Bearing Capacity Analysis of the Weak Basement, Progressive Destruction Analysis, and Evaluation of the Dump on an Inclined Strip Section Using the Upper-Limit Method: A Case Study in an Anonymous Open-Cast Coal Mine

Abstract

1. Introduction

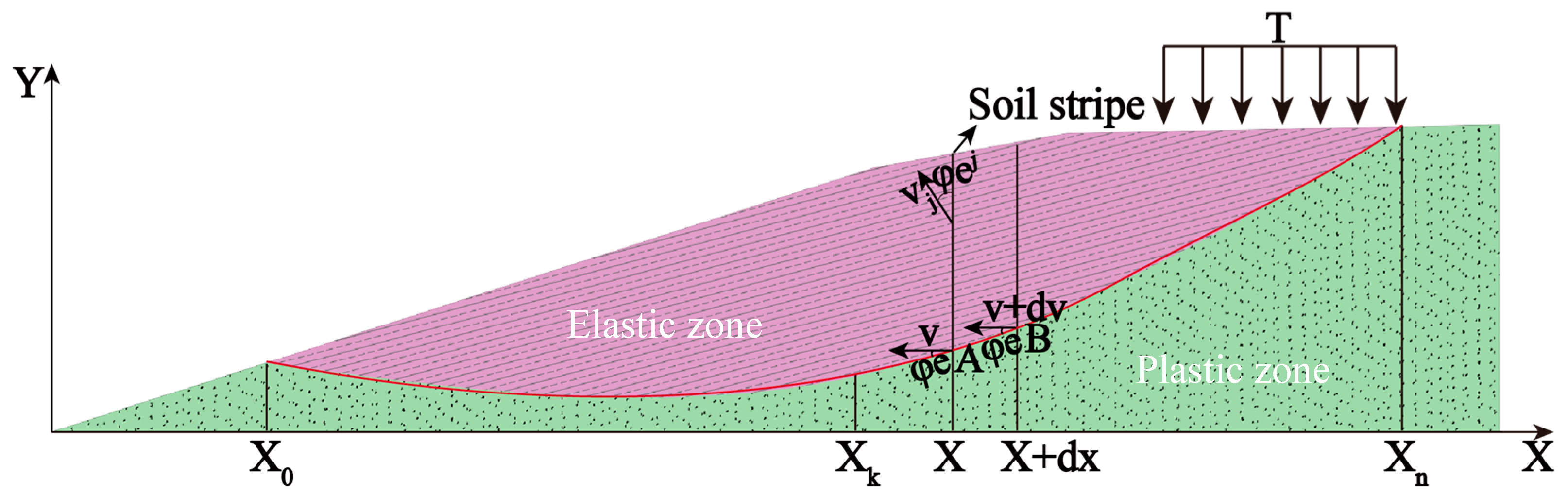

