Research on the Distribution of Overlying Rock Fractures Caused by Mining in Ultra-Thick Coal Seams and Its Impact on the Near-Surface Aquifer

Abstract

:1. Introduction

2. Theory

2.1. Interaction between Rock Blocks on Both Sides of Penetrated Fracture

2.2. Rock Mass Fracture Process

2.3. Plastic Deformation Law of Rocks

3. Method and Verification

3.1. Numerical Simulation Method

- (a)

- Firstly, the entire calculation area is divided into solid elements and zero-thickness cohesive elements.

- (b)

- Assign parameters and boundary conditions to the numerical model. The initial ground stress, the nodal force and displacement of solid elements under mining conditions, and the fracture energy of cohesive elements are calculated by the finite element method (FEM). When the fracture energy is greater than or equal to the fracture energy obtained in the experiment, delete the cohesive element and assign the state variable state = 0.

- (c)

- Traversing and searching cohesive elements with state = 0 in the entire numerical model, determining the area enclosed by the above elements, denoting it as Ωi. The FEM method is used in the Ωi to calculate the nodal force and nodal displacement of each element after the boundary cohesive elements of the Ωi area is deleted (self-balancing calculation).

- (d)

- The node force on the interface between the region Ωi and the adjacent Ωi+1 region acts on the discrete element nodes through shared nodes. Under this condition, the displacement w1 and rotation angle α1 of the discrete element area Ωi under the action of external load, body force, and nodal force are calculated by DEM within Δt time.

- (e)

- Judging whether the “mutual intrusion displacement w1” on the interface between the area Ωi and the adjacent Ωi+1 area satisfies the tolerance Wtolerance. If yes, further calculate the mechanical response in the FEM area Ωi, see step (f) for details; otherwise, take the displacement tolerance Wtolerance as the displacement boundary condition, superimpose the initial stress condition, and calculate the nodal forces and nodal displacements in the area Ωi by FEM.

- (f)

- Apply the displacement value calculated by DEM to the finite element Ωi and the adjacent Ωi+1 area as the continuous displacement boundary conditions. According to the constitutive relationship in Section 2, Ωi area mechanical response is implicitly solved by FEM.

- (g)

- If the difference between the nodal force on the interface obtained by FEM and DEM , where PF is the nodal force obtained by FEM, PD is the nodal force obtained by DEM, and is the tolerance, then the calculation of this iterative step ends; otherwise, the nodal force is taken as (PF + PD)/2 is the force boundary, which is reapplied in the FEM area and DEM area, and the nodal force and nodal displacement are calculated, respectively, until the inequality is established.

