1. Introduction

Wind energy has received wide attention from the scientific community as a renewable energy source. The wind turbine generator system (WTGS) is prone to wear and tear during long-term operation in harsh and random load environments, which remarkably increases the maintenance cost, thereby affecting the sustainable development of the wind power industry.

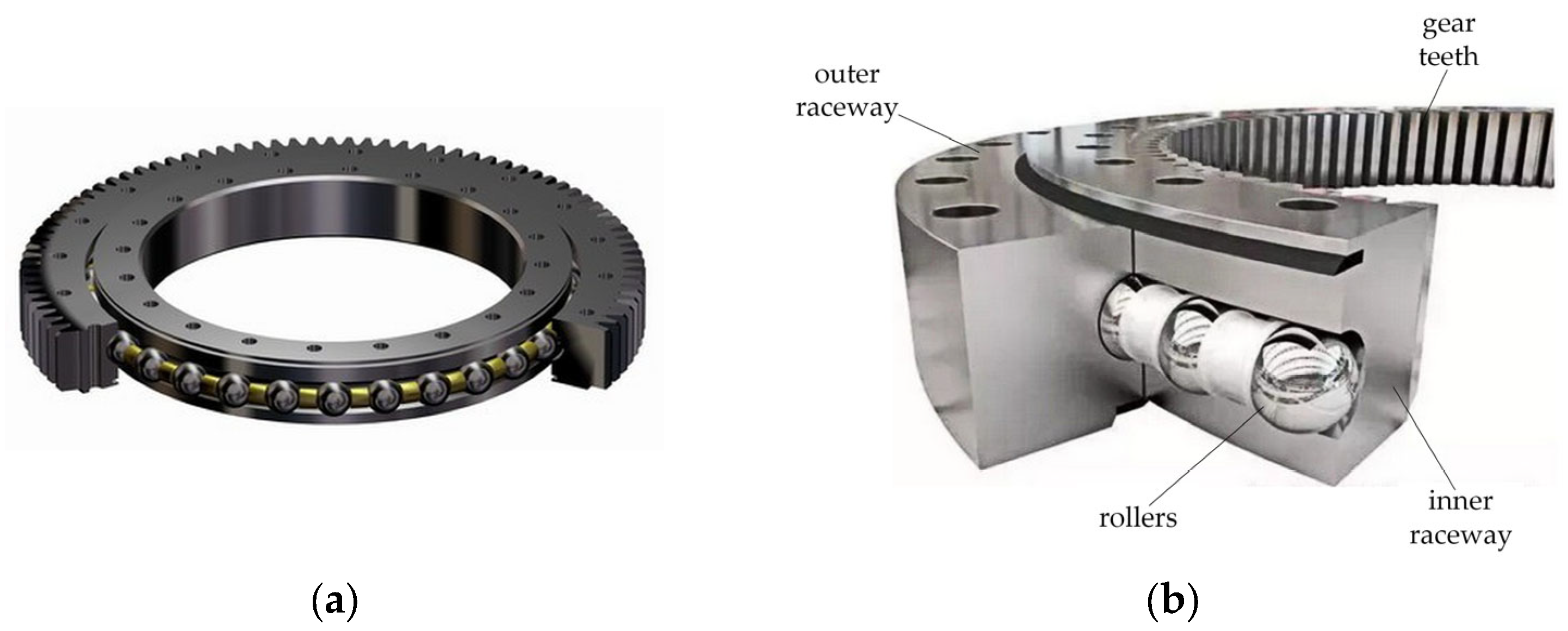

The slewing bearing is considered an important component of the wind turbine, and two structures are commonly used, which mainly act on the variable paddle and yaw [

1] (

Figure 1). The structures of the slewing bearings in WTGS are more complicated than drivetrain bearings, including outer raceway, inner raceway, rollers, and gear teeth [

1]. The rotary movement of the slewing bearing is achieved by the meshing and transmission of the gears of the inner or external ring. Particularly, the inner or external ring can be connected to the frame chain, and the other ring is directly connected to the driving device of the slewing part, and then the slewing part is driven to rotate together.

According to the authors of [

2], the failure rate of the blade and pitch system is about 14%, and the yaw system is about 8%, which indicates the high failure rate component in the wind turbine. Therefore, the effective RUL estimation of the key components of the wind turbine is considered of vital importance for the robustness of the generator unit.

