Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement

Abstract

1. Introduction

Research Significance

2. Materials and Methods

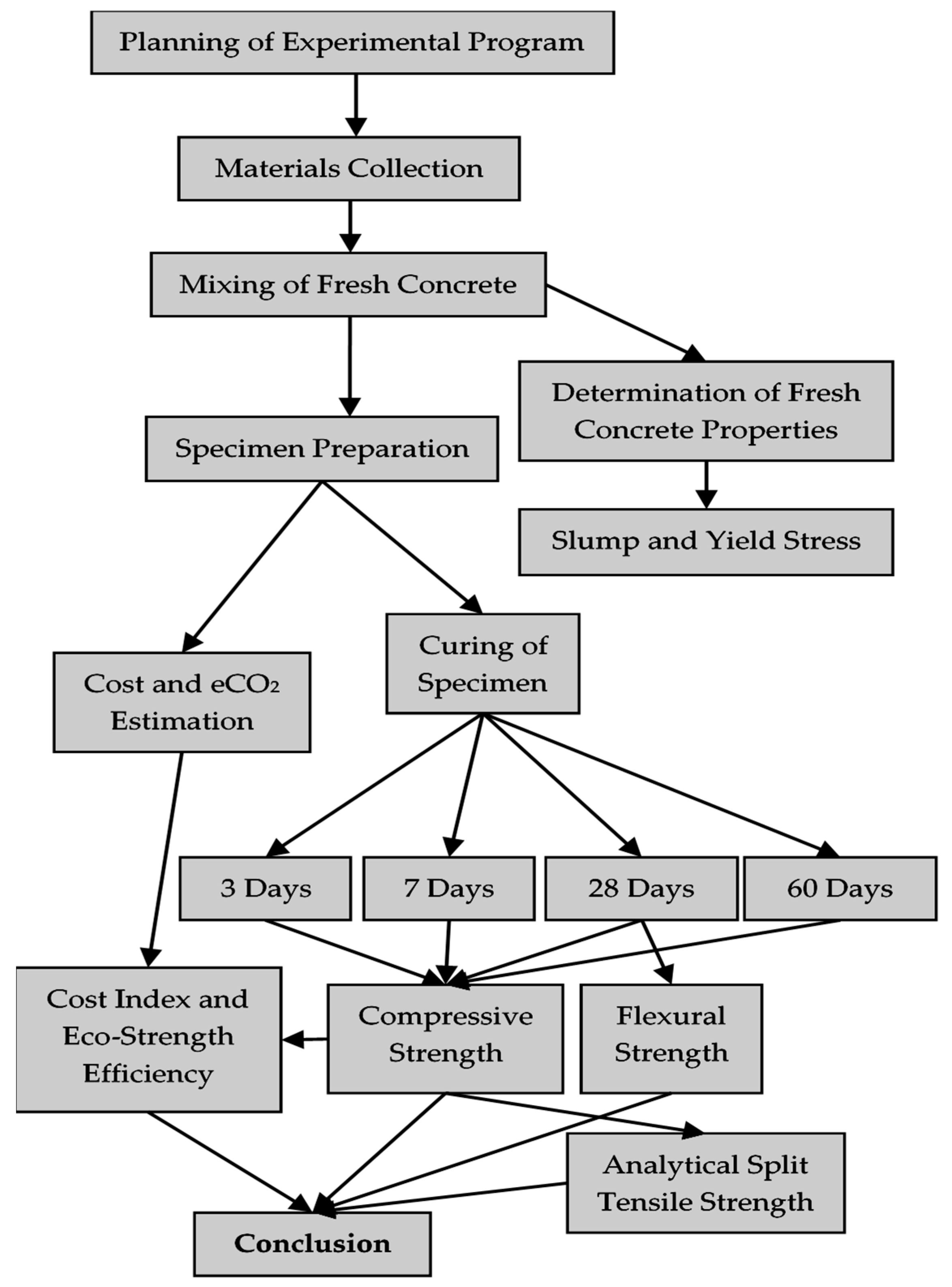

2.1. Research Plan

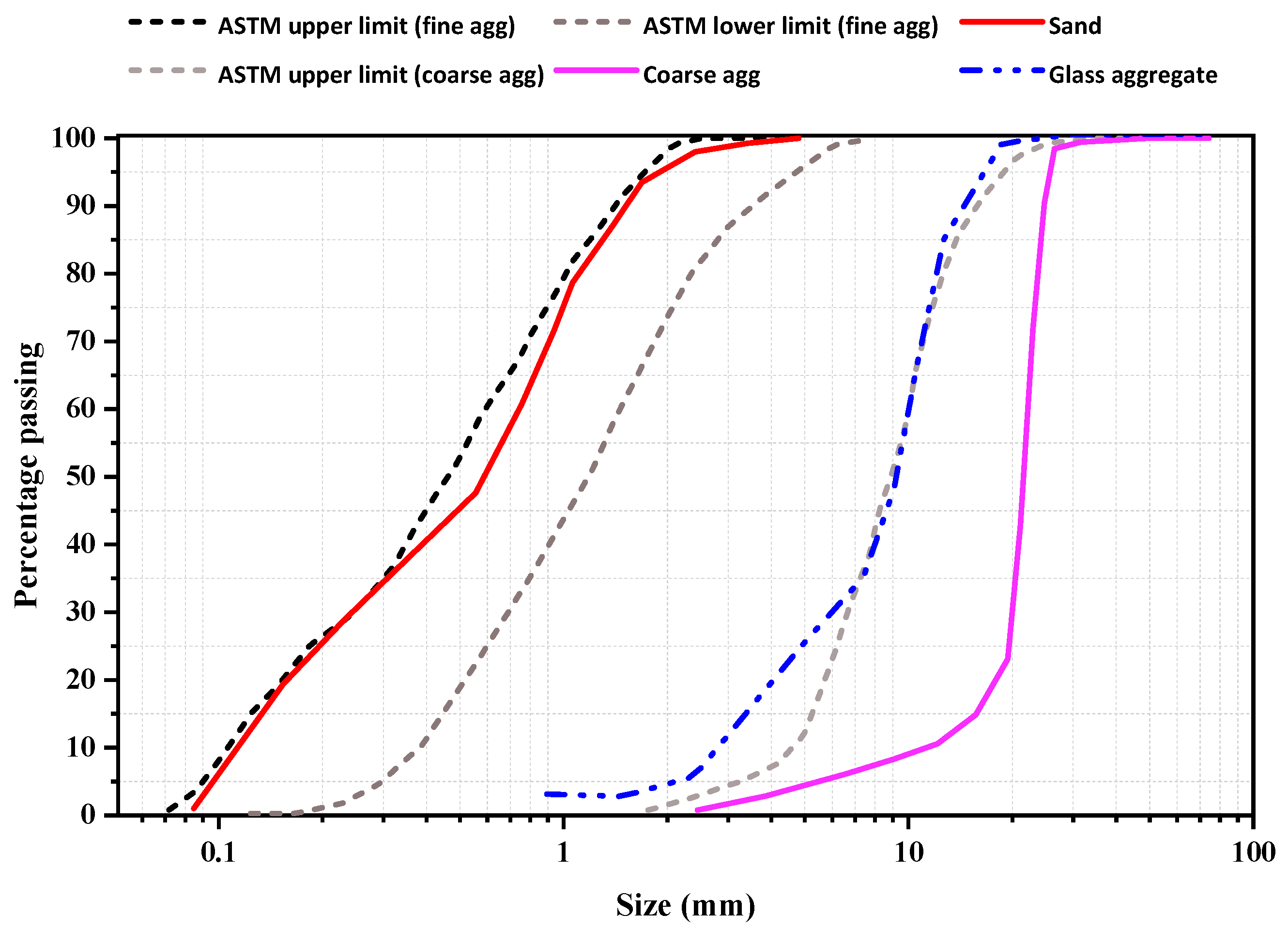

2.2. Materials

2.3. Mix Proportioning and Specimen Preparation

2.4. Testing Methods

3. Results and Discussion

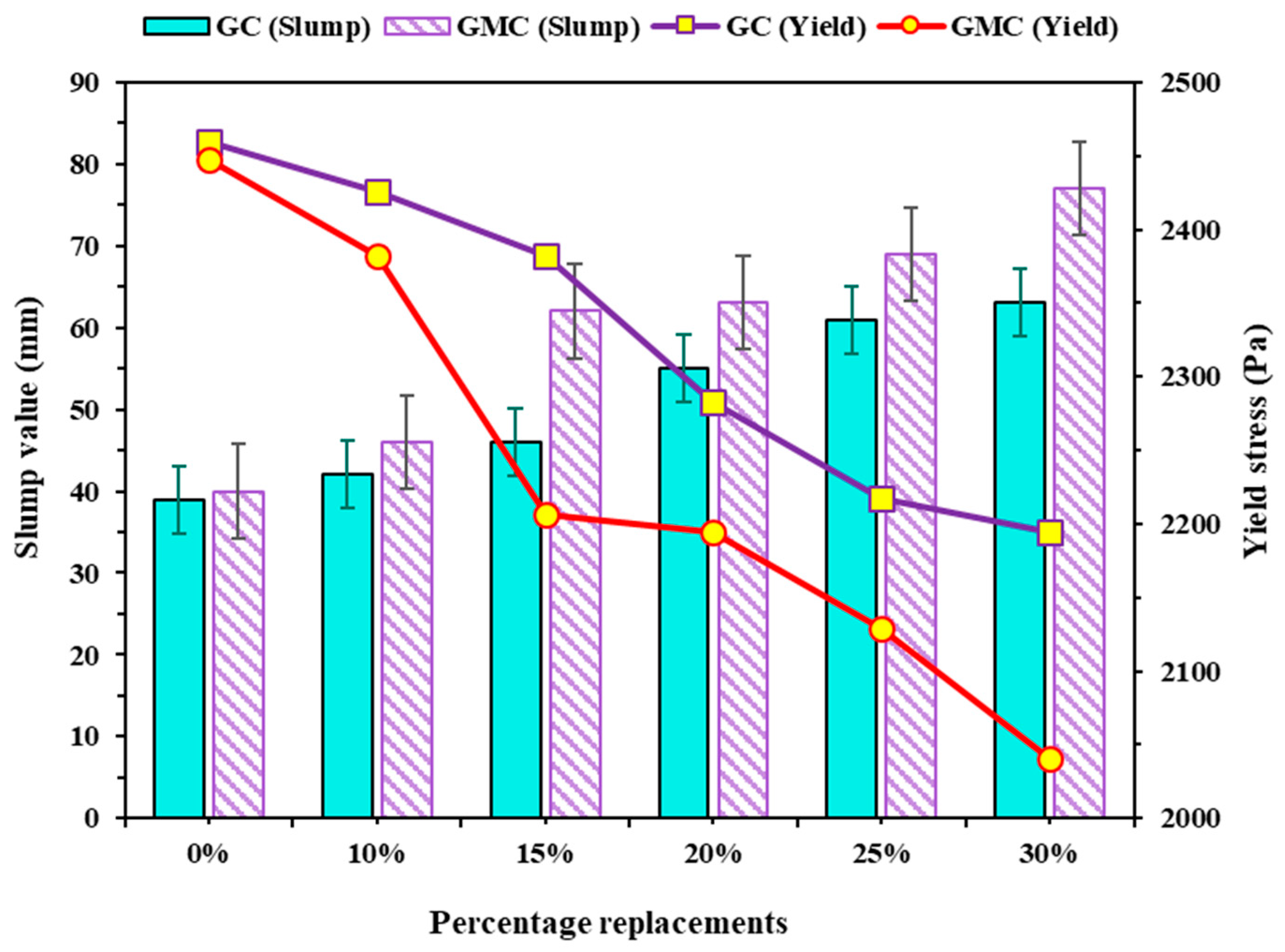

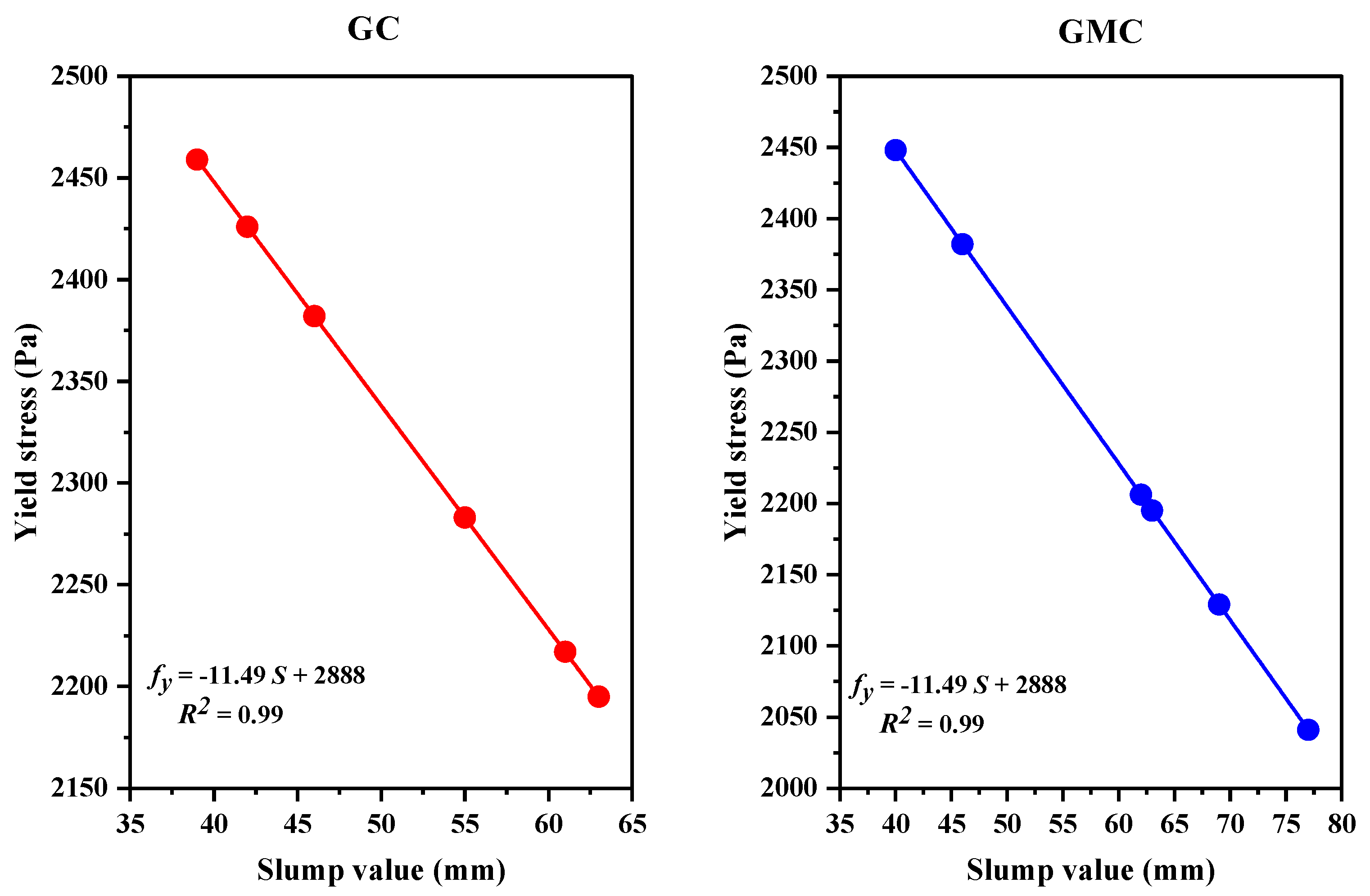

3.1. Rheological Properties

3.1.1. Slump and Yield Stress

3.2. Mechanical Properties

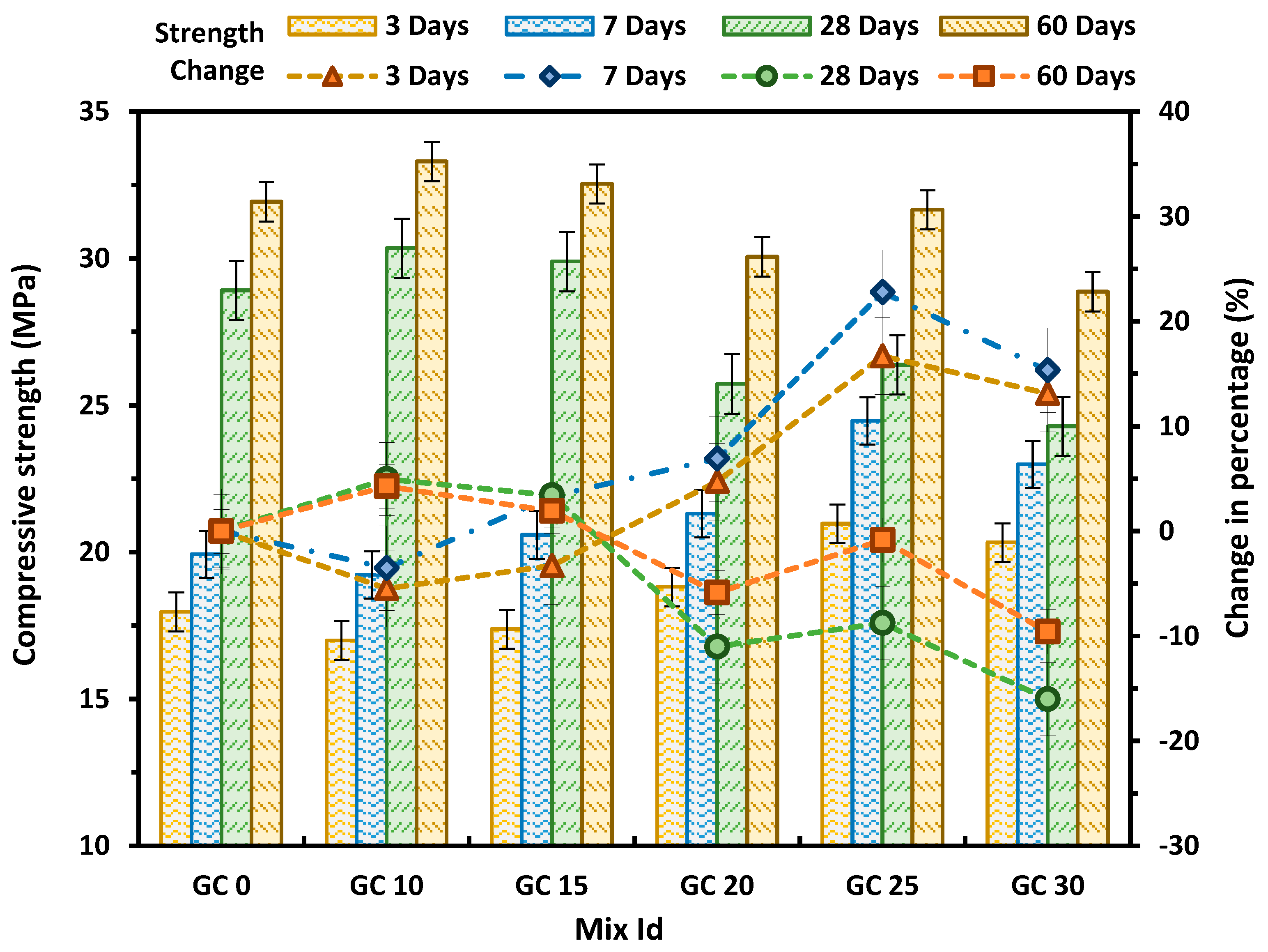

3.2.1. Effect of Crushed Glass Aggregates on Compressive Strength for GC

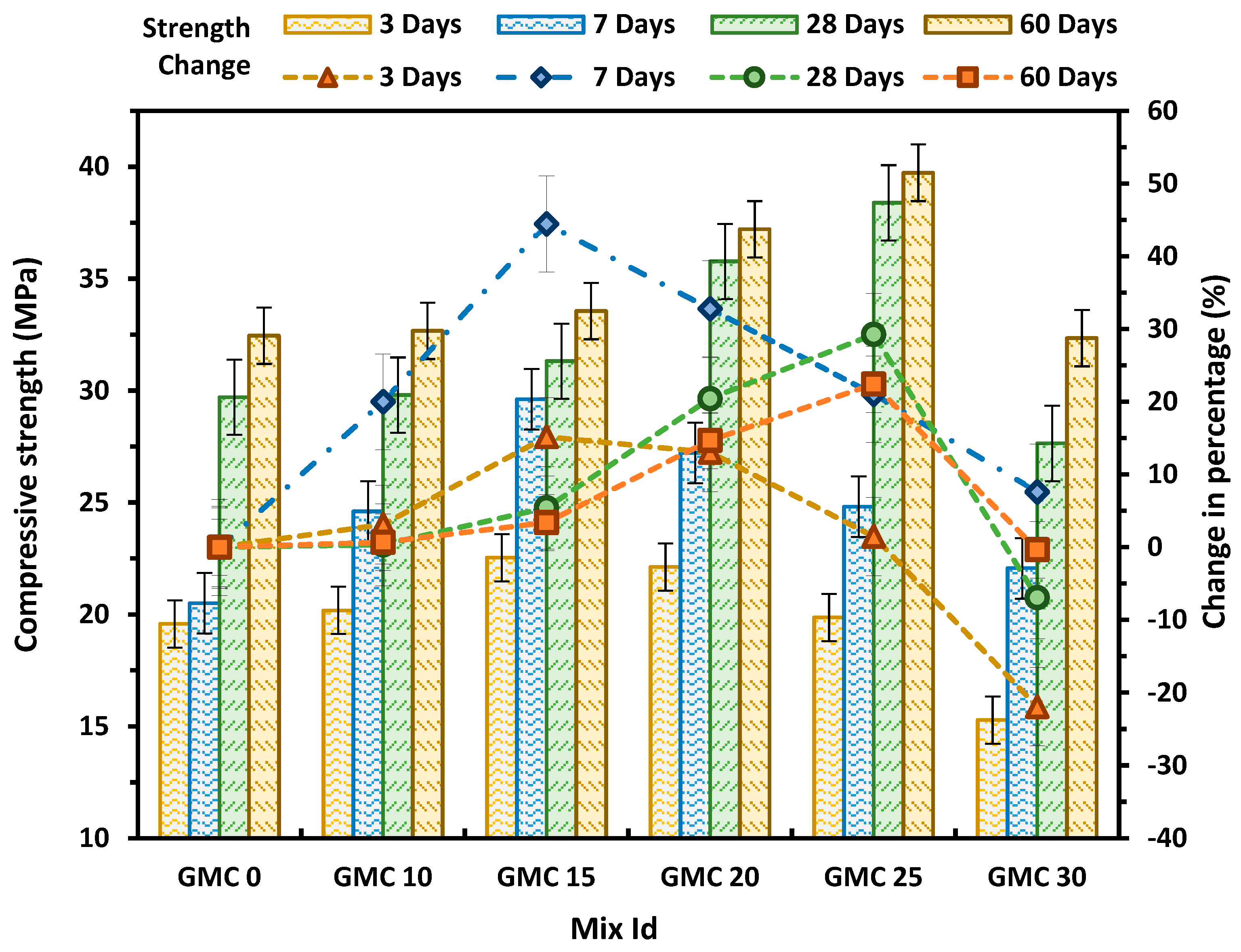

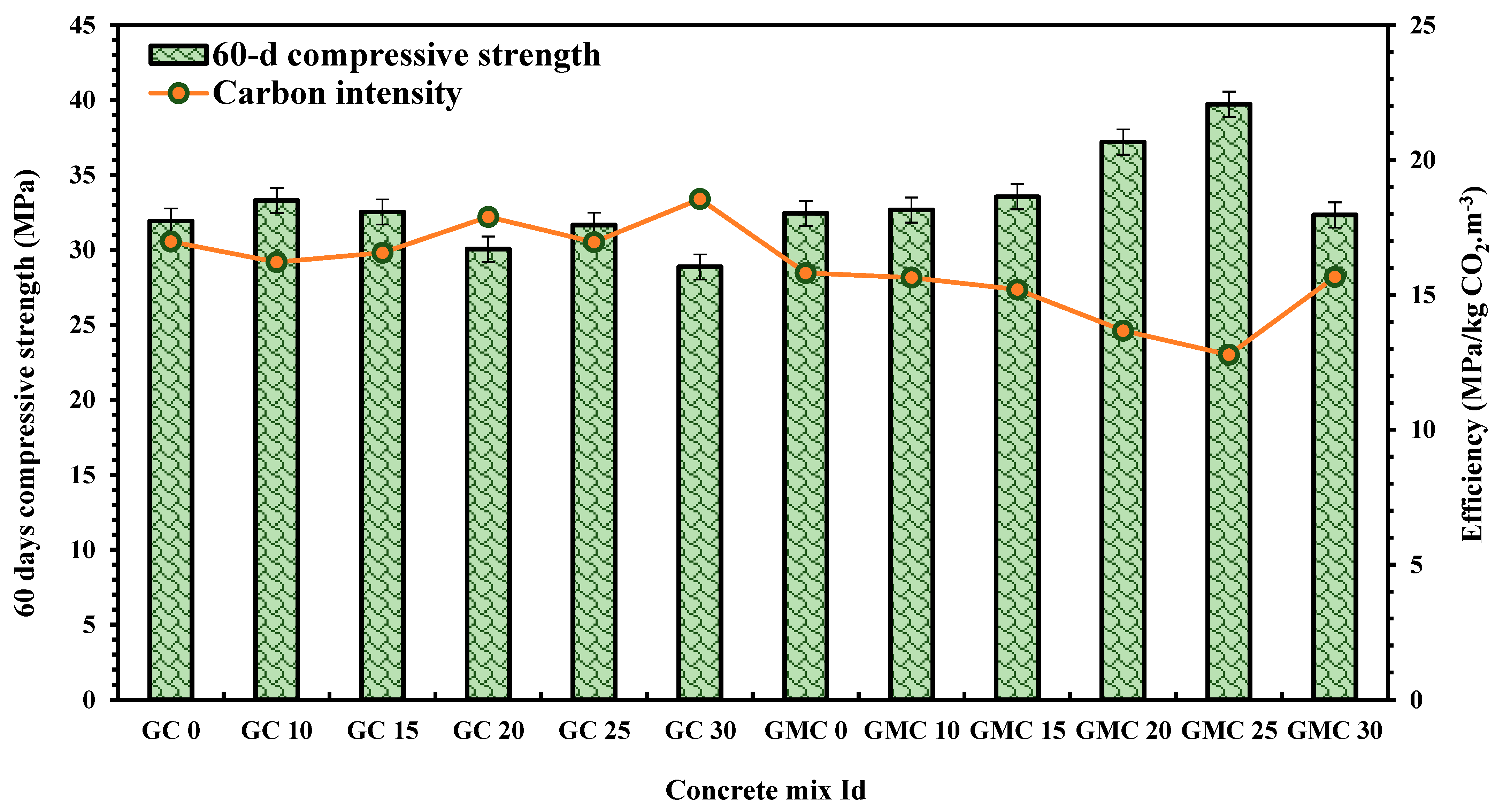

3.2.2. Effect of Crushed Glass Aggregates on Compressive Strength for GMC

3.2.3. Analysis of Variance (ANOVA) for Compressive Strength Test Results

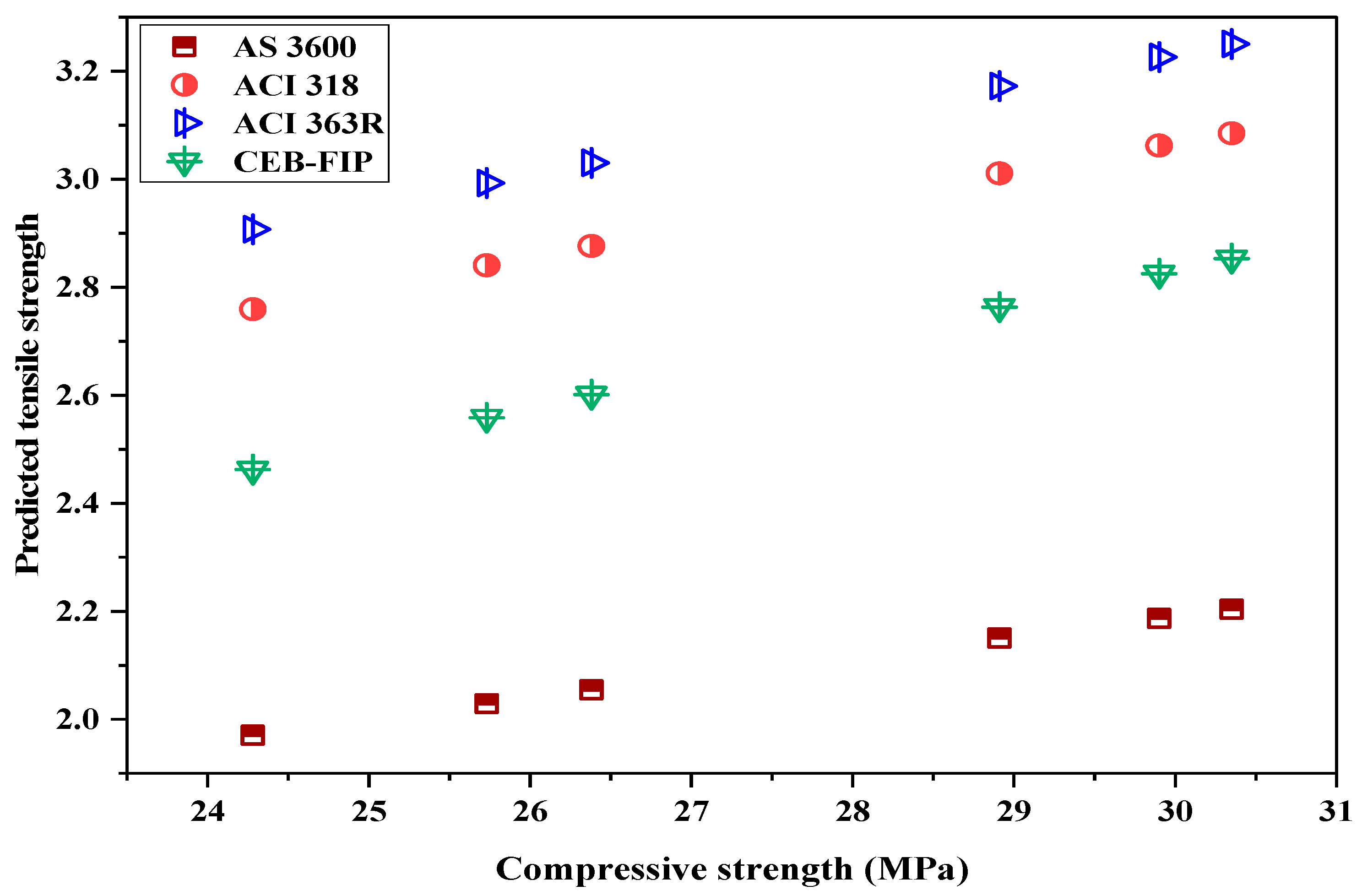

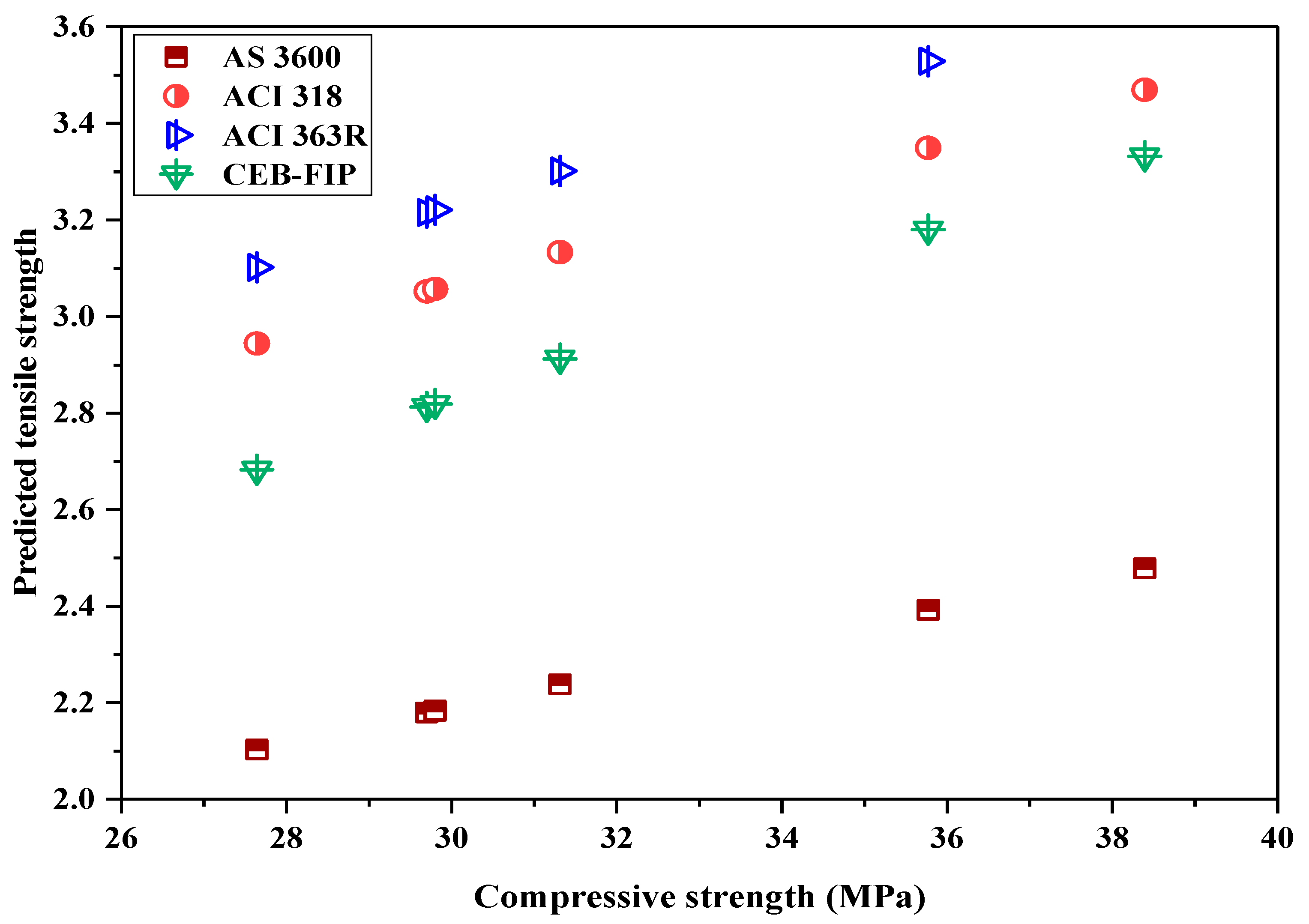

