Effect of Whey Protein Concentrate on Rheological Properties of Gluten-Free Doughs and Their Performance in Cookie Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Flours

2.2. Mixograph and Dynamic Rheometer

2.3. Cookie Preparation and Properties Evaluation

2.4. Statistical Analysis

3. Results and Discussion

3.1. Optimal Water Absorption of Flour Mixtures

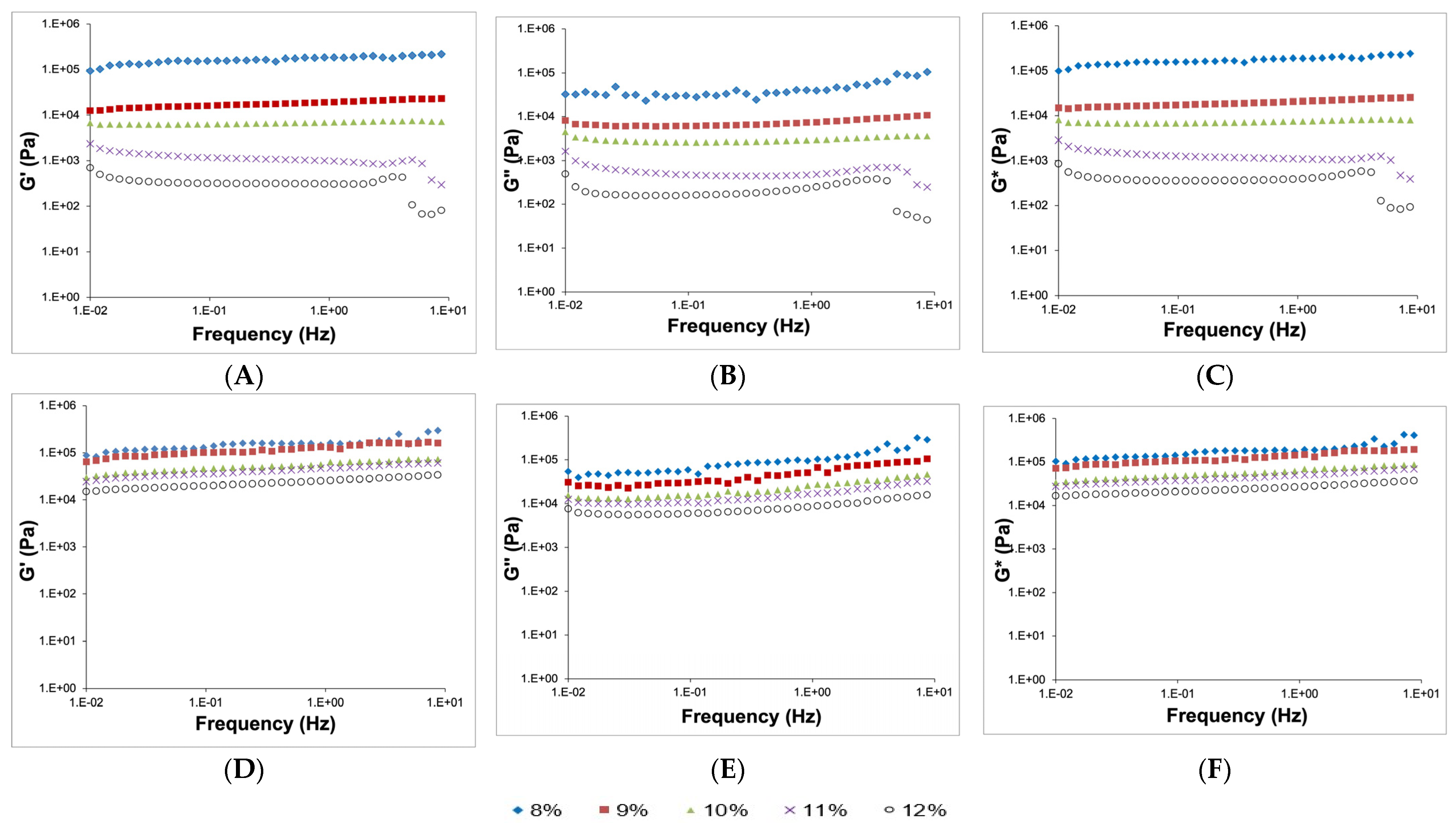

3.2. Rheological Properties of Sorghum and Corn Doughs with 8–12% WPC

