The Influence of Overburden Stress and Molding Water Content on the Microstructure of Remolded Loess

Abstract

1. Introduction

2. Materials and Methods

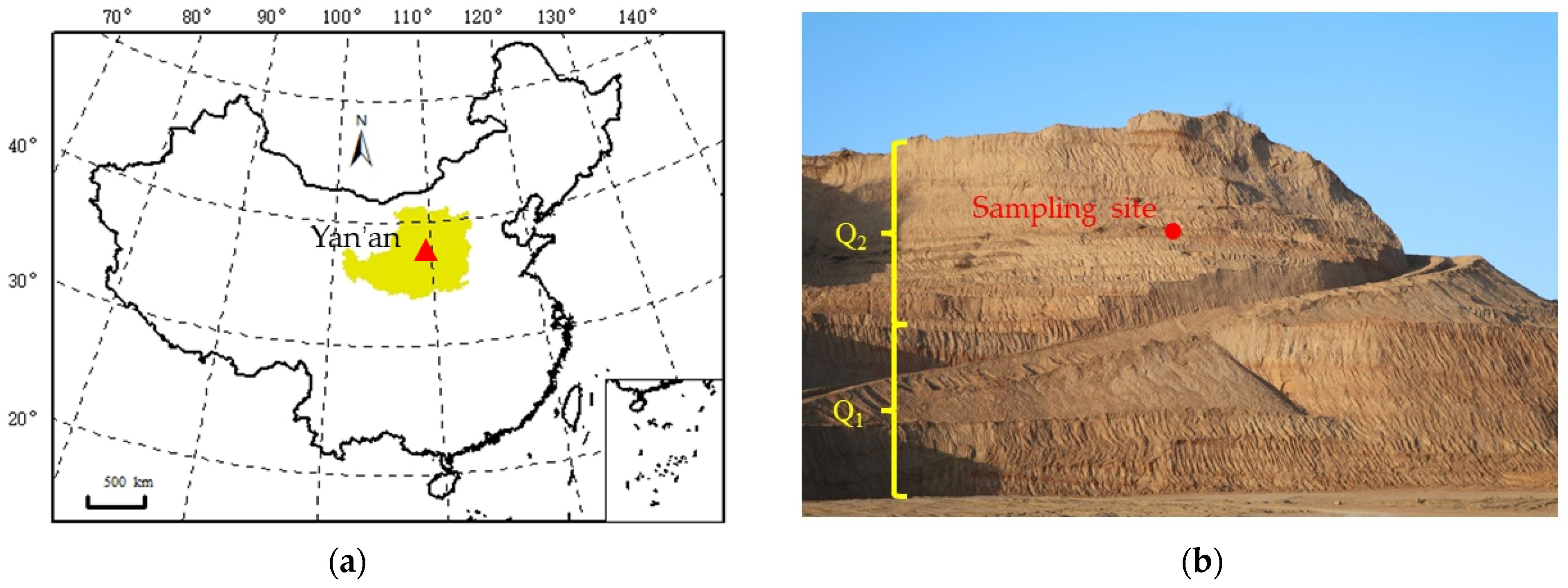

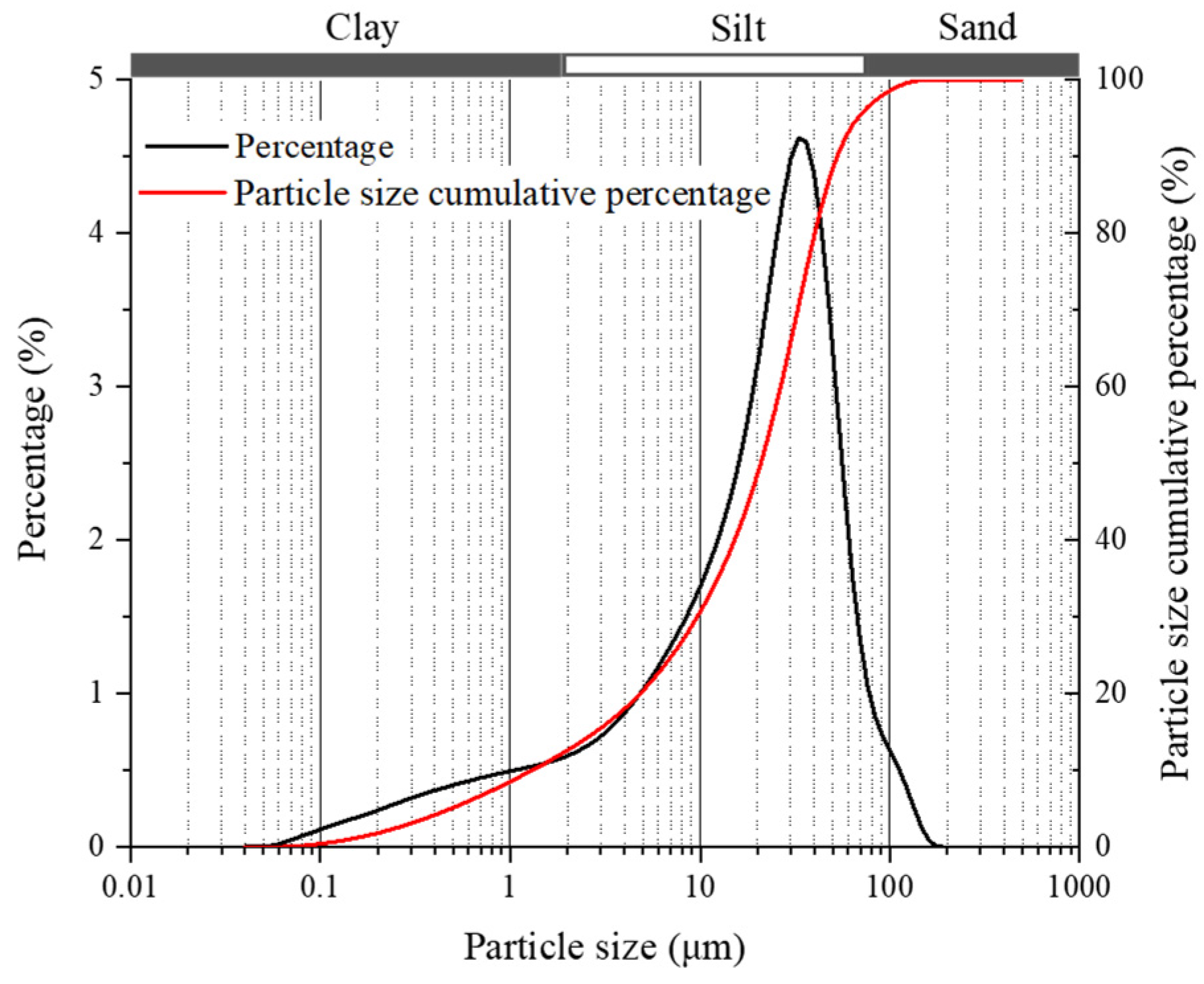

2.1. Test Materials

2.2. Sample Preparation

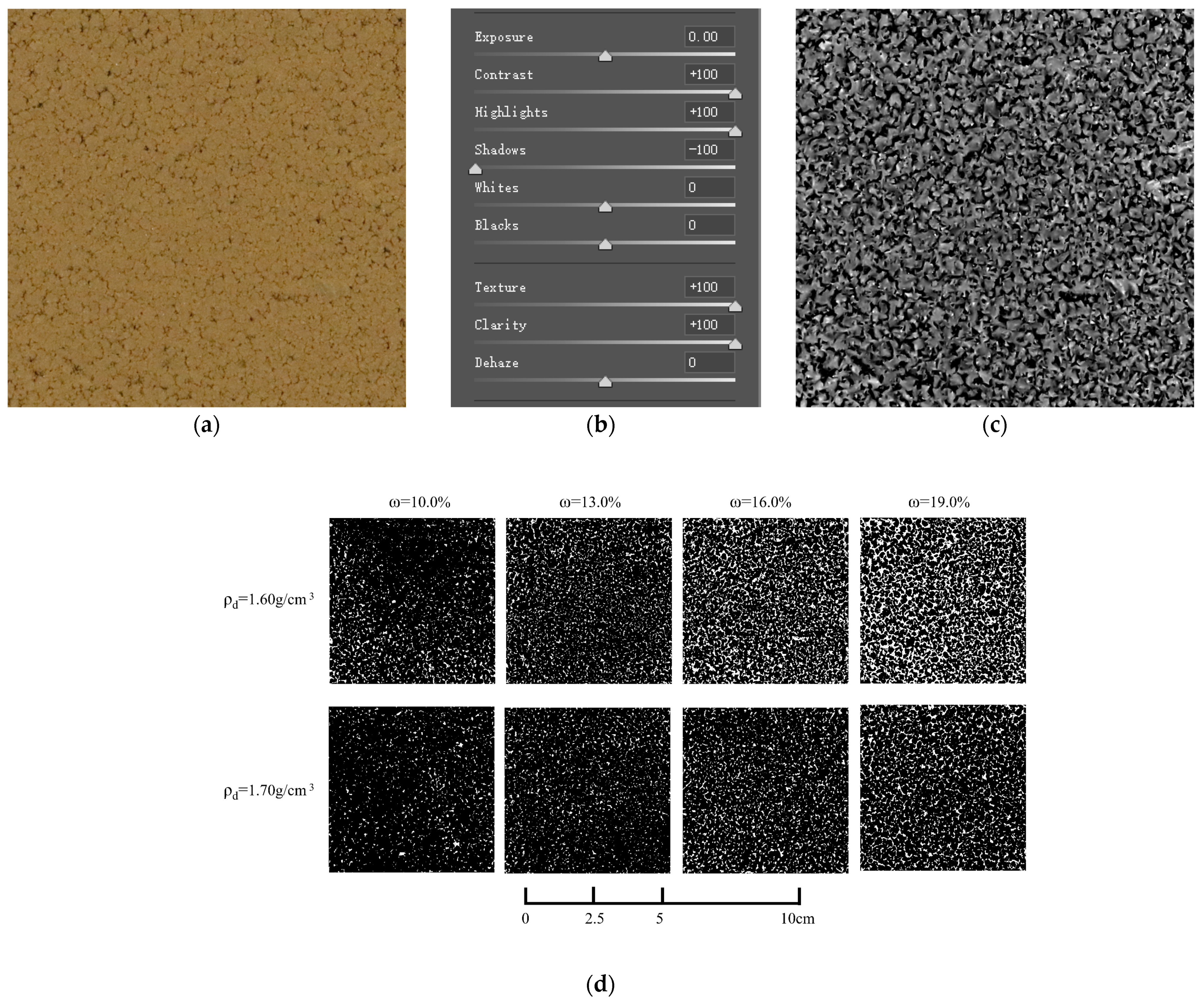