3.2.4. Comparison of Analytical Values of the Splitting Tensile Strength

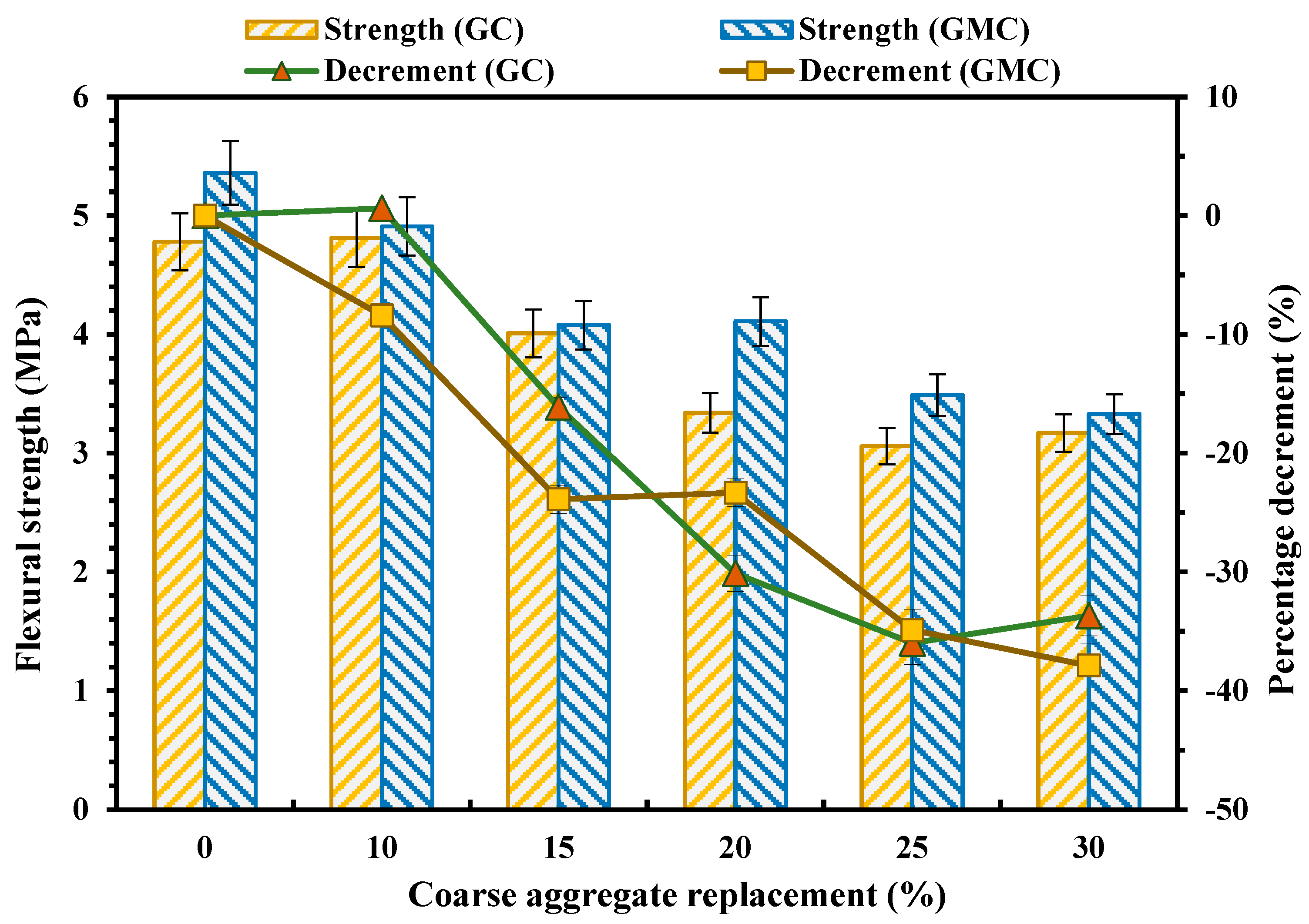

3.2.5. Effect of Metakaolin and Crushed Glass Aggregates on Flexural Strength

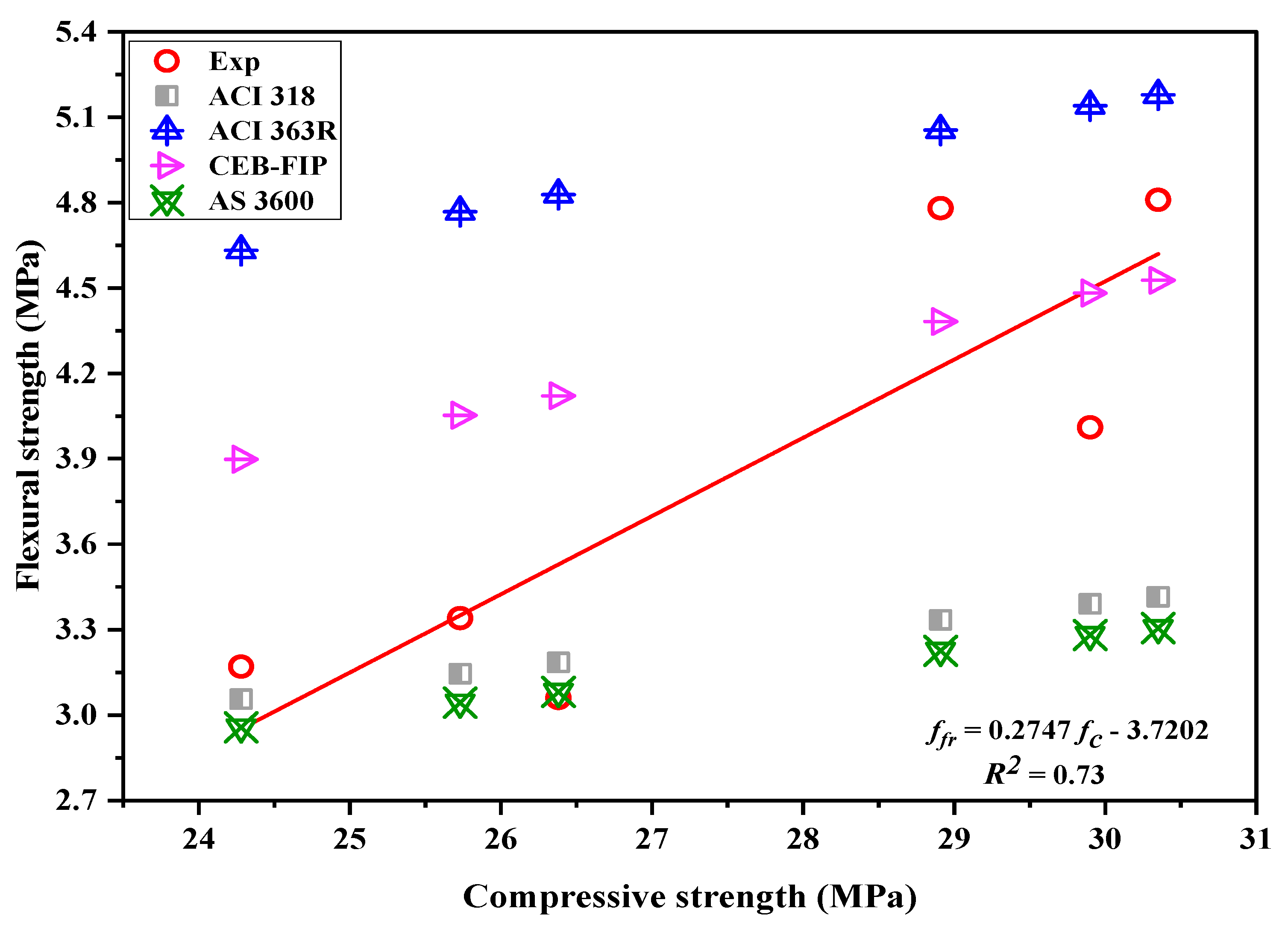

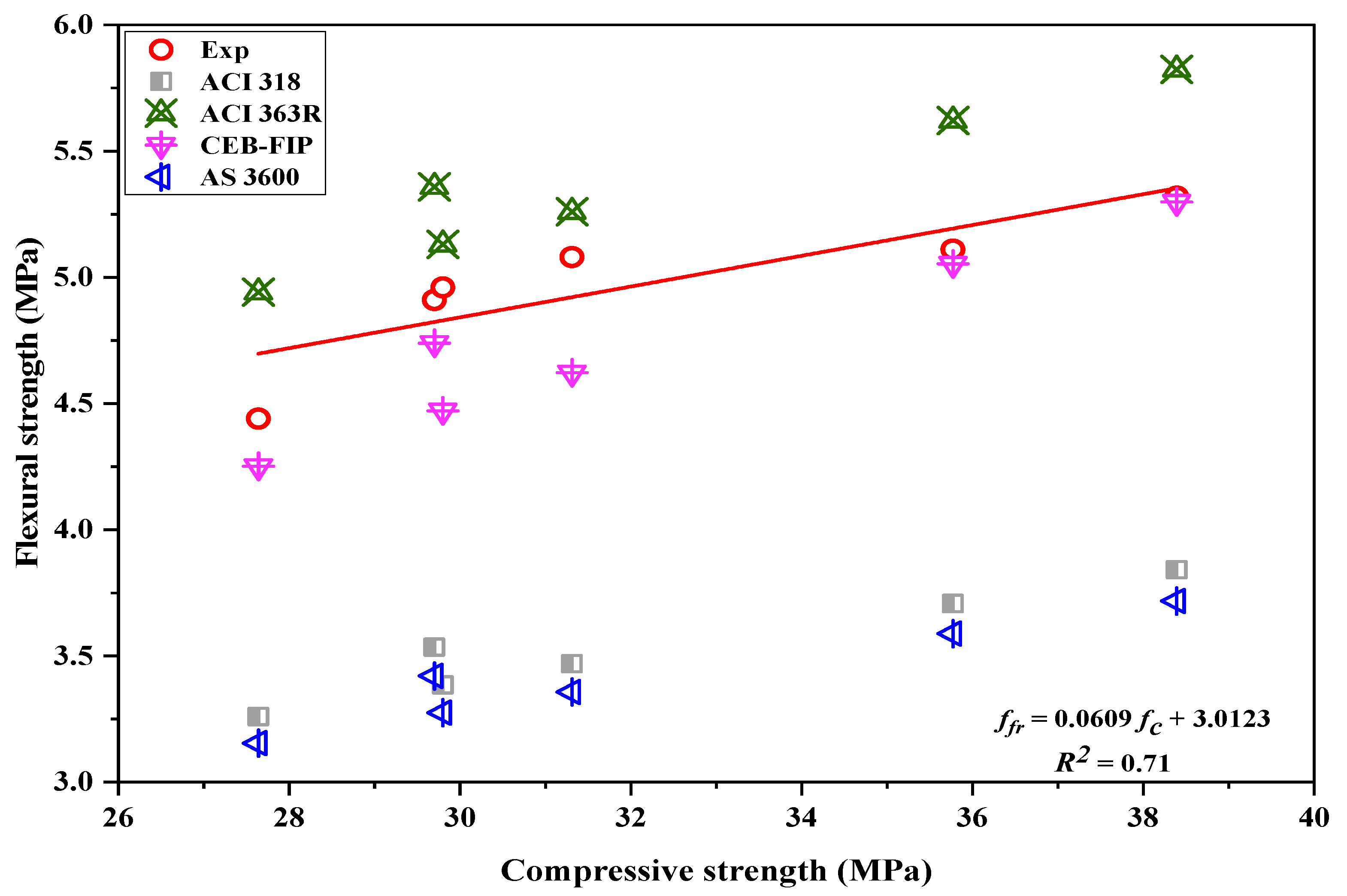

3.2.6. Relationship between Compressive Strength and Flexural Strength

3.3. Sustainability Analysis

- 1 m3 is the functional unit, meaning that each mixture yields 1 m3.

- Every mix proportion uses the same concrete processing parameters; hence they are irrelevant to this comparative analysis. The framework includes the necessary processing information for materials.

- Any emissions allocated to the materials from steel or electricity production are not seen as relevant in terms of concrete production and have not been included inside the system boundary. Only processing and transportation emissions are allocated to the materials for this assessment.

