Study on the Effects of Exhaust Gas Recirculation and Fuel Injection Strategy on Transient Process Performance of Diesel Engines

Abstract

1. Introduction

2. Method and Materials

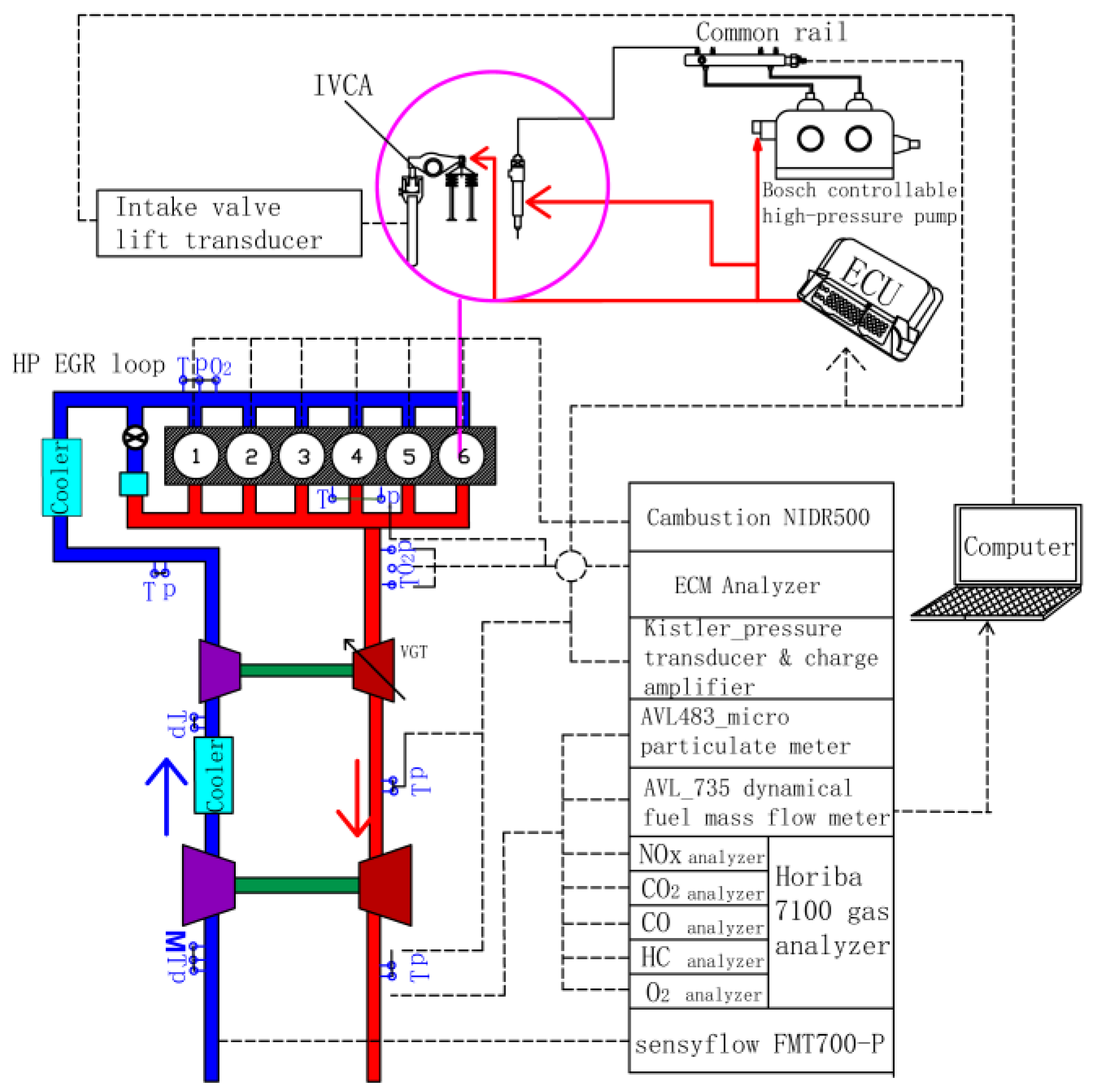

2.1. Experimental System

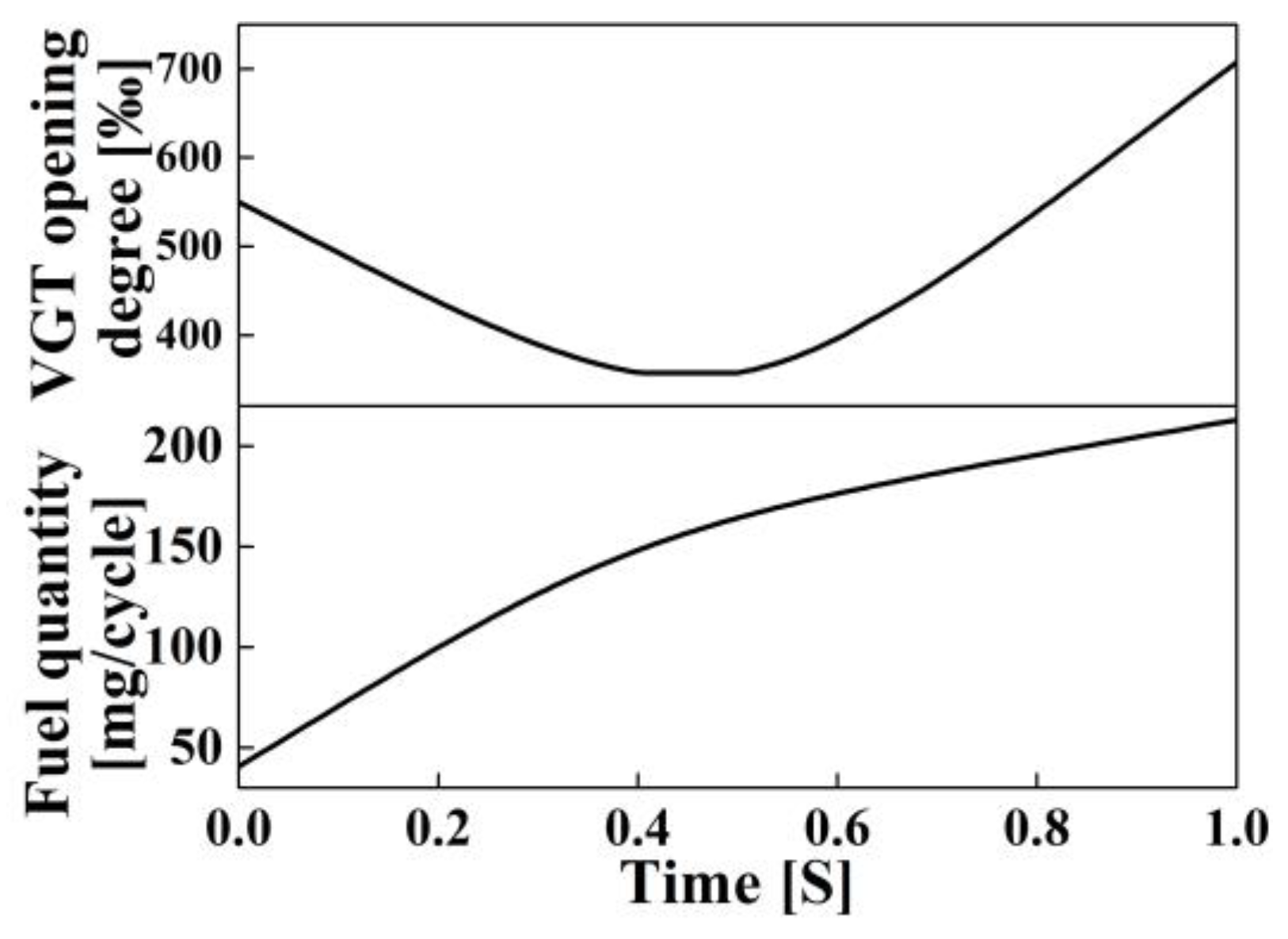

2.2. Experiment Scheme

2.3. Data Processing

3. Results and Discussion

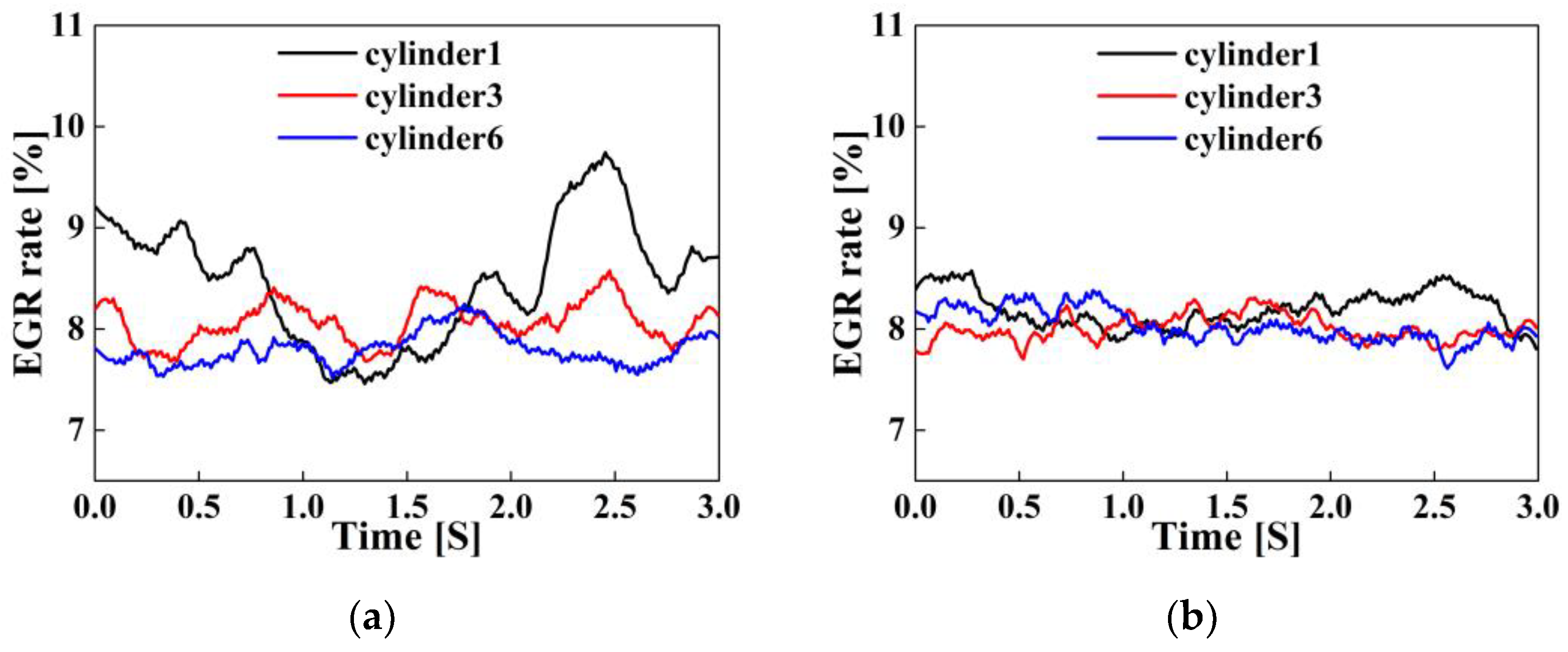

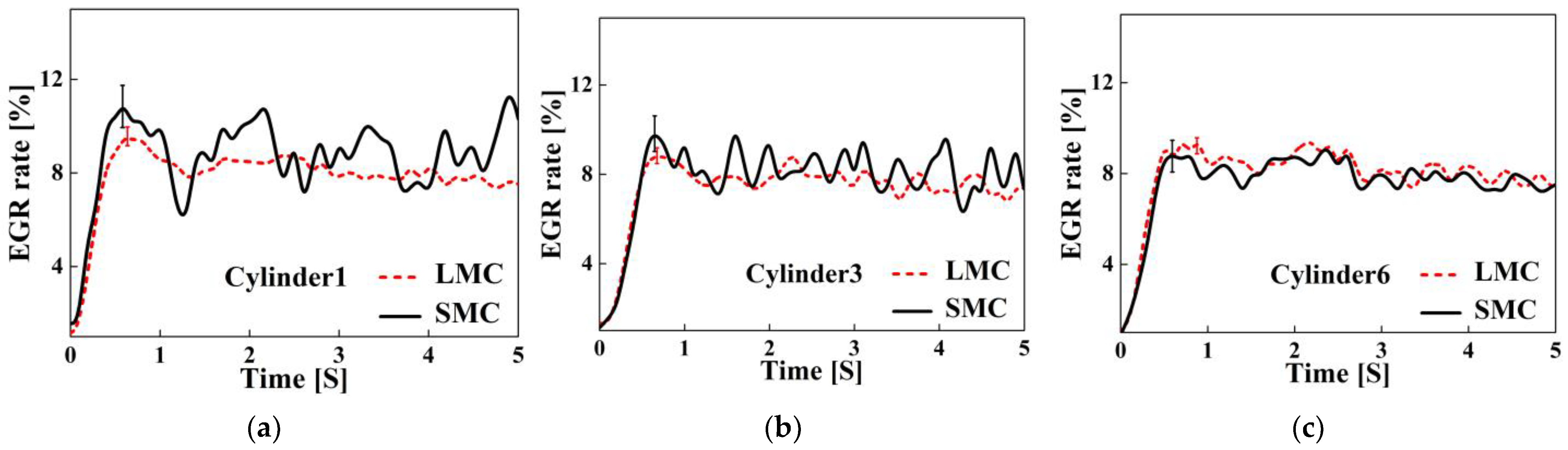

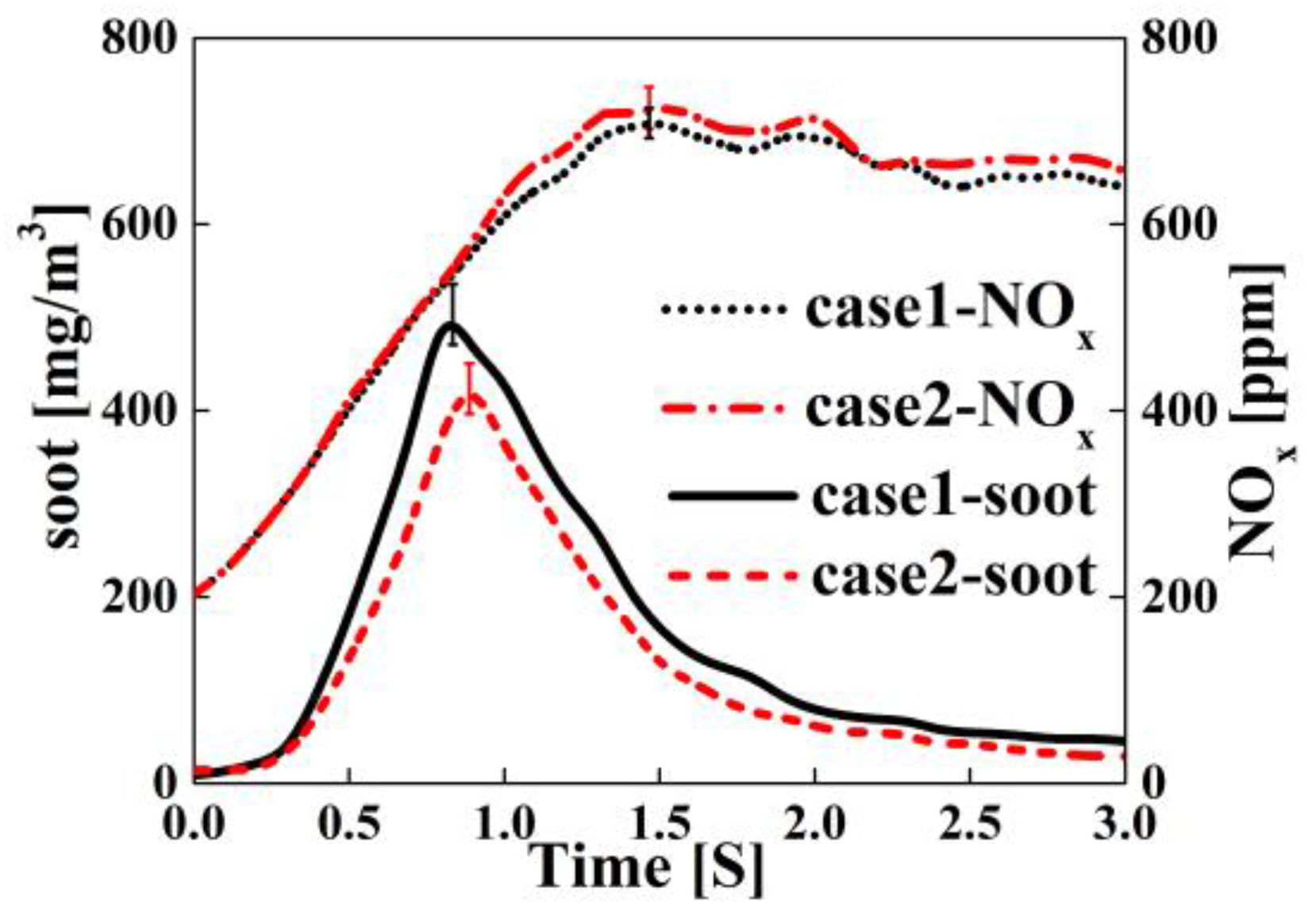

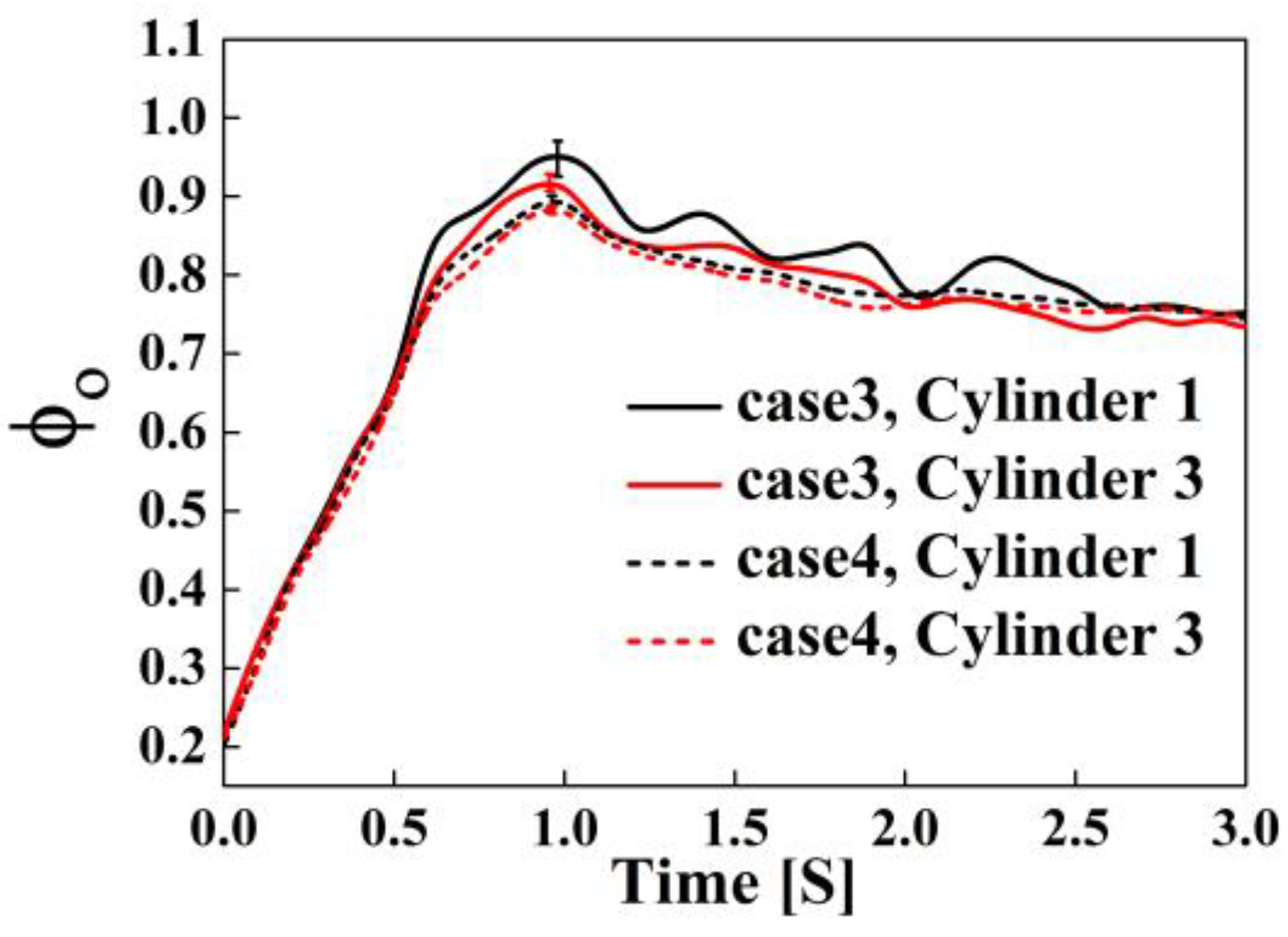

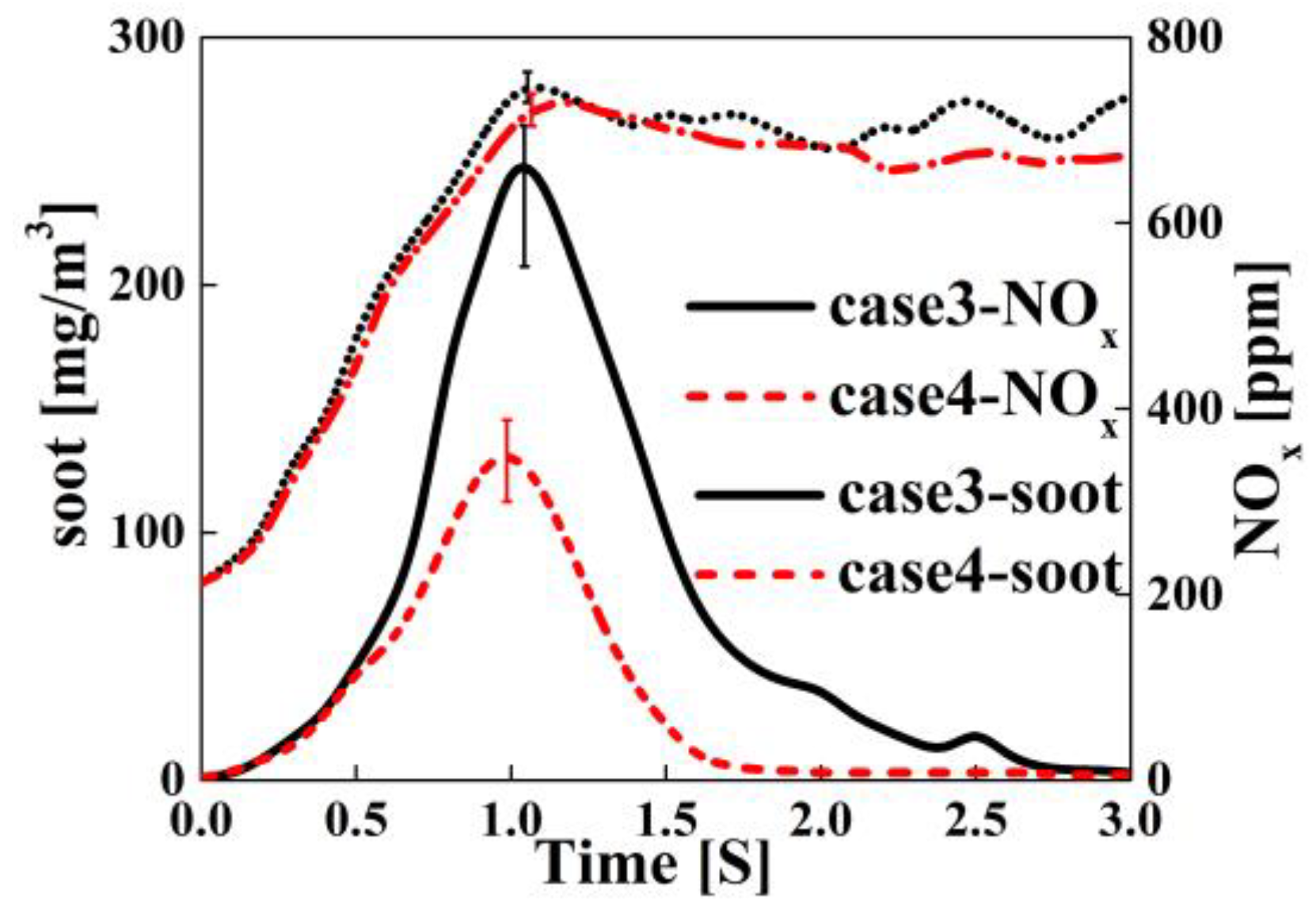

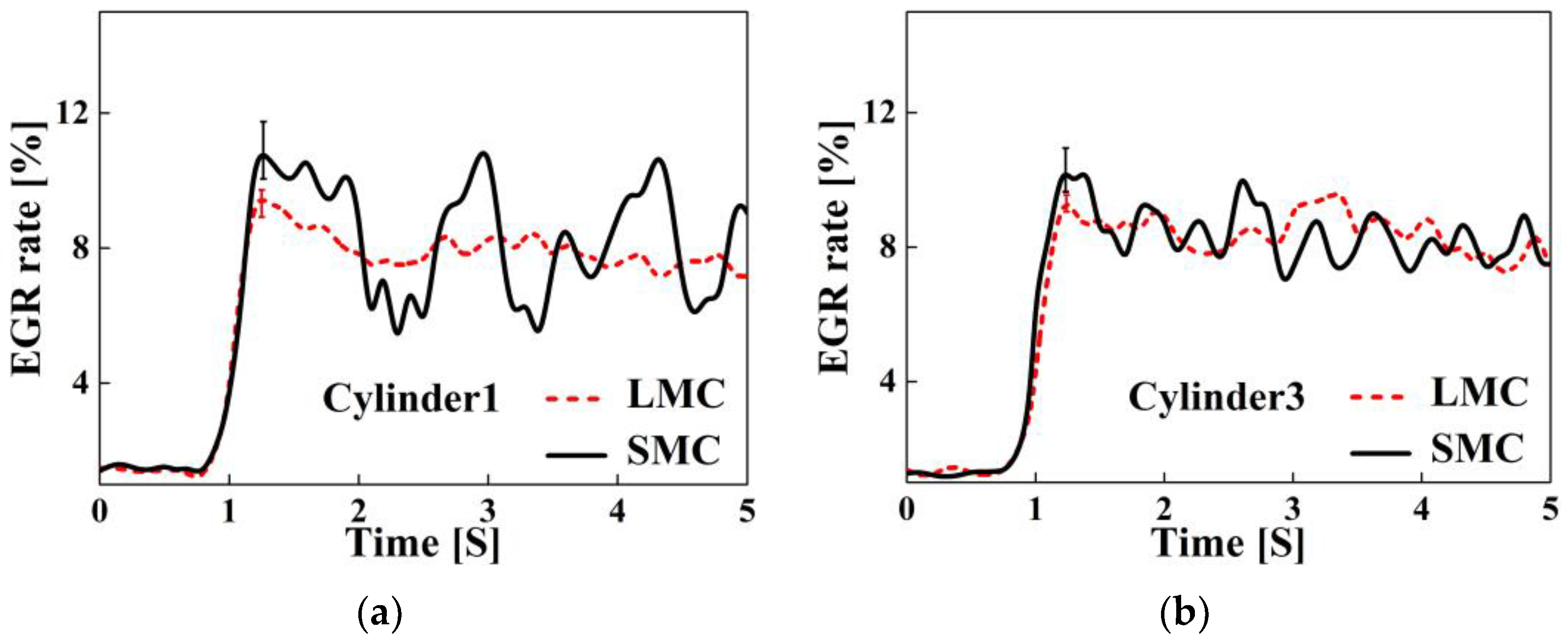

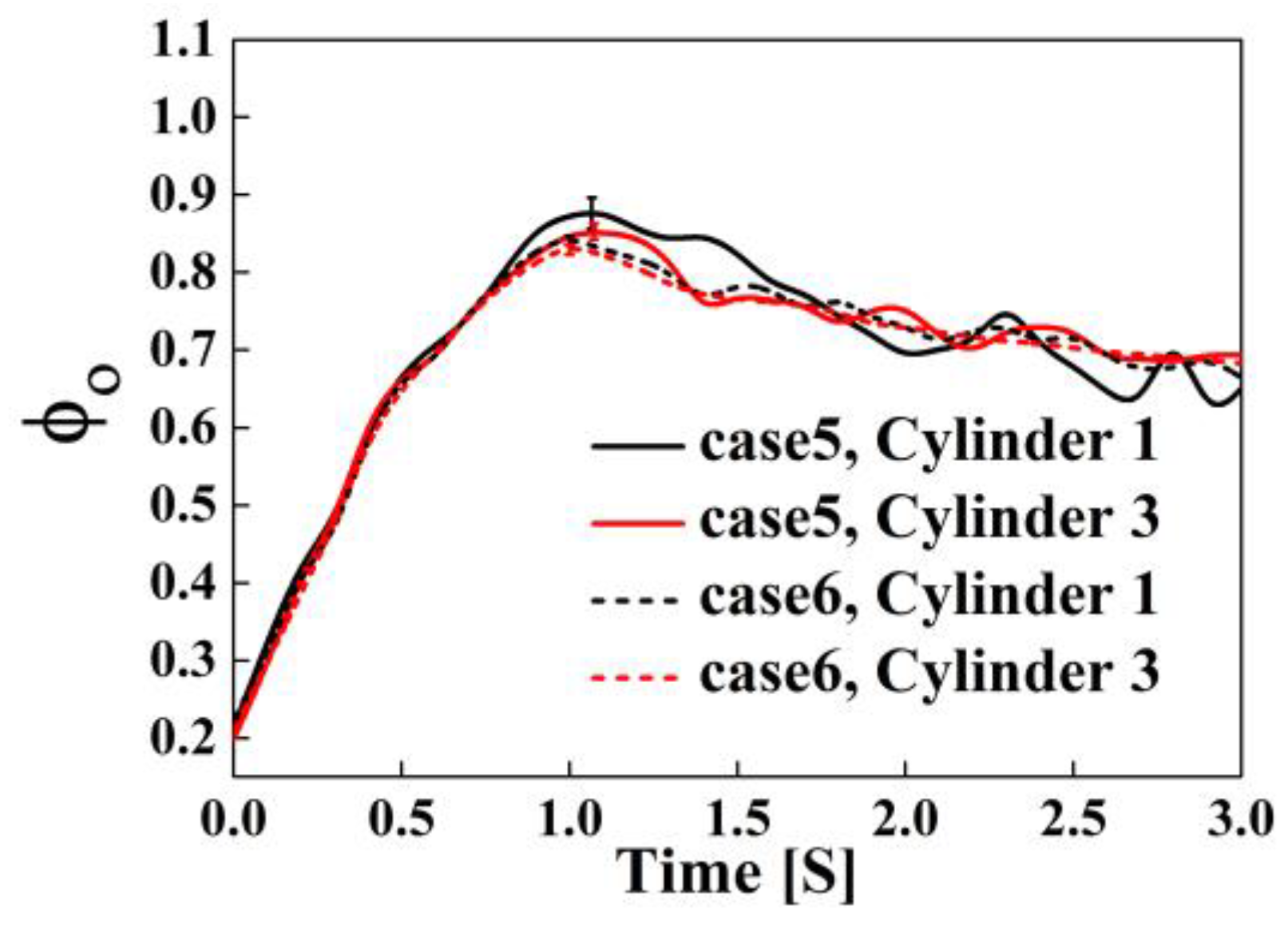

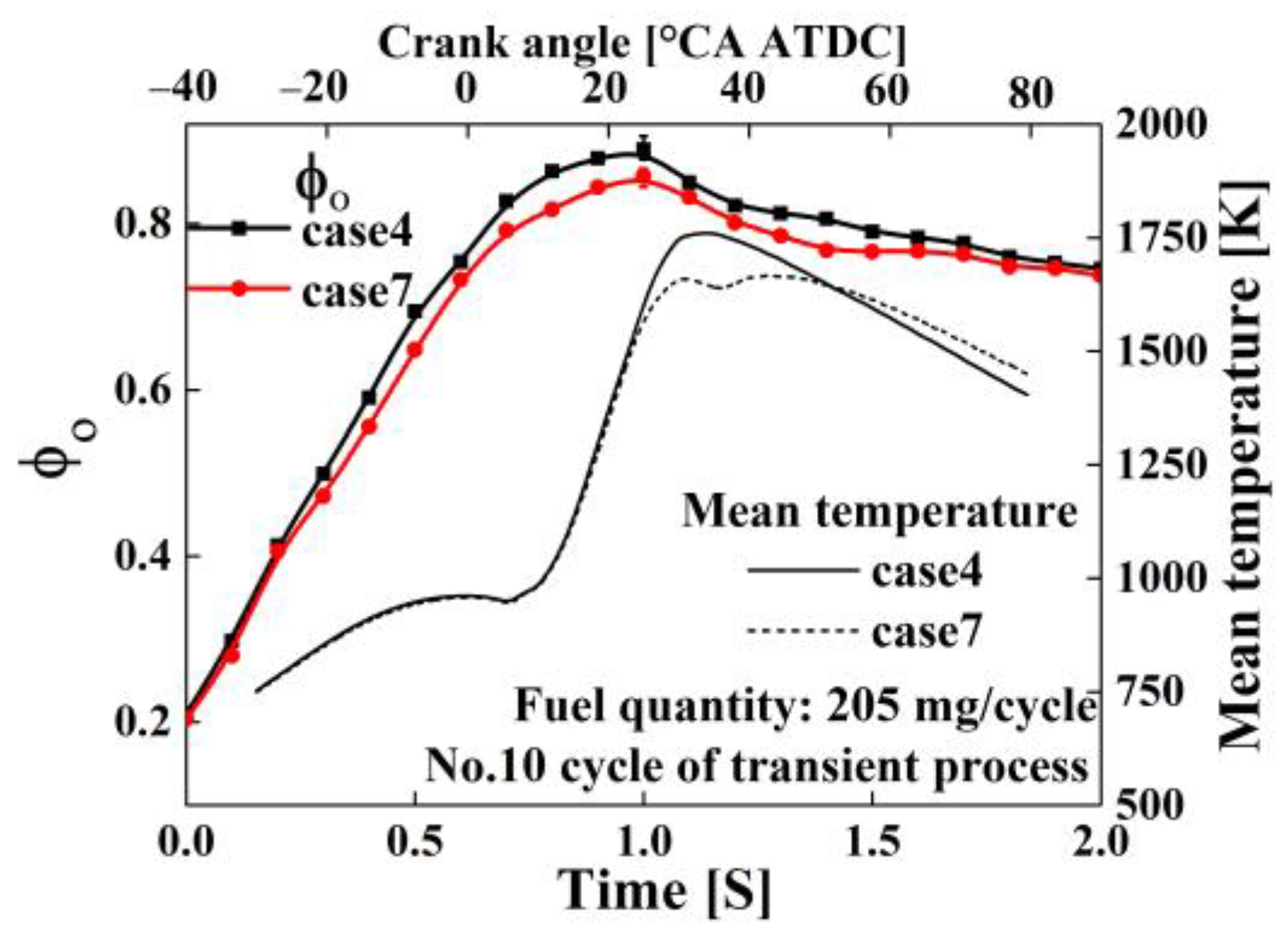

3.1. The Effect of High-Pressure EGR Systems on Transient Process

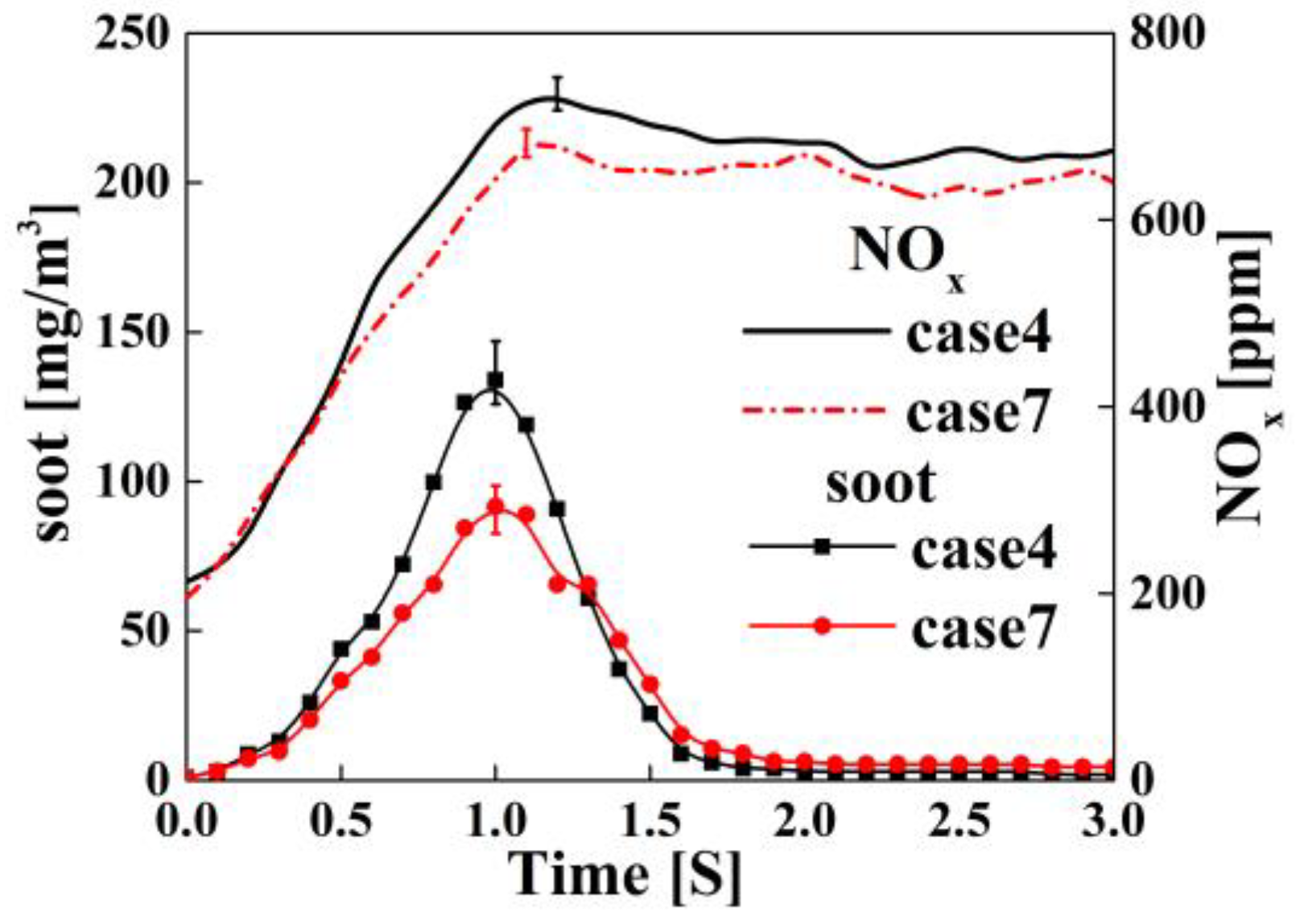

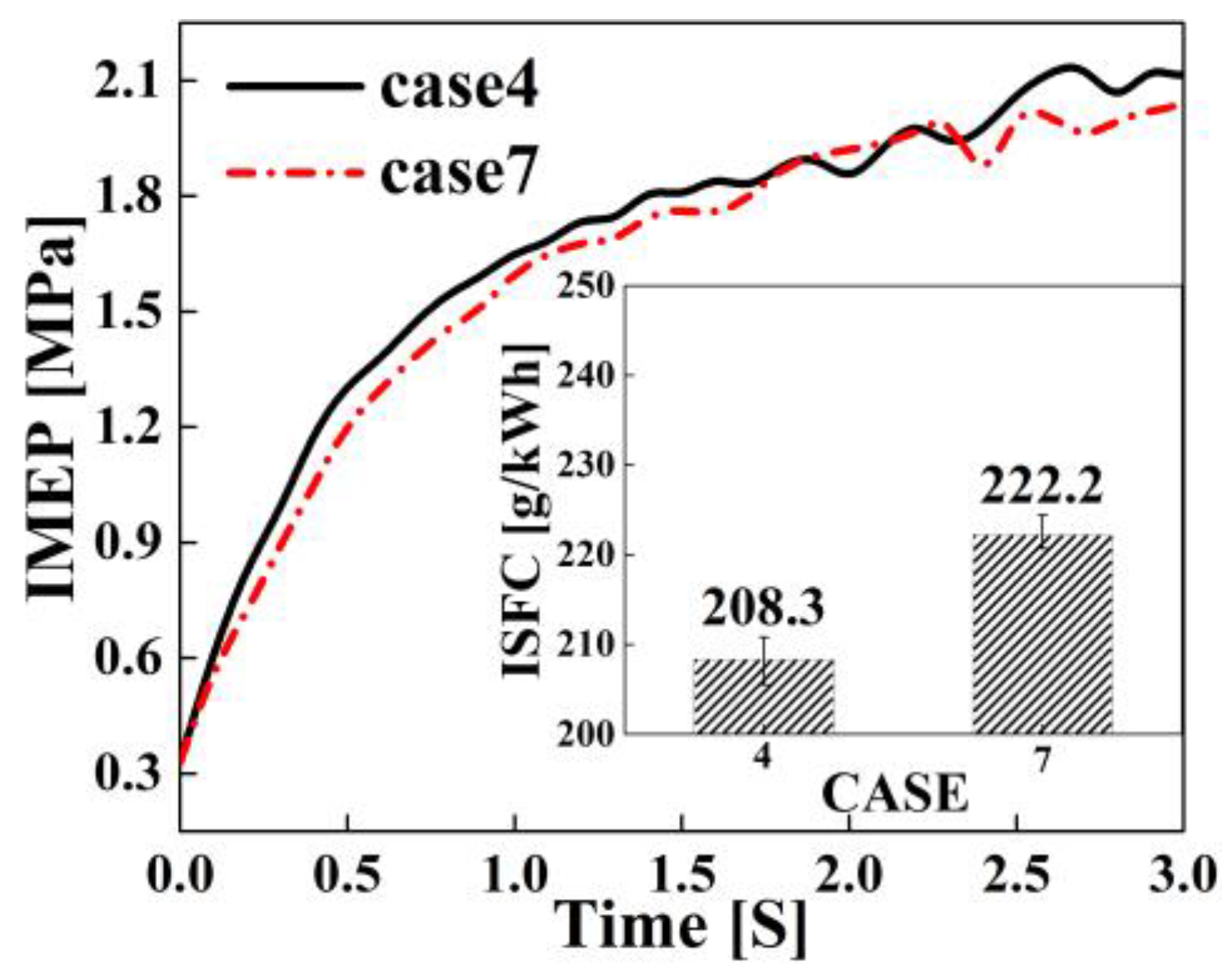

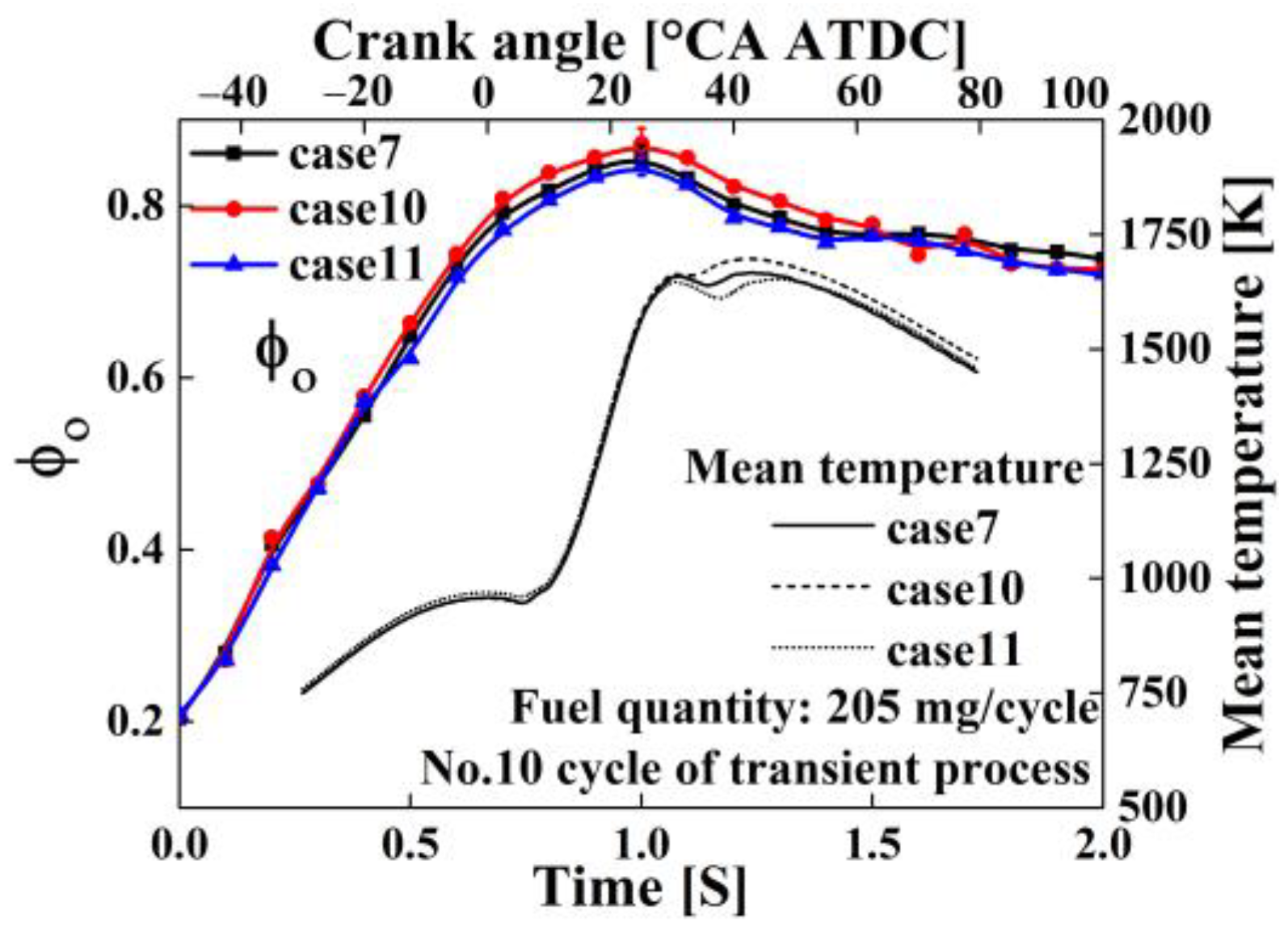

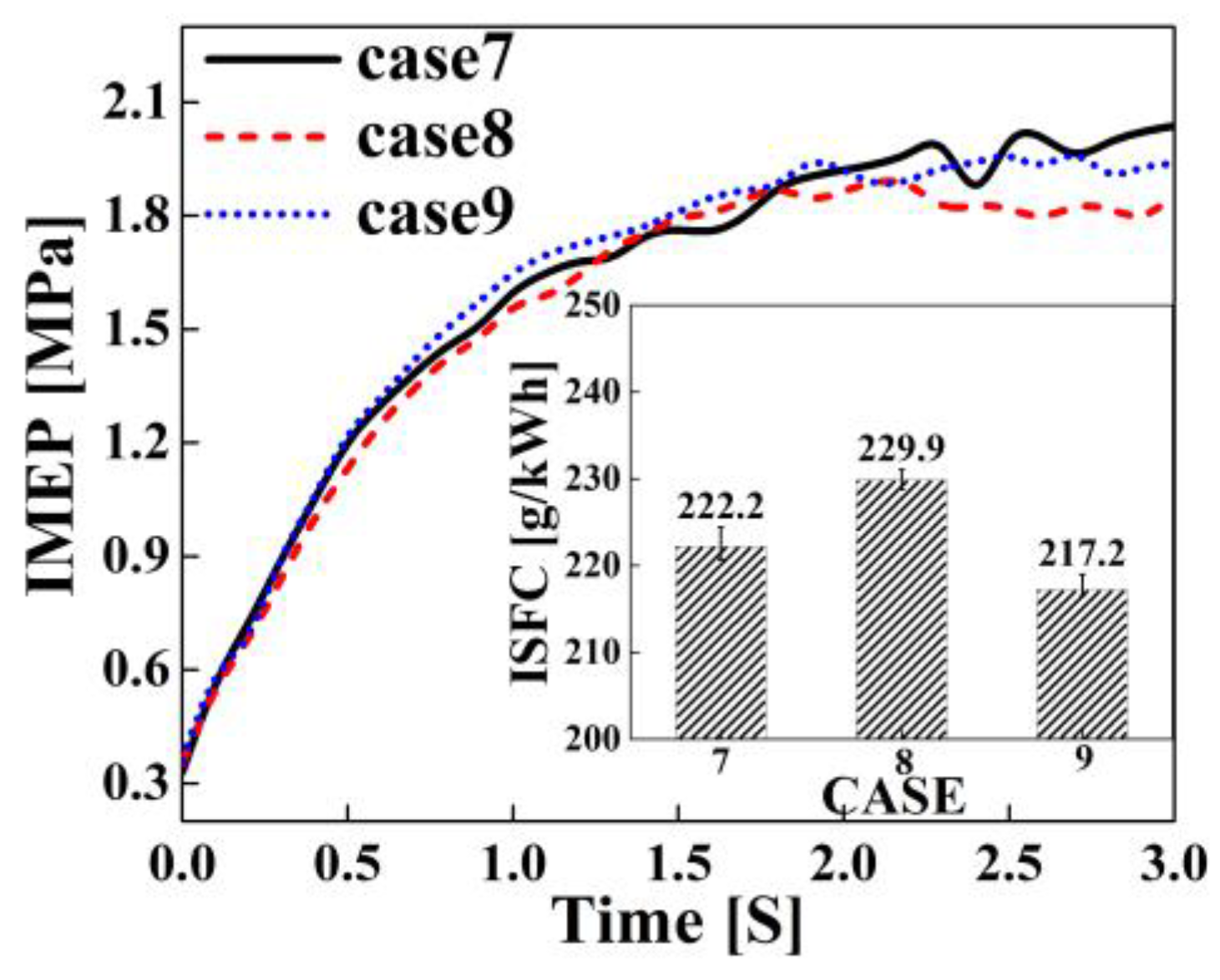

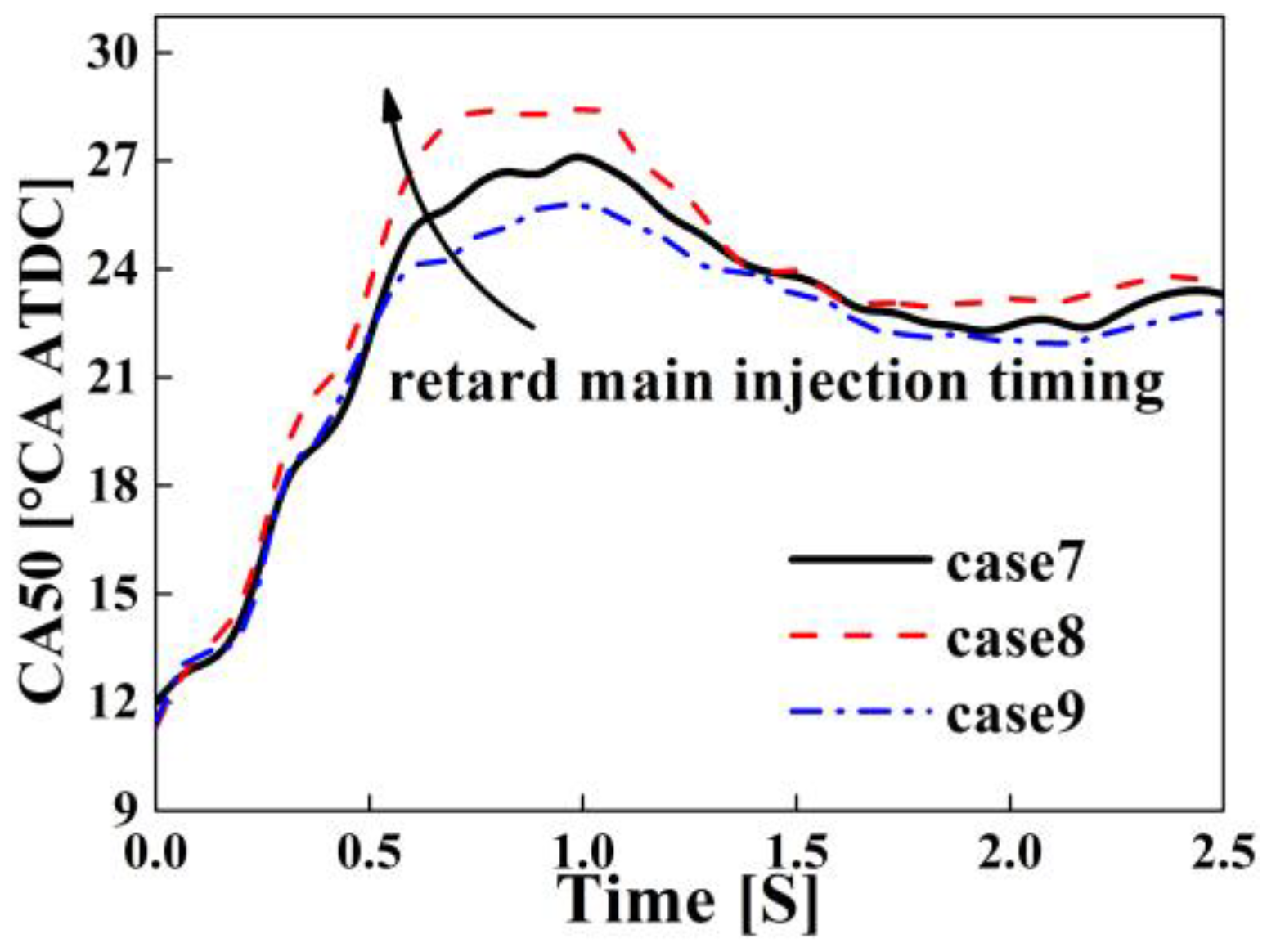

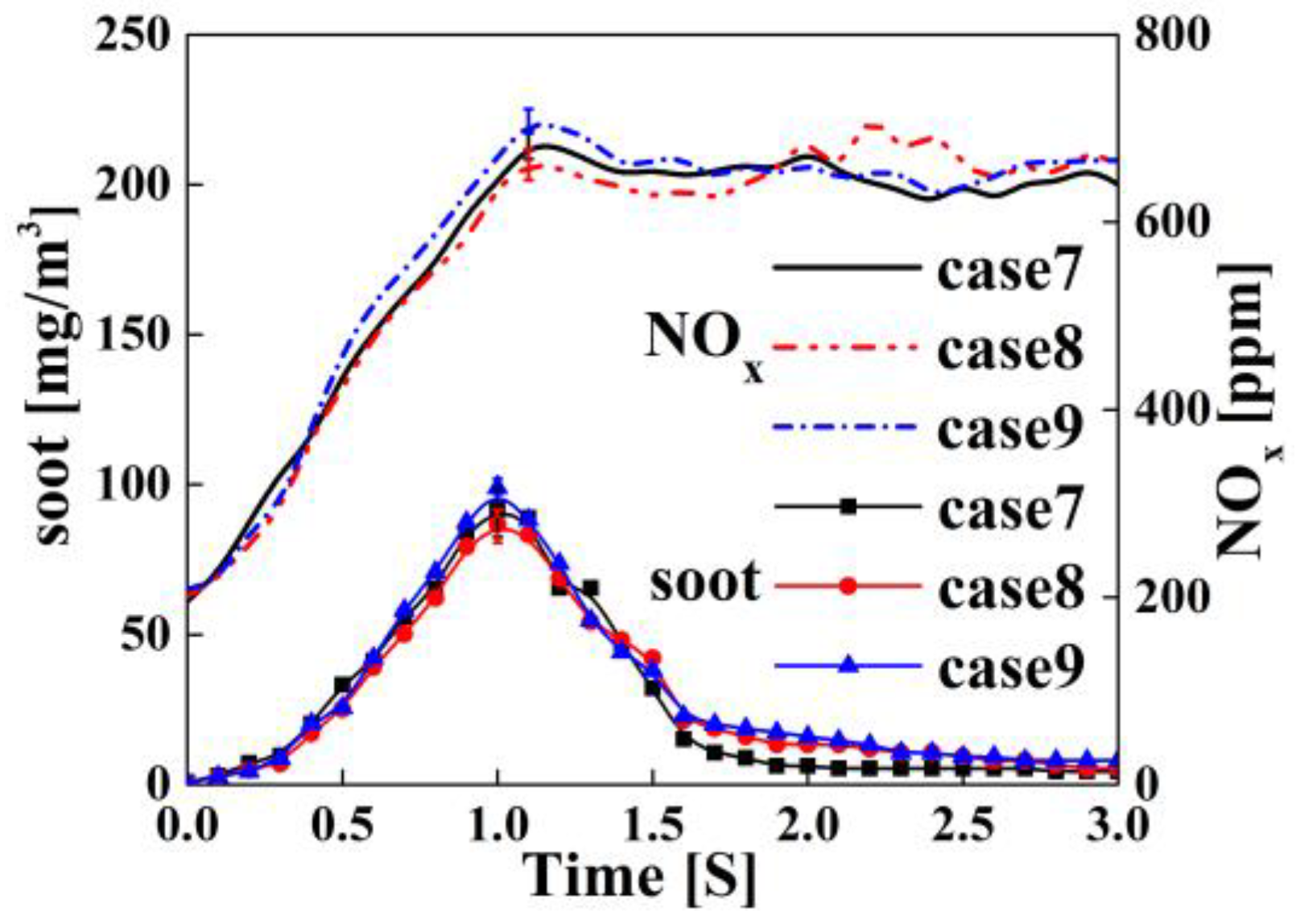

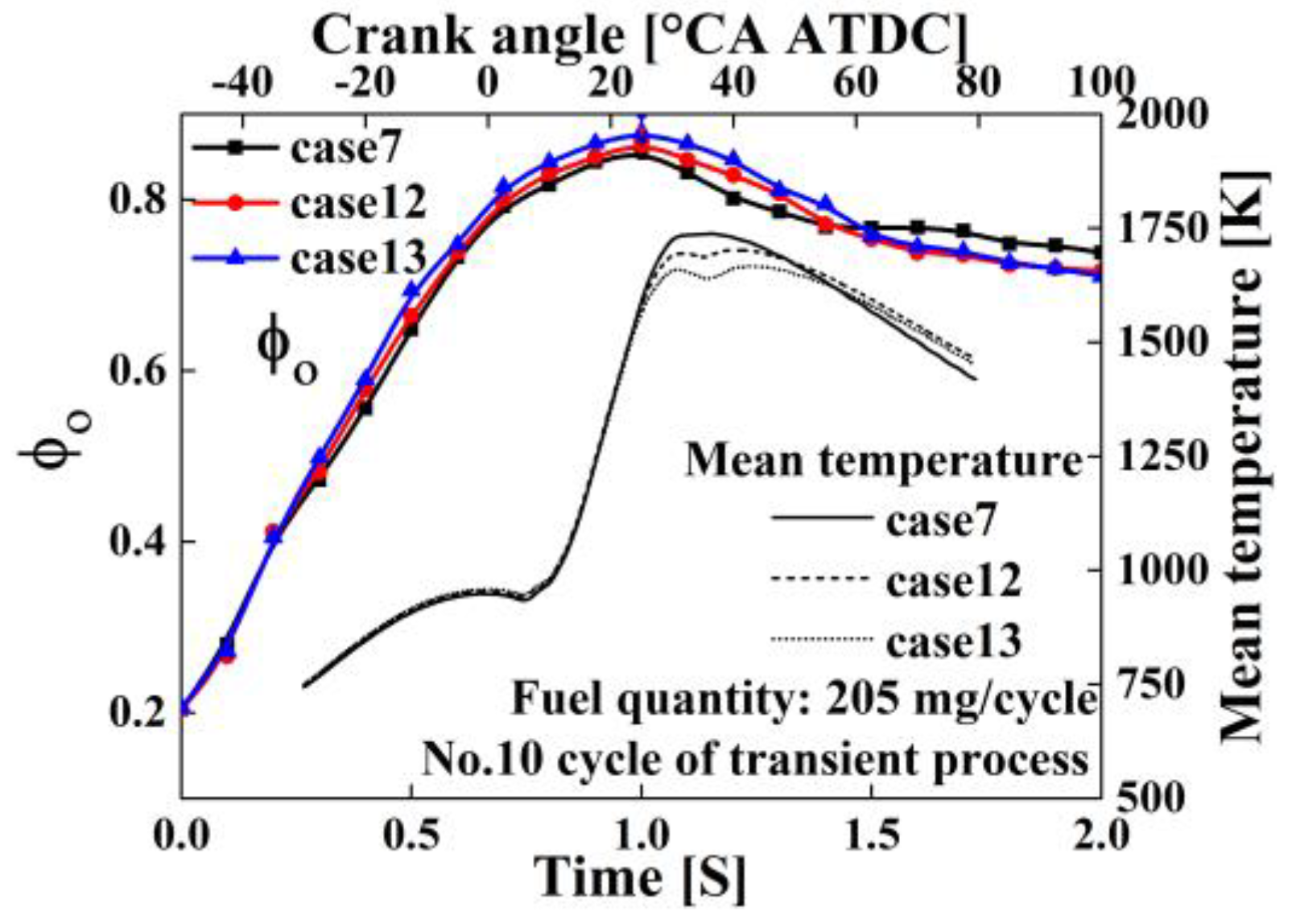

