Effect of Curing Condition and Solvent Content on Mechanical Properties of Zein-Biopolymer-Treated Soil

Abstract

:1. Introduction

2. Materials

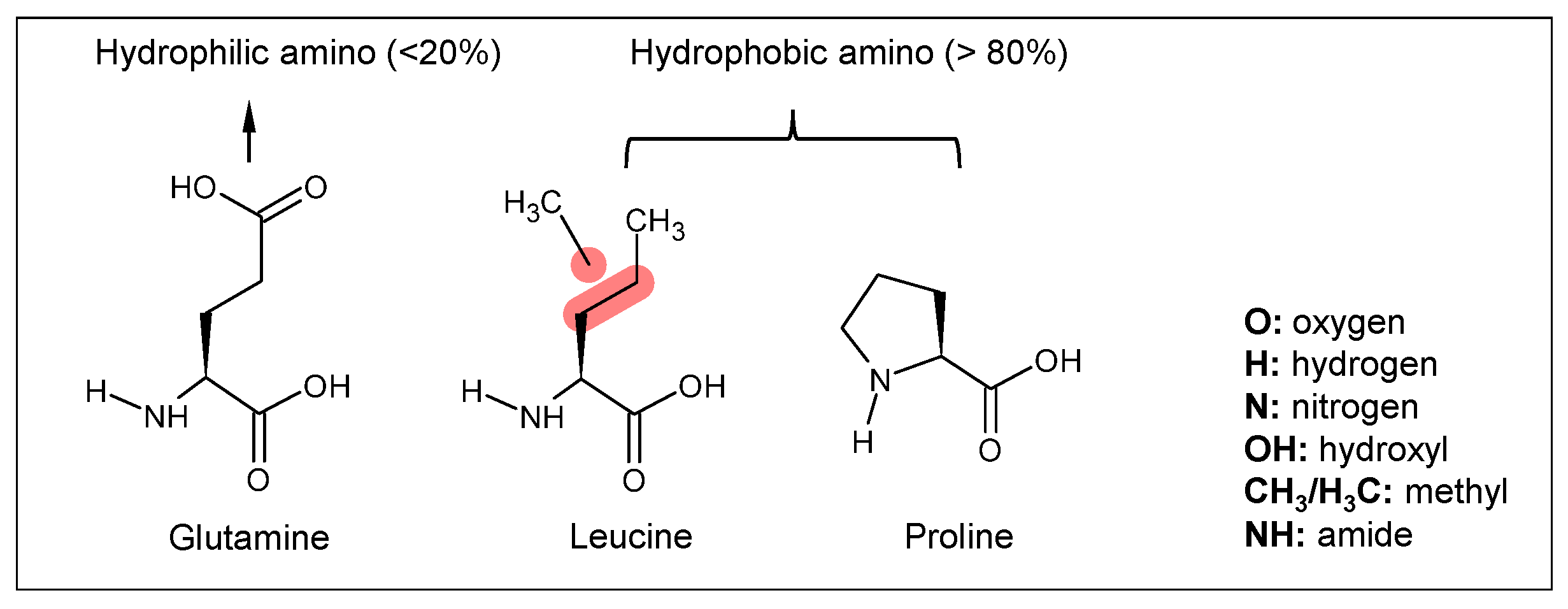

2.1. Zein Biopolymer

2.2. Soils

2.3. Solvent

2.4. Sample Preparation

3. Experimental Study

3.1. Unconfined Compressive Test

3.2. Microscopic Investigation

4. Results and Discussion

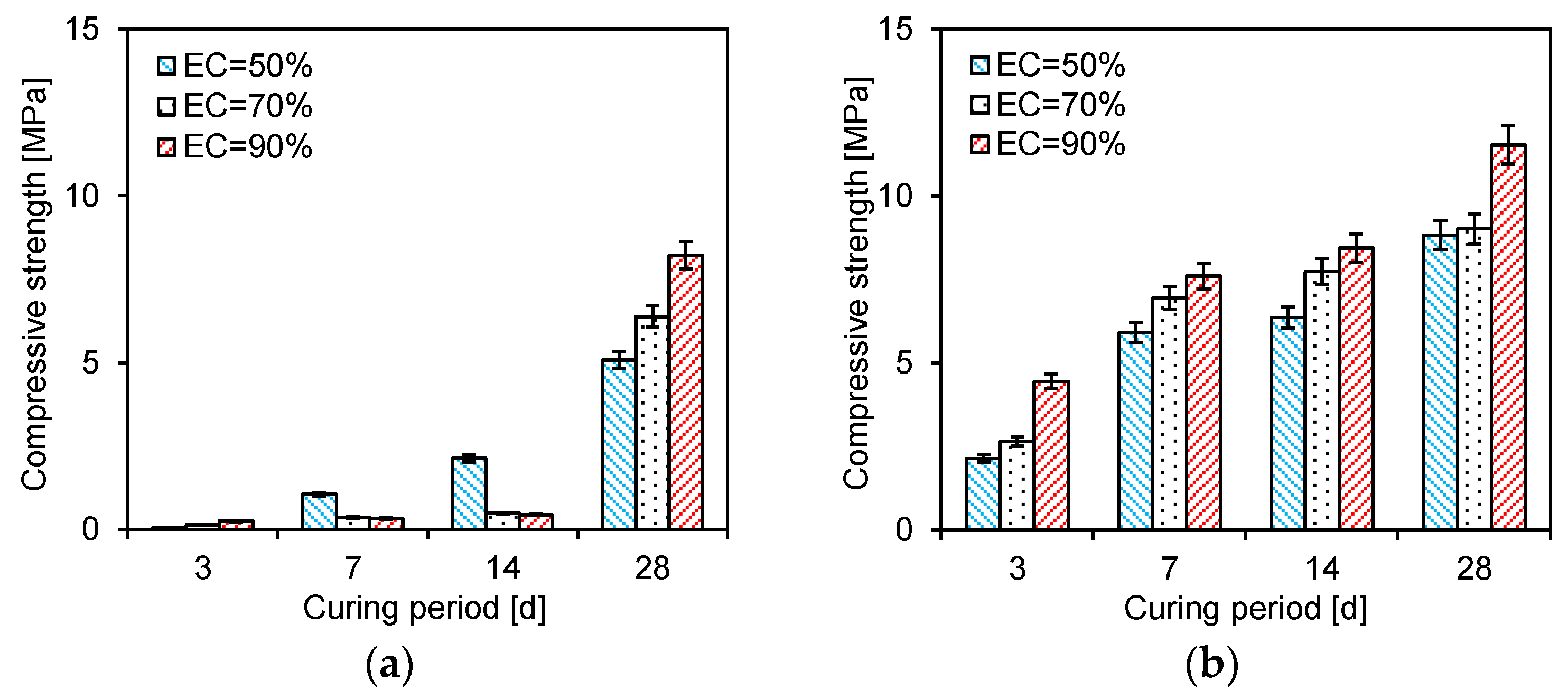

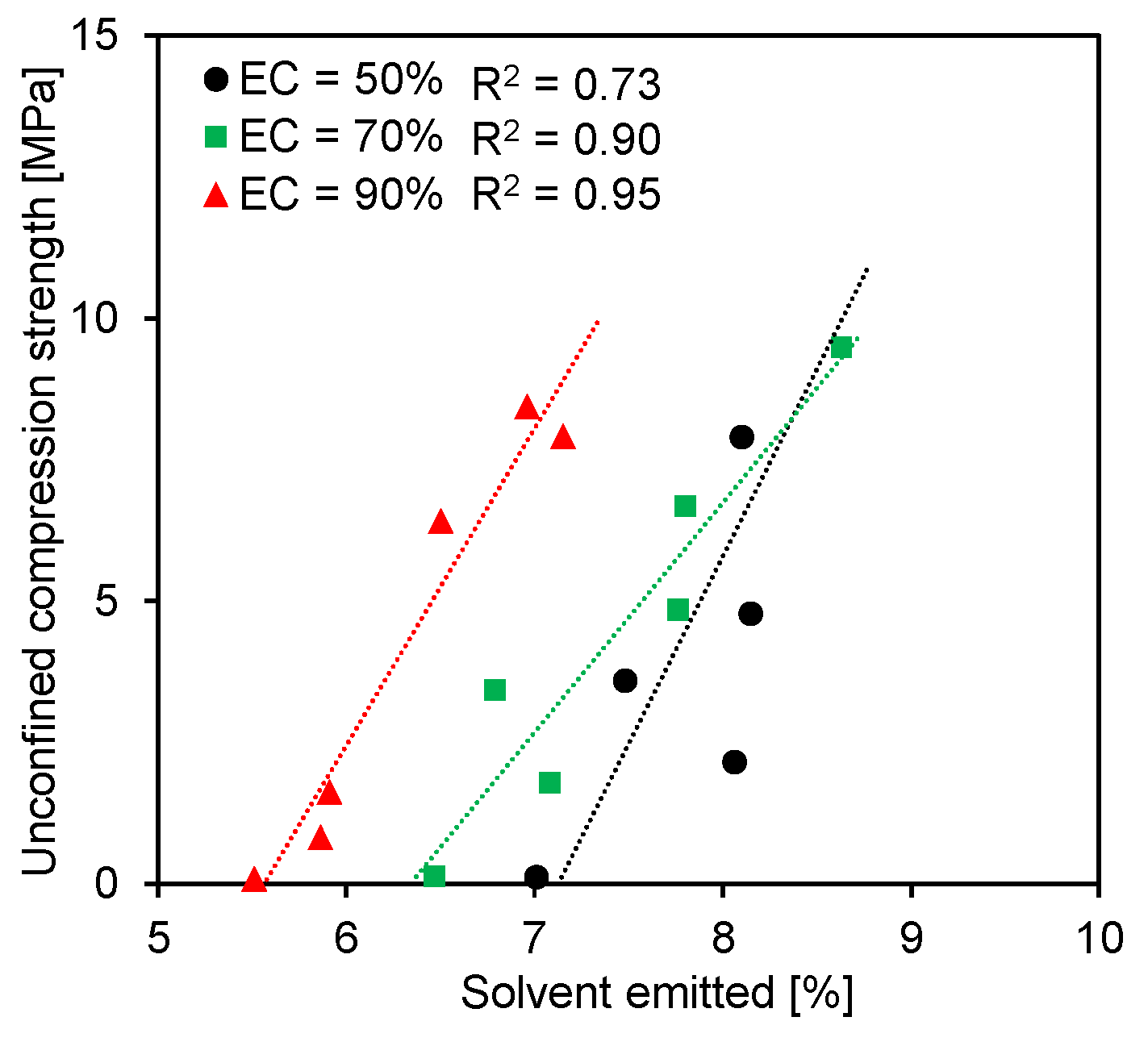

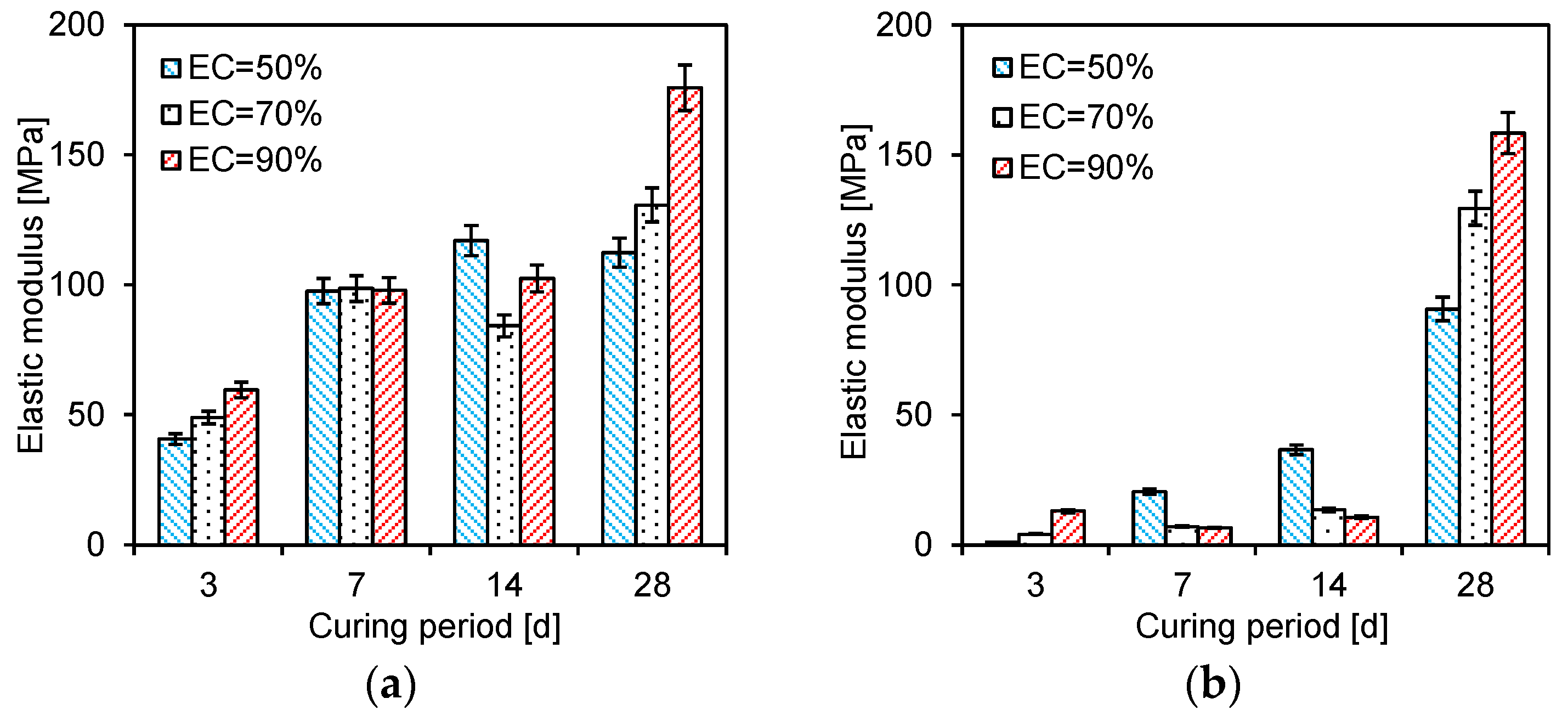

4.1. Compressive Strength and Elastic Modulus

