Servitization, Digitalization or Hand in Hand: A Study on the Sustainable Development Path of Manufacturing Enterprises

Abstract

1. Introduction

2. Literature Review and Research Hypotheses

2.1. Servitization Path and SDA of Manufacturing Enterprises

2.2. Digitalization Path and SDA of Manufacturing Enterprises

2.3. Digital Servitization Path and SDA of Manufacturing Enterprises

3. Methods

3.1. Construction of Evaluation Index System of SDA of Manufacturing Enterprises

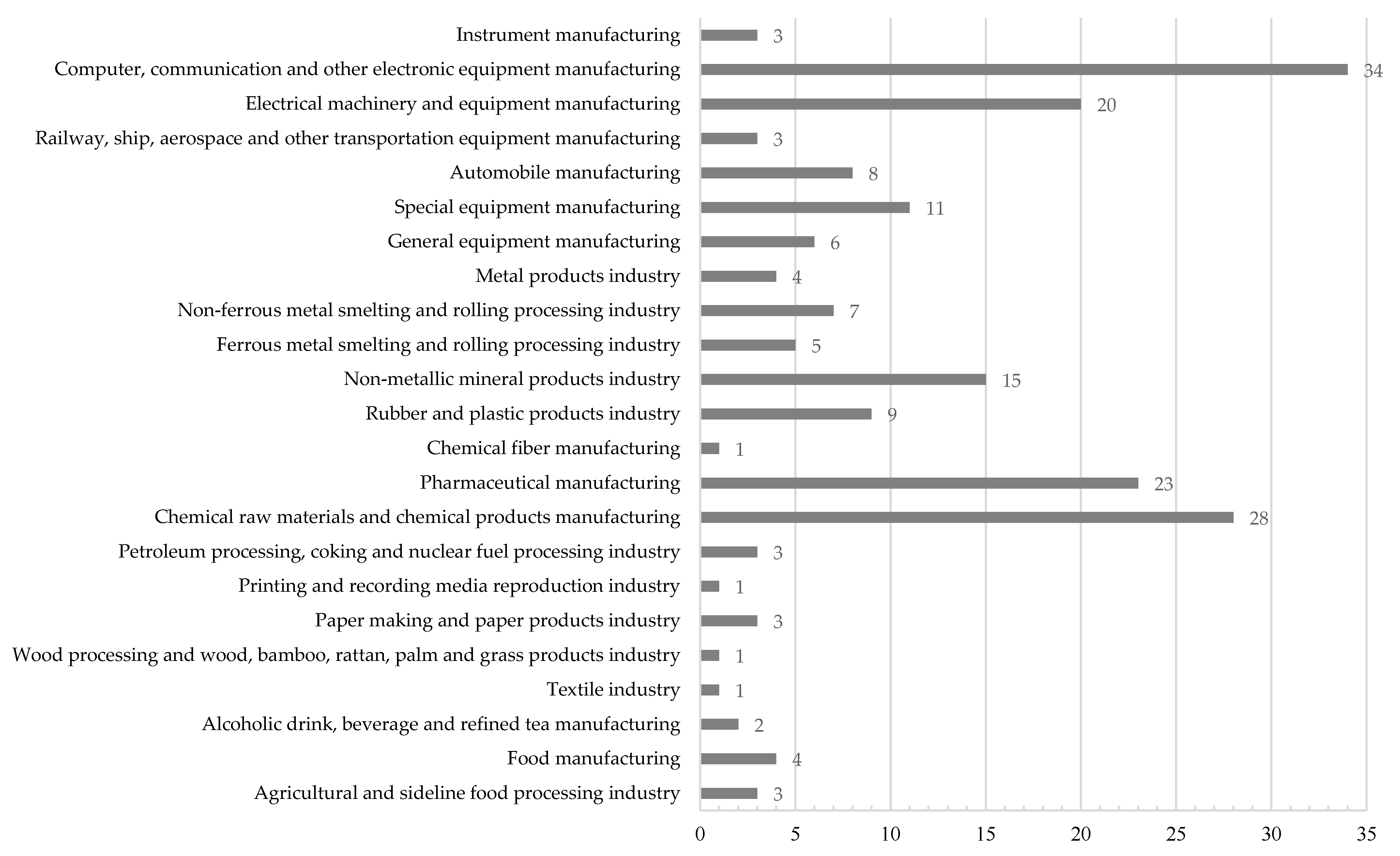

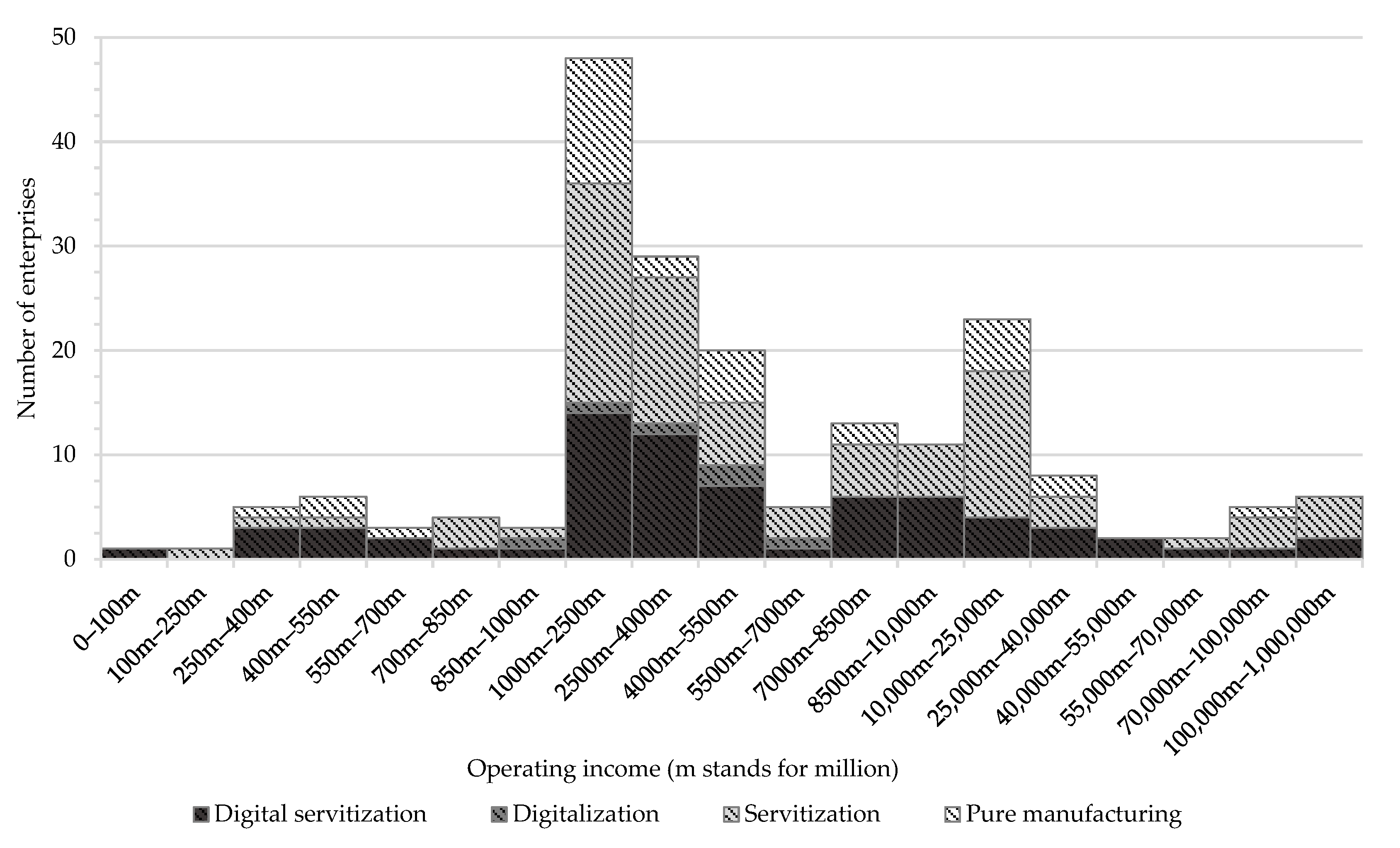

3.2. Data Collection and Sample Distribution

3.3. Division of Development Paths of Sample Enterprises

4. Empirical Analysis

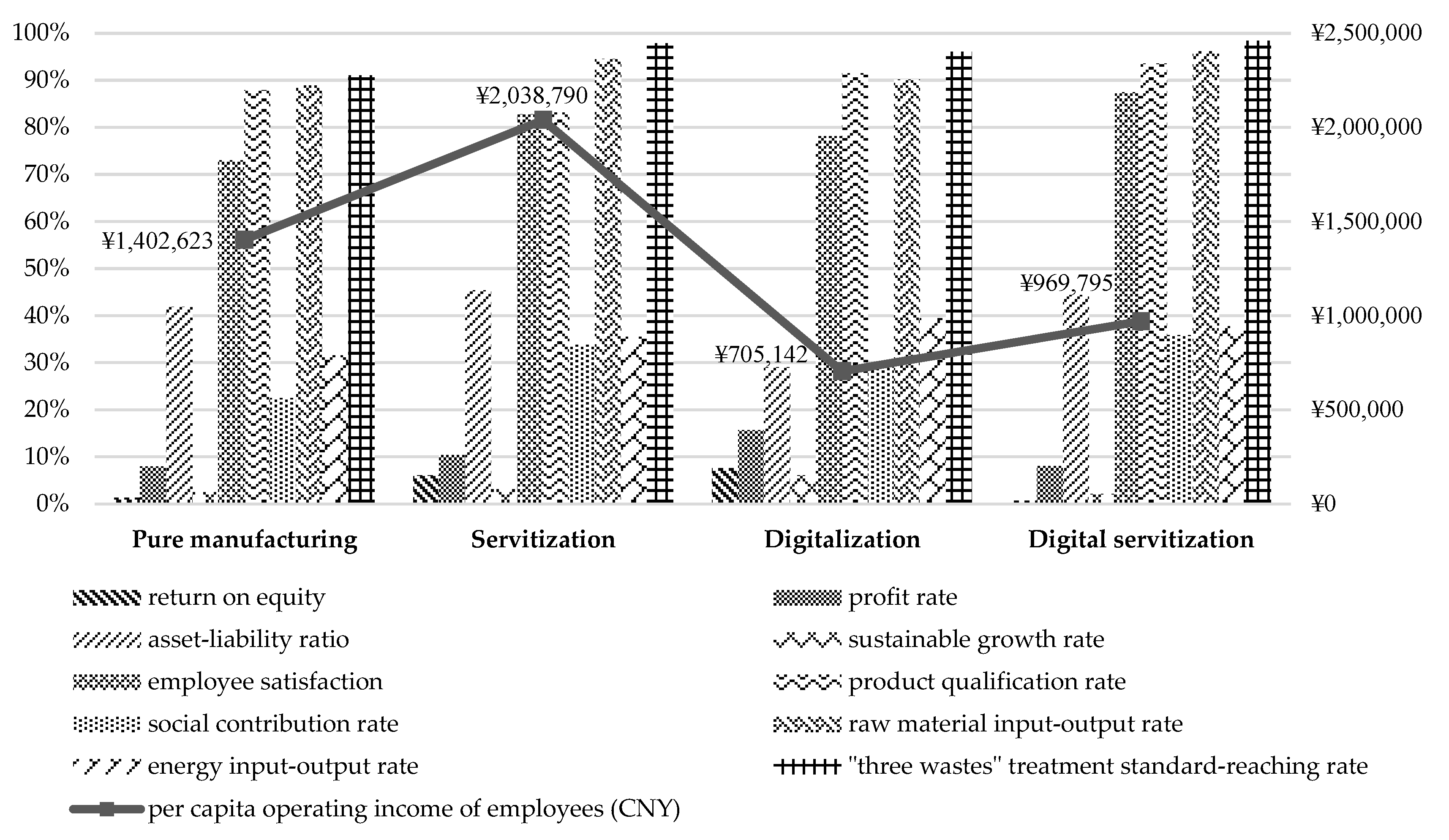

4.1. Descriptive Statistics

4.2. Non-Parametric Mann–Whitney–Wilcoxon (MWW) Test

4.3. Polynomial Logit Regression Cluster Analysis

