4.2. Results

In

Table 2, the priorities of the criteria are shown, which were obtained by comparing all the criteria to the first-ranked (most significant one). The first criterion, inventory costs, was highlighted as the most important criterion, and all other criteria were compared to it. These values were obtained as an average based on the evaluations of five logistics experts. The significance of the first criterion is 1 since it is compared to itself.

The FUCOM model in this paper has the following formulation.

s.t.Using the Lingo Solver program and solving this model, the following weight coefficients (0.294, 0.196, 0.155, 0.105, 0.072, 0.056, 0.046, 0.042, and 0.033)T were obtained and used further to obtain the final rank of alternatives using the ADAM method.

In

Table 3, the alternative ratings for all criteria are shown. These values were obtained as an average based on the evaluations of five logistics experts. When evaluating, experts used a 1–10 scale. The first two criteria should be minimized, whereas the remaining criteria should be maximized.

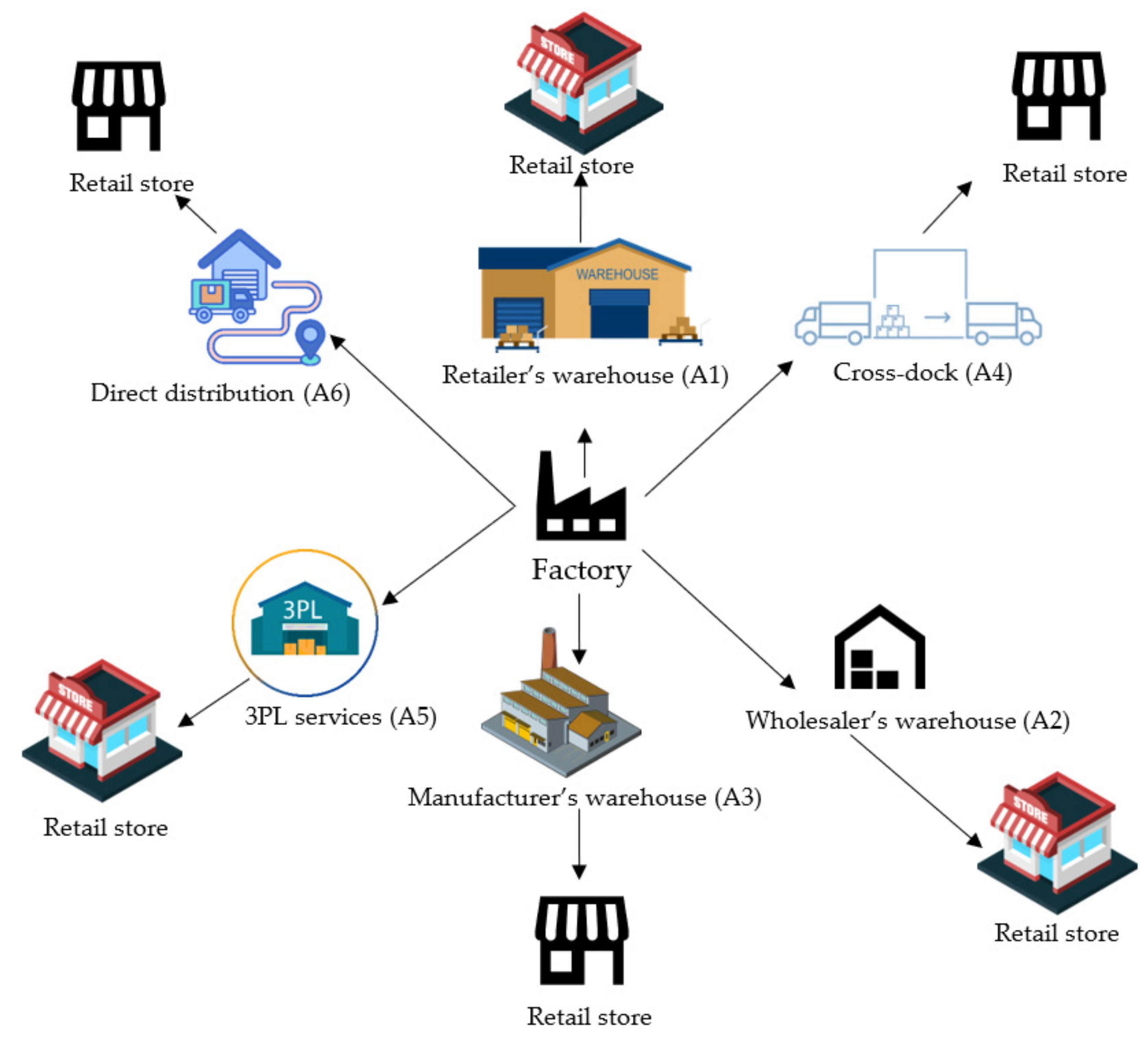

According to criterion C1, alternative A3 has the best rating as there are no or only short-term inventory holdings of goods on the cross-docking platform. However, at the manufacturer’s warehouse and in the channel with the 3PL provider, there must always be a large amount of inventory to ensure that there is no shortage of products, and for these reasons, these alternatives have the worst rating. Direct delivery has a similar rating, while the inventory costs in alternative A1 are lower than those in alternative A2 because there is a wider range of products in wholesale warehouses.

