1. Introduction

Tight sandstone gas is an unconventional natural gas resource with broad prospects. The production of gas well-water is an important reason for low single well production and reduced oil recovery in tight sandstone gas wells [

1]. Therefore, it is particularly important to control water production in tight sandstone gas reservoirs. However, it is difficult to judge the water outlet position of gas wells, the water outlet damages the gas reservoir, and the swept volume of the water shutoff agent is small [

2]. This makes the water shutoff operation quite difficult. The Linxing area is located in the eastern margin of Ordos Basin, where micro-fractures have developed in the upper ancient deep coal measures strata, but production is not high [

3]. Reservoir reconstruction is a necessary measure to increase the production of natural gas wells. Obtaining water from deep formations after reconstruction is one of the important reasons why low single-well production of natural gas wells occurs [

4]. Due to gas–liquid two-phase seepage, it is difficult to judge the position of gas well water production [

5], the water production damages the gas layer, the swept volume of the water shutoff agent is small [

6], and the complexity of gas well water shutoff technology makes the overall water shutoff operation of the gas well difficult [

7]. Therefore, selecting reasonable water shutoff technology for gas wells and achieving water control and gas stabilization in the process are the key factors contributing towards improving gas well productivity after successful water shutoff [

8].

At present, there are two water shutoff agents, selective water shutoff agents and non-selective water shutoff agents, according to whether the agent is selective or not. Ultra-fine cement and inorganic saltwater shutoff agents are non-selective water shutoff agents, which are limited by defining the water outlet position in advance and using water shutoff fluid in a specific water outlet horizon. The widely used water shutoff fluids at home and abroad are polymers [

9], microemulsions [

10], superfine cement [

11], and inorganic salts [

12]. Dai et al. [

13] aimed to solve the problem of low permeability and active edge and bottom water in the East China Sea formation; they used polymer gel water shutoff fluid, which changed the plugging strength according to the change in permeability, to plug the water from the high permeability layer without affecting the gas production of the low-permeability layer. Lakatos et al. [

14] used microemulsion, which can increase water flow resistance and has little influence on gas flow for low-permeability tight gas fields, but it is relatively weak in controlling water output and the water output speed of gas wells due to its low viscosity and small particle size. In view of the strong heterogeneity of the reservoir and the serious invasion of edge and bottom water, Liu et al. used superfine cement to solve the problem of the clear water production horizon and non-selective water shutoff [

15]. Considering the fact that water shutoff fluid cannot be effectively injected into low-permeability reservoirs, Liu et al. used hydrolyzed aluminum chloride solution to produce precipitation in pores in order to achieve water shutoff [

16].

Fuzzy ball is a deformable material formed by self-matching polymers and surfactants according to fuzzy plugging theory, which can adapt to pores and fractures according to downhole conditions.

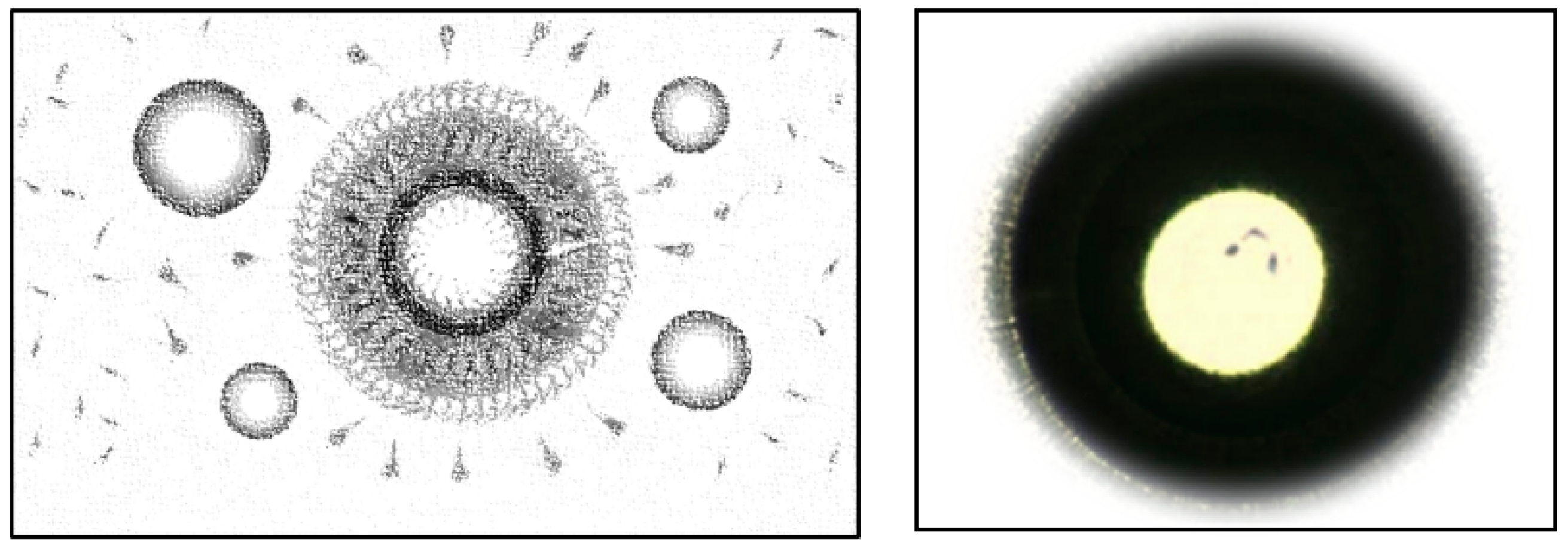

Figure 1 shows the schematic diagram and images of fuzzy ball fluids. The microstructure of fuzzy ball is quite different from that of ordinary foam. The fuzzy ball contains gas enclosed by a dense layer, and outside this dense layer are layers of fluffy material, giving it a resemblance to a furry balloon. The microstructure of the fuzzy ball is “one nucleus, two layers, three membranes”, including the “vesicle nucleus”, “high-viscosity water layer”, “gas–liquid surface tension reducing membrane”, “high-viscosity water layer fixing membrane”, and the “water solubility improvement membrane”. The outer layer of the fuzzy ball is thick, with distinct transition layers, and does not easily aggregate. Using a combination of bench micrometers and eye micrometers, the fuzzy ball is measured to be between 15 to 150 microns in size, with a wall thickness of 3 to 10 microns [

17].

In view of the fractured reservoir with an unknown water outlet position, it is theoretically possible to use fuzzy ball fluid for water shutoff operations. In addition, in practical applications, fuzzy ball fluid has been proven to be effective in fracturing fractures [

18] and has been applied to water plugging operations in fractures after the fracturing of high-yield water, such as in Zheng 3X coalbed methane wells to achieve water plugging in coalbed methane wells. During the operation period, the production of water in the drainage period and gas production period decreased by 79% and 68%, respectively, while gas production increased by 44%, indicating that the water control and stimulation test of fuzzy ball fluid in the Zheng 3X well were successful and had a good gas stabilization and water control effect [

19].

Fuzzy ball fluid is an intelligent fluid system with a self-adapting reservoir, deformable and self-matching leakage channel, and good plugging ability [

20]. It has been successfully applied in the fields of gas well fracturing [

21] and water control [

22], coalbed methane well fracturing and water plugging [

23], selective water plugging [

21], oil stabilization, and water control in high-salinity water formation and gas well workovers [

24]. However, the breakthrough ability of gas and water after fuzzy ball plugging has not been systematically studied in the laboratory. Verifying the change in gas–water breakthrough pressure after plugging is an important basis for proving that plugging fluid can stabilize gas and control water; this is also a key argument contributing towards the above disputes about improving gas well productivity using plugging water. Therefore, sandstone plunger with a 25 mm diameter in the Linxing He-2 reservoir was drilled indoors, and artificial fractures were made. Using the self-made gas–water breakthrough pressure tester, the pressure gradient of the gas and water fractures plugged by fuzzy ball sac fluid was simulated and measured using simulated formation water and nitrogen as the flowing media, and the gas-stabilizing and water-controlling ability of fuzzy ball sac fluid was assessed in three kinds of water-producing channels with different scales, such as matrix, artificial fractures, and edge and bottom water influx.