- It is optimistically predicted that all transportation will be done via roadway.

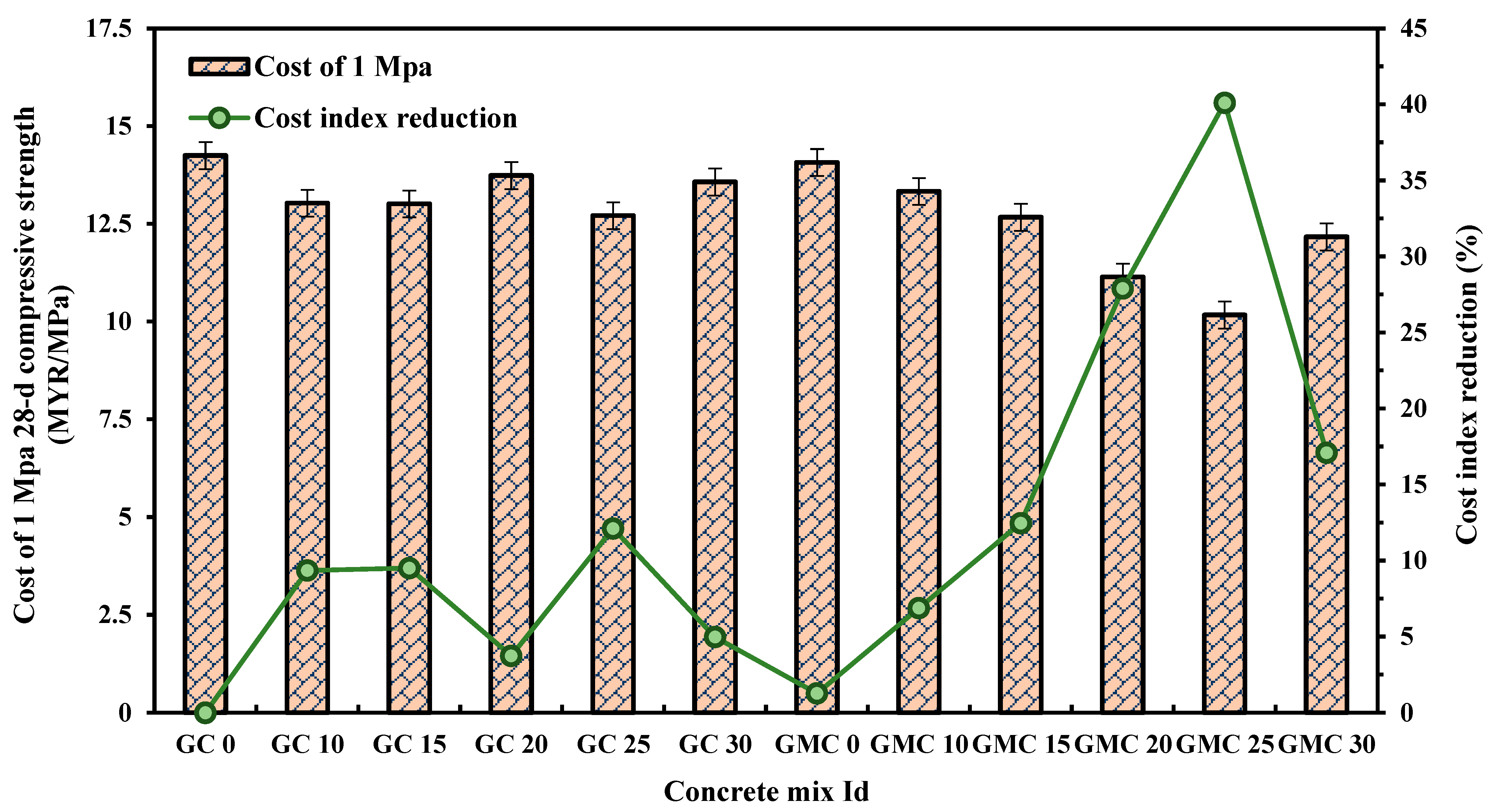

3.3.1. Effect of Metakaolin and Crushed Glass Aggregates on the Concrete Production Cost

3.3.2. Effect of Metakaolin and Crushed Glass Aggregates on the eCO2 Emission of Concrete

4. Conclusions

- The overall workability of the concrete mixtures incorporating glass aggregate increased gradually, both for the GC and GMC. The smooth surface and weaker cohesive bonding of the crushed glass aggregates enhanced the overall workability. On the other hand, the decelerating trend of MK increased the workability and moveability even further.

- The optimum compressive strength was achieved with GC 10 for only glass aggregate incorporated concrete, which was 5% higher than the control mix at 28 days. Increased GC content reduced the compressive strength due to their flat and flaky shape, which can alter the aggregate matrix and induce inhomogeneity.