3.3. Evaluation of Cookies from Sorghum and Corn Flour with 8–12% WPC

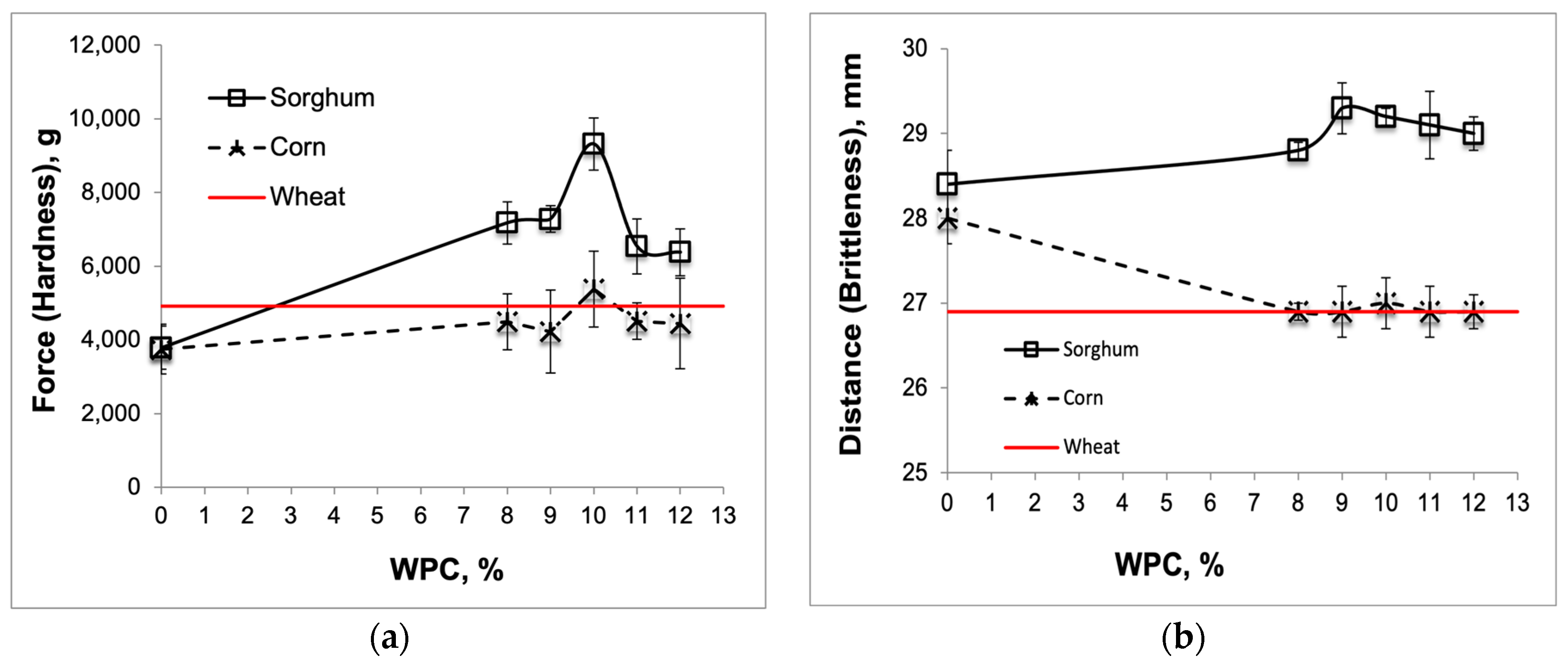

3.4. Textural Characteristics of Cookies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anyango, J.O.; Taylor, J.R.N. Sorghum flour and flour products: Production, nutritional quality, and fortification. In Flour and Breads and Their Fortification in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2019; pp. 137–151. [Google Scholar]

