Supplier Selection for a Power Generator Sustainable Supplier Park: Interval-Valued Neutrosophic SWARA and EDAS Application

Abstract

1. Introduction

2. Literature Review

3. Methodology

3.1. Preliminaries on Interval-Valued Neutrosophic Sets

3.2. SWARA Method

3.3. Fuzzy EDAS Method

3.4. Proposed IVN SWARA & EDAS Methodology

4. Case Study

4.1. Description of the Problem

4.2. Numerical Application

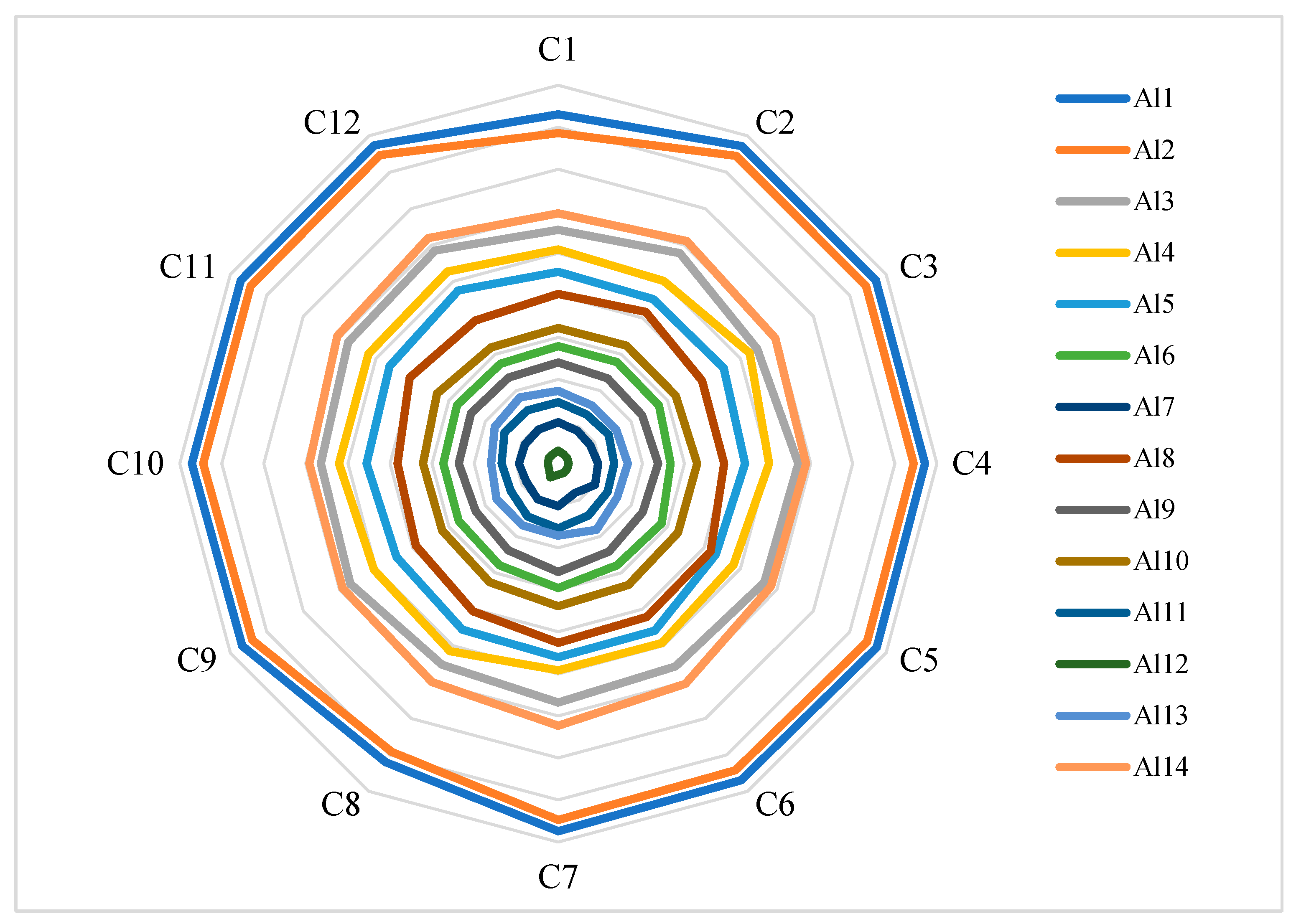

5. Sensitivity Analysis

6. Comparative Analysis

7. Conclusions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Decision Maker 1 | ||||||||||||||

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

| C1 | VH | VH | A | AA | AA | A | A | A | A | A | A | A | A | AA |

| C2 | A | A | BA | BA | BA | L | L | L | L | L | L | L | L | A |

| C3 | H | H | A | H | A | A | A | A | A | A | A | A | A | A |

| C4 | H | H | A | A | A | L | L | L | L | L | L | L | L | A |

| C5 | CH | CH | H | A | A | AA | AA | AA | A | AA | A | A | A | A |

| C6 | AA | AA | A | A | A | A | A | AA | AA | AA | AA | AA | AA | AA |

| C7 | BA | BA | A | A | A | BA | BA | AA | AA | A | A | A | A | H |

| C8 | CH | CH | H | A | A | A | A | A | A | A | A | A | A | A |

| C9 | A | A | A | A | A | A | A | L | L | L | L | L | L | A |

| C10 | BA | BA | BA | A | A | A | A | L | A | L | L | L | L | AA |

| C11 | H | H | H | H | H | AA | AA | AA | AA | AA | AA | AA | AA | AA |

| C12 | A | A | A | H | H | A | A | A | A | A | A | A | A | A |

| Decision Maker 2 | ||||||||||||||

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

| C1 | CH | CH | CH | H | H | VH | AA | CH | H | H | AA | A | A | CH |

| C2 | CH | CH | CH | H | H | H | AA | CH | H | H | AA | A | A | CH |

| C3 | CH | CH | H | AA | AA | H | A | H | AA | H | AA | A | A | VH |

| C4 | CH | CH | H | AA | AA | A | A | H | H | H | A | BA | AA | H |

| C5 | CH | CH | H | H | H | H | A | CH | H | H | AA | A | AA | VH |

| C6 | CH | CH | H | H | H | H | A | CH | H | H | A | BA | H | VH |

| C7 | CH | CH | CH | H | CH | CH | AA | CH | VH | CH | VH | L | AA | CH |

| C8 | CH | CH | H | AA | AA | AA | BA | AA | A | H | BA | L | AA | H |

| C9 | CH | CH | H | A | AA | AA | A | AA | A | H | AA | H | AA | H |

| C10 | CH | CH | H | A | AA | AA | A | A | A | H | AA | A | A | H |

| C11 | CH | CH | VH | VH | H | H | H | VH | H | VH | H | AA | H | CH |

| C12 | CH | CH | VH | H | H | H | AA | H | H | H | H | A | H | CH |

| Decision Maker 3 | ||||||||||||||

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

| C1 | H | CH | VH | AA | AA | A | A | A | A | VH | A | A | A | AA |

| C2 | H | H | BA | BA | A | BA | L | L | L | BA | L | L | L | BA |

| C3 | VH | VH | A | VH | H | A | A | A | A | A | A | A | A | AA |

| C4 | H | H | H | AA | A | L | BA | L | L | A | VL | L | L | A |

| C5 | CH | CH | H | A | A | AA | AA | AA | A | AA | A | A | A | AA |

| C6 | AA | AA | AA | A | H | AA | A | A | A | AA | AA | A | AA | AA |

| C7 | H | H | A | A | A | BA | AA | AA | AA | A | A | A | AA | H |

| C8 | CH | CH | H | BA | AA | A | A | A | A | A | A | A | A | A |

| C9 | H | H | H | H | A | A | A | BA | BA | L | L | L | AA | A |

| C10 | CH | CH | H | CH | H | A | BA | L | AA | BA | L | L | L | A |

| C11 | AA | AA | H | H | H | AA | L | AA | AA | AA | AA | A | AA | AA |

| C12 | H | H | VH | H | H | A | A | A | A | A | A | A | AA | H |

| Criterion | Al1 | Al2 | Al3 |

|---|---|---|---|

| C1 | <[0.163, 0.314], [0.484, 0.585], [0.635, 0.786]> | <[0.091, 0.242], [0.558, 0.658], [0.708, 0.859]> | <[0.24, 0.421], [0.275, 0.402], [0.555, 0.734]> |