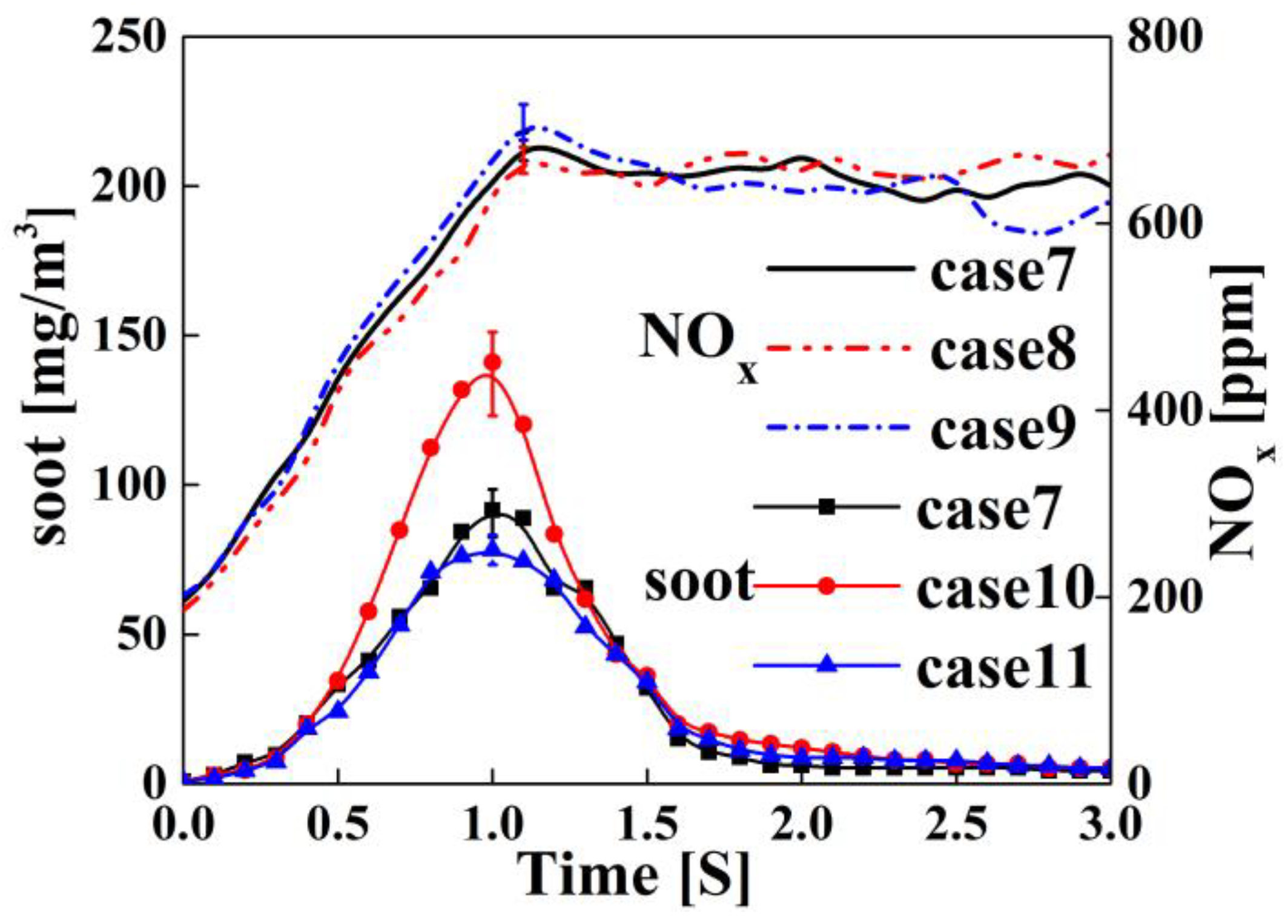

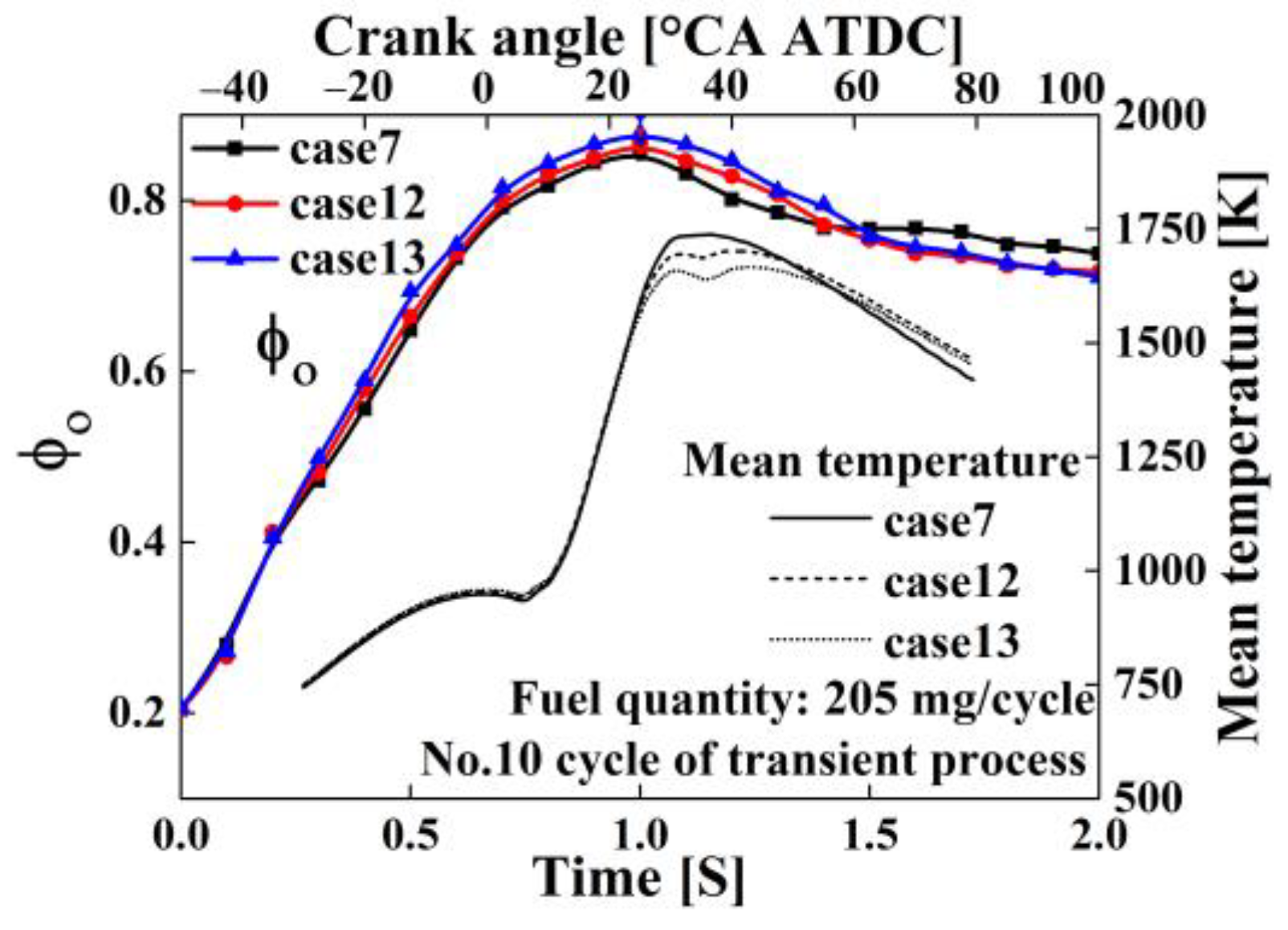

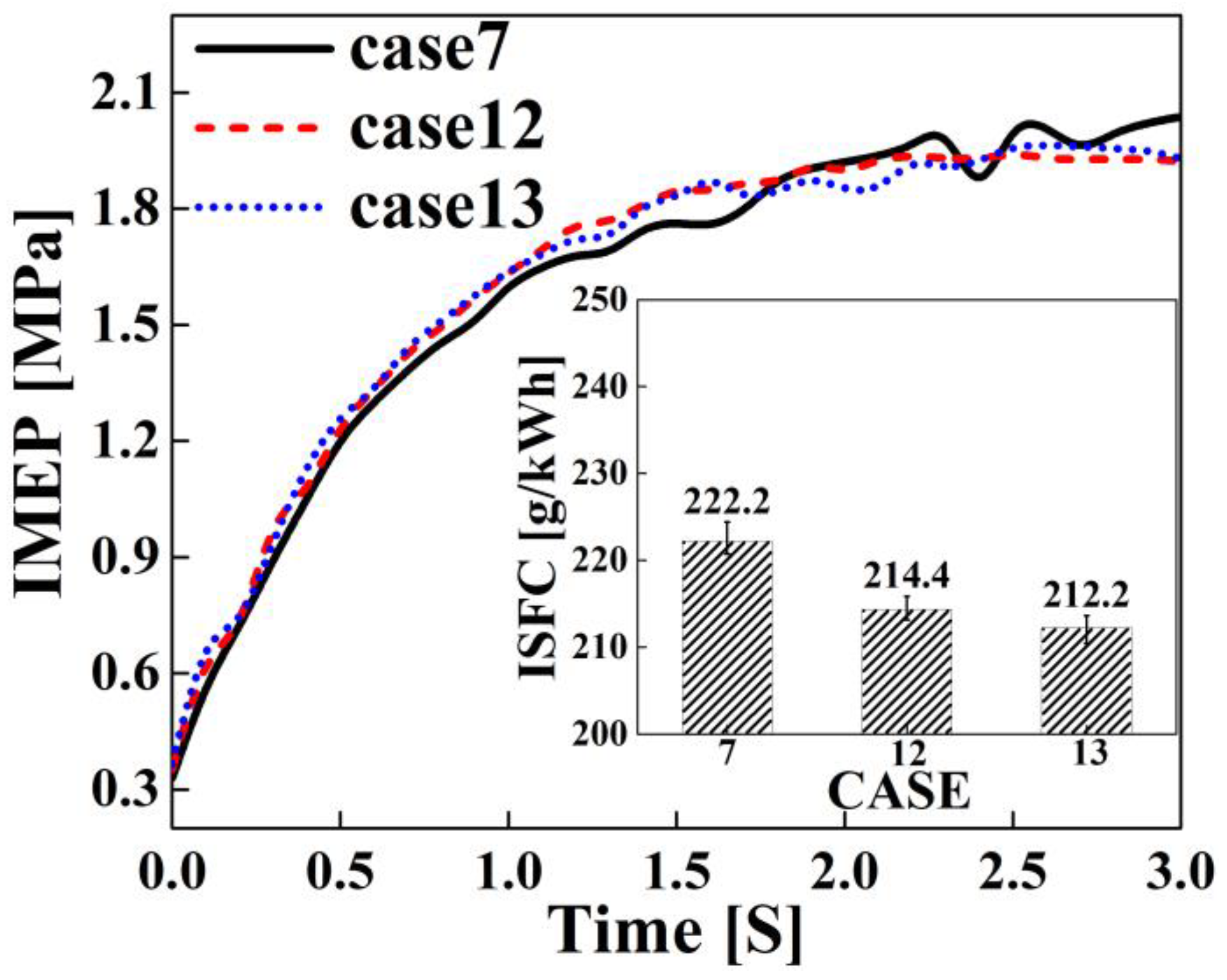

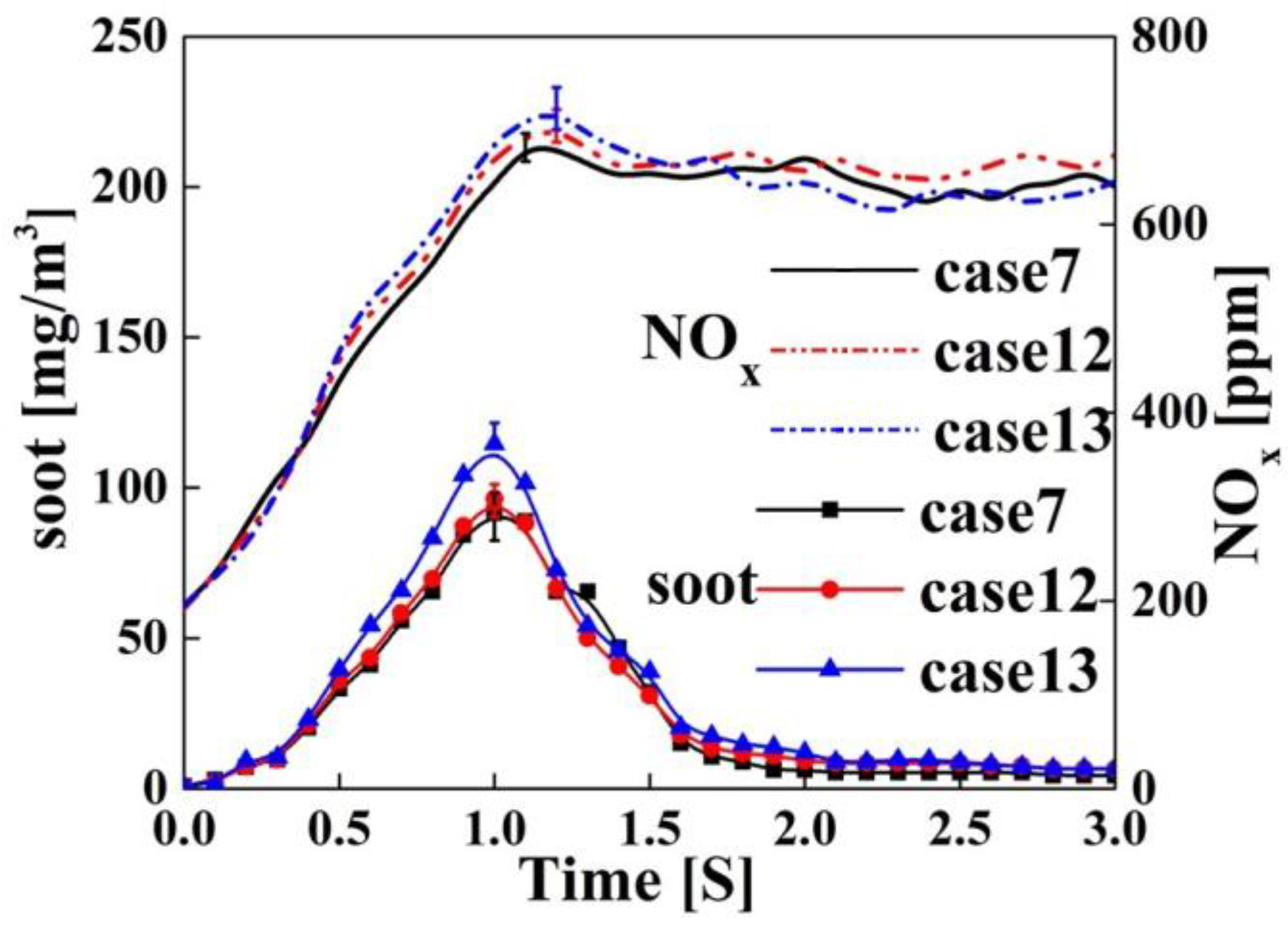

3.2. Effect of Injection Strategy on Transient Process

4. Conclusions and Prospects

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Item | Definition |

| IVCA | Intake valve closing actuator |

| EGR | Exhaust gas recirculation |

| SMC | Short mixing circuit |

| LMC | Long mixing circuit |

| ISFC | Indicated fuel specific consumption (g/kWh) |

| IMEP | Indicated mean effective pressure (MPa) |

| Fuel–oxygen equivalent ratio | |

| CA50 | Crank angle at 50% accumulated heat release |

| PM | Particulate matter |

| DPF | Diesel particulate filters |

| VGT | Variable geometry turbocharger |

| NOx | Nitrogen oxide |

| IVO | Intake valve opening |

| EVO | Exhaust valve opening |

| IVC | Intake valve closing |

| EVC | Exhaust valve closing |

| ATDC | After top dead center |

| BTDC | Before top dead center |

| CA | Crank angle |

| FSO | Full scale output |

| Fuel consumption measured by ECU | |