3.2. Parameter Identification

3.3. Verification of Constitutive Equations

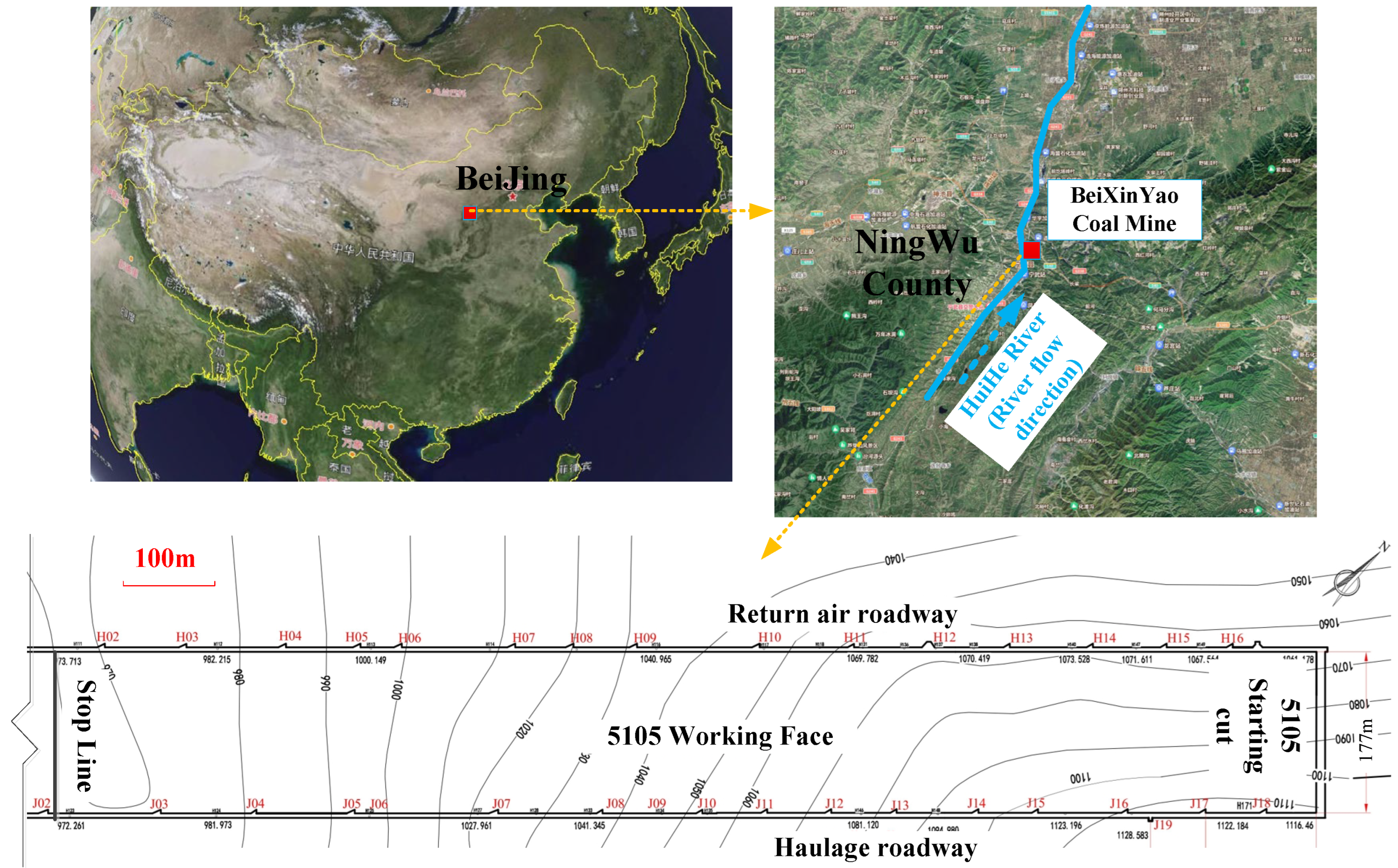

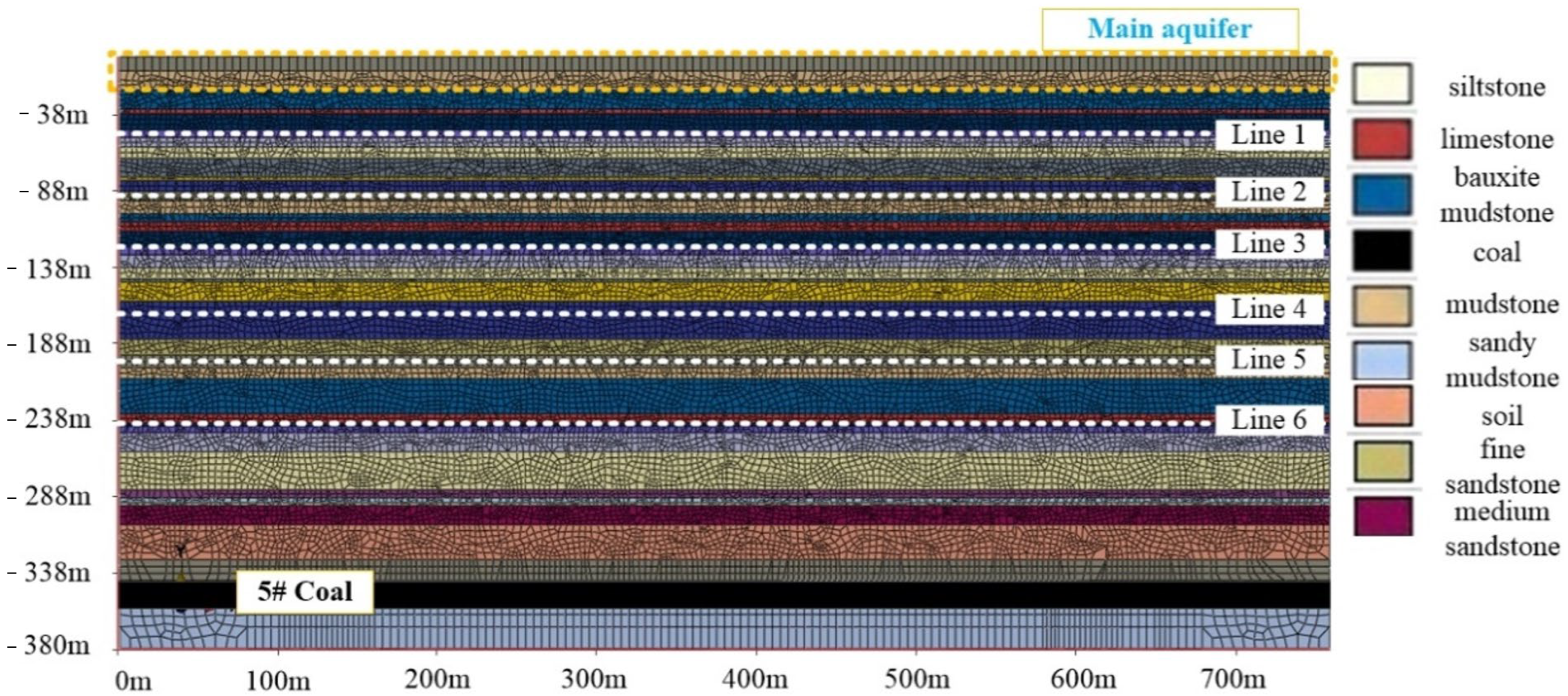

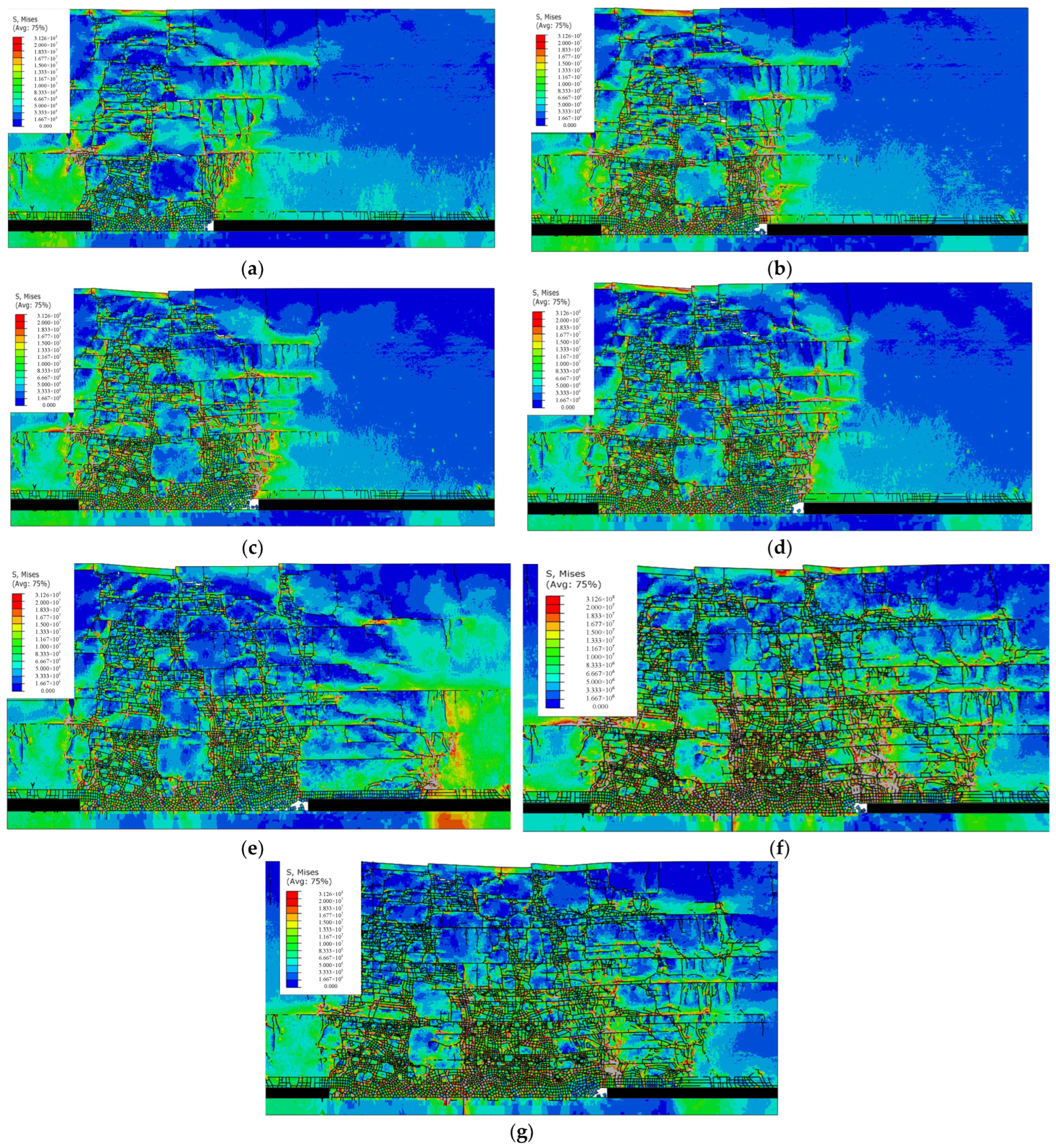

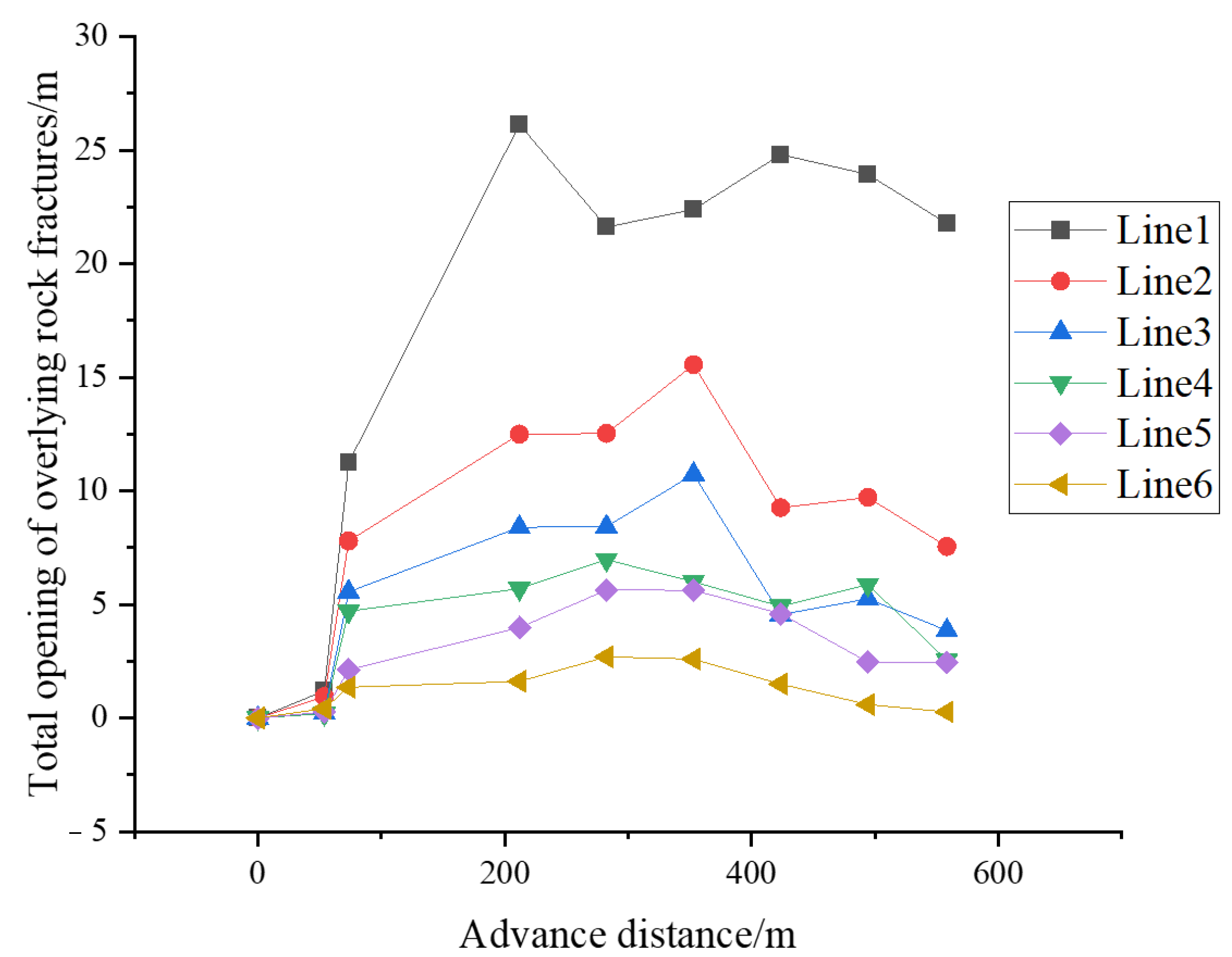

4. Numerical Simulation

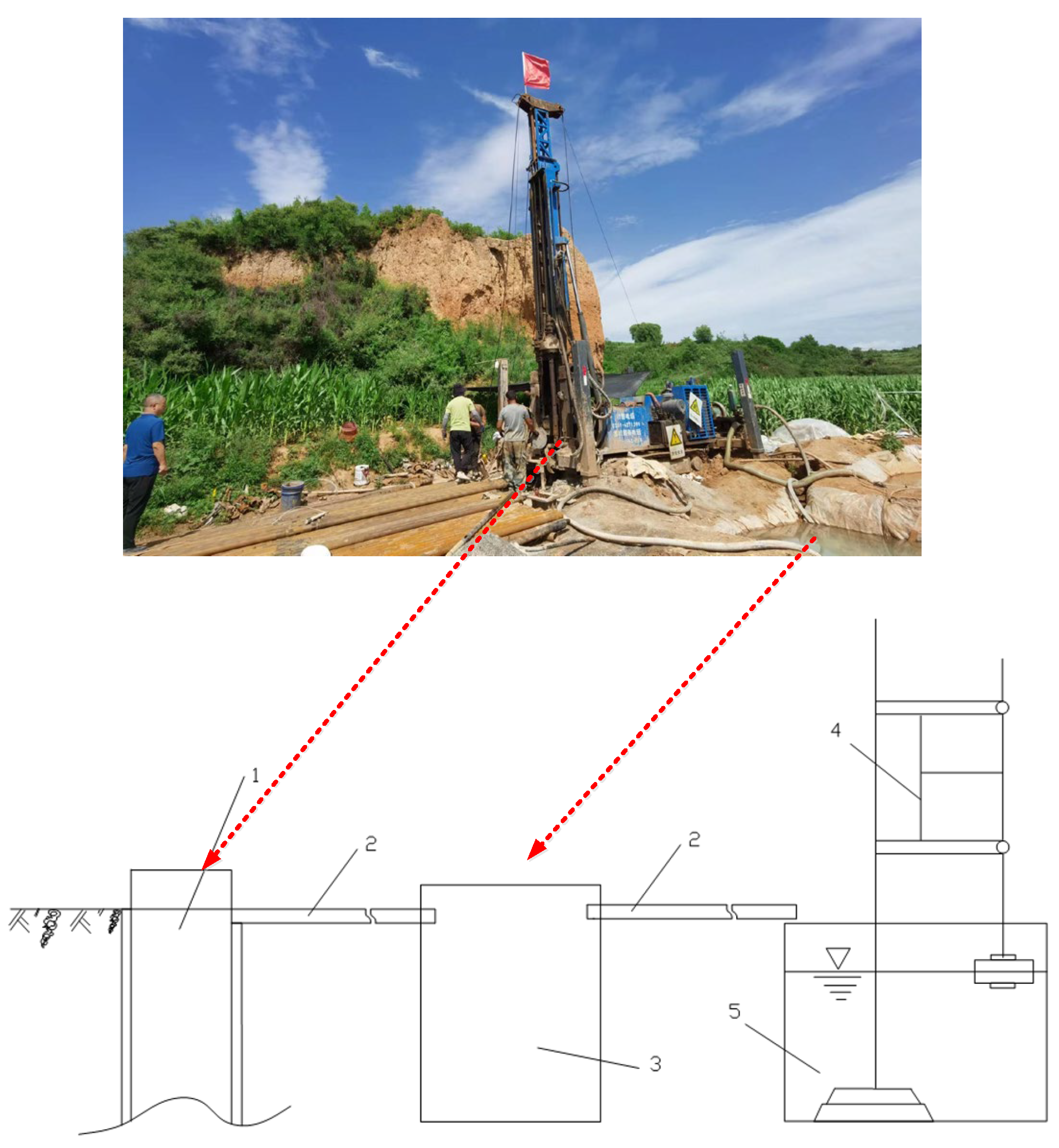

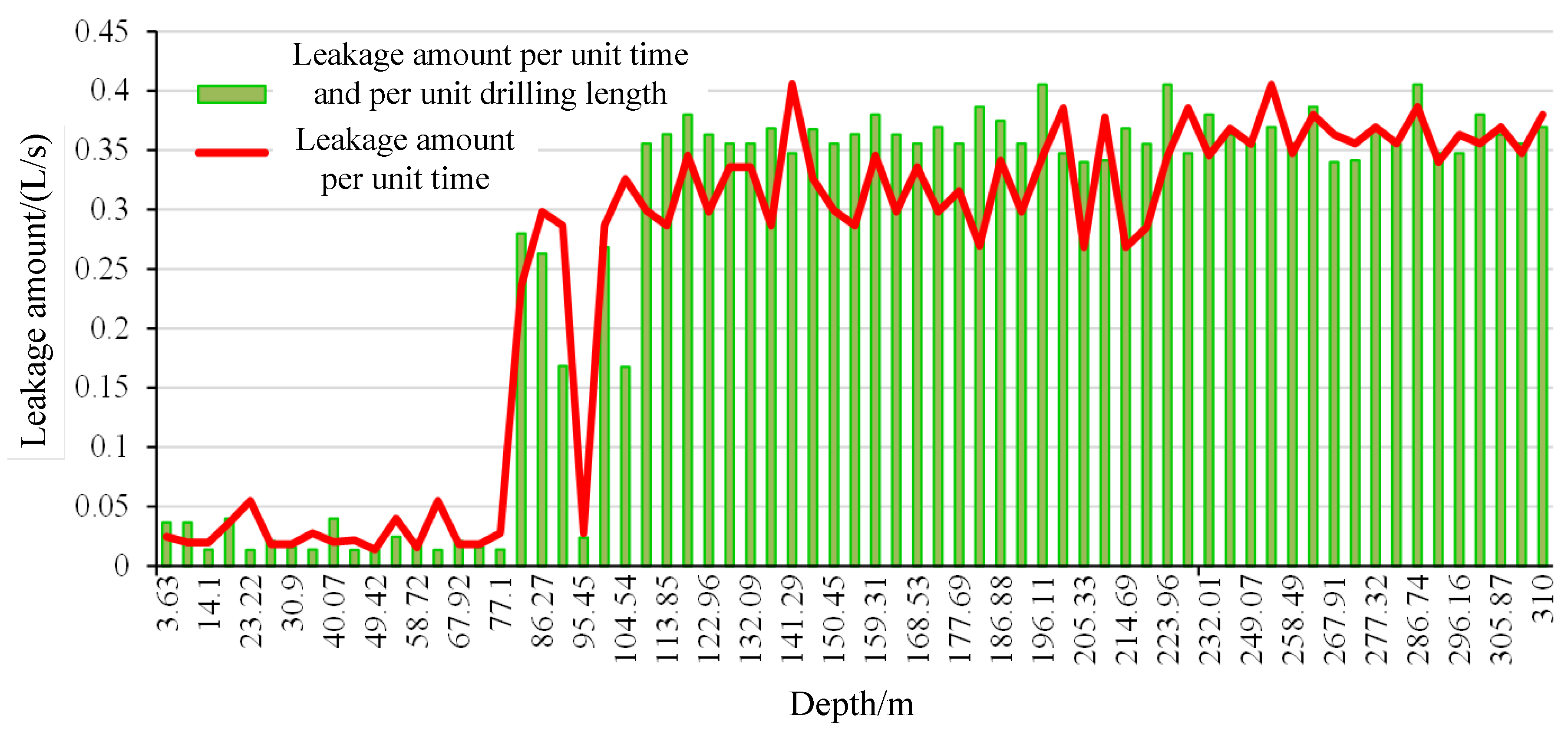

5. In Situ Testing

5.1. Test Methods

- (1)

- The consumption of flushing fluid increases with the drilling depth of the borehole;

- (2)