2.3. Test Method

SEM and MIP Testing

3. Test Results

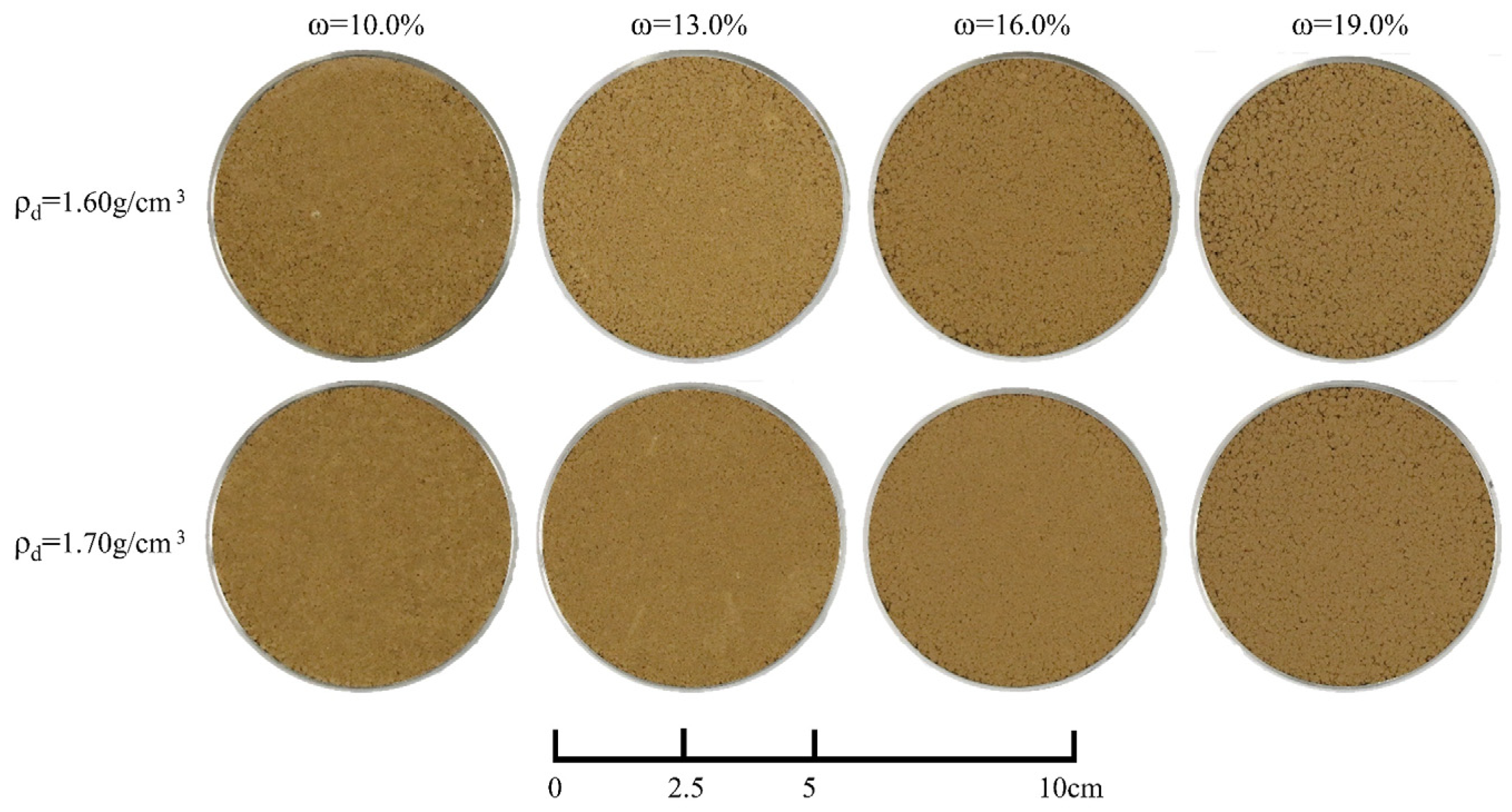

3.1. Macroscopic Characteristics of Remolded Loess

3.1.1. Macroscopic Pore Space of Remolded Loess

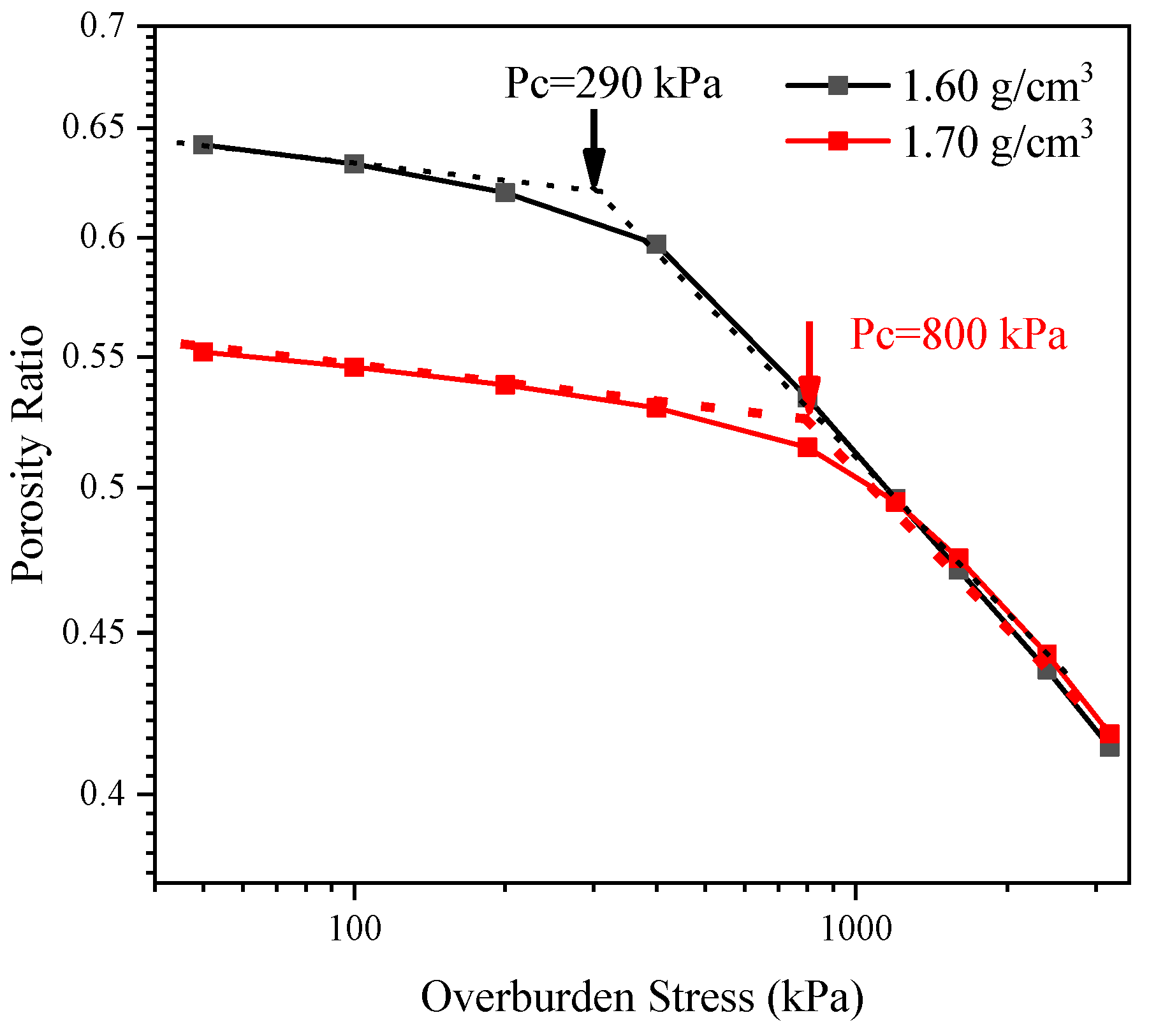

3.1.2. Compressibility of Remolded Loess

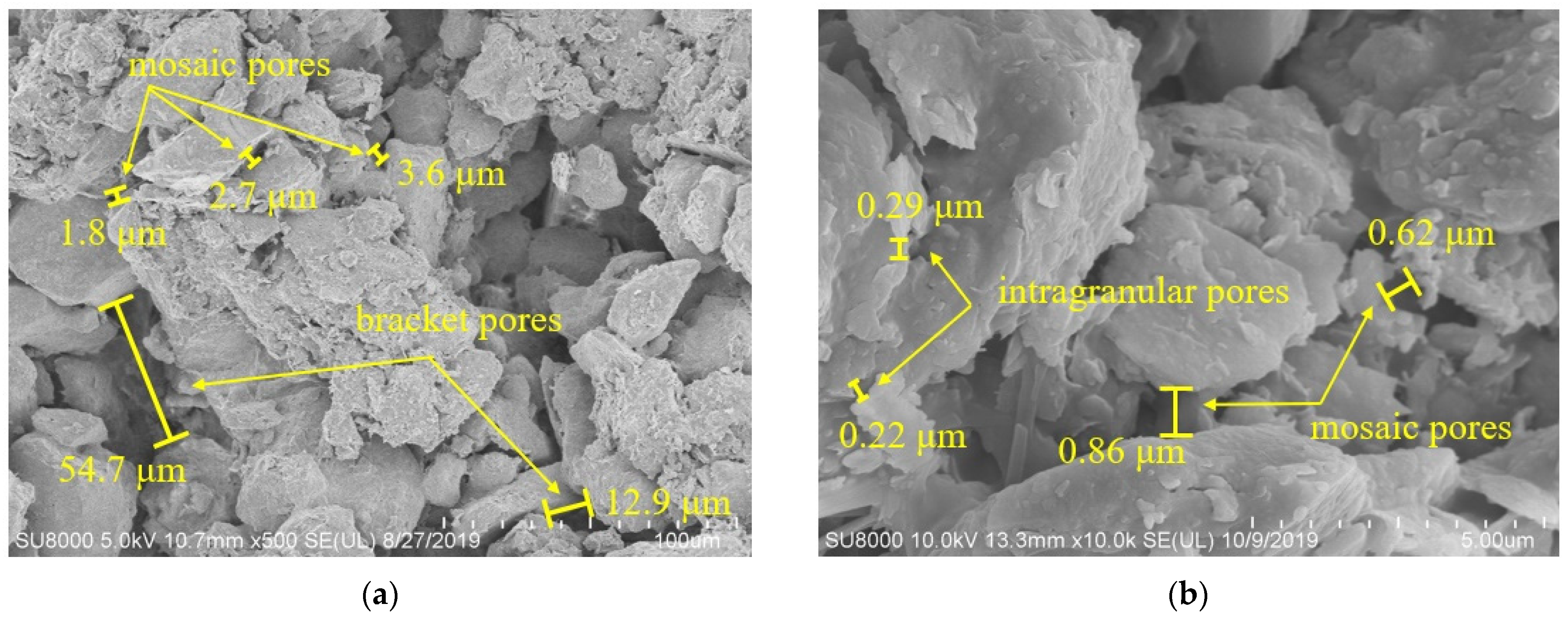

