Abstract

Wood is a sustainable renewable material that is widely used in the building sector. Due to recent trends in green initiatives in European and other countries, wood waste is becoming more popular for sound absorption and insulation because of its renewability. Recycled wood material granulated charcoal is an effective acoustic treatment. In this study, we investigated the sound absorption coefficients of raw wood and granulated charcoal species: birch (Betula pendula), pine (Pinus sylvestris), and oak (Quercus robur). The impedance tube method was used to characterize the sound absorption properties of the granulated charcoal. The maximum bulk densities of the materials investigated were 567 kg/m3 for birch (B. pendula) wood and 247 kg/m3 for granulated charcoal. The airflow resistivity of wood and granulated charcoal was found using the static airflow method according to the standard. The grain size distribution of charcoal was also determined, with the highest percentage (25–29%) of the birch and pine grain distribution of charcoal species having a size of 400 µm and 30.7% of the oak a size of 1 mm. All species had the lowest grain size value, i.e., 900 µm (1–4%). The sound absorption of granulated charcoal does not depend on the carbonization temperature at 400, 500, or 600 °C. Granular charcoal of 25 mm has a better sound absorption thickness coefficient for birch at 600 °C (0.57 at 315 Hz) compared to wood of the same thickness. The effectiveness of absorption for wood and granular charcoal depends on the type of wood (birch > pine > oak), grain size, airflow resistivity, and bulk density.

1. Introduction

Noise pollution from primary outdoor and indoor sources is an important issue, along with other environmental problems. The primary sources of sound outside are vehicles, planes, and railways. Indoor sound is caused by floor impacts, airborne sound between households, home appliances, plumbing, etc. Noise affects human health and well-being, causing hearing loss, cardiovascular diseases, and cerebrovascular diseases [1,2,3,4]. Therefore, it is important to investigate materials that could reduce sound levels in indoor and outdoor spaces.

Increasing the availability and use of forest biomass through the wood-waste recovery process has been suggested as a solution to environmental contamination. A large amount of waste accumulates on the planet, which is of great concern. In 2018, Lithuania generated 5.4 million tons of construction and demolition waste. According to the European Environment Agency, of the total waste generated in Lithuania, only 44.30% was recycled. Directive 2018/2001/EU 33 of 2018 promotes the use of renewable energy. Lithuania must increase its renewable energy sources. The main reasons for the absence of waste reduction are the low profitability of wood waste management, lack of awareness and understanding, and little or no guidance on how to recycle waste [5].

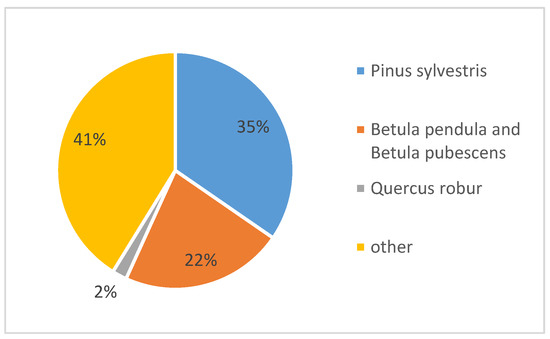

Recycled wood is an alternative to traditional plastic materials. Wood waste species common in Lithuania could be recycled and used for acoustic purposes. Most wood materials and their composite products can potentially be used in industry [5]. The Department of Statistics of Lithuania reported the amount of general wood waste in 2020 to be 82 million tons. Waste recycling will contribute to the sustainable development of the country [6,7]. The most common pine species in Europe (P. sylvestris L.) covers 0.711 Mha of all forest areas. The silver birch (B. pendula Roth and Betula pubescens Ehrh.) covers 0.453 Mha of the entire forest area, and oak (Q. robur L.) covers 0.0434 Mha in respect of Lithuania’s tree species. Figure 1 shows the percentage of research on wood species that are found in Lithuania [7,8].

Figure 1.

Some of the common wood species: birch (B. pendula), pine (P. sylvestris), and oak (Q. robur) studied in Lithuania.

The use of natural materials in acoustics has been previously explored [9,10]. With the decrease in the number of forests and the increase in the global population, wood-based composites and low-quality wood materials are the keys to sustainability. Due to the development of technology, a significant amount of wood products have been invented. These technologies are used in construction and have good acoustic and thermal insulation properties. The acoustic efficiency of wooden materials is dependent on different non-acoustic characteristics [9,11,12]. Wood-based products are well-known materials that are widely used in acoustics research, and research with respect to wood composites is a growing scientific field. Additionally, recycled wood materials are considered to reduce sound levels in rooms [13].