2. The Basic Principle of the Oblique Slice Upper-Limit Method

2.1. The Basic Equation of the Upper-Limit Method

2.2. Determination of the Critical Sliding Surface

3. Project Overview

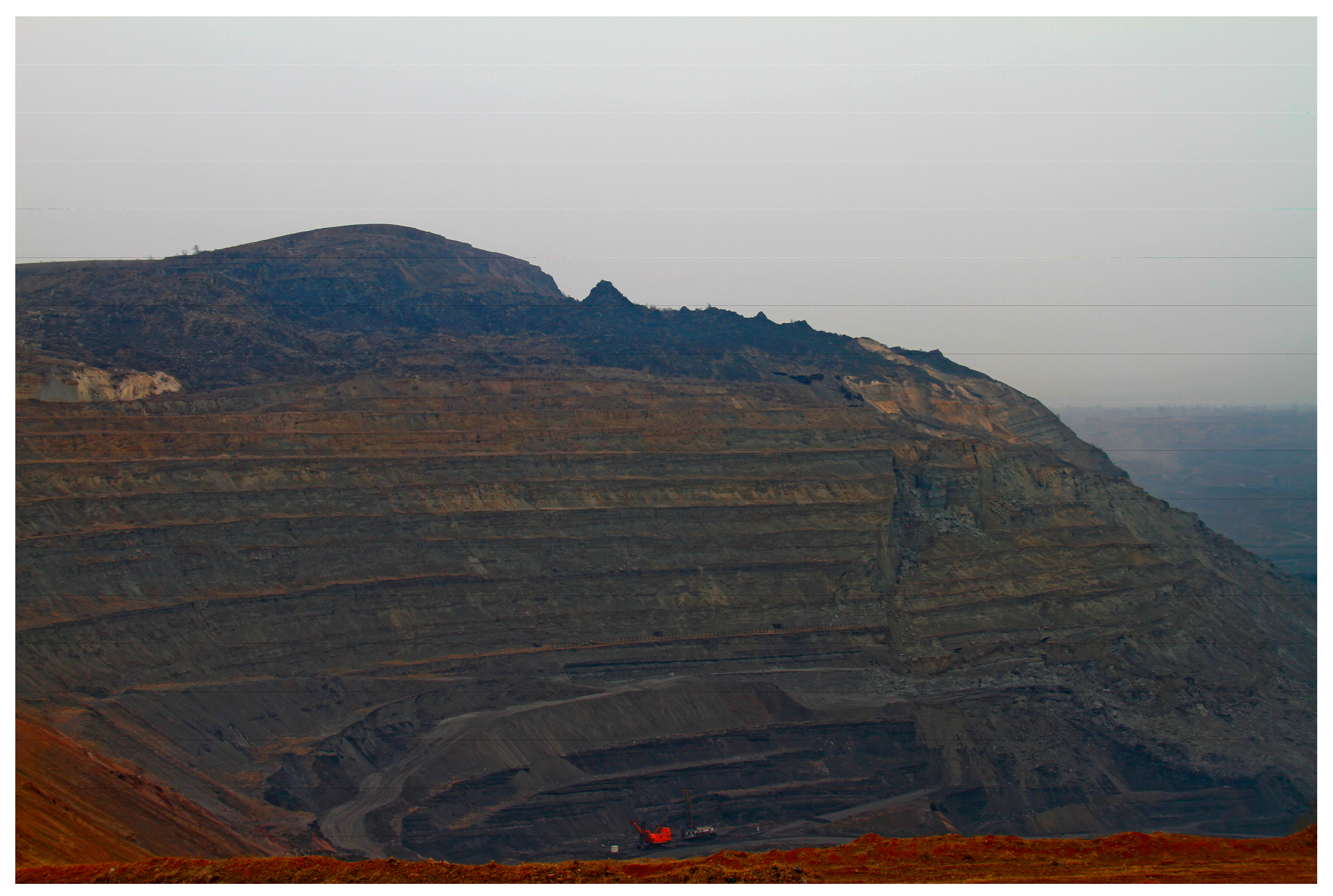

3.1. Disposal Status