3.2. Microstructural Characteristics of Remolded Loess

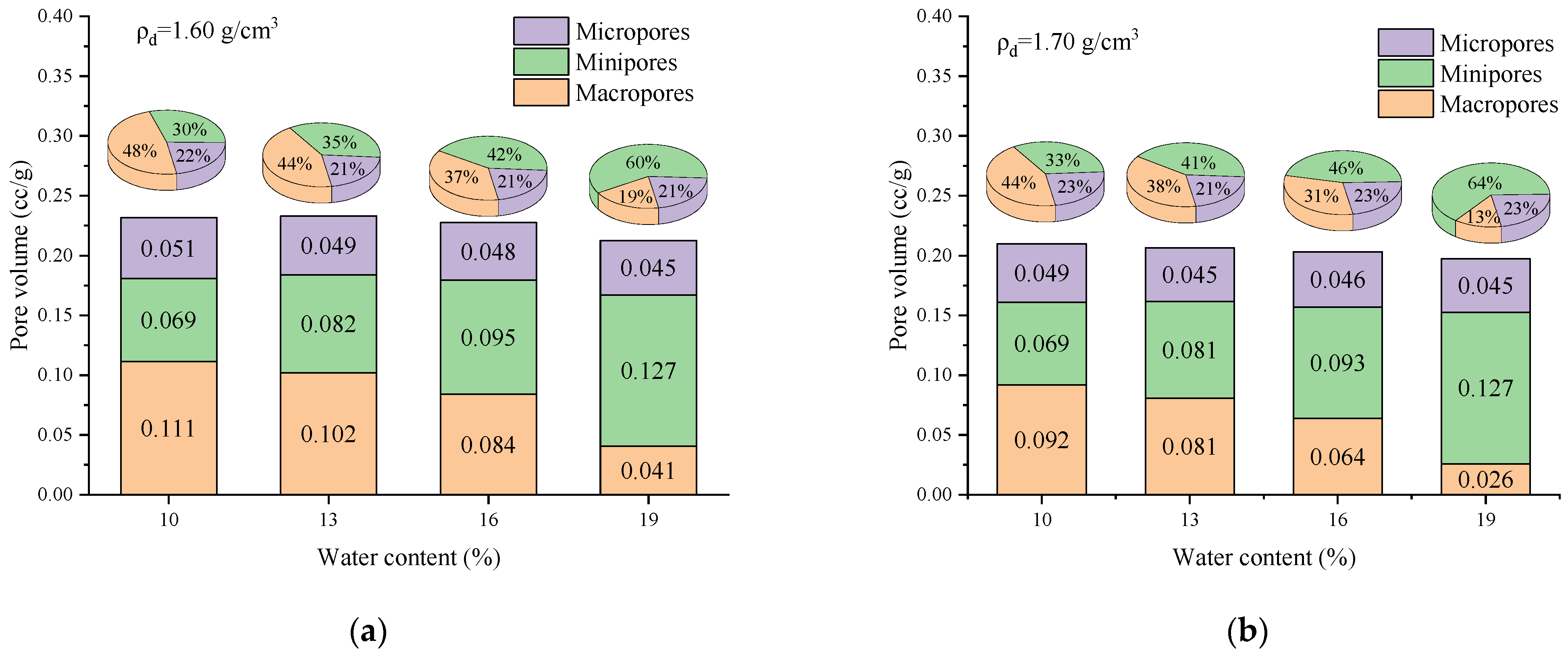

3.2.1. The Influence of Molding Water Content on the Microstructure of Remolded Loess

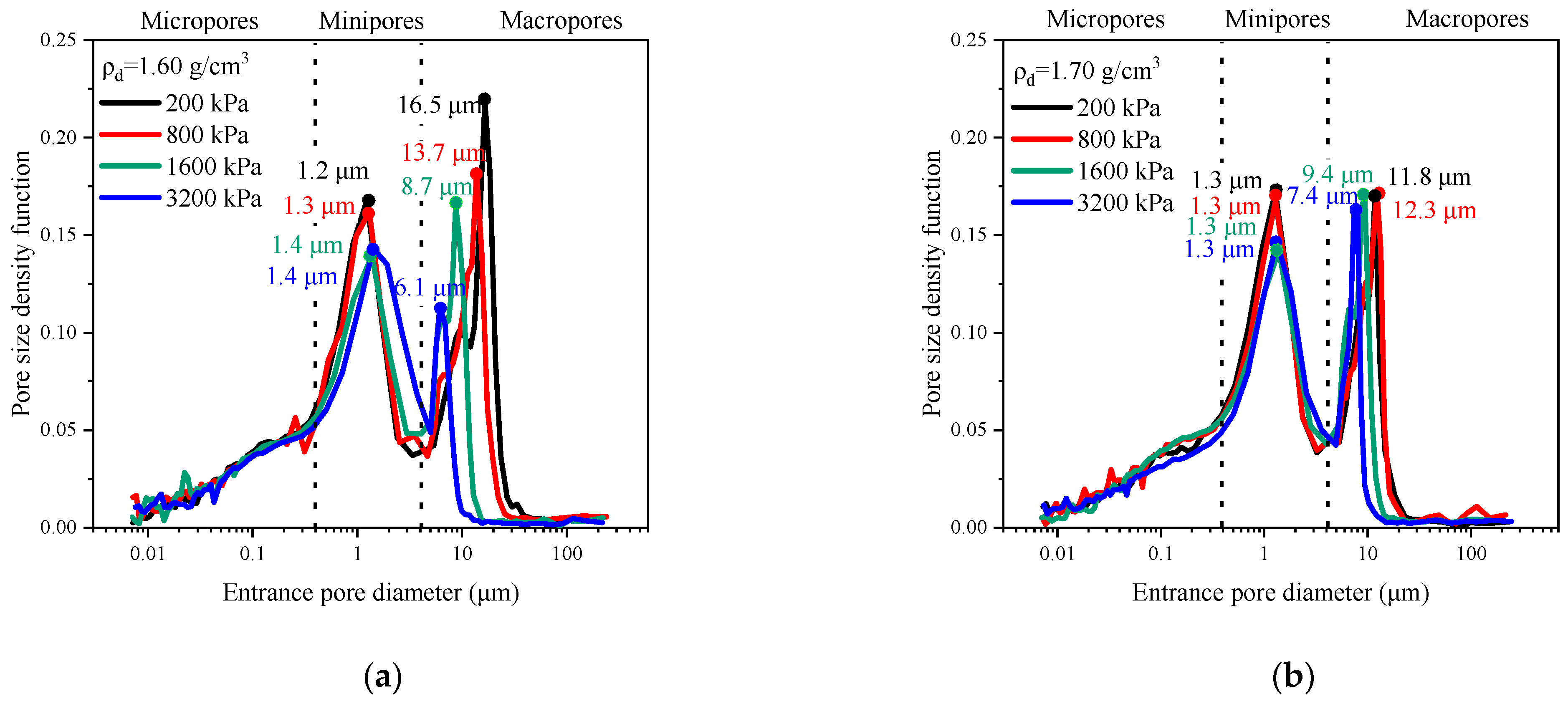

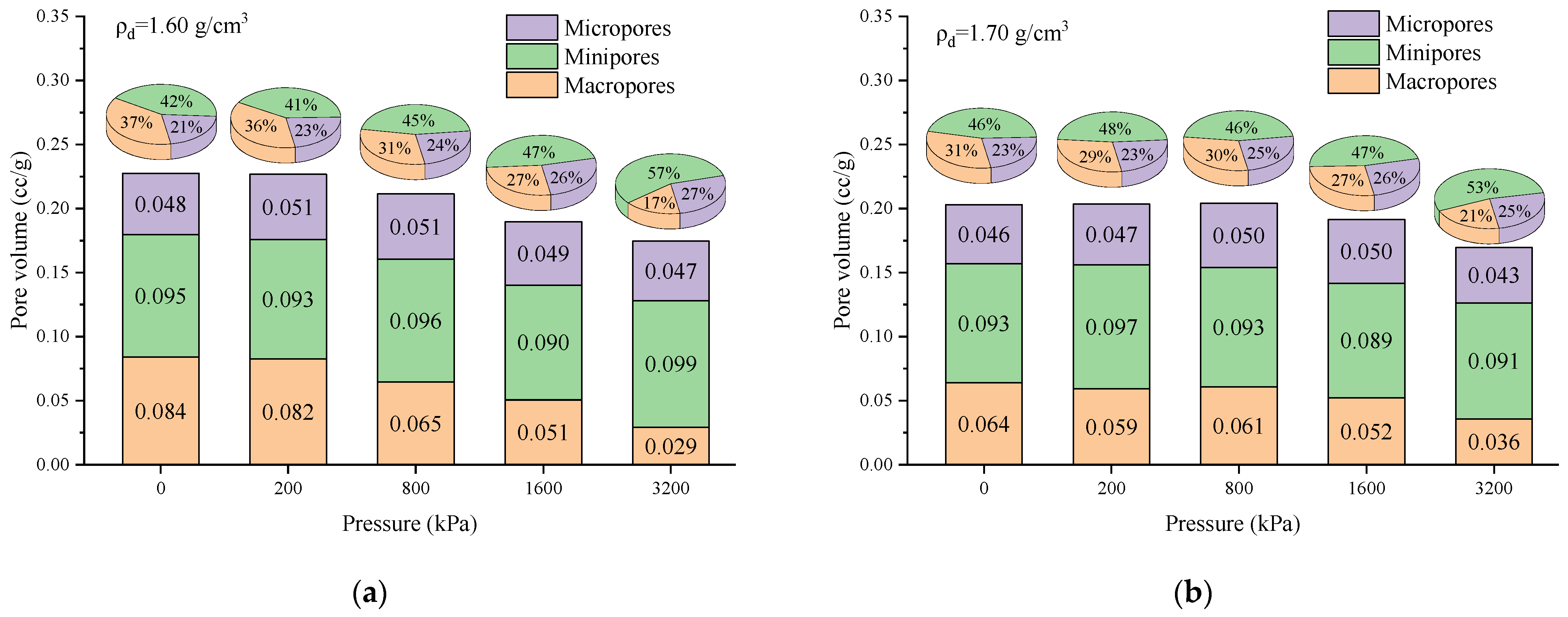

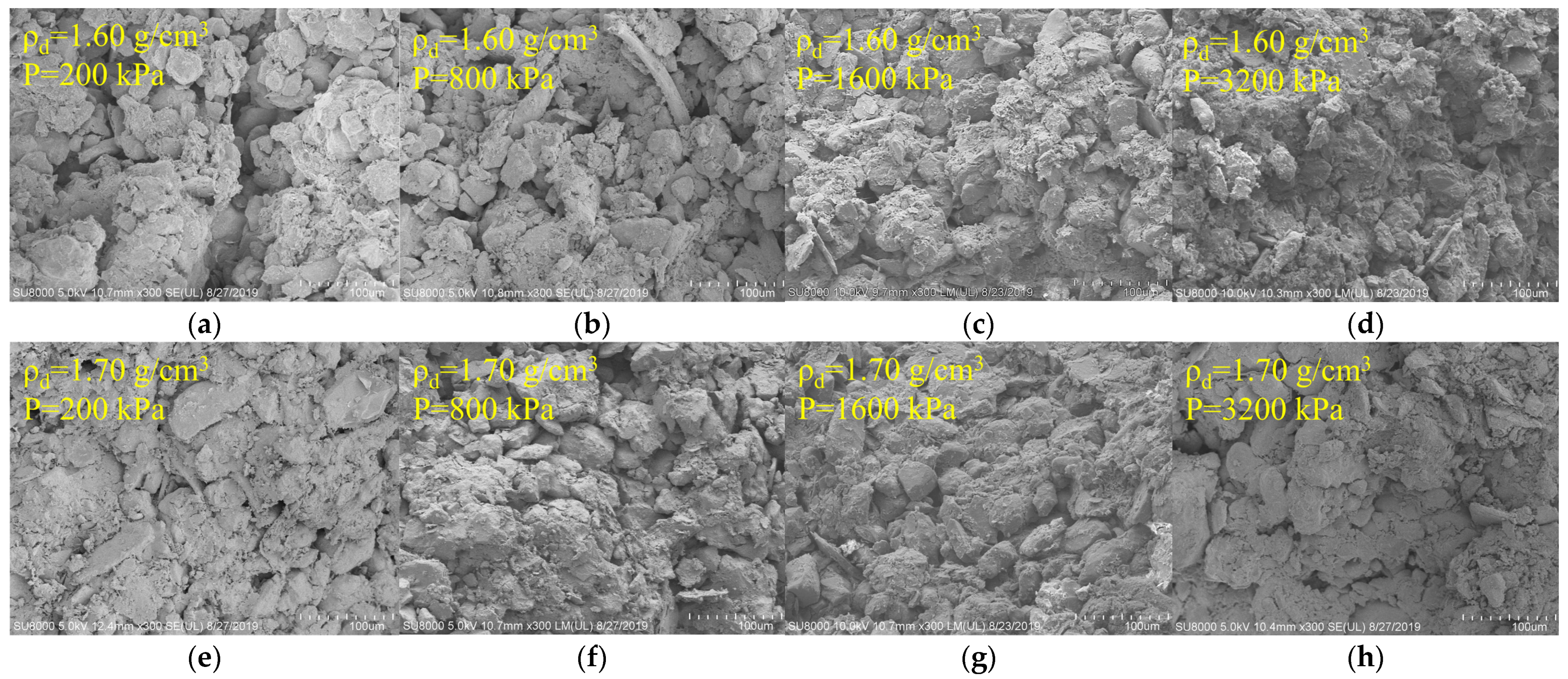