| C2 | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> | <[0.488, 0.666], [0.357, 0.46], [0.26, 0.456]> |

| C3 | <[0.644, 0.802], [0.479, 0.58], [0.14, 0.304]> | <[0.644, 0.802], [0.479, 0.58], [0.14, 0.304]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> |

| C4 | <[0.611, 0.772], [0.443, 0.544], [0.167, 0.336]> | <[0.611, 0.772], [0.443, 0.544], [0.167, 0.336]> | <[0.495, 0.663], [0.23, 0.347], [0.302, 0.47]> |

| C5 | <[0.75, 0.9], [0.6, 0.7], [0.05, 0.2]> | <[0.75, 0.9], [0.6, 0.7], [0.05, 0.2]> | <[0.55, 0.7], [0.4, 0.5], [0.25, 0.4]> |

| C6 | <[0.548, 0.717], [0.357, 0.46], [0.215, 0.398]> | <[0.548, 0.717], [0.357, 0.46], [0.215, 0.398]> | <[0.458, 0.628], [0.208, 0.321], [0.339, 0.509]> |

| C7 | <[0.55, 0.72], [0.395, 0.497], [0.211, 0.396]> | <[0.55, 0.72], [0.395, 0.497], [0.211, 0.396]> | <[0.518, 0.717], [0.157, 0.274], [0.238, 0.456]> |

| C8 | <[0.05, 0.2], [0.6, 0.7], [0.75, 0.9]> | <[0.05, 0.2], [0.6, 0.7], [0.75, 0.9]> | <[0.25, 0.4], [0.4, 0.5], [0.55, 0.7]> |

| C9 | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> | <[0.495, 0.663], [0.23, 0.347], [0.302, 0.47]> |

| C10 | <[0.634, 0.81], [0.455, 0.56], [0.12, 0.31]> | <[0.634, 0.81], [0.455, 0.56], [0.12, 0.31]> | <[0.479, 0.632], [0.357, 0.457], [0.316, 0.47]> |

| C11 | <[0.583, 0.748], [0.4, 0.503], [0.188, 0.364]> | <[0.583, 0.748], [0.4, 0.503], [0.188, 0.364]> | <[0.577, 0.729], [0.423, 0.523], [0.22, 0.372]> |

| C12 | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> | <[0.566, 0.736], [0.263, 0.387], [0.222, 0.396]> |

| Al4 | Al5 | Al6 | |

| C1 | <[0.326, 0.477], [0.322, 0.423], [0.473, 0.624]> | <[0.326, 0.477], [0.322, 0.423], [0.473, 0.624]> | <[0.345, 0.54], [0.15, 0.263], [0.452, 0.645]> |

| C2 | <[0.407, 0.56], [0.322, 0.423], [0.389, 0.542]> | <[0.423, 0.593], [0.219, 0.332], [0.373, 0.542]> | <[0.372, 0.527], [0.362, 0.462], [0.421, 0.577]> |

| C3 | <[0.567, 0.72], [0.402, 0.504], [0.227, 0.382]> | <[0.469, 0.638], [0.214, 0.328], [0.328, 0.497]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> |

| C4 | <[0.431, 0.6], [0.193, 0.303], [0.369, 0.538]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.291, 0.458], [0.283, 0.398], [0.508, 0.674]> |

| C5 | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> |

| C6 | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.495, 0.663], [0.23, 0.347], [0.302, 0.47]> | <[0.458, 0.628], [0.208, 0.321], [0.339, 0.509]> |

| C7 | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.518, 0.717], [0.157, 0.274], [0.238, 0.456]> | <[0.488, 0.666], [0.357, 0.46], [0.26, 0.456]> |

| C8 | <[0.406, 0.577], [0.193, 0.303], [0.393, 0.563]> | <[0.37, 0.543], [0.193, 0.303], [0.429, 0.6]> | <[0.388, 0.577], [0.132, 0.238], [0.412, 0.6]> |

| C9 | <[0.457, 0.638], [0.162, 0.276], [0.339, 0.521]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> |

| C10 | <[0.558, 0.754], [0.187, 0.31], [0.193, 0.408]> | <[0.469, 0.638], [0.214, 0.328], [0.328, 0.497]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> |

| C11 | <[0.577, 0.729], [0.423, 0.523], [0.22, 0.372]> | <[0.55, 0.7], [0.4, 0.5], [0.25, 0.4]> | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> |

| C12 | <[0.55, 0.7], [0.4, 0.5], [0.25, 0.4]> | <[0.55, 0.7], [0.4, 0.5], [0.25, 0.4]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> |

| Al7 | Al8 | Al9 | |

| C1 | <[0.388, 0.577], [0.132, 0.238], [0.412, 0.6]> | <[0.327, 0.524], [0.157, 0.274], [0.468, 0.664]> | <[0.366, 0.557], [0.141, 0.251], [0.433, 0.624]> |

| C2 | <[0.306, 0.458], [0.372, 0.473], [0.491, 0.644]> | <[0.43, 0.617], [0.443, 0.544], [0.302, 0.512]> | <[0.34, 0.495], [0.4, 0.5], [0.452, 0.609]> |

| C3 | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> |

| C4 | <[0.325, 0.491], [0.256, 0.368], [0.473, 0.638]> | <[0.34, 0.495], [0.4, 0.5], [0.452, 0.609]> | <[0.34, 0.495], [0.4, 0.5], [0.452, 0.609]> |

| C5 | <[0.438, 0.6], [0.228, 0.336], [0.362, 0.523]> | <[0.548, 0.717], [0.357, 0.46], [0.215, 0.398]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> |

| C6 | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> | <[0.534, 0.717], [0.243, 0.361], [0.225, 0.424]> | <[0.461, 0.628], [0.219, 0.332], [0.337, 0.504]> |

| C7 | <[0.412, 0.563], [0.3, 0.4], [0.387, 0.538]> | <[0.548, 0.717], [0.357, 0.46], [0.215, 0.398]> | <[0.509, 0.664], [0.341, 0.443], [0.283, 0.44]> |

| C8 | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.388, 0.577], [0.132, 0.238], [0.412, 0.6]> | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> |

| C9 | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> | <[0.34, 0.491], [0.337, 0.437], [0.458, 0.61]> | <[0.325, 0.491], [0.256, 0.368], [0.473, 0.638]> |

| C10 | <[0.383, 0.568], [0.147, 0.255], [0.417, 0.6]> | <[0.291, 0.458], [0.283, 0.398], [0.508, 0.674]> | <[0.418, 0.6], [0.147, 0.255], [0.382, 0.563]> |

| C11 | <[0.417, 0.571], [0.357, 0.457], [0.377, 0.532]> | <[0.509, 0.664], [0.341, 0.443], [0.283, 0.44]> | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> |

| C12 | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> |

| Al10 | Al11 | Al12 | |

| C1 | <[0.283, 0.462], [0.248, 0.369], [0.513, 0.69]> | <[0.388, 0.577], [0.132, 0.238], [0.412, 0.6]> | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> |

