Rheological, Mechanical, and Micro-Structural Property Assessment of Eco-Friendly Concrete Reinforced with Waste Areca Nut Husk Fiber

Abstract

:1. Introduction

2. Experimental Program

2.1. Research Methodology

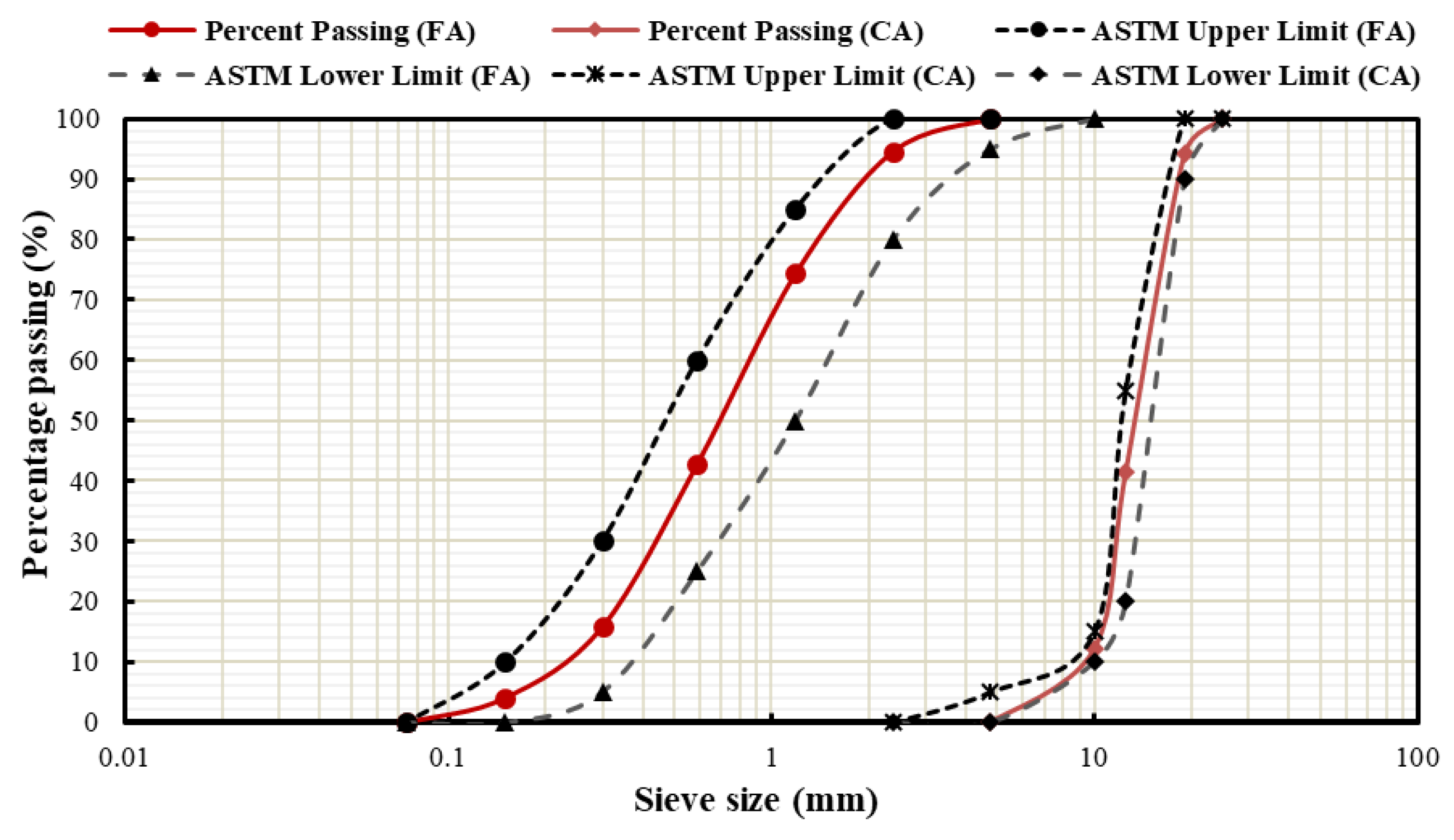

2.2. Materials

2.3. Areca Fiber

2.4. Mix Proportion of the Specimens

2.5. Specimen Preparation and Curing

2.6. Testing Methods

3. Results and Discussion

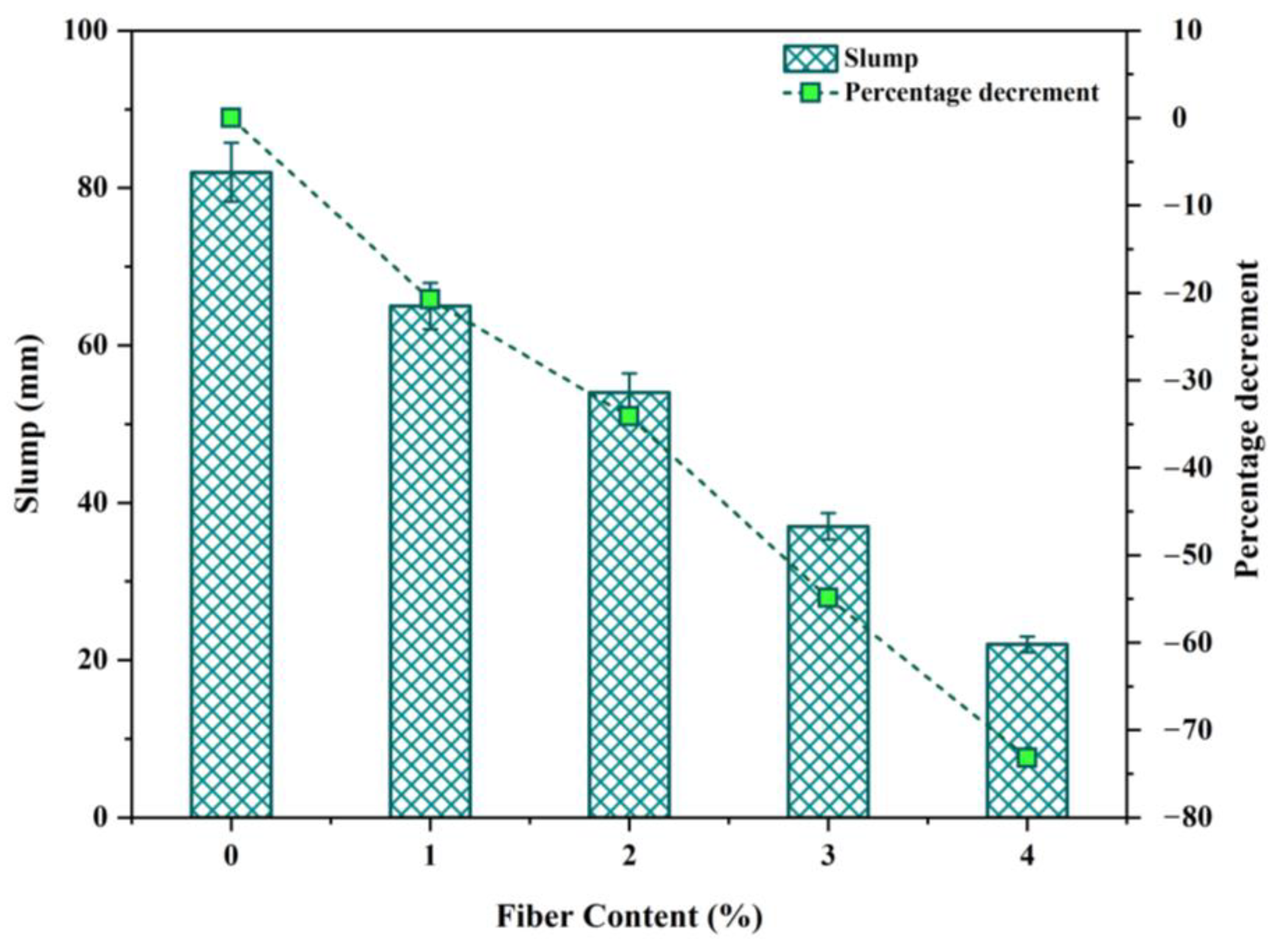

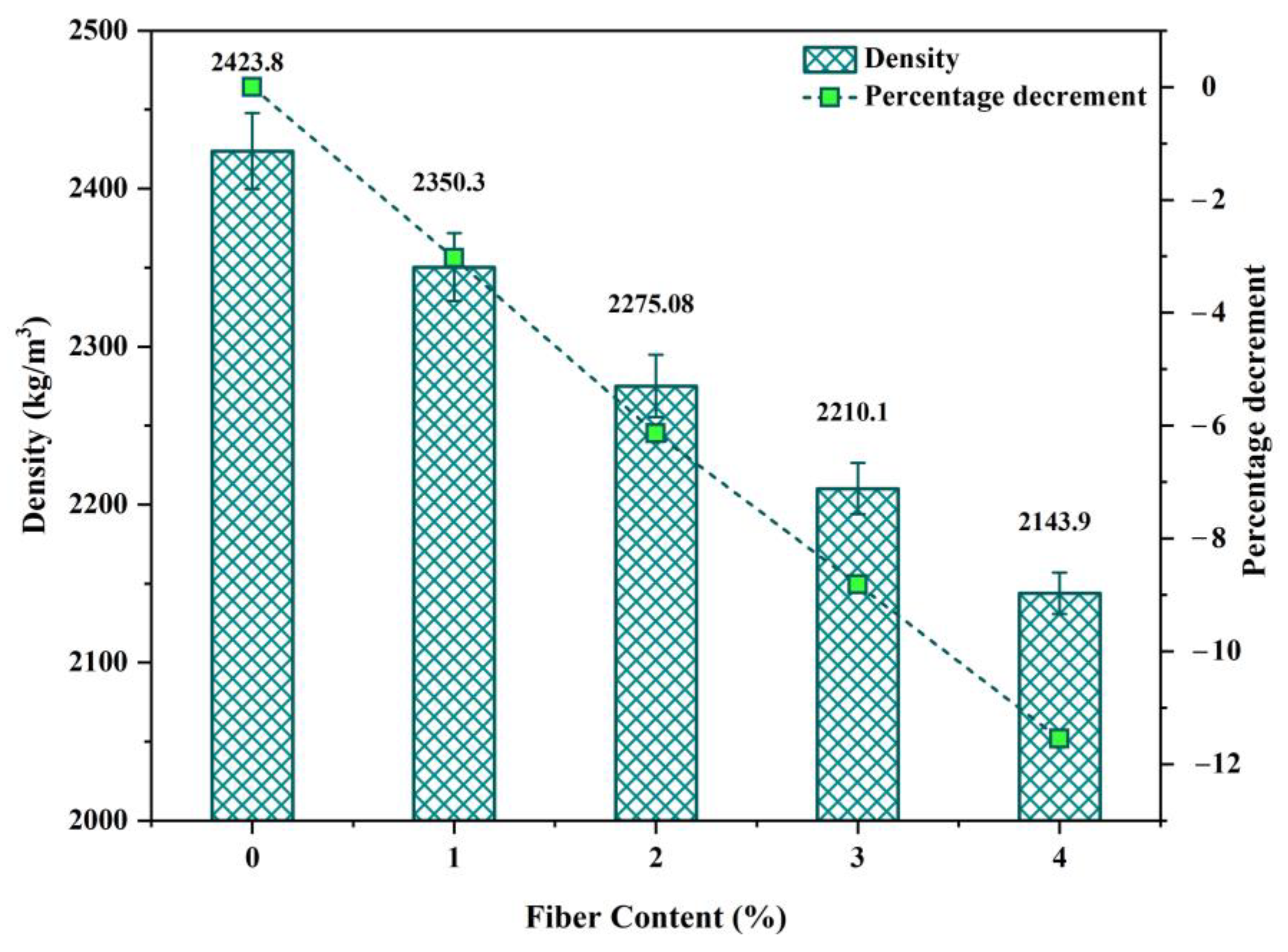

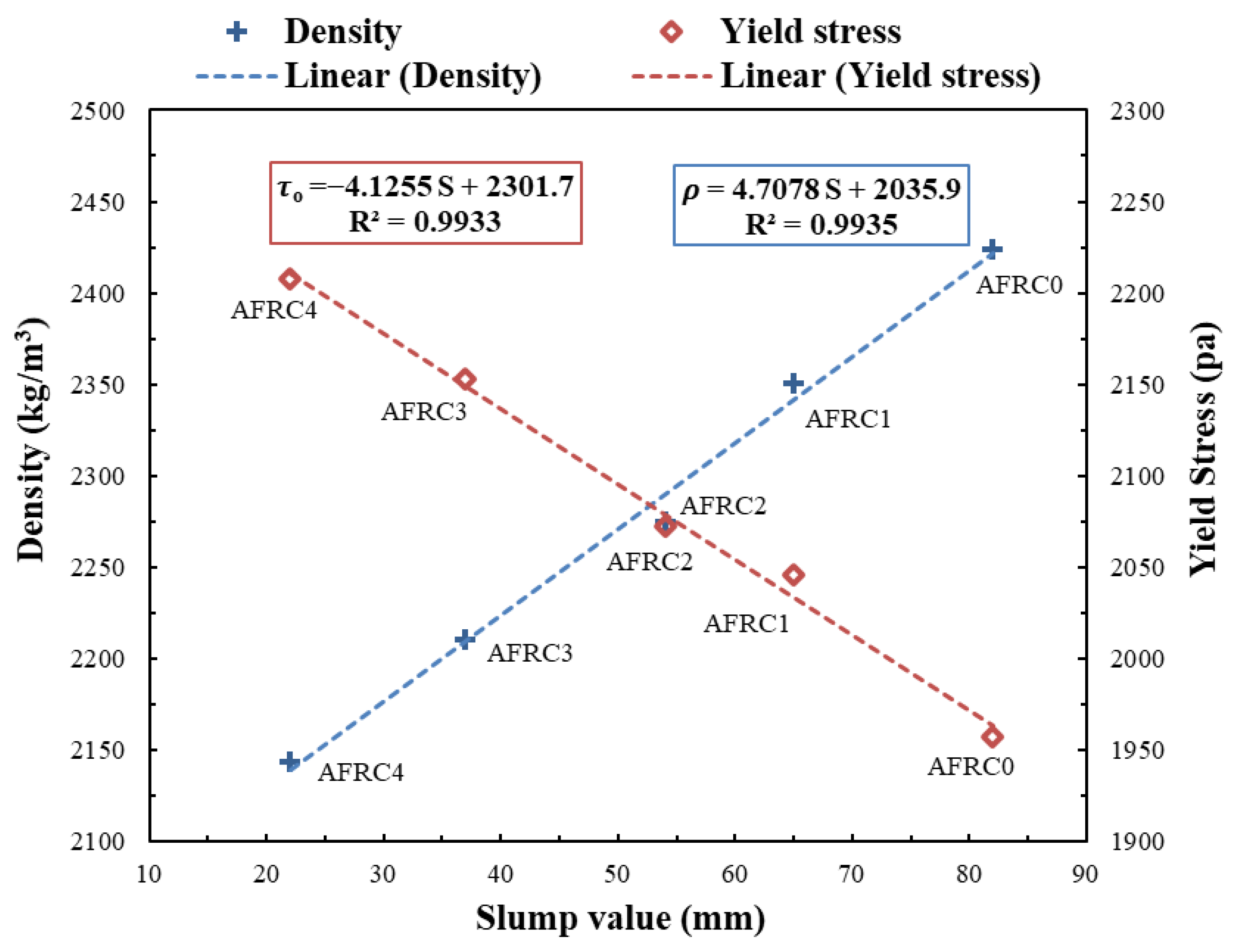

3.1. Rheological Properties

3.1.1. Slump Value of Fresh Concrete Mixes

3.1.2. Density of Fresh Concrete Mixes

3.1.3. Relationship between Rheological Properties of Concrete