1.1. Motivation

Many factors affect the accuracy of the estimation of the remaining useful life (RUL) of the fan slewing bearings. More specifically, the traditional vibration data, which are easily disturbed by noises, cannot comprehensively characterize the health status; thus, the physical model is difficult to establish, and when the data-driven model analyzes the status, it results in unclear physical mechanisms. Moreover, the volume of the fan slewing bearings is relatively large, the operating state randomly changes, and the cost is high, which makes it difficult to obtain a large amount of destructive data. On top of that, in the majority of the reported works in the literature, the research on the RUL prediction methods for wind turbine slewing bearings mostly focuses on the basis of physical models, which limits the development of RUL prediction technology for slewing bearings. Therefore, a new nonlinear Wiener degradation model was established based on the fusion of the physical models and the data-driven models, which was employed to characterize the degradation process of slewing bearings in this work, and for the local temperature distribution, which has a strong anti-interference ability, the multi-sensor temperature data fusion was selected to analyze the RUL prediction.

1.2. Related Works

In general, the RUL estimation methods for the fan slewing bearings mainly include the physical model and the data-driven methods. Potocnik [

3,

4] analyzed the parameters of the physical model related to the material properties and the level of stress, studied the underlying physical failure mechanism, and calculated the RUL using the finite element method. In another interesting work, Aguirrebeitia [

5] proposed an RUL prediction model of the pitch and yaw bearings, considering the geometric interaction influence of the static load capacity. Plaza [

6] introduced a supplement-based finite element (FE) model, which significantly reduced computational costs with a negligible accuracy loss. He [

7] obtained the contact stress distribution in ABAQUS, which was input to FESAFE, and then combined with the Morrow average stress correction and the Brown Miller criterion to perform fatigue analysis. He [

8] also used nonlinear spring elements to simulate the rolling elements in the yaw bearings and studied the influence of the hardening depth on the fatigue strength based on the distribution of the contact loads.

In the above-mentioned works, the contact load, geometric parameters, material physical mechanism, and other factors are mainly considered, while a small amount of data is selected to realize the component life analysis. During the actual operation process, it is difficult to accurately obtain the relevant physical parameters and establish a physical degradation model, which is not conducive to the RUL estimation. Compared to the physical models, a data-driven method does not completely depend on the physical or engineering principles, but the degradation process is characterized by running state information and is easy to be operated.

During the actual operation process, considering that the operation process of the fan slewing bearings is stochastic and nonlinear, the Wiener process can better describe this degradation procedure of the slewing bearings [

9]. In 2018, Zhang [

10] introduced the latest modeling development of the Wiener-based models on the implementation of the degradation data analysis and RUL estimation methods, as well as the application of Wiener-based models in degradation testing. Additionally, Gebraeel [

11] used bearings vibration data as the degradation state and first proposed the utilization of Bayesian analysis to update the exponential degradation model of random parameters. Particularly, the authors described the equipment degradation process as a linear Wiener process that is applied to the estimation of the bearings RUL estimation. Si [

12] proposed general nonlinear diffusion processes describing the degenerate data and produced an analytical form of the RUL time based on the nonlinear Wiener model. Many works in the literature [

13,

14] are based on the Wiener approach, which is derived from many theoretical extensions and application research.

The data-driven model does not rely on the device failure mechanism for carrying out the RUL analysis but requires a large amount of data to train the estimation model and improve the accuracy. In recent years, due to the difficulty of the physical model modeling and the inconspicuous physical mechanism of the data-driven models, the physical model and data-driven hybrid method have been developed [

15].

As far as the traditional vibration data are concerned, they are easily disturbed by various types of noises (such as signals transmission paths, sensors installation foundations, and changes in surrounding environments). On top of that, the temperature of the large-sized ring part is sensitive to the operating state, whereas the temperature characteristics reflecting the deterioration of the fan slewing bearings have thermal inertia and strong anti-interference ability [

10,

16,

17,

18,

19]. However, in these works, the Wiener degradation model, which combines the mechanism and the data-driven models, is mainly used to examine the degradation process of the slewing bearings.

In practical applications, the volume of the fan slewing bearing is large, and the operation speed is slow. As a result, the data collected by a single sensor cannot comprehensively characterize the health state of the fan slewing bearings, and there is a correlation between the multiple performance data affecting the results of the RUL estimation. With the development of sensor technology, the degradation process of the slewing bearings can be analyzed by the fusion of multiple state information.