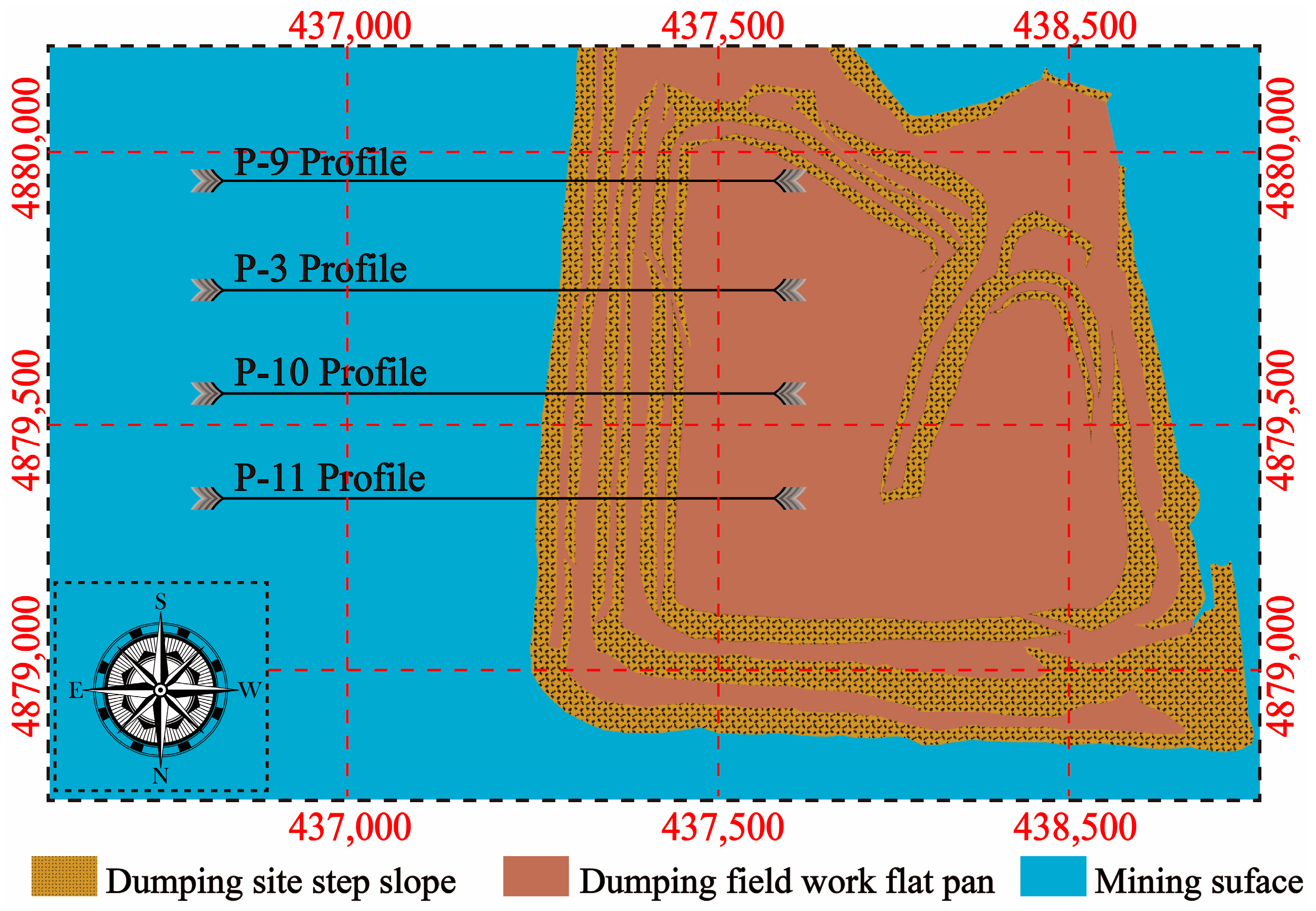

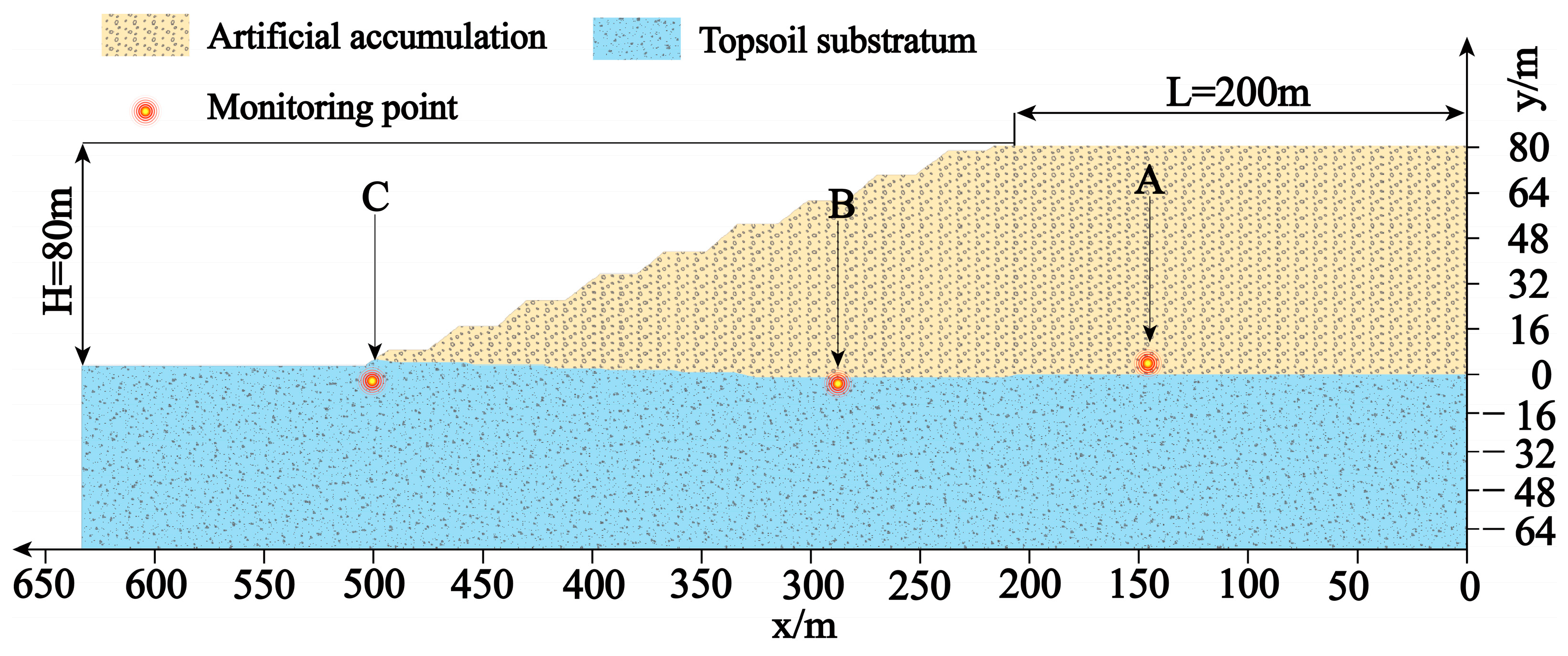

3.2. Base Form

3.3. Physical and Mechanical Indicators

4. Calculation of the Ultimate Bearing Capacity of the Base of the Earthworks Using the Oblique Strip Method and Numerical Simulation