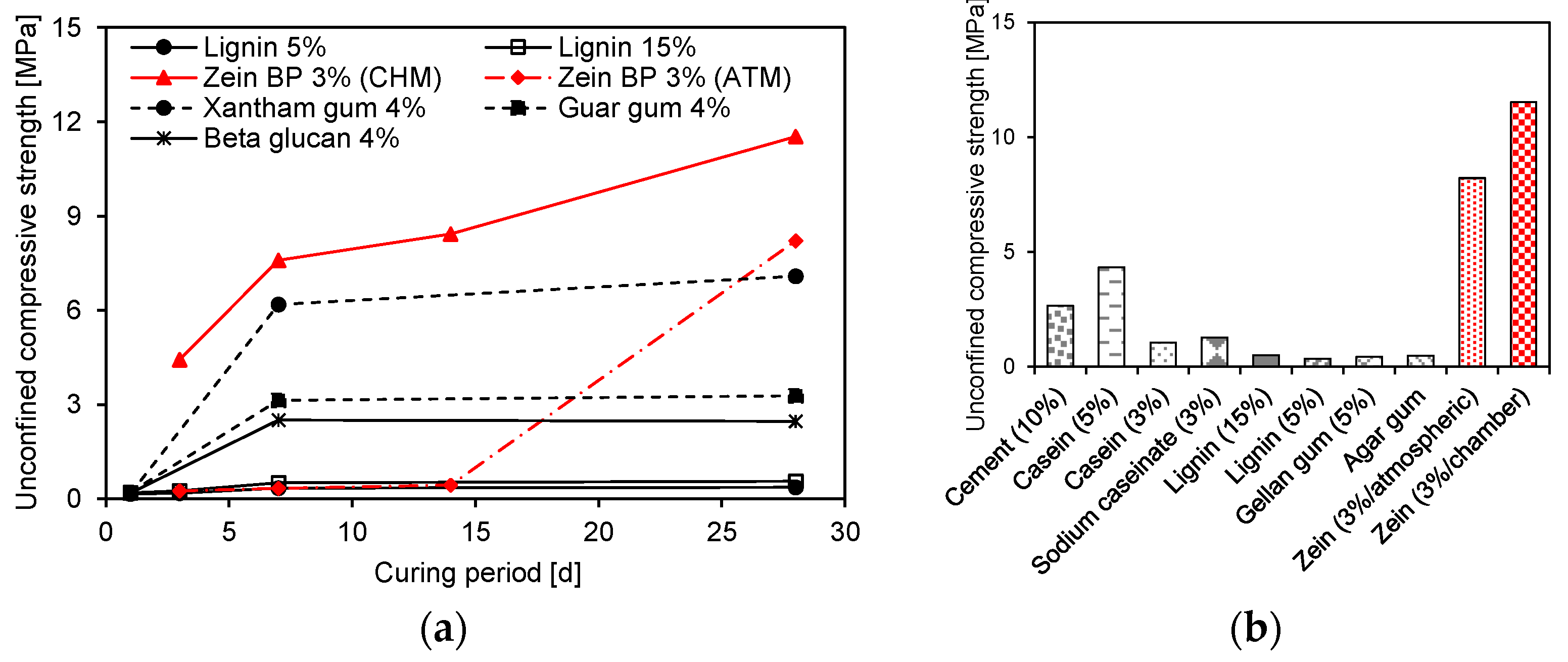

4.2. Comparison

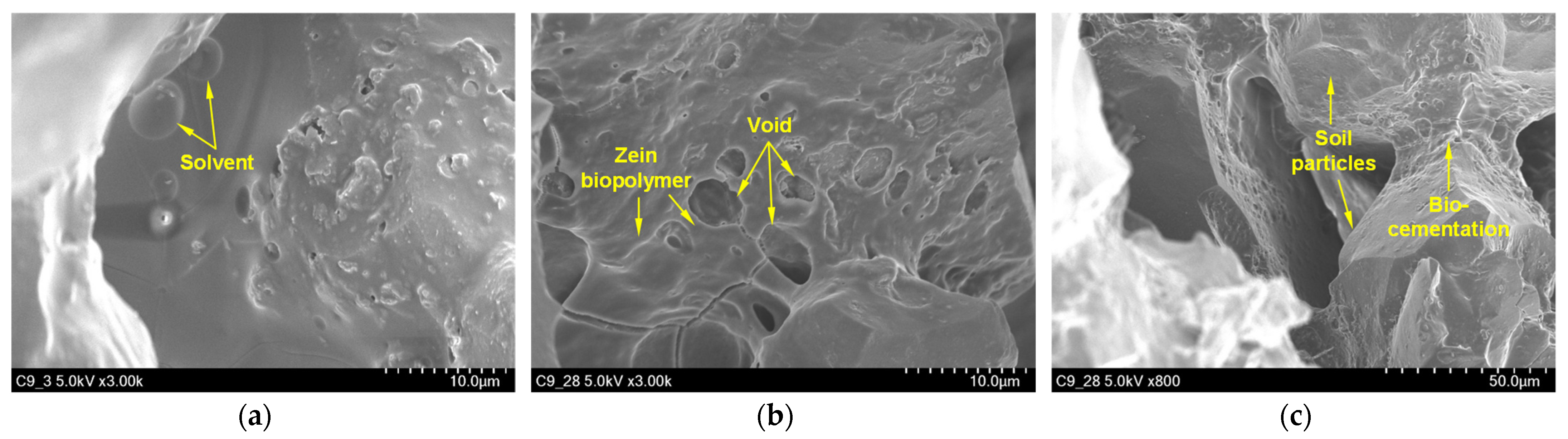

4.3. Microstructure

5. Conclusions

- Compressive strength and elastic modulus of zein-treated soils increased with the curing period. Strength and stiffness variation occurred under different ethanol contents and curing conditions.

- Hydrophobic cementation of zein biopolymers formed under atmospheric conditions. The rate of strength increase during curing was influenced by ethanol content.

