The Study on Solving Large Pore Heat Transfer Simulation in Malan Loess Based on Volume Averaging Method Combined with CT Scan Images

Abstract

1. Introduction

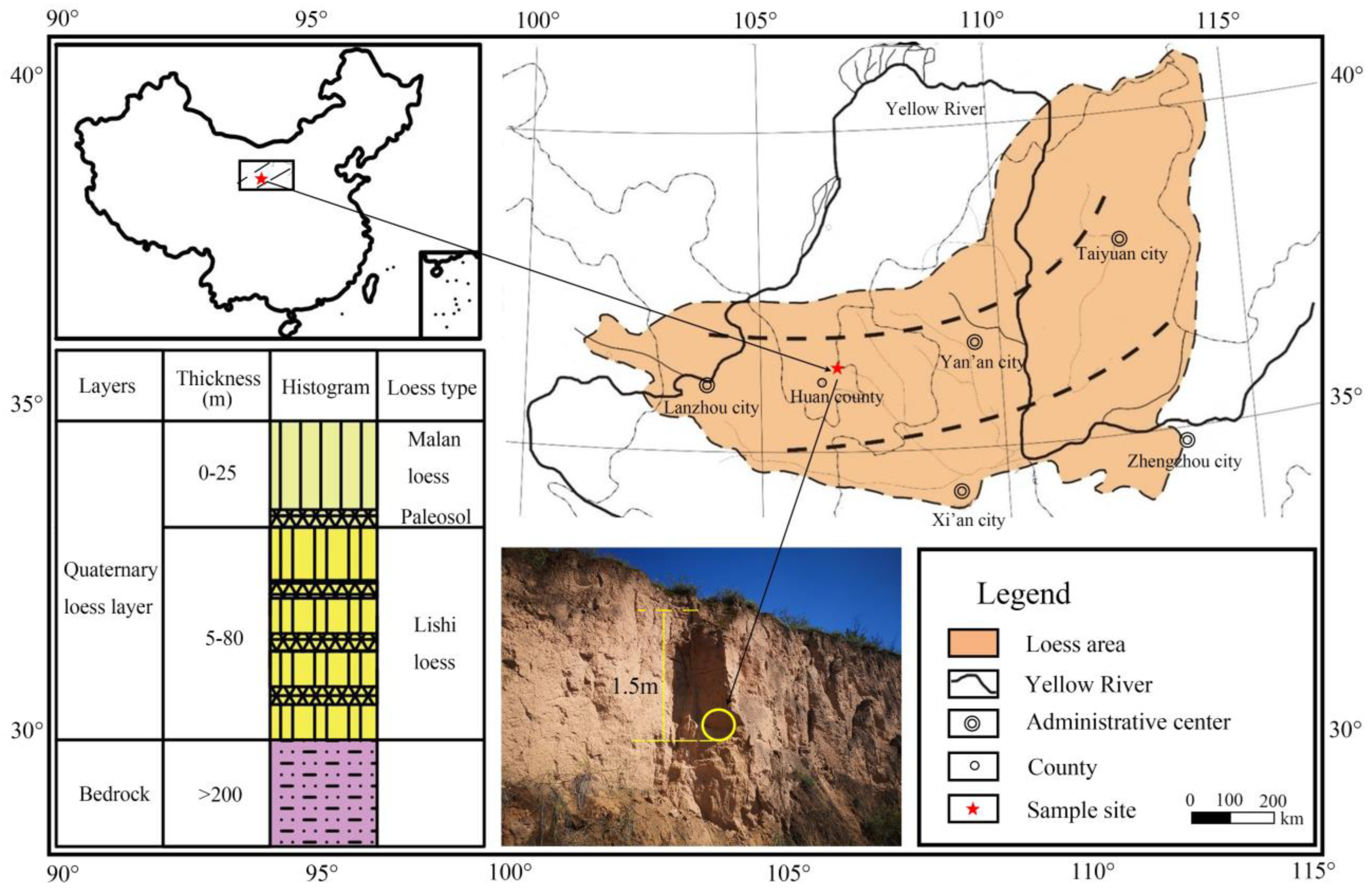

2. Study Area and Dataset

2.1. Collection and Preparation of Malan Loess Samples

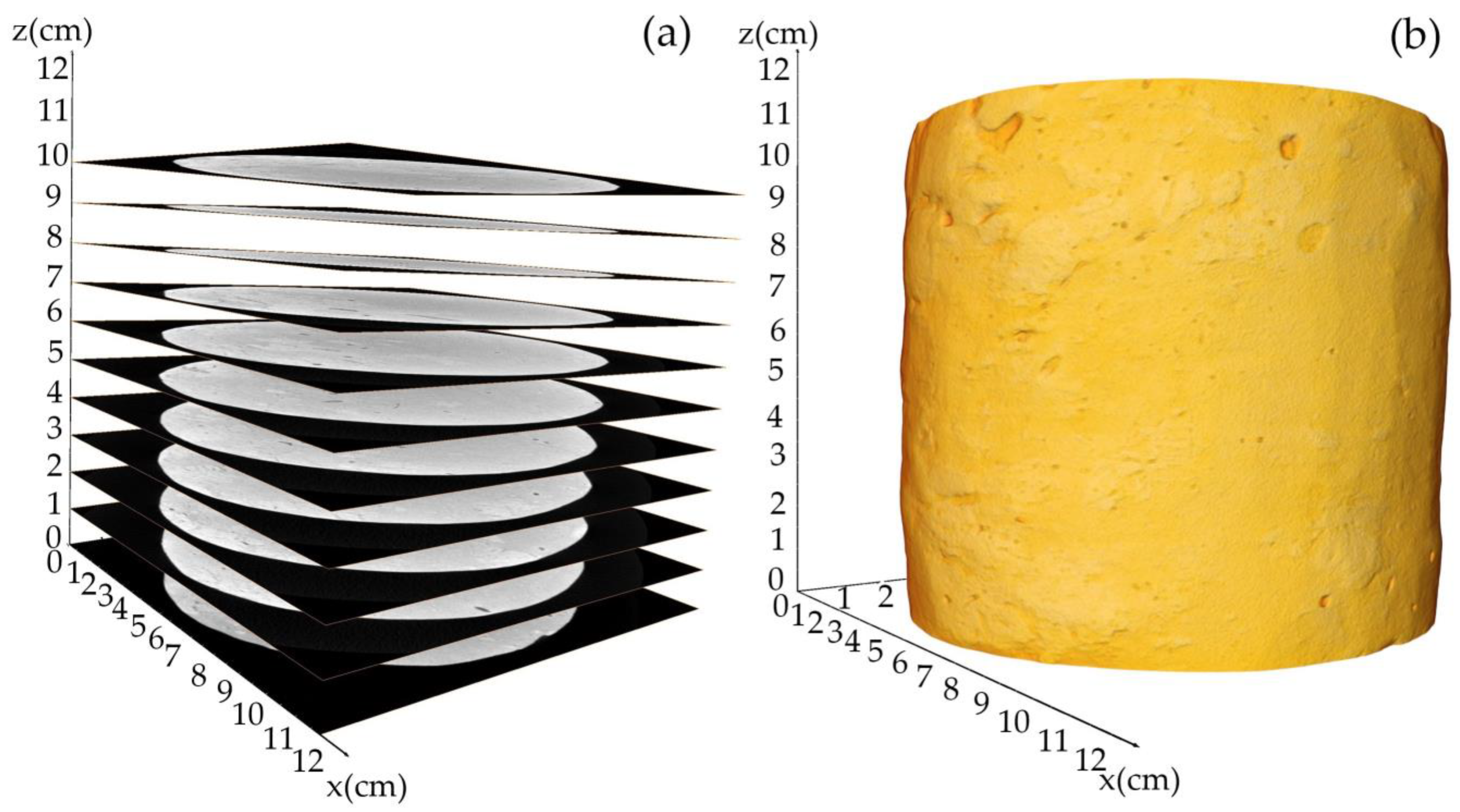

2.2. CT Scan

3. Methods

3.1. Intact Loess Heat Conduction Experiment

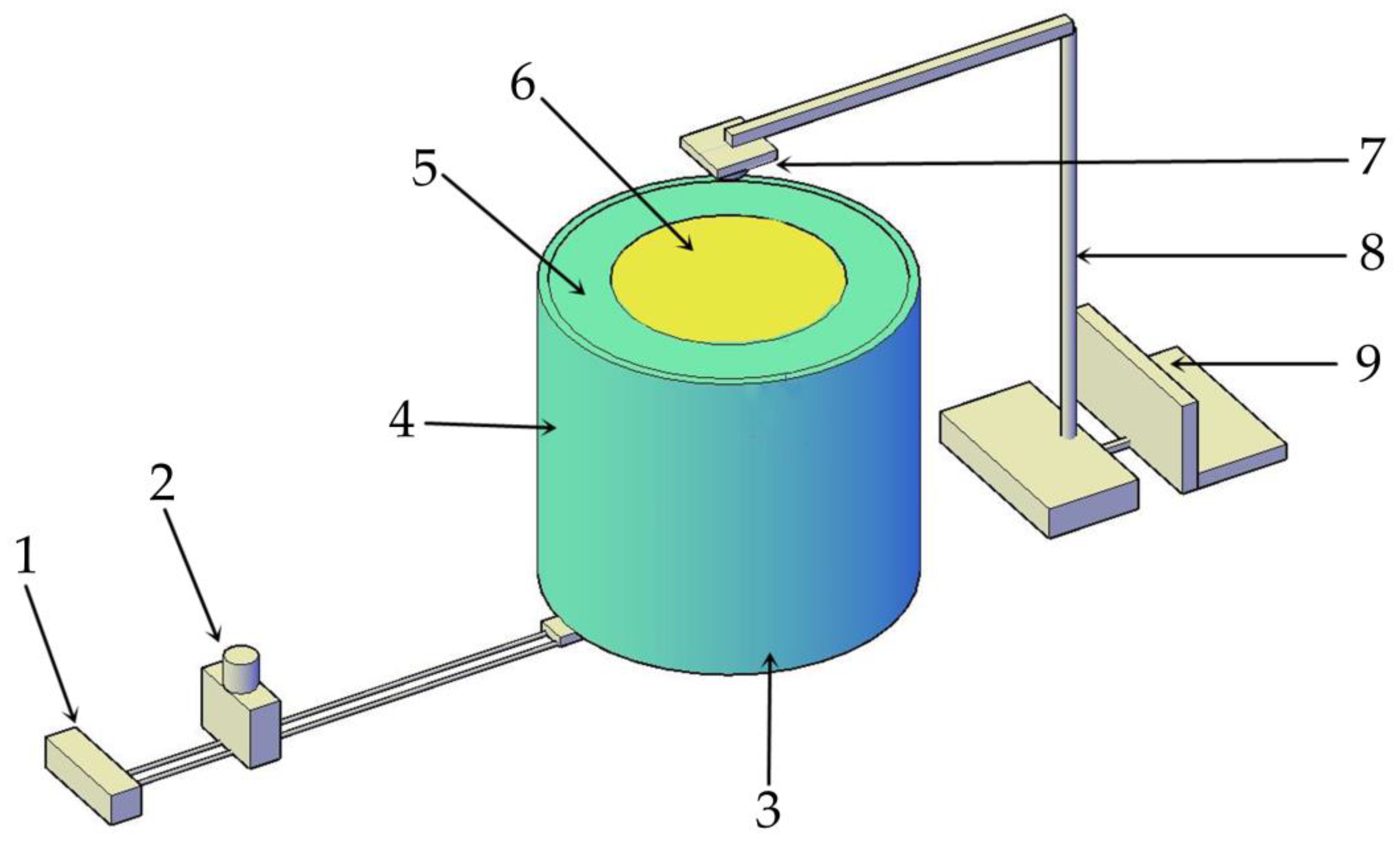

3.1.1. Experimental Design and Experimental Setup

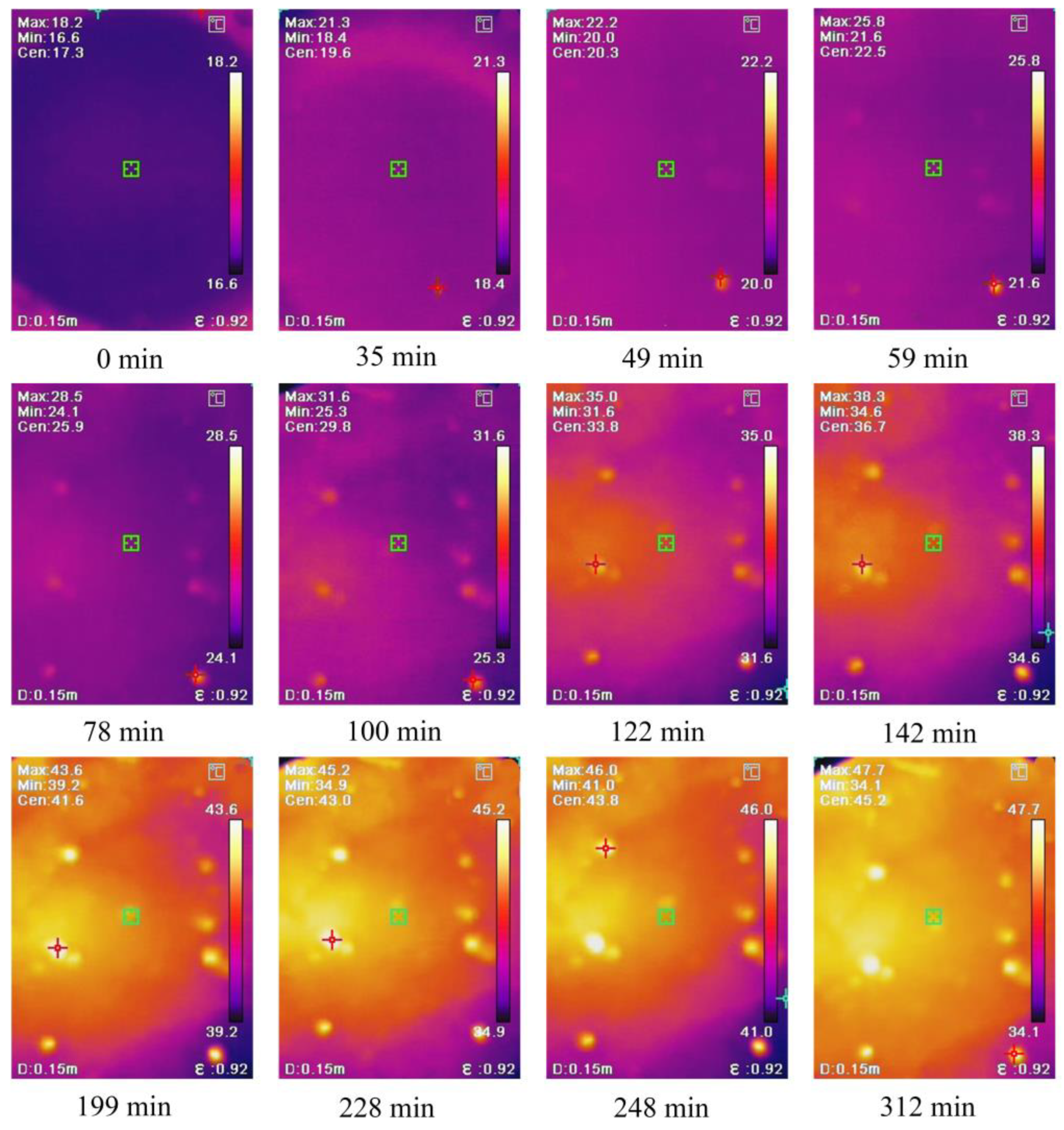

3.1.2. Thermal Imaging Experiments

3.1.3. Thermal Imaging Validation Experiments

3.2. Heat Conduction Simulation of Intact Malan Loess

3.2.1. Fundamentals

3.2.2. Conditions for the Application of the Equation

- (1)

- The solid skeleton is incompressible () and is fixed and immobile (). In this heat conduction simulation, the pore skeleton structure of the intact Malan loess was extracted using CT scan images, and the 3D model parameters of the pore structure could be extracted quantitatively. In order to ensure the expansion of the soil in the Malan loess during the heat conduction experiments, a heat-insulating Styrofoam was fixed between the Malan loess and the PVC pipe, which on the one hand provided thermal insulation and preservation, and on the other hand overcame the expansion of the soil during the heating process and changed the pore skeleton (although this phenomenon was minimal).