| Indicated engine power (kW) | |

| Engine speed (rpm) | |

| Indicated engine torque (N∙m) | |

| Engine cylinder displacement (dm3) | |

| Number of cylinders | |

| Number of engine strokes | |

| Mass of in-cylinder fuel (g) | |

| Mass of in-cylinder oxygen (g) | |

| Theoretical fuel–oxygen ratio | |

| CO2 concentration in the intake air (%) | |

| CO2 concentration in exhaust (%) | |

| CO2 concentration in the fresh air (%) | |

| EGR rate (%) | |

| Specific emission of NOx (g/kWh) | |

| Exhaust gas constant for NOx | |

| Instantaneous concentration of NOx in the exhaust gas (ppm) | |

| Instantaneous exhaust mass flow (kg/h) | |

| Humidity correction factor for NOx | |

| Instantaneous engine power (kW) | |

| Specific emission of soot [g/kWh] | |

| Dilution ratio | |

| Density of the exhaust gas under standard conditions (kg/m3) | |

| Instantaneous concentration of soot in the exhaust gas (mg/m3) | |

| Mean temperature in cylinder (K) | |

| In-cylinder pressure (Pa) | |

| Instantaneous cylinder volume (m3) | |

| Molar mass of the gas (g/mol) | |

| Mass of the in-cylinder charge (g) | |

| Ideal gas constant (Pa∙m3∙mol−1∙K−1) |

References

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust emissions of diesel engines operating under transient conditions with biodiesel fuel blends. Prog. Energy Combust. Sci. 2012, 38, 691–715. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Diesel Engine Transient Operation: Principles of Operation and Simulation Analysis; Springer Science & Business Media: London, UK, 2009. [Google Scholar]

- Nilsson, T.; Froberg, A.; Aslund, J. Optimal Operation of a Turbocharged Diesel Engine during Transients. SAE Int. J. Engines 2012, 5, 571–578. [Google Scholar] [CrossRef]

- Rakopoulos, C.; Dimaratos, A.; Giakoumis, E.; Peckham, M. Experimental Assessment of Turbocharged Diesel Engine Transient Emissions during Acceleration, Load Change and Starting; SAE Technical Paper 2010-01-1287; SAE International: Troy, MI, USA, 2010. [Google Scholar]