The main target layer of the LX-Y well in the Linxing area is a low-porosity and low-permeability sandstone formation, which belongs to the tight sandstone reservoir with great changes in lithology and lithofacies and strong heterogeneity [

25]. The daily water production reaches 70 m

3/d, and the daily gas production is less than 300 m

3/d, so it is a gas well with a high level of water and low gas production. To test the gas production capacity of the well because the water production position is unknown, it is necessary to use a water shutoff agent without defining the formation water production position in order to solve the water production problem, ensuring the smooth progress of the estimated gas production and accurately evaluating the productivity. In view of the fact that the gas production in the Linxing dense gas reservoir is not high and accompanied by a large amount of water production, pile bag water shutoff fluid is used to stabilize gas and control water, hoping to control water production and test the gas production capacity of the well.

2. Materials and Methods

2.1. Preparation of Core Plunger with and without Artificial Fractures

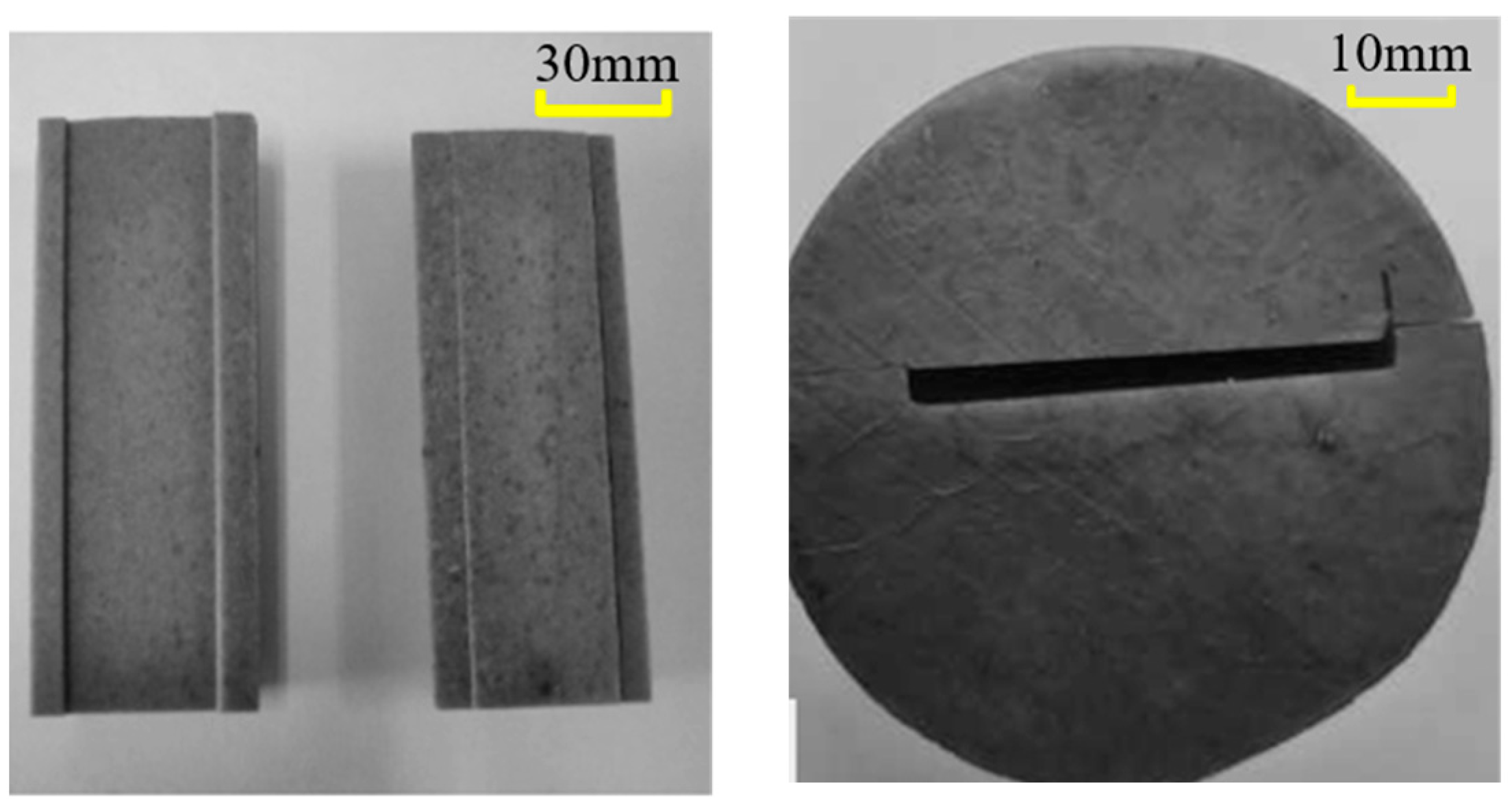

In order to simulate the gas stabilization and water control ability of fuzzy ball fluid in three different scale water production channels, namely microporous fractures, artificial fractures, and edge and bottom water inflow, the matrix core plunger and core plunger with 4 mm artificial fractures cut by using wire are taken as the objects (as shown in

Figure 2). The “breakthrough pressure-flow” experiment of fuzzy ball fluid plugging matrix cores and artificial fractured cores was carried out using a physical model method.

The on-site fuzzy ball fluid preparation ratio was 1.8% capsule agent (mainly composed of hydroxyethyl starch), +1.2% capsule hair agent (mainly composed of polyanionic cellulose), +1.0% capsule core agent (mainly composed of sodium dodecyl sulfonate), and +1.0% capsule agent (mainly composed of sodium dodecyl benzene sulfonate). In total, 10,000 mL of deionized water was measured indoors, and the capsular agent, capsular hair agent, capsular core agent, and capsular membrane agent with a high mass ratio were weighed, respectively, and then they were added into 1000 mL of deionized water in sequence and stirred for 40 min at a stirring rate of 8000 r/min. The measured fluid density of the fuzzy ball bag was 0.894 g/cm3; the viscosity was 57 mPa·s; and the average particle size distribution of the fuzzy ball ranged from 100 μm to 120 μm.