Zhao [

20] established an information fusion model based on Euclidean distance and combined it with the nonlinear Wiener model. The PCA analysis can extract as few new indicators as possible to replace the original indicators and contain more information from the original index variable [

21,

22,

23]. This method can model the evaluation of the processed data, making the degradation analysis less difficult. Zhao and Yang [

24,

25] adopted the PCA analysis to fuse data features, combined it with the linear Wiener model, and applied it to the RUL estimation of the bearings and aviation engine. However, the engine bearings running process is a nonlinear random process. Thus, the linear Wiener model mode that is used to describe the nonlinear random process will inevitably affect the accuracy of the RUL estimation.

Table 1 presents a summary of the contributions of the aforementioned works made on the Wiener model and PCA in the context of treating RUL challenges. It is noticeable that all these works treat RUL prediction from the data-driven methods. In other words, these studies have achieved many achievements that have been reported in modeling from linear Wiener [

24,

25] to nonlinear Wiener [

26,

27,

28], ranging from vibration signals [

11] to multi-data PCA fusion [

24,

25].

1.3. Contributions

Targeting a fewer number of samples’ issues: Accurate prognostic and health management of wind turbines can reduce the losses caused by faults and contribute to the sustainable development of wind power generation. Since the operating environment of the wind turbines was harsh, the volume of the slewing bearings was large, and the operating speed was slow. As a result, the monitored vibration signal of a fewer number of samples has a poor signal-to-noise ratio, which cannot fully reflect the degradation state of the fan slewing bearings. For the local temperature distribution to have strong anti-interference ability, PCA was carried out to fuse multi-sensor temperature data to obtain the comprehensive health index (CHI), which represents the fan slewing bearings. Then, a fewer number of samples can better reflect the degradation information of the slewing bearings.

Establishing a new fusion model: Many factors affect the accuracy of the estimation of the remaining useful life (RUL) of the fan slewing bearings. More specifically, the physical model was difficult to establish, and when the data-driven model analyzes the status, it results in unclear physical mechanisms. Considering the sensitive characteristics of the temperature characterizing the degradation process of slewing bearings, the fusion of the physical models representing degradation and data-driven models was examined. Then, the Arrhenius Equation, which characterizes the degradation using temperature, was introduced into the nonlinear Wiener model, and a new degradation model was established for the fan slewing bearings.

Targeting the closed expression of the PDF of RUL: Moreover, considering the random change of the drift coefficients and the individual differences, the closed expression of the PDF of RUL was derived. MLE was used to estimate RUL parameters based on the CHI. In addition, Bayesian analysis was used to update the parameters and achieve online estimation.

Case analysis and results: To verify the effectiveness of the introduced method, the validity of the proposed method was verified by using the temperature data of three groups of the fan slewing bearings. The prediction result of the proposed method was used to compare the traditional nonlinear Wiener degradation model with the temperature signals, the nonlinear Wiener model with the vibration signals, and CNN. To ensure the accuracy of the proposed method, well-known prognostic metrics were adopted in this work, including relative errors, SOA, and MSE.

4. Parameter Estimation and Online Updating

Now, the parameters, , in Equation (19) were estimated and updated. First, the MLE method was used to estimate the initial parameter values by the fused CHI data. Second, the online update of the parameters was implemented using the Bayesian analysis. is a drift coefficient vector, represents the parameter vector based on the degradation observation value, and stands for the parameter estimation vector.

The measurement interval was assumed to be the same, namely . The degradation observation value is . follows a Gaussian distribution, . According to Property 1, follows the Gaussian distribution, .

Let

where the total degradation state information is . The times of the measurement of the product is , and the cumulative degradation value is , , .

Then, it can be obtained that

where

,

,

.

The RUL of

training samples is

. The unknown initial parameter values,

, can be estimated using MLE. The log-likelihood function (Log-LF) of the RUL PDF can be written as follows:

According to , it has , .

First, given

, the maximized

was calculated. The formulas are as follows:

Second,

was estimated by Equations (22) and (26).

Using the one-dimensional search method, the parameter can be estimated, then is let into Equations (23)–(25) to estimate .