| C2 | <[0.372, 0.527], [0.362, 0.462], [0.421, 0.577]> | <[0.306, 0.458], [0.372, 0.473], [0.491, 0.644]> | <[0.291, 0.458], [0.283, 0.398], [0.508, 0.674]> |

| C3 | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> |

| C4 | <[0.39, 0.562], [0.246, 0.363], [0.404, 0.577]> | <[0.259, 0.428], [0.306, 0.424], [0.538, 0.706]> | <[0.276, 0.427], [0.372, 0.473], [0.523, 0.674]> |

| C5 | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> |

| C6 | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> | <[0.438, 0.6], [0.228, 0.336], [0.362, 0.523]> | <[0.409, 0.577], [0.204, 0.314], [0.391, 0.558]> |

| C7 | <[0.518, 0.717], [0.157, 0.274], [0.238, 0.456]> | <[0.476, 0.664], [0.15, 0.263], [0.313, 0.505]> | <[0.366, 0.557], [0.141, 0.251], [0.433, 0.624]> |

| C8 | <[0.366, 0.557], [0.141, 0.251], [0.433, 0.624]> | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> |

| C9 | <[0.34, 0.495], [0.4, 0.5], [0.452, 0.609]> | <[0.306, 0.458], [0.372, 0.473], [0.491, 0.644]> | <[0.34, 0.495], [0.4, 0.5], [0.452, 0.609]> |

| C10 | <[0.372, 0.527], [0.362, 0.462], [0.421, 0.577]> | <[0.306, 0.458], [0.372, 0.473], [0.491, 0.644]> | <[0.291, 0.458], [0.283, 0.398], [0.508, 0.674]> |

| C11 | <[0.509, 0.664], [0.341, 0.443], [0.283, 0.44]> | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> | <[0.433, 0.6], [0.204, 0.314], [0.367, 0.533]> |

| C12 | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> |

| Al13 | Al14 | ||

| C1 | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> | <[0.285, 0.438], [0.357, 0.46], [0.511, 0.664]> | |

| C2 | <[0.291, 0.458], [0.283, 0.398], [0.508, 0.674]> | <[0.504, 0.694], [0.23, 0.349], [0.248, 0.456]> | |

| C3 | <[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]> | <[0.491, 0.664], [0.22, 0.335], [0.299, 0.473]> | |

| C4 | <[0.306, 0.458], [0.372, 0.473], [0.491, 0.644]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | |

| C5 | <[0.413, 0.6], [0.132, 0.238], [0.387, 0.573]> | <[0.491, 0.664], [0.22, 0.335], [0.299, 0.473]> | |

| C6 | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> | <[0.509, 0.664], [0.341, 0.443], [0.283, 0.44]> | |

| C7 | <[0.431, 0.6], [0.193, 0.303], [0.369, 0.538]> | <[0.611, 0.772], [0.443, 0.544], [0.167, 0.336]> | |

| C8 | <[0.388, 0.577], [0.132, 0.238], [0.412, 0.6]> | <[0.366, 0.557], [0.141, 0.251], [0.433, 0.624]> | |

| C9 | <[0.377, 0.53], [0.337, 0.437], [0.419, 0.572]> | <[0.442, 0.628], [0.141, 0.251], [0.356, 0.542]> | |

| C10 | <[0.291, 0.458], [0.283, 0.398], [0.508, 0.674]> | <[0.461, 0.628], [0.219, 0.332], [0.337, 0.504]> | |

| C11 | <[0.477, 0.628], [0.322, 0.423], [0.322, 0.473]> | <[0.548, 0.717], [0.357, 0.46], [0.215, 0.398]> | |

| C12 | <[0.458, 0.628], [0.208, 0.321], [0.339, 0.509]> | <[0.564, 0.744], [0.254, 0.377], [0.202, 0.396]> |

| PDA | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

| C1 | 0 | 0 | 0 | 0.017 | 0.017 | 0.009 | 0.047 | 0 | 0.027 | 0 | 0.047 | 0.039 | 0.039 | 0 |

| C2 | 0.305 | 0.305 | 0.167 | 0 | 0 | 0 | 0 | 0.071 | 0 | 0 | 0 | 0 | 0 | 0.17 |

| C3 | 0.423 | 0.423 | 0 | 0.235 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.042 |

| C4 | 0.465 | 0.465 | 0.138 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C5 | 0.463 | 0.463 | 0.063 | 0 | 0 | 0 | 0 | 0.087 | 0 | 0 | 0 | 0 | 0 | 0 |

| C6 | 0.192 | 0.192 | 0 | 0 | 0.029 | 0 | 0 | 0.143 | 0 | 0.007 | 0 | 0 | 0.007 | 0.081 |

| C7 | 0.133 | 0.133 | 0.002 | 0 | 0.002 | 0.019 | 0 | 0.122 | 0.017 | 0.002 | 0 | 0 | 0 | 0.247 |

| C8 | 0 | 0 | 0 | 0.093 | 0.024 | 0.014 | 0.06 | 0.014 | 0.006 | 0 | 0.06 | 0.137 | 0.014 | 0 |

| C9 | 0.342 | 0.342 | 0.14 | 0.021 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C10 | 0.456 | 0.456 | 0.06 | 0.219 | 0.004 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| C11 | 0.147 | 0.147 | 0.113 | 0.113 | 0.056 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.079 |

| C12 | 0.193 | 0.193 | 0.183 | 0.149 | 0.149 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0.193 |

| NDA | ||||||||||||||

| C1 | 0.206 | 0.307 | 0.06 | 0 | 0 | 0 | 0 | 0.005 | 0 | 0.025 | 0 | 0 | 0 | 0.036 |

| C2 | 0 | 0 | 0 | 0.044 | 0.038 | 0.09 | 0.192 | 0 | 0.134 | 0.09 | 0.192 | 0.208 | 0.208 | 0 |

| C3 | 0 | 0 | 0.102 | 0 | 0.011 | 0.102 | 0.205 | 0.102 | 0.162 | 0.102 | 0.162 | 0.205 | 0.205 | 0 |

| C4 | 0 | 0 | 0 | 0.023 | 0.093 | 0.188 | 0.157 | 0.112 | 0.112 | 0.047 | 0.214 | 0.214 | 0.171 | 0.027 |

| C5 | 0 | 0 | 0 | 0.199 | 0.199 | 0.083 | 0.171 | 0 | 0.199 | 0.083 | 0.253 | 0.291 | 0.253 | 0.07 |

| C6 | 0 | 0 | 0.056 | 0.121 | 0 | 0.056 | 0.222 | 0 | 0.047 | 0 | 0.091 | 0.146 | 0 | 0 |

| C7 | 0 | 0 | 0 | 0.173 | 0 | 0 | 0.169 | 0 | 0 | 0 | 0.103 | 0.276 | 0.169 | 0 |

| C8 | 0.385 | 0.385 | 0.117 | 0 | 0 | 0 | 0 | 0 | 0 | 0.006 | 0 | 0 | 0 | 0.006 |

| C9 | 0 | 0 | 0 | 0 | 0.091 | 0.091 | 0.138 | 0.128 | 0.156 | 0.11 | 0.17 | 0.11 | 0.066 | 0.026 |

| C10 | 0 | 0 | 0 | 0 | 0 | 0.15 | 0.185 | 0.239 | 0.132 | 0.125 | 0.224 | 0.239 | 0.239 | 0.012 |

| C11 | 0 | 0 | 0 | 0 | 0 | 0.089 | 0.172 | 0.022 | 0.089 | 0.022 | 0.089 | 0.193 | 0.089 | 0 |

| C12 | 0 | 0 | 0 | 0 | 0 | 0.134 | 0.192 | 0.134 | 0.134 | 0.134 | 0.134 | 0.234 | 0.07 | 0 |

References

- Fernández, L. Primary Energy Consumption by Country 2021. Statista. 2023. Available online: https://www.statista.com/statistics/263455/primary-energy-consumption-of-selected-countries/ (accessed on 15 June 2023).