2.2. Gas–Water Breakthrough Pressure Tests

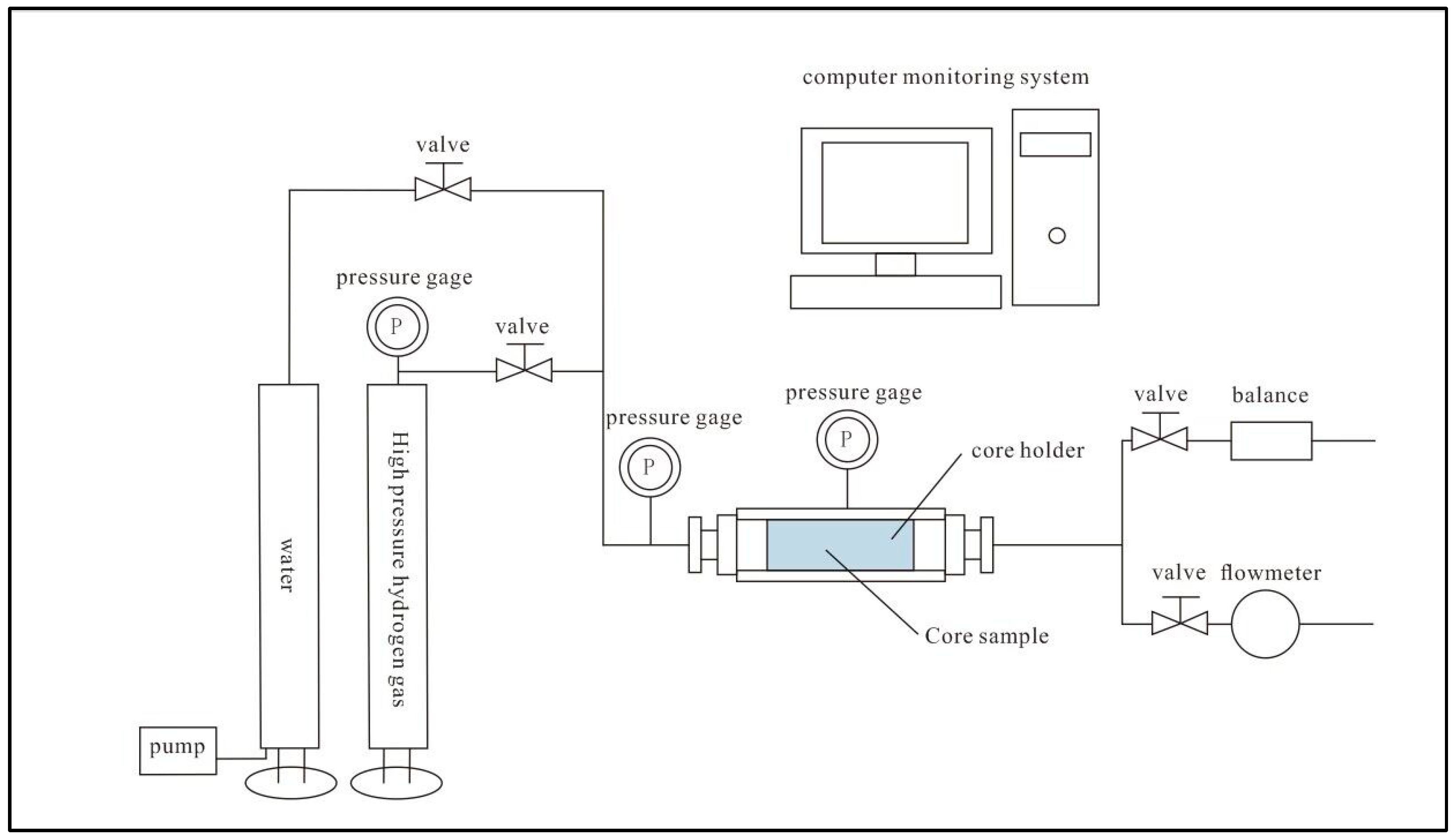

Using simulated formation water and nitrogen as gas–liquid two-phase flow media, the self-made gas–water breakthrough pressure testing device (the principle flow chart is shown in

Figure 3) was used to test the pressure of gas–liquid two-phase breakthrough through the fuzzy ball plugging structure. This paper evaluates the plugging effect of fluids in the core matrix or fractures on water and gas, analyzes the ability to stabilize gas and control water in the process of plugging water, and discusses the controversial issue of improving productivity by plugging water with fluids in fluids.

After the core was vacuumed and saturated with simulated formation water, the gas flow through the core plunger was measured under the condition of a confining pressure of 3 MPa and a constant displacement pressure of 1.5 MPa, and the collection period was 1 min. When the flow rate reached 0.1 mL/min, the flow rate through the core plunger was measured under the same experimental conditions by injecting the cashmere bag in reverse direction until the liquid was seen at the exit end of the core plunger. Under the same conditions, the liquid flow through the core plunger was measured, and the collection period was 1 min. When the flow rate reached 0.1 mL/min, the pile bag was injected in reverse until the liquid was seen at the outlet end of the core plunger. Under the same experimental conditions, the liquid flow through the core plunger was measured, respectively, and the breakthrough pressure gradient data of gas–liquid two phases were recorded, respectively.

2.3. Wetting Abilities Test

In order to investigate the hydrophilic–lipophilic characteristics of fuzzy ball fluid on the surface of the tight sand reservoir, the contact angle between the oil and water contact surface was measured using a wetting angle tester after oil–water equilibrium was reached under constant temperature conditions.

3. Field Application

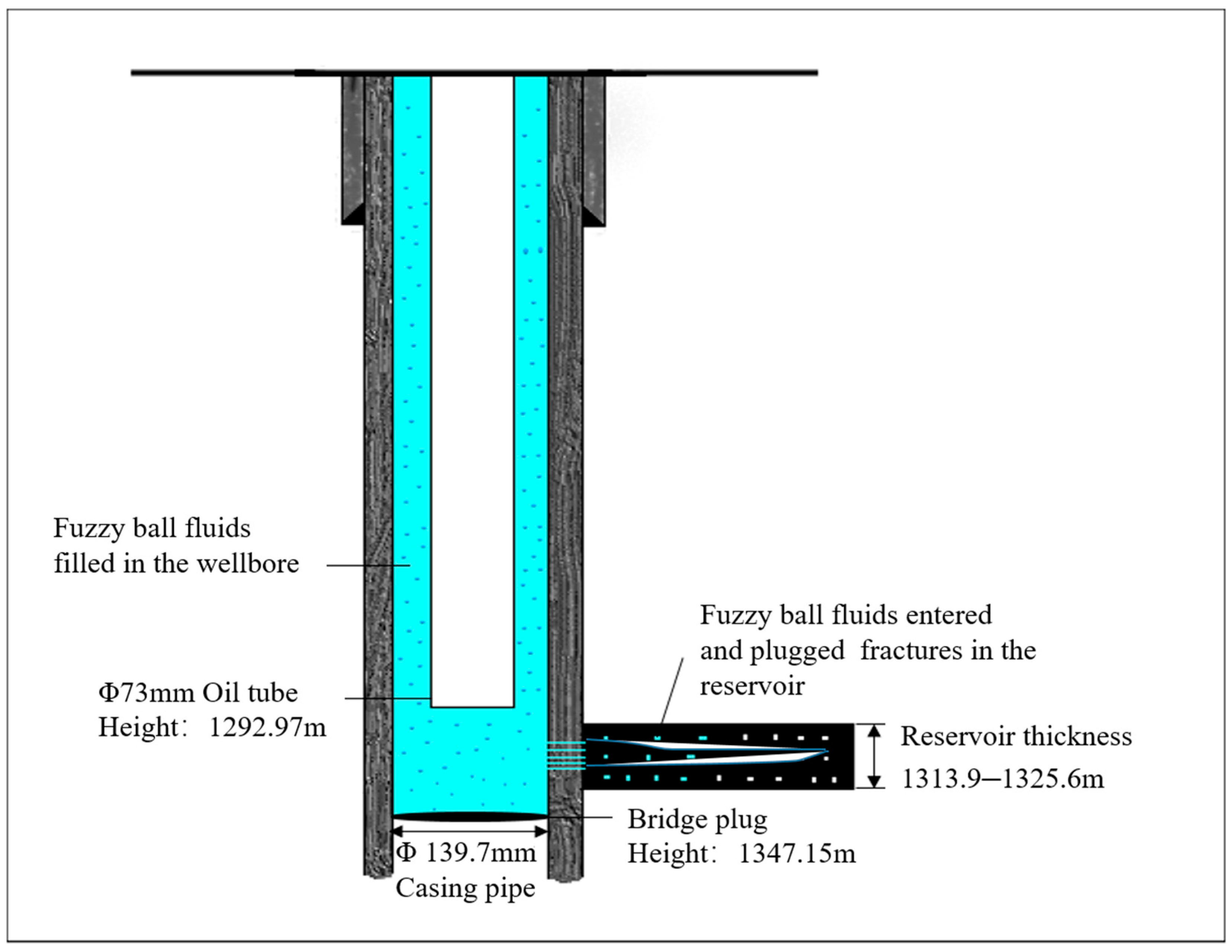

The LX-Y well was drilled on 11 September 2015, with a drilling depth of 2004.00 m. The drilling horizon is Majiagou Formation of Ordovician, which is a straight exploration well located in Rixin Village, Xing County, Luliang City, Shanxi Province. The upper reservoir depth of Qian 5 member in the LX-Y well is 1313.9~1325.5 m, and the reservoir thickness is 11.6 m. In the water shutoff operation, the tubing should be shut off first, and 67 m

3 of pile bag water shutoff fluid should be squeezed directly from the casing, and the pump pressure should be 8MPa. A 1347.15 m liquid column was formed in the annulus, with a total of 15.3 m

3, and the remaining 51.7 m

3 fuzzy ball water shutoff fluid entered the formation to form a plugging zone, as shown in

Figure 4. After that, 15.3 m

3 clear water was squeezed from the annulus, and the remaining pile bags in the annulus were squeezed into the formation, and the well was soaked for 24 h. A total of 67 m

3 fuzzy ball bladder water shutoff fluid was pumped into the formation.