3.2.2. The Influence of Overburden Stress on the Microstructure of Remolded Loess

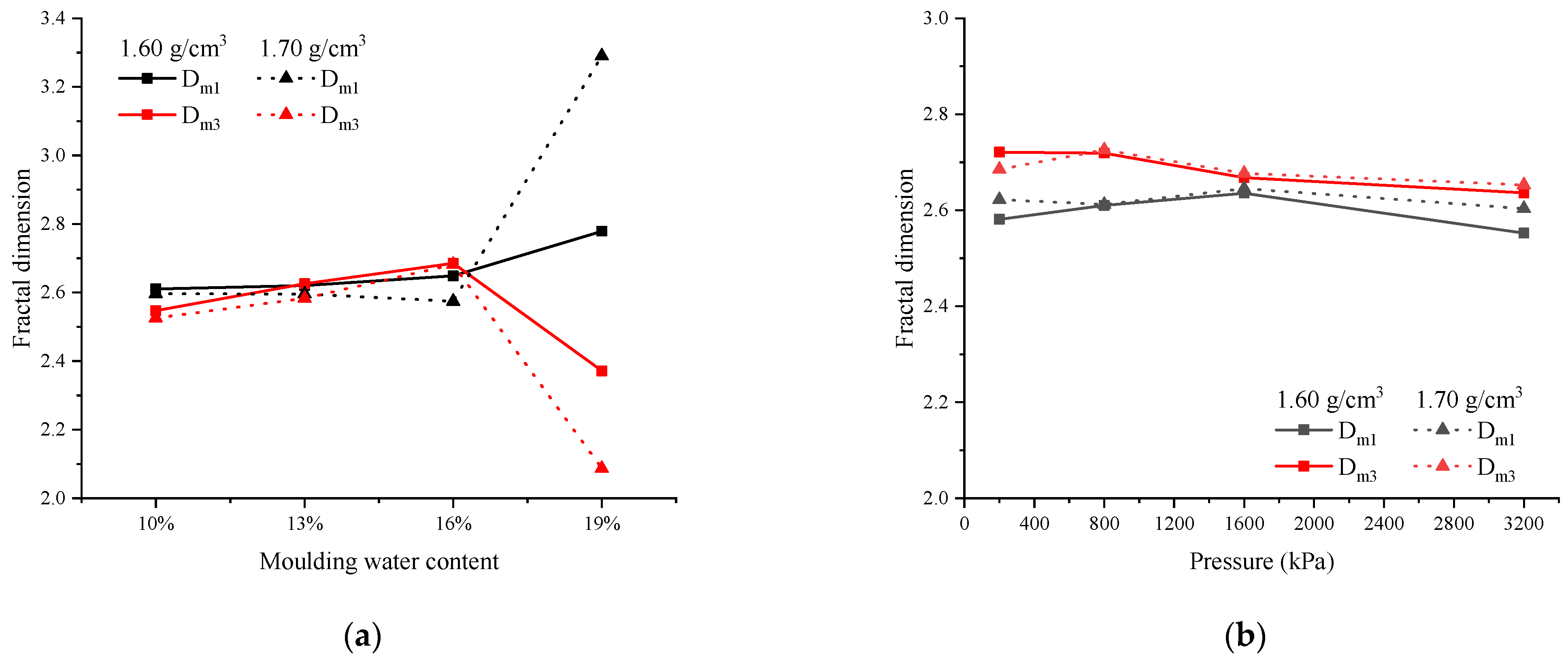

3.3. Pore Fractal Characteristics of Remodeled Loess

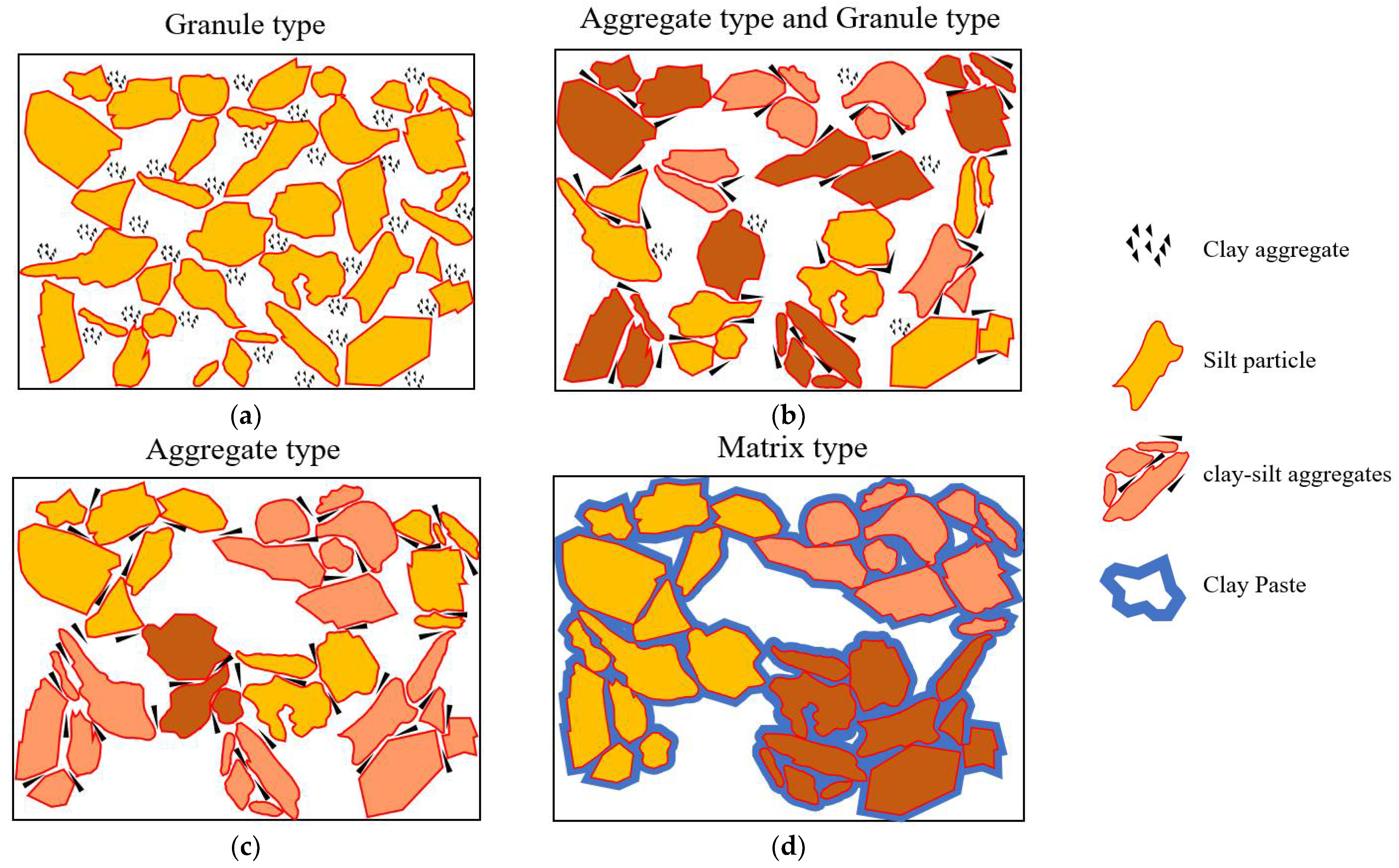

4. Discussion

5. Conclusions

- An increase in molding water content results in the enlargement of visually discernible pore volume and leads to a slenderization of their shape. However, the pore distribution consistently maintains a bimodal pattern. The volume and peak aperture of minipores (0.4–4 μm) increase, while the volume of macropores (4–200 μm) decreases, albeit with an enlargement of their peak aperture. Micropores (<0.4 μm) remain minimally affected. Changes in the pore Menger fractal dimension occur only when the molding water content surpasses the optimal level. Molding water content primarily governs the microstructure and pore distribution of remolded loess by controlling the morphology of clay;