3.2. Mechanical Properties

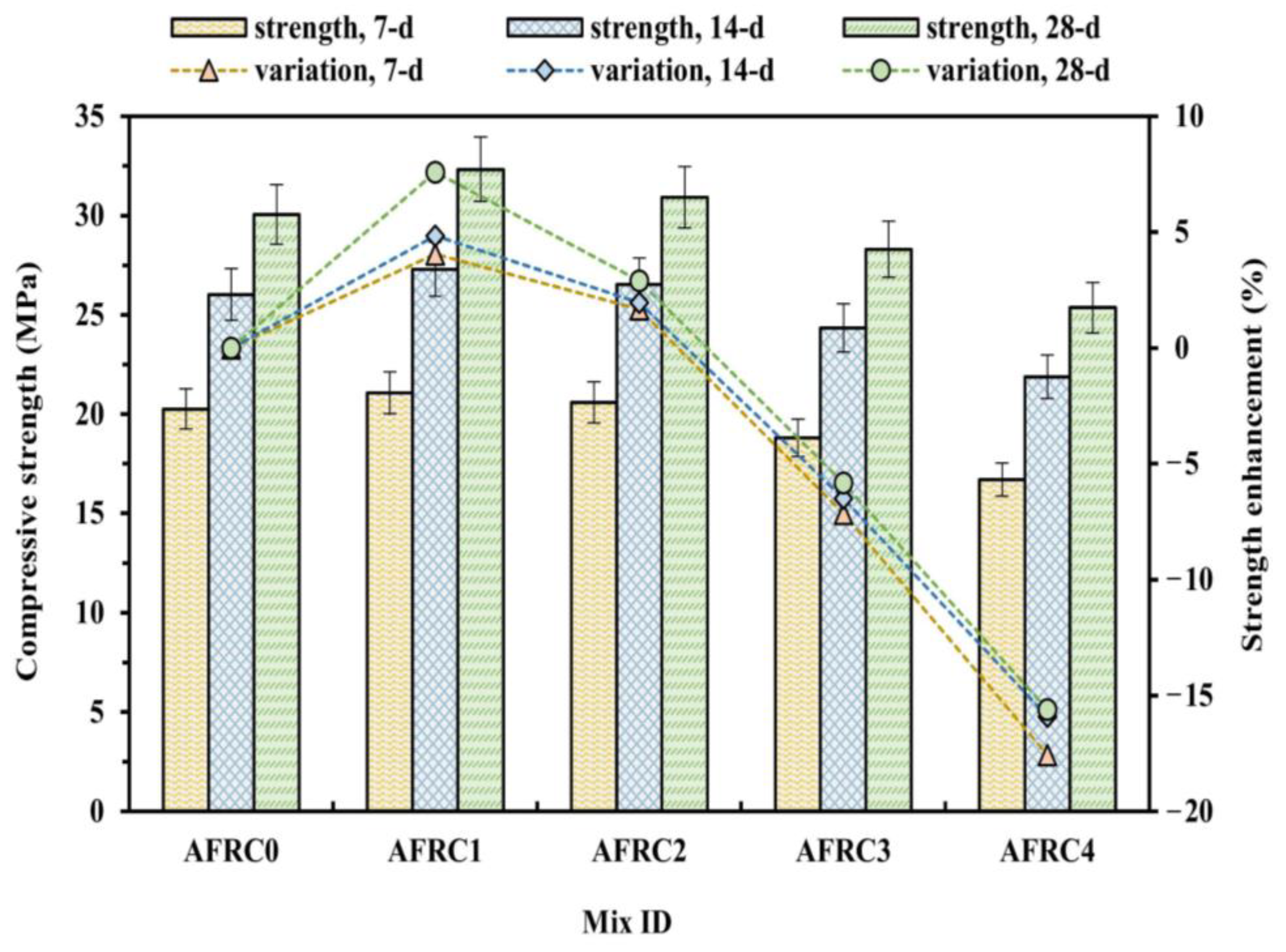

3.2.1. Compressive Strength of Concrete Samples

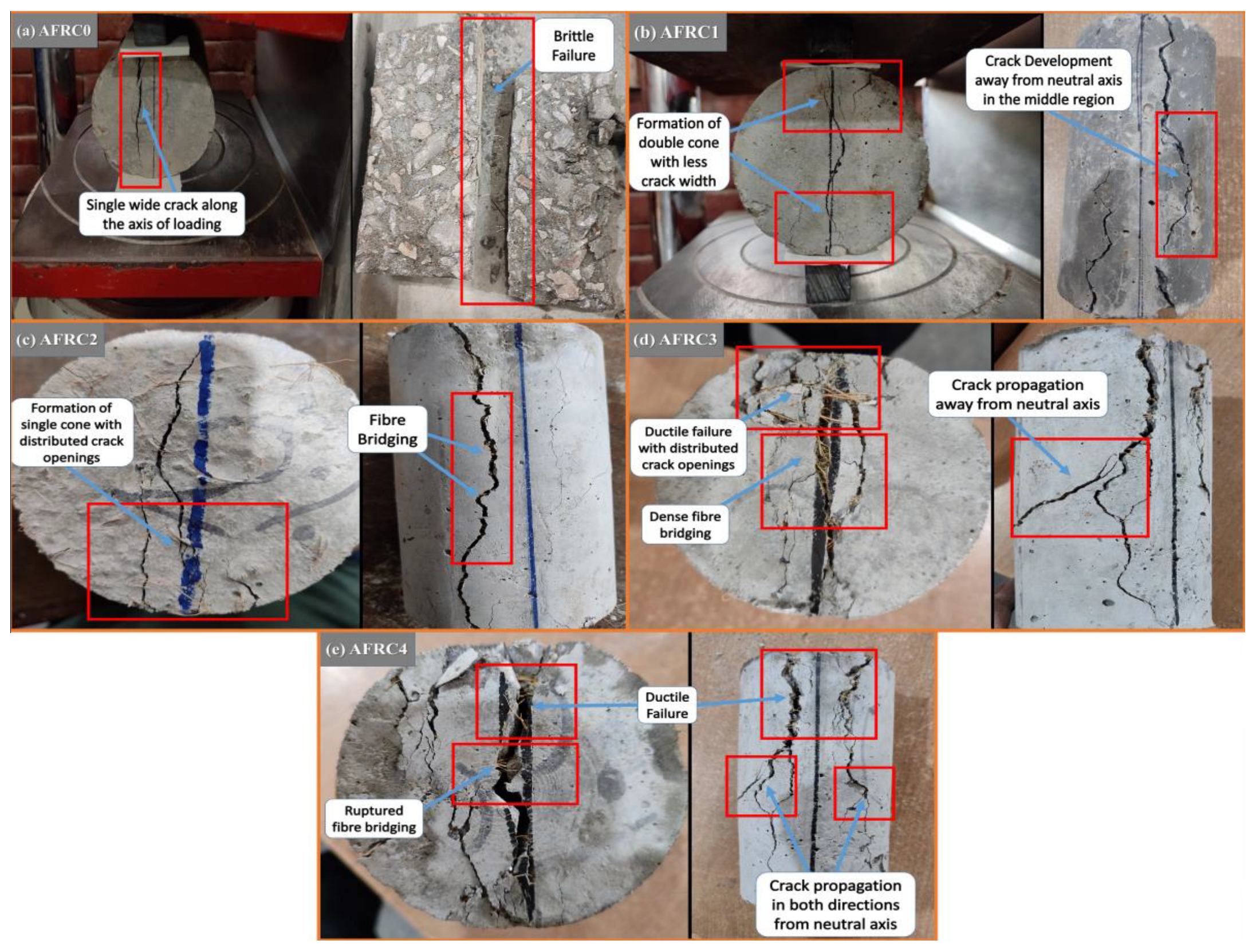

3.2.2. Observed Crack Patterns after Compression Failure

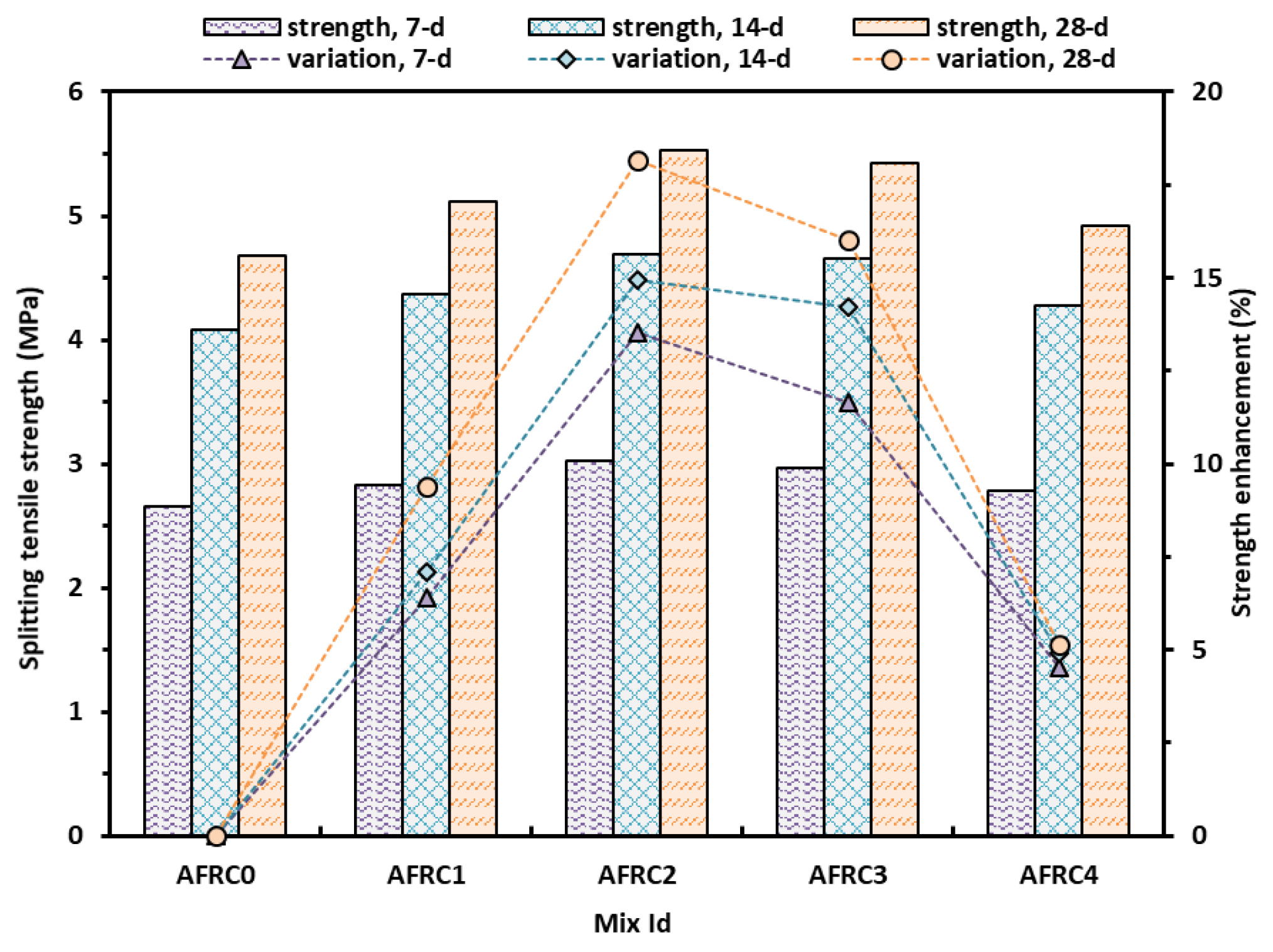

3.2.3. Split Tensile Strength of Concrete Samples

3.2.4. Observed Crack Pattern after Splitting Tensile Failure

3.2.5. Effect of Areca Fiber on the Brittleness of Concrete

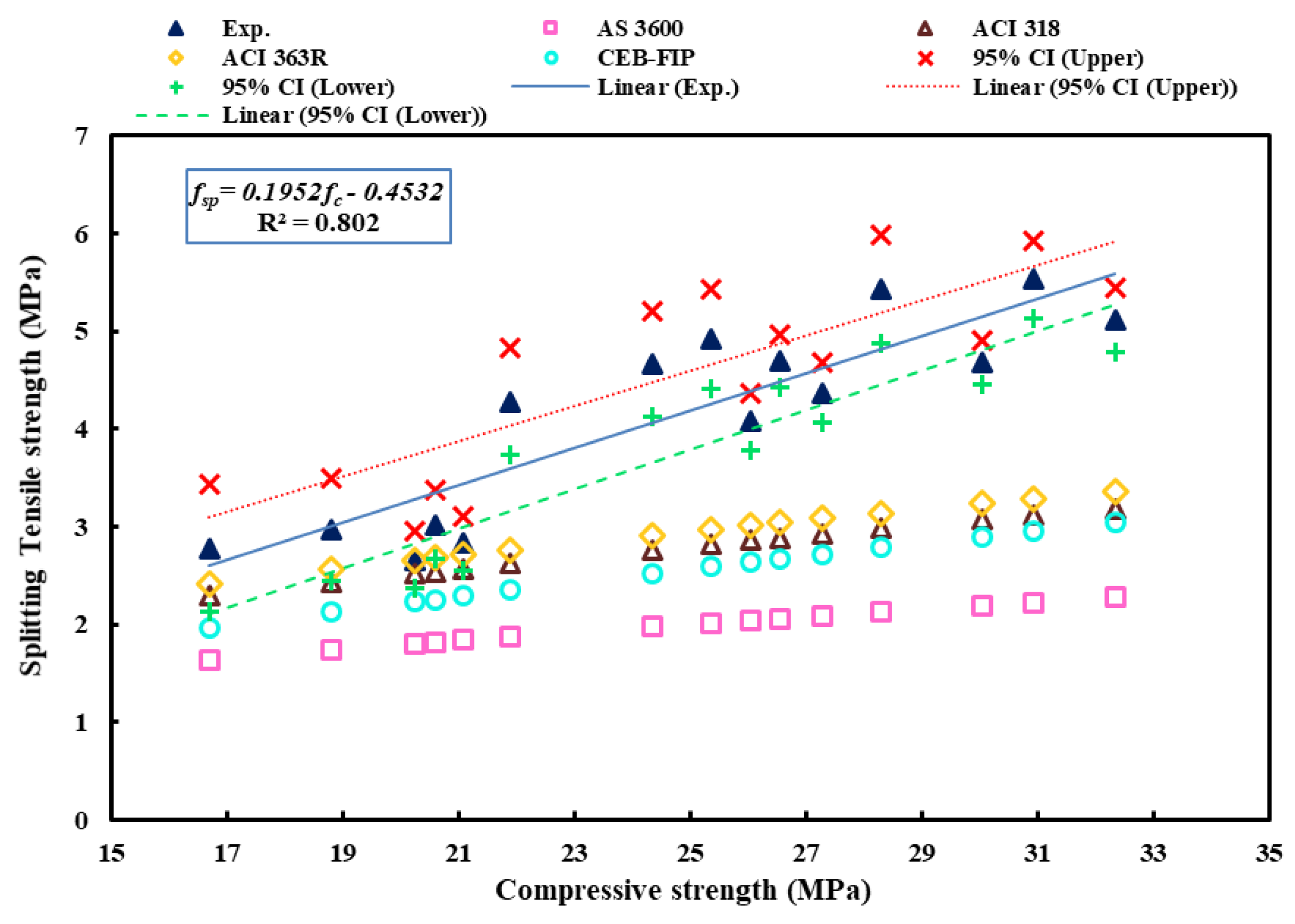

3.2.6. Relationship between Compressive Strength and Splitting Tensile Strength

3.3. Micro-Structural Characterization of Hardened Concrete

3.3.1. Scanning Electron Microscopy (SEM)

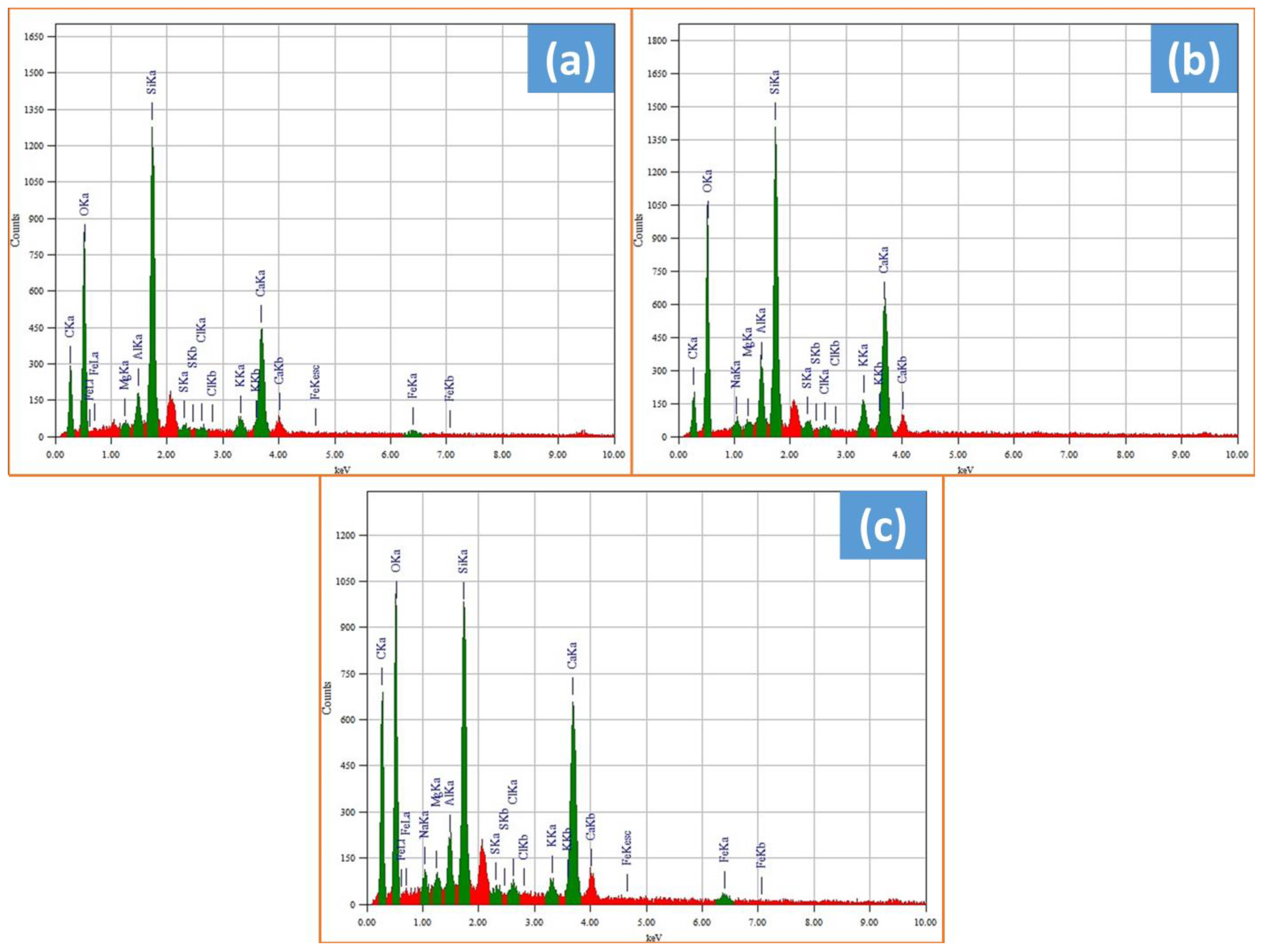

3.3.2. Energy-Dispersive X-ray Spectroscopy (EDX)