Wood recovered from the sawmill industry and used for acoustic purposes is of interest to researchers for determining the sound absorption coefficient. Jiang et al. investigated the wood sound absorption coefficient of solid wood and wood board eucalyptus species. Their study reported the growth of the absorption coefficient with the thickness of the wood. It was found that the acoustic efficiency of eucalyptus wood is much higher at high frequencies [14]. Ivanova investigated the sound absorption coefficient of Scots pine (P. sylvestris L.) wood for flooring and wall lining material using impedance tube equipment. The maximum value of the sound absorption coefficient of Scots pine was α = 0.177 for a sample of 20 mm thickness [15]. In another study, Godshall measured the sound absorption coefficients of wood-based panel materials using the impedance tube method for a variety of applications. According to this study, composite materials consisting of a loose fibrous mat covered with a perforated surface material appeared to offer the best acoustic performance [16]. Hwang studied the sound absorption characteristics of wooden resonators. It was shown that the sound absorption characteristics of installed perforated resonators were better than those of untreated samples [17].

Temperature affects the physical and mechanical properties of wood. In previous studies, wood, typically used as a building material, was heat-treated at different temperatures for different times. As a result of microwave treatment, the maximum sound absorption coefficient was observed to increase with increasing temperature and burning time [18,19,20].

The recycling of rotting wood waste is an effective method for conserving wood resources and protecting the environment. Wang investigated the sound absorption property of decayed poplar wood. The sound absorption coefficients of decayed wood improved significantly compared to healthy wood. The average sound absorption coefficients for the decayed wood samples were 0.269, 0.177, and 0.188 from the root, trunk, and treetop, respectively [21].

Samsudin et al. investigated the physical properties of wood fiber, such as thickness, density, and porosity. Measurements have shown that samples of a mineralized wood panel with lower densities of wood fiber absorb more sound energy. The maximum absorption for wood fiber is 0.91 at 2000 Hz compared to mineralized wood, which achieves a maximum value of 0.4 at the same frequency [22,23]. Other studies have suggested that the sound absorption coefficient of fibrous materials increases with decreasing density. Natural fiber materials, synthetic fibers, and agricultural lignocellulose fibers have high sound absorption and noise reduction coefficients [12,24]. According to previous studies, it is possible to improve the properties of wood via carbonization. Activated carbon is a lightweight material that also contains a considerable amount of lightweight and easier-to-use nanopores that provide the ability to absorb sound. Two factors contribute to the ability of activated charcoal to effectively absorb sound porosity and a large surface area. They have three scales of heterogeneities: millimeter, micrometer, and nanometer inner grains. The presence of nanometer-wide pores leads to a decrease in the static bulk modulus and, consequently, in the effective low-frequency sound speed. Activated charcoal felts also show promising low-frequency sound absorption, but they have a simpler microstructure [25].

The difference between standard charcoals and activated charcoals lies in the use of activating substances, such as steam or carbon dioxide, at high temperatures of 900 and 1000 °C. This leads to differences in the microscopic structure of granular activated charcoal. The influence of the microstructure on the acoustical properties of granular-activated charcoal has been researched. Certain absorption mechanisms have been described, such as sound waves hitting the surface of a porous material and causing the air inside the pores to oscillate. A pore exposed to a sound wave loses some of its original energy. This phenomenon occurs because some energy is converted to heat as a result of thermal and viscosity losses on the walls of internal pores and tunnels inside the material.

Granular activated charcoal from wood biomass has a high sound absorption coefficient and has been used as an acoustic treatment [26,27,28,29,30]. Factors that influence the sound absorption properties of granular charcoal include grain size, bulk density, and temperature. Granular charcoal contains various pore sizes, from micropores to large macropores.

Overall, the use of wood-filled polymer composites for a variety of applications has increased dramatically over the past decade or so. The sound absorption characteristics of various wood species from Europe (such as oak, pine, and birch) and the tropical zone have been investigated via the sound absorption coefficient using the impedance tube method [15,31,32]. However, there are few studies on the sound absorption qualities of charcoal [33,34].

In this research, using the impedance tube method, we investigated possible applications for the sound absorption of granular charcoal heat-treated at different temperatures and compared the absorption differences with raw wood from pine, birch, and oak. Section 2 describes the materials and methods used in this study. In Section 3, we present and discuss the main results, and present the conclusions in Section 4

2. Materials and Methods

2.1. Sample Preparation

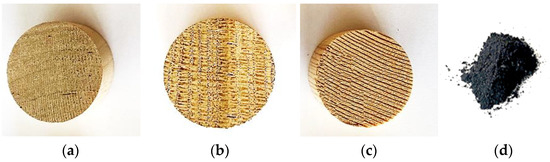

Wood samples of widespread, common species in the region (birch, pine, and oak) and of similar ages were collected using rotary drills (Figure 2). The wood was kept at room temperature (22 °C) for air-drying. The prepared wood samples had the same diameter (30 mm), cut at different thicknesses (10, 18, 25, and 30 mm).

Figure 2.

Wood samples for impedance tube measurements: (a) oak; (b) birch; (c) pine; (d) granular charcoal.

