. [Google Scholar] [CrossRef]

- Cai, M. Influence Of Intermediate Principal Stress On Rock Fracturing And Strength Near Excavation Boundaries—Insight From Numerical Modeling. Int. J. Rock Mech. Min. Sci. 2008, 45, 763–772. [Google Scholar] [CrossRef]

- Feng, F.; Li, X.-B.; Li, D.-Y. Modeling Of Failure Characteristics Of Rectangular Hard Rock Influenced By Sample Height-To-Width Ratios: A Finite/Discrete Element Approach. C. R. Mec. 2017, 345, 317–328. [Google Scholar] [CrossRef]

- Feng, F.; Li, X.-B.; Rostami, J.; Li, D.-Y. Modeling Hard Rock Failure Induced By Structural Planes Around Deep Circular Tunnels. Eng. Fract. Mech. 2019, 205, 152–174. [Google Scholar] [CrossRef]

- Feng, F.; Li, X.-B.; Jamal, R.; Peng, D.-X.; Li, D.-Y.; Du, K. Numerical investigation of hard rock strength and fracturing under polyaxial compression based on Mogi-Coulomb failure criterion. Int. J. Geomech. 2019, 19, 04019005. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).