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, J.Q.; Jiang, Q.W. The influence of digital technology on product and service innovation: A review and prospects. Sci. Technol. Prog. Pol. 2020, 37, 152–160. [Google Scholar]

- Jang, K.K.; Bae, J.; Kim, K.H. Servitization experience measurement and the effect of servitization experience on brand resonance and customer retention. J. Bus. Res. 2021, 130, 384–397. [Google Scholar] [CrossRef]

- Shen, L.; Sun, C.; Ali, M. Role of servitization, digitalization, and innovation performance in manufacturing enterprises. Sustainability 2021, 13, 9878. [Google Scholar] [CrossRef]

- Hao, Z.R.; Liu, C.G.; Goh, M. Determining the effects of lean production and servitization of manufacturing on sustainable performance. Sustain. Prod. Consum. 2021, 25, 374–389. [Google Scholar] [CrossRef]

- Brax, S.A.; Calabrese, A.; Ghiron, N.L.; Tiburzi, L.; Grnroos, C. Explaining the servitization paradox: A configurational theory and a performance measurement framework. Int. J. Oper. Prod. Manag. 2021, 41, 517–546. [Google Scholar] [CrossRef]

- Hellemans, I.; Porter, A.J.; Diriker, D. Harnessing digitalization for sustainable development: Understanding how interactions on sustainability-oriented digital platforms manage tensions and paradoxes. Bus. Strat. Environ. 2021, 31, 668–683. [Google Scholar] [CrossRef]

- Neely, A. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 1, 103–118. [Google Scholar] [CrossRef]

- Benedettini, O.; Neely, A.; Swink, M. Why do servitized firms fail? A risk-based explanation. Int. J. Oper. Prod. Manag. 2015, 35, 946–979. [Google Scholar] [CrossRef]

- Baines, T.; Lightfoot, H.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef]

- Kolagar, M.; Parida, V.; Sjödin, D. Ecosystem transformation for digital servitization: A systematic review, integrative framework, and future research agenda. J. Bus. Res. 2022, 146, 176–200. [Google Scholar] [CrossRef]

- Vandermerwe, S.; Rada, J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Reiskin, E.D.; White, A.L.; Johnson, J.K.; Votta, T.J. Servicizing the chemical supply chain. J. Ind. Ecol. 1999, 3, 19–31. [Google Scholar] [CrossRef]

- Szalavetz, A. Tertiarization of manufacturing industry in the new economy: Experiences in Hungarian companies. J. Mark. 2003, 134, 54–55. [Google Scholar]

- Kowalkowski, C.; Gebauer, H.; Kamp, B.; Parry, G. Servitization and deservitization: Overview, concepts, and definitions. Ind. Mark. Manag. 2017, 60, 4–10. [Google Scholar] [CrossRef]

- Brax, S.A.; Visintin, F. Meta-model of servitization: The integrative profiling approach. Ind. Mark. Manag. 2017, 60, 17–32. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, Z.J.; Yi, W.C.; Wang, B.J.; Yao, J.H.; Pei, Z.; Chen, J.L. Bibliometric method for manufacturing servitization: A review and future research directions. Sustainability 2022, 14, 8743. [Google Scholar] [CrossRef]