- Jin, J.; Ma, H.; Wang, K.; Yagoub, A.E.-G.A.; Owusu, J.; Qu, W.; He, R.; Zhou, C.; Ye, X. Effects of multi-frequency power ultrasound on the enzymolysis and structural characteristics of corn gluten meal. Ultrason. Sonochemistry 2015, 24, 55–64. [Google Scholar] [CrossRef]

- Yu, X.; Liu, J.; Liu, Y.; Fang, G. Critical role of glutelin in ultrasound-assisted isolation of corn starch. Int. J. Food Sci. Technol. 2022, 57, 489–498. [Google Scholar] [CrossRef]

- El Khoury, D.; Balfour-Ducharme, S.; Joye, I.J. A review on the gluten-free diet: Technological and nutritional challenges. Nutrients 2018, 10, 1410. [Google Scholar] [CrossRef]

- Taylor, J.R.N.; Taylor, J.; Campanella, O.H.; Hamaker, B.R. Functionality of the storage proteins in gluten-free cereals and pseudocereals in dough systems. J. Cereal Sci. 2016, 67, 22–34. [Google Scholar] [CrossRef]

- Bacenetti, J.; Bava, L.; Schievano, A.; Zucali, M. Whey protein concentrate (WPC) production: Environmental impact assessment. J. Food Eng. 2018, 224, 139–147. [Google Scholar] [CrossRef]

- Zandona, E.; Blažić, M.; Režek Jambrak, A. Whey utilization: Sustainable uses and environmental Approach. Food Technol. Biotechnol. 2021, 59, 147–161. [Google Scholar] [CrossRef]

- Amer, S.A.; Osman, A.; Al-Gabri, N.A.; Elsayed, S.A.; Abd El-Rahman, G.I.; Elabbasy, M.T.; Ahmed, S.A.; Ibrahim, R.E. The effect of dietary replacement of fish meal with whey protein concentrate on the growth performance, fish health, and immune status of nile tilapia fingerlings, Oreochromis niloticus. Animals 2019, 9, 1003. [Google Scholar] [CrossRef]

- Stojkov, K. Infestations as a Natural Disaster: The Economic Impacts of the Fonterra Whey Protein Concentrate Contamination Incident. Master’s Thesis, Vctoria University of Wellington, Wellington, New Zealand, 2016. Available online: http://hdl.handle.net/10063/5018 (accessed on 20 June 2023).

- Long, Z.; Zhao, M.; Sun-Waterhouse, D.; Lin, Q.; Zhao, Q. Effects of sterilization conditions and milk protein composition on the rheological and whipping properties of whipping cream. Food Hydrocoll. 2016, 52, 11–18. [Google Scholar] [CrossRef]

- Mantovani, R.A.; Cavallieri, Â.L.F.; Cunha, R.L. Gelation of oil-in-water emulsions stabilized by whey protein. J. Food Eng. 2016, 175, 108–116. [Google Scholar] [CrossRef]

- Mohammadian, M.; Salami, M.; Momen, S.; Alavi, F.; Emam-Djomeh, Z.; Moosavi-Movahedi, A.A. Enhancing the aqueous solubility of curcumin at acidic condition through the complexation with whey protein nanofibrils. Food Hydrocoll. 2019, 87, 902–914. [Google Scholar] [CrossRef]

- Peters, J.P.; Vergeldt, F.J.; Van As, H.; Luyten, H.; Boom, R.M.; van der Goot, A.J. Time domain nuclear magnetic resonance as a method to determine and characterize the water-binding capacity of whey protein microparticles. Food Hydrocoll. 2016, 54, 170–178. [Google Scholar] [CrossRef]