- Aizarani, J. Energy prices in Latin America. Statista. 2023. Available online: https://www.statista.com/topics/7158/energy-prices-in-latin-america/ (accessed on 3 June 2023).

- Lichter, E. Israel: Number of Electric Cars. Statista. 2023. Available online: https://www.statista.com/statistics/1358744/number-of-electric-cars-in-israel/ (accessed on 15 June 2023).

- Hoggett, R. Supply Chains and Energy Security. In New Challenges in Energy Security; Mitchell, C., Watson, J., Whiting, J., Eds.; Palgrave Macmillan: London, UK, 2013; pp. 161–181. [Google Scholar] [CrossRef]

- Hu, G.; Mu, X.; Xu, M.; Miller, S.A. Potentials of GHG emission reductions from cold chain systems: Case studies of China and the United States. J. Clean. Prod. 2019, 239, 118053. [Google Scholar] [CrossRef]

- Pandey, V.K.; Dar, A.H.; Rohilla, S.; Mahanta, C.L.; Shams, R.; Khan, S.A.; Singh, R. Recent Insights on the Role of Various Food Processing Operations Towards the Development of Sustainable Food Systems. Circ. Econ. Sustain. 2023, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Shaharudin, M.S.; Fernando, Y. Cold supply chain of leafy green vegetables: A social network analysis approach. J. Sci. Technol. Policy Manag. 2023. [Google Scholar] [CrossRef]

- Barkas, D.A.; Psomopoulos, C.S.; Papageorgas, P.; Kalkanis, K.; Piromalis, D.; Mouratidis, A. Sustainable energy harvesting through triboelectric nano—Generators: A review of current status and applications. Energy Procedia 2019, 157, 999–1010. [Google Scholar] [CrossRef]

- Ufa, R.A.; Malkova, Y.Y.; Rudnik, V.E.; Andreev, M.V.; Borisov, V.A. A review on distributed generation impacts on electric power system. Int. J. Hydrogen Energy 2022, 47, 20347–20361. [Google Scholar] [CrossRef]

- Mohammad, S.N.; Das, N.K.; Roy, S. A review of the state of the art of generators and power electronics for wind energy conversion systems. In Proceedings of the 3rd International Conference on the Developments in Renewable Energy Technology, Dhaka, Bangladesh, 29–31 May 2014. [Google Scholar] [CrossRef]

- PSS. Generator Manufacturers List. Power System Services. 2020. Available online: https://www.pssas.com/generator-manufacturers (accessed on 10 August 2023).

- Thomas. Top Manufacturers and Suppliers of Portable Generators in the USA. Thomas Xometry Company. 2023. Available online: https://www.thomasnet.com/articles/top-suppliers/generator-manufacturers-and-suppliers/ (accessed on 15 July 2023).

- Yan, B. What’s next for “Generator City of China”? BoliPower. 2020. Available online: https://bolipower.com/whats-next-for-generator-city-of-china/ (accessed on 1 June 2023).

- Fang, Y.; Fan, R.; Liu, Z. A study on the energy storage scenarios design and the business model analysis for a zero-carbon big data industrial park from the perspective of source-grid-load-storage collaboration. Energy Rep. 2023, 9, 2054–2068. [Google Scholar] [CrossRef]

- Graehl, S.; Fïchtner, W.; Rentz, O. Regionalisation and sustainability in the field of industrial production. Int. J. Sustain. Dev. World Ecol. 2001, 8, 111–118. [Google Scholar] [CrossRef]

- Lyons, A.; Coronado, A.; Michaelides, Z. The relationship between proximate supply and build-to-order capability. Ind. Manag. Data Syst. 2006, 106, 1095–1111. [Google Scholar] [CrossRef]

- Ye, J.; Shi, S.; Feng, Y. The effects of market orientation and market knowledge search on business model innovation: Evidence for two distinct pathways. Eur. J. Innov. Manag. 2023. [Google Scholar] [CrossRef]

- Faria, A.S.; Soares, T.; Goumas, G.; Abotzios, A.; Cunha, J.M.; Silva, M. Market integration analysis of heat recovery under the EMB3Rs platform: An industrial park case in Greece. In 2nd International Workshop on Open Source Modelling and Simulation of Energy Systems; IEEE: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, F. Packed parts delivery problem of automotive inbound logistics with a supplier park. Comput. Oper. Res. 2019, 101, 116–129. [Google Scholar] [CrossRef]

- Li, Y.; Feng, C.; Wen, F.; Wang, K.; Huang, Y. Energy Pricing and Management for Park-level Energy Internets with Electric Vehicles and Power-to-gas Devices. Dianli Xitong Zidonghua/Autom. Electr. Power Syst. 2018, 42, 1–10. [Google Scholar] [CrossRef]

- Gschwind, T.; Irnich, S.; Tilk, C.; Emde, S. Branch-cut-and-price for scheduling deliveries with time windows in a direct shipping network. J. Sched. 2020, 23, 363–377. [Google Scholar] [CrossRef]

- Vallabh, G.; Tati, R.K. Impact of make in India on the msme supply chain- a study of the Jamshedpur auto cluster. Int. J. Appl. Bus. Econ. Res. 2016, 14, 4919–4929. [Google Scholar]

- Fredriksson, P. Cooperation and conflict in modular production and supplier parks: The case of Volvo Cars’ modular assembly system. Int. J. Automot. Technol. Manag. 2006, 6, 298–314. [Google Scholar] [CrossRef]

- Howard, M.; Miemczyk, J.; Graves, A. Automotive supplier parks: An imperative for build-to-order? J. Purch. Supply Manag. 2006, 12, 91–104. [Google Scholar] [CrossRef]

- Mammen, V.; Steyn, J.L. Decision factors for locating in an automotive supplier park: A South African case. In AFRICON; IEEE: New York, NY, USA, 2013. [Google Scholar] [CrossRef]

- Bennett, D.; Klug, F. Logistics supplier integration in the automotive industry. Int. J. Oper. Prod. Manag. 2012, 32, 1281–1305. [Google Scholar] [CrossRef]

- Mondragon, A.E.C.; Lyons, A.C.; Michaelides, Z.; Kehoe, D.F. Automotive supply chain models and technologies: A review of some latest developments. J. Enterp. Inf. Manag. 2006, 19, 551–562. [Google Scholar] [CrossRef]

- Reichhart, A.; Holweg, M. Co-located supplier clusters: Forms, functions and theoretical perspectives. Int. J. Oper. Prod. Manag. 2008, 28, 53–78. [Google Scholar] [CrossRef]

- Joshi, K.; Singh, K.N.; Kumar, S. Two-sided supplier-manufacturer selection in BTO supply chain. J. Model. Manag. 2012, 7, 257–273. [Google Scholar] [CrossRef]

- Su, Z.; Zhang, M.; Wu, W. Visualizing sustainable supply chain management: A systematic scientometric review. Sustainability 2021, 13, 4409. [Google Scholar] [CrossRef]

- Fotova Čiković, K.; Martinčević, I.; Lozić, J. Application of data envelopment analysis (DEA) in the selection of sustainable suppliers: A review and bibliometric analysis. Sustainability 2022, 14, 6672. [Google Scholar] [CrossRef]

- Smarandache, F. Neutrosophic set—A generalization of the intuitionistic fuzzy set. In Proceedings of the 2006 IEEE International Conference on Granular Computing, Atlanta, GA, USA, 10–12 May 2006; pp. 38–42. [Google Scholar] [CrossRef]