- Hagena, J.R.; Filipi, Z.; Assanis, D.N. Transient Diesel Emissions: Analysis of Engine Operation during a Tip-In; SAE Technical Paper 2006-01-1151; SAE International: Troy, MI, USA, 2006. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, X.; Qian, Y.; Shi, L.; Deng, K. Study on optimal control strategy for regulated two-stage turbocharged diesel engine during transient process. J. Mech. Sci. Technol. 2021, 35, 5699–5712. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, X.; Tian, J.; Han, Y.; Li, R.; Gao, G. Investigation of Sectional-Stage Loading Strategies on a Two-Stage Turbocharged Heavy-Duty Diesel Engine under Transient Operation with EGR. Energies 2018, 11, 69. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Tsolakis, A.; Alagumalai, A.; Mahian, O.; Lam, S.S.; Pan, J.; Peng, W.; Tabatabaei, M.; Aghbashlo, M. Use of hydrogen in dual-fuel diesel engines. Prog. Energy Combust. Sci. 2023, 98, 101100. [Google Scholar] [CrossRef]

- Onorati, A.; Payri, R.; Vaglieco, B.; Agarwal, A.; Bae, C.; Bruneaux, G.; Canakci, M.; Gavaises, M.; Günthner, M.; Hasse, C.; et al. The role of hydrogen for future internal combustion engines. Int. J. Engine Res. 2022, 23, 529–540. [Google Scholar] [CrossRef]