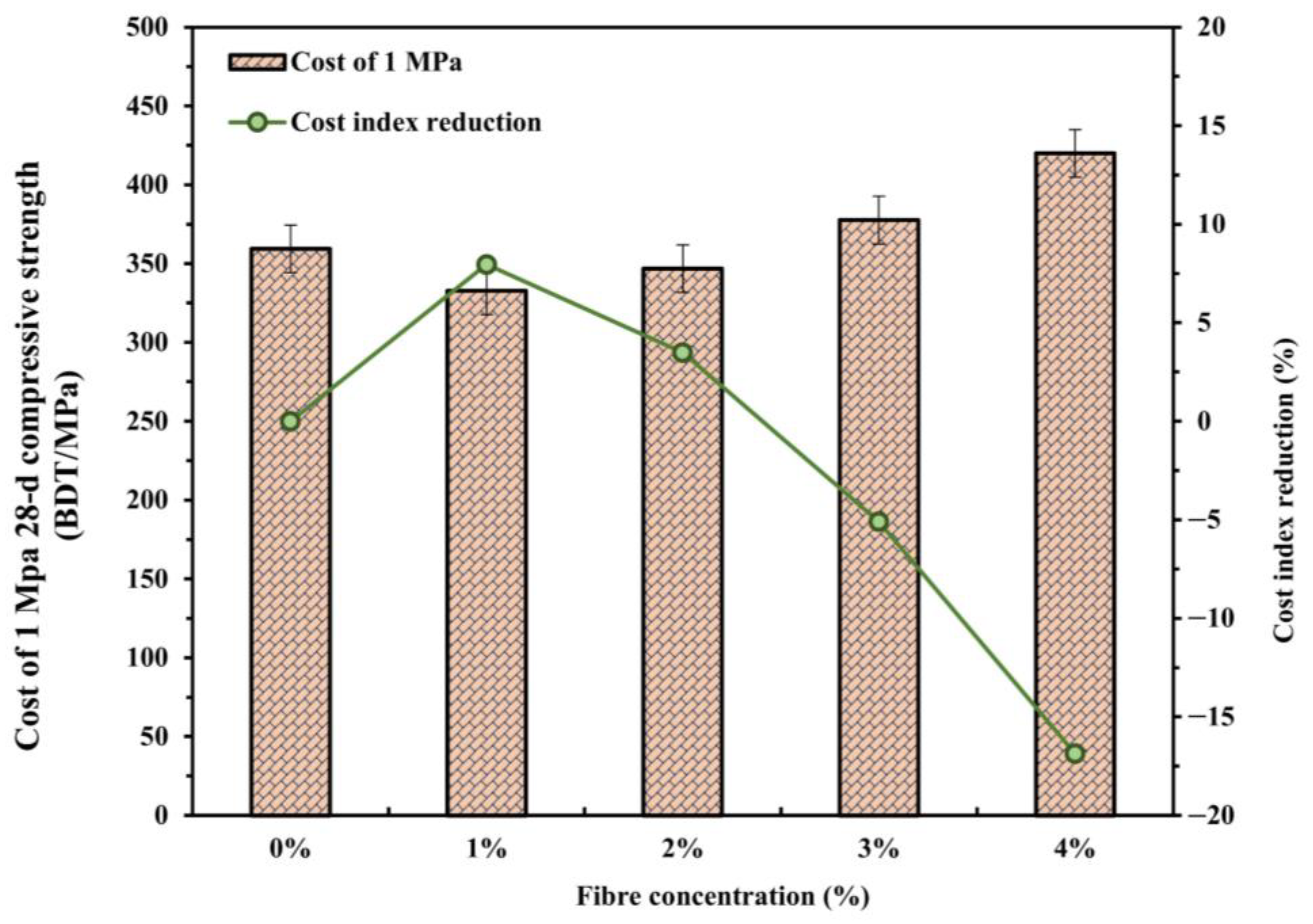

3.4. Cost Analysis of Concrete Mixtures

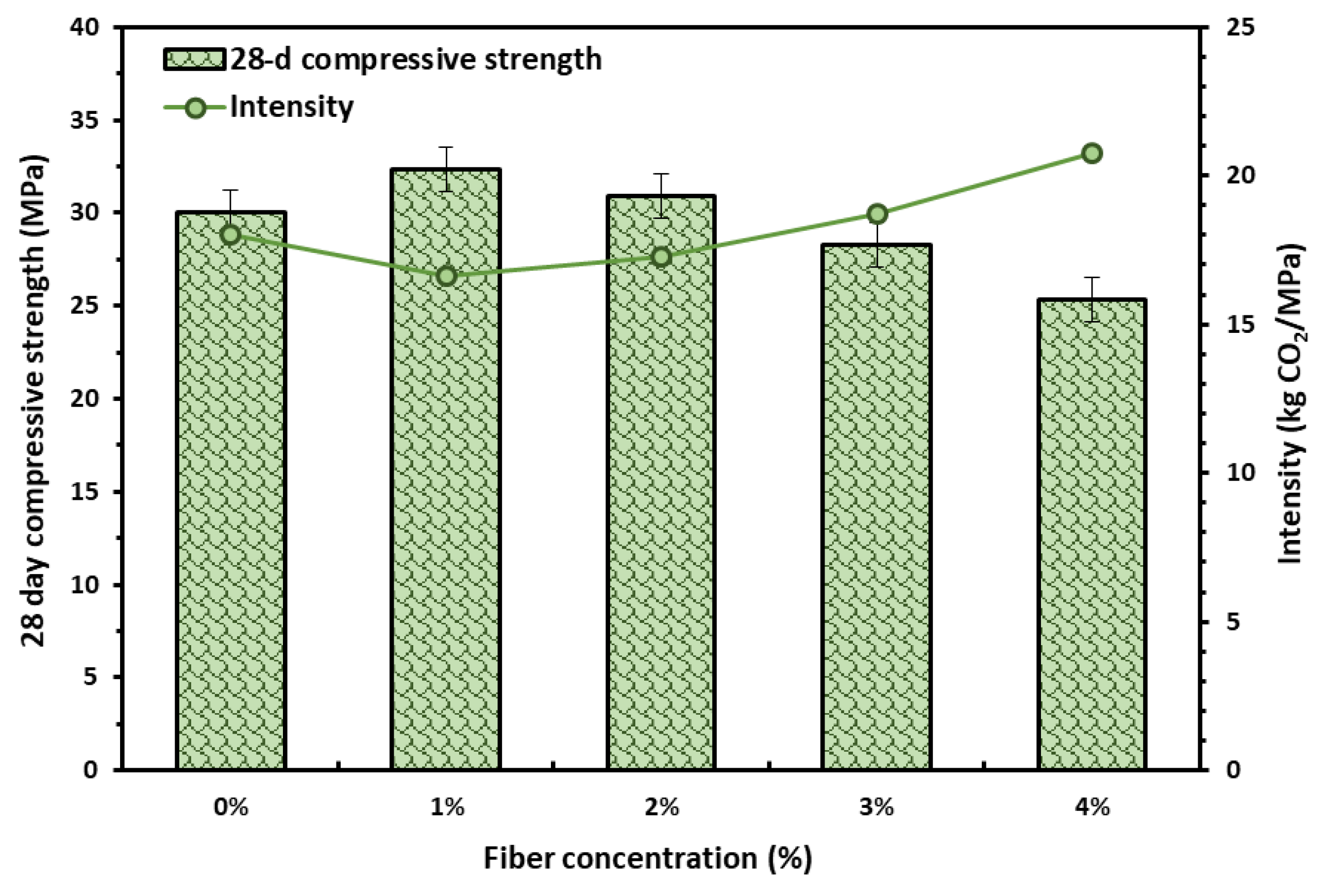

3.5. Equivalent CO2 Assessment for Concrete Mixtures

4. Conclusions and Recommendations

- The workability of concrete decreases with the use of areca husk fiber, and by using 2% fiber, concrete with medium workability can be produced. Additionally, areca fiber can reduce the density and increase the yield stress of fresh concrete.

- By using areca fiber up to 2%, the compressive strength of concrete can be slightly enhanced to a degree of 3% to 8%. Further increments in fiber concentration decrease compressive strength due to fiber balling effects, irregularities in fiber distribution, and increased voids.

- In terms of splitting tensile strength, reinforcing concrete with waste areca husk fiber at a 2% dosage can substantially increase the splitting tensile strength by up to 18%. Interlocked fiber bridging of cement and areca fiber increased the splitting tensile strength.

- Observed crack patterns after the compressive and splitting tensile failures revealed that the control mix showed poor performance after the failure in load bearing. In contrast, the fiber-reinforced concrete mixes showed better post-cracking performances. The higher concentration of areca fiber increased the post-cracking ductile response by exhibiting a lesser crack width, more distributed cracks, and no cracks in a single defined plane of the axis.

- The inclusion of fiber reduced the cost and carbon emissions of concrete mixtures. Among all the mix combinations considered, the incorporation of areca fiber as a partial substitute for cement at an optimum dosage of up to 2% exhibited the best outcomes in terms of cost index and carbon intensity, with reductions ranging from almost 4% to 8%.

- SEM analysis showed adequate interfacial bonding between the fiber and cement matrix, while EDX results showed that the Ca:Si ratio was reduced by the incorporation of areca fiber, which proves the proper reaction between Ca and Si. The conversion of CH to secondary C-S-H is the primary reason for the decrease in the Ca:Si ratio of C-S-H.