- Yazdani, M.; Pamučar, D.; Chatterjee, P.; Torkayesh, A.E. A multi-tier sustainable food supplier selection model under uncertainty. Oper. Manag. Res. 2021, 15, 116–145. [Google Scholar] [CrossRef]

- Koska, A.; Erdem, M.B. Performance Analysis of Manufacturing Waste Using SWARA and VIKOR Methods: Evaluation of Turkey within the Scope of the Circular Economy. Sustainability 2023, 15, 12110. [Google Scholar] [CrossRef]

- Demircan, M.L.; Özcan, B. A Proposed Method to Evaluate Warehouse Location for 3PL Cold Chain Suppliers in Gulf Countries Using Neutrosophic Fuzzy EDAS. Int. J. Comput. Intell. Syst. 2021, 14, 202. [Google Scholar] [CrossRef]

- Cakmak, E.; Guney, E. Spare parts inventory classification using Neutrosophic Fuzzy EDAS method in the aviation industry. Expert Syst. Appl. 2023, 224, 120008. [Google Scholar] [CrossRef]

- Reichhart, A.; Holweg, M. What Is the Right Supplier Park for Your Supply Chain? Supply Chain. Forum: Int. J. 2006, 7, 4–13. [Google Scholar] [CrossRef]

- Núñez, G.R.; Perez-Castillo, D. Business Models for Industrial Symbiosis: A Literature Review. Sustainability 2023, 15, 9142. [Google Scholar] [CrossRef]

- Eng, T.-Y. Relationship value of firms in alliance capitalism and implications for FDI. Int. J. Bus. Stud. 2007, 15, 43–68. [Google Scholar]

- Koerber, T.; Schiele, H. Is COVID-19 a turning point in stopping global sourcing? Differentiating between declining continental and increasing transcontinental sourcing. J. Glob. Oper. Strateg. Sourc. 2022, 15, 219–234. [Google Scholar] [CrossRef]

- Mitze, T.; Kreutzer, F. Relocation, innovation, and the difference that firm size makes: Insights for global sourcing strategies of SMEs. J. Int. Entrep. 2023, 1–31. [Google Scholar] [CrossRef]

- Larsson, A. The development and regional significance of the automotive industry: Supplier parks in western Europe. Int. J. Urban Reg. Res. 2002, 26, 767–784. [Google Scholar] [CrossRef]

- Nellore, R.; Chanaron, J.-J.; Eric Söderquist, K. Lean supply and price-based global sourcing—The interconnection. Eur. J. Purch. Supply Manag. 2001, 7, 101–110. [Google Scholar] [CrossRef]

- Pfohl, H.-C.; Gareis, K. Supplier parks in the German automotive industry: A critical comparison with similar concepts. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 302–317. [Google Scholar] [CrossRef]

- Kotabe, M.; Parente, R.; Murray, J.Y. Antecedents and outcomes of modular production in the Brazilian automobile industry: A grounded theory approach. J. Int. Bus. Stud. 2007, 38, 84–106. [Google Scholar] [CrossRef]

- Dimkow, S. Production system concept for implementing mass customization strategy in furniture industry. Int. J. Ind. Eng. Manag. 2012, 3, 185–194. [Google Scholar] [CrossRef]

- Kedziora, D.; Lewandowski, J. Transitional challenges cycle of service offshoring delivery centres in Central and Eastern Europe. Int. J. Technol. Policy Manag. 2020, 20, 35–53. [Google Scholar] [CrossRef]

- Meutia, I.F.; Yulianti, D.; Djausal, G.P.; Sujadmiko, B. Fostering entrepreneurial ecosystem within rural enterpreneurship. Int. J. Entrep. 2021, 25, 1–10. [Google Scholar]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Veiga, L.B.E.; Magrini, A. Eco-industrial park development in Rio de Janeiro, Brazil: A tool for sustainable development. J. Clean. Prod. 2009, 17, 653–661. [Google Scholar] [CrossRef]

- Cui, S.; Lu, L.X. Optimizing local content requirements under technology gaps. Manuf. Serv. Oper. Manag. 2019, 21, 213–230. [Google Scholar] [CrossRef]

- Bohnenkamp, T.; Schiele, H.; De Visser, M. Replacing global sourcing with deep localisation: The role of social capital in building local supply chains. Int. J. Procure. Manag. 2020, 13, 83–111. [Google Scholar] [CrossRef]

- Palit, S.; Hora, M.; Ghosh, S. Global buyer–supplier networks and innovation: The role of technological distance and technological breadth. J. Oper. Manag. 2022, 68, 755–774. [Google Scholar] [CrossRef]

- Franke, H.; Foerstl, K. Goals, Conflict, Politics, and Performance of Cross-Functional Sourcing Teams—Results from a Social Team Experiment. J. Bus. Logist. 2020, 41, 6–30. [Google Scholar] [CrossRef]

- Unterberger, P.; Müller, J.M. Clustering and Classification of Manufacturing Enterprises Regarding Their Industry 4.0 Reshoring Incentives. Procedia Comput. Sci. 2021, 180, 696–705. [Google Scholar] [CrossRef]

- Dankbaar, B. Global sourcing and innovation: The consequences of losing both organizational and geographical proximity. Eur. Plan. Stud. 2007, 15, 271–288. [Google Scholar] [CrossRef]

- Tietze-Stöckinger, I.; Fichtner, W.; Rentz, O. Integrated transport, storage capacity and investment planning in the context of cooperation between waste producers and disposal enterprises. Int. J. Integr. Supply Manag. 2004, 1, 199–218. [Google Scholar] [CrossRef]

- Wu, Y.; Li, G.; An, T. Toxic metals in particulate matter and health risks in an E-waste Dismantling Park and its surrounding areas: Analysis of three PM size groups. Int. J. Environ. Res. Public Health 2022, 19, 15383. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, H.; Xu, M.; Cai, C.; Yao, S.; Ma, Y.; Li, S. Integrated Energy System Operation Optimization Based on Reinforcement Learning. J. Phys. Conf. Ser. 2022, 2205, 012008. [Google Scholar] [CrossRef]

- Fichtner, W.; Tietze-Stöckinger, I.; Rentz, O. On industrial symbiosis networks and their classification. Prog. Ind. Ecol. 2004, 1, 130–142. [Google Scholar] [CrossRef]

- Ghasemy Yaghin, R.; Sarlak, P. Joint order allocation and transportation planning under uncertainty within a socially responsible supply chain. J. Model. Manag. 2020, 15, 531–565. [Google Scholar] [CrossRef]

- Turrini, L.; Meissner, J. Spare parts inventory management: New evidence from distribution fitting. Eur. J. Oper. Res. 2019, 273, 118–130. [Google Scholar] [CrossRef]

- Wang, C.-N.; Nguyen, T.-L.; Dang, T.-T. Two-Stage Fuzzy MCDM for Green Supplier Selection in Steel Industry. Intell. Autom. Soft Comput. 2009, 33, 1245–1260. [Google Scholar] [CrossRef]

- Hemmati, M.; Pasandideh, S.H.R. A bi-objective supplier location, supplier selection and order allocation problem with green constraints: Scenario-based approach. J. Ambient Intell. Humaniz. Comput. 2021, 12, 8205–8228. [Google Scholar] [CrossRef]

- Ranjbar Tezenji, F.; Mohammadi, M.; Pasandideh, S.H.R.; Nouri Koupaei, M. An integrated model for supplier location-selection and order allocation under capacity constraints in an uncertain environment. Sci. Iran. 2016, 23, 3009–3025. [Google Scholar] [CrossRef][Green Version]

- Tezenji, F.R.; Mohammadi, M.; Pasandideh, S.H.R. Bi-objective location-allocation-inventory-network design in a two-echelon supply chain using de novo programming, NSGA-II and NRGA. Int. J. Logist. Syst. Manag. 2017, 28, 308–337. [Google Scholar] [CrossRef]