- (2)

- The thermal conductivity of the solid and gas phases is a constant, that is . Enthalpy: , where . In this study, when doing the heat transfer experiments of the intact Malan loess, the intact sample was dried and a uniform heat source was added at the bottom to provide a stable heat drive, allowing heat to form thermal convection in the pore skeleton of the Malan loess. And the pore skeleton in the intact Malan loess is extracted unions obtained from CT scans, and only the heat convection process is calculated during the heat transfer simulation, with the thermal conductivity of the gas phase as a constant.

- (3)

- There is no chemical reaction in each phase, and there is no mass source or sink. Ignore the compressibility of gases. The gas phase dissipation is also zero, and . is liquid temperature and is gas temperature.

- (4)

- The surface energy of the solid–gas two-phase interface is negligible.

- (5)

- Near the solid wall , there is no slip flow occurs.

3.2.3. Solution Method

3.2.4. Discretization of Systems of Equations and System Resolution

4. Results and Analysis

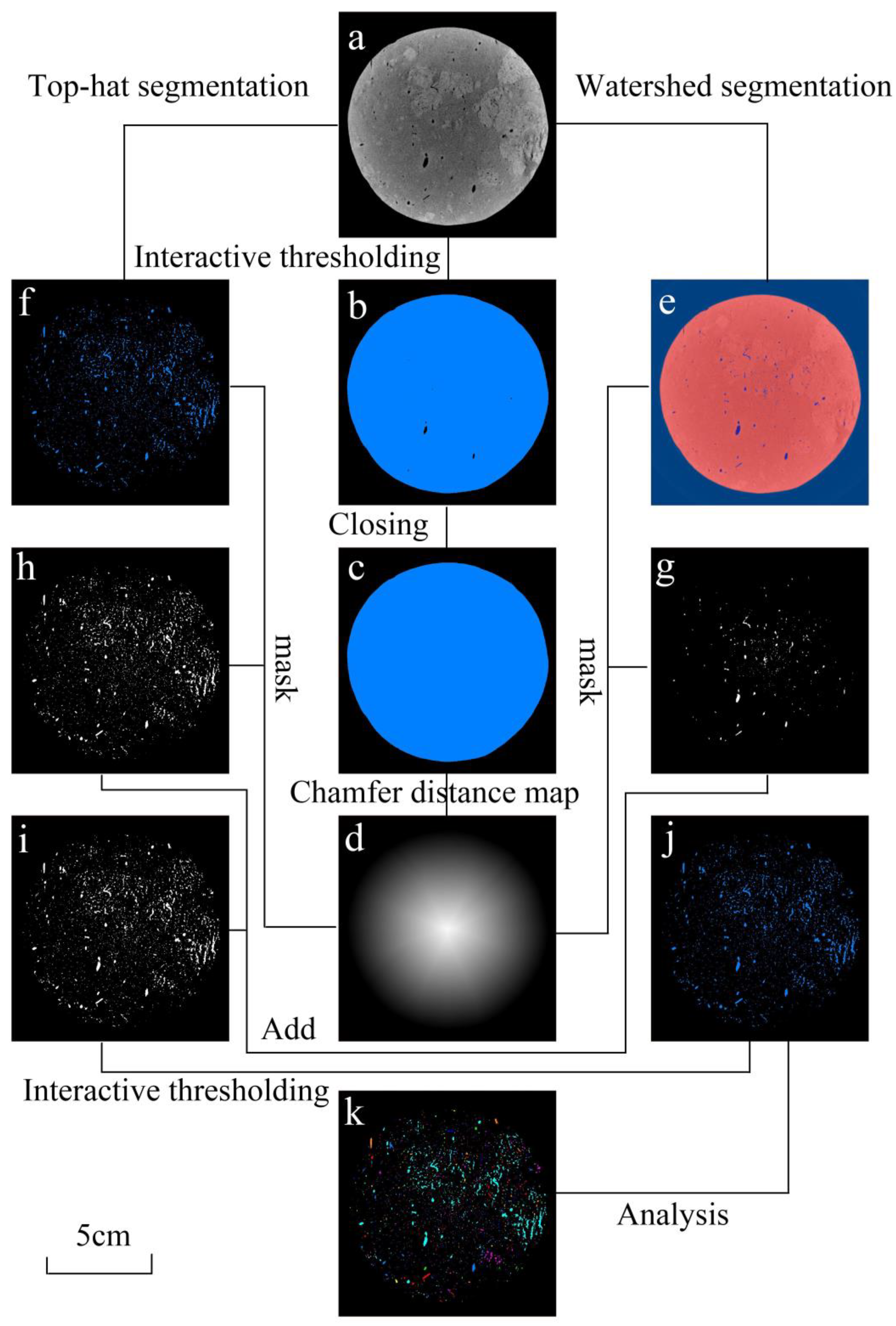

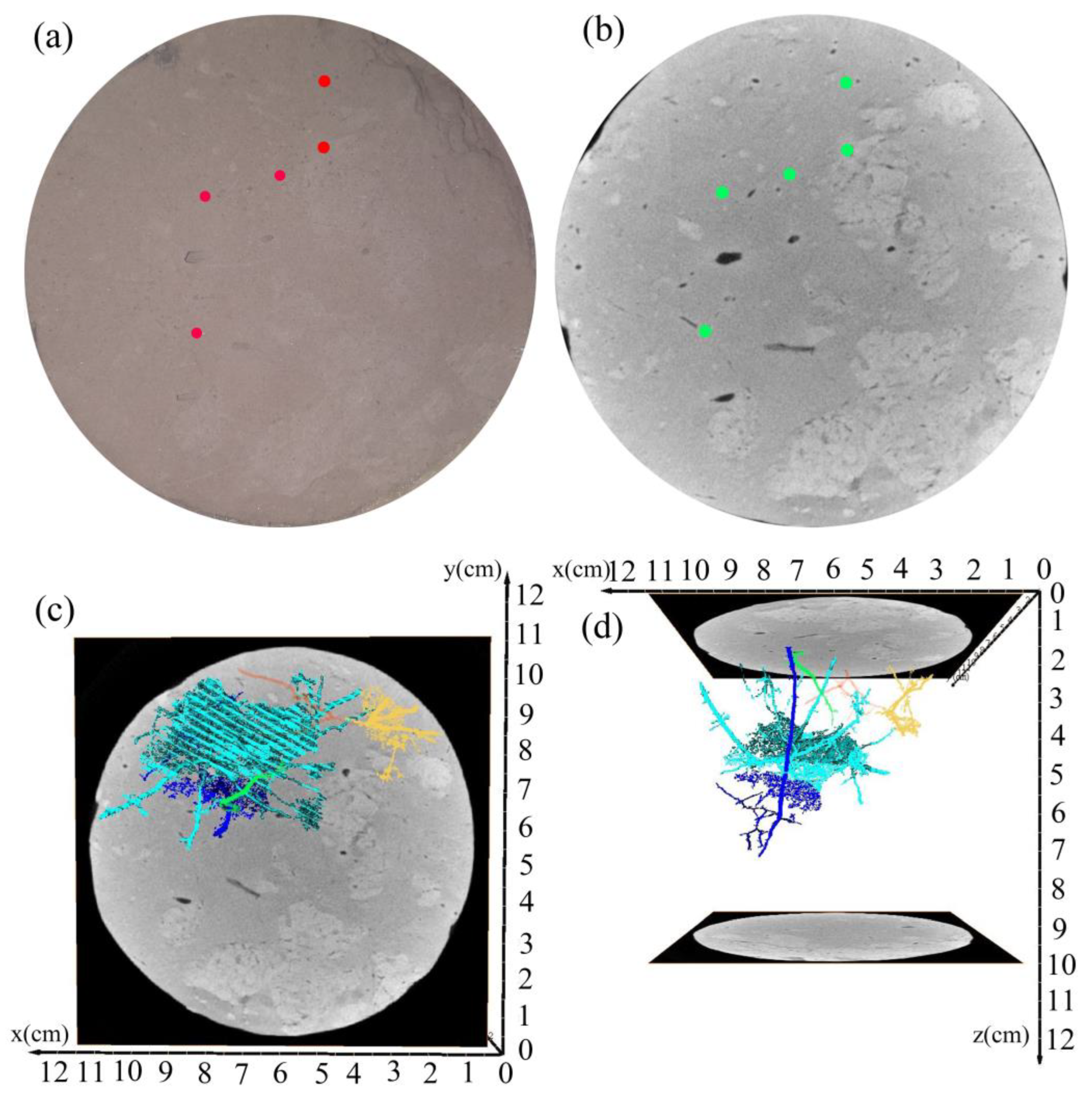

4.1. CT Scan Section Processing

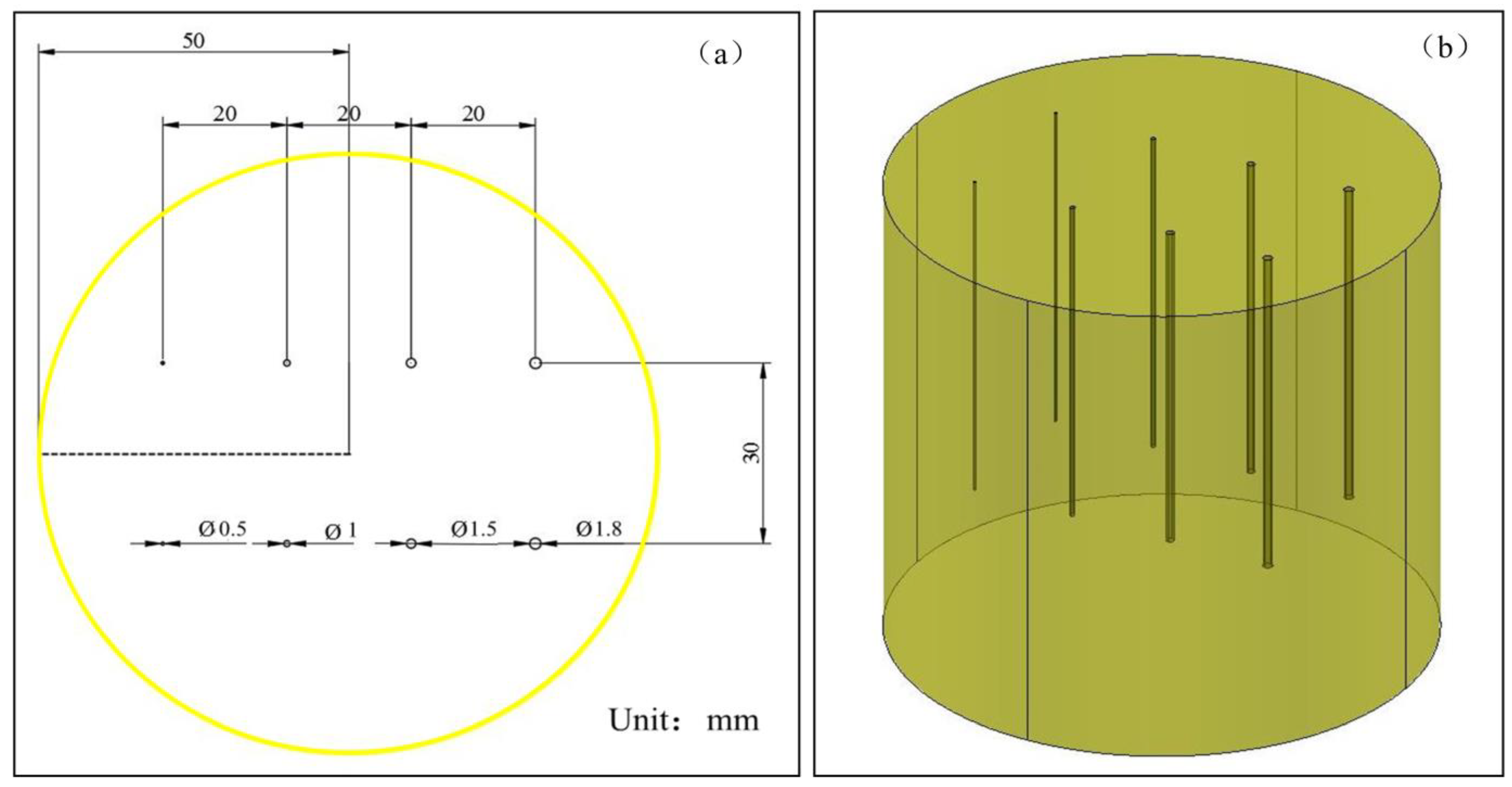

4.2. Pore Network Model

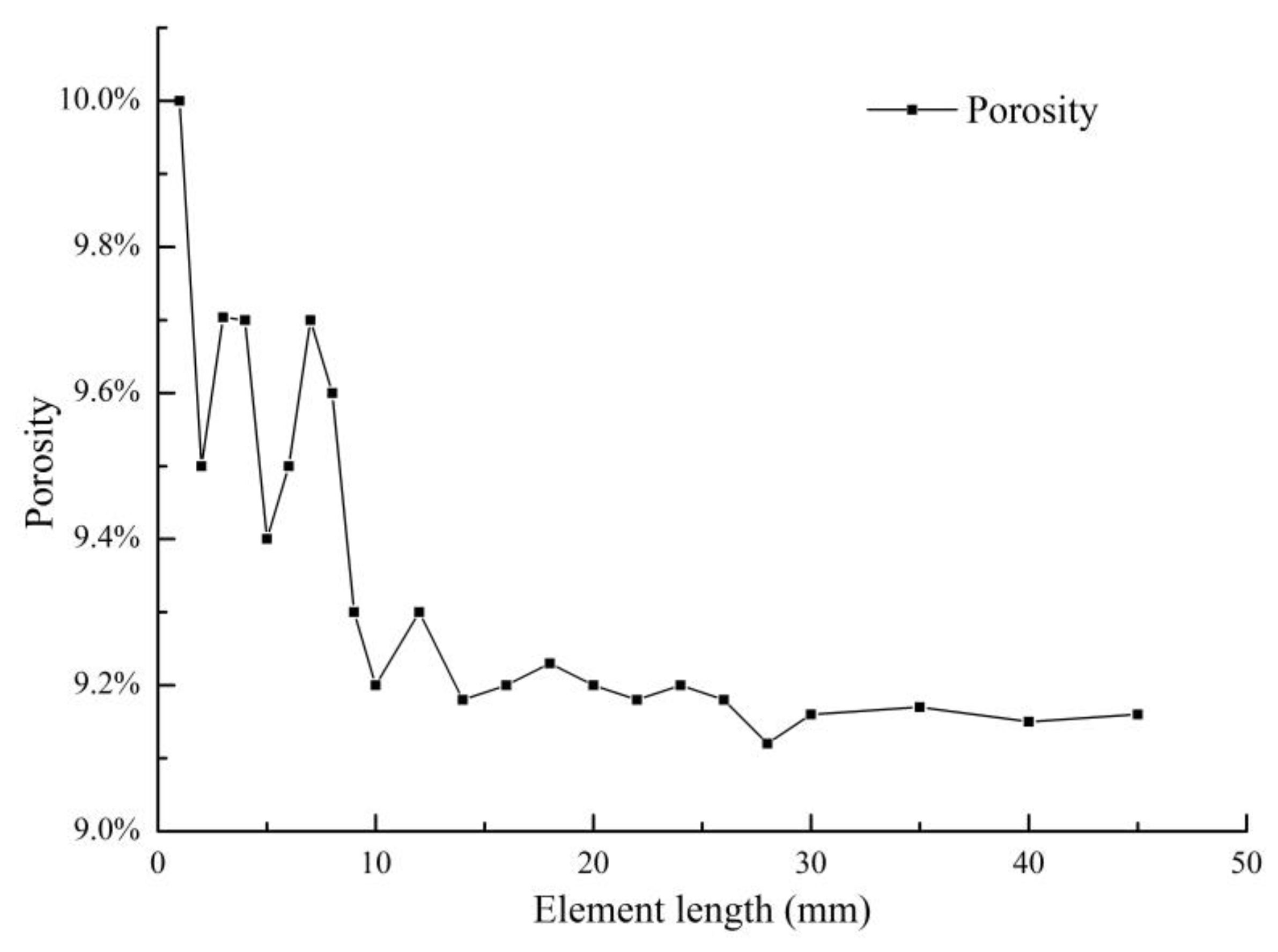

4.2.1. Determination of Representative Volume Units

4.2.2. Construction of Pore Network Model

4.3. Pore Network Model Analysis

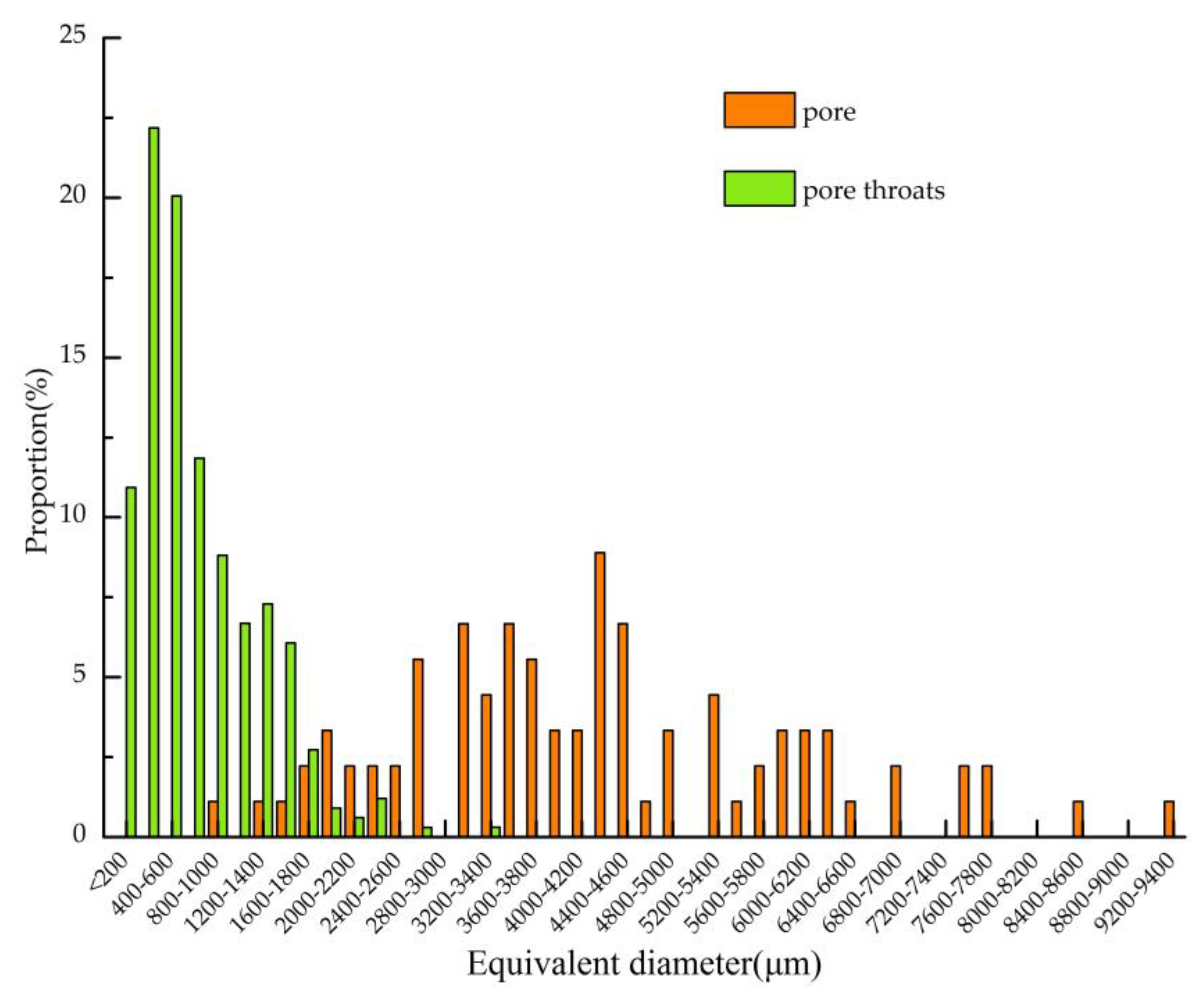

4.3.1. Analysis of the Distribution Characteristics of Pores and Pore Throats