Before the water shutoff operation, the daily gas production of the LX-Y well was 300 m3/d, and the gas layer thickness of Qian 5 member was 11.6 m. There are adjacent wells, such as LX-A well and LX-B well, nearby, all of which have drilled-into gas reservoirs in the Qian 5 member. Among them, the gas layer thickness of the Qian 5 member of LX-A well is 9.3 m, and the daily gas production is 8280 m3/d; the thickness of the gas layer in Qian 5 section of the LX-12 well is 8.9 m, and the daily gas production is 1800 m3/d.

Before water shutoff, the daily gas production per unit gas layer thickness of the LX-Y well was 25.86 m3/d, while the daily gas production per unit gas layer thickness of the LX-A well was 890.32 m3/d, which is 34.42 times that of the LX-Y well; the daily gas production per unit gas layer thickness of the LX-12 well was 202.25 m3/d, which is 7.82 times that of the LX-Y well. The gas production of LX-Y well Qian 5 section does not reach the same level as that of adjacent wells.

4. Results Discussion

4.1. Plugging and Wetting Abilities of Fuzzy Ball Fluid

4.1.1. Fuzzy Ball Fluid Can Block Matrix Effluent

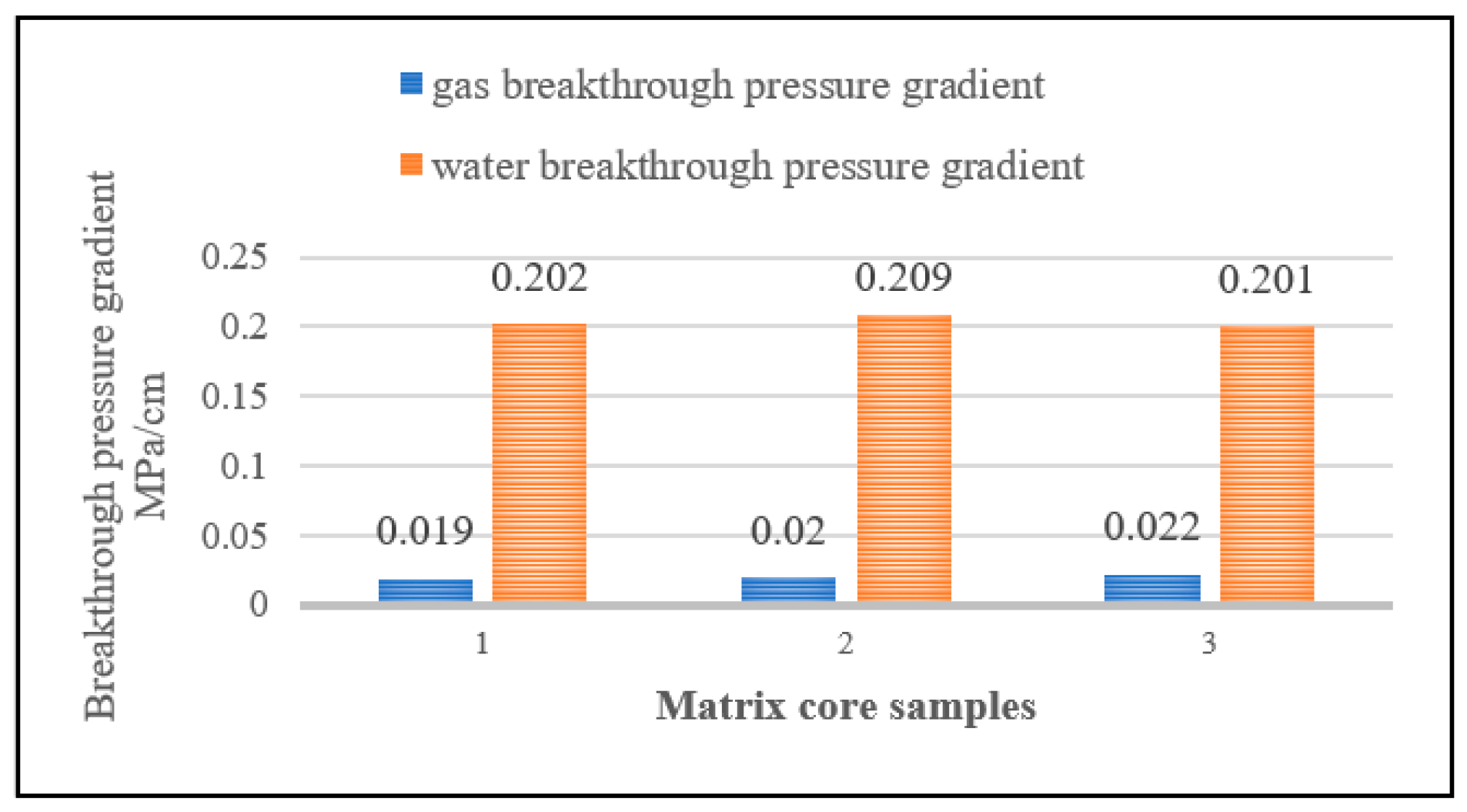

The comparison results of gas–water breakthrough pressure after plugging the matrix core with fuzzy ball fluid measured by the experiment are shown in

Figure 5. It can be seen from

Figure 5 that the breakthrough pressure gradients of nitrogen were 0.019 MPa/cm, 0.02 MPa/cm, and 0.022 MPa/cm, respectively. The breakthrough pressure gradients of simulated formation water were 0.202 MPa/cm, 0.209 MPa/cm, and 0.201 MPa/cm, respectively. After plugging the matrix core with fuzzy ball fluid, the breakthrough pressure gradient of water was about 10 times that of gas.

Research has shown that the pore size of fractures in a formation is generally considered to have a certain correlation with the permeability of the formation. Shi Shenglong and others believe that the correlation between core permeability and average pore diameter is shown in the following formula when studying the matching relationship between micro-foam diameter and formation pore diameter [

26]:

where

is the average pore diameter (μm) and

k is the permeability (mD).

According to Formula (1), the maximum average pore diameter of the formation in this area is 0.445 μm, which is much smaller than the minimum average particle diameter of the water shutoff fluid (110 μm). Therefore, when the fuzzy ball water shutoff fluid plugs the matrix core, because the particle size of the vesicle in the fluid system is larger than the pore diameter, it stays on the core surface and cannot enter the pore interior, while the tiny polymer components in the system gather on the core end face to form a polymer film [

6]. When there are pores on the end face, the polymer components enter the pores and block the matrix cracks. Moreover, the polymer film produces flow resistance to water, which hardly affects the flow resistance of gas, thus achieving water shutoff and gas stabilization for the matrix core [

27].