- Maiorova, K.; Balashova, E. Digital supply chain inventory management: International experience and Russian perspective. E3S Web Conf. 2023, 371. [Google Scholar] [CrossRef]

- Rilling, G. Dm-drogerie markt: Conversion of an Assortment Area from Decentralized to Centralized Inventory Management and Supply. Springer Ser. Supply Chain Manag. 2022, 15, 323–346. [Google Scholar] [CrossRef]

- Hsu, M.-C.; Lee, H.-S. Applying AHP-IFNs-DEMATEL in Establishing a Supplier Selection Model: A Case Study of Offshore Wind Power Companies in Taiwan. Energies 2023, 16, 4481. [Google Scholar] [CrossRef]

- Ijuin, H.; Yamada, S.; Yamada, T.; Takanokura, M.; Matsui, M. Solar Energy Demand-to-Supply Management by the On-Demand Cumulative-Control Method: Case of a Childcare Facility in Tokyo. Energies 2022, 15, 4608. [Google Scholar] [CrossRef]

- Chien, C.-H.; Chen, P.-Y.; Trappey, A.J.C.; Trappey, C.V. Intelligent Supply Chain Management Modules Enabling Advanced Manufacturing for the Electric-Mechanical Equipment Industry. Complexity 2022, 2022, 8221706. [Google Scholar] [CrossRef]

- Negash, Y.T.; Kartika, J.; Tseng, M.-L.; Tan, K. A novel approach to measure product quality in sustainable supplier selection. J. Clean. Prod. 2020, 252, 119838. [Google Scholar] [CrossRef]

- Shingare, P.; Seetharaman, A.; Maddulety, K. Determinants of Customer Perceived Value in the Indian Renewable Energy Market. Indian J. Ecol. 2020, 47, 56–66. [Google Scholar]

- Scala, N.M.; Rajgopal, J.; Needy, K.L. An inventory criticality classification method for nuclear spare parts: A case study. In Decision Making in Service Industries: A Practical Approach; CRC Press: Boca Raton, FL, USA, 2012; pp. 365–392. [Google Scholar] [CrossRef]

- Zindani, D.; Maity, S.R.; Bhowmik, S. Interval-valued intuitionistic fuzzy TODIM method based on Schweizer–Sklar power aggregation operators and their applications to group decision making. Soft Comput. 2020, 24, 14091–14133. [Google Scholar] [CrossRef]

- Kirkwood, J.P. Mass Ingest! Logistics and Workflow for A Rapid Large-Scale Ingesting. Collect. Manag. 2023, 48, 56–67. [Google Scholar] [CrossRef]

- Li, X.; Li, P. Simulation optimization under random conditions tg business model of spare parts inventory. In Proceedings of the 4th International Conference on Mechanical Control and Computer Engineering, Hohhot, China, 24–26 October 2019; pp. 1025–1028. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Zhang, J.; Song, Z.; Li, J.; Zhou, J. Manufacturing industry supply chain management based on the ethereum blockchain. In Proceedings of the IEEE International Conferences on Ubiquitous Computing and Communications and Data Science and Computational Intelligence and Smart Computing Networking and Services, Shenyang, China, 21–23 October 2019; pp. 592–596. [Google Scholar] [CrossRef]

- Oliveira, F.S.; Zahur, N.B.; Wu, F. Analysis of the optimal policy for managing strategic petroleum reserves under long-term uncertainty: The ASEAN case. Comput. Ind. Eng. 2023, 175, 108834. [Google Scholar] [CrossRef]

- Schrotenboer, A.H.; Veenstra, A.A.T.; uit het Broek, M.A.J.; Ursavas, E. A Green Hydrogen Energy System: Optimal control strategies for integrated hydrogen storage and power generation with wind energy. Renew. Sustain. Energy Rev. 2022, 168, 112744. [Google Scholar] [CrossRef]

- Xiong, C.; Devlin, A.G.; Gupta, J.N.D.; Liu, X. Effect of price reduction on renewable energy technology supply chain performance and contract design. J. Oper. Res. Soc. 2022, 73, 822–839. [Google Scholar] [CrossRef]

- Liang, Y.; Ju, Y.; Martínez, L.; Tu, Y. Sustainable battery supplier evaluation of new energy vehicles using a distributed linguistic outranking method considering bounded rational behavior. J. Energy Storage 2022, 48, 103901. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Pasetti, M. Multi-period newsvendor problem for the management of battery energy storage systems in support of distributed generation. Energies 2019, 12, 4598. [Google Scholar] [CrossRef]

- Ecer, F. Multi-criteria decision making for green supplier selection using interval type-2 fuzzy AHP: A case study of a home appliance manufacturer. Oper. Res. 2022, 22, 199–233. [Google Scholar] [CrossRef]

- Gardas, B.B.; Raut, R.D.; Narkhede, B. Identifying critical success factors to facilitate reusable plastic packaging towards sustainable supply chain management. J. Environ. Manag. 2019, 236, 81–92. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-S.; Ho, J.-W.; Kao, W.-Y. Availability and reliability of information transmission for supply chain coordination with demand information sharing. Comput. Ind. Eng. 2022, 172, 108642. [Google Scholar] [CrossRef]

- Zaripova, R.; Nikitin, A.; Hadiullina, Y.; Pokaninova, E.; Kuznetsov, M. Vendor selection information system on the electronic trading platform for energy supply companies. E3S Web Conf. 2021, 288, 01072. [Google Scholar] [CrossRef]

- Guo, J.-X.; Zhu, K. Operation management of hybrid biomass power plant considering environmental constraints. Sustain. Prod. Consum. 2022, 29, 1–13. [Google Scholar] [CrossRef]

- Guo, J.-X.; Tan, X.; Gu, B.; Zhu, K. Integration of supply chain management of hybrid biomass power plant with carbon capture and storage operation. Renew. Energy 2022, 190, 1055–1065. [Google Scholar] [CrossRef]

- Khare, V.; Khare, C.; Nema, S.; Baredar, P. Decision Science and Operations Management of Solar Energy Systems; Elsevier: Amsterdam, The Netherlands, 2022; p. 376. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control. 1965, 8, 338–356. [Google Scholar] [CrossRef]

- Turksen, I.B. Interval valued fuzzy sets based on normal forms. Fuzzy Sets Syst. 1986, 20, 191–210. [Google Scholar] [CrossRef]

- Atanassov, K. Intuitionistic fuzzy sets. Fuzzy Sets Syst 1986, 20, 87–96. [Google Scholar] [CrossRef]

- Torra, V. Hesitant fuzzy sets. Int. J. Intell. Syst. 2010, 25, 529–539. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Liu, P. Multiple attribute group decision-making methods based on trapezoidal fuzzy two-dimension linguistic power generalized aggregation operators. Soft Comput. 2015, 20, 2689–2704. [Google Scholar] [CrossRef]

- Karasan, A.; Kahraman, C. A novel interval-valued neutrosophic EDAS method: Prioritization of the United Nations national sustainable development goals. Soft Comput. 2018, 22, 4891–4906. [Google Scholar] [CrossRef]

- Wang, H.; Smarandache, F.; Zhang, Y.-Q.; Sunderraman, R. Interval Neutrosophic Sets and Logic: Theory and Applications in Computing; Hexis: Phoenix, AZ, USA, 2005. [Google Scholar]

- Zhang, H.; Wang, J.; Chen, X. Interval neutrosophic Sets and Their Application in Multicriteria Decision Making Problems. Sci. World J. 2014, 2014, 645953. [Google Scholar] [CrossRef] [PubMed]