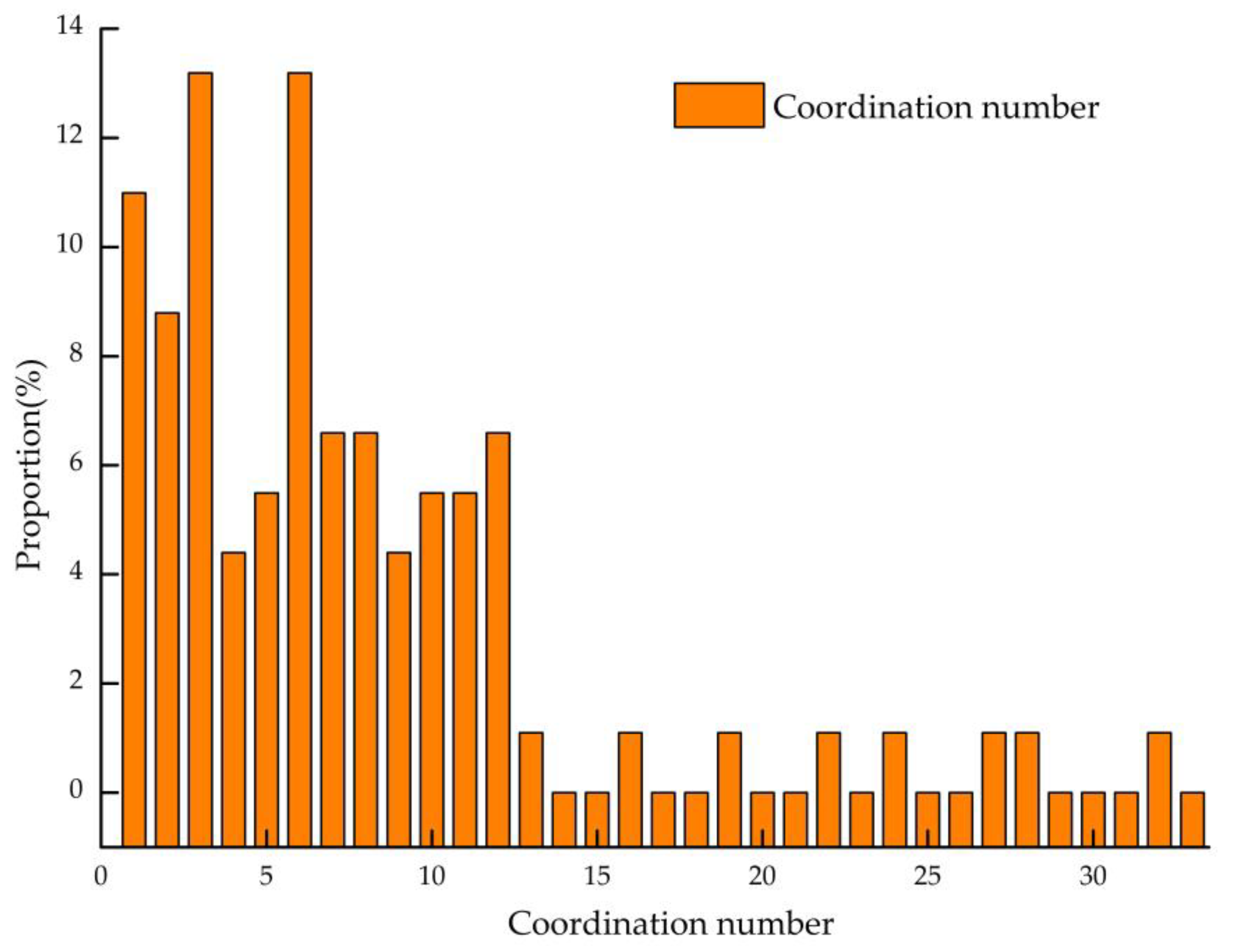

4.3.2. Pore Connectivity Characteristics Analysis

4.4. Analysis of Heat Conduction Experimental Results

4.4.1. Analysis of Heat Conduction Experimental Verification Results

4.4.2. Analysis of Heat Conduction Experimental Results

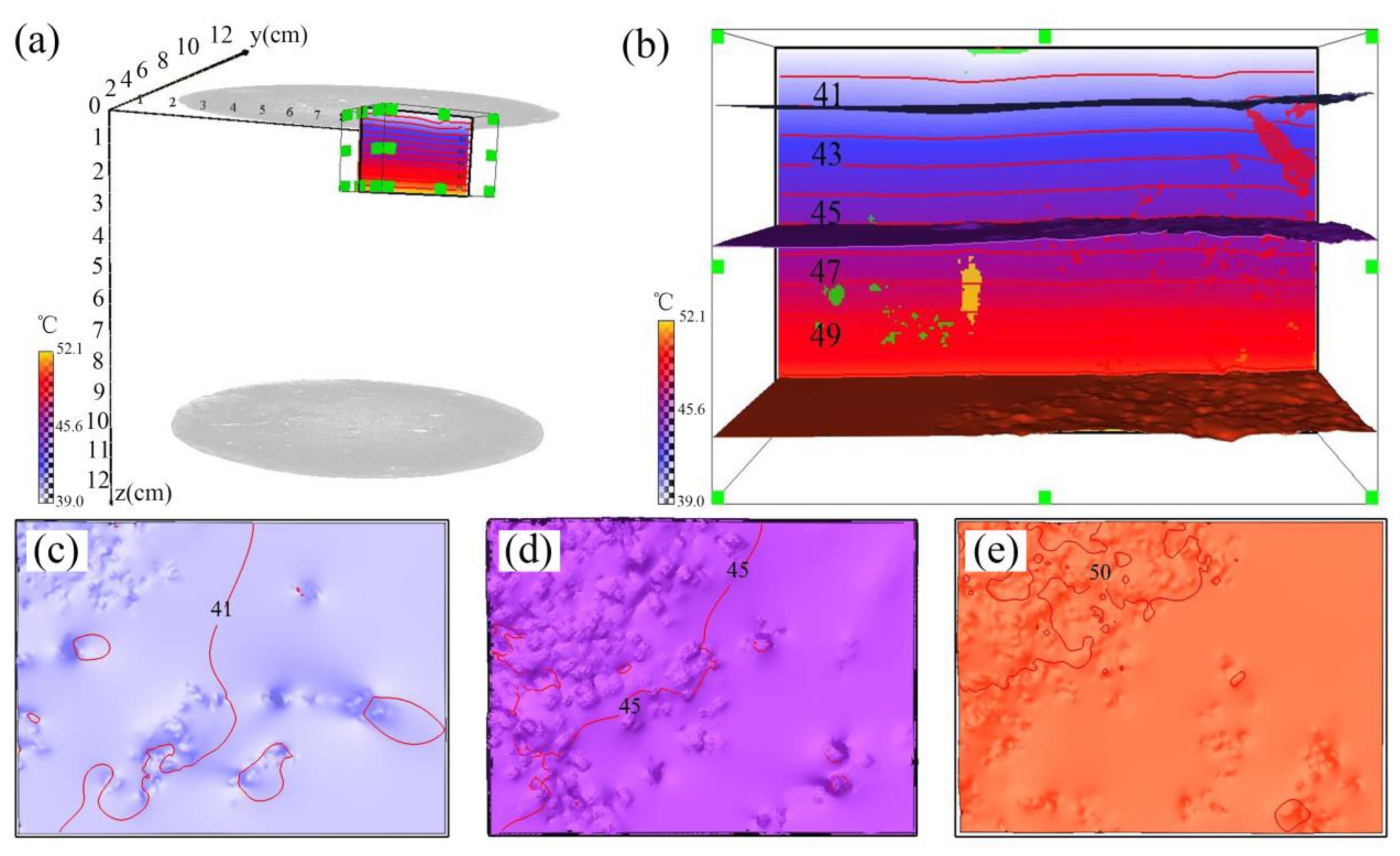

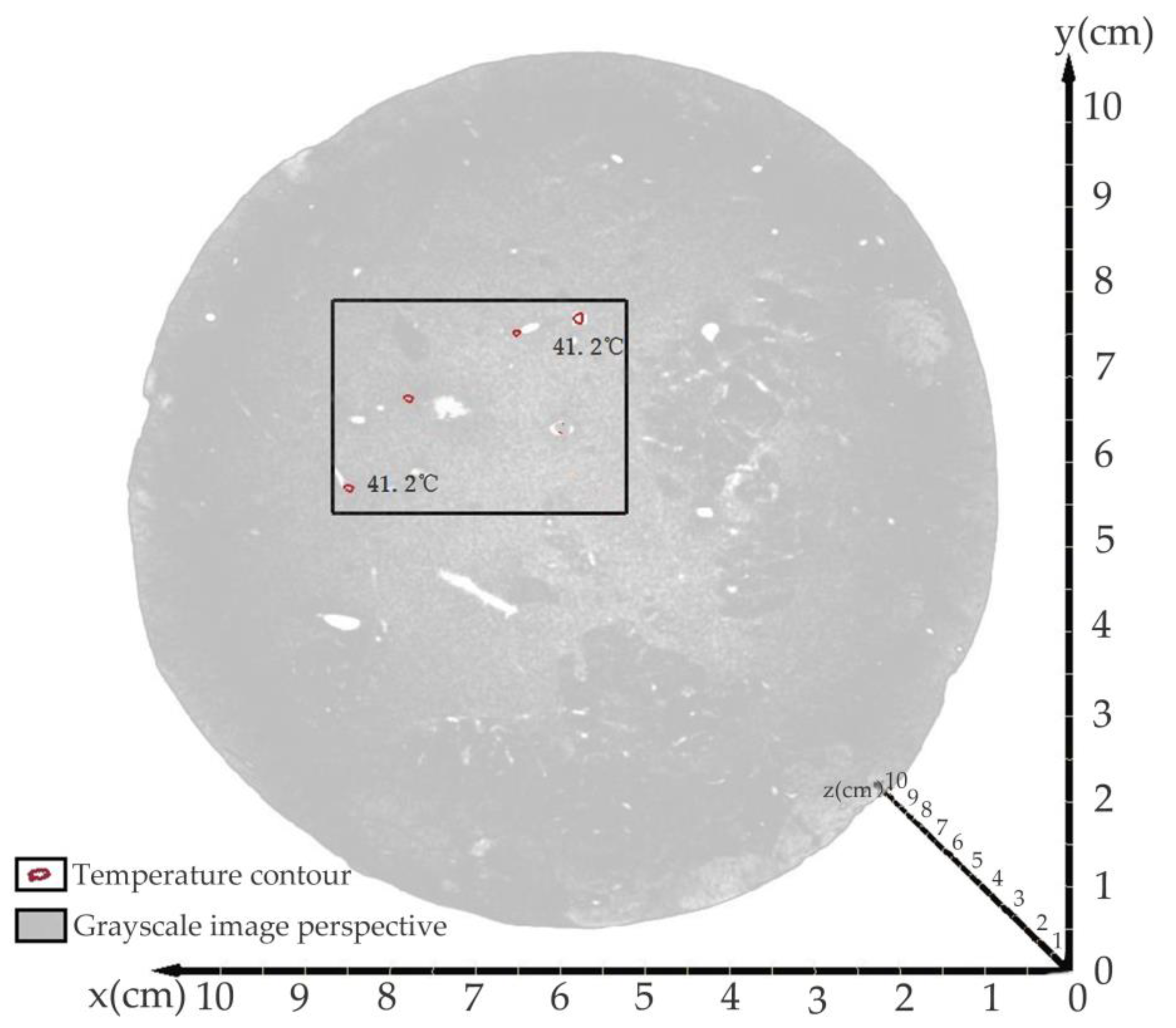

4.4.3. Heat Conduction Experiment Abnormal Temperature Point Extraction

4.5. Analysis of Simulation Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Heat flow (W·m−2) | |

| Thermal conductivity of the material (W·m−1·K−1) | |

| T | Temperature (K) |

| Heat capacity of the α phase (J·m−3·K−1) | |

| Density of the α phase (kg·m−3) | |

| Specific heat capacity of the α phase (J·kg−1·K−1) | |

| Thermal conductivity of the α phase (W·m−1·K−1) | |

| Temperature of the α phase (K) | |

| Total heat flux through the input surface (W·m−2) | |

| Area of the material in contact with the heat input surface (m2) | |

| Apparent thermal conductivity of the material (W·m−1·K−1) | |

| Input temperatures (K) | |

| Output temperatures (K) | |

| L | Length of the material sample (m) |

| Thermal conductivity in any phase (α phase) | |

| Temperature in any phase (α phase) | |

| Area of the material in contact with the heat input surface (m2) | |

| Considered as a perturbation of the temperature field | |

| Effective thermal conductivity tensor | |

| V | Total volume of the sample (m3) |

| A conduction phase | |

| Volume of each conduction phase (m3) | |

| Unit normal vector at the interface from α phase to β phase |