- Schmidt, F.C.; Zanini, R.R.; Korzenowski, A.L.; Schmidt, R.; do Nascimento, K.B.X. Evaluation of sustainability practices in small and medium-sized manufacturing enterprises in southern Brazil. Sustainability 2018, 10, 2460. [Google Scholar] [CrossRef]

- Chang, A.Y.; Cheng, Y.T. Analysis model of the sustainability development of manufacturing small and medium-sized enterprises in Taiwan. J. Clean. Prod. 2018, 207, 458–473. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Neri, A.; Howard, M. Measuring industrial sustainability performance: Empirical evidence from Italian and German manufacturing small and medium enterprise. J. Clean. Prod. 2019, 229, 1355–1376. [Google Scholar] [CrossRef]

- Doni, F.; Corvino, A.; Martini, S.B. Servitization and sustainability actions. Evidence from European manufacturing companies. J. Environ. Manag. 2019, 234, 367–378. [Google Scholar] [CrossRef]

- Szasz, L.; Seer, L. Towards an operations strategy model of servitization: The role of sustainability pressure. Oper. Manag. Res. 2018, 11, 51–66. [Google Scholar] [CrossRef]

- Hojnik, J. Ecological modernization through servitization: EU regulatory support for sustainable product-service systems. Rev. Eur. Comp. Int. Environ. 2018, 27, 162–175. [Google Scholar] [CrossRef]

- Baines, T.S.; Bigdeli, A.Z.; Bustinza, O.F.; Shi, V.G.; Baldwin, J.; Ridgway, K. Servitization: Revisiting the state-of-the-art and research priorities. Int. J. Oper. Prod. Manag. 2017, 37, 256–278. [Google Scholar] [CrossRef]

- Story, V.M.; Raddats, C.; Burton, J.; Zolkiewski, J.; Baines, T. Capabilities for advanced services: A multi-actor perspective. Ind. Mark. Manag. 2017, 60, 54–68. [Google Scholar] [CrossRef]

- Kamp, B.; Parry, G. Servitization and advanced business services as levers for competitiveness. Ind. Mark. Manag. 2017, 60, 11–16. [Google Scholar] [CrossRef]

- Crozet, M.; Milet, E. Should everybody be in services? The effect of servitization on manufacturing firm performance. J. Econ. Manag. Strat. 2017, 26, 820–841. [Google Scholar] [CrossRef]

- Visnjic Kastalli, I.; Van Looy, B. Servitization: Disentangling the impact of service business model innovation on manufacturing firm performance. J. Oper. Manag. 2013, 31, 169–180. [Google Scholar] [CrossRef]

- Dmitrijeva, J.; Schroeder, A.; Bigdeli, A.Z.; Baines, T. Paradoxes in servitization: A processual perspective. Ind. Mark. Manag. 2022, 101, 145–152. [Google Scholar] [CrossRef]

- Chang, Y.; Ming, X.G.; Zhang, X.Y.; Zhou, T.T.; Liao, X.Q.; Cao, S.J. Servitization and sustainable value creation strategy for China’s manufacturing industry: A multiple case study in the Belt and Road Initiative. Sustainability 2021, 13, 11334. [Google Scholar] [CrossRef]

- Oyelakin, I.O.; Johl, S.K. Does ISO 14001 and green servitization provide a push factor for sustainable performance? A study of manufacturing firms. Sustainability 2022, 14, 9784. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Oghazi, P.; Gebauer, H.; Baines, T. Digital servitization business models in ecosystems: A theory of the firm. J. Bus. Res. 2019, 104, 380–392. [Google Scholar] [CrossRef]

- Parida, V.; Sjödin, D.; Reim, W. Leveraging digitalization for advanced service business models: Reflections from a systematic literature review and special issue contributions. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef]

- Chen, J.; Huang, S.; Liu, Y.H. Operations management in the digitalization era: From empowering to enabling. J. Manag. World 2020, 36, 117–128. [Google Scholar]