- Schröder, A.; Berton-Carabin, C.; Venema, P.; Cornacchia, L. Interfacial properties of whey protein and whey protein hydrolysates and their influence on O/W emulsion stability. Food Hydrocoll. 2017, 73, 129–140. [Google Scholar] [CrossRef]

- Sutariya, S.G.; Huppertz, T.; Patel, H.A. Influence of milk pre-heating conditions on casein–whey protein interactions and skim milk concentrate viscosity. Int. Dairy J. 2017, 69, 19–22. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Y.; Yadav, M.P.; Li, J. Effect of various hydrocolloids on the physical and fermentation properties of dough. Food Chem. 2019, 271, 165–173. [Google Scholar] [CrossRef]

- Liu, N.; Ma, S.; Li, L.; Wang, X. Study on the effect of wheat bran dietary fiber on the rheological properties of dough. Grain Oil Sci. Technol. 2019, 2, 1–5. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, E.; Zhang, T.; Li, M.; Bian, K. Influence of water addition methods on water mobility characterization and rheological properties of wheat flour dough. J. Cereal Sci. 2019, 89, 102791. [Google Scholar] [CrossRef]

- Paz, R.D.; Landázuri, A.C.; Vernaza, M.G. Development of a cereal-based product using residual Moringa oleifera Lam. seed powder biomass and pseudo-plastic behavior of the dough mixtures. Nutr. Food Sci. 2020, 51, 594–603. [Google Scholar] [CrossRef]

- Carrillo-Navas, H.; Guadarrama-Lezama, A.Y.; Vernon-Carter, E.J.; García-Díaz, S.; Reyes, I.; Alvarez-Ramírez, J. Effect of gelatinized flour fraction on thermal and rheological properties of wheat-based dough and bread. J. Food Sci. Technol. 2016, 53, 3996–4006. [Google Scholar] [CrossRef]

- Ghoshal, G.; Shivhare, U.S.; Banerjee, U.C. Rheological properties and microstructure of xylanase containing whole wheat bread dough. J. Food Sci. Technol. 2017, 54, 1928–1937. [Google Scholar] [CrossRef]

- Ma, J.; Kaori, F.; Ma, L.; Gao, M.; Dong, C.; Wang, J.; Luan, G. The effects of extruded black rice flour on rheological and structural properties of wheat-based dough and bread quality. Int. J. Food Sci. Technol. 2019, 54, 1729–1740. [Google Scholar] [CrossRef]

- Khemiri, S.; Khelifi, N.; Nunes, M.C.; Ferreira, A.; Gouveia, L.; Smaali, I.; Raymundo, A. Microalgae biomass as an additional ingredient of gluten-free bread: Dough rheology, texture quality and nutritional properties. Algal Res. 2020, 50, 101998. [Google Scholar] [CrossRef]

- Matos, M.E.; Rosell, C.M. Understanding gluten-free dough for reaching breads with physical quality and nutritional balance. J. Sci. Food Agric. 2015, 95, 653–661. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Linter, B.R.; Linforth, R.; Foster, T.J. A comprehensive investigation of gluten free bread dough rheology, proving and baking performance and bread qualities by response surface design and principal component analysis. Food Funct. 2020, 11, 5333–5345. [Google Scholar] [CrossRef]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; AACC: Arnold, MD, USA, 2000. [Google Scholar]

- Gajula, H.; Alavi, S.; Adhikari, K.; Herald, T. Precooked bran-enriched wheat flour using extrusion: Dietary fiber profile and sensory characteristics. J. Food Sci. 2008, 73, S173–S179. [Google Scholar] [CrossRef]

- Iuga, M.; Boestean, O.; Ghendov-Mosanu, A.; Mironeasa, S. Impact of dairy ingredients on wheat flour dough rheology and bread properties. Foods 2020, 9, 828. [Google Scholar] [CrossRef]