References

- Li, X.; Lu, Y.; Zhang, X.; Fan, W.; Lu, Y.; Pan, W. Quantification of macropores of Malan loess and the hydraulic significance on slope stability by X-ray computed tomography. Environ. Earth Sci. 2019, 78, 522. [Google Scholar] [CrossRef]

- Li, Y.; Mo, P.; Wang, Y.; Zhang, T.; Zhang, H. Strength anisotropy of Malan loess and the implications for the formation of loess walls and columns. Catena 2020, 194, 104809. [Google Scholar] [CrossRef]

- Lu, Q.; Qiao, J.; Peng, J.; Liu, Z.; Liu, C.; Tian, L.; Zhao, J. A typical Earth fissure resulting from loess collapse on the loess plateau in the Weihe Basin, China. Eng. Geol. 2019, 259, 105189. [Google Scholar] [CrossRef]

- Yuan, K.; Ni, W.; Lü, X.; Zhu, M.; Wang, H.; Nie, Y. Mechanical properties and microstructure evolution of Malan loess. Quat. Int. 2022, 637, 74–84. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, Y.; Li, X.; Lu, Y.; Sun, J.; Pan, W. Multilevel Collapsibility of Loess under Irrigation in Jinya Town, Gansu Province, China. Adv. Civ. Eng. 2019, 2019, 2153679. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, Y.; Lu, T.; Wang, B.; Zeng, G.; Zhang, X. Computing of Permeability Tensor and Seepage Flow Model of Intact Malan Loess by X-ray Computed Tomography. Water 2023, 15, 2851. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, T.; Zhang, Y.; Xu, Q. Geometrical appearance and spatial arrangement of structural blocks of the Malan loess in NW China: Implications for the formation of loess columns. J. Asian Earth Sci. 2018, 158, 18–28. [Google Scholar] [CrossRef]