- After 28 days, zein biocementation reached peak compressive strength and stiffness. Ethanol contents of 50% and 90% yielded the lowest and highest compressive strengths, respectively.

- Specimens cured in a chamber outperformed those cured under atmospheric conditions.

- Zein-treated soils demonstrated a linear relationship between compressive strength and elastic modulus, exhibiting a higher strength and lower elastic modulus compared to rock.

- Zein biopolymers showed higher long-term compressive strength with lower binder contents, compared to other biopolymers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Q.; Indraratna, B.; Carter, J.; Rujikiatkamjorn, C. A Theoretical and Experimental Study on the Behaviour of Lignosulfonate-Treated Sandy Silt. Comput. Geotech. 2014, 61, 316–327. [Google Scholar] [CrossRef]

- Kang, G.-O.; Tsuchida, T.; Kim, Y.-S. Strength and Stiffness of Cement-Treated Marine Dredged Clay at Various Curing Stages. Constr. Build. Mater. 2017, 132, 71–84. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Negm, A.; El-Sawwaf, M.; Kitazume, M. Enhancing Mechanical Behaviors of Collapsible Soil Using Two Biopolymers. J. Rock Mech. Geotech. Eng. 2017, 9, 329–339. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Cho, G.C. Soil Strengthening Using Thermo-Gelation Biopolymers. Constr. Build. Mater. 2015, 77, 430–438. [Google Scholar] [CrossRef]

- Sharma, M.; Satyam, N.; Reddy, K.R. Effect of Freeze-Thaw Cycles on Engineering Properties of Biocemented Sand under Different Treatment Conditions. Eng. Geol. 2021, 284, 106022. [Google Scholar] [CrossRef]