Bayesian analysis was also used to achieve online parameter updates. Considering the individual differences of the system, thus is the random variables, and it was supposed to follow a Gaussian distribution, . Then, the prior distribution was marked as , and .

The principal parameters obtained from

to

were recorded as follows:

, and the posterior estimation

of

are expressed as follows:

where

is the likelihood function.

And can be obtained by Theorem 2.

Theorem 2. If the principal element parameters are known, can be updated towhere , , , .

When the degradation data at was obtained, was obtained according to Theorem 2. The updated parameter was substituted to Equation (19), and then the RUL PDF can be calculated at .

5. Case Analysis and Results

This section provides a numerical analysis and practical cases for WTGS slewing bearing to demonstrate the usefulness of the proposed method, including the parameter estimation and RUL prediction.

5.1. Experimental Setup

To verify the validity of the proposed method, a homemade test rig by combining the sensor technology was used, which was provided by the authors of [

17,

32] and was used to monitor data. The structure of the system is depicted in

Figure 4, where G1, G2, and G3 are hydraulic rams to apply axial force, radial force, and turnover movement to a tested slewing bearing, and G4 refers to the hydraulic motor to drive the accompanied slewing bearing. a1–a4 is the accelerometer used for the vibration measurement of the slewing bearing. Meanwhile, the grease temperature and the vibration signals, which were collected by a high-accuracy data acquisition (DAQ) module, were also provided by the authors of [

17,

32]. The structure of the DAQ system is displayed in

Figure 5.

As can be observed in

Figure 4, an internal gear slewing bearing was selected to test for life fatigue, of which the inner ring is the rotatable ring, and the outer ring is the fixed ring. The inner ring of slewing bearing was connected with the outer ring, and the outer ring was fixed with the upper flange. Then, in order to simulate the working environment of WTGS, the experiment started at a constant rotational speed of 4 r/min to apply extreme loads to the slewing bearing. Meanwhile, to monitor the operating condition, four accelerometers a1–a4 were installed along with the radial direction of the slewing bearing for vibration measurement. Moreover, a high-accuracy data acquisition (DAQ) module NI PXIe-4492 was used to collect vibration signals at a sampling rate of 2 kHz. Moreover, to monitor more operating conditions of the slewing bearing, a NI PXI-6238 was also used to measure the lubricating grease temperature, driving torque, and speed at a sampling rate of 10 Hz. In

Figure 5, the DAQ system, NI PXIe-1062Q, collected all the data from PXIe-4492 and PXI-6238 through the LabVIEW interface. The test stopped when the slewing bearing became stuck and came to a critical failure after 12,000 min.

5.2. Multisensor Data Fusion

According to reference [

33], the material of the yaw and variable paddle bearings casing was 42CrMo. By using the data collected by the sensor, the curve of the degradation data can be obtained after sampling. The a1 data, a2 data, and a3 data are the surface temperature data of the slewing bearing. The three groups of data are fitted in

Figure 6. The three groups of data showed an increasing trend with the increase in the monitoring time, especially with a sharp increase in the later stage. These results are consistent with the trend of the signal changes during the device degradation. After our analysis, the three groups of temperature data were selected for experimental verification.

To accurately estimate the RUL of the fan slewing bearings, it is necessary to select features by calculating the Spearman correlation coefficients. According to Equation (28), the correlation coefficient is presented in

Table 2, and the selected feature is shown in

Figure 7.

In

Table 2, the Spearman correlation coefficient of the maximum feature was the highest, indicating that it has a high similarity to the degradation mechanism of the original temperature signal. As can also be observed in

Figure 7a, as the monitoring time increased, the maximum feature generally showed an overall up trend with good tenability. To the random variation of the operation process of the wind turbine slewing bearing, the maximum feature also exhibited up and down fluctuations, which have non-monotonic characteristics. This effect indicates that the maximum feature can effectively represent temperature data, and its calculation method is simple. Therefore, the maximum features were selected as the experimental data to validate the model. The maximum features of three groups of data were extracted, respectively, as can be observed in

Figure 8.

In

Figure 8, the curve contains state data of 12,000 min from the observation time stage to the complete failure.

Due to the fluctuation and rise of the temperature difference between day and night and the external ambient temperature, the temperature rise curve slowly raised before 5000 min and 9000 min. The temperature rise increased after 10,000~11,000 min.

To improve the estimation accuracy by using the data collected from sensors, the three groups of temperature eigenvalues were fused.