4.1.2. The Fluids Can Block The Artificial Cracks

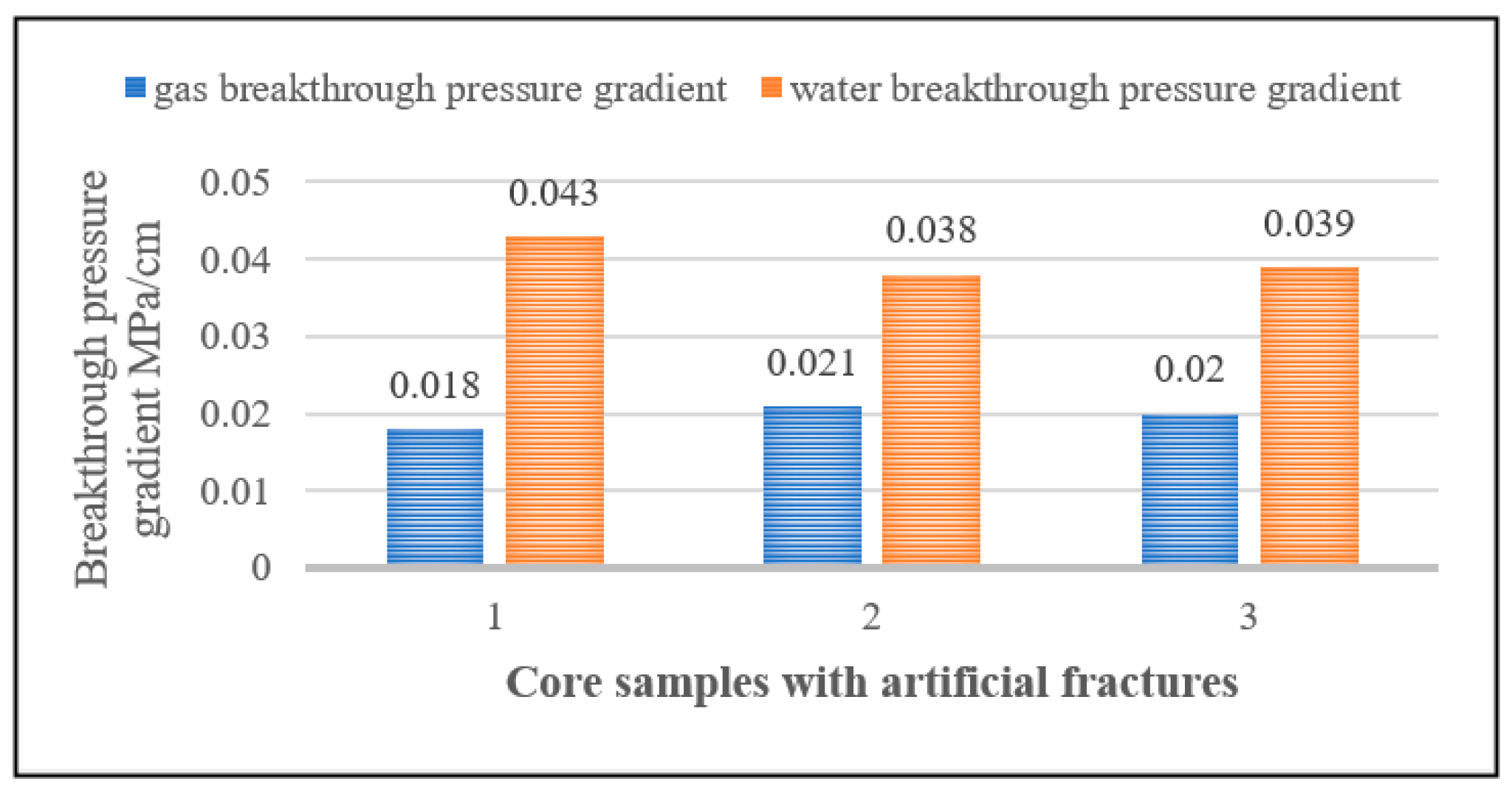

The breakthrough pressure gradients of nitrogen were 0.018 MPa/cm, 0.021 MPa/cm, and 0.020 MPa/cm, respectively, with an average value of 0.0197 MPa/cm after plugging three cores with 4 mm artificial fractures. The breakthrough pressure gradients of simulated formation water were 0.043 MPa/cm, 0.038 MPa/cm, and 0.039 MPa/cm, respectively, with an average value of 0.040 MPa/cm. The comparison results of gas–water breakthrough pressure after plugging cores containing artificial fractures with fuzzy ball fluid are shown in

Figure 6.

It can be seen from

Figure 6 that after plugging fractured cores with fuzzy ball fluid, the water breakthrough pressure gradient is about two times that of the gas breakthrough pressure gradient, and the ratio of the water and gas breakthrough pressure gradient decreases to a certain extent compared with plugging matrix cores. The analysis shows that when plugging large-scale water-producing channels such as artificial fractures, fuzzy ball fluid is plugged under pressure in the form of the accumulation of fuzzy balls [

9], and there is a certain scale circulation channel between fuzzy balls where gas can pass freely and water molecules can pass partially, showing that there is a difference in the breakthrough pressure gradient between gas and water, but the difference is not big. In field applications, when the scale of the water production channel is large and the water volume is large, it is possible to increase the amount of fuzzy ball fluid or the number of fuzzy ball in the current system, strengthening the vesicle plugging structure, increasing the water circulation resistance and increasing the water breakthrough pressure, and achieving stable air control and water control.

4.1.3. Fuzzy Ball Fluid Has Good Hydrophilic Ability

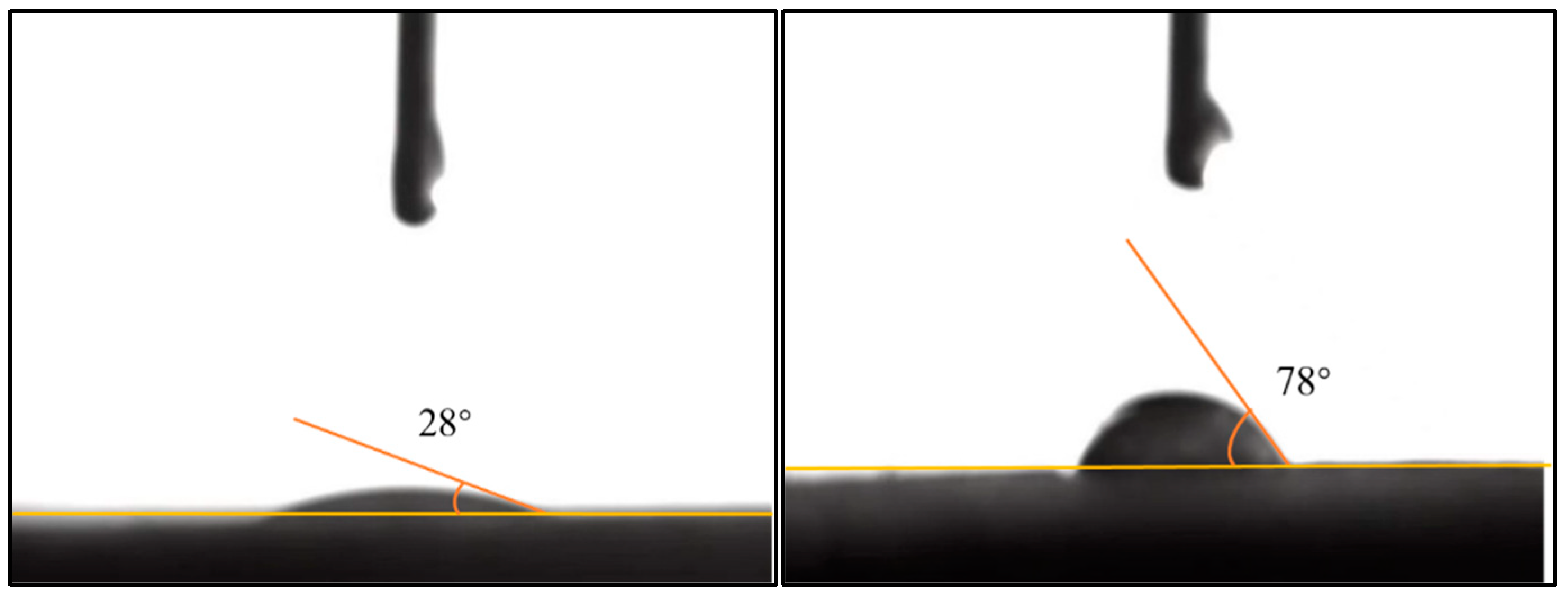

There is a certain relationship between the wetting angle and interfacial tension, which is a quantitative characterization method of wettability. The wettability of a rock surface can reflect its hydrophilic or hydrophobic ability, which is generally expressed by contact angle θ. The contact angle of tight sandstone saturated with formation water and kerosene between fuzzy ball fluid was tested and is displayed in

Figure 7.

As is shown in

Figure 7, the contact angle between the tight sandstone saturated with formation water and the fuzzy ball fluid is 28°, and that of the tight sandstone saturated with kerosene and the fuzzy ball fluid is 78°, indicating that the fuzzy ball fluid has good hydrophilic ability. The temporarily plugged fuzzy ball fluid in the fractures of tight sand reservoirs enhances the flow resistance of water and does not hinder the passage of gas.