- Luo, H.; Wu, F.; Chang, J.; Xu, J. Microstructural constraints on geotechnical properties of Malan Loess: A case study from Zhaojiaan landslide in Shaanxi province, China. Eng. Geol. 2018, 236, 60–69. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Lu, Y.; Lu, Y.; Fan, W. A study on the collapse characteristics of loess based on energy spectrum superposition method. Heliyon 2023, 9. [Google Scholar] [CrossRef]

- Chen, Y.; Shen, C.; Lu, P.; Huang, Y. Role of pore structure on liquid flow behaviors in porous media characterized by fractal geometry. Chem. Eng. Process. Process Intensif. 2014, 87, 75–80. [Google Scholar] [CrossRef]

- Pia, G.; Sanna, U. Case studies on the influence of microstructure voids on thermal conductivity in fractal porous media. Case Stud. Therm. Eng. 2014, 2, 8–13. [Google Scholar] [CrossRef]

- Qin, X.; Cai, J.; Xu, P.; Dai, S.; Gan, Q. A fractal model of effective thermal conductivity for porous media with various liquid saturation. Int. J. Heat Mass Transf. 2019, 128, 1149–1156. [Google Scholar] [CrossRef]

- Zheng, C.; Šimůnek, J.; Zhao, Y.; Lu, Y.; Liu, X.; Shi, C.; Li, H.; Yu, L.; Zeng, Y.; Su, Z. Development of the Hydrus-1D freezing module and its application in simulating the coupled movement of water, vapor, and heat. J. Hydrol. 2021, 598, 126250. [Google Scholar] [CrossRef]

- To, Q.D.; Bonnet, G. Fourier transform approach to homogenization of frequency-dependent heat transfer in porous media. Int. J. Numer. Methods Heat Fluid Flow 2023, 33, 2023–2048. [Google Scholar] [CrossRef]