- Keršuliene, V.; Kazimieras Zavadskas, E.; Turskis, Z.; Keršulienė, V. Selection of rational dispute resolution method by applying new step-wise weight assessment ratio analysis (SWARA). J. Bus. Econ. Manag. 2010, 11, 243–258. [Google Scholar] [CrossRef]

- Yazdani, M.; Torkayesh, A.E.; Stević, Ž.; Chatterjee, P.; Ahari, S.A.; Hernandez, V.D. An interval valued neutrosophic decision-making structure for sustainable supplier selection. Expert Syst. Appl. 2021, 183, 115354. [Google Scholar] [CrossRef]

- Mardani, A.; Nilashi, M.; Zakuan, N.; Loganathan, N.; Soheilirad, S.; Saman, M.Z.M.; Ibrahim, O. A systematic review and meta-Analysis of SWARA and WASPAS methods: Theory and applications with recent fuzzy developments. Appl. Soft Comput. 2017, 57, 265–292. [Google Scholar] [CrossRef]

- Ghorabaee, M.K.; Zavadskas, E.K.; Olfat, L.; Turskis, Z. Multi-Criteria Inventory Classification Using a New Method of Evaluation Based on Distance from Average Solution (EDAS). Inform. Lith. Acad. Sci. 2015, 26, 435–451. [Google Scholar] [CrossRef]

- Ghorabaee, M.K.; Zavadskas, E.K.; Amiri, M.; Turskis, Z. Extended EDAS method for fuzzy multi-criteria decision-making: An application to supplier selection. Int. J. Comput. Commun. Control. 2016, 11, 358. [Google Scholar] [CrossRef]

- Wang, P.; Wang, J.J.; Wei, G. EDAS method for multiple criteria group decision making under 2-tuple linguistic neutrosophic environment. J. Intell. Fuzzy Syst. 2019, 37, 1597–1608. [Google Scholar] [CrossRef]

| Criteria | Publication |

|---|---|

| C1.1 Delivery lead time | [61,62,63] |

| C1.2 Supplier location | [64,65,66] |

| C1.3 Product range | [67,68] |

| C1.4 Production facilities and capacity | [69,70] |

| C1.5 Technical capability—product quality | [71,72,73] |

| C1.6 Criticality | [74,75] |

| C2.1 Raw material circulation—usage rate | [76,77,78] |

| C2.2 Price of products | [79,80,81] |

| C2.3 Flexibility | [82,83] |

| C2.4 Packaging quality—condition | [84,85] |

| C3.1 Reliability | [82,86,87] |

| C3.2 Operation controls | [88,89,90] |

| Linguistic Term for Alternative Evaluation | Abb. | Linguistic Term for Criteria Evaluation | Abb. | 〈T,I,F〉 |

|---|---|---|---|---|

| Very High | VH | Very High Importance | AHI | ⟨[0.65, 0.8], [0.5, 0.6], [0.15, 0.3]⟩ |

| High | H | High Importance | VHI | ⟨[0.55, 0.7], [0.4, 0.5], [0.25, 0.4]⟩ |

| Above Average | AA | Above Average Importance | HI | ⟨[0.45, 0.6], [0.3, 0.4], [0.35, 0.5]⟩ |

| Average | A | Average Importance | SHI | ⟨[0.4, 0.6], [0.1, 0.2], [0.4, 0.6]⟩ |

| Below Average | BA | Below Average Importance | MI | ⟨[0.35, 0.5], [0.3, 0.4], [0.45, 0.6]⟩ |

| Low | L | Low Importance | SLI | ⟨[0.25, 0.4], [0.4, 0.5], [0.55, 0.7]⟩ |

| Very Low | VL | Very Low Importance | LI | ⟨[0.15, 0.3], [0.5, 0.6], [0.65, 0.8]⟩ |

| Certainly Low | CL | Certainly Low Importance | VLI | ⟨[0.05, 0.2], [0.6, 0.7], [0.75, 0.9]⟩ |

| Code | Explanation | Weights |

|---|---|---|

| DM1 | Sales & Operations and Material Planning Manager | 40% |

| DM2 | Master Data Manager | 25% |

| DM3 | Logistics and Warehouse Manager | 35% |

| Criteria | Description | Type of Criterion |

|---|---|---|

| C1.1 Delivery lead time | The length of time starting from the order placement until its delivery | Cost |

| C1.2 Supplier location | The proximity of the supplier’s location to the manufacturer’s | Benefit |

| C1.3 Product range | The product variety of a supplier | Benefit |

| C1.4 Production facilities and capacity | The production capabilities of a supplier | Benefit |

| C1.5 Technical capability—product quality | The quality of the products served by a supplier | Benefit |

| C1.6 Criticality | The asset criticality of parts delivered by a supplier | Benefit |

| C2.1 Raw material circulation—usage rate | The usage rate of the parts | Benefit |

| C2.2 Price of products | The price of the products | Cost |

| C2.3 Flexibility | The ability of a supplier to handle disruptions | Benefit |

| C2.4 Packaging quality—condition | The delivery conditions of the product | Benefit |

| C3.1 Reliability | The consistency and quality of a supplier’s deliveries | Benefit |

| C3.2 Operation controls | The level of engagement of the manufacturer in the control of the supplier’s operational activities | Benefit |