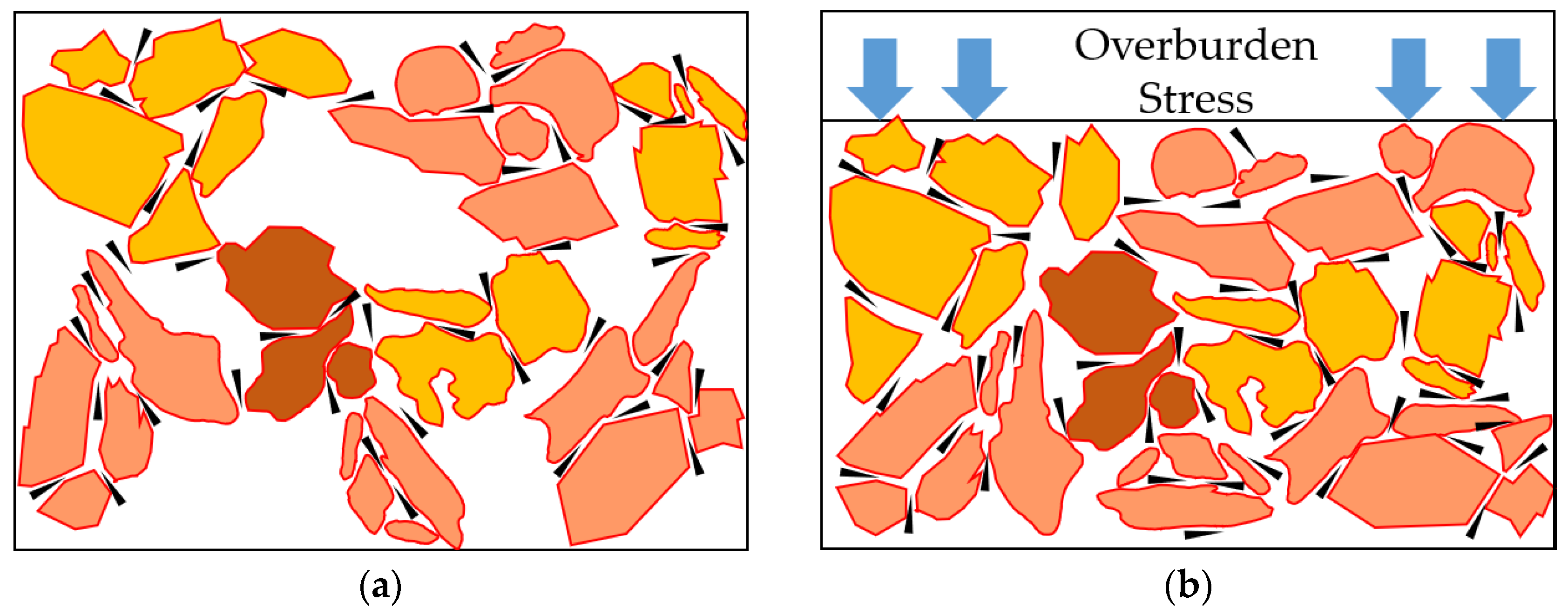

- An increase in overburden stress or dry density results in a reduction in the volume and peak aperture of macropores, while small and micropores experience negligible changes. The Menger fractal dimension also remains largely unaltered. Remolded loess exhibits a specific yield stress, wherein higher dry density leads to increased contact area between clay particles, subsequently elevating yield stress. Beyond the yield stress, significant movement of skeletal particles occurs, thereby reducing macropore volume;

- A microstructural evolution model for remolded loess under varying overburden stress and molding water content is proposed. With increasing molding water content, the microstructure of remolded loess transitions from a granule-type to an aggregate-type and, ultimately, to a matrix-type structure. Moreover, as overburden pressure surpasses yield stress, the displacement of skeletal particles in remolded loess triggers the disintegration and recombination of aggregates, leading to a progressive reduction in bracket pores.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, Y.; Zeng, R.; Yang, Z.; Chen, X.; Zhao, F.; Meng, X. Detection of Land Subsidence Associated with Land Creation and Rapid Urbanization in the Chinese Loess Plateau Using Time Series InSAR: A Case Study of Lanzhou New District. Remote Sens. 2018, 10, 270. [Google Scholar] [CrossRef]

- Wang, F.; Li, G.; Mu, Y.; Wu, Y.; Fan, S. Study on collapse characteristic of compacted loess subjected to cyclic drying and wetting. J. Glaciol. Geocryol. 2016, 38, 416–423. [Google Scholar] [CrossRef]

- Hou, X.; Qi, S.; Li, T.; Guo, S.; Wang, Y.; Li, Y.; Zhang, L. Microstructure and soil-water retention behavior of compacted and intact silt loess. Eng. Geol. 2020, 277, 105814. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural characterization of natural loess and remolded loess under triaxial tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Xu, L.; Coop, M.R.; Zhang, M.; Wang, G. The mechanics of a saturated silty loess and implications for landslides. Eng. Geol. 2018, 236, 29–42. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Sadeghi, H.; Jafarzadeh, F.; Sadeghi, M.; Zhou, C.; Baghbanrezvan, S. Effect of microstructure on shear strength and dilatancy of unsaturated loess at high suctions. Can. Geotech. J. 2019, 57, 221–235. [Google Scholar] [CrossRef]

- Vanapalli, S.K.; Fredlund, D.G.; Pufahl, D.E. The influence of soil structure and stress history on the soil-water characteristics of a compacted till. Géotechnique 1999, 49, 143–159. [Google Scholar] [CrossRef]

- Li, P.; Qian, H.; Wu, J. Environment: Accelerate research on land creation. Nature 2014, 510, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Rogers, C.D.F.; Dijkstra, T.A.; Smalley, I.J. Hydroconsolidation and subsidence of loess: Studies from China, Russia, North America and Europe: In memory of Jan Sajgalik. Eng. Geol. 1994, 37, 83–113. [Google Scholar] [CrossRef]

- Tan Tjong, K. Fundamental properties of loess from Northwestern China. Eng. Geol. 1988, 25, 103–122. [Google Scholar] [CrossRef]

- Derbyshire, E. Geological hazards in loess terrain, with particular reference to the loess regions of China. Earth-Sci. Rev. 2001, 54, 231–260. [Google Scholar] [CrossRef]

- Li, P.; Vanapalli, S.; Li, T. Review of collapse triggering mechanism of collapsible soils due to wetting. J. Rock. Mech. Geotech. 2016, 8, 256–274. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Sadeghi, H.; Hossen, S.K.B.; Chiu, C.F.; Alonso, E.E.; Baghbanrezvan, S. Water retention and volumetric characteristics of intact and re-compacted loess. Can. Geotech. J. 2016, 53, 1258–1269. [Google Scholar] [CrossRef]

- Wen, B.P.; Yan, Y.J. Influence of structure on shear characteristics of the unsaturated loess in Lanzhou, China. Eng. Geol. 2014, 168, 46–58. [Google Scholar] [CrossRef]

- Xie, W.L.; Li, P.; Zhang, M.S.; Cheng, T.-e.; Wang, Y. Collapse behavior and microstructural evolution of loess soils from the Loess Plateau of China. J. Mt. Sci.-Engl. 2018, 15, 1642–1657. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, Q.; Qian, H.; Li, M.; Yang, F. An investigation into the relationship between saturated permeability and microstructure of remolded loess: A case study from Chinese Loess Plateau. Geoderma 2021, 382, 114774. [Google Scholar] [CrossRef]

- Yuan, K.; Ni, W.; Lü, X.; Zhu, M.; Wang, H.; Nie, Y. Mechanical properties and microstructure evolution of Malan loess. Quatern. Int. 2022, 637, 74–84. [Google Scholar] [CrossRef]

- Li, P.; Xie, W.; Pak, R.Y.S.; Vanapalli, S.K. Microstructural evolution of loess soils from the Loess Plateau of China. CATENA 2019, 173, 276–288. [Google Scholar] [CrossRef]

- Liu, C.; Tang, C.S.; Shi, B.; Suo, W.B. Automatic quantification of crack patterns by image processing. Comput. Geosci. 2013, 57, 77–80. [Google Scholar] [CrossRef]

- Shao, X.; Zhang, H.; Tan, Y. Collapse behavior and microstructural alteration of remolded loess under graded wetting tests. Eng. Geol. 2018, 233, 11–22. [Google Scholar] [CrossRef]

- Wang, J.D.; Li, P.; Ma, Y.; Vanapalli, S.K. Evolution of pore-size distribution of intact loess and remolded loess due to consolidation. J. Soils Sediment. 2019, 19, 1226–1238. [Google Scholar] [CrossRef]

- Xiao, T.; Li, P.; Pan, Z.; Wang, J. Effect of compaction condition on the water retention capacity, microstructure and its evolution during drying of compacted loess. Geoenviron. Disasters 2022, 9, 27. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Yang, S.; Liu, S.; Li, Y. Characteristics of Microstructural Changes of Malan Loess in Yan’an Area during Creep Test. Water 2022, 14, 438. [Google Scholar] [CrossRef]

- Xiao, T.; Li, P.; Shao, S. Fractal dimension and its variation of intact and compacted loess. Powder Technol. 2022, 395, 476–490. [Google Scholar] [CrossRef]

- Yuan, K.; Ni, W.; Lü, X.; Vecchia, G.D.; Wang, H.; Li, L.; Nie, Y. Influence of wetting-drying cycles on the compression behavior of a compacted loess from microstructure analysis. Bull. Eng. Geol. Environ. 2022, 81, 348. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, J.; Wu, Z.; Huang, W.; Li, C.; Liu, Q. Effect of Water Content Variation on the Tensile Characteristic of Clayey Loess in Ili Valley, China. Appl. Sci. 2022, 12, 8470. [Google Scholar] [CrossRef]

- Liu, D. Loess and the Environment; Science Press: Beijing, China, 1985. [Google Scholar]