- Based on all the experiments and analysis, this study suggests that the most suitable areca husk fiber concentration, which replaces 2% of the cement content by weight, offers optimal results in terms of concrete’s performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Hegde, A. Ready Mix Concrete Market Worth 624.82 Billion USD by 2025; Market Study Report: Selbyville, DE, USA, 2018. [Google Scholar]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Taylor & Francis: London, UK, 2007. [Google Scholar]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Z.; Wang, S.; Zhang, J. Macro-micro mechanical properties and reinforcement mechanism of alkali-resistant glass fiber-reinforced concrete under alkaline environments. Constr. Build. Mater. 2023, 368, 130365. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Q.-C.; Li, W.-J.; Gu, X.-L.; Dai, H.-H. Study on model of flexure response of carbon fiber textile reinforced concrete (CTRC) sheets with short AR-glass fibers. Case Stud. Constr. Mater. 2023, 18, e01791. [Google Scholar] [CrossRef]

- Aksoylu, C.; Özkılıç, Y.O.; Hadzima-Nyarko, M.; Işık, E.; Arslan, M.H. Investigation on Improvement in Shear Performance of Reinforced-Concrete Beams Produced with Recycled Steel Wires from Waste Tires. Sustainability 2022, 14, 13360. [Google Scholar] [CrossRef]

- Yıldızel, S.A.; Özkılıç, Y.O.; Bahrami, A.; Aksoylu, C.; Başaran, B.; Hakamy, A.; Arslan, M.H. Experimental investigation and analytical prediction of flexural behaviour of reinforced concrete beams with steel fibres extracted from waste tyres. Case Stud. Constr. Mater. 2023, 19, e02227. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Çelik, A.İ.; Deifalla, A.F.; Ahmad, M.; Sabri, M.M.S. Performance evaluation of fiber-reinforced concrete produced with steel fibers extracted from waste tire. Front. Mater. 2022, 9, 1057128. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Luo, Y.; Shao, H.; Zhou, X.; Bai, S. Early-age autogenous shrinkage, tensile creep, and restrained cracking behavior of ultra-high-performance concrete incorporating polypropylene fibers. Cem. Concr. Compos. 2023, 138, 104948. [Google Scholar] [CrossRef]

- Ashraf, M.J.; Idrees, M.; Akbar, A. Performance of silica fume slurry treated recycled aggregate concrete reinforced with carbon fibers. J. Build. Eng. 2023, 66, 105892. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Özdöner, N.; Tayeh, B.A. Performance Assessment of Fiber-Reinforced Concrete Produced with Waste Lathe Fibers. Sustainability 2022, 14, 11817. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Deifalla, A.F.; Aksoylu, C.; Arslan, M.H.; Ahmad, M.; Sabri, M.M.S. Improvement in Bending Performance of Reinforced Concrete Beams Produced with Waste Lathe Scraps. Sustainability 2022, 14, 12660. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Yang, H.; Wang, Y.; Tang, S. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals 2021, 29, 2140002. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, X.; Li, Y.; Yang, H.; Tang, S. Influences of MgO and PVA Fiber on the Abrasion and Cracking Resistance, Pore Structure and Fractal Features of Hydraulic Concrete. Fractal Fract. 2022, 6, 674. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Mathavan, M.; Sakthieswaran, N.; Ganesh Babu, O. Experimental investigation on strength and properties of natural fibre reinforced cement mortar. Mater. Today Proc. 2021, 37, 1066–1070. [Google Scholar] [CrossRef]

- Vijayan, D.; Rajmohan, T. Influence of Fiber Content on Tensile and Flexural Properties of Ramie/Areca Fiber Composite—Ān Algorithmic Approach Using Firefly Algorithm. In Bio-Fiber Reinforced Composite Materials: Mechanical, Thermal and Tribological Properties; Palanikumar, K., Thiagarajan, R., Latha, B., Eds.; Springer Nature: Singapore, 2022; pp. 235–252. [Google Scholar]

- Aishwarya, K.P.; Muralidhar, N.; Praveen, J.V. Study on areca nut husk fine fiber fabric reinforced composites panels under dynamic loading conditions. Mater. Today: Proc. 2022, 66, 633–641. [Google Scholar] [CrossRef]

- Loganathan, T.M.; Sultan, M.T.H.; Jawaid, M.; Md Shah, A.U.; Ahsan, Q.; Mariapan, M.; Majid, M.S.b.A. Physical, Thermal and Mechanical Properties of Areca Fibre Reinforced Polymer Composites—An Overview. J. Bionic Eng. 2020, 17, 185–205. [Google Scholar] [CrossRef]

- Banagar, A.; Chikkol, S.V.; Bennehalli, B. Studies on physical and mechanical properties of untreated (raw) and treated areca leaf sheaths. Mater. Res. Innov. 2021, 25, 404–411. [Google Scholar] [CrossRef]

- Ashok, R.B.; Srinivasa, C.V.; Basavaraju, B. A review on the mechanical properties of areca fiber reinforced composites. Sci. Tecnol. Mater. 2018, 30, 120–130. [Google Scholar] [CrossRef]

- Divakar, L.; Babu, A.P.V.; Chethan Gowda, R.K.; Nithin Kumar, S. Experimental Study on Mechanical Properties of Areca Nut Fibre-Reinforced Self-compacting Concrete. In Green Buildings and Sustainable Engineering; Springer: Singapore, 2020; pp. 313–321. [Google Scholar]

- Makunza, J.K. Application of Areca Palm Fibers as Strength Enhancement in Conventional Concrete. Adv. Mater. Res. 2022, 1168, 11–22. [Google Scholar] [CrossRef]

- Srinivasa, C.V.; Arifulla, A.; Goutham, N.; Santhosh, T.; Jaeethendra, H.J.; Ravikumar, R.B.; Anil, S.G.; Santhosh Kumar, D.G.; Ashish, J. Static bending and impact behaviour of areca fibers composites. Mater. Des. 2011, 32, 2469–2475. [Google Scholar] [CrossRef]

- Castillo-Lara, J.; Flores-Johnson, E.; Valadez, A.; Herrera-Franco, P.; Carrillo, J.; Gonzalez-Chi, P.; Li, Q. Mechanical Properties of Natural Fiber Reinforced Foamed Concrete. Materials 2020, 13, 3060. [Google Scholar] [CrossRef] [PubMed]

- Jamshaid, H.; Mishra, R.K.; Raza, A.; Hussain, U.; Rahman, M.L.; Nazari, S.; Chandan, V.; Muller, M.; Choteborsky, R. Natural Cellulosic Fiber Reinforced Concrete: Influence of Fiber Type and Loading Percentage on Mechanical and Water Absorption Performance. Materials 2022, 15, 874. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Sobuz, M.H.R.; Tam, V.W.Y.; Akid, A.S.M.; Sutan, N.M.; Rahman, F.M.M. Effects of incorporating hybrid fibres on rheological and mechanical properties of fibre reinforced concrete. Constr. Build. Mater. 2020, 262, 120561. [Google Scholar] [CrossRef]

- Yinh, S.; Hussain, Q.; Joyklad, P.; Chaimahawan, P.; Rattanapitikon, W.; Limkatanyu, S.; Pimanmas, A. Strengthening effect of natural fiber reinforced polymer composites (NFRP) on concrete. Case Stud. Constr. Mater. 2021, 15, e00653. [Google Scholar] [CrossRef]

- Zhao, C.; Yi, Z.; Wu, W.; Zhu, Z.; Peng, Y.; Liu, J. Experimental Study on the Mechanical Properties and Durability of High-Content Hybrid Fiber-Polymer Concrete. Materials 2021, 14, 6234. [Google Scholar] [CrossRef] [PubMed]

- Zaid, O.; Ahmad, J.; Siddique, M.S.; Aslam, F.; Alabduljabbar, H.; Khedher, K.M. A step towards sustainable glass fiber reinforced concrete utilizing silica fume and waste coconut shell aggregate. Sci. Rep. 2021, 11, 12822. [Google Scholar] [CrossRef] [PubMed]

- Walbrück, K.; Maeting, F.; Witzleben, S.; Stephan, D. Natural Fiber-Stabilized Geopolymer Foams-A Review. Materials 2020, 13, 3198. [Google Scholar] [CrossRef]

- Ellis, L.D.; Badel, A.F.; Chiang, M.L.; Park, R.J.; Chiang, Y.M. Toward electrochemical synthesis of cement-An electrolyzer-based process for decarbonating CaCO3 while producing useful gas streams. Proc. Natl. Acad. Sci. USA 2020, 117, 12584–12591. [Google Scholar] [CrossRef] [PubMed]

- Hasan, N.M.S.; Sobuz, M.H.R.; Shaurdho, N.M.N.; Basit, M.A.; Paul, S.C.; Meraz, M.M.; Saha, A.; Miah, M.J. Investigation of Lightweight and Green Concrete Characteristics Using Coconut Shell Aggregate as a Replacement for Conventional Aggregates. Int. J. Civ. Eng. 2023. [Google Scholar] [CrossRef]

- Tridge. Overview of Areca Nut Market in Bangladesh. Available online: https://www.tridge.com/intelligences/areca-nut/BD (accessed on 8 December 2022).

- Jena, B.; Patra, R.K.; Mukharjee, B.B. Influence of incorporation of jute fibre and ferrochrome slag on properties of concrete. Aust. J. Civ. Eng. 2022, 20, 13–30. [Google Scholar] [CrossRef]

- Srivastava, V.; Mehta, P.; Nath, S. Natural Fiber in Cement and Concrete Matrices—A Review. J. Environ. Nanotechnol. 2014, 2, 62–65. [Google Scholar] [CrossRef]

- Malkawi, A.B.; Habib, M.; Aladwan, J.; Alzubi, Y. Engineering properties of fibre reinforced lightweight geopolymer concrete using palm oil biowastes. Aust. J. Civ. Eng. 2020, 18, 82–92. [Google Scholar] [CrossRef]

- ASTM-C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2020.