- Broccardo, L.; Zicari, A.; Jabeen, F.; Bhatti, Z.A. How digitalization supports a sustainable business model: A literature review. Technol. Forecast. Soc. Change 2023, 187, 122146. [Google Scholar] [CrossRef]

- Kamaladin, A.; Linde, L.; Sjödin, D.; Parida, V. Transforming provider-customer relationships in digital servitization: A relational view on digitalization. Ind. Mark. Manag. 2020, 89, 306–325. [Google Scholar] [CrossRef]

- Cenamor, J.; Sjödin, D.; Parida, V. Adopting a platform approach in servitization: Leveraging the value of digitalization. Int. J. Prod. Econ. 2017, 192, 54–65. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, J.P. Input digitalization and climbing global value chain: Micro evidence from Chinese manufacturing enterprises. Econ. Rev. 2020, 6, 72–89. [Google Scholar]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Broccardo, L.; Truant, E.; Dana, L.P. The interlink between digitalization, sustainability, and performance: An Italian context. J. Bus. Res. 2023, 158, 113621. [Google Scholar] [CrossRef]

- Wamba, S.F.; Gunasekaran, A.; Akter, S.; Ren, S.J.F.; Dubey, R.; Childe, S.J. Big data analytics and firm performance: Effects of dynamic capabilities. J. Bus. Res. 2017, 70, 356–365. [Google Scholar] [CrossRef]

- Ehret, M.; Wirtz, J. Unlocking value from machines: Business models and the industrial internet of things. J. Mark. Manag. 2017, 33, 111–130. [Google Scholar] [CrossRef]

- Hasselblatt, M.; Huikkola, T.; Kohtamäki, M.; Nickell, D. Modeling manufacturer's capabilities for the internet of things. J. Bus. Ind. Mark. 2018, 33, 822–836. [Google Scholar] [CrossRef]

- Sjödin, D.; Parida, V.; Wincent, J. An agile co-creation process for digital servitization: A micro-service innovation approach. J. Bus. Res. 2020, 112, 478–491. [Google Scholar] [CrossRef]

- Grybauskas, A.; Stefanini, A.; Ghobakhloo, M. Social sustainability in the age of digitalization: A systematic literature review on the social implications of industry 4.0. Technol. Soc. 2022, 70, 101997. [Google Scholar] [CrossRef]

- Chen, X.X.; Despeisse, M.; Johansson, B. Environmental sustainability of digitalization in manufacturing: A review. Sustainability 2021, 12, 10298. [Google Scholar] [CrossRef]

- Triki, R.; Maaloul, M.H.; Bahou, Y.; Kadria, M. The impact of digitization to ensure competitiveness of the Ha’il region to achieve sustainable development goals. Sustainability 2023, 15, 1661. [Google Scholar] [CrossRef]

- Sanders, N.R.; Boone, T.; Ganeshan, R.; Wood, J.D. Sustainable supply chains in the age of AI and digitization: Research challenges and opportunities. J. Bus. Logist. 2019, 40, 229–240. [Google Scholar] [CrossRef]

- Favoretto, C.; Mendes, G.H.S.; Oliveira, M.G.; Cauchick-Miguel, P.A.; Coreynen, W. From servitization to digital servitization: How digitalization transforms companies' transition towards services. Ind. Mark. Manag. 2022, 102, 104–121. [Google Scholar] [CrossRef]

- Khin, S.; Ho, T.C.F. Digital technology, digital capability and organizational performance. Int. J. Inov. Sci. 2019, 11, 177–195. [Google Scholar] [CrossRef]

- Coreynen, W.; Matthyssens, P.; Bockhaven, V.W. Boosting servitization through digitization: Pathways and dynamic resource configurations for manufacturers. Ind. Mark. Manag. 2017, 60, 42–53. [Google Scholar] [CrossRef]