- At a certain location, all the flushing fluid in the drilling hole has been lost, and there is no flushing fluid in the hole. Moreover, after plugging, there is still a phenomenon of all the flushing fluid leaking when drilling again;

- (3)

- As the drilling depth increases, the water level inside the borehole decreases faster;

- (4)

- There are longitudinal fractures in the rock core or slight air suction in the borehole.

5.2. In Situ Test Results

6. Conclusions

- (1)

- Compared to the theory based on the assumption of continuous media, the theory established in this article and the corresponding CFE-DEM numerical method can numerically simulate the distribution and evolution of mining-induced overlying rock fractures.

- (2)

- The numerical calculation results indicate that direct roof cracks generally occur between 18 m and 32 m in front of the working face.

- (3)

- The water-conducting cracks in the overlying strata of the direct roof of the ultra-thick coal seam generally extend in a trapezoidal shape towards the working face, with an angle between 62° and 75° with the advancing direction.

- (4)

- The on-site test and numerical simulation results indicate that the height of the water-conducting fracture zone in the overlying strata of the ultra-thick coal seam is between 209 m and 230 m.

- (5)

- There are multiple muddy weak permeable layers between 230 m and 252 m above the top boundary of the water-conducting fracture zone. Therefore, the mining of ultra-thick coal seams will not have a serious impact on the surface ecological environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Afshar, A.; Khosravi, M.; Molajou, A. Assessing adaptability of cyclic and non-cyclic approach to conjunctive use of groundwater and surface water for sustainable management plans under climate change. Water Resour. Manag. 2021, 35, 3463–3479. [Google Scholar] [CrossRef]

- Arens, M.; Åhman, M.; Vogl, V. Which countries are prepared to green their coal-based steel industry with electricity?—Reviewing climate and energy policy as well as the implementation of renewable electricity. Renew. Sustain. Energy Rev. 2021, 143, 110938. [Google Scholar] [CrossRef]