- Romero, E.; Simms, P.H. Microstructure Investigation in Unsaturated Soils: A Review with Special Attention to Contribution of Mercury Intrusion Porosimetry and Environmental Scanning Electron Microscopy. Geotech. Geol. Eng. 2008, 26, 705–727. [Google Scholar] [CrossRef]

- Delage, P.; Audiguier, M.; Cui, Y.-J.; Howat, M.D. Microstructure of a compacted silt. Can. Geotech. J. 1996, 33, 150–158. [Google Scholar] [CrossRef]

- Liu, C.; Shi, B.; Zhou, J.; Tang, C. Quantification and characterization of microporosity by image processing, geometric measurement and statistical methods: Application on SEM images of clay materials. Appl. Clay Sci. 2011, 54, 97–106. [Google Scholar] [CrossRef]

- Prakash, K.; Sridharan, A. Log-Log Method of Pre-consolidation/Yield Stress Determination: An Appraisal. Geotech. Geol. Eng. 2020, 38, 947–959. [Google Scholar] [CrossRef]

- Jose, B.T.; Sridharan, A.; Abraham, B. Log-log method for determination of preconsolidation pressure. Geotech. Test. J. 1989, 12, 230–237. [Google Scholar] [CrossRef]

- Lei, X. Pore types of loess soils in China and its collapsibility. Sci. China B 1987, 12, 1310–1316. [Google Scholar]

- Friesen, W.I.; Mikula, R.J. Fractal dimensions of coal particles. J. Colloid Interface Sci. 1987, 120, 263–271. [Google Scholar] [CrossRef]

- Sun, H.; Mašín, D.; Najser, J.; Neděla, V.; Navrátilová, E. Fractal characteristics of pore structure of compacted bentonite studied by ESEM and MIP methods. Acta Geotech. 2020, 15, 1655–1671. [Google Scholar] [CrossRef]

- Ou, K.; Wang, C.; Cao, R.-H.; Lin, H.; Fang, L. Experimental investigation of the pore fractal characteristics and damage degradation mechanism of sandstone after cyclic Freeze-thaw treatments. J. Mater. Res. Technol. 2023, 23, 4843–4859. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, H.; Li, J.; Li, H.; Ma, W. Study on the Changing Rules of Silty Clay’s Pore Structure under Freeze-Thaw Cycles. Adv. Civ. Eng. 2019, 2019, 7493872. [Google Scholar] [CrossRef]

- Pfeifer, P.; Avnir, D. Chemistry in noninteger dimensions between two and three. I. Fractal theory of heterogeneous surfaces. J. Chem. Phys. 1983, 79, 3558–3565. [Google Scholar] [CrossRef]

- Li, P.; Pan, Z.; Xiao, T.; Wang, J. Effects of molding water content and compaction degree on the microstructure and permeability of compacted loess. Acta Geotech. 2023, 18, 921–936. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Q.; Li, P.; He, P.; Pu, C.; Zhao, K.; Peng, D.; Wang, Z. Saturated permeability of compacted loess based on low-field nuclear magnetic resonance (NMR). Bull. Eng. Geol. Environ. 2022, 81, 464. [Google Scholar] [CrossRef]

- Sasanian, S.; Newson, T.A. Use of mercury intrusion porosimetry for microstructural investigation of reconstituted clays at high water contents. Eng. Geol. 2013, 158, 15–22. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, F.; Ma, F.; Wang, M.; Bai, X.; Zheng, Y.; Yin, H.; Zhang, G. Collapsibility, composition, and microstructure of loess in China. Can. Geotech. J. 2016, 53, 673–686. [Google Scholar] [CrossRef]

| Moisture Content ω (%) | Dry Density ρ (g/cm3) | Specific Gravity Gs | Atterberg Limits (%) | Grain-Size Distribution (μm, %) | Optimum Moisture Content ω (%) | Maximum Dry Density (g/cm3) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Liquid Limit ωL | Plastic Limit ωP | Plasticity Index IP | Sand (>75) | Silt (75–5) | Clay (<5) | |||||

| 13.3 | 1.54 | 2.71 | 28.5 | 18.7 | 9.8 | 3.7 | 74.8 | 21.5 | 16 | 1.80 |

| Mineral | Quartz | K-Feldspar | Plagioclase | Calcspar | Dolomite | Pyrite | Total Amount of Caly Minerals |

|---|---|---|---|---|---|---|---|

| Content (%) | 38.9 | 4.0 | 12.5 | 16.8 | 3.9 | 2.4 | 21.5 |

| Sample ID | Dry Density g/cm3 | Water Content % | Consolidation Pressure kPa |

|---|---|---|---|

| W-1.6-10 | 1.60 | 10.0 | 0 |

| W-1.6-13 | 13.0 | ||

| W-1.6-16 | 16.0 | ||

| W-1.6-19 | 19.0 | ||

| W-1.7-10 | 1.70 | 10.0 | 0 |

| W-1.7-13 | 13.0 | ||

| W-1.7-16 | 16.0 | ||

| W-1.7-19 | 19.0 | ||

| C-1.6-200 | 1.60 | 16.0 | 200 |

| C-1.6-800 | 800 | ||

| C-1.6-1600 | 1600 | ||

| C-1.6-3200 | 3200 | ||

| C-1.7-200 | 1.70 | 16.0 | 200 |

| C-1.7-800 | 800 | ||

| C-1.7-1600 | 1600 | ||

| C-1.7-3200 | 3200 |

| Sample ID | Dm1 | Dm2 | Dm3 |

|---|---|---|---|

| W-1.6-10 | 2.61048 | 7.43070 | 2.54722 |

| W-1.6-13 | 2.62053 | 7.81859 | 2.62541 |

| W-1.6-16 | 2.64831 | 6.31308 | 2.68520 |

| W-1.6-19 | 2.77874 | 5.24280 | 2.37166 |

| W-1.7-10 | 2.5961 | 8.54381 | 2.52552 |

| W-1.7-13 | 2.59564 | 9.81093 | 2.58307 |

| W-1.7-16 | 2.57450 | 7.35865 | 2.68182 |

| W-1.7-19 | 3.29024 | 5.64443 | 2.08718 |

| C-1.6-200 | 2.58117 | 7.16689 | 2.72107 |

| C-1.6-800 | 2.60997 | 8.12846 | 2.71913 |

| C-1.6-1600 | 2.69288 | 9.68280 | 2.66771 |

| C-1.6-3200 | 2.55239 | 8.02293 | 2.63612 |

| C-1.7-200 | 2.62184 | 7.37648 | 2.68542 |

| C-1.7-800 | 2.61201 | 7.80125 | 2.72574 |

| C-1.7-1600 | 2.64515 | 9.95030 | 2.6769 |

| C-1.7-3200 | 2.60360 | 9.55646 | 2.65292 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, Z.; Li, Z. The Influence of Overburden Stress and Molding Water Content on the Microstructure of Remolded Loess. Sustainability 2023, 15, 12401. https://doi.org/10.3390/su151612401

Qi Z, Li Z. The Influence of Overburden Stress and Molding Water Content on the Microstructure of Remolded Loess. Sustainability. 2023; 15(16):12401. https://doi.org/10.3390/su151612401

Chicago/Turabian StyleQi, Zhiyu, and Zhiqing Li. 2023. "The Influence of Overburden Stress and Molding Water Content on the Microstructure of Remolded Loess" Sustainability 15, no. 16: 12401. https://doi.org/10.3390/su151612401

APA StyleQi, Z., & Li, Z. (2023). The Influence of Overburden Stress and Molding Water Content on the Microstructure of Remolded Loess. Sustainability, 15(16), 12401. https://doi.org/10.3390/su151612401