When it comes to the second criterion, i.e., distribution costs (C2), the best-rated alternative is A6, as the goods move directly from the manufacturer to the retailer without any intermediate stops or transshipments. The alternative A4 has the worst rating for this criterion, given the numerous transshipment manipulations of goods from one transport vehicle to another. Alternative A5 is the second-worst due to the costs of engaging a 3PL provider, as well as the transportation of goods to their warehouse, transshipment, and final distribution to the retailer. Distribution costs at the retailer’s warehouse (A1) are slightly lower than those at the wholesaler’s warehouse (A2) but higher than those at the manufacturer’s warehouse, as it is considered that this warehouse is located near the production site.

According to the third criterion, i.e., delivery speed (C3), the logical sequence is that direct delivery (A6) has the best rank, followed by the 3PL service (A5), given that 3PL providers perform transportation services in the most efficient way for their clients, and delivery is direct without any additional activities. Then, in the third place, is the retailer’s warehouse (A1), as their goal is to deliver goods to their retail stores as soon as possible, which is not the case with wholesaler’s (A2) and manufacturer’s (A3) warehouses, so they received lower ratings. The worst-ranked alternative in accordance with this criterion is undoubtedly the cross-dock (A4) due to numerous transshipments of goods.

Criterion C4 refers to the service level, which is based on product availability, delivery speed, reliability, and many other factors. According to this criterion, the best-ranked alternatives are A5 and A6, i.e., 3PL service and direct delivery, given the high delivery speed and product availability, so in those cases, products will be in retail stores shortly after the order is placed. In third place is the alternative A1, as the goal is to provide excellent service to its customers, whereas wholesaler’s (A2) and manufacturer’s (A3) warehouses received lower ratings. The cross-dock (A4) is the worst-rated alternative in accordance with this criterion given the very high possibility of errors during consolidation and deconsolidation.

Market coverage (C5) is very important since the amount of income and costs, as well as customer satisfaction, depend on it. According to this criterion, the best alternative is A5 because 3PL providers specialize in providing transportation services, and they can cover the requirements in different geographical areas in the easiest way. In second place is alternative A2, because wholesaler’s warehouses can be found anywhere, followed by the retailer’s warehouses (A1), which cover a smaller geographical area compared to wholesalers. The cross-dock alternative (A4) came in fourth place with a score of 5, because it does not cover larger geographical areas, but it is significantly better than the manufacturer’s warehouse (A3) and direct delivery (A6), which are limited to smaller coverage.

When ranking in accordance with the product availability (C6), the best alternatives are direct delivery and the retailer’s warehouse, taking into account that the endpoint is a retail store, so in those cases, there is the greatest possibility of fast delivery of the requested products. As the 3PL provider covers a large geographical area and has a high delivery speed, it can also have a high product availability, only if the manufacturer has ensured that the product is in the provider’s warehouse, therefore this alternative (A5) has a score of 8. For similar reasons, the second alternative (A2) has a score of 7, while the alternatives A3 and A4 are significantly worse. Cross-dock is the least reliable of the observed alternatives, and according to this criterion, it received the lowest rating.

The order consolidation capability (C7) is certainly the greatest with the cross-dock (A4). However, alternative retailer’s and wholesaler’s warehouses, as well as 3PL services, also have a high possibility of consolidation, and accordingly, they received the highest rating as well. Retailer’s warehouse, as well as wholesalers, deliver fully consolidated goods to retail stores, whereas 3PL providers specialize in this type of service. A manufacturer in his warehouse, in which there are several types of products, can perform consolidation, but this is a rare case. In the case of direct delivery, the only thing that matters is that the entire cargo space is filled because otherwise such delivery cannot be realized, so the consolidation of the goods, in this case, is not a priority.

According to criterion C8, i.e., reverse logistics, the alternatives related to the retailer’s warehouse and direct delivery are the best rated. The retailer’s warehouse will collect waste and returnable goods from its own retail stores, whereas direct delivery, as a rule, should also have a reverse flow, and such goods can also be transported in it. The 3PL service provider can also transport waste or goods that must be withdrawn from sale for some reason on the return trip, and for these reasons, alternative A5 received a score of 9. If the manufacturers distribute to retail stores through their own warehouse, they can also collect the goods that need to be returned, so alternative A3 was in third place. A somewhat worse alternative is distribution through wholesaler’s warehouses, whereas the worst alternative, due to its complexity, is A4 (cross-dock), where it is practically impossible to carry out these flows.

Order tracking is the ninth criterion and in relation to it, the best alternatives are definitely direct delivery and 3PL services because they are very reliable and accompanied by accurate and timely information. As the end-user, in this case, is a retailer’s store; the alternative related to the retailer’s warehouse is ranked second according to this criterion, considering the close connection of these participants in the distribution channel. The wholesaler’s warehouse has a slightly lower rating, but in principle, they also provide great opportunities for tracking the goods they ship to retail stores. The ability to provide order tracking is not too important for the manufacturer, whereas cross-dock tracking is practically at a very low level and even impossible; therefore, this alternative has the lowest score according to this criterion (

Table 3).