- Dinesha, P.; Kumar, S.; Rosen, M.A. Effects of particle size of cerium oxide nanoparticles on the combustion behavior and exhaust emissions of a diesel engine powered by biodiesel/diesel blend. Biofuel Res. J. 2021, 8, 1374–1383. [Google Scholar] [CrossRef]

- Zhang, W.; Song, C.; Lv, G.; Bi, F.; Qiao, Y.; Wang, L.; Zhang, X. Properties and oxidation of in-cylinder soot associated with exhaust gas recirculation (EGR) in diesel engines. Proc. Combust. Inst. 2021, 38, 1319–1326. [Google Scholar] [CrossRef]

- Pan, M.; Qian, W.; Wei, H.; Feng, D.; Pan, J. Effects on performance and emissions of gasoline compression ignition engine over a wide range of internal exhaust gas recirculation rates under lean conditions. Fuel 2020, 265, 116881. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, G.; Zheng, Z.; Liu, H.; Xu, J.; Yao, M. Combustion and emissions of 2,5-dimethylfuran addition on a diesel engine with low temperature combustion. Fuel 2013, 103, 730–735. [Google Scholar] [CrossRef]

- Park, Y.; Bae, C. Experimental study on the effects of high/low pressure EGR proportion in a passenger car diesel engine. Appl. Energy 2014, 133, 308–316. [Google Scholar] [CrossRef]

- Dimitriou, P.; Turner, J.; Burke, R.; Copeland, C. The benefits of a mid-route exhaust gas recirculation system for two-stage boosted engines. Int. J. Engine Res. 2018, 19, 553–569. [Google Scholar] [CrossRef]

- Cornolti, L.; Onorati, A.; Cerri, T.; Montenegro, G.; Piscaglia, F. 1D simulation of a turbocharged Diesel engine with comparison of short and long EGR route solutions. Appl. Energy 2013, 111, 1–15. [Google Scholar] [CrossRef]

- Van Aken, M.; Willems, F.; de Jong, D.-J. Appliance of High EGR Rates with a Short and Long Route EGR System on a Heavy Duty Diesel Engine; SAE Technical Paper 2007-01-0906; SAE International: Troy, MI, USA, 2007. [Google Scholar] [CrossRef]

- Luján, J.M.; Guardiola, C.; Pla, B.; Reig, A. Switching strategy between HP (high pressure)- and LPEGR (low pressure exhaust gas recirculation) systems for reduced fuel consumption and emissions. Energy 2015, 90, 1790–1798. [Google Scholar] [CrossRef]