- Wang, J.; Carson, J.K.; North, M.F.; Cleland, D.J. A new approach to modelling the effective thermal conductivity of heterogeneous materials. Int. J. Heat Mass Transf. 2006, 49, 3075–3083. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, C.; Liu, Y.; Wang, D.; Liu, J. A model for the effective thermal conductivity of moist porous building materials based on fractal theory. Int. J. Heat Mass Transf. 2018, 125, 387–399. [Google Scholar] [CrossRef]

- Yu, B.; Cheng, P. Fractal Models for the Effective Thermal Conductivity of Bidispersed Porous Media. J. Thermophys. Heat Transf. 2002, 16, 22–29. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.-S.; Lin, Z.-Z.; Tian, B.-G.; Shi, B. Measurement of water content at bare soil surface with infrared thermal imaging technology. J. Hydrol. 2022, 615, 128715. [Google Scholar] [CrossRef]

- Zhao, W.; Dong, X.; Wu, Z.; Wei, C.; Li, L.; Yu, D.; Fan, X.; Ma, Y. Using infrared thermal imaging technology to estimate the transpiration rate of citrus trees and evaluate plant water status. J. Hydrol. 2022, 615, 128671. [Google Scholar] [CrossRef]

- Reyes-Urrutia, A.; Venier, C.; Mariani, N.J.; Nigro, N.; Rodriguez, R.; Mazza, G. A CFD Comparative Study of Bubbling Fluidized Bed Behavior with Thermal Effects Using the Open-Source Platforms MFiX and OpenFOAM. Fluids 2021, 7, 1. [Google Scholar] [CrossRef]

- Kou, J.; Liu, Y.; Wu, F.; Fan, J.; Lu, H.; Xu, Y. Fractal analysis of effective thermal conductivity for three-phase (unsaturated) porous media. J. Appl. Phys. 2009, 106, 054905. [Google Scholar] [CrossRef]