- Gupta, S.D. Using real options to value capacity additions and investment expenditures in renewable energies in India. Energy Policy 2021, 148, 111916. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhi-Jun WA, N.; Fu-Chen, L.I. Large deformation mechanism of roadway driving along goaf under unstable overlying rock strata. J. Min. Saf. Eng. 2012, 29, 451. [Google Scholar]

- Wang, Z.; Li, W.; Wang, Q.; Hu, Y.; Du, J. Monitoring the Dynamic Response of the Overlying Rock–Soil Composite Structure to Underground Mining Using BOTDR and FBG Sensing Technologies. Rock Mech. Rock Eng. 2021, 54, 5095–5116. [Google Scholar] [CrossRef]

- Liu, H.; Deng, K.; Zhu, X.; Jiang, C. Effects of mining speed on the developmental features of mining-induced ground fissures. Bull. Eng. Geol. Environ. 2019, 78, 6297–6309. [Google Scholar] [CrossRef]

- Miao, X.; Cui, X.; Wang, J.; Xu, J. The height of fractured water-conducting zone in undermined rock strata. Eng. Geol. 2011, 120, 32–39. [Google Scholar] [CrossRef]

- Li, L.; Li, F.; Zhang, Y.; Yang, D.; Liu, X. Formation mechanism and height calculation of the caved zone and water-conducting fracture zone in solid backfill mining. Int. J. Coal Sci. Technol. 2020, 7, 208–215. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Tan, Y.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

- Du, W.; Chai, J.; Zhang, D.; Lei, W. The study of water-resistant key strata stability detected by optic fiber sensing in shallow-buried coal seam. Int. J. Rock Mech. Min. Sci. 2021, 141, 104604. [Google Scholar] [CrossRef]

- Liu, W.; Pang, L.; Liu, Y.; Du, Y. Characteristics Analysis of Roof Overburden Fracture in Thick Coal Seam in Deep Mining and Engineering Application of Super High Water Material in Backfill Mining. Geotech. Geol. Eng. 2018, 37, 2485–2494. [Google Scholar] [CrossRef]

- Xu, J.L.; Qin, W.; Xuan, D.Y.; Zhu, W.B. Accumulative effect of overburden strata expansion induced by stress relief. J. China Coal Soc. 2020, 45, 35–43. [Google Scholar]

- Jun, W.; Weibing, Z.; Jianlin, X. Research on subsidence law of overlying strata in full mining of extra-thick coal seam. Ind. Mine Autom. 2021, 47, 21–26. [Google Scholar]

- Maosen, Y.; Weibing, Z.; Lin, L.; Xu, Z.; Jialin, X. Water-inrush mechanism and prevention for fourth panel roof in Bulianta coal mine. J. China Coal Soc. 2008, 33, 241–245. [Google Scholar]

- Fan, H.; Wang, L.; Lu, Y.; Li, Z.; Li, W.; Wang, K. Height of water-conducting fractured zone in a coal seam overlain by thin bedrock and thick clay layer: A case study from the Sanyuan coal mine in North China. Environ. Earth Sci. 2020, 79, 125. [Google Scholar] [CrossRef]

- Ilyukhin, D.; Gusev, V. The Use of the Finite Element Method for Ensuring Efficient and Safe Extraction of Minerals. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2017; Volume 743, pp. 411–416. [Google Scholar]

- Qile, D. Overlying Strata Movement Law and Control of Underground Mining in End Slope. Ph.D. Thesis, University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

- Liu, Y.; Liu, Q.; Li, W.; Li, T.; He, J. Height of water-conducting fractured zone in coal mining in the soil–rock composite structure overburdens. Environ. Earth Sci. 2019, 78, 242. [Google Scholar] [CrossRef]

- Liu, S.; Fei, Y.; Wang, J.; Wu, D.; Guo, D.; Dong, Y.; Liu, X.; Shangguan, Y. A novel method to retain a waterproof coal pillar near water-conducting fault. J. Geophys. Eng. 2023, 20, 225–239. [Google Scholar] [CrossRef]

- Ning, S.; Zhu, W.; Yi, X.; Wang, L. Evolution law of floor fracture zone above a confined aquifer using backfill replacement mining technology. Geofluids 2021, 2021, 8842021. [Google Scholar] [CrossRef]

- Qi, D.; Ru, X.; Li, D.; Chu, F.; Zhang, J. Study of the Height of Water Flowing Fracture Zone Based on Strain Energy Failure Criterion. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 330. [Google Scholar]