The samples were carbonized in diameters 30 mm. The wood was burnt at different temperatures: 400 °C, 500 °C, and 600 °C. An E5CK-T carbonization system (SNOL, Umega, Lithuania, Utena) was used as a muffle furnace with a heating rate of 10 °C/min; burning time was 2 h under oxygen-limited conditions and under atmospheric pressure. The crushed charcoal varied in grain size from 50 µm–5 mm. The charcoal was sieved through different mesh sizes. Fine charcoal was prepared manually using a mortar and pestle and placed in a cylindrical bag made of two layers of gauze.

The mass of the measured samples of granulated charcoal was 4–5 g; prepared samples were ~25 mm thick and ~30 mm in diameter. The 25 mm thick samples of granulated charcoal were chosen to present more representative results of the sound absorption coefficient (α) and bulk density measurements. Thicker samples of granulated charcoal for α measurements are difficult to manufacture.

The connection between airflow resistivity and sample thickness resulted in samples of 25 mm, with fewer standard deviations compared to 10, 18, 25, and 30 mm. This is an indicator of how the granulated charcoal sample was used for impedance tube measurements.

2.2. Measurement of Airflow Resistivity

Airflow resistivity measurement was performed using the method according to ISO 9053-1: “Acoustics. Determination of the resistivity to airflow. Part 1. Static air flow method” [35]. Airflow resistivity is one of the non-acoustic parameters that determine the acoustic performance of the material. Using this parameter, the sound absorption coefficient was theoretically predicted. The airflow resistivity of the wood material was measured using a tube (through which a near-laminar airflow passes), an air compressor, a manometer, and a flow area meter (Figure 3). Measurement of airflow resistivity is based on determining the difference in air pressure in a tube. The bench tube had a length of 127.5 cm and a diameter of 30 mm. This tube design allows the prediction of the sound absorption to be more precise because the same sample is used in airflow resistivity and sound absorption experimental studies. The pressure drop was measured using a differential pressure gauge with an accuracy of 0.1 Pa; the air velocity during the test was 0.01 m/s.

Figure 3.

Experimental equipment for airflow resistivity measurements. (1) Airflow tube; (2) flow meter; (3) manometer; (4) sample holder.

Airflow resistivity was calculated based on the air pressure difference on different sides of the sample within the tube and the air resistance, as described in Equations (1)–(4):

where is the air pressure in front of the material, Pa; is the air pressure behind the material, Pa; R is the airflow resistance, ; q is the volumetric airflow rate, ; Rs is the specific airflow resistance, ; A is the cross-sectional area of the sample, m2; and σ is the airflow resistivity, .

2.3. Measuring Device and Impedance Tube Method

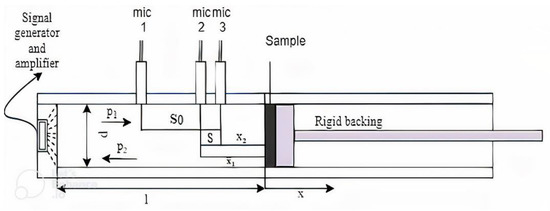

Figure 4 shows the impedance tube for the measurement of the sound absorption coefficient according to the standards [36,37]. During the measurement, the samples were sealed with lithium grease to prevent sound leakage through the samples’ boundaries. A loudspeaker produced a signal source of one-dimensional waves transmitting acoustic energy directly through the holder. The impedance tube consisted of three microphones and was terminated with an anechoic terminal. The excitation of signal generation was a logarithmic envelope sine and 1/3 octave filter in the frequency range of 160–5000 Hz, and the signal was averaged 50 times. The sound absorption coefficient was calculated from the measurement using MATLAB software R2022b.

Figure 4.

Scheme setup of AED1000 impedance tube type-3 microphone. 1, 2, 3: microphones; S, S0: distance between microphones (distance between microphones 1 and 2–3 is 100 mm). x1, x2: distance between sample holders and microphones (distance between 2 and 3 is 20 mm, and between the 3rd microphone and the sample is 60 mm), and loudspeaker and sample holder, with an inner diameter of 30 mm and a wide frequency range.

The tube calculation for the two-microphone transfer function method is as follows. For the measured sound pressure calculation at each frequency using the transfer function method between microphones 1 and 2, and 2 and 3, in the frequency ranges of 160–5000 Hz, the following equations were used:

where H12 and H23 is the acoustic transfer function between two microphone locations, HI and HR are microphone locations 1 and 2, and microphones 2 and 3, at 160–5000 Hz frequency; P2 is the pressure recorded by microphone 2 (Pa); P1 is the pressure recorded by microphone 1 (Pa); f is the frequency (Hz). The sound wave reflection was calculated using the following equations:

where R is the reflection coefficient; k0 is the wave number; j is the imaginary number in the complex number; is the distance between microphones 1 and 2, mm; is the distance between microphones 2 and 3 mm, and 3 S is the distance between microphone 3 and the sample holder mm. The sound absorption coefficient was calculated following Equation (9):

where α is the absorption coefficient; R is the reflection coefficient.