The three groups of temperature eigenvalues were recorded as

. First, the eigenvalues were normalized by Equation (2) to obtain

,

. Second, the PCA analysis was used to obtain the correlation coefficient matrix, the eigenvalues, and the contribution rate, as can be seen in

Table 3 and

Table 4, which were verified by the Bartlett and Kaiser–Meyer–Olkin (KMO) test (

Table 5).

As can be ascertained from

Table 3,

Table 4 and

Table 5, the KMO reached 0.733, which is greater than 0.5, and the last row of significance data value is less than 0.005, which meets the criteria, whereas the variables are independent of each other to some extent. The contribution rate of the first principal element Q1 alone reached 98.8%, more than 80%. Therefore, the first principal element was selected to reflect the original three groups’ sample characterization parameters, which reflect the degradation process of the equipment. The principal element coefficients were hence derived (

Table 6).

To verify that the main metadata can reflect the degradation process of the equipment, the three groups of temperature eigenvalues are displayed in

Figure 8. More specifically, the

X1 sample degradation curve, the

X2 sample degradation curve, the

X3 sample degradation curve, and the fused data were derived, as can be seen in

Figure 9. Moreover, compared to the original characterization parameters, the degradation trend was more obvious and can well represent the equipment degradation process.

Finally, the pair of principal element thresholds were determined. In ref. [

34], the failure thresholds can be obtained by performing many destructive experiments. The failure threshold of each sample data was set as the value of the last moment of fault occurrence, and the fused principal threshold can be calculated. The degradation thresholds of the three characterization parameters were 39.49 °C, 39.65 °C, and 39.94 °C, and the fused threshold

was 68.74 °C.

In

Figure 10, the overall trend of the entire curve reflects the corresponding relationship between the wear of the monitoring points of the slewing bearing and the temperature changes.

The system reached a stable state through running-in in the initial stage. After a monitoring time of 9000 min, the gear wear increased, and CHI data significantly increased until 120,000 min when the equipment stopped due to a malfunction, then a failure threshold of 68.74 °C.

5.3. Arrhenius Parameter Calculation

In this work, a new random degradation model, the nonlinear Wiener model, which was combined with the Arrhenius model, was established to accurately describe the degradation process of the slewing bearings. According to reference [

35], Equation (11) was taken to obtain the following Equation:

Before the estimation of the parameters, and should be calculated. As can be seen from Equation (29), a linear relationship between and exists. Combined with the temperature data, it can be calculated, , . was used in Equation (11), and can be calculated, . Since the variation of both and in the studied temperature range is negligible, they can be regarded as constants.

5.4. PDF of Degradation Incremental Simulation

To verify the rationality of Equation (13), a Monte Carlo simulation was conducted to fit the PDF of

model. The fused temperature eigenvalue was used for verification. Then,

were calculated,

. First, according to the occurrence frequency of

, the obtained is represented by b1. Second, the probability histogram represented by b2 was used to fit the curve. Third, based on the collected temperature data, the expectation and variance of

were calculated as 0.08478 and 0.79876, respectively. The curve following the Gaussian distribution of the expectation and variance is represented by b3, as can be seen in

Figure 11.

By considering

Figure 11, the b2 and b3 curves are close to each other. Then, Equation (13) can be applied to characterize the degradation process of the slewing bearings.

5.5. RUL Estimation

For the convenience of analyzing the estimated results, the estimation results of RUL of the model proposed, which are represented as M1, were compared with those of the nonlinear Wiener degradation model based on the temperature signals, which are represented as M2 [

26]. The nonlinear Wiener degradation model based on vibration signals was also represented as M3 [

27,

28]. The M2 model can be expressed as follows:

The parameter,

, needs to be estimated. The estimated parameter values at 4 and 7 times are presented in

Table 7 and

Table 8.

To compare the fit degree of the degenerate models to the data, the Akaike information criterion (AIC) and the Log-LF were introduced as the evaluation criteria of the modeling method. The equation is as follows:

where

is the likelihood function value, and

denotes the number of the unknown parameters in the model (

Table 8).

As can be observed in

Table 7 and

Table 8, the parameters,

, were constantly updated with the increase in the monitoring time and degradation data. The parameter

was less than 1, indicating a nonlinear degradation process.