- Rebata-Landa, V.; Santamarina, J.C. Mechanical Limits to Microbial Activity in Deep Sediments. Geochem. Geophys. Geosystems 2006, 7, 11006. [Google Scholar] [CrossRef]

- Jayan, J.S.; Deeraj, B.D.S.; Saritha, A.; Joseph, K. Biopolymer-Derived Carbonaceous Composites and Their Potential Applications. In Hybrid Natural Fiber Composites: Material Formulations, Processing, Characterization, Properties, and Engineering Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 253–280. [Google Scholar] [CrossRef]

- Mekonnen, E.; Amdie, Y.; Etefa, H.; Tefera, N.; Tafesse, M. Stabilization of expansive black cotton soil using bioenzymes produced by ureolytic bacteria. Int. J. Geo-Eng. 2022, 13, 10. [Google Scholar] [CrossRef]

- Che, W.; Liu, J.; Hao, S.; Ren, J.; Song, Z.; Bu, F. Application of Colloid-Sand Coating Treated by a Hydrophilic Polysaccharide Biopolymer Material for Topsoil Stability Control. Geoderma 2022, 424, 115994. [Google Scholar] [CrossRef]

- Song, Z.; Liu, J.; Yu, Y.; Hao, S.; Jiang, B.; Song, J.; Kanungo, D.P.; Sun, S.; Bai, Y. Characterization of Artificially Reconstructed Clayey Soil Treated by Polyol Prepolymer for Rock-Slope Topsoil Erosion Control. Eng. Geol. 2021, 287, 106114. [Google Scholar] [CrossRef]

- Ham, S.-M.; Chang, I.; Noh, D.-H.; Kwon, T.-H.; Muhunthan, B. Improvement of Surface Erosion Resistance of Sand by Microbial Biopolymer Formation. J. Geotech. Geoenviron. Eng. 2018, 144, 06018004. [Google Scholar] [CrossRef] [Green Version]

- Biju, M.S.; Arnepalli, D.N. Effect of Biopolymers on Permeability of Sand-Bentonite Mixtures. J. Rock Mech. Geotech. Eng. 2020, 12, 1093–1102. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Akbulut, N.; Demir, S.; Yildiz, O. Use of a Biopolymer for Road Pavement Subgrade. Sustainability 2023, 15, 8231. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Chung, M.K.; Cho, G.C. Bovine Casein as a New Soil Strengthening Binder from Diary Wastes. Constr. Build. Mater. 2018, 160, 1–9. [Google Scholar] [CrossRef]

- Gao, X.; Li, T.; Li, X.; Cao, X.; Cui, Z. Preparation of a Newly Synthesized Biopolymer Binder and Its Application to Reduce the Erosion of Tailings. J. Environ. Manag. 2022, 301, 113857. [Google Scholar] [CrossRef]

- Lawton, J.W. Zein: A History of Processing and Use. Cereal Chem. 2002, 79, 1–18. [Google Scholar] [CrossRef]

- Dong, S.R.; Han, Q.; Xu, W.; Bian, C. Effect of Solvent Polarity on the Formation of Flexible Zein Nanoparticles and Their Environmental Adaptability. J. Cereal Sci. 2021, 102, 103340. [Google Scholar] [CrossRef]

- Yang, S.B.; Rabbani, M.M.; Ji, B.C.; Han, D.-W.; Lee, J.S.; Kim, J.W.; Yeum, J.H. Optimum Conditions for the Fabrication of Zein/Ag Composite Nanoparticles from Ethanol/H2O Co-Solvents Using Electrospinning. Nanomaterials 2016, 6, 230. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Guzmán, C.J.; Castro-Muñoz, R. A Review of Zein as a Potential Biopolymer for Tissue Engineering and Nanotechnological Applications. Processes 2020, 8, 1376. [Google Scholar] [CrossRef]

- Huang, S.; He, J.; Han, L.; Lin, H.; Liu, G.; Zhang, W. Zein-Polyglycerol Conjugates with Enhanced Water Solubility and Stabilization of High Oil Loading Emulsion. J. Agric. Food Chem. 2020, 68, 11810–11816. [Google Scholar] [CrossRef]

- Wang, Y.; Padua, G.W. Formation of Zein Microphases in Ethanol-Water. Langmuir 2010, 26, 12897–12901. [Google Scholar] [CrossRef]

- Silva, P.M.; Torres-Giner, S.; Vicente, A.A.; Cerqueira, M.A. Electrohydrodynamic Processing for the Production of Zein-Based Microstructures and Nanostructures. Curr. Opin. Colloid. Interface Sci. 2021, 56, 101504. [Google Scholar] [CrossRef]