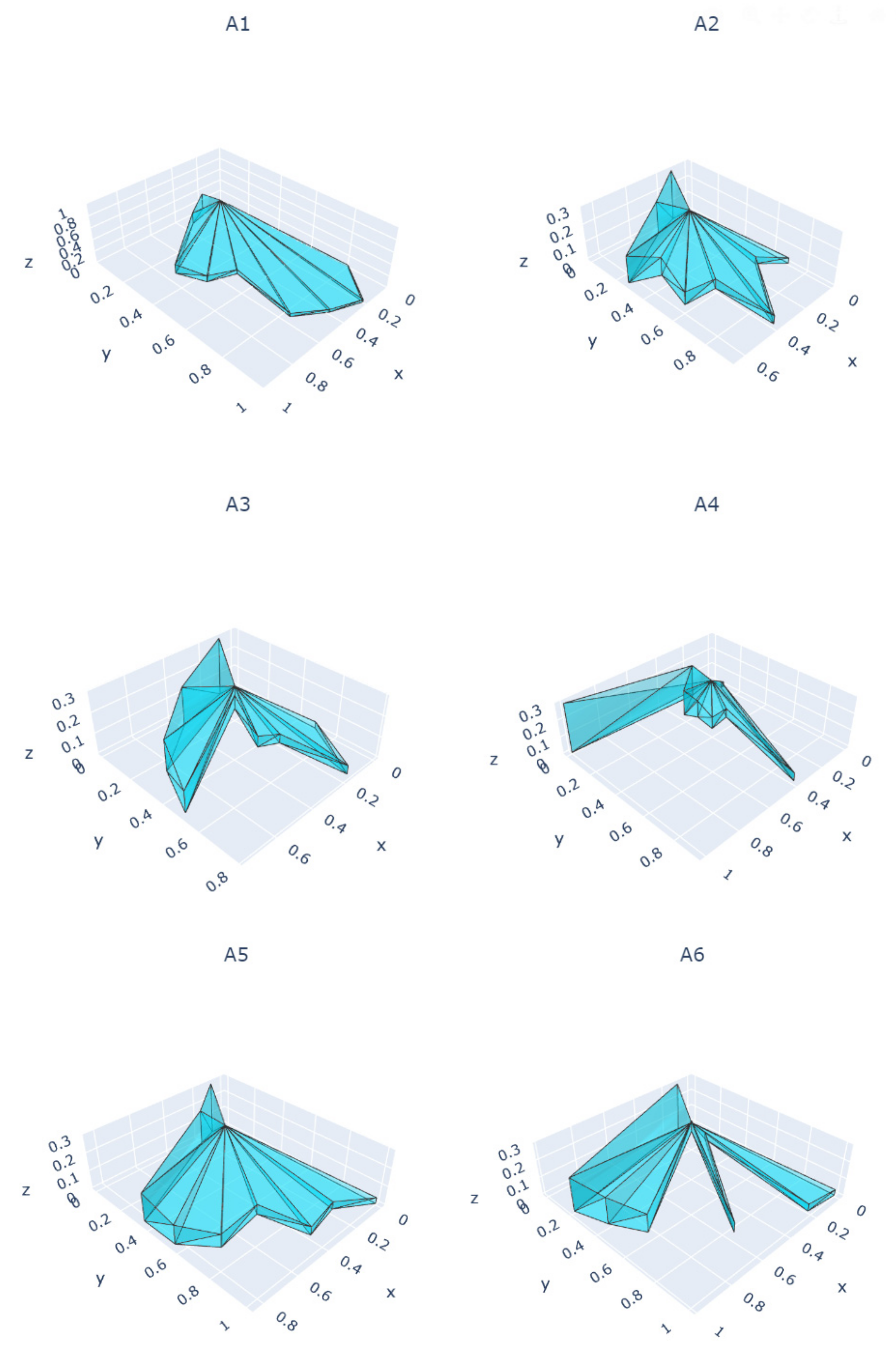

In the second phase, the ADAM method was applied in order to obtain the final ranking of the alternatives. A software [

37] was used to obtain the results. In other words, after determining the alternatives, criteria used in this paper, and initial decision-making matrix, the results were obtained by using Equations (10)–(26) (

Table 4). In order to rank the alternatives, the complex polyhedra defined by the reference and weighted reference points need to be obtained.

Figure 3 represents the complex polyhedral volumes that are used for alternative ranking, and, as can be seen, the best-ranked alternative is A5 followed by A6, A1, A2, A3, and A4. Based on these results, distribution using 3PL services is ranked as the best alternative, whereas cross-dock was determined to be the worst-ranked alternative. Also, alternative A5 has only a slightly higher value in volume when compared with A6. The final ranking of the alternatives can be shown as A5 > A6 > A1 > A2 > A3 > A4.