- Kelimu, A.; da Silva, D.F.; Geng, X.; Ipsen, R.; Hougaard, A.B. Effects of different dairy ingredients on the rheological behaviour and stability of hot cheese emulsions. Int. Dairy J. 2017, 71, 35–42. [Google Scholar] [CrossRef]

- Kumar, L.; Brennan, M.; Zheng, H.; Brennan, C. The effects of dairy ingredients on the pasting, textural, rheological, freeze-thaw properties and swelling behaviour of oat starch. Food Chem. 2018, 245, 518–524. [Google Scholar] [CrossRef]

- Balestra, F.; Laghi, L.; Saa, D.T.; Gianotti, A.; Rocculi, P.; Pinnavaia, G. Physico-chemical and metabolomic characterization of KAMUT® Khorasan and durum wheat fermented dough. Food Chem. 2015, 187, 451–459. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L.; Al-Attar, H. Oscillatory rheology and creep behavior of barley β-glucan concentrate dough: Effect of particle size, temperature, and water content. J. Food Sci. 2015, 80, E73–E83. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, H.; Wang, L.; Qian, H.; Qi, X.; Xiao, J. Effect of barley antifreeze protein on thermal properties and water state of dough during freezing and freeze-thaw cycles. Food Hydrocoll. 2015, 47, 32–40. [Google Scholar] [CrossRef]

- Peng, B.; Li, Y.; Ding, S.; Yang, J. Characterization of textural, rheological, thermal, microstructural, and water mobility in wheat flour dough and bread affected by trehalose. Food Chem. 2017, 233, 369–377. [Google Scholar] [CrossRef] [PubMed]

- Asghar, A.; Anjum, F.M.; Allen, J.C.; Daubert, C.R.; Rasool, G. Effect of modified whey protein concentrates on empirical and fundamental dynamic mechanical properties of frozen dough. Food Hydrocoll. 2009, 23, 1687–1692. [Google Scholar] [CrossRef]

- Patil, S.P.; Arya, S.S. Influence of additive premix, whey proteins, extruded and germinated flour on gluten free dough rheological parameters and flatbread characteristics: A mixture design approach. J. Microbiol. Biotechnol. Food Sci. 2019, 8, 1198–1204. [Google Scholar] [CrossRef]

- Pico, J.; Reguilón, M.P.; Bernal, J.; Gómez, M. Effect of rice, pea, egg white and whey proteins on crust quality of rice flour-corn starch based gluten-free breads. J. Cereal Sci. 2019, 86, 92–101. [Google Scholar] [CrossRef]

- Waziiroh, E.; Bender, D.; Jäger, H.; Schönlechner, R. Ohmic baking of gluten-free bread: Role of non-gluten protein on GF bread structure and properties. Int. J. Food Sci. Technol. 2023, 58, 595–609. [Google Scholar] [CrossRef]

- Aprodu, I.; Banu, I. Effect of starch and dairy proteins on the gluten free bread formulation based on quinoa. J. Food Meas. Charact. 2021, 15, 2264–2274. [Google Scholar] [CrossRef]

- Romero, H.M.; Santra, D.; Rose, D.; Zhang, Y. Dough rheological properties and texture of gluten-free pasta based on proso millet flour. J. Cereal Sci. 2017, 74, 238–243. [Google Scholar] [CrossRef]

- Berezina, N.A.; Komolikov, A.S.; Galagan, T.V.; Rumyanceva, V.V.; Nikitin, I.A.; Zavalishin, I.V. Investigation of ultrasonic dough processing influence on bread quality. In Proceedings of the International Scientific and Practical Conference “Agro-SMART-Smart Solutions for Agriculture”(Agro-SMART 2018), Tyumen, Russia, 16–20 July 2018. [Google Scholar]

- Jia, F.; Ma, Z.; Wang, X.; Li, X.; Liu, L.; Hu, X. Effect of kansui addition on dough rheology and quality characteristics of chickpea-wheat composite flour-based noodles and the underlying mechanism. Food Chem. 2019, 298, 125081. [Google Scholar] [CrossRef]