- BS EN 197; Cement: Composition, Specifications and Conformity Criteria for Common Cements. British Standards Institution: London, UK, 2011.

- BDS EN-197; Cement—Part 1: Composition, Specification and Conformity Criteria for Common Cements. Bangladesh Standards and Testing Institution: Dhaka, Bangladesh, 2010.

- ASTM-C33; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM-C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM-C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM-C138; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Hu, C.; de Larrard, F.; Sedran, T.; Boulay, C.; Bosc, F.; Deflorenne, F. Validation of BTRHEOM, the new rheometer for soft-to-fluid concrete. Mater. Struct. 1996, 29, 620–631. [Google Scholar] [CrossRef]

- ASTM-C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM-C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM-C1723; Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy. ASTM International: West Conshohocken, PA, USA, 2010.

- Islam, S.M.; Hussain, R.R.; Morshed, M.A.Z. Fiber-reinforced concrete incorporating locally available natural fibers in normal- and high-strength concrete and a performance analysis with steel fiber-reinforced composite concrete. J. Compos. Mater. 2012, 46, 111–122. [Google Scholar] [CrossRef]

- Khan, M.M.H.; Sobuz, M.H.R.; Meraz, M.M.; Tam, V.W.Y.; Hasan, N.M.S.; Shaurdho, N.M.N. Effect of various powder content on the properties of sustainable self-compacting concrete. Case Stud. Constr. Mater. 2023, 19, e02274. [Google Scholar] [CrossRef]

- Miah, M.J.; Li, Y.; Paul, S.C.; Babafemi, A.J.; Jang, J.G. Mechanical strength, shrinkage, and porosity of mortar reinforced with areca nut husk fibers. Constr. Build. Mater. 2023, 363, 129688. [Google Scholar] [CrossRef]

- Tattersall, G.; Banfill, P. The Rheology of Fresh Concrete; Pitman: London, UK, 1983; p. 356. [Google Scholar]

- Ahmad, J.; Arbili, M.M.; Majdi, A.; Althoey, F.; Farouk Deifalla, A.; Rahmawati, C. Performance of concrete reinforced with jute fibers (natural fibers): A review. J. Eng. Fibers Fabr. 2022, 17, 15589250221121871. [Google Scholar] [CrossRef]

- Miah, M.J.; Pei, J.; Kim, H.; Sharma, R.; Jang, J.G.; Ahn, J. Property assessment of an eco-friendly mortar reinforced with recycled mask fiber derived from COVID-19 single-use face masks. J. Build. Eng. 2023, 66, 105885. [Google Scholar] [CrossRef]

- Yusof, M.A.; Nor, N.M.; Fauzi, M.; Zain, M.; Ismail, A.; Sohaimi, R.M.; Mujahid, A.Z.A.; Zaidi, A.M.A. Mechanical Properties of Hybrid Steel Fibre Reinforced Concrete with Different Aspect Ratio. Aust. J. Basic Appl. Sci. 2011, 5, 159–166. [Google Scholar]

- Kachouh, N.; El-Hassan, H.; El-Maaddawy, T. Influence of steel fibers on the flexural performance of concrete incorporating recycled concrete aggregates and dune sand. J. Sustain. Cem.-Based Mater. 2021, 10, 165–192. [Google Scholar] [CrossRef]

- Savastano, H.; Santos, S.F.; Radonjic, M.; Soboyejo, W.O. Fracture and fatigue of natural fiber-reinforced cementitious composites. Cem. Concr. Compos. 2009, 31, 232–243. [Google Scholar] [CrossRef]

- Yusra, A.; Triwulan, T.; Safriani, M.; Ikhsan, M. Use of bamboo fiber on the relationship between compressive strength and split tensile strength of high strength concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 933, 012010. [Google Scholar] [CrossRef]

- Gao, D.; Wang, F. Effects of recycled fine aggregate and steel fiber on compressive and splitting tensile properties of concrete. J. Build. Eng. 2021, 44, 102631. [Google Scholar] [CrossRef]

- Lumingkewas, R.H.; Husen, A.; Andrianus, R. Effect of Fibers Length and Fibers Content on the Splitting Tensile Strength of Coconut Fibers Reinforced Concrete Composites. Key Eng. Mater. 2017, 748, 311–315. [Google Scholar] [CrossRef]

- Boulekbache, B.; Hamrat, M.; Chemrouk, M.; Amziane, S. Failure mechanism of fibre reinforced concrete under splitting test using digital image correlation. Mater. Struct. 2015, 48, 2713–2726. [Google Scholar] [CrossRef]

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S.; Cwirzen, A. Comprehensive review on sustainable fiber reinforced concrete incorporating recycled textile waste. J. Sustain. Cem.-Based Mater. 2022, 11, 28–42. [Google Scholar] [CrossRef]

- ACI Committee-318. Building Code Requirements for Structural Concrete (ACI 318-99) and Commentary (318R-99); American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- ACI Committee-363. State-of-the Art Report on High Strength Concrete (ACI 363R-92); American Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Béton, C.E.-I.d. CEB-FIP Model Code 1990: Design Code; Thomas Telford Ltd.: London, UK, 1990. [Google Scholar]

- AS-3600; AS 3600: Australian Standard for Concrete Structures. Standards Association of Australia: Sydney, Australia, 2001.

- Paglia, C.; Antonietti, S.; Caroselli, M.; Corredig, G. Steel fibre-cement matrix interaction in a ultra high-strength concrete: An investigation at the microstructural level. In Proceedings of the Bond in Concrete—Bond, Anchorage, Detailing: 5th International Conference, Stuttgart, Germany, 25–27 July 2022. [Google Scholar]

- Aly, T.; Sanjayan, J.; Collins, F. Effect of polypropylene fibers on shrinkage and cracking of concretes. Mater. Struct. 2014, 41, 1741–1753. [Google Scholar] [CrossRef]

- Kannan, V.; Ganesan, K. Chloride and chemical resistance of self compacting concrete containing rice husk ash and metakaolin. Constr. Build. Mater. 2014, 51, 225–234. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Sobuz, M.H.R.; Khan, M.M.H.; Mim, N.J.; Meraz, M.M.; Datta, S.D.; Rana, M.J.; Saha, A.; Akid, A.S.M.; Mehedi, M.T.; et al. Integration of Rice Husk Ash as Supplementary Cementitious Material in the Production of Sustainable High-Strength Concrete. Materials 2022, 15, 8171. [Google Scholar] [CrossRef]

- Sobuz, M.H.R.; Datta, S.D.; Akid, A.S.M.; Tam, V.W.Y.; Islam, S.; Rana, M.J.; Aslani, F.; Yalçınkaya, Ç.; Sutan, N.M. Evaluating the effects of recycled concrete aggregate size and concentration on properties of high-strength sustainable concrete. J. King Saud Univ. Eng. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C.; Lowrie, E.F.; Tse, P. Embodied Carbon. The Inventory of Carbon and Energy (ICE), Version (2.0); BSRIA Limited: Bracknell, Berkshire, UK, 2011. [Google Scholar]

- Datta, S.D.; Rana, M.J.; Assafi, M.N.; Mim, N.J.; Ahmed, S. Investigation on the generation of construction wastes in Bangladesh. Int. J. Constr. Manag. 2022, 23, 2260–2269. [Google Scholar] [CrossRef]

- Bostanci, S.C. Use of waste marble dust and recycled glass for sustainable concrete production. J. Clean. Prod. 2020, 251, 119785. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Shaurdho, N.M.N.; Sobuz, M.H.R.; Meraz, M.M.; Islam, M.S.; Miah, M.J. Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement. Sustainability 2023, 15, 11254. [Google Scholar] [CrossRef]

| Constituents | Weight (%) |

|---|---|

| Silica (SiO2) | 21.45 |

| Alumina (Al2O3) | 4.30 |

| Ferric oxide (Fe2O3) | 3.28 |

| Calcium oxide (CaO) | 64.32 |

| Magnesium oxide (MgO) | 1.18 |

| Sulfur trioxide (SO3) | 3.56 |

| Insoluble residue (IR) | 0.35 |

| Loss on ignition (LOI) | 2.055 |

| Free lime | 1.274 |

| Physical Properties | Areca Fiber |

|---|---|

| Average length (mm) | 50 |

| Average diameter (mm) | 0.75 |

| Aspect ratio | 66.67 |

| Mix Id | Fiber Percentage | Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Fiber (kg/m3) | Water (kg/m3) | w/c Ratio |