- Corradini, E.; Curti, P.S.; Meniqueti, A.B.; Martins, A.F.; Rubira, A.F.; Muniz, E.C. Recent Advances in Food-Packing, Pharmaceutical and Biomedical Applications of Zein and Zein-Based Materials. Int. J. Mol. Sci. 2014, 15, 22438–22470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghorbani, M.; Nezhad-Mokhtari, P.; Ramazani, S. Aloe Vera-Loaded Nanofibrous Scaffold Based on Zein/Polycaprolactone/Collagen for Wound Healing. Int. J. Biol. Macromol. 2020, 153, 921–930. [Google Scholar] [CrossRef] [PubMed]

- Babatunde, Q.O.; Byun, Y.-H. Soil Stabilization Using Zein Biopolymer. Sustainability 2023, 15, 2075. [Google Scholar] [CrossRef]

- Babatunde, Q.O.; Yoon, H.K.; Byun, Y.H. Rheological Behavior of Zein Biopolymer and Stiffness Characteristic of Biopolymer Treated Soil. Constr. Build. Mater. 2023, 384, 131466. [Google Scholar] [CrossRef]

- Nonthanum, P. Rheological Characterization and Applications of Zein and Whey Protein GELS. Bachelor’s Dissertation, University of Illinois at Urbana-Champaign, Champaign, IL, USA, 2013. [Google Scholar]

- ASTM D6913/D6913M; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2012.

- Wypych, G. Handbook of Solvents, Volume 2: Use, Health, and Environment; Chemtec Publishing: Toronto, ON, Canada, 2019; Volume 2. [Google Scholar]

- Kar, M.; Chourasiya, Y.; Maheshwari, R.; Tekade, R.K. Current Developments in Excipient Science: Implication of Quantitative Selection of Each Excipient in Product Development. In Basic Fundamentals of Drug Delivery; Elsevier: Amsterdam, The Netherlands, 2018; pp. 29–83. ISBN 9780128179093. [Google Scholar]

- Zhang, R.; Li, L.; Ma, C.; Ettoumi, F.; Ezzahra; Javed, M.; Lin, X.; Shao, X.; Xiao, G.; Luo, Z. Shape-Controlled Fabrication of Zein and Peach Gum Polysaccharide Based Complex Nanoparticles by Anti-Solvent Precipitation for Curcumin-Loaded Pickering Emulsion Stabilization. Sustain. Chem. Pharm. 2022, 25, 100565. [Google Scholar] [CrossRef]

- Liu, C.; Bonaccurso, E.; Butt, H.-J. Evaporation of sessile water/ethanol drops in a controlled environment. Phys. Chem. Chem. Phys. 2008, 10, 7150–7157. [Google Scholar] [CrossRef]

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. Annual Book of ASTM Standards, ASTM International: West Conshohocken, PA, USA, 2006.

- Han, W.J.; Lee, J.S.; Byun, Y.H. Volume, Strength, and Stiffness Characteristics of Expandable Foam Grout. Constr. Build. Mater. 2021, 274, 122013. [Google Scholar] [CrossRef]

- Kim, S.C.; Kim, D.J.; Byun, Y.H. Effect of Fly Ash on Strength and Stiffness Characteristics of Controlled Low-Strength Material in Shear Wave Monitoring. Materials 2021, 14, 3022. [Google Scholar] [CrossRef]

- ASTM E986; Standard Practice for Scanning Electron Microscope Beam Size Characterization. Annual Book of ASTM Standards, ASTM International: West Conshohocken, PA, USA, 2017.

- Chen, C.; Wu, L.; Perdjon, M.; Huang, X.; Peng, Y. The Drying Effect on Xanthan Gum Biopolymer Treated Sandy Soil Shear Strength. Constr. Build. Mater. 2019, 197, 271–279. [Google Scholar] [CrossRef] [Green Version]

- Fatehi, H.; Ong, D.E.L.; Yu, J.; Chang, I. Biopolymers as Green Binders for Soil Improvement in Geotechnical Applications: A Review. Geosciences 2021, 11, 291. [Google Scholar] [CrossRef]

- Patel, A.R.; Velikov, K.P. Zein as a Source of Functional Colloidal Nano- and Microstructures. Curr. Opin. Colloid. Interface Sci. 2014, 19, 450–458. [Google Scholar] [CrossRef]