- The incorporation of 10% metakaolin into the glass concrete mix accelerated the compressive strength increment. The pozzolanic action of MK creates secondary C-S-H gels and micro-filler effect reduces pore sizes. As a result, a 30% increment of compressive strength was observed for GMC 25.

- The flexural strength results were identical to those of the compressive strength tests, where the incorporation of MK augmented in higher strengths. According to these determinations, concrete incorporating 10% glass aggregate possessed optimum flexural strength of 4.81 MPa for GC mixes. On the other hand, GMC 0 with 10% metakaolin attained the maximum flexural strength of 5.36 MPa.

- The attained compressive strength for both the GC and GMC mixes was compared with different standards like ACI 318, ACI 363R, AS 3600, and CEB-FIP to determine analytical tensile strength values without performing experiments. The outcomes of the comparison were plotted in a scattered manner where all the standards except ACI 363R exhibited conservative results.

- The outcomes of the relation between flexural strength and compressive strength tests revealed a decent linear connection. The outcomes were also calculated with different standards, and a conservative correlation was found for both the GC and GMC mixes.

- Among all mix proportions, the GMC 25 produced a satisfactory optimal performance in terms of rheological and mechanical characteristics. It is feasible to generate high-strength concrete by employing the crushed glass aggregate alongside metakaolin incorporation as an additional cementing element which leads to waste manufacture modification and a sustainable alternative for the concrete industry.

- The production cost and equivalent carbon dioxide emission by concrete can respectively be reduced by up to 13.5% and 8% with the incorporation of glass cullet and metakaolin at optimal concentrations of 25% and 10%.