4.2. Fuzzy Ball Fluids Improve the Gas Production Capacity via Water Cutting

4.2.1. Sustainability Analysis of Water Control Ability of Fuzzy Ball Fluid

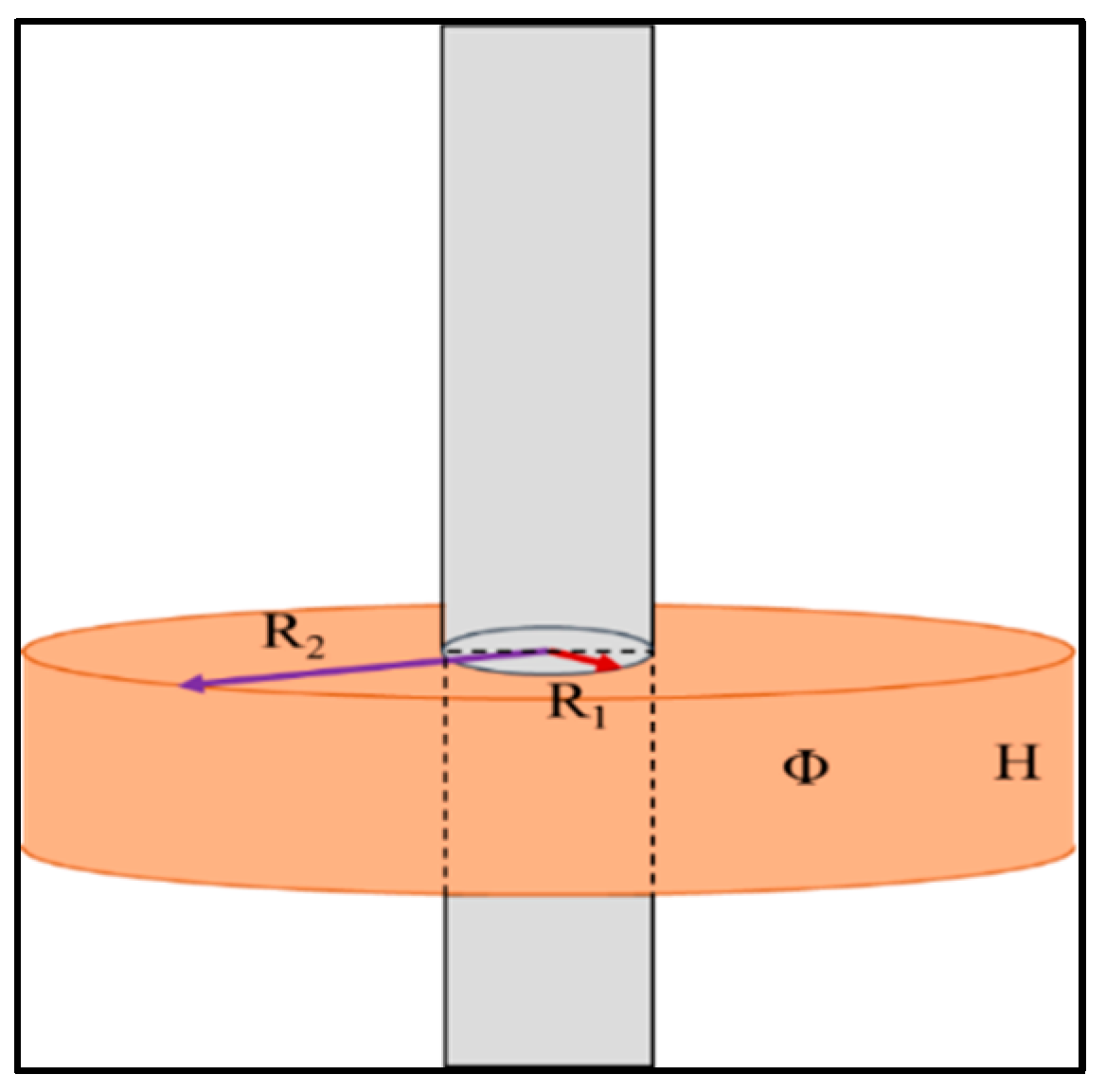

Under the guidance of fuzzy plugging theory, plugging materials are plugged in the form of accumulation, stretching, and plugging, and the shape and size can be adjusted along with the leakage channel. The plugging zone is formed with an “annular shape” when the plugging fluid is pumped into the formation, and the gas-producing layer enters the pore of the rock matrix and fractures. Therefore, the downhole plugging model of fuzzy ball water plugging fluid is established, as shown in

Figure 8. According to this model, the length of the plugging zone is calculated, and the formula for calculating the length of the plugging zone of fuzzy ball water shutoff fluid in the reservoir is denoted as Formula (2). Combined with the breakthrough pressure test results of the fracture-making core in a laboratory, the plugging effect is compared with that of field construction.

where

R1 is the outer diameter (m) of the casing,

Rf is the length (m) of the plugging belt,

R2 is the sum (m) of the length of the plugging belt and the outer diameter of the casing, Φ is the porosity of the working horizon (%),

H is the thickness of the working layer (m), and

V is the amount of water shutoff fluid (m

3).

A total of 67 m3 of fluid was injected into the field. The casing diameter of the LX-35 well is 0.2445 m, the radius is 0.1223 m, the upper reservoir thickness of Qian 5 member is 11.6 m, and the formation porosity is 11.90%. According to Equation (2), the length of the plugging zone is 3.80 m. In laboratory experiments, the mean pressure gradients of gas and water are 0.0197 MPa/cm and 0.0400 MPa/cm, respectively, and the calculated plugging strength of water and gas in the fractures is 7.48 MPa and 15.20 MPa, respectively.

With the continuous drainage process, the liquid column pressure in the wellbore gradually decreases, and the casing pressure is adjusted to maintain a reasonable pressure difference between formation pressure, casing pressure, and liquid column pressure, so that when the pressure difference between formation pressure, hydrostatic column pressure, and casing pressure is higher than the breakthrough pressure of tight gas, tight gas begins to be discharged from the reservoir. Among them, the formation pressure refers to the previous fracturing analysis report, and the value is 14.5 MPa. On 5 May, when the liquid column height reached 83.67 m and the casing pressure reached 6.1 MPa, gas was produced in the LX-35 well, and the production pressure difference was calculated according to Formula (3):

where P

P is the producing drop (MPa), P is the formation pressure (MPa), P

L is the liquid column hydrostatic pressure (MPa), and P

C is the casing pressure (MPa).

At this time, the production pressure difference was 7.6 MPa, which is higher than the gas plugging strength. The plugging strength of water plugging fluid had no effect on gas production, which indicates that the plugging strength provided by the length of the plugging zone can produce gas reasonably.

From 26 April to 8 May, the daily water output decreased from 82.97 m3/d to 42.96 m3/d. At this time, the plugging strength provided by the fuzzy ball plugging zone was 15.2 MPa, which is higher than the formation pressure of 14.5 MPa, but the water is not completely plugged, which indicates that the energy of the edge and bottom water horizon is abundant, and the pressure is much higher than the plugging strength of fuzzy ball fluid. At this time, aiming to solve the problem of fracture water output, it is necessary to increase the amount of water shutoff fluid in the pile bag, make it have a reasonable length within the plugging zone, improve the plugging strength of gas and water in the pile bag water shutoff fluid, and achieve the purpose of completely plugging the edge and bottom water. At this time, gas production can ensure that the gas well has a reasonable production pressure difference by adjusting the height of the liquid column and casing pressure in the wellbore and that tight gas production is not affected.

4.2.2. The Fluids Can Avoid the Edge and Bottom Water Invading

When the fractures after artificial reconstruction communicate with the edge and bottom water in other horizons, it is easy to form edge and bottom water channeling. This kind of water outlet channel combines the characteristics of a matrix pore water outlet and artificial fracture water outlet.

Based on the above analysis, it can be seen that the polymer molecules dispersed in the system enter the tiny pores of the formation and wrap with each other to form a polymer plugging membrane structure. Water molecules rarely or hardly break through this polymer membrane, but gas molecules easily break through. For artificial fractured cores with a large leakage channel size, fuzzy ball fluid simultaneously forms a pressure-bearing plugging structure via fuzzy ball fluid accumulating in the system.