|---|---|---|---|---|---|---|---|

| AFRC0 | 0% | 395 | 800 | 985 | 0 | 177.8 | 0.45 |

| AFRC1 | 1% | 391.1 | 800 | 985 | 3.95 | 176.0 | 0.45 |

| AFRC2 | 2% | 387.1 | 800 | 985 | 7.90 | 174.2 | 0.45 |

| AFRC3 | 3% | 383.2 | 800 | 985 | 11.85 | 172.4 | 0.45 |

| AFRC4 | 4% | 379.2 | 800 | 985 | 15.80 | 170.6 | 0.45 |

| Mix ID | Curing (Days) | Mean Strength (MPa) | Standard Deviation | CoV | Standard Error | 95% Confidence Interval | |

|---|---|---|---|---|---|---|---|

| Upper Range | Lower Range | ||||||

| AFRC0 | 7 | 20.3 | 0.365 | 0.018 | 0.211 | 21.17 | 19.36 |

| 14 | 26.0 | 0.523 | 0.020 | 0.302 | 27.33 | 24.73 | |

| 28 | 30.1 | 0.420 | 0.014 | 0.243 | 31.10 | 29.01 | |

| AFRC1 | 7 | 21.1 | 0.447 | 0.021 | 0.258 | 22.19 | 19.97 |

| 14 | 27.3 | 0.493 | 0.018 | 0.285 | 28.52 | 26.07 | |

| 28 | 32.3 | 0.514 | 0.016 | 0.297 | 33.60 | 31.05 | |

| AFRC2 | 7 | 20.6 | 0.558 | 0.027 | 0.322 | 21.99 | 19.22 |

| 14 | 26.5 | 0.532 | 0.020 | 0.307 | 27.86 | 25.21 | |

| 28 | 30.9 | 0.856 | 0.028 | 0.494 | 33.05 | 28.79 | |

| AFRC3 | 7 | 18.8 | 0.751 | 0.040 | 0.434 | 20.68 | 16.95 |

| 14 | 24.3 | 0.777 | 0.032 | 0.448 | 26.27 | 22.41 | |

| 28 | 28.3 | 0.961 | 0.034 | 0.555 | 30.69 | 25.91 | |

| AFRC4 | 7 | 16.7 | 1.071 | 0.064 | 0.618 | 19.36 | 14.04 |

| 14 | 21.9 | 1.081 | 0.049 | 0.624 | 24.58 | 19.20 | |

| 28 | 25.4 | 1.098 | 0.043 | 0.634 | 28.09 | 22.63 | |

| Mix ID | Curing (Days) | Mean Strength (MPa) | Standard Deviation | CoV | Standard Error | 95% Confidence Interval | |

|---|---|---|---|---|---|---|---|

| Upper Range | Lower Range | ||||||

| AFRC0 | 7 | 2.66 | 0.118 | 0.044 | 0.068 | 2.96 | 2.37 |

| 14 | 4.08 | 0.119 | 0.029 | 0.069 | 4.37 | 3.78 | |

| 28 | 4.68 | 0.092 | 0.020 | 0.053 | 4.91 | 4.46 | |

| AFRC1 | 7 | 2.83 | 0.111 | 0.039 | 0.064 | 3.10 | 2.55 |

| 14 | 4.37 | 0.125 | 0.029 | 0.072 | 4.68 | 4.06 | |

| 28 | 5.12 | 0.134 | 0.026 | 0.077 | 5.45 | 4.78 | |

| AFRC2 | 7 | 3.02 | 0.141 | 0.047 | 0.082 | 3.37 | 2.67 |

| 14 | 4.69 | 0.111 | 0.024 | 0.064 | 4.97 | 4.42 | |

| 28 | 5.53 | 0.161 | 0.029 | 0.093 | 5.93 | 5.13 | |

| AFRC3 | 7 | 2.97 | 0.213 | 0.072 | 0.123 | 3.50 | 2.45 |

| 14 | 4.66 | 0.217 | 0.047 | 0.126 | 5.20 | 4.12 | |

| 28 | 5.43 | 0.226 | 0.042 | 0.131 | 5.99 | 4.87 | |

| AFRC4 | 7 | 2.78 | 0.264 | 0.095 | 0.152 | 3.44 | 2.13 |

| 14 | 4.28 | 0.221 | 0.052 | 0.128 | 4.83 | 3.73 | |

| 28 | 4.92 | 0.205 | 0.042 | 0.118 | 5.43 | 4.41 | |

| Element | AFRC0 | AFRC2 | AFRC4 | |||

|---|---|---|---|---|---|---|

| Mass (%) | Atom (%) | Mass (%) | Atom (%) | Mass (%) | Atom (%) | |

| C | 14.18 | 22.37 | 23.36 | 34.38 | 31.80 | 44.21 |

| O | 46.35 | 54.88 | 43.18 | 47.71 | 40.38 | 42.15 |

| Na | 0.60 | 0.49 | - | - | 0.88 | 0.64 |

| Mg | 0.28 | 0.22 | 0.35 | 0.26 | 0.37 | 0.26 |

| Al | 3.03 | 2.13 | 1.54 | 1.01 | 1.49 | 0.92 |

| Si | 14.58 | 9.83 | 14.99 | 9.44 | 8.31 | 4.94 |

| S | 0.90 | 0.53 | 0.55 | 0.30 | 0.41 | 0.21 |

| Cl | 0.23 | 0.13 | 0.23 | 0.11 | 0.53 | 0.25 |

| K | 3.32 | 1.61 | 1.56 | 0.71 | 0.95 | 0.40 |

| Ca | 16.54 | 7.82 | 12.66 | 5.58 | 13.32 | 5.55 |

| Fe | - | - | 1.58 | 0.50 | 1.58 | 0.47 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Unit Cost | Concrete Mix ID | Mixture Cost (BDT/m3) | Total | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Material | Cost (BDT/kg) | Cement | NCA | FA | Water | ||||

| Production | Transportation | Total | |||||||

| Cement | 9 | 0.34 | 9.34 | AFRC0 | 3689 | 5181 | 1912 | 16 | 10,798 |

| NCA | 5 | 0.26 | 5.26 | AFRC1 | 3652 | 5181 | 1912 | 15 | 10,761 |

| FA | 2.17 | 0.22 | 2.39 | AFRC2 | 3616 | 5181 | 1912 | 15 | 10,724 |

| Water | 0.088 | - | 0.088 | AFRC3 | 3579 | 5181 | 1912 | 15 | 10,687 |

| AFRC4 | 3542 | 5181 | 1912 | 15 | 10,650 | ||||

| Material Name | Material Embodied Energy (MJ/kg) | eCO2 Emission (kg CO2/kg) | ||

|---|---|---|---|---|

| Production | Transportation | Total | ||

| Cement | 5.5 (1) | 0.95 (1) | 0.021 * | 0.971 |

| Coarse aggregate | 0.083 (1) | 0.005 (1) | 0.021 * | 0.026 |

| Fine aggregate | 0.08 (2) | 0.0048 (2) | 0.16 * | 0.1648 |

| Water | 0.0009 (3) | 0.00155 (3) | - | 0.00155 |

| Concrete Mix Id | eCO2 Emission (kg CO2/m3 Concrete) | Percentage of CO2 Emission | |||

|---|---|---|---|---|---|

| Production | Transportation | Total | Production (%) | Transportation (%) | |

| AFRC0 | 384.29 | 156.98 | 541.27 | 71 | 29 |

| AFRC1 | 380.53 | 156.90 | 537.43 | 70.81 | 29.19 |

| AFRC2 | 376.78 | 156.81 | 533.59 | 70.61 | 29.39 |

| AFRC3 | 373.03 | 156.73 | 529.76 | 70.41 | 29.59 |

| AFRC4 | 369.27 | 156.65 | 525.92 | 70.21 | 29.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, N.M.S.; Shaurdho, N.M.N.; Sobuz, M.H.R.; Meraz, M.M.; Basit, M.A.; Paul, S.C.; Miah, M.J. Rheological, Mechanical, and Micro-Structural Property Assessment of Eco-Friendly Concrete Reinforced with Waste Areca Nut Husk Fiber. Sustainability 2023, 15, 14131. https://doi.org/10.3390/su151914131

Hasan NMS, Shaurdho NMN, Sobuz MHR, Meraz MM, Basit MA, Paul SC, Miah MJ. Rheological, Mechanical, and Micro-Structural Property Assessment of Eco-Friendly Concrete Reinforced with Waste Areca Nut Husk Fiber. Sustainability. 2023; 15(19):14131. https://doi.org/10.3390/su151914131

Chicago/Turabian StyleHasan, Noor Md. Sadiqul, Nur Mohammad Nazmus Shaurdho, Md. Habibur Rahman Sobuz, Md. Montaseer Meraz, Md. Abdul Basit, Suvash Chandra Paul, and Md Jihad Miah. 2023. "Rheological, Mechanical, and Micro-Structural Property Assessment of Eco-Friendly Concrete Reinforced with Waste Areca Nut Husk Fiber" Sustainability 15, no. 19: 14131. https://doi.org/10.3390/su151914131

APA StyleHasan, N. M. S., Shaurdho, N. M. N., Sobuz, M. H. R., Meraz, M. M., Basit, M. A., Paul, S. C., & Miah, M. J. (2023). Rheological, Mechanical, and Micro-Structural Property Assessment of Eco-Friendly Concrete Reinforced with Waste Areca Nut Husk Fiber. Sustainability, 15(19), 14131. https://doi.org/10.3390/su151914131