- The cost index and carbon index can respectively be reduced by 40% and 33% with the optimum dosages of GC and MK, establishing that glass cullet and metakaolin can be termed as sustainable building materials and reduce the carbon footprint of the concrete industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Ueno, A.; Ogawa, Y. Influence of coarse aggregate shape on optimum fine to total aggregate ratio using a virtual voids-ratio diagram in concrete compaction. Cem. Concr. Compos. 2020, 106, 103463. [Google Scholar] [CrossRef]

- Wagih, A.M.; El-Karmoty, H.Z.; Ebid, M.; Okba, S.H. Recycled construction and demolition concrete waste as aggregate for structural concrete. HBRC J. 2013, 9, 193–200. [Google Scholar] [CrossRef]

- Sadati, S.; Arezoumandi, M.; Khayat, K.H.; Volz, J.S. Shear performance of reinforced concrete beams incorporating recycled concrete aggregate and high-volume fly ash. J. Clean. Prod. 2016, 115, 284–293. [Google Scholar] [CrossRef]

- Malhotra, V. Use of fly ash, slag and condensed silica fume in North America and Europe. In Proceedings of the Concrete Workshop, Sydney, Australia, 4–6 July 1988; pp. 23–55. [Google Scholar]

- Naseri, H.; Jahanbakhsh, H.; Moghadas Nejad, F.; Golroo, A. Developing a novel machine learning method to predict the compressive strength of fly ash concrete in different ages. AUT J. Civ. Eng. 2020, 4, 423–436. [Google Scholar]

- Olofinnade, O.M.; Ndambuki, J.M.; Ede, A.N.; Olukanni, D.O. Effect of substitution of crushed waste glass as partial replacement for natural fine and coarse aggregate in concrete. Mater. Sci. Forum 2016, 866, 58–62. [Google Scholar] [CrossRef]

- De Andrade Salgado, F.; de Andrade Silva, F. Recycled aggregates from construction and demolition waste towards an application on structural concrete: A review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Joseph, H.S.; Pachiappan, T.; Avudaiappan, S.; Maureira-Carsalade, N.; Roco-Videla, Á.; Guindos, P.; Parra, P.F. A Comprehensive Review on Recycling of Construction Demolition Waste in Concrete. Sustainability 2023, 15, 4932. [Google Scholar] [CrossRef]

- Rodríguez, C.; Parra, C.; Casado, G.; Miñano, I.; Albaladejo, F.; Benito, F.; Sánchez, I. The incorporation of construction and demolition wastes as recycled mixed aggregates in non-structural concrete precast pieces. J. Clean. Prod. 2016, 127, 152–161. [Google Scholar] [CrossRef]

- Czop, M.; Łaźniewska-Piekarczyk, B. Use of slag from the combustion of solid municipal waste as a partial replacement of cement in mortar and concrete. Materials 2020, 13, 1593. [Google Scholar] [CrossRef]

- Liu, J.; Li, Z.; Zhang, W.; Jin, H.; Xing, F.; Tang, L. The impact of cold-bonded artificial lightweight aggregates produced by municipal solid waste incineration bottom ash (MSWIBA) replace natural aggregates on the mechanical, microscopic and environmental properties, durability of sustainable concrete. J. Clean. Prod. 2022, 337, 130479. [Google Scholar] [CrossRef]

- Sharifikolouei, E.; Canonico, F.; Salvo, M.; Baino, F.; Ferraris, M. Vitrified and nonvitrified municipal solid wastes as ordinary Portland cement (OPC) and sand substitution in mortars. Int. J. Appl. Ceram. Technol. 2020, 17, 573–583. [Google Scholar] [CrossRef]

- Al-kroom, H.; Atyia, M.M.; Mahdy, M.G.; Abd Elrahman, M. The Effect of Finely-Grinded Crushed Brick Powder on Physical and Microstructural Characteristics of Lightweight Concrete. Minerals 2022, 12, 159. [Google Scholar] [CrossRef]

- Noaman, M.A.; Islam, M.N.; Islam, M.R.; Karim, M.R. Mechanical properties of brick aggregate concrete containing rice husk ash as a partial replacement of cement. J. Mater. Civ. Eng. 2018, 30, 04018086. [Google Scholar] [CrossRef]

- Rodsin, K.; Joyklad, P.; Hussain, Q.; Mohamad, H.; Buatik, A.; Zhou, M.; Chaiyasarn, K.; Nawaz, A.; Mehmood, T.; Elnemr, A. Behavior of steel clamp confined brick aggregate concrete circular columns subjected to axial compression. Case Stud. Constr. Mater. 2022, 16, e00815. [Google Scholar] [CrossRef]

- Younis, M.O.; Amin, M.; Tahwia, A.M. Durability and mechanical characteristics of sustainable self-curing concrete utilizing crushed ceramic and brick wastes. Case Stud. Constr. Mater. 2022, 17, e01251. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Mustafa, M.A.-T.; Hanafi, I.; Mahmoud, R.; Tayeh, B. Effect of partial replacement of sand by plastic waste on impact resistance of concrete: Experiment and simulation. Structures 2019, 20, 519–526. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Bhat, Z.R.; Gupta, A.; Sharma, G. Effect of Steel Slag as Partial Replacement of Coarse Aggregate in M35 Grade of Concrete. Int. J. Eng. Tech. 2018, 4, 367–373. [Google Scholar]

- Harishankar, S. Study on prestressed concrete beams and poles with cement replaced by steel dust. Adv. Concr. Constr. 2017, 5, 391–405. [Google Scholar]

- Babajide Olabimtan, S.; Mosaberpanah, M.A. The Implementation of a Binary Blend of Waste Glass Powder and Coal Bottom Ash as a Partial Cement Replacement toward More Sustainable Mortar Production. Sustainability 2023, 15, 8776. [Google Scholar] [CrossRef]

- Ghareeb, K.S.; Ahmed, H.E.; El-Affandy, T.H.; Deifalla, A.F.; El-Sayed, T.A. The novelty of using glass powder and lime powder for producing UHPSCC. Buildings 2022, 12, 684. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Manjunath, B.A. Partial replacement of E-plastic waste as coarse-aggregate in concrete. Procedia Environ. Sci. 2016, 35, 731–739. [Google Scholar] [CrossRef]

- Rathore, V.; Rawat, A. Effective utilization of electronic waste in concrete mixture as a partial replacement to coarse aggregates. AIP Conf. Proc. 2019, 2158, 020037. [Google Scholar]

- Raut, S.R.; Dhapudkar, R.S.; Mandaokar, M.G. Experimental study on utilization of E-waste in cement concrete. Int. J. Eng. Sci. (IJES) 2018, 5, 82–86. [Google Scholar]

- Saleh, H.M.; Moussa, H.R.; El-Saied, F.A.; Dawoud, M.; Bayoumi, T.A.; Abdel Wahed, R.S. Mechanical and physicochemical evaluation of solidified dried submerged plants subjected to extreme climatic conditions to achieve an optimum waste containment. Prog. Nucl. Energy 2020, 122, 103285. [Google Scholar] [CrossRef]

- Eskander, S.B.; Saleh, H.M.; Tawfik, M.E.; Bayoumi, T.A. Towards potential applications of cement-polymer composites based on recycled polystyrene foam wastes on construction fields: Impact of exposure to water ecologies. Case Stud. Constr. Mater. 2021, 15, e00664. [Google Scholar] [CrossRef]

- Bawab, J.; Khatib, J.; El-Hassan, H.; Assi, L.; Kırgız, M.S. Properties of cement-based Materials Containing Cathode-Ray Tube (CRT) glass waste as fine aggregates—A Review. Sustainability 2021, 13, 11529. [Google Scholar] [CrossRef]

- Srivastava, V.; Gautam, S.; Agarwal, V.; Mehta, P. Glass wastes as coarse aggregate in concrete. J. Environ. Nanotechnol. 2014, 3, 67–71. [Google Scholar]

- Drzymała, T.; Zegardło, B.; Tofilo, P. Properties of concrete containing recycled glass aggregates produced of exploded lighting materials. Materials 2020, 13, 226. [Google Scholar] [CrossRef]

- Federico, L.; Chidiac, S. Waste glass as a supplementary cementitious material in concrete–critical review of treatment methods. Cem. Concr. Compos. 2009, 31, 606–610. [Google Scholar] [CrossRef]

- Al-jburi Najad, A.; Hasan Kareem, J.; Azline, N.; Ostovar, N. Waste glass as partial replacement in cement–A review. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 012023. [Google Scholar] [CrossRef]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Rahman, S.; Uddin, M. Experimental investigation of concrete with glass powder as partial replacement of cement. Civ. Eng. Archit. 2018, 6, 149–154. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Rajitha, D.; Srinivas, V.; Nawaz, M.Z. Experimental study on partial replacement of fine and coarse aggregate with waste glass. Int. J. Civ. Eng. Technol. 2017, 8, 1521–1525. [Google Scholar]

- Atoyebi, O.D.; Sadiq, O.M. Experimental data on flexural strength of reinforced concrete elements with waste glass particles as partial replacement for fine aggregate. Data Brief 2018, 18, 846–859. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, S.; Nagar, R. Feasibility assessment for partial replacement of fine aggregate to attain cleaner production perspective in concrete: A review. J. Clean. Prod. 2016, 135, 490–507. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef] [PubMed]

- Mansour, A.M.; Al Biajawi, M.I. The effect of the addition of metakaolin on the fresh and hardened properties of blended cement products: A review. Mater. Today Proc. 2022, 66, 2811–2817. [Google Scholar] [CrossRef]

- Jindal, B.B.; Alomayri, T.; Hasan, A.; Kaze, C.R. Geopolymer concrete with metakaolin for sustainability: A comprehensive review on raw material’s properties, synthesis, performance, and potential application. Environ. Sci. Pollut. Res. 2023, 30, 25299–25324. [Google Scholar] [CrossRef] [PubMed]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Neelakanta Reddy, I.; Shim, J. Preparation and validation of sustainable metakaolin based geopolymer concrete for structural application. Constr. Build. Mater. 2023, 371, 130688. [Google Scholar] [CrossRef]

- Chen, M.; Yang, T.; Han, J.; Zhang, Y.; Zhao, L.; Zhao, J.; Li, R.; Huang, Y.; Gu, Z.; Wu, J. The Application of Mineral Kaolinite for Environment Decontamination: A Review. Catalysts 2023, 13, 123. [Google Scholar] [CrossRef]

- Homayoonmehr, R.; Ramezanianpour, A.A.; Moodi, F.; Ramezanianpour, A.M.; Gevaudan, J.P. A Review on the Effect of Metakaolin on the Chloride Binding of Concrete, Mortar, and Paste Specimens. Sustainability 2022, 14, 15022. [Google Scholar] [CrossRef]

- He, C.; Osbaeck, B.; Makovicky, E. Pozzolanic reactions of six principal clay minerals: Activation, reactivity assessments and technological effects. Cem. Concr. Res. 1995, 25, 1691–1702. [Google Scholar] [CrossRef]

- Zhang, M.H.; Malhotra, V.M. Characteristics of a thermally activated alumino-silicate pozzolanic material and its use in concrete. Cem. Concr. Res. 1995, 25, 1713–1725. [Google Scholar] [CrossRef]

- Khatib, J.M.; Wild, S. Sulphate Resistance of Metakaolin Mortar. Cem. Concr. Res. 1998, 28, 83–92. [Google Scholar] [CrossRef]

- Wild, S.; Khatib, J.M. Portlandite consumption in metakaolin cement pastes and mortars. Cem. Concr. Res. 1997, 27, 137–146. [Google Scholar] [CrossRef]

- Meraz, M.M.; Sobuz, M.H.R.; Tam, V.W.Y.; Shaurdho, N.M.N. Effect of Various Powder Content on The Properties of Sustainable Self-Compacting Concrete. Case Stud. Constr. Mater. 2023, e02274. [Google Scholar] [CrossRef]

- Dong, Y.; Pei, L.; Fu, J.; Yang, Y.; Liu, T.; Liang, H.; Yang, H. Investigating the Mechanical Properties and Durability of Metakaolin-Incorporated Mortar by Different Curing Methods. Materials 2022, 15, 2035. [Google Scholar] [CrossRef] [PubMed]

- Tafraoui, A.; Escadeillas, G.; Vidal, T. Durability of the Ultra High Performances Concrete containing metakaolin. Constr. Build. Mater. 2016, 112, 980–987. [Google Scholar] [CrossRef]

- Duan, P.; Shui, Z.; Chen, W.; Shen, C. Enhancing microstructure and durability of concrete from ground granulated blast furnace slag and metakaolin as cement replacement materials. J. Mater. Res. Technol. 2013, 2, 52–59. [Google Scholar] [CrossRef]

- Siddique, R.; Kaur, A. Effect of metakaolin on the near surface characteristics of concrete. Mater. Struct. 2011, 44, 77–88. [Google Scholar] [CrossRef]

- Dinakar, P.; Sahoo, P.K.; Sriram, G. Effect of Metakaolin Content on the Properties of High Strength Concrete. Int. J. Concr. Struct. Mater. 2013, 7, 215–223. [Google Scholar] [CrossRef]

- ASTM C150/C150M-20; Standard Specification for Portland Cement. ASTM: West Conshohocken, PA, USA, 2021.