The sound absorption coefficient of materials measured in the impedance tube follows equations. The measurements were repeated 3 times for 12 wood samples (10, 18, 25, and 30 mm) thick and 9 charcoal samples of 25 mm thickness.

3. Results and Discussion

Characterization of Non-Acoustic Parameters of the Samples

The non-acoustic measured bulk densities of the wood and the airflow resistivity of different types of wood are presented in Table 1. The bulk density of wood was found to be the mass of wood divided by the volume of samples.

Table 1.

Non-acoustic parameters of wood and charcoal samples of 25 mm thickness.

The bulk density of wood related to the lowest bulk density (248 ± 7.1), while the granular charcoal specimen had a lower value of airflow resistivity (201.5 ± 77). The bulk densities of wood species and granular charcoal followed the order granular charcoal < birch < oak.

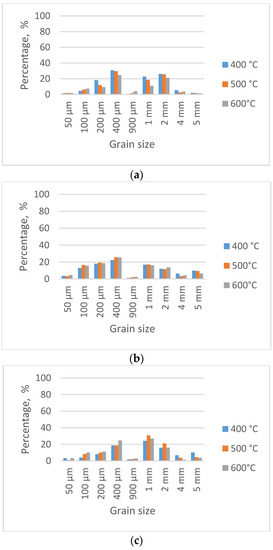

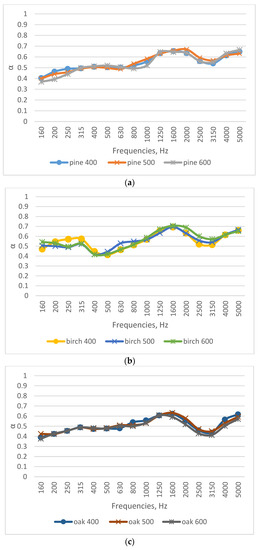

Figure 5 presents the influence of pyrolysis temperature on the sound absorption coefficient of the wood charcoal grain; this was classified into three temperatures: 400 °C, 500 °C, and 600 °C. The grain sizes of the charcoals prepared at different temperatures, and the granulated charcoal are presented in the figure. The grain size distribution is an important non-acoustic parameter with smaller grain sizes and better absorption properties. The α corresponds to the particle size distribution; birch has a maximum α and a greater percentage (3–30%) of small particles (50–400 µm). Oak has a minimum α value of 0.1 at 2500 Hz and a larger percentage (3–31%) of small charcoal particles (50–400 µm). The carbonization temperatures of 400 °C, 500 °C, and 600 °C did not influence the grain size distribution of the granular charcoal.

Figure 5.

The grain size of common granular charcoal wood species carbonized at different temperatures (400 °C, 500 °C, 600 °C). Types of wood charcoal samples: (a) pine; (b) birch; (c) oak.

The highest percentage (25–29%) of the distribution of the grain size of the charcoal species (i.e., birch and pine) had a size of 400 µm; oak had a size of 1 mm and consisted of 30.7% (Figure 5). The minimum percentage (1–3%) of the grain size of granulated charcoal comprised 50–100 µm grains. Samples of grain charcoal had a higher number of small particles (50–400 µm) of birch and pine (3–29%). Oak comprised the largest percentage in terms of size distribution (30%), with a larger particle size of 1 mm. All species contained the smallest grain size (900 µm), at 1–4%. The literature shows that samples with a smaller grain size of granular media have higher absorption properties [38].