- Li, J.; Yadav, M.P.; Li, J. Effect of different hydrocolloids on gluten proteins, starch and dough microstructure. J. Cereal Sci. 2019, 87, 85–90. [Google Scholar] [CrossRef]

- Pérez-Quirce, S.; Lazaridou, A.; Biliaderis, C.G.; Ronda, F. Effect of β-glucan molecular weight on rice flour dough rheology, quality parameters of breads and in vitro starch digestibility. LWT-Food Sci. Technol. 2017, 82, 446–453. [Google Scholar] [CrossRef]

- Yazar, G.; Duvarci, O.C.; Tavman, S.; Kokini, J.L. Effect of mixing on LAOS properties of hard wheat flour dough. J. Food Eng. 2016, 190, 195–204. [Google Scholar] [CrossRef]

- Meerts, M.; Cardinaels, R.; Oosterlinck, F.; Courtin, C.M.; Moldenaers, P. The impact of water content and mixing time on the linear and non-linear rheology of wheat flour dough. Food Biophys. 2017, 12, 151–163. [Google Scholar] [CrossRef]

- Villanueva, M.; Abebe, W.; Collar, C.; Ronda, F. Tef [Eragrostis tef (Zucc.) Trotter] variety determines viscoelastic and thermal properties of gluten-free dough and bread quality. LWT 2020, 135, 110065. [Google Scholar] [CrossRef]

- Sahagún, M.; Gómez, M. Influence of protein source on characteristics and quality of gluten-free cookies. J. Food Sci. Technol. 2018, 55, 4131–4138. [Google Scholar] [CrossRef] [PubMed]

- Sarabhai, S.; Prabhasankar, P. Influence of whey protein concentrate and potato starch on rheological properties and baking performance of Indian water chestnut flour based gluten free cookie dough. LWT 2015, 63, 1301–1308. [Google Scholar] [CrossRef]

- Wani, S.H.; Gull, A.; Allaie, F.; Safapuri, T.A. Effects of incorporation of whey protein concentrate on physicochemical, texture, and microbial evaluation of developed cookies. Cogent Food Agric. 2015, 1, 1092406. [Google Scholar] [CrossRef]

- Sinthusamran, S.; Benjakul, S.; Kijroongrojana, K.; Prodpran, T. Chemical, physical, rheological and sensory properties of biscuit fortified with protein hydrolysate from cephalothorax of Pacific white shrimp. J. Food Sci. Technol. 2019, 56, 1145–1154. [Google Scholar] [CrossRef]

- Žilić, S.; Kocadaugli, T.; Vančetović, J.; Gökmen, V. Effects of baking conditions and dough formulations on phenolic compound stability, antioxidant capacity and color of cookies made from anthocyanin-rich corn flour. LWT-Food Sci. Technol. 2016, 65, 597–603. [Google Scholar] [CrossRef]

- Pérez, S.; Matta, E.; Osella, C.; de la Torre, M.; Sánchez, H. Effect of soy flour and whey protein concentrate on cookie color. LWT-Food Sci. Technol. 2013, 50, 120–125. [Google Scholar] [CrossRef]

- Sahagún, M.; Gómez, M. Assessing influence of protein source on characteristics of gluten-free breads optimising their hydration level. Food Bioprocess Technol. 2018, 11, 1686–1694. [Google Scholar] [CrossRef]

- Komeroski, M.R.; Homem, R.V.; Schmidt, H.D.O.; Rockett, F.C.; de Lira, L.; da Farias, D.V.; Kist, T.L.; Doneda, D.; Rios, A.D.O.; de Oliveira, V.R. Effect of whey protein and mixed flours on the quality parameters of gluten-free breads. Int. J. Gastron. Food Sci. 2021, 24, 100361. [Google Scholar] [CrossRef]

- Parate, V.R.; Kawadkar, D.K.; Sonawane, S.S. Study of whey protein concentrate fortification in cookies variety biscuits. Int. J. Food Eng. 2011, 2, 7. [Google Scholar] [CrossRef]