At different monitoring times, the Log LF of the M1 model was the largest, and the corresponding AIC was the smallest. The Log-LF of the M2 model was smaller than that of the M3 model, and the corresponding AIC value was smaller than that of the M3 model. Therefore, it can be inferred that the fitting effect of the M1 model was better than that of the M2 and M3 models, while the fitting effect of the M3 model was the worst.

To verify the effectiveness of the proposed models, the RUL estimation results at different observation times were compared, as can be observed in

Figure 12.

In

Figure 12, the RUL estimation results of degenerate data at 1, 2, 4, 5, 7, 9, and 10 times are presented. At the same time, the RUL PDF and the true values are included. The RUL estimation of the M1 model was compared with the RUL estimation of the M2 model, the M3 model, and the real RUL. The error between the RUL and the true value became progressively smaller as the observation time increased. In the early stage of the equipment operation, due to the lack of monitoring data, the estimation results of all models exhibited significant errors. As the monitoring time and data increased, the curve of RUL PDF gradually became narrower, the amplitude increased, the variance decreased, and the predicted results were closer to the real value. The estimation accuracy of the M1 model was better than that of the M2 and M3 models, and the M3 model had the worst estimation performance. Therefore, this result indicates that the RUL estimation results of the M1 model had the least uncertainty, the predicted results were closer to the true values, and the estimation effect was the best.

In addition, to validate the overall prediction level of the M1 model, the overall prediction results of the M1 model, M2 model, and M3 model are displayed in

Figure 13. From these results, it can be concluded that the prediction result of the M1 model was closer to the true values, indicating that the proposed model was more accurate.

To further quantify the estimation results of the three models, the relative error (

RE), the mean square value error (

MSE), and the score of accuracy (

SOA) of the estimated RUL [

36] were used to compare the estimation results of the RUL at different estimation moments. The relative error comparison results were derived, as can be seen in

Table 9.

The

SOAi of the estimated RUL at the

time can be expressed as follows:

The

MSEi of the estimated RUL at the

time can be expressed as follows:

In

Table 9, by increasing the measurement time, the estimation

RE of the three models was progressively reduced, while the estimation accuracy of the proposed model was better than the others.

According to

Figure 14, the curve of

SOAi at each measurement point

of the three models was obtained by Equation (32), as shown in

Figure 14. As can be seen, although the

SOA has certain fluctuations, the

SOAi of the M1 model were higher than those of M2 and M3 at almost all monitoring times. The RUL estimation of M1 was the more accurate.

The curve of

MSEi at each measurement point

of the three models was obtained by Equation (33), as shown in

Table 10 and

Figure 15.

As can be ascertained from

Table 10 and

Figure 15, the

MSEi was relatively large at 1 time, whereas the observation data increased, the

MSEi of the estimated RUL gradually decreased. From the general comparison, the RUL estimation of the M1 method at a different time was less than the others. The M1 method can be effectively used to describe the remaining life estimation of the fan slewing bearings.

In addition, the

SOA and

MSE values were calculated by Equation (32) and Equation (33), respectively, and the overall

SOA and

MSE by Equations (34) and (35) of the three models are illustrated in

Figure 16.

According to the results in

Figure 13, the overall

SOA decreased in the following order: M1, M2, and M3; thus, the proposed model M1 achieved more accurate estimation results than the other models. Similarly, model M1 had the smallest

MSE values and was followed by M2, and M3 had the largest

MSE values. Thus, the RUL estimation results of M1 exhibited less uncertainty than those of the other models.

To further illustrate the effectiveness of the M1 model in predicting the RUL of the fan slewing bearing, the estimation results of the method proposed were compared with those based on Convolutional Neural Networks (CNN). The three groups of original temperature data were also used as input data for network training. A three-layer CNN was selected to train the data, and the estimated RUL was obtained, as can be seen in

Figure 17.

According to the results depicted in

Figure 17, compared with the different monitoring points at 9, 10, and 11, the RUL error of the CNN model gradually decreased as the monitoring time and data increased. In

Figure 17c, at the monitoring time

min, the average failure time, which was predicted by the CNN model, was

min. However, the average failure time predicted by the M1 model was

min, and the real failure time was

min. This result indicates that the estimation error of RUL based on the M1 model was less than that using the CNN model, and the estimation accuracy was higher.

In

Table 11, the prediction results of different methods were summarized and compared. The method proposed in this work possesses higher SOA, lower MSE, and better prediction performance than other methods.