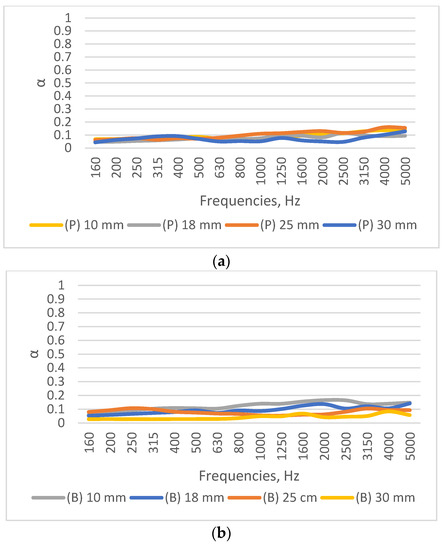

Figure 6 shows the average values of the measured α of common wood types, birch (B. pendula), pine (P. sylvestris), and oak (Q. robur), at thicknesses of 10 mm, 18 mm, 25 mm, and 30 mm. The α of wood ranges from 0.02 to 0.16. The 30 mm birch sample had a higher α (0.16) at 2500 Hz. Wood species can absorb low-frequency and high-frequency sounds. The α for charcoal was a maximum of 0.15 for pine at 4000 Hz and a minimum of 0.04 at 2500 Hz; birch had a maximum value of 0.16 at 250 Hz and a minimum of 0.02; the maximum for oak was 0.11 at 5000 Hz, and its minimum is 0.02 at 160 Hz. Wood samples with high thickness values had a lower α. Samples of 30 mm thickness had higher α values than 10 mm samples. The α for wood reached a peak for 30 mm birch (0.16) at 2000 Hz; 18 mm birch (0.13) at 2000 Hz; 25 mm pine (0.15) at 4000 Hz; and 30 mm pine (0.12) at 5000 Hz. All wood species samples indicated that the α at high frequencies was higher than that at lower frequencies. As was found in other studies, the sound absorption coefficients increased with the increasing frequency range [15,19,39]. The wood type had a significant influence on sound absorption effectiveness; the α of wood samples increased in the following order: birch > pine > oak; this phenomenon could be related to different wood species. The α could be explained by the morphological properties of the material densities and the thickness of the material. Therefore, sound absorption depends on wood species [39]. The thickness of wood influences the absorption of wood, so a sample with a higher thickness value has a higher absorption coefficient. Studies have shown that wood is not very effective at absorbing sound, which is why we are interested in improving the absorption capacity of wood with heat treatment. Carbonized charcoal from wood waste materials is a useful granular charcoal acoustic treatment.

Figure 6.

Sound absorption coefficient (α) measurements from wood samples with different thicknesses at frequencies in the range of 160–5000 Hz: (a) pine; (b) birch; (c) oak.

The airflow resistivity of the wood in this experiment shows a corresponding result because of its bulk density since the wood densities were constant for all samples. The bulk densities of the wood investigated in this research were as follows: birch (B. pendula), 567 kg/m3; pine (P. sylvestris), 578 kg/m3; and oak (Q. robur), 589 kg/m3. The airflow resistivity of the wood samples depended on their α values. Samples with higher airflow resistivity had lower α values; the samples of 10 mm pine had maximum α values and maximum airflow resistivity (2580 Pa × s/m2). The airflow resistivity of the samples was 2486 Pa × s/m2, and they had a minimum airflow capacity. The type of wood influences the airflow resistivity. The density influenced the airflow resistivity; samples with the lowest densities had higher airflow resistivity. Oak samples had a lower absorption coefficient maximum of 0.11 and a high airflow resistivity maximum of 2688 Pa × s/m2 compared to the maximum of 2730 Pa × s/m2 for pine samples. Wood with a lower airflow had a high α.

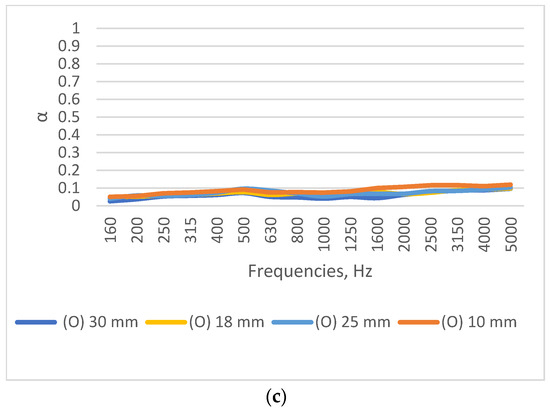

Figure 7 shows α values of granular charcoal from 0.42 to 0.70. According to our studies, the 25 mm sample showed higher absorption properties of wood material than the 10 mm sample. As was found in other studies, the α increased with the increasing thickness of the sample in granular media [27]. The 25 mm granular charcoal samples were prepared with higher precision. We found that the α of the granular charcoal does not depend on a temperature rate of 400, 500, or 600 °C. The α for charcoal was a maximum of 0.7 for birch at 1600 Hz and a minimum of 0.42 at 200 Hz; pine had a maximum value of 0.66 at 2000 Hz and a minimum of 0.42 at 500 Hz; the maximum for oak was 0.63 at 1600 Hz, and the minimum was 0.37 at 160 Hz. Bechwati et al. show the maximum absorption of 0.5 at 500 Hz sample of activated carbon 24.2 mm thick [27]. Granular charcoal had a higher α than raw wood; the highest absorption of birch granular charcoal was 0.7 at 1600 Hz, compared to the highest absorption of birch wood at 0.16 at 2000 Hz. Granular charcoal had a high absorption coefficient at low frequencies; the maximum absorption for birch at 600 °C was 0.57 at 315 Hz. The α of granular charcoal was higher compared to that of wood of the same thickness and species. The granular charcoal sample absorption increased in the order of birch > pine > oak. α grew in the same order as the wood samples. This means that the α of granular charcoal depends on the type of wood. The size distribution analyses showed that birch and pine have smaller particles than oak. For this reason, the absorption is better in materials with smaller particle sizes.

Figure 7.

Sound absorption coefficient (α) of granular charcoal samples with heat-treated temperature rates of 400 °C, 500 °C, and 600 °C: (a) pine; (b) birch; (c) oak.