- Paiola, M.; Gebauer, H. Internet of things technologies, digital servitization and business model innovation in BtoB manufacturing firms. Ind. Mark. Manag. 2020, 89, 245–264. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y.D.; Gao, J. Servitization and product innovation: The moderating role of environment uncertainty. Sci. Res. Manag. 2020, 41, 140–150. [Google Scholar]

- Kohtamäki, M.; Parida, V.; Patel, P.C.; Gebauer, H. The relationship between digitalization and servitization: The role of servitization in capturing the financial potential of digitalization. Technol. Forecast. Soc. Change 2020, 151, 119804. [Google Scholar] [CrossRef]

- Jankovic-Zugic, A.; Medic, N.; Pavlovic, M.; Todorovic, T.; Rakic, S. Servitization 4.0 as a trigger for sustainable business: Evidence from automotive digital supply chain. Sustainability 2023, 15, 2217. [Google Scholar] [CrossRef]

- Paiola, M.; Schiavone, F.; Grandinetti, R.; Chen, J. Digital servitization and sustainability through networking: Some evidences from IoT-based business models. J. Bus. Res. 2021, 132, 507–516. [Google Scholar] [CrossRef]

- Schiavone, F.; Leone, D.; Caporuscio, A.; Lan, S. Digital servtization and new sustainable configurations of manufacturing systems. Technol. Forecast. Soc. Change 2022, 176, 121441. [Google Scholar] [CrossRef]

- Benedettini, O.; Swink, M.; Neely, A. Examining the influence of service additions on manufacturing firms' bankruptcy likelihood. Ind. Mark. Manag. 2017, 60, 112–125. [Google Scholar] [CrossRef]

- Sklyar, A.; Kowalkowski, C.; Tronvoll, B.; Sorhammar, D. Organizing for digital servitization: A service ecosystem perspective. J. Bus. Res. 2019, 104, 450–460. [Google Scholar] [CrossRef]

| First-Level Indicators | Second-Level Indicators | |

|---|---|---|

| Economic indicators | Production ability | Per capita operating income of employees |

| Profitability | Return on equity and profit rate | |

| Debt-paying ability | Asset–liability ratio | |

| Development ability | Sustainable growth rate | |

| Social indicators | Responsibility to employees | Employee satisfaction |

| Responsibility to customers | Product qualification rate | |

| Responsibility to society | Social contribution rate | |

| Environmental indicators | Raw material utilization | Raw material input–output rate |

| Energy utilization | Energy input–output rate | |

| Environmental protection intensity | “Three-wastes” treatment compliance rate |

| Servitization | Digitalization | ||||||

|---|---|---|---|---|---|---|---|

| Keywords | Frequency | Keywords | Frequency | Keywords | Frequency | Keywords | Frequency |

| Service | 119 | Test/Detection | 16 | Electronics | 95 | Telecom | 4 |

| Development | 101 | After sales | 12 | Communication | 63 | New energy | 3 |

| Research/R&D | 90 | Training | 10 | Software | 29 | Digital | 2 |

| Consulting | 80 | Recycling | 7 | Technology | 25 | High-end control | 1 |

| Transportation/Freight/Logistics | 56 | Maintenance | 6 | Automatic | 21 | ||

| Leasing/Rental | 55 | Support | 4 | Information | 18 | ||

| Management | 53 | Procurement | 4 | Intelligence | 17 | ||

| Design | 53 | Advertising | 3 | Network | 15 | ||

| Agent | 42 | Planning | 2 | Data | 9 | ||

| Installation | 35 | Intermediary | 1 | Digit | 8 | ||

| Repair | 31 | Outsourcing | 1 | High-tech | 8 | ||

| Warehousing/Storage | 19 | Internet | 6 | ||||

| (a) Per capita operating income of employees | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.269 | 0.000 *** | 0.000 *** | |

| S-enterprise | 0.000 *** | 0.000 *** | ||

| D-enterprise | 0.007 ** | |||

| DS-enterprise | ||||

| (b) Return on equity | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.000 *** | 0.074 | 0.037 * | |