Combined with indoor research, it is concluded that the fuzzy ball fluid can block small-scale water outlet channels such as matrix pores through the formation of polymer winding film formation and can block artificial cracks and large-scale water outlet channels flowing into edge and bottom water through a high amount of fuzzy ball accumulation, which basically does not hinder gas circulation. However, the productivity of the LX-Y gas well is still not high after using pile bladder water plugging in the trial production process, so there are many controversies towards the evaluation of the water plugging effect. According to some studies, the micro-fracture development area of Linxing ancient deep coal measure strata is the potential area for single-well breakthrough in a deep coal seam, which is characterized by fast gas, more water production, stress sensitivity, and a slow increase in gas production in some areas, showing weak productivity after the water shutoff of gas wells. In the follow-up, it was suggested that a further systematical evaluation of the natural gas productivity of the LX-Y well in combination with the geological reservoir-forming characteristics of the Linxing deep coal measure natural gas wells and the production data of adjacent wells takes places, and that corresponding adjustments are made.

According to the laboratory experiments and discussion, it is suggested that the dosage of the plugging agent be increased, or the number of fuzzy balls in the existing system be increased, improving the breakthrough pressure gradient of water and achieving stable gas control and water control for the field water plugging operation of fuzzy ball fluid, especially for the large-scale artificial fracture water and edge and bottom water influx.

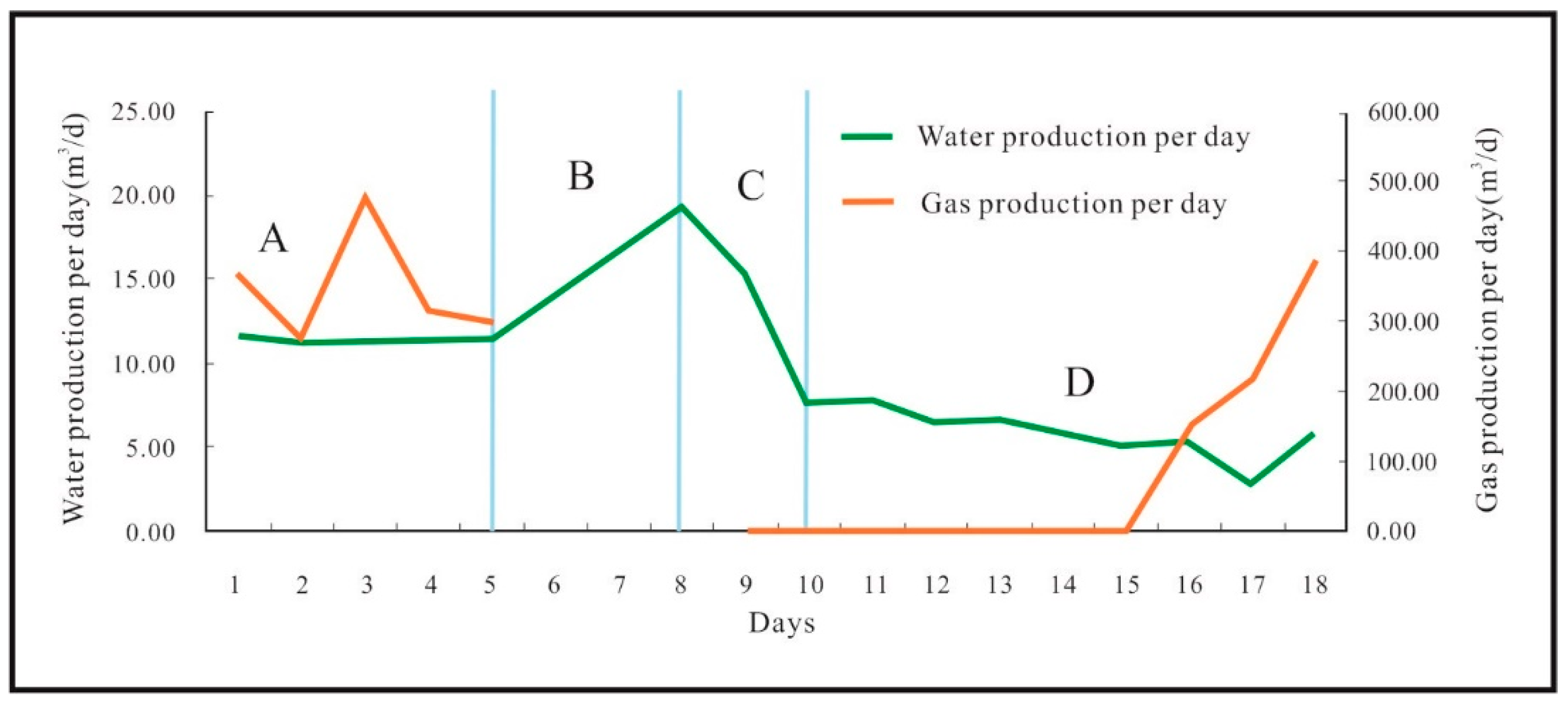

The changes in water/gas production before and after the water shutoff operation in the LX-Y well are shown in

Figure 9. It can be seen from the figure that when the water shutoff operation was carried out, the water production per unit pressure difference gradually increased and reached its peak on the eighth day after the operation, and the gas production decreased to 0 (displayed in B zone). After water shutoff, drainage was carried out, and the daily water production per unit pressure difference gradually decreased, tended to be stable after 10 days(displayed in C zone), maintained gas production at 0 until 5 days later, and then the gas production returned to the level it was at before the water shutoff operation(displayed in D zone). Seventeen days after the operation, water production was maintained at 42.96 m

3/d, and the formation gas production recovered to 394 m

3/d.

The gas production capacity of a gas well is directly proportional to the gas content of the reservoir. The greater the gas content, the richer the reservoir gas storage, the better the gas production capacity, and the greater the daily gas production. The daily gas production of the LX-Y well is 394 m

3/d, which is lower than that of its adjacent wells, indicating that the reservoir gas content of this well is low, and that the gas production capacity of this well is not high due to the heterogeneity of the reservoir and insufficient natural gas [

28].

The effluent of a gas well also has a serious influence on the productivity of the gas well. Water production is related to gas production, which is usually characterized by the water/gas ratio. The higher the water/gas ratio, the greater the influence on the effluent gas well productivity. Compared with the production water/gas ratio which reached 0.5 m

3/10

4 m

3, it is seen that the gas can be stably outgassed. That is to say, under this gas production, when the interlayer water–gas pressure is the same, the tight gas production speed is fast, and the effluent cannot stay in the wellbore to form a liquid column, which increases the liquid column pressure and withstands the effluent pores, meaning that interlayer water will be taken away from the wellbore with gas production. When the water/gas ratio exceeds this, the liquid-carrying capacity of gas wells decreases, resulting in a decrease in gas production with an increase in the water/gas ratio. The ratio of production water to gas in the LX-Y well is 1090.36 m

3/10

4 m

3, and the daily production water of 42.96 m

3/d is higher than the minimum production water during gas production, which indicates that the gas production rate of the LX-Y well cannot bring out water under this production, which allows water to easily accumulate in the wellbore to form a liquid column and affects the production of tight gas [

29].