| DM1 | DM2 | DM3 | |

|---|---|---|---|

| C1 | HI | VHI | VHI |

| C2 | AA | HI | HI |

| C3 | VHI | AI | AI |

| C4 | BAI | AI | HI |

| C5 | HI | AA | AI |

| C6 | HI | BAI | AI |

| C7 | AI | VHI | AA |

| C8 | AI | VLI | LI |

| C9 | LI | LI | LI |

| C10 | VLI | LI | AI |

| C11 | VHI | HI | VLI |

| C12 | VHI | AA | VHI |

| Criterion | 〈T,I,F〉 | |

|---|---|---|

| C1 | <[0.613, 0.765], [0.457, 0.558], [0.184, 0.337]> | 0.791 |

| C2 | <[0.512, 0.663], [0.357, 0.457], [0.286, 0.437]> | 0.656 |

| C3 | <[0.516, 0.697], [0.19, 0.31], [0.27, 0.455]> | 0.642 |

| C4 | <[0.44, 0.605], [0.252, 0.364], [0.356, 0.521]> | 0.564 |

| C5 | <[0.477, 0.643], [0.229, 0.343], [0.321, 0.487]> | 0.598 |

| C6 | <[0.454, 0.623], [0.229, 0.343], [0.341, 0.51]> | 0.575 |

| C7 | <[0.491, 0.664], [0.22, 0.335], [0.299, 0.473]> | 0.617 |

| C8 | <[0.292, 0.47], [0.243, 0.363], [0.505, 0.68]> | 0.445 |

| C9 | <[0.25, 0.4], [0.4, 0.5], [0.55, 0.7]> | 0.413 |

| C10 | <[0.271, 0.446], [0.269, 0.39], [0.526, 0.7]> | 0.436 |

| C11 | <[0.492, 0.657], [0.473, 0.573], [0.285, 0.454]> | 0.646 |

| C12 | <[0.608, 0.762], [0.44, 0.542], [0.185, 0.341]> | 0.788 |

| Criterion | |||||

|---|---|---|---|---|---|

| C1 | 0.7909 | 0 | 1 | 1 | 0.0996 |

| C12 | 0.7876 | 0.0033 | 1.0033 | 0.9967 | 0.0993 |

| C2 | 0.6556 | 0.1320 | 1.1320 | 0.8805 | 0.0877 |

| C11 | 0.6460 | 0.0096 | 1.0096 | 0.8721 | 0.0869 |

| C3 | 0.6416 | 0.0044 | 1.0044 | 0.8683 | 0.0865 |

| C7 | 0.6166 | 0.0251 | 1.0251 | 0.8471 | 0.0844 |

| C5 | 0.5980 | 0.0186 | 1.0186 | 0.8316 | 0.0828 |

| C6 | 0.5751 | 0.0229 | 1.0229 | 0.8131 | 0.0810 |

| C4 | 0.5638 | 0.0113 | 1.0113 | 0.8040 | 0.0801 |

| C8 | 0.4445 | 0.1193 | 1.1193 | 0.7183 | 0.0715 |

| C10 | 0.4360 | 0.0085 | 1.0085 | 0.7122 | 0.0709 |

| C9 | 0.4125 | 0.0235 | 1.0235 | 0.6959 | 0.0693 |

| Criterion | 〈T,I,F〉 | |

|---|---|---|

| C1 | <[0.314, 0.496], [0.213, 0.331], [0.482, 0.661]> | 0.453 |

| C2 | <[0.412, 0.585], [0.315, 0.426], [0.358, 0.541]> | 0.560 |

| C3 | <[0.479, 0.661], [0.177, 0.293], [0.307, 0.494]> | 0.591 |

| C4 | <[0.406, 0.578], [0.281, 0.396], [0.377, 0.553]> | 0.546 |

| C5 | <[0.519, 0.698], [0.232, 0.35], [0.252, 0.443]> | 0.663 |

| C6 | <[0.477, 0.647], [0.235, 0.348], [0.309, 0.484]> | 0.604 |

| C7 | <[0.499, 0.679], [0.239, 0.356], [0.27, 0.461]> | 0.642 |

| C8 | <[0.345, 0.529], [0.186, 0.303], [0.451, 0.635]> | 0.467 |

| C9 | <[0.419, 0.595], [0.228, 0.344], [0.367, 0.547]> | 0.545 |

| C10 | <[0.441, 0.621], [0.257, 0.373], [0.328, 0.519]> | 0.583 |

| C11 | <[0.517, 0.675], [0.347, 0.451], [0.27, 0.432]> | 0.667 |

| C12 | <[0.492, 0.672], [0.194, 0.311], [0.293, 0.478]> | 0.613 |

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP | 0.254 | 0.254 | 0.073 | 0.07 | 0.026 | 0.004 | 0.009 | 0.036 | 0.005 | 0.001 | 0.009 | 0.014 | 0.005 | 0.072 |

| NP | 0.048 | 0.058 | 0.028 | 0.047 | 0.034 | 0.081 | 0.15 | 0.059 | 0.096 | 0.062 | 0.134 | 0.177 | 0.121 | 0.015 |

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NSP | 1 | 1 | 0.288 | 0.278 | 0.102 | 0.014 | 0.036 | 0.143 | 0.018 | 0.003 | 0.036 | 0.054 | 0.021 | 0.283 |

| NSN | 0.728 | 0.672 | 0.843 | 0.737 | 0.805 | 0.542 | 0.150 | 0.665 | 0.457 | 0.650 | 0.245 | 0 | 0.316 | 0.917 |

| Al1 | Al2 | Al3 | Al4 | Al5 | Al6 | Al7 | Al8 | Al9 | Al10 | Al11 | Al12 | Al13 | Al14 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AS | 0.864 | 0.836 | 0.566 | 0.507 | 0.454 | 0.278 | 0.093 | 0.404 | 0.237 | 0.327 | 0.140 | 0.027 | 0.169 | 0.600 |

| Rank | 1 | 2 | 4 | 5 | 6 | 9 | 13 | 7 | 10 | 8 | 12 | 14 | 11 | 3 |

| Rank | Initial Problem | C4 Increased by 125% | C9 Increased by 150% | |||

|---|---|---|---|---|---|---|

| Alternative | AS | Alternative | AS | Alternative | AS | |

| 1 | Al1 | 0.8642 | Al1 | 0.8821 | Al1 | 0.8747 |

| 2 | Al2 | 0.8359 | Al2 | 0.8570 | Al2 | 0.8479 |

| 3 | Al14 | 0.6003 | Al3 | 0.5772 | Al3 | 0.5811 |

| 4 | Al3 | 0.5657 | Al14 | 0.5726 | Al14 | 0.5752 |

| 5 | Al4 | 0.5074 | Al4 | 0.4922 | Al4 | 0.5016 |

| 6 | Al5 | 0.4538 | Al5 | 0.4300 | Al5 | 0.424 |

| 7 | Al8 | 0.4040 | Al8 | 0.3798 | Al8 | 0.364 |

| 8 | Al10 | 0.3265 | Al10 | 0.3348 | Al10 | 0.3024 |

| 9 | Al6 | 0.2781 | Al6 | 0.2501 | Al6 | 0.2637 |

| 10 | Al9 | 0.2372 | Al9 | 0.2375 | Al9 | 0.2043 |

| 11 | Al13 | 0.1686 | Al13 | 0.1598 | Al13 | 0.1709 |

| 12 | Al11 | 0.1404 | Al11 | 0.1223 | Al11 | 0.1097 |

| 13 | Al7 | 0.0930 | Al7 | 0.0974 | Al7 | 0.0757 |

| 14 | Al12 | 0.0269 | Al12 | 0.0218 | Al12 | 0.0228 |

| Rank | IVN TOPSIS | IVN CODAS | IVN EDAS | |||

|---|---|---|---|---|---|---|

| Closeness Coefficient | Alternative | Relative Assessment Score | Alternative | Appraisal Score | Alternative | |

| 1 | 0.7848 | Al1 | 0.3563 | Al1 | 0.8642 | Al1 |

| 2 | 0.7581 | Al2 | 0.2969 | Al2 | 0.8359 | Al2 |

| 3 | 0.6127 | Al14 | 0.0677 | Al14 | 0.6003 | Al14 |

| 4 | 0.5682 | Al4 | 0.0473 | Al4 | 0.5657 | Al3 |

| 5 | 0.5475 | Al3 | 0.0419 | Al3 | 0.5074 | Al4 |

| 6 | 0.5287 | Al5 | 0.0073 | Al8 | 0.4538 | Al5 |

| 7 | 0.4987 | Al8 | 0.0058 | Al5 | 0.4040 | Al8 |

| 8 | 0.4571 | Al10 | −0.0415 | Al10 | 0.3265 | Al10 |

| 9 | 0.4277 | Al6 | −0.0789 | Al9 | 0.2781 | Al6 |

| 10 | 0.4180 | Al9 | −0.0850 | Al6 | 0.2372 | Al9 |

| 11 | 0.3630 | Al13 | −0.1146 | Al11 | 0.1686 | Al13 |

| 12 | 0.3566 | Al11 | −0.1159 | Al13 | 0.1404 | Al11 |

| 13 | 0.3403 | Al7 | −0.1281 | Al7 | 0.0930 | Al7 |

| 14 | 0.2789 | Al12 | −0.2592 | Al12 | 0.0269 | Al12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cakmak, E. Supplier Selection for a Power Generator Sustainable Supplier Park: Interval-Valued Neutrosophic SWARA and EDAS Application. Sustainability 2023, 15, 13973. https://doi.org/10.3390/su151813973

Cakmak E. Supplier Selection for a Power Generator Sustainable Supplier Park: Interval-Valued Neutrosophic SWARA and EDAS Application. Sustainability. 2023; 15(18):13973. https://doi.org/10.3390/su151813973

Chicago/Turabian StyleCakmak, Emre. 2023. "Supplier Selection for a Power Generator Sustainable Supplier Park: Interval-Valued Neutrosophic SWARA and EDAS Application" Sustainability 15, no. 18: 13973. https://doi.org/10.3390/su151813973

APA StyleCakmak, E. (2023). Supplier Selection for a Power Generator Sustainable Supplier Park: Interval-Valued Neutrosophic SWARA and EDAS Application. Sustainability, 15(18), 13973. https://doi.org/10.3390/su151813973

.jpg)