- García-Solís, S.E.; Bello-Pérez, L.A.; Agama-Acevedo, E.; Flores-Silva, P.C. Plantain flour: A potential nutraceutical ingredient to increase fiber and reduce starch digestibility of gluten-free cookies. Starch-Stärke 2018, 70, 1700107. [Google Scholar] [CrossRef]

| Stickiness Scale | ||||

| 1 | 3 | 5 | 7 | 10 |

| -Not sticky at all; falls off hands | -Sticking to hands and itself a little | -Sticking to hands and to itself, but weak dough that easily breaks | -Sticking well to hands and itself | -Extremely sticky and bind well with itself |

| Cohesiveness Scale | ||||

| 1 | 3 | 5 | 7 | 10 |

| -Falls apart easily | -Did not stretch when elongated, just broke with a little shaking | -Stretches a little when elongated | -Stretched a few inches when elongated | -Stretches seemingly indefinitely |

| Firmness Scale | ||||

| 1 | 3 | 5 | 7 | 10 |

| -Falls apart when pressed | -Hard and cracks appeared quickly with little press | -Little soft, press to see cracks | -Fairly visco-elastic when pressed | -Good visco-elastic, little to no cracks appear when pressed |

| Flour Type | % WPC | Mixograph | Subjective Evaluation | ||

|---|---|---|---|---|---|

| Optimum Water Absorption, % | Stickiness | Cohesiveness | Firmness | ||

| Sorghum Flour | 0 | 70.00 | - | - | - |

| 8 | 55.00 | 5.5 | 7 | 5 | |

| 9 | 57.50 | 5.5 | 5 | 6 | |

| 10 | 57.50 | 5.5 | 6 | 6.5 | |

| 11 | 57.50 | 5 | 6.5 | 6.5 | |

| 12 | 60.00 | 7 | 8 | 8 | |

| Corn Flour | 0 | 75.00 | - | - | - |

| 8 | 50.00 | 5 | 4 | 3 | |

| 9 | 50.00 | 4.5 | 4.5 | 4 | |

| 10 | 52.50 | 4 | 5.5 | 5 | |

| 11 | 52.50 | 5 | 5.5 | 6 | |

| 12 | 55.00 | 6 | 5.5 | 5.5 | |

| Wheat Flour | 0 | 60.00 | 10 | 10 | 10 |

| Sample | Diameter, cm | Thickness, cm | D/T * | Weight, g | Color Values | ||

|---|---|---|---|---|---|---|---|

| L | a | b | |||||

| Wheat Control | 7.59 ± 0.03 bc | 0.90 ± 0.03 a | 8.45 ± 0.29 e | 19.46 ± 0.67 a | 61.6 ± 1.2 f | 6.4 ± 0.6 c | 21.3 ± 0.2 f |

| Sorghum | 7.12 ± 0.03 a | 1.26 ± 0.04 e | 5.67 ± 0.16 a | 21.30 ±0.10 a | 63.4 ± 0.4 g | 2.9 ± 0.2 a | 18.1 ± 0.1 g |

| Sorghum + 8% WPC | 7.46 ± 0.01 b | 1.20 ± 0.03 de | 6.22 ± 0.17 b | 20.15 ± 0.40 a | 52.3 ± 0.8 e | 9.2 ± 0.3 d | 19.6 ± 0.6 e |

| Sorghum + 9% WPC | 7.66 ± 0.08 c | 1.14 ± 0.02 cde | 6.69 ± 0.10 c | 20.36 ± 0.42 a | 50.9 ± 1.1 e | 9.6 ± 0.4 d | 19.6 ± 0.3 e |

| Sorghum + 10% WPC | 7.73 ± 0.03 cd | 1.12 ± 0.02 cde | 6.89 ± 0.13 c | 19.43 ± 0.26 a | 48.7 ± 0.9 d | 10.4 ± 0.2 e | 19.1 ± 0.4 d |