4.1. Calculation Sections

4.2. Calculation Hypothesis Conditions

4.3. Calculation of the Current Base Ultimate Bearing Capacity of the Earthworks

4.4. Analysis of Factors Affecting Base Ultimate Bearing Capacity and Stability

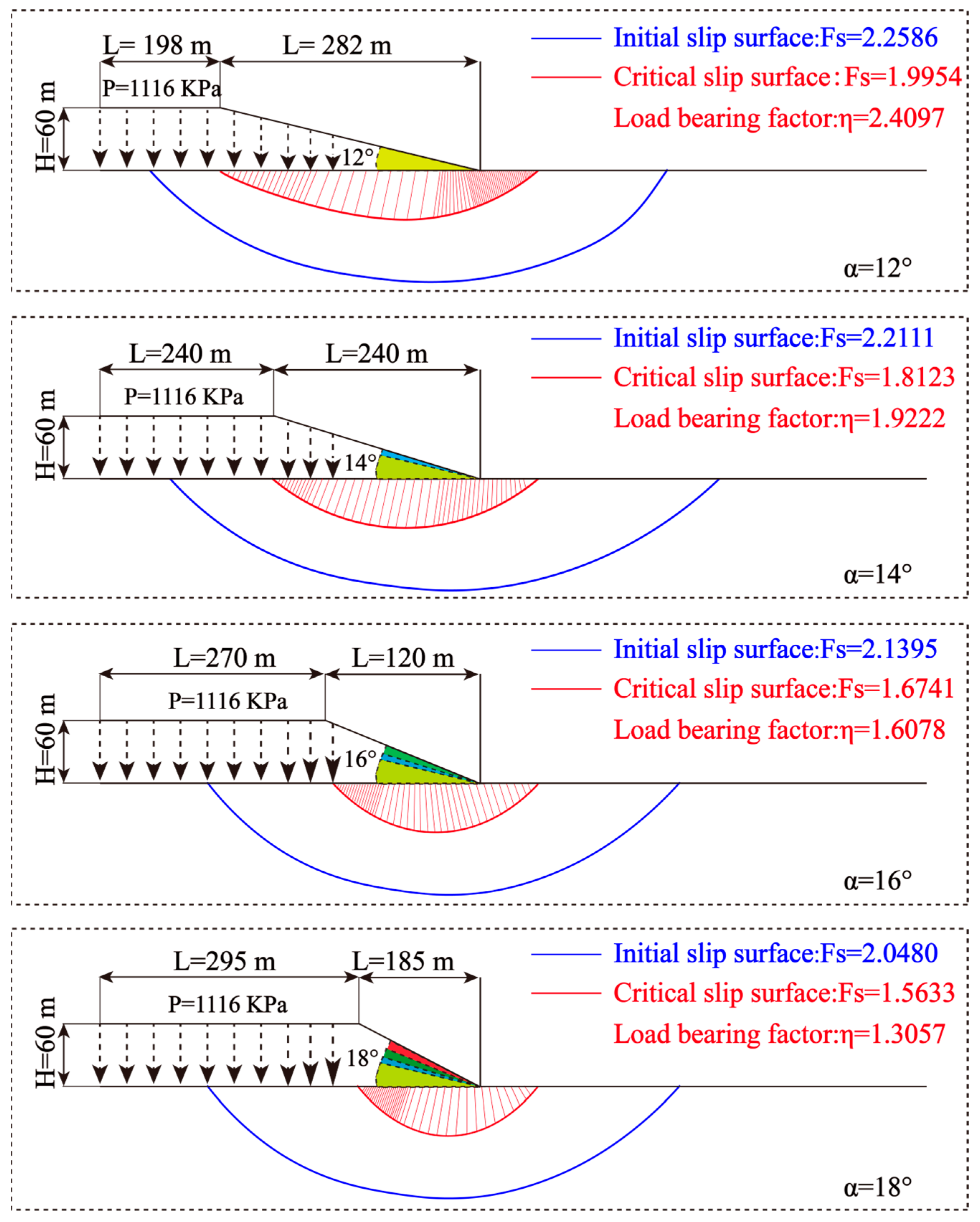

4.4.1. Slope Angle

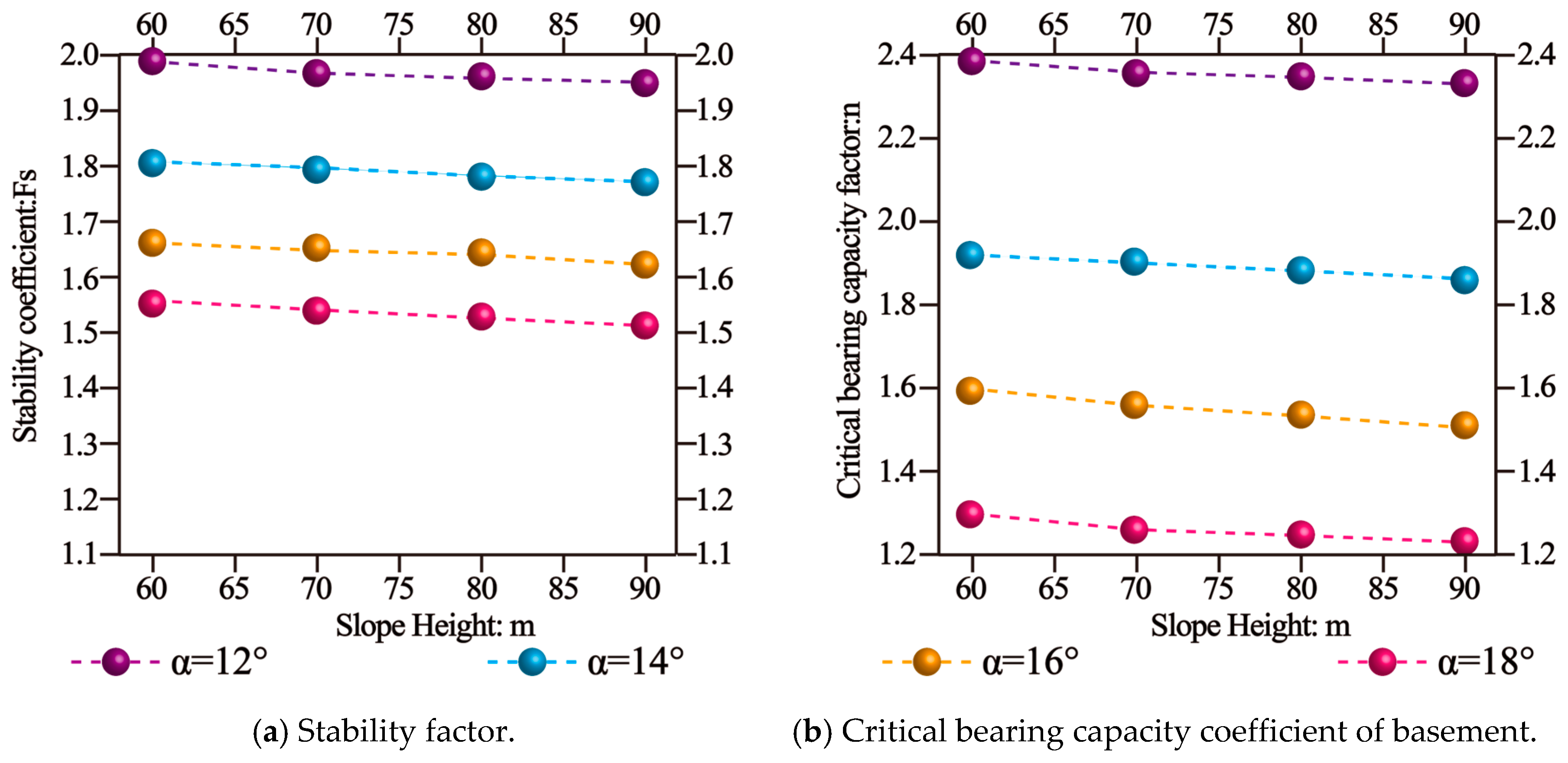

4.4.2. Foundation Width B

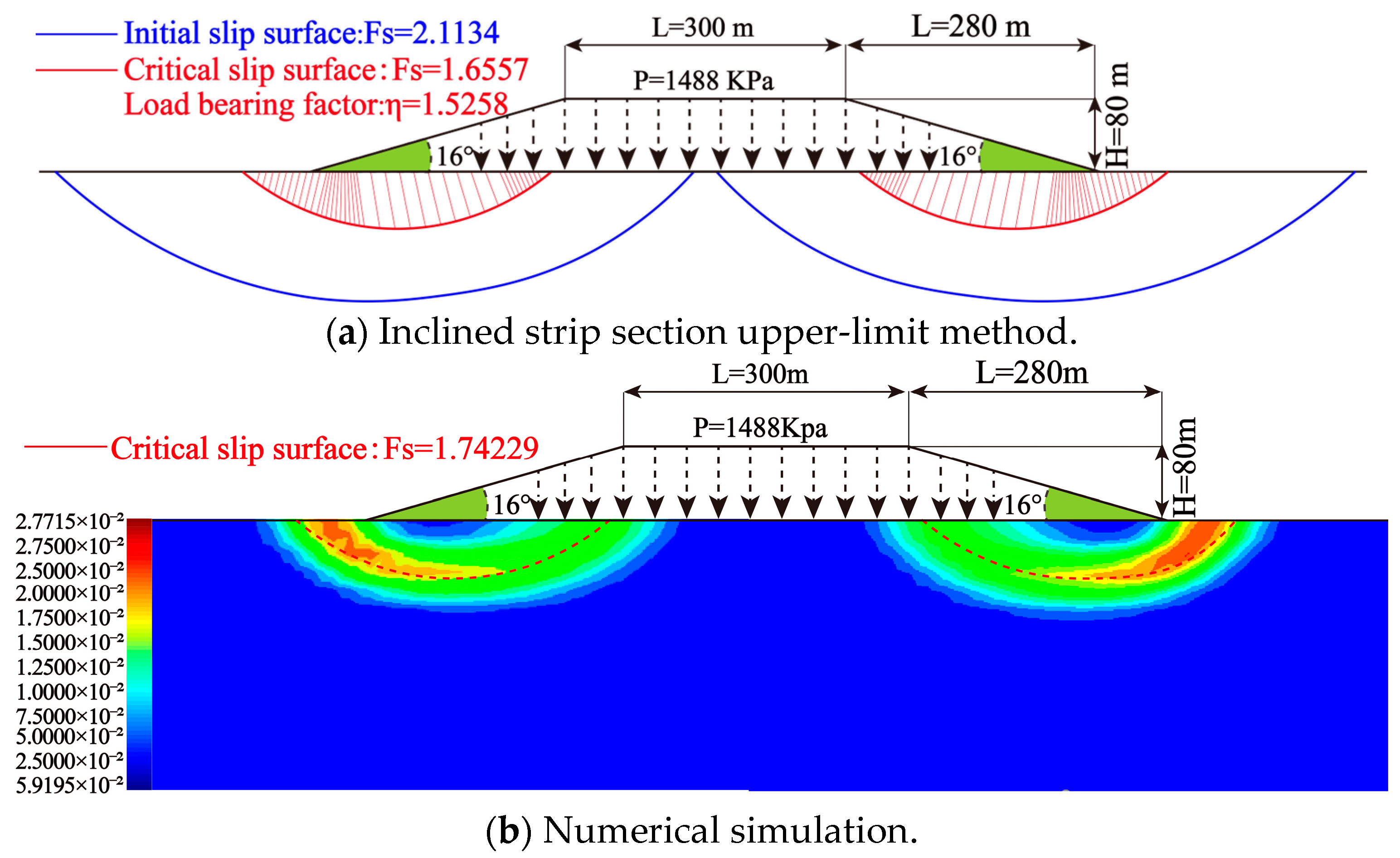

5. Comparative Explication of Computational Results

6. Conclusions

- (1)

- The results of the slope strip upper-limit method and numerical simulation are very close, with a calculation error within 5%, and the critical sliding surface is consistent, proving the reliability of the slope strip upper-limit method in solving the ultimate bearing capacity of the soft foundation of the open-pit mine dumping ground.