The high α of 0.7 at 1600 Hz of granular charcoal is explained by the smaller grain size increasing the porosity of the samples, which allows us to create highly porous and airflow-resistant material. Ultimately, these non-acoustic parameters increase the α considerably compared with wood samples. The pore size distribution ranges from micropores to wide macropores. The porous structure of the granular media increases the absorption of the dissipated material due to the movement of the sound-absorbing material and heat [27,28,40], and the low amount of grain charcoal of 400 µm and 1 mm with large bulk densities (247 kg/m3). This means that powdered charcoal is more compact and takes up less space per unit of mass compared to wood. The small grain size results in a large surface area, which increases the absorption ability. The absorption also depends on the bulk densities, and wood species with lower densities (567–589 kg/m3) have a lower absorption ability compared to granular charcoal, with a density of 247 kg/m3. Granular charcoal with lower densities has a higher sound absorption capacity than raw wood. The wood samples showed 10 times higher airflow resistivity, resulting in relatively low sound-absorption properties. The absorption of wood and granular charcoal depends on frequency. Granular charcoal can absorb low-frequency sound, unlike wood. Wood has fewer absorption properties at a higher frequency than granular charcoal.

Granular charcoal showed greater α values at higher frequencies; the α ranged from 0.42 to 0.57 at 160–800 Hz, 0.48 to 0.7 at 800–2500 Hz and 0.41 to 0.55 at 2500–5000 Hz. The samples of all species had a maximum α (0.63–0.7) at a frequency of 1600 Hz and a minimum absorption (0.36–0.57) at 3150 Hz. Granular charcoal is effective in the absorption of sound at middle frequencies (800–2000 Hz).

4. Conclusions

We investigated the experimental sound absorption coefficients of wood and grained charcoal samples. Samples of tree wood species of birch (B. pendula), pine (P. sylvestris), and oak (Q. Robur) of 10, 18, 25, and 30 mm thickness, and granular charcoal samples of 25 mm thickness of the same species, burnt at different temperatures of 400 °C, 500 °C, and 600 °C, were measured in an impedance tube. The sound absorption coefficients of wood of different thicknesses increase with frequency. The maximum absorption coefficient compared to other species was for a birch sample of 30 mm, which had a higher α of 0.16 at 2500 Hz. The wood type influenced the sound absorption effectiveness of the wood samples. α depends on the morphological properties of the wood, e.g., pore shape, grain shape, or the particular order of the grains in the material.

The α of wood increases with the thickness of the material. In wood-measured samples, the absorption coefficient grows to high frequencies (2000–5000 Hz). Granular charcoal is the peak of sound absorption at middle frequencies (800–2000 Hz). This frequency range is relevant for acoustic applications and related to the airflow resistivity of the materials. When the airflow resistivity of wood materials increases, the sound absorption coefficient grows at high frequencies. The granular charcoal has lover airflow resistivity and a higher absorption coefficient at middle frequencies (800–2000 Hz).

When the charcoal was produced using wood-waste heat treatment, we were able to increase the α by 15% compared to the raw material. Granular charcoal manufactured from wood waste has a high absorption coefficient over a wide frequency range. The grain size of charcoal ranges from 50 µm to 5 mm, with a higher grain size value of 400 mm and 1 µm depending on the type of wood for each sample. The bulk density of charcoal is related to the airflow resistivity of the sample, with the lowest bulk density of the granular charcoal sample having a lower value of airflow resistivity. The bulk densities of wood species and granular charcoal follow the order of granular charcoal < birch < oak. The sound absorption of granulated charcoal does not depend on the carbonization temperature rate at 400, 500, or 600 °C. The sound absorption coefficient of 25 mm birch at 600 °C is 0.7 at 1600 Hz compared to wood at the same thickness. Granular charcoal has good absorption properties for low-frequency sound. The α of the birch at 600 °C was 0.57 at 315 Hz. The effectiveness of the sound absorption properties of wood and granular charcoal depends on the bulk densities in the order of birch > pine > oak grain charcoal. The average α of birch charcoal was 0.56, while for pine, it was 0.55, and for oak, it was 0.50. Bulk densities have a significant influence on the sound absorption effectiveness of granular charcoal, with high densities being more effective at absorption than similar wood species. Charcoal could use such as a composite with building materials. A solid fraction of charcoal could use for indoor acoustic as a sound-reflected material. The object of future research should be to assess acoustic treatments with composite structures of granular charcoal.