- Ismail, M.H.; Megat Johari, M.A.; Ariffin, K.S.; Jaya, R.P.; Wan Ibrahim, M.H.; Yugashini, Y. Performance of High Strength Concrete Containing Palm Oil Fuel Ash and Metakaolin as Cement Replacement Material. Adv. Civ. Eng. 2022, 2022, 6454789. [Google Scholar] [CrossRef]

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM: West Conshohocken, PA, USA, 2020.

- ASTM C39/C39M-20; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM C78/C78M-22; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM: West Conshohocken, PA, USA, 2022.

- Tian, Y.L.; Liu, W.C.; Cui, S.P.; Sun, S.B.; Wang, Y.; Li, J.H.; Fu, Y.S.; Wang, J. Recycled CRT Funnel Glass as Coarse Aggregate and Fine Aggregate in the Radiation Protection Concrete. Mater. Sci. Forum 2016, 847, 437–444. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A.; Jabbour, J.; Jreige, J.; Yacoub, A. Recycled Glass Concrete: Coarse and Fine Aggregates. Eur. J. Eng. Res. Sci. 2018, 3(1), 1–9. [Google Scholar] [CrossRef]

- Tattersall, G.H.; Banfill, P.F. The Rheology of Fresh Concrete; Pitman Books Limited: London, UK, 1983. [Google Scholar]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of recycled materials in development of self-compacting concrete: Mixing recycled concrete aggregates—Windshield waste glass aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Deng, P.; Xu, K.; Guo, S. Effects of coarse aggregate morphology on concrete mechanical properties. J. Build. Eng. 2023, 63, 105408. [Google Scholar] [CrossRef]

- Lyu, K.; Garboczi, E.J.; She, W.; Miao, C. The effect of rough vs. smooth aggregate surfaces on the characteristics of the interfacial transition zone. Cem. Concr. Compos. 2019, 99, 49–61. [Google Scholar] [CrossRef]

- Kuri, J.C.; Hosan, A.; Shaikh, F.U.A.; Biswas, W.K. The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings 2023, 13, 586. [Google Scholar] [CrossRef]

- Ganiron, T.U., Jr. The Effect of Waste Glass Bottles as an Alternative Coarse Aggregate in Concrete Mixture. Int. J. ICT-Aided Archit. Civ. Eng. 2014, 1, 1–10. [Google Scholar] [CrossRef]

- Sujjavanich, S.; Suwanvitaya, P.; Chaysuwan, D.; Heness, G. Synergistic effect of metakaolin and fly ash on properties of concrete. Constr. Build. Mater. 2017, 155, 830–837. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Bahrami Jovein, H. Influence of metakaolin as supplementary cementing material on strength and durability of concretes. Constr. Build. Mater. 2012, 30, 470–479. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Impact of combined use of ground glass powder and crushed glass aggregate on selected properties of Portland cement concrete. Constr. Build. Mater. 2016, 117, 263–272. [Google Scholar] [CrossRef]

- Lee, G.; Poon, C.S.; Wong, Y.L.; Ling, T.C. Effects of recycled fine glass aggregates on the properties of dry–mixed concrete blocks. Constr. Build. Mater. 2013, 38, 638–643. [Google Scholar] [CrossRef]

- Homayoonmehr, R.; Ramezanianpour, A.A.; Mirdarsoltany, M. Influence of metakaolin on fresh properties, mechanical properties and corrosion resistance of concrete and its sustainability issues: A review. J. Build. Eng. 2021, 44, 103011. [Google Scholar] [CrossRef]

- Kadri, E.-H.; Kenai, S.; Ezziane, K.; Siddique, R.; de Schutter, G. Influence of metakaolin and silica fume on the heat of hydration and compressive strength development of mortar. Appl. Clay Sci. 2011, 53, 704–708. [Google Scholar] [CrossRef]

- ACI Committee 363. State-of-the Art Report on High Strength Concrete (ACI 363R-92); American Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-99) and Commentary (318R-99); American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- Comité Euro-International du Béton. CEB-FIP Model Code 1990: Design Code; Thomas Telford Services Ltd.: London, UK, 1990. [Google Scholar]

- AS 3600-2009; Concrete Structures. Standards Australia: Sydney, Australia, 2009.

- Sobuz, M.H.R.; Datta, S.D.; Akid, A.S.M.; Tam, V.W.Y.; Islam, S.; Rana, M.J.; Aslani, F.; Yalçınkaya, Ç.; Sutan, N.M. Evaluating the effects of recycled concrete aggregate size and concentration on properties of high-strength sustainable concrete. J. King Saud Univ.-Eng. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C.; Lowrie, E.F.; Tse, P. Embodied Carbon: The Inventory Carbon and Energy (ICE); Version (2.0); Building Services Research & Information Association: Berkshire, UK, 2011. [Google Scholar]

- Datta, S.D.; Rana, M.J.; Assafi, M.N.; Mim, N.J.; Ahmed, S. Investigation on the generation of construction wastes in Bangladesh. Int. J. Constr. Manag. 2022, 1–10. [Google Scholar] [CrossRef]

- Bostanci, S.C. Use of waste marble dust and recycled glass for sustainable concrete production. J. Clean. Prod. 2020, 251, 119785. [Google Scholar] [CrossRef]

- Maddalena, R.; Roberts, J.J.; Hamilton, A. Can Portland cement be replaced by low-carbon alternative materials? A study on the thermal properties and carbon emissions of innovative cements. J. Clean. Prod. 2018, 186, 933–942. [Google Scholar] [CrossRef]

- Mim, N.J.; Meraz, M.M.; Islam, M.H.; Noroozinejad Farsangi, E.; Mehedi, M.T.; Arafin, S.A.K.; Shrestha, R.K. Eco-friendly and cost-effective self-compacting concrete using waste banana leaf ash. J. Build. Eng. 2023, 64, 105581. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Miah, M.J.; Babafemi, A.J.; Paul, S.C.; Kong, S.Y.; Li, Y.; Jang, J.G. Eco-friendly concrete with chemically treated end-of-life tires: Mechanical strength, shrinkage, and flexural performance of RC beams. Constr. Build. Mater. 2022, 351, 128970. [Google Scholar] [CrossRef]

- Khern, Y.C.; Paul, S.C.; Kong, S.Y.; Babafemi, A.J.; Anggraini, V.; Miah, M.J.; Šavija, B. Impact of chemically treated waste rubber tire aggregates on mechanical, durability and thermal properties of concrete. Front. Mater. 2020, 7, 90. [Google Scholar] [CrossRef]

| Parameters | Cement (%) | Kaolin (%) |

|---|---|---|

| Silica (SiO2) | 20.1 | 55 |

| Alumina (Al2O3) | 4.9 | 29 |

| Iron Oxide (Fe2O3) | 2.5 | 1 |

| Calcium Oxide (CaO) | 65 | - |

| Magnesium Oxide (MgO) | 3.1 | 0.5 |

| Sodium (Na2O) | 0.2 | 0.02 |

| Potassium Oxide (K2O) | 0.4 | 3.1 |

| Titanium Dioxide (TiO2) | 0.2 | - |

| Loss On Ignition | 2.5 | 8.8 |

| Fineness (2 μm) | 2.4 | 10 |

| Mix Id | Cullet Percentage | Water (Kg/m3) | Cement (Kg/m3) | Metakaolin (Kg/m3) | Fine Aggregate (Kg/m3) | Coarse Aggregate (Kg/m3) | Cullet (Kg/m3) |

|---|---|---|---|---|---|---|---|

| GC 0 | Control | 177.75 | 395 | - | 805 | 989 | 0 |

| GC 10 | 10% | 177.75 | 395 | - | 805 | 890.1 | 98.9 |

| GC 15 | 15% | 177.75 | 395 | - | 805 | 840.65 | 148.35 |

| GC 20 | 20% | 177.75 | 395 | - | 805 | 791.2 | 197.8 |

| GC 25 | 25% | 177.75 | 395 | - | 805 | 741.75 | 247.25 |

| GC 30 | 30% | 177.75 | 395 | - | 805 | 692.3 | 296.7 |

| GMC 0 | 0% | 177.75 | 355.5 | 39.5 | 805 | 989 | 0 |

| GMC 10 | 10% | 177.75 | 355.5 | 39.5 | 805 | 890.1 | 98.9 |

| GMC 15 | 15% | 177.75 | 355.5 | 39.5 | 805 | 840.65 | 184.35 |

| GMC 20 | 20% | 177.75 | 355.5 | 39.5 | 805 | 791.2 | 197.8 |

| GMC 25 | 25% | 177.75 | 355.5 | 39.5 | 805 | 741.75 | 247.25 |

| GMC 30 | 30% | 177.75 | 355.5 | 39.5 | 805 | 692.3 | 296.7 |

| Mix Id | Curing Days | Mean Strength (MPa) | Standard Deviation | CoV (%) | Standard Error | 95% Confidence Interval | |

|---|---|---|---|---|---|---|---|

| Lower Range | Upper Range | ||||||

| GC 0 | 3 | 17.97 | 0.87 | 0.048 | 0.50 | 15.81 | 20.13 |

| 7 | 19.93 | 1.11 | 0.056 | 0.64 | 17.17 | 22.69 | |

| 28 | 28.91 | 1.05 | 0.036 | 0.61 | 26.30 | 31.52 | |

| 60 | 31.93 | 1.23 | 0.039 | 0.71 | 28.87 | 34.99 | |

| GC 10 | 3 | 16.99 | 0.92 | 0.054 | 0.53 | 14.69 | 19.29 |

| 7 | 19.23 | 1.06 | 0.055 | 0.61 | 16.59 | 21.87 | |

| 28 | 30.35 | 1.16 | 0.038 | 0.67 | 27.47 | 33.23 | |

| 60 | 33.30 | 1.24 | 0.037 | 0.72 | 30.22 | 36.38 | |

| GC 15 | 3 | 17.38 | 0.99 | 0.057 | 0.57 | 14.93 | 19.83 |

| 7 | 20.59 | 1.04 | 0.051 | 0.60 | 18.00 | 23.18 | |

| 28 | 29.90 | 1.18 | 0.039 | 0.68 | 26.97 | 32.83 | |

| 60 | 32.54 | 1.48 | 0.046 | 0.86 | 28.85 | 36.23 | |

| GC 20 | 3 | 18.82 | 0.77 | 0.041 | 0.44 | 16.91 | 20.73 |

| 7 | 21.31 | 0.98 | 0.046 | 0.57 | 18.87 | 23.75 | |

| 28 | 25.73 | 0.45 | 0.017 | 0.26 | 24.62 | 26.84 | |

| 60 | 30.06 | 1.03 | 0.034 | 0.60 | 27.50 | 32.62 | |

| GC 25 | 3 | 20.97 | 0.74 | 0.035 | 0.43 | 19.14 | 22.80 |

| 7 | 24.47 | 1.33 | 0.054 | 0.77 | 21.17 | 27.77 | |

| 28 | 26.38 | 1.15 | 0.044 | 0.67 | 23.51 | 29.25 | |

| 60 | 31.66 | 1.24 | 0.039 | 0.71 | 28.59 | 34.73 | |

| GC 30 | 3 | 20.33 | 1.05 | 0.051 | 0.60 | 17.73 | 22.93 |

| 7 | 22.99 | 1.36 | 0.059 | 0.79 | 19.61 | 26.37 | |

| 28 | 24.28 | 1.02 | 0.042 | 0.59 | 21.75 | 26.81 | |

| 60 | 28.87 | 1.41 | 0.049 | 0.81 | 25.38 | 32.36 | |

| Mix Id | Curing Days | Mean Strength (MPa) | Standard Deviation | CoV (%) | Standard Error | 95% Confidence Interval | |