- (2)

- The ultimate bearing capacity of the soft foundation of the open-pit mine dumping ground is mainly controlled by the triangular load, the current ultimate bearing capacity of the foundation is 3781 kPa, and the foundation destruction mode is along the whole shearing sliding of the foundation of the dumping ground.

- (3)

- For slopes with a height of 60–100 m, the slope base angle increases from 12° to 18°, and the foundation stability coefficient and the critical bearing capacity coefficient decrease by about 21% and 46%, respectively; when the slope height increases from 60 m to 100 m, and the slope base increases to 18°, the foundation stability coefficient and the critical bearing capacity coefficient of the slope decrease by about 2.1% and 6.6%, respectively; when the foundation width increases from 860 m to 1260 m, the foundation stability coefficient and the critical bearing capacity coefficient of the foundation increase by about 0.01% and 0.48%, respectively. It can be seen that the foundation stability coefficient and the critical bearing capacity coefficient of the slope are greatly affected by the slope angle and are relatively little affected by the slope height, and there is almost no width effect.

- (4)

- Compared with the Terzaghi method and the Prandtl method, the ultimate bearing capacity of the foundation of the dumping ground determined by the slope strip upper-limit method proposed in this paper is closer to the numerical simulation calculation results and is also more consistent with the surface uplift parts monitored by engineering practice. Adopting the slope strip upper-limit method to analyze the soft foundation of the open cast mine dumping ground can provide a more reliable reference for engineering design and construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| V | Displacement velocity of rigid body |

| C | Cohesion of soil strip |

| u | Pore water pressure |

| Tx | The component of the external load T in the x direction |

| Ty | The component of the external load T in the y direction |

| T* | Limit value of bearing capacity of substrate |

| L | Length of adjacent boundary surfaces |

| T0 | The actual external load on the basement |

| Greek Alphabets | |

| φ | Internal friction angle of soil strip |

| φej | Angle between soil strip and adjacent interface |

| Ce, φe | Strength index reduced by safety factor Fs |

| α | Positive angle between base interface and x axis |

| η′ | Horizontal seismic acceleration coefficient |

| η | Critical bearing coefficient |

| θj | The angle between the velocity Vj and the positive x axis |

References

- Kumar, A.; Das, S.K.; Nainegali, L.; Reddy, K.R. Phytostabilization of coalmine overburden waste rock dump slopes: Current status, challenges, and perspectives. Bull. Eng. Geol. Environ. 2023, 82, 130. [Google Scholar] [CrossRef]

- Upadhyay, O.P.; Sharma, D.K.; Singh, D.P. Factors affecting stability of waste dumps in mines. Int. J. Surf. Min. Reclam. Environ. 1990, 4, 95–99. [Google Scholar] [CrossRef]

- Tian, Y.; Zhou, W.; Jiskani, I.M.; Cai, Q.; Li, Z.; Lu, X. Stability analysis of varying height waste dump in open-pit mine under particle size gradation and reconstruction effect of waste materials. Int. J. Surf. Min. Reclam. Environ. 2022, 36, 587–604. [Google Scholar] [CrossRef]

- Kasmer, O.; Ulusay, R. Stability of Spoil Piles at Two Coal Mines in Turkey: Geotechnical Characterization and Design Considerations. Environ. Eng. Geosci. 2006, 12, 337–352. [Google Scholar] [CrossRef]

- Rakhmangulov, A.; Burmistrov, K.; Osintsev, N. Sustainable Open Pit Mining and Technical Systems: Concept, Principles, and Indicators. Sustainability 2021, 13, 1101. [Google Scholar] [CrossRef]

- Werner, T.T.; Mudd, G.M.; Schipper, A.M.; Huijbregts, M.A.J.; Taneja, L.; Northey, S.A. Global-scale remote sensing of mine areas and analysis of factors explaining their extent. Glob. Environ. Chang. 2020, 60, 102007. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Akbari, F. Investigation of Soil Active Wedge Angle with Linear Matric Suction Distribution Below the Footing. Int. J. Civ. Eng. 2020, 18, 161–168. [Google Scholar] [CrossRef]

- Purhamadani, E.; Bagherpour, R.; Tudeshki, H. Energy consumption in open-pit mining operations relying on reduced energy consumption for haulage using in-pit crusher systems. J. Clean. Prod. 2021, 291, 125228. [Google Scholar] [CrossRef]

- Mikhailov, V.G.; Koryakov, A.G.; Mikhailov, G.S. Ecological risk management in coal mining and processing. J. Min. Sci. 2015, 51, 930–936. [Google Scholar] [CrossRef]

- Xu, D.; Li, X.; Chen, J.; Li, J. Research Progress of Soil and Vegetation Restoration Technology in Open-Pit Coal Mine: A Review. Agriculture 2023, 13, 226. [Google Scholar] [CrossRef]