Author Contributions

Methodology, O.K. and T.A.; Validation, O.K.; Formal analysis, O.K. and R.G.; Investigation, O.K. and T.A.; Data curation, R.G.; Writing—original draft, O.K.; Writing—review & editing, O.K., T.A. and R.G.; Visualization, R.G.; Supervision, R.G.; Funding acquisition, R.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from thecorresponding author upon reasonable request.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Kim, K. Sources, effects and control of noise in indoor / outdoor living environments. J. Ergon. Soc. Korea 2015, 34, 265–278. [Google Scholar] [CrossRef]

- Montes-González, D.; Vílchez-Gómez, R.; Barrigón-Morillas, J.M.; Atanasio-Moraga, P.; Rey-Gozalo, G.; Trujillo-Carmona, J. Noise and Air Pollution Related to Health in Urban Environments. Proceedings 2018, 2, 1311. [Google Scholar] [CrossRef]

- Abd AL-Rahman, L.; Raja, R.I.; Rahman, R.A.; Ibrahim, Z. Acoustic properties of innovative material from date palm fibre. Am. J. Appl. Sci. 2012, 9, 1390–1395. [Google Scholar]

- Juraga, I.; Paviotti, M.; Berger, B. The Environmental Noise Directive at a Turning Point, 2015. pp. 1041–1044. Available online: https://www.conforg.fr/euronoise2015/proceedings/data/articles/000437.pdf (accessed on 31 May 2015).

- Daian, G.; Ozarska, B. Wood Waste Management Practises and Strategies to Increase Sustainability Standards in the Australian Wooden Furniture Manufacturing Sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Official Statistics Portal. Statistics Lithuania. 2016. Available online: https://osp.stat.gov.lt/ (accessed on 1 June 2016).

- Varnagiryt-Kabainskien, I.; Lukmin, D.; Mizaras, S.; Beniuien, L.; Armolaitis, K. Lithuanian Forest Biomass Resources: Legal, Economic and Ecological Aspects of Their Use and Potential. Energy Sustain. Soc. 2019, 9, 1–19. [Google Scholar] [CrossRef]

- Vasinauskienė, R.; Šilingienė, G.; Sinkevičienė, J. Surface sterilization of english oak (Quercus robur L.) acorns using wet water steam. Balt. For. 2000, 26, 435. [Google Scholar] [CrossRef]

- Su, S.; Gao, Y.; Zhou, X.; Xiong, X.; Wang, Y.; Lyu, L. Structure of waste hemp stalks and their sound absorbing properties. Polymers 2022, 14, 4844. [Google Scholar] [CrossRef]

- Berardi, U.; Iannace, G. Predicting the Sound Absorption of Natural Materials: Best-Fit Inverse Laws for the Acoustic Impedance and the Propagation Constant. Appl. Acoust. 2017, 115, 131–138. [Google Scholar] [CrossRef]

- Gong, M. Engineered Wood Products for Construction; BoD–Books on Demand: Norderstedt, Germany, 2022. [Google Scholar] [CrossRef]

- Seddeq, H.S.; Aly, N.M.; Marwa, A.A.; Elshakankery, M.H. Investigation on Sound Absorption Properties for Recycled Fibrous Materials. J. Ind. Text. 2013, 43, 56–73. [Google Scholar] [CrossRef]

- El-Hadad, A.; Brodie, G.I.; Ahmed, B.S. The Effect of Wood Condition on Sound Wave Propagation. Open J. Acoust. 2018, 8, 37–51. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhao, R.; Fei, B. Sound Absorption Property of Wood for Five Eucalypt Species. J. For. Res. 2004, 15, 207–210. [Google Scholar] [CrossRef]

- Ivanova, Y.; Vitchev, P.; Hristodorova, D. Study on the Influence of Some Factors on the Sound Absorption Characteristics of Wood from Scots Pine. Chip Chipless Woodwork. Process 2018, 11, 65–72. Available online: https://kod.tuzvo.sk/sites/default/files/ivanova_vitchev_hristodorova.pdf (accessed on 17 October 2018).

- Godshall, W.; Davis, J.H. Acoustical Absorption Properties of Wood-Base Panel Materials; Forest Products Lab: Madison, WI, USA, 1969. [Google Scholar] [CrossRef]

- Hwang, K.; Kim, G.-H.; Park, B.; Park, J.-H.; Byeon, H.-S.; Lee, W.-H. Sound Absorption Characteristic of Resonator by Hole Position and Wood Species. J. Korean Wood Sci. Technol. 2008, 36, 9–16. [Google Scholar]

- Fan, Z.; Peng, L.; Liu, M.; Feng, Y.; He, J.; Wu, S. Analysis of Influencing Factors on Sound Absorption Capacity in Microwave-Treated Pinus Radiata Wood. Eur. J. Wood Wood Prod. 2022, 80, 985–995. [Google Scholar] [CrossRef]

- Chung, H.; Park, Y.; Yang, S.-Y.; Kim, H.; Han, Y.; Chang, Y.-S.; Yeo, H. Effect of Heat Treatment Temperature and Time on Sound Absorption Coefficient of Larix Kaempferi Wood. J. Wood Sci. 2017, 63, 575–579. [Google Scholar] [CrossRef]

- Şahin, H.İ.; Yalçın, M.; Yaglıca, N. Determination of screw holding power and thermal conductivity values of particle boards with a middle layer of compost waste added. J. For. Fac. 2017, 18, 121–129. [Google Scholar]

- Wang, D.; Peng, L.M.; Fu, F.; Song, B.Q.; Liu, M.H. Changes of Microscopic Structures and Sound Absorption Properties of Decayed Wood. Wood Res. 2017, 62, 529–538. Available online: https://koreascience.kr/article/JAKO200830335054475.pdf (accessed on 1 January 2017).