- Lee, M.; Kwon, Y.-M.; Park, D.-Y.; Chang, I.; Cho, G.-C. Durability and strength degradation of xanthan gum based biopolymer treated soil subjected to severe weathering cycles. Sci. Rep. 2022, 12, 19453. [Google Scholar] [CrossRef]

- Elhakim, A.F. The Use of Point Load Test for Dubai Weak Calcareous Sandstones. J. Rock Mech. Geotech. Eng. 2015, 7, 452–457. [Google Scholar] [CrossRef] [Green Version]

- Chang, I.; Cho, G.C. Strengthening of Korean Residual Soil with β-1,3/1,6-Glucan Biopolymer. Constr. Build. Mater. 2012, 30, 30–35. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.C. Introduction of Microbial Biopolymers in Soil Treatment for Future Environmentally-Friendly and Sustainable Geotechnical Engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef] [Green Version]

- Fatehi, H.; Abtahi, S.M.; Hashemolhosseini, H.; Hejazi, S.M. A Novel Study on Using Protein Based Biopolymers in Soil Strengthening. Constr. Build. Mater. 2018, 167, 813–821. [Google Scholar] [CrossRef]

- Soldo, A.; Miletić, M.; Auad, M.L. Biopolymers as a sustainable solution for the enhancement of soil mechanical properties. Sci. Rep. 2020, 10, 267. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Liu, S.; Cai, G.; Puppala, A.J. Experimental Investigation of Thermal and Mechanical Properties of Lignin Treated Silt. Eng. Geol. 2015, 196, 1–11. [Google Scholar] [CrossRef]

- Bera, H.; Guo, X.; Abbasi, Y.F.; Mahanty, A.; Nayak, A.K.; Saha, S.; Baqui, M.N. Curdlan-Based Nanomaterials in Drug Delivery Applications. In Biopolymer-Based Nanomaterials in Drug Delivery and Biomedical Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 253–273. ISBN 9780128208748. [Google Scholar]

- Selling, G.W.; Lawton, J.; Bean, S.; Dunlap, C.; Sessa, D.J.; Willett, J.L.; Byars, J. Rheological Studies Utilizing Various Lots of Zein in N,N-Dimethylformamide Solutions. J. Agric. Food Chem. 2005, 53, 9050–9055. [Google Scholar] [CrossRef]

| Types | Molecular Weight [kDa] | Total Mass [%] |

|---|---|---|

| α-zein | 22–24 | 70–85 |

| β-zein | 14–17 | 20 |

| γ-zein | 14–16 | 5 |

| δ-zein | 10–12 | <1 |

| Particle Sizes Corresponding to Percent Finer [mm] | Coefficient of Uniformity Cu | Coefficient of Curvature Cc | Specific Gravity Gs | Unified Soil Classification System | |||

|---|---|---|---|---|---|---|---|

| D10 | D30 | D50 | D60 | ||||

| 0.13 | 0.19 | 0.64 | 1.07 | 8.4 | 0.26 | 2.61 | SP |

| Reference | Material Type | Slope, α | Coefficient of Determination, R2 |

|---|---|---|---|

| Elhakim [42] | Rock | 127.5 | 0.850 |

| This study | Zeinbinder-treated soil | 15.0 | 0.917 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babatunde, Q.O.; Son, D.G.; Kim, S.Y.; Byun, Y.-H. Effect of Curing Condition and Solvent Content on Mechanical Properties of Zein-Biopolymer-Treated Soil. Sustainability 2023, 15, 12048. https://doi.org/10.3390/su151512048

Babatunde QO, Son DG, Kim SY, Byun Y-H. Effect of Curing Condition and Solvent Content on Mechanical Properties of Zein-Biopolymer-Treated Soil. Sustainability. 2023; 15(15):12048. https://doi.org/10.3390/su151512048

Chicago/Turabian StyleBabatunde, Quadri Olakunle, Dong Geon Son, Sang Yeob Kim, and Yong-Hoon Byun. 2023. "Effect of Curing Condition and Solvent Content on Mechanical Properties of Zein-Biopolymer-Treated Soil" Sustainability 15, no. 15: 12048. https://doi.org/10.3390/su151512048

APA StyleBabatunde, Q. O., Son, D. G., Kim, S. Y., & Byun, Y.-H. (2023). Effect of Curing Condition and Solvent Content on Mechanical Properties of Zein-Biopolymer-Treated Soil. Sustainability, 15(15), 12048. https://doi.org/10.3390/su151512048