- Huang, Y.; Ng, E.C.; Surawski, N.C.; Zhou, J.L.; Wang, X.; Gao, J.; Lin, W.; Brown, R.J. Effect of diesel particulate filter regeneration on fuel consumption and emissions performance under real-driving conditions. Fuel 2022, 320, 123937. [Google Scholar] [CrossRef]

- Galindo, J.; Climent, H.; de la Morena, J.; González-Domínguez, D.; Guilain, S. Assessment of air management strategies to improve the transient response of advanced gasoline engines operating under high EGR conditions. Energy 2022, 262, 125586. [Google Scholar] [CrossRef]

- Pennington, J.; Puzinauskas, P.V.; Cook, J. Simultaneous Control Optimization of Variable-Geometry Turbocharger and High Pressure EGR on a Medium Duty Diesel Engine; SAE Technical Paper 2021-01-1178; SAE International: Troy, MI, USA, 2021. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Z.; Tian, J.; Li, L.; Yu, K.; He, K. Effect of EGR and Fuel Injection Strategies on the Heavy-Duty Diesel Engine Emission Performance under Transient Operation. Energies 2020, 13, 566. [Google Scholar] [CrossRef]

- Hariganesh, S.K.R.; Sathyanadan, M.; Krishnan, S.; Vadivel, P.; Vamsidhar, D. Computational analysis of EGR mixing inside the intake system & experimental investigation on diesel engine for LCV. Int. J. Eng. Sci. Technol. 2011, 3, 2350–2358. [Google Scholar]

- Dhatkar, S.A.; Rajesh, S.K.; Garg, S.; Emran, A.; Sharma, V. EGR Mixer Optimization for Achieving Uniform Cylinder EGR Distribution Using 1D-3D CFD Coupled Simulation Approach to Meet Future Stage V Emission Legislation in India; SAE Technical Paper 2020-28-0390; SAE International: Troy, MI, USA, 2020. [Google Scholar] [CrossRef]

- Benajes, J.; Martín, J.; García, A.; Villalta, D.; Warey, A. Swirl ratio and post injection strategies to improve late cycle diffusion combustion in a light-duty diesel engine. Appl. Therm. Eng. 2017, 123, 365–376. [Google Scholar] [CrossRef]

- O’Connor, J.; Musculus, M.P.; Pickett, L.M. Effect of post injections on mixture preparation and unburned hydrocarbon emissions in a heavy-duty diesel engine. Combust. Flame 2016, 170, 111–123. [Google Scholar] [CrossRef]

- Mancaruso, E.; Merola, S.S.; Vaglieco, B.M. Study of the multi-injection combustion process in a transparent direct injection common rail diesel engine by means of optical techniques. Int. J. Engine Res. 2008, 9, 483–498. [Google Scholar] [CrossRef]

- Bobba, M.; Musculus, M.; Neel, W. Effect of Post Injections on In-Cylinder and Exhaust Soot for Low-Temperature Combustion in a Heavy-Duty Diesel Engine. SAE Int. J. Eng. 2010, 3, 496–516. [Google Scholar] [CrossRef]

- Nimodia, S.; Senthilkumar, K.; Halbe, V.; Ghodke, P.R.; Velusamy, R. Simultaneous Reduction of NOx and Soot Using Early Post Injection; SAE Technical Paper 2013-26-0055; SAE International: Troy, MI, USA, 2013. [Google Scholar] [CrossRef]

- Pan, W.; Wu, Y.; Jing, Y.; Zizeng, H. Impact of Post-Injection Parameters on Soot and Hydrocarbon Emissions in a Common-Rail Heavy-Duty Diesel Engine; SAE Technical Paper 2020-01-0374; SAE International: Troy, MI, USA, 2020. [Google Scholar] [CrossRef]

- Su, W.; Zhan, Q.; Pei, Y.; Liu, E.; Wu, S. Self-Adaptive Hydraulic Variable Valve Timing System for Diesel Engine and Control Method. U.S. Patent 9,163,531, 20 October 2015. [Google Scholar]

- GB 19147-2016; National Technical Committee on Petroleum Products and Lubricants of Standardization Administration of China. Automobile Diesel Fuels. Standards Press of China: Beijing, China, 2016.

- Su, W.; Lin, T.; Pei, Y. A Compound Technology for HCCI Combustion in a DI Diesel Engine Based on the Multi-Pulse Injection and the BUMP Combustion Chamber; SAE Technical Paper 2003-01-0741; SAE International: Troy, MI, USA, 2003. [Google Scholar] [CrossRef]

- UNECE. Uniform Provisions Concerning the Measures to Be Taken against the Emission of Gaseous and Particulate Pollutants from Compression Ignition Engines and Positive Ignition Engines for Use in Vehicles; Regulation No. 49. Revision 6; United Nations Economic Commission for Europe: Geneva, Switzerland, 2013. [Google Scholar]

- Kemp, A.W. Industrial Mechanics, 1st ed.; American Technical Publishers: Orland Park, IL, USA, 1998; p. 154. [Google Scholar]

- Heywood, J.B. “MEAN EFFECTIVE PRESSURE.” Chap. 2.7 in Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Yu, X.; Wu, B.; Su, W. Experimental study on the approach for improved brake thermal efficiency on a two-stage turbocharged heavy-duty diesel engine. Fuel 2021, 305, 121523. [Google Scholar] [CrossRef]

- AVL List GmbH. AVL Micro Soot Sensor Avl Exhaust Conditioning Unit Operating Manual; Rev. 13; AVL List GmbH: Graz, Austria, 2013; pp. 130–132. [Google Scholar]

- Kautz, C.H.; Heron, P.R.L.; Loverude, M.E.; McDermott, L.C. Student understanding of the ideal gas law, Part I: A macroscopic perspective. Am. J. Phys. 2005, 73, 1055–1063. [Google Scholar] [CrossRef]

- Zhang, C.; Pan, J.; Tong, J.; Li, J. Effects of Intake Temperature and Excessive Air Coefficient on Combustion Characteristics and Emissions of HCCI Combustion. Procedia Environ. Sci. 2011, 11, 1119–1127. [Google Scholar] [CrossRef]

- Feneley, A.J.; Pesiridis, A.; Andwari, A.M. Variable Geometry Turbocharger Technologies for Exhaust Energy Recovery and Boosting—A Review. Renew. Sustain. Energy Rev. 2017, 71, 959–975. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Thermodynamic Aspects of Transient Operation. In Diesel Engine Transient Operation: Principles of Operation and Simulation Analysis; Springer: London, UK, 2009; pp. 23–74. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, P.; Farhan, S.M.; Yi, J.; Lei, L. Effect of post-injection on combustion and exhaust emissions in DI diesel engine. Fuel 2019, 258, 116131. [Google Scholar] [CrossRef]

- Wang, Z.; Shen, L.; Lei, J.; Yao, G.; Wang, G. Impact characteristics of post injection on exhaust temperature and hydrocarbon emissions of a diesel engine. Energy Rep. 2022, 8, 4332–4343. [Google Scholar] [CrossRef]

- Mohan, B.; Yang, W.; Chou, S.K. Fuel injection strategies for performance improvement and emissions reduction in compression ignition engines—A review. Renew. Sustain. Energy Rev. 2013, 28, 664–676. [Google Scholar] [CrossRef]

- Feng, S.; Hong, W.; Yao, Y.; You, T. Research of Post Injection Strategy of an EGR Diesel Engine to Improve Combustion and Particulate Emissions Performance: Application on the Transient Operation. Symmetry 2020, 12, 2002. [Google Scholar] [CrossRef]

- Poorghasemi, K.; Saray, R.K.; Ansari, E.; Irdmousa, B.K.; Shahbakhti, M.; Naber, J.D. Effect of diesel injection strategies on natural gas/diesel RCCI combustion characteristics in a light duty diesel engine. Appl. Energy 2017, 199, 430–446. [Google Scholar] [CrossRef]

- Liu, W.; Song, C. Effect of post injection strategy on regulated exhaust emissions and particulate matter in a HSDI diesel engine. Fuel 2016, 185, 1–9. [Google Scholar] [CrossRef]

- O’Connor, J.; Musculus, M. Post Injections for Soot Reduction in Diesel Engines: A Review of Current Understanding. SAE Int. J. Eng. 2013, 6, 400–421. [Google Scholar] [CrossRef]

- Wu, B.; Ma, Y.; Yu, X.; Gu, W.; Li, Y.; Su, W. Effects of exhaust gas recycle loop layout and retarded intake valve closing on variations in combustion in a heavy-duty diesel engine. Int. J. Engine Res. 2015, 16, 340–355. [Google Scholar] [CrossRef]

| Item | Definition |

|---|---|

| Fuel | GB 19147-2016 diesel [32] |

| Bore × stroke | 126 mm × 155 mm |

| Swirl ratio | 1.2 |

| Compression ratio | 17:1 |

| Combustion chamber | “BUMP” [33] |

| Injection system | Common rail |

| Injection pressure | 180 MPa |

| Number of injector nozzle holes | 8 holes |

| Injector nozzle hole diameter | 0.217 mm |

| Injector spray angle (included) | 143° |

| Original valve train (4 valve) | IVO: 340° ATDC IVC: 146° BTDC EVO: 131° ATDC EVC: 339° BTDC |

| Equipment | Type | Range | Accuracy |

|---|---|---|---|

| Air flow meter | ABB FMT700-P | 0–5000 kg/h | <±0.8% of measured value |

| Fuel mass flow meter | AVL733s + AVL753c | 0–150 kg/h | <±0.12% of measured value |

| In-cylinder pressure sensor | Kistler 6125C | 0–300 Bar | ≤±0.4% FSO |

| Intake pressure sensor | Kistler 4007B | 0–10 Bar | ≤±0.2% FSO |

| Exhaust pressure sensor | Kistler 4049A | 0–10 Bar | ≤±0.3% FSO |

| Exhaust gas analyzer | Horiba MEXA-7100DEG | 0–5000 ppm (NOx) | 1 ppm |

| EGR analyzer | Cambustion NIDR500 | 0–20% (CO2) | 0.1% |

| Soot measurement | AVL483 | 0–1000 mg/m3 | 0.1 mg/m3 |

| CASE | EGR Layout | EGR Valve Opening Timing (S) | Injection Timing (°CA ATDC) | Post-Injection Ratio (%) |

|---|---|---|---|---|

| 1 | SMC | 0.1 | 1~−2 | |

| 2 | LMC | 0.1 | 1~−2 | |

| 3 | SMC | 0.5 | 1~−2 | |

| 4 | LMC | 0.5 | 1~−2 | |

| 5 | SMC | 0.9 | 1~−2 | |

| 6 | LMC | 0.9 | 1~−2 | |

| 7 | LMC | 0.5 | (1, 6)~(−2, 6) | 16 |

| 8 | LMC | 0.5 | (1, 6)~(−1, 6) | 16 |

| 9 | LMC | 0.5 | (1, 6)~(−3, 6) | 16 |

| 10 | LMC | 0.5 | (1, 3)~(−2, 3) | 16 |

| 11 | LMC | 0.5 | (1, 9)~(−2, 9) | 16 |

| 12 | LMC | 0.5 | (1, 6)~(−2, 6) | 12 |

| 13 | LMC | 0.5 | (1, 6)~(−2, 6) | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, W.; Su, W. Study on the Effects of Exhaust Gas Recirculation and Fuel Injection Strategy on Transient Process Performance of Diesel Engines. Sustainability 2023, 15, 12403. https://doi.org/10.3390/su151612403

Gu W, Su W. Study on the Effects of Exhaust Gas Recirculation and Fuel Injection Strategy on Transient Process Performance of Diesel Engines. Sustainability. 2023; 15(16):12403. https://doi.org/10.3390/su151612403

Chicago/Turabian StyleGu, Wenyu, and Wanhua Su. 2023. "Study on the Effects of Exhaust Gas Recirculation and Fuel Injection Strategy on Transient Process Performance of Diesel Engines" Sustainability 15, no. 16: 12403. https://doi.org/10.3390/su151612403

APA StyleGu, W., & Su, W. (2023). Study on the Effects of Exhaust Gas Recirculation and Fuel Injection Strategy on Transient Process Performance of Diesel Engines. Sustainability, 15(16), 12403. https://doi.org/10.3390/su151612403