| S-enterprise | 0.715 | 0.027 * | ||

| D-enterprise | 0.472 | |||

| DS-enterprise | ||||

| (c) Profit rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.031 * | 0.000 *** | 0.031 * | |

| S-enterprise | 0.000 *** | 0.986 | ||

| D-enterprise | 0.000 *** | |||

| DS-enterprise | ||||

| (d) Asset–liability ratio | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.005 ** | 0.000 *** | 0.146 | |

| S-enterprise | 0.000 *** | 0.092 | ||

| D-enterprise | 0.000 *** | |||

| DS-enterprise | ||||

| (e) Sustainable growth rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.000 *** | 0.050 * | 0.000 *** | |

| S-enterprise | 0.308 | 0.102 | ||

| D-enterprise | 0.817 | |||

| DS-enterprise | ||||

| (f) Employee satisfaction | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.002 ** | 0.049 * | 0.036 * | |

| S-enterprise | 0.000 *** | 0.000 *** | ||

| D-enterprise | 0.006 ** | |||

| DS-enterprise | ||||

| (g) Product qualification rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.000 *** | 0.000 *** | 0.004 ** | |

| S-enterprise | 0.000 *** | 0.002 ** | ||

| D-enterprise | 0.000 *** | |||

| DS-enterprise | ||||

| (h) Social contribution rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.378 | 0.007 ** | 0.000 *** | |

| S-enterprise | 0.128 | 0.002 ** | ||

| D-enterprise | 0.000 *** | |||

| DS-enterprise | ||||

| (i) Raw material input–output rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.003 ** | 0.000 *** | 0.001 ** | |

| S-enterprise | 0.002 ** | 0.000 *** | ||

| D-enterprise | 0.000 *** | |||

| DS-enterprise | ||||

| (j) Energy input–output rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.000 *** | 0.000 *** | 0.000 *** | |

| S-enterprise | 0.000 *** | 0.003 ** | ||

| D-enterprise | 0.179 | |||

| DS-enterprise | ||||

| (k) “Three-wastes” treatment compliance rate | ||||

| P-enterprise | S-enterprise | D-enterprise | DS-enterprise | |

| P-enterprise | 0.025 * | 0.036 * | 0.007 ** | |

| S-enterprise | 0.421 | 0.000 *** | ||

| D-enterprise | 0.192 | |||

| DS-enterprise | ||||

| Coef. | Robust Std. Err. | p > z | ||

|---|---|---|---|---|

| S-enterprise | Profit rate | 0.622 | 0.325 | 0.000 *** |

| Constant | 0.901 | 0.071 | 0.056 | |

| D-enterprise | Profit rate | 1.727 | 0.590 | 0.000 *** |

| Constant | −1.903 | 0.163 | 0.003 ** | |

| DS-enterprise | Profit rate | 0.013 | 0.313 | 0.000 *** |

| Constant | 0.751 | 0.071 | 0.968 | |

| Number of obs | 1950 | |||

| Pseudo R2 | 0.065 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Ma, L.; Li, J. Servitization, Digitalization or Hand in Hand: A Study on the Sustainable Development Path of Manufacturing Enterprises. Sustainability 2023, 15, 10644. https://doi.org/10.3390/su151310644

Xie J, Ma L, Li J. Servitization, Digitalization or Hand in Hand: A Study on the Sustainable Development Path of Manufacturing Enterprises. Sustainability. 2023; 15(13):10644. https://doi.org/10.3390/su151310644

Chicago/Turabian StyleXie, Jifei, Lulu Ma, and Jiamin Li. 2023. "Servitization, Digitalization or Hand in Hand: A Study on the Sustainable Development Path of Manufacturing Enterprises" Sustainability 15, no. 13: 10644. https://doi.org/10.3390/su151310644

APA StyleXie, J., Ma, L., & Li, J. (2023). Servitization, Digitalization or Hand in Hand: A Study on the Sustainable Development Path of Manufacturing Enterprises. Sustainability, 15(13), 10644. https://doi.org/10.3390/su151310644