- Yadong, J.; Haidong, C.; Baofeng, Z. Mechanism and Control of Water Inrush from Separated Roof Layers in the Jurassic Coalfields. Mine Water Environ. 2021, 40, 357–365. [Google Scholar]

- Zhu, T.; Li, W.; Wang, Q.; Hu, Y.; Fan, K.; Du, J. Study on the Height of the Mining-Induced Water-Conducting Fracture Zone Under the Q 2l Loess Cover of the Jurassic Coal Seam in Northern Shaanxi, China. Mine Water Environ. 2020, 39, 57–67. [Google Scholar] [CrossRef]

- Sun, W.B.; Wang, Y.; Qiu, H.F.; Ding, Z.W. Numerical simulation study of strip filling for water-preserved coal mining. Environ. Sci. Pollut. Res. 2019, 27, 12899–12907. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhang, Q.-Y. Study of the Crack Propagation Model Under Seepage–Stress Coupling Based on XFEM. Geotech. Geol. Eng. 2017, 35, 2433–2444. [Google Scholar] [CrossRef]

- Sargin, M. Stress-Strain Relationships for Concrete and Analysis of Structural Concrete Sections. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 1971. [Google Scholar]

- Labuz, J.F.; Zang, A. Mohr–Coulomb failure criterion. Rock Mech. Rock Eng. 2012, 45, 975–979. [Google Scholar] [CrossRef]

| Name | ρ /(kg·m−3) | ts0,tt0 /MPa | tn0 /MPa | Enn /GPa | Ess, Ett /GPa | /m | E/GPa | μ | φ /(°) | c /MPa | ψ/(°) | wn,max /mm | Dn/GPa | DS/GPa | /MPa | /mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| siltstone | 2500 | 7.2 | 3.6 | 4 | 16.23 | 0.06 | 17.23 | 0.22 | 40 | 12.35 | 34 | 0.36 | 20.11 | 9.75 | 7.31 | 0.75 |

| limestone | 2500 | 20 | 5.7 | 6.2 | 37.28 | 0.04 | 41.56 | 0.25 | 45 | 22.70 | 34 | 0.40 | 42.15 | 15.62 | 12.53 | 0.86 |

| coal | 1500 | 10 | 3.5 | 3 | 3.98 | 0.06 | 10.21 | 0.25 | 30 | 4.77 | 25 | 0.41 | 10.21 | 3.06 | 3.43 | 1.12 |

| mudstone | 1500 | 3.5 | 2 | 3 | 3.56 | 0.12 | 11.85 | 0.25 | 32 | 7.36 | 26 | 0.20 | 11.85 | 0.94 | 2.71 | 2.87 |

| sandy mudstone | 2500 | 10 | 3.5 | 15 | 6.71 | 0.07 | 15.33 | 0.25 | 38 | 9.88 | 32 | 0.29 | 15.33 | 4.10 | 4.72 | 1.15 |

| Method | Advantage | Disadvantage |

|---|---|---|

| FEM | Effectively simulate the plastic deformation and damage of intact rock blocks | Ideal continuum assumption, Convergence |

| FDM | Effectively simulate the plastic deformation and damage of intact rock blocks | Ideal continuum assumption, Convergence |

| DEM | Unconditional convergence, cracks propagation | Ideal discrete medium Assumption, distribution of cracks in masonry form |

| CFE-DEM | Numerical implementation of the entire process of deformation, cracking, and movement of mining overburden, with random cracking of cracks | High computational cost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Yu, X. Research on the Distribution of Overlying Rock Fractures Caused by Mining in Ultra-Thick Coal Seams and Its Impact on the Near-Surface Aquifer. Sustainability 2023, 15, 13974. https://doi.org/10.3390/su151813974

Zhou Y, Yu X. Research on the Distribution of Overlying Rock Fractures Caused by Mining in Ultra-Thick Coal Seams and Its Impact on the Near-Surface Aquifer. Sustainability. 2023; 15(18):13974. https://doi.org/10.3390/su151813974

Chicago/Turabian StyleZhou, Yang, and Xueyi Yu. 2023. "Research on the Distribution of Overlying Rock Fractures Caused by Mining in Ultra-Thick Coal Seams and Its Impact on the Near-Surface Aquifer" Sustainability 15, no. 18: 13974. https://doi.org/10.3390/su151813974

APA StyleZhou, Y., & Yu, X. (2023). Research on the Distribution of Overlying Rock Fractures Caused by Mining in Ultra-Thick Coal Seams and Its Impact on the Near-Surface Aquifer. Sustainability, 15(18), 13974. https://doi.org/10.3390/su151813974