|---|---|---|---|---|---|---|---|

| Lower Range | Upper Range | ||||||

| GMC 0 | 3 | 19.57 | 0.87 | 0.044 | 0.50 | 17.41 | 21.73 |

| 7 | 20.50 | 0.68 | 0.033 | 0.39 | 18.82 | 22.18 | |

| 28 | 29.70 | 0.75 | 0.023 | 0.43 | 30.63 | 34.37 | |

| 60 | 32.45 | 0.82 | 0.024 | 0.47 | 32.23 | 36.29 | |

| GMC 10 | 3 | 20.18 | 0.67 | 0.033 | 0.39 | 18.51 | 21.85 |

| 7 | 24.60 | 0.91 | 0.037 | 0.52 | 22.35 | 26.85 | |

| 28 | 29.80 | 1.23 | 0.041 | 0.71 | 26.75 | 32.85 | |

| 60 | 32.67 | 1.13 | 0.035 | 0.65 | 29.85 | 35.49 | |

| GMC 15 | 3 | 22.54 | 1.02 | 0.045 | 0.59 | 20.01 | 25.07 |

| 7 | 29.61 | 0.96 | 0.032 | 0.55 | 27.23 | 31.99 | |

| 28 | 31.31 | 1.06 | 0.034 | 0.61 | 28.68 | 33.94 | |

| 60 | 33.55 | 1.34 | 0.040 | 0.77 | 30.23 | 36.87 | |

| GMC 20 | 3 | 22.12 | 0.89 | 0.040 | 0.51 | 19.92 | 24.32 |

| 7 | 27.22 | 0.98 | 0.036 | 0.56 | 24.79 | 29.65 | |

| 28 | 35.77 | 1.19 | 0.033 | 0.69 | 32.81 | 38.73 | |

| 60 | 37.21 | 1.14 | 0.031 | 0.66 | 34.37 | 40.05 | |

| GMC 25 | 3 | 19.86 | 0.84 | 0.042 | 0.49 | 17.77 | 21.95 |

| 7 | 24.81 | 0.92 | 0.037 | 0.53 | 22.51 | 27.11 | |

| 28 | 38.39 | 0.69 | 0.018 | 0.40 | 36.67 | 40.11 | |

| 60 | 39.73 | 0.96 | 0.024 | 0.55 | 37.36 | 42.10 | |

| GMC 30 | 3 | 15.28 | 0.89 | 0.058 | 0.51 | 13.08 | 17.48 |

| 7 | 22.06 | 0.95 | 0.043 | 0.55 | 19.69 | 24.43 | |

| 28 | 27.64 | 1.31 | 0.047 | 0.75 | 24.39 | 30.89 | |

| 60 | 32.34 | 1.09 | 0.034 | 0.63 | 29.63 | 35.05 | |

| Group | Curing Days | Source of Variation | Degree of Freedom | Sum of Squares | Mean Square | F-Test | p-Value | Significance |

|---|---|---|---|---|---|---|---|---|

| GC% to Compressive Strength | 3 | Between Groups | 1 | 12.94 | 12.94 | 0.217 | 0.65135 | No |

| Within Groups | 10 | 596.35 | 59.63 | |||||

| 7 | Between Groups | 1 | 67.78 | 67.78 | 1.124 | 0.31391 | No | |

| Within Groups | 10 | 602.82 | 60.28 | |||||

| 28 | Between Groups | 1 | 358.07 | 358.07 | 5.833 | 0.03637 | Yes | |

| Within Groups | 10 | 613.91 | 61.39 | |||||

| 60 | Between Groups | 1 | 650.62 | 650.62 | 10.902 | 0.00799 | Yes | |

| Within Groups | 10 | 596.79 | 59.68 | |||||

| GMC% to Compressive Strength | 3 | Between Groups | 1 | 31.85 | 31.85 | 0.516 | 0.48883 | No |

| Within Groups | 10 | 616.76 | 61.68 | |||||

| 7 | Between Groups | 1 | 198.45 | 198.45 | 3.109 | 0.10835 | No | |

| Within Groups | 10 | 638.36 | 63.84 | |||||

| 28 | Between Groups | 1 | 758.59 | 758.59 | 11.476 | 0.00691 | Yes | |

| Within Groups | 10 | 661.02 | 66.10 | |||||

| 60 | Between Groups | 1 | 1003.94 | 1003.94 | 16.044 | 0.00250 | Yes | |

| Within Groups | 10 | 625.74 | 62.57 |

| Material | Unit Cost (MYR/kg) | Material Embodied Energy (MJ/kg) | eCO2 Emission (kg CO2/kg) | |||

|---|---|---|---|---|---|---|

| Production | Transportation | Production | Transportation | Total | ||

| Cement | 0.378 [84] | 0.01428 | 5.5 [85] | 0.95 [85] | 0.02 | 0.971 |

| Metakaolin | 0.42 | 0.0126 | 3.48 [88] | 0.218 [88] | 0.018 | 0.236 |

| NCA | 0.21 [84] | 0.01092 | 0.083 [85] | 0.005 [85] | 0.021 | 0.026 |

| GCA | - | 0.0084 | 0.052 [85] | 0.0038 [85] | 0.0005 | 0.0043 |

| FA | 0.09114 [84] | 0.00924 | 0.08 [86] | 0.0048 [86] | 0.16 | 0.1648 |

| Water | 0.003696 [84] | - | 0.0009 [87] | 0.00155 [87] | - | 0.00155 |

| Mix ID | Cost of Materials (MYR/m3 Concrete) | Total Cost (MYR/m3 Concrete) | Total Cost (USD/m3 Concrete) | |||||

|---|---|---|---|---|---|---|---|---|

| Cement | Metakaolin | NCA | GCA | FA | Water | |||

| GC 0 | 154.95 | - | 218.49 | - | 80.81 | 0.66 | 454.91 | 97.41 |

| GC 10 | 154.95 | - | 196.64 | 0.83 | 80.81 | 0.66 | 433.89 | 92.91 |

| GC 15 | 154.95 | - | 185.72 | 1.25 | 80.81 | 0.66 | 423.38 | 90.66 |

| GC 20 | 154.95 | - | 174.79 | 1.66 | 80.81 | 0.66 | 412.87 | 88.41 |

| GC 25 | 154.95 | - | 163.87 | 2.07 | 80.81 | 0.66 | 402.36 | 86.16 |

| GC 30 | 154.95 | - | 152.94 | 2.49 | 80.81 | 0.66 | 391.85 | 83.91 |

| GMC 0 | 139.46 | 17.15 | 218.49 | - | 80.81 | 0.66 | 456.57 | 97.77 |

| GMC 10 | 139.46 | 17.15 | 196.64 | 0.83 | 80.81 | 0.66 | 435.55 | 93.27 |

| GMC 15 | 139.46 | 17.15 | 185.72 | 1.25 | 80.81 | 0.66 | 425.04 | 91.01 |

| GMC 20 | 139.46 | 17.15 | 174.79 | 1.66 | 80.81 | 0.66 | 414.53 | 88.76 |

| GMC 25 | 139.46 | 17.15 | 163.87 | 2.07 | 80.81 | 0.66 | 404.02 | 86.51 |

| GMC 30 | 139.46 | 17.15 | 152.94 | 2.49 | 80.81 | 0.66 | 393.51 | 82.26 |

| Mix ID | eCO2 Emission (kg CO2/m3 Concrete) | Percentage of CO2 Emission | |||

|---|---|---|---|---|---|

| Production | Transportation | Total | Production (%) | Transportation (%) | |

| GC 0 | 384.33 | 157.86 | 542.20 | 70.88 | 29.12 |

| GC 10 | 384.22 | 155.84 | 540.05 | 71.144 | 28.86 |

| GC 15 | 384.16 | 154.82 | 538.98 | 71.27 | 28.73 |

| GC 20 | 384.10 | 153.81 | 537.91 | 71.41 | 28.59 |

| GC 25 | 384.03 | 152.79 | 536.83 | 71.54 | 28.46 |

| GC 30 | 383.98 | 151.78 | 535.76 | 71.67 | 28.33 |

| GMC 0 | 355.42 | 157.75 | 513.17 | 69.26 | 30.74 |

| GMC 10 | 355.30 | 155.72 | 511.02 | 69.53 | 30.47 |

| GMC 15 | 355.24 | 154.7 | 509.95 | 69.66 | 30.34 |

| GMC 20 | 355.18 | 153.69 | 508.87 | 69.79 | 30.2 |

| GMC 25 | 355.12 | 152.68 | 507.80 | 69.93 | 30.07 |

| GMC 30 | 355.06 | 151.66 | 506.73 | 70.07 | 29.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasan, N.M.S.; Shaurdho, N.M.N.; Sobuz, M.H.R.; Meraz, M.M.; Islam, M.S.; Miah, M.J. Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement. Sustainability 2023, 15, 11254. https://doi.org/10.3390/su151411254

Hasan NMS, Shaurdho NMN, Sobuz MHR, Meraz MM, Islam MS, Miah MJ. Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement. Sustainability. 2023; 15(14):11254. https://doi.org/10.3390/su151411254

Chicago/Turabian StyleHasan, Noor Md. Sadiqul, Nur Mohammad Nazmus Shaurdho, Md. Habibur Rahman Sobuz, Md. Montaseer Meraz, Md. Saidul Islam, and Md Jihad Miah. 2023. "Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement" Sustainability 15, no. 14: 11254. https://doi.org/10.3390/su151411254

APA StyleHasan, N. M. S., Shaurdho, N. M. N., Sobuz, M. H. R., Meraz, M. M., Islam, M. S., & Miah, M. J. (2023). Utilization of Waste Glass Cullet as Partial Substitutions of Coarse Aggregate to Produce Eco-Friendly Concrete: Role of Metakaolin as Cement Replacement. Sustainability, 15(14), 11254. https://doi.org/10.3390/su151411254