- Nait-Ali, B.; Haberko, K.; Vesteghem, H.; Absi, J.; Smith, D.S. Thermal conductivity of highly porous zirconia. J. Eur. Ceram. Soc. 2006, 26, 3567–3574. [Google Scholar] [CrossRef]

- Raed, K.; Gross, U. Modeling of Influence of Gas Atmosphere and Pore-Size Distribution on the Effective Thermal Conductivity of Knudsen and Non-Knudsen Porous Materials. Int. J. Thermophys. 2009, 30, 1343–1356. [Google Scholar] [CrossRef]

- Chen, Y.-C. Non-Darcy flow stability of mixed convection in a vertical channel filled with a porous medium. Int. J. Heat Mass Transf. 2004, 47, 1257–1266. [Google Scholar] [CrossRef]

- Babaei, H.; McGaughey, A.J.H.; Wilmer, C.E. Effect of pore size and shape on the thermal conductivity of metal-organic frameworks. Chem. Sci. 2017, 8, 583–589. [Google Scholar] [CrossRef]

- Brzić, D.; Pešić, R.; Arsenijević, Z.; Đuriš, M.; Bošković-Vragolović, N.; Kaluđerović-Radoičić, T. Heat transfer to a sphere immersed in a fluidized bed of coarse particles with transition from bubbling to turbulent flow regime. Part. Sci. Technol. 2022, 41, 75–83. [Google Scholar] [CrossRef]

- Freitas, S.K.S.; Borges, R.S.; Merlini, C.; Barra, G.M.O.; Esteves, P.M. Thermal Conductivity of Covalent Organic Frameworks as a Function of Their Pore Size. J. Phys. Chem. C 2017, 121, 27247–27252. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, M.; Shen, S. Heat Transfer around and through Multiple Porous Particles. Ind. Eng. Chem. Res. 2022, 61, 8269–8278. [Google Scholar] [CrossRef]

- Carmignato, S.; Dewulf, W.; Leach, R. Industrial X-Ray Computed Tomography||Applications of CT for Non-destructive Testing and Materials Characterization. Ind. X-ray Comput. Tomogr. 2018, 17, 267–331. [Google Scholar]

- Ivanov, A.L.; Shein, E.V.; Skvortsova, E.B. Tomography of Soil Pores: From Morphological Characteristics to Structural–Functional Assessment of Pore Space. Eurasian Soil Sci. 2019, 52, 50–57. [Google Scholar] [CrossRef]

- Samant, P.; Trevisi, L.; Ji, X.; Xiang, L. X-ray induced acoustic computed tomography. Photoacoustics 2020, 19, 100177. [Google Scholar] [CrossRef]

- Shanti, N.O.; Chan, V.W.L.; Stock, S.R.; De Carlo, F.; Thornton, K.; Faber, K.T. X-ray micro-computed tomography and tortuosity calculations of percolating pore networks. Acta Mater. 2014, 71, 126–135. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, X.-P. An integrated method for 3D reconstruction model of porous geomaterials through 2D CT images. Comput. Geosci. 2019, 123, 83–94. [Google Scholar] [CrossRef]

- Weigand, T.M.; Schultz, P.B.; Giffen, D.H.; Farthing, M.W.; Crockett, A.; Kelley, C.T.; Gray, W.G.; Miller, C.T. Modeling Nondilute Species Transport Using the Thermodynamically Constrained Averaging Theory. Water Resour. Res. 2018, 54, 6656–6682. [Google Scholar] [CrossRef]

- Wood, B.D.; Valdés-Parada, F.J. Volume averaging: Local and nonlocal closures using a Green’s function approach. Adv. Water Resour. 2013, 51, 139–167. [Google Scholar] [CrossRef]

- Yang, C.; Huang, R.; Lin, Y.; Qiu, T. Volume averaging theory (VAT) based modeling for longitudinal mass dispersion in structured porous medium with porous particles. Chem. Eng. Res. Des. 2020, 153, 582–591. [Google Scholar] [CrossRef]

- Battiato, I.; Ferrero, V.P.T.; O’ Malley, D.; Miller, C.T.; Takhar, P.S.; Valdés-Parada, F.J.; Wood, B.D. Theory and Applications of Macroscale Models in Porous Media. Transp. Porous Media 2019, 130, 5–76. [Google Scholar] [CrossRef]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef]

- Bu, S.S.; Yang, J.; Zhou, M.; Li, S.Y.; Wang, Q.W.; Guo, Z.X. On contact point modifications for forced convective heat transfer analysis in a structured packed bed of spheres. Nucl. Eng. Des. 2014, 270, 21–33. [Google Scholar] [CrossRef]

- Huo, A.; Wang, X.; Zhao, Z.; Yang, L.; Zhong, F.; Zheng, C.; Gao, N. Risk Assessment of Heavy Metal Pollution in Farmland Soils at the Northern Foot of the Qinling Mountains, China. Int. J. Environ. Res. Public Health 2022, 19, 14962. [Google Scholar] [CrossRef]

- Huo, A.; Yang, L.; Luo, P.; Cheng, Y.; Peng, J.; Nover, D. Influence of landfill and land use scenario on runoff, evapotranspiration, and sediment yield over the Chinese Loess Plateau. Ecol. Indic. 2021, 121, 107208. [Google Scholar] [CrossRef]

- Huo, A.; Zhao, Z.; Luo, P.; Zheng, C.; Peng, J.; Abuarab, M.E.L.S. Assessment of Spatial Heterogeneity of Soil Moisture in the Critical Zone of Gully Consolidation and Highland Protection. Water 2022, 14, 3674. [Google Scholar] [CrossRef]

- Baveye, P.; Sposito, G. The Operational Significance of the Continuum Hypothesis in the Theory of Water Movement through Soils and Aquifers. Water Resour Res. 1984, 20, 521–530. [Google Scholar] [CrossRef]

- Quintard, M.; Kaviany, M.; Whitaker, S. Two-medium treatment of heat transfer in porous media: Numerical results for effective properties. Adv. Water Resour. 1997, 20, 77–94. [Google Scholar] [CrossRef]

- Quintard, M.; Whitaker, S. Convection, dispersion, and interfacial transport of contaminants: Homogeneous porous media. Adv Water Resour. 1994, 17, 221–239. [Google Scholar] [CrossRef]

| Dry Density (g/cm3) | Void Ratio | Clay (%) (d < 5 μm) | Silt (%) (5 < d < 50 μm) | Sand (%) (d > 50 μm) | Liquid Limit | Plastic Limit | Plastic Index | Permeability Coefficient K (cm/s) |

|---|---|---|---|---|---|---|---|---|

| 1.219 | 1.18 | 9.46 | 61.07 | 29.74 | 11.5% | 8% | 11.83% | 1.38 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Lu, T.; Lu, Y.; Wang, B.; Zeng, G.; Zhang, X. The Study on Solving Large Pore Heat Transfer Simulation in Malan Loess Based on Volume Averaging Method Combined with CT Scan Images. Sustainability 2023, 15, 12389. https://doi.org/10.3390/su151612389

Lu Y, Lu T, Lu Y, Wang B, Zeng G, Zhang X. The Study on Solving Large Pore Heat Transfer Simulation in Malan Loess Based on Volume Averaging Method Combined with CT Scan Images. Sustainability. 2023; 15(16):12389. https://doi.org/10.3390/su151612389

Chicago/Turabian StyleLu, Yangchun, Ting Lu, Yudong Lu, Bo Wang, Guanghao Zeng, and Xu Zhang. 2023. "The Study on Solving Large Pore Heat Transfer Simulation in Malan Loess Based on Volume Averaging Method Combined with CT Scan Images" Sustainability 15, no. 16: 12389. https://doi.org/10.3390/su151612389

APA StyleLu, Y., Lu, T., Lu, Y., Wang, B., Zeng, G., & Zhang, X. (2023). The Study on Solving Large Pore Heat Transfer Simulation in Malan Loess Based on Volume Averaging Method Combined with CT Scan Images. Sustainability, 15(16), 12389. https://doi.org/10.3390/su151612389