| Sorghum + 11% WPC | 7.84 ± 0.09 d | 1.12 ± 0.04 cde | 6.99 ± 0.17 c | 19.83 ± 1.09 a | 48.1 ± 1.1 d | 10.4 ± 0.2 e | 18.9 ± 0.4 d |

| Sorghum + 12% WPC | 7.81 ± 0.05 d | 1.16 ± 0.02 de | 6.76 ± 0.15 c | 20.27 ± 0.65 a | 47.3 ± 1.3 d | 10.8 ± 0.2 e | 18.9 ± 0.6 d |

| Corn | 7.68 ± 0.08 cd | 1.02 ± 0.04 bc | 7.52 ± 0.22 d | 20.91 ± 0.82 a | 64.0 ± 1.0 g | 4.2 ± 0.6 b | 28.1 ± 0.5 g |

| Corn + 8% WPC | 8.63 ± 0.10 e | 0.91 ± 0.02 a | 9.48 ± 0.09 f | 21.00 ± 0.74 a | 47.5 ± 1.2 d | 12.1 ± 0.4 f | 21.5 ± 0.7 d |

| Corn + 9% WPC | 8.64 ± 0.03 e | 0.91 ± 0.02 a | 9.48 ± 0.17 f | 21.02 ± 0.43 a | 45.4 ± 1.0 c | 12.5 ± 0.2 fg | 20.3 ± 0.7 c |

| Corn + 10% WPC | 8.62 ± 0.07 e | 0.92 ± 0.04 ab | 9.36 ± 0.31 f | 21.30 ± 1.07 a | 44.6 ± 1.1 bc | 12.6 ± 0.2 fg | 19.9 ± 0.7 bc |

| Corn + 11% WPC | 8.66 ± 0.01 e | 0.96 ± 0.02 ab | 9.06 ± 0.18 f | 21.05 ± 0.46 a | 43.3 ± 1.2 b | 12.7 ± 0.2 g | 19.2 ± 0.7 b |

| Corn + 12% WPC | 8.64 ± 0.06 e | 0.91 ± 0.02 a | 9.48 ± 0.14 f | 20.70 ± 0.80 a | 41.5 ± 1.5 a | 12.9 ± 0.1 g | 18.1 ± 0.9 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Snider, L.; Vu, T.H.; Desam, G.P.; Herald, T.J.; Dogan, H.; Khaled, A.Y.; Adedeji, A.A.; Alavi, S. Effect of Whey Protein Concentrate on Rheological Properties of Gluten-Free Doughs and Their Performance in Cookie Applications. Sustainability 2023, 15, 10170. https://doi.org/10.3390/su151310170

Zhu L, Snider L, Vu TH, Desam GP, Herald TJ, Dogan H, Khaled AY, Adedeji AA, Alavi S. Effect of Whey Protein Concentrate on Rheological Properties of Gluten-Free Doughs and Their Performance in Cookie Applications. Sustainability. 2023; 15(13):10170. https://doi.org/10.3390/su151310170

Chicago/Turabian StyleZhu, Lijia, Luke Snider, Thanh Hien Vu, Gnana Prasuna Desam, Tomas J. Herald, Hulya Dogan, Alfadhl Y. Khaled, Akinbode A. Adedeji, and Sajid Alavi. 2023. "Effect of Whey Protein Concentrate on Rheological Properties of Gluten-Free Doughs and Their Performance in Cookie Applications" Sustainability 15, no. 13: 10170. https://doi.org/10.3390/su151310170

APA StyleZhu, L., Snider, L., Vu, T. H., Desam, G. P., Herald, T. J., Dogan, H., Khaled, A. Y., Adedeji, A. A., & Alavi, S. (2023). Effect of Whey Protein Concentrate on Rheological Properties of Gluten-Free Doughs and Their Performance in Cookie Applications. Sustainability, 15(13), 10170. https://doi.org/10.3390/su151310170