- Gao, M.; Xie, J.; Gao, Y.; Wang, W.; Li, C.; Yang, B.; Liu, J.; Xie, H. Mechanical behavior of coal under different mining rates: A case study from laboratory experiments to field testing. Int. J. Min. Sci. Technol. 2021, 31, 825–841. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, Y.; Han, P.; Bai, Q. Coal pillar failure analysis and instability evaluation methods: A short review and prospect. Eng. Fail. Anal. 2022, 138, 106344. [Google Scholar] [CrossRef]

- Jiang, S.; Li, J.; Zhang, S.; Gu, Q.; Lu, C.; Liu, H. Landslide risk prediction by using GBRT algorithm: Application of artificial intelligence in disaster prevention of energy mining. Process Saf. Environ. Prot. 2022, 166, 384–392. [Google Scholar] [CrossRef]

- Du, C.; Wang, J.; Wang, Y. Study on environmental pollution caused by dumping operation in open pit mine under different factors. J. Wind Eng. Ind. Aerodyn. 2022, 226, 105044. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, Q.; Liu, X.; Li, Y. Preparation of topsoil alternatives for open-pit coal mines in the Hulunbuir grassland area, China. Appl. Soil Ecol. 2020, 147, 103431. [Google Scholar] [CrossRef]

- Fu, Z.; Asad, M.W.A.; Topal, E. A new model for open-pit production and waste-dump scheduling. Eng. Optim. 2019, 51, 718–732. [Google Scholar] [CrossRef]

- Kia, S.; Flesch, T.K.; Freeman, B.S.; Aliabadi, A.A. Atmospheric transport over open-pit mines: The effects of thermal stability and mine depth. J. Wind Eng. Ind. Aerodyn. 2021, 214, 104677. [Google Scholar] [CrossRef]

- deBoer, R.; Schiffman, R.L.; Gibson, R.E. The origins of the theory of consolidation: The Terzaghi-Fillunger dispute. Geotechnique 1996, 46, 175–186. [Google Scholar]

- Badalyan, G.G.; Dmitrienko, V.A.; Skomorokhov, A.A. Resource-saving Technology of Building of Vertical Mine Working in Soil. Procedia Eng. 2016, 150, 2293–2301. [Google Scholar] [CrossRef]

- Ahmadi, S.; Kamalian, M.; Askari, F. Evaluation of the Static Bearing Capacity Coefficients of Rough Strip Footing Using the Stress Characteristics Method. Int. J. Civ. Eng. 2021, 19, 155–165. [Google Scholar] [CrossRef]

- Chakraborty, D.; Kumar, J. Bearing capacity of foundations on slopes. Geomech. Geoengin. 2013, 8, 274–285. [Google Scholar] [CrossRef]

- Tang, W.; Li, F.; Xiang, G.; Liu, M. Investigation on flow field characteristics in an open-pit coal mine. Environ. Sci. Pollut. Res. 2022, 29, 27585–27594. [Google Scholar] [CrossRef] [PubMed]

- Siña, M.; Guzmán, J.I. Real option valuation of open pit mines with two processing methods. J. Commod. Mark. 2019, 13, 30–39. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Akbari, F. Determining the bearing capacity factor due to nonlinear matric suction distribution in the soil. Can. J. Soil Sci. 2019, 99, 434–446. [Google Scholar] [CrossRef]

- Yang, G.; Huang, Z.; Jiang, Y.; Zhang, Y. Double controlling method for determining bearing capacity of foundation soils. Rock Soil Mech. 2016, 37, 232–242. [Google Scholar] [CrossRef]

- Yang, X.L.; Li, L.; Yin, J.-H. Seismic and static stability analysis for rock slopes by a kinematical approach. Geotechnique 2004, 54, 543–549. [Google Scholar] [CrossRef]

- Zhao, M.H.; Hu, X.; Zhang, R. Numerical simulation of the bearing capacity of a foundation near slope using the upper bound finite element method. Rock Soil Mech. 2016, 37, 1137–1143+1152. [Google Scholar] [CrossRef]

- Nie, R.-s. Experimental study on bearing capacity of the gravel soil. J. Railw. Sci. Eng. 2011, 8, 57–61. [Google Scholar]

- Tovele, G.S.V.; Han, L.; Shu, J.S. Variation of Open-Pit Waste Dump Specimens Under Effective Pressure Influence. Front. Earth Sci. 2021, 8, 582918. [Google Scholar] [CrossRef]

- Guo, J.X.; Graeber, P.W. Landslide forecasting based on hydrological process simulation for a dump slope in an open mining pit. J. Groundw. Sci. Eng. 2018, 6, 92–103. [Google Scholar] [CrossRef]

- Burmistrov, K.V.; Osintsev, N.A.; Shakshakpaev, A.N. Selection of Open-Pit Dump Trucks during Quarry Reconstruction. Procedia Eng. 2017, 206, 1696–1702. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, R.; Lv, S.; Wang, Y. Open-pit mine truck fuel consumption pattern and application based on multi-dimensional features and XGBoost. Sustain. Energy Technol. Assess. 2021, 43, 100977. [Google Scholar] [CrossRef]

- Bajany, D.M.; Zhang, L.; Xia, X. An Optimization Approach for Shovel Allocation to Minimize Fuel Consumption in Open-pit Mines: Case of Heterogeneous Fleet of Shovels. IFAC-PapersOnLine 2019, 52, 207–212. [Google Scholar] [CrossRef]