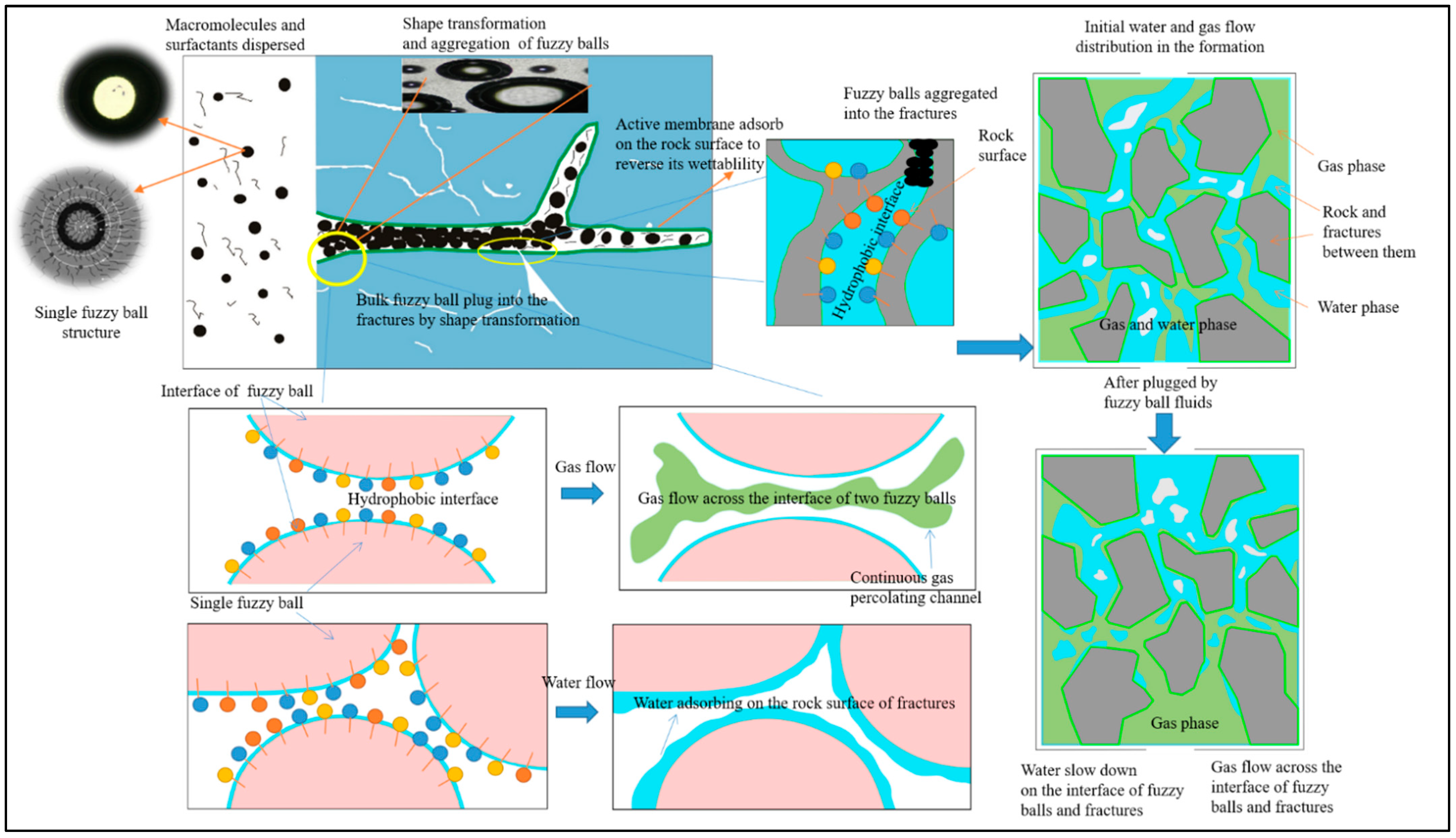

4.3. Mechanisms of Water Shutoff and Oil Recovery Enhancement of Fuzzy Ball Fluid

According to the base analysis, as a fracturing fluid, fuzzy ball fluid transfers pressure in the direction perpendicular to the wellbore through temporary plugging cleats and natural fractures during fracturing, thus promoting the formation of regular long fractures. This is helpful to solve the problem of unsatisfactory fracture formation in coal and rock reservoirs. In addition, because it is easy to communicate with water layers during the fracturing of tight gas reservoirs in coal measures, resulting in water production in gas wells, fuzzy ball fluid has the ability to control water while fracturing. If the dimension or width of the leakage channel is larger than the dimension of the fuzzy ball, the fuzzy ball will accumulate and decompose into a conical shape lying on its side. When the dimension or width of the leakage channel is equal to the dimension of the fuzzy ball, the fuzzy ball is drawn by the low-pressure area and it changes from a circle to an ellipse. When the dimension or width of the leakage channel are smaller than the dimension of the fuzzy ball, high-strength gel is used to form a non-permeable membrane to shield the leakage channel to achieve leakage prevention and plugging. Fuzzy balls amalgamate at the tip of the fracture to form a tight plugging structure. Hydrological fuzzy ball core agents adsorb on the rock’s surface and form a polymer membrane, which increases the persistence of water intruding into the formation [

30]. Moreover, fuzzy ball fluid is an environmentally friendly functional fluid [

31], which makes it easy to unchoke the plugging structure and restore the flowback channels [

32], resulting in good compatibility with the formation and causing less damage to the reservation permeability [

33].

Furthermore, during the drilling process of the coalbed method, it has been shown that fuzzy ball fluid can increase the strength of the coal rock by reducing the brittleness of the rock and improving its plasticity [

34]. After reporting, the pressure-bearing capacity of the original ortho-acidified high-conductivity wormhole was improved without damaging the gas production capacity, and a new production contribution was added [

35,

36]. At the same time, the macromolecules and surfactants disperse in the fluid system after the fluid enters the formation because the fuzzy ball blocks the leakage channel, stays on the rock surface of the fracture/fracture channel, and forms a compact, scouring-resistant, and high-strength active membrane on the rock surface of the fracture. The active membrane changes the wettability of the rock surface from hydrophilic to hydrophobic, improves the flow resistance of water, and does not affect the passage of oil and gas. Laboratory experiments show that the starting pressure of the water phase is greater than that of gas. This application shows that after plugging old fractures temporarily, the fracturing fluid can be forced to turn to open new fractures without damaging the original fractures, which is suitable for repeated fracturing and resuming production in old coalbed methane wells. Generally speaking, in the process of tight gas production in coal measures, the pressure is transmitted to the direction perpendicular to the wellbore via the dynamic temporary plugging of old fractures, which promotes the formation of regular long fractures. In the process of plugging, the flow resistance of water is improved without changing the flow resistance of oil and gas. After fracturing, the temporary plugging body plays a role in controlling water at the same time, thus achieving the integrated operation of fracturing, and controlling water in the process of reservoir reconstruction. This process is outlined schematically in

Figure 10.

After the field application of the LX-Y well in the water shutoff operation, the water production per unit pressure difference and before water shutoff operation decreased significantly, and the daily gas production maintained the level of daily gas production without a water shutoff operation and showed an increasing trend. However, there are still water problems and low gas production in the LX-Y well after the water shutoff operation. There are three possible reasons for the conclusions of this analysis.

(1) The effluent from the LX-Y well derives from the same layer of water. The formation has low porosity and permeability, the permeability is between 0.01 mD and 0.03 mD, and the particle size of fuzzy ball is between 10 μm and 150 μm. The pore diameter is much smaller than the particle size of the cashmere vesicle, which makes the cashmere vesicle unable to enter the pore of the formation rock, weakens the plugging effect, and cannot play the role of plugging the interlayer water;

(2) After fracturing in the LX-Y well, fractures communicate with upper and lower horizons and high water cut positions, resulting in the problem of edge and bottom water spilling out. Due to the small injection amount of cashmere bags in the field, the plugging belt is not long enough, which leads to the insufficient plugging strength of cashmere bags and affects the water plugging effect;

(3) The gas production capacity of the formation is not enough, resulting in a poor overall effect. The daily gas production of the LX-Y well is 394 m3/d, compared with the adjacent well daily gas production, which is poor. The actual formation gas production capacity is also poor, and the formation gas production capacity is low, resulting in the water shutoff operations having a poor overall effect.

5. Conclusions

(1) In the process of plugging, fuzzy balls change their shape to match the fracture channel sizes and an active membrane is formed on the surface of fractured rocks, which changes the wettability of the rock surface, causes wetting reversal, improves the flow resistance of water, and does not change the flow resistance of oil and gas. The fuzzy balls aggregating and plugging into the fractures also play a role in controlling water after the fracturing operation with their hydrophobic interface, which slows down the flow of water and provides a continuous gas percolating channel after, thus achieving the integration of fracturing and water control in the process of reservoir reconstruction.

(2) It has been proven that the breakthrough pressure of gas and simulated formation water is different after water shutoff; the breakthrough pressure gradient of gas is lower than that of water, and the flow resistance of water is increased after water shutoff, outlining the high level of sustainability achieved by stabilizing gas and controlling water. The breakthrough pressure of water after plugging can be increased by increasing the amount of fluids in the fuzzy ball bladder or the density of fuzzy ball in the system, so as to achieve the stable control of gas and water.

(3) There are many factors affecting gas well productivity after water shutoff, which are limited by indoor simulation conditions and cannot be completely matched with field construction conditions. The influence of gas well productivity reserves and construction technology on productivity requires further verification.