In

Table 12, the prediction results between three models and CNN at 9, 10, and 11 times were summarized. However, the volume of the fan slewing bearings is large, the operating state randomly changes, and the cost is high, which renders it difficult to obtain a large amount of destructive data. Moreover, when using CNN for prediction, the quantitative uncertainty ability is insufficient. Therefore, the prediction accuracy using CNN was lower than the other three methods. The proposed method in this work has the smallest prediction error.

5.6. PCA Principal Component Threshold Selection Analysis

To verify the impact of the selection of principal component thresholds on the PCA fusion effect. The RUL prediction results were extracted by selecting PCA fusion results with thresholds of 80%, 85%, and 90%, respectively, in

Figure 18.

From

Figure 18, the RUL prediction results with a total contribution rate of the principal element greater than 90% were closer to the actual RUL, and the prediction effect was better than those greater than 85% and 80%, respectively. This outcome indicates that a better PCA fusion effect, combined with the fusion degradation model proposed in this work, leads to more accurate prediction results of the RUL of the fan slewing bearings.

Based on the above-mentioned comparative research, it can be argued that the fusion nonlinear Wiener mode of the data-driven model and the physical model based on temperature data fusion have better RUL estimation accuracy and fitting effect than the nonlinear Wiener model based on vibration data, the nonlinear Wiener model based on single temperature data, and the CNN method. As a result, the proposed model is more suitable for RUL estimation of the fan slewing bearings.

6. Conclusions

It is well-established that many factors affect the estimation RUL of the fan slewing bearings. Moreover, considering the large volume and slow speed of the fan slewing bearing, the monitored vibration signal can be easily disturbed by the external environment. And the physical model is difficult to establish, and the physical mechanism of the data-driven model is not obvious. In addition, to improve the accuracy of RUL estimation of the fan slewing bearings, based on multi-sensor temperature data fusion, a new nonlinear Wiener model, which was based on the fusion of the machine model and the data-driven model, was proposed to accurately describe the degradation process of the fan slewing bearings. First, considering the sensitive characteristics of the temperature characterizing the degradation process of the slewing bearings, the temperature data were selected to analyze the RUL prediction. A PCA analysis was also performed to calculate the correlation coefficient matrix, eigenvalues, and contribution rates for all temperature data detected by multiple sensors and obtain the fused degraded data, which characterize the comprehensive health index CHI. Second, a new random degradation model, which combined the Arrhenius physical model with the nonlinear Wiener model, was established to describe the degradation process of the slewing bearings. The RUL prediction was analyzed using the physical properties and surface temperature data of the equipment. Moreover, the closed expression for the RUL PDF was derived for the random variation of drift coefficients and the individual differences. The parameter initial values of the degenerate model were estimated using MLE, and Bayesian analysis was utilized to update online. Consequently, real-time estimation can be realized. Third, compared with the traditional nonlinear Wiener degradation model with the temperature signals, the nonlinear Wiener model with the vibration signals, and the CNN, the RUL estimation results of the proposed method yielded high accuracy and small relative errors, high SOA, and small MSE. Therefore, the proposed method improved the reliability of the model estimation. On top of that, the developed model can be effectively used for the degenerative process of the fan slewing bearings and contribute to the sustainable development of wind power generation. Although the accuracy of the RUL prediction was significantly improved, further optimization is needed to improve the stability.

In this work, the importance of principal component selection thresholds in PCA for feature extraction was analyzed, as well as their impact on the accuracy of RUL prediction. In ref. [

37], a method for adaptive principal component threshold selection was proposed by combining principal component analysis (PCA) with a Bayesian network (BN). This method avoids the influence of artificial threshold setting, improves the accuracy of feature selection, and thus enhances the robustness of RUL prediction. Moreover, the fan slewing bearings have a large volume, slow operating speed, and high maintenance cost, and the degradation process can be easily affected by the external environment. Therefore, it is difficult to obtain a large amount of destructive data. To provide a more accurate analysis of the RUL, multiple factors need to be considered, including modeling for the degradation process as accurately as possible, fusing multiple sensor data, more accurate feature extraction methods, and developing fused degradation models. We are currently working on these issues. Therefore, in the case of limited samples, the efficient and accurate prediction of the RUL of wind turbine slewing bearings remains a challenge.