- Samsudin, E.M.; Ismail, L.H.; Kadir, A.A. A Review on Physical Factors Influencing Absorption Performance of Fibrous Sound Absorption Material from Natural Fibers. ARPN J. Eng. Appl. Sci. 2016, 11, 3703–3711. [Google Scholar]

- Nandanwar, A.; Kiran, M.; Varadarajulu, K.C. Influence of Density on Sound Absorption Coefficient of Fibre Board. Open J. Acoust. 2017, 7, 1. [Google Scholar] [CrossRef]

- Delany, M.; Bazley, E. Acoustical properties of fibrous absorbent materials. Appl. Acoust. 1970, 3, 105–116. [Google Scholar] [CrossRef]

- Shen, Y.; Jiang, G. Sound absorption properties of composite structure with activated carbon fiber felts. J. Text. Inst. 2014, 105, 1100–1107. [Google Scholar] [CrossRef]

- Venegas, R. Microstructure Influence on Acoustical Properties of Multiscale Porous Materials. Ph.D. Thesis, University of Salford, Salford, UK, 2011. Available online: https://www.researchgate.net/profile/Rodolfo-Venegas/publication/255709047 (accessed on 1 August 2011).

- Bechwati, F.; Avis, M.; Bull, D.; Cox, T.; Hargreaves, J.; Moser, D.; Ross, D.; Umnova, O.; Venegas, R. Low Frequency Sound Propagation in Activated Carbon. J. Acoust. Soc. Am. 2012, 132, 239–248. [Google Scholar] [CrossRef] [PubMed]

- Venegas, R.; Umnova, O. Acoustical Properties of Double Porosity Granular Materials. J. Acoust. Soc. Am. 2011, 130, 2765–2776. [Google Scholar] [CrossRef]

- Bandosz, T.J. Activated Carbon Surfaces in Environmental Remediation; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Arenas, J.P.; Crocker, M.J. Recent Trends in Porous Sound-Absorbing Materials. Sound Vib. 2010, 44, 12–18. Available online: http://www.sandv.com/downloads/1007croc.pdf (accessed on 1 July 2010).

- Smardzewski, J.; Batko, W.; Kamisiński, T.; Flach, A.; Pilch, A.; Dziurka, D.; Mirski, R.; Roszyk, E.; Majewski, A. Experimental Study of Wood Acoustic Absorption Characteristics. Holzforschung 2014, 68, 467–476. Available online: https://www.degruyter.com/document/doi/10.1515/hf-2013-0160/html (accessed on 21 November 2013). [CrossRef]

- Sağlam, S.; Güzelçimen, F.; Bingöl, D.; Özkan, U.Y.; Ekici, B. An Evaluation on Acoustic Behavior of Untreated Tree Trunks Depending on Bark Physical Properties and Fiber Cell Structure. J. Nat. Fibers 2022, 19, 1507–1521. [Google Scholar] [CrossRef]

- Khrystoslavenko, O.; Grubliauskas, R. Investigation of Acoustic Efficiency of Wood Charcoal in Impedance Tube for Usage in Sound-Reflective Devices. Sustainability 2022, 14, 9431. [Google Scholar] [CrossRef]

- Suh, J.G.; Baik, K.M.; Kim, Y.T.; Jung, S.S. Measurement and calculation of the sound absorption coefficient of pine wood charcoal. J. Korean Phys. Soc. 2013, 63, 1576–1582. [Google Scholar] [CrossRef]

- ISO 9053-1; Acoustics—Materials for Acoustical Applications—Determination of Airflow Resistance (ISO, 1991). International Organization for Standardization: Genève, Switzerland, 1991.

- ISO 10534-2; Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes-Part 2: Transfer-Function Method. International Organization for Standardization: Genève, Switzerland, 1998; Volume 26.

- ISO 11654; Acoustical Sound Absorbers for Use in Buildings-Rating of Sound Absorption. International Organization for Standardization: Geneva, Switzerland, 1997.

- Astrauskas, T.; Januševicius, T.; Grubliauskas, R. Acoustic Panels Made of Paper Sludge and Clay Composites. Sustainability 2021, 13, 637. [Google Scholar] [CrossRef]

- Kolya, H.; Kang, C.W. High Acoustic Absorption Properties of Hackberry Compared to Nine Different Hardwood Species: A Novel Finding for Acoustical Engineers. Appl. Acoust. 2020, 169, 107475. [Google Scholar] [CrossRef]

- Pastor-Villegas, J.; Pastor-Valle, J.; Rodríguez, J.M.; García, M.G. Study of Commercial Wood Charcoals for the Preparation of Carbon Adsorbents. J. Anal. Appl. Pyrolysis 2006, 76, 103–108. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).