- Das, S.; Maheshwari, B.K. Seismic Bearing Capacity and Elastic Settlement of Footing on Slopes. In Soil Dynamics: Select Proceedings of 7th Icragee 2020; Lecture Notes in Civil Engineering (LNCE 119); Springer: Singapore, 2021; pp. 399–407. [Google Scholar] [CrossRef]

- Ahmadi, S.; Kamalian, M.; Askari, F. Evaluating the Nγ coefficient for rough strip footing located adjacent to the slope using the stress characteristics method. Comput Geotech. 2022, 142, 104543. [Google Scholar] [CrossRef]

- Kumar, J.; Ghosh, P. Seismic bearing capacity for embedded footings on sloping ground. Geotechnique 2006, 56, 133–140. [Google Scholar] [CrossRef]

- Tyulenev, M.; Markov, S.; Cehlár, M.; Zhironkin, S.; Gasanov, M. The model of direct dumping technology implementation for open pit coal mining by high benches. Acta Montan. Slovaca 2018, 23, 368–377. [Google Scholar]

- Bednarczyk, Z. Slope Stability Analysis for the Design of a New Lignite Open-Pit Mine. Procedia Engineering. 2017, 191, 51–58. [Google Scholar] [CrossRef]

- Dandin, S.; Kulkarni, M.; Wagale, M.; Sathe, S. A review on the geotechnical response of fly ash-colliery spoil blend and stability of coal mine dump. Clean. Waste Syst. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Baza-Varas, A.; Canals, M.; Frigola, J.; Cerdà-Domènech, M.; Rodés, N.; Tarrés, M.; Sanchez-Vidal, A. Multiproxy characterization of sedimentary facies in a submarine sulphide mine tailings dumping site and their environmental significance: The study case of Portmán Bay (SE Spain). Sci. Total Environ. 2022, 810, 151183. [Google Scholar] [CrossRef]

- Ahmadi, S.; Kamalian, M.; Askari, F. Considerations on Bearing Capacity Factors of Rough Strip Footing Using the Stress Characteristics Method. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 2611–2621. [Google Scholar] [CrossRef]

- Batlle, J.A.; Barjau Condomines, A. Interaction Forces between Rigid Bodies. In Rigid Body Dynamics; Barjau Condomines, A., Batlle, J.A., Eds.; Cambridge University Press: Cambridge, UK, 2022; pp. 79–150. [Google Scholar]

| Material | γ/kN·m−3 | E/GPa | μ | c/kPa | φ/(°) |

|---|---|---|---|---|---|

| Man-made deposits | 18.6 | 0.12 | 0.4 | 15.13 | 14 |

| Topsoil substrate | 18.6 | 0.15 | 0.28 | 7 | 11 |

| B/m | Terzaghi Method P1/kPa | Prandtl Method P2/kPa | Inclined Strip Section Upper-Limit Method P3/kPa | Finite Difference Method P4/kPa | P-S Numerical Method P5/kPa |

|---|---|---|---|---|---|

| 330 | 1896.8 | 306.2 | 3772 | 3965 | 4000 |

| 380 | 2174.9 | 306.2 | 3775 | 3965 | 4000 |

| 430 | 2453 | 306.2 | 3780 | 3965 | 4000 |

| 480 | 2731.1 | 306.2 | 3781 | 3965 | 4000 |

| 530 | 3009.1 | 306.2 | 3775 | 3965 | 4000 |

| 580 | 3287.2 | 306.2 | 3783 | 3965 | 4000 |

| 630 | 3565.2 | 306.2 | 3779 | 3965 | 4000 |

| 680 | 3843.3 | 306.2 | 3780 | 3965 | 4000 |

| 730 | 4121.4 | 306.2 | 3781 | 3965 | 4000 |

| 780 | 4399.4 | 306.2 | 3780 | 3965 | 4000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Y.; Du, H.; Chen, M. Bearing Capacity Analysis of the Weak Basement, Progressive Destruction Analysis, and Evaluation of the Dump on an Inclined Strip Section Using the Upper-Limit Method: A Case Study in an Anonymous Open-Cast Coal Mine. Sustainability 2023, 15, 10240. https://doi.org/10.3390/su151310240

Hong Y, Du H, Chen M. Bearing Capacity Analysis of the Weak Basement, Progressive Destruction Analysis, and Evaluation of the Dump on an Inclined Strip Section Using the Upper-Limit Method: A Case Study in an Anonymous Open-Cast Coal Mine. Sustainability. 2023; 15(13):10240. https://doi.org/10.3390/su151310240

Chicago/Turabian StyleHong, Yan, Han Du, and Mingxi Chen. 2023. "Bearing Capacity Analysis of the Weak Basement, Progressive Destruction Analysis, and Evaluation of the Dump on an Inclined Strip Section Using the Upper-Limit Method: A Case Study in an Anonymous Open-Cast Coal Mine" Sustainability 15, no. 13: 10240. https://doi.org/10.3390/su151310240

APA StyleHong, Y., Du, H., & Chen, M. (2023). Bearing Capacity Analysis of the Weak Basement, Progressive Destruction Analysis, and Evaluation of the Dump on an Inclined Strip Section Using the Upper-Limit Method: A Case Study in an Anonymous Open-Cast Coal Mine. Sustainability, 15(13), 10240. https://doi.org/10.3390/su151310240