Optical Wireless Power Transfer for Implanted and Wearable Devices

Abstract

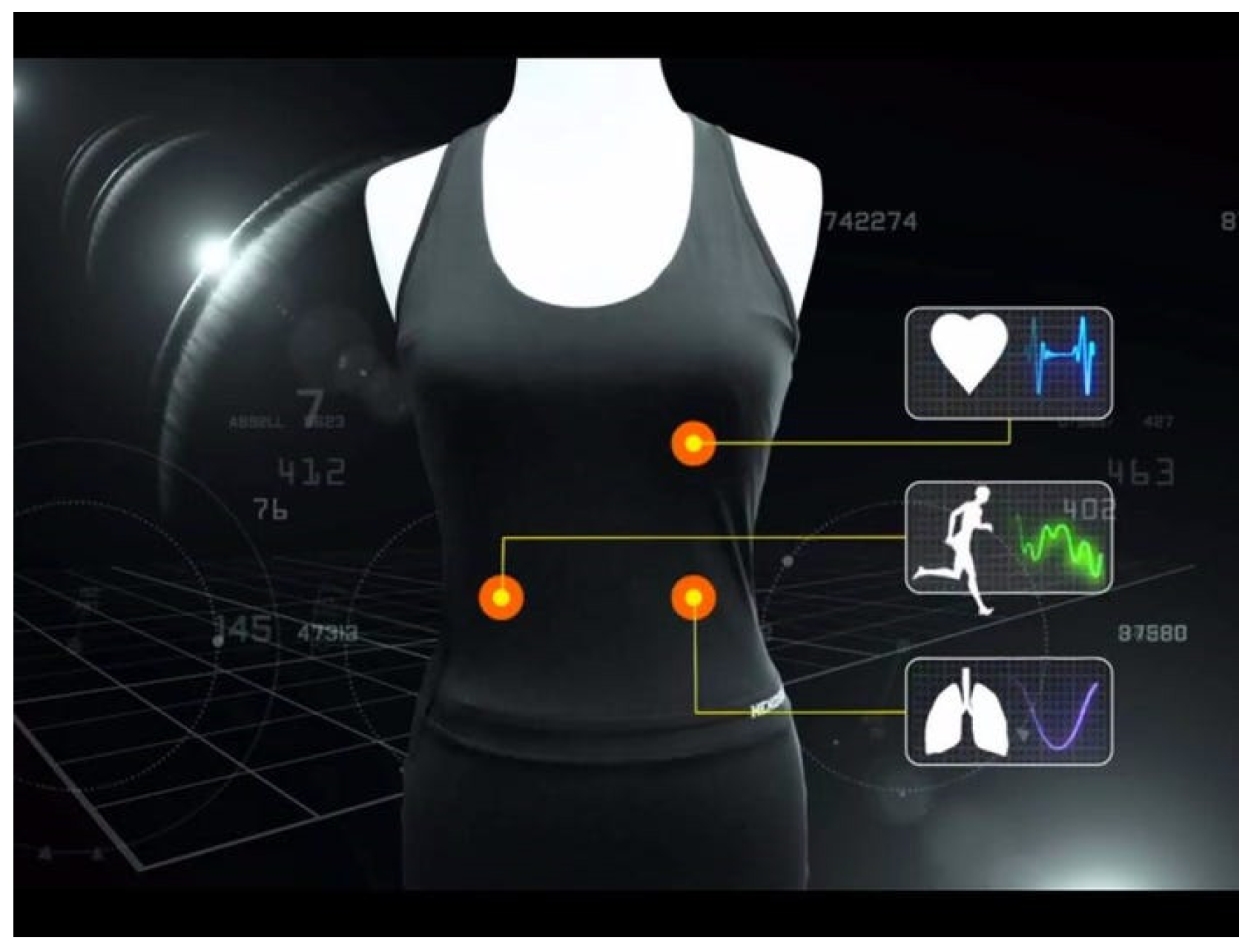

1. Introduction

2. Methods

2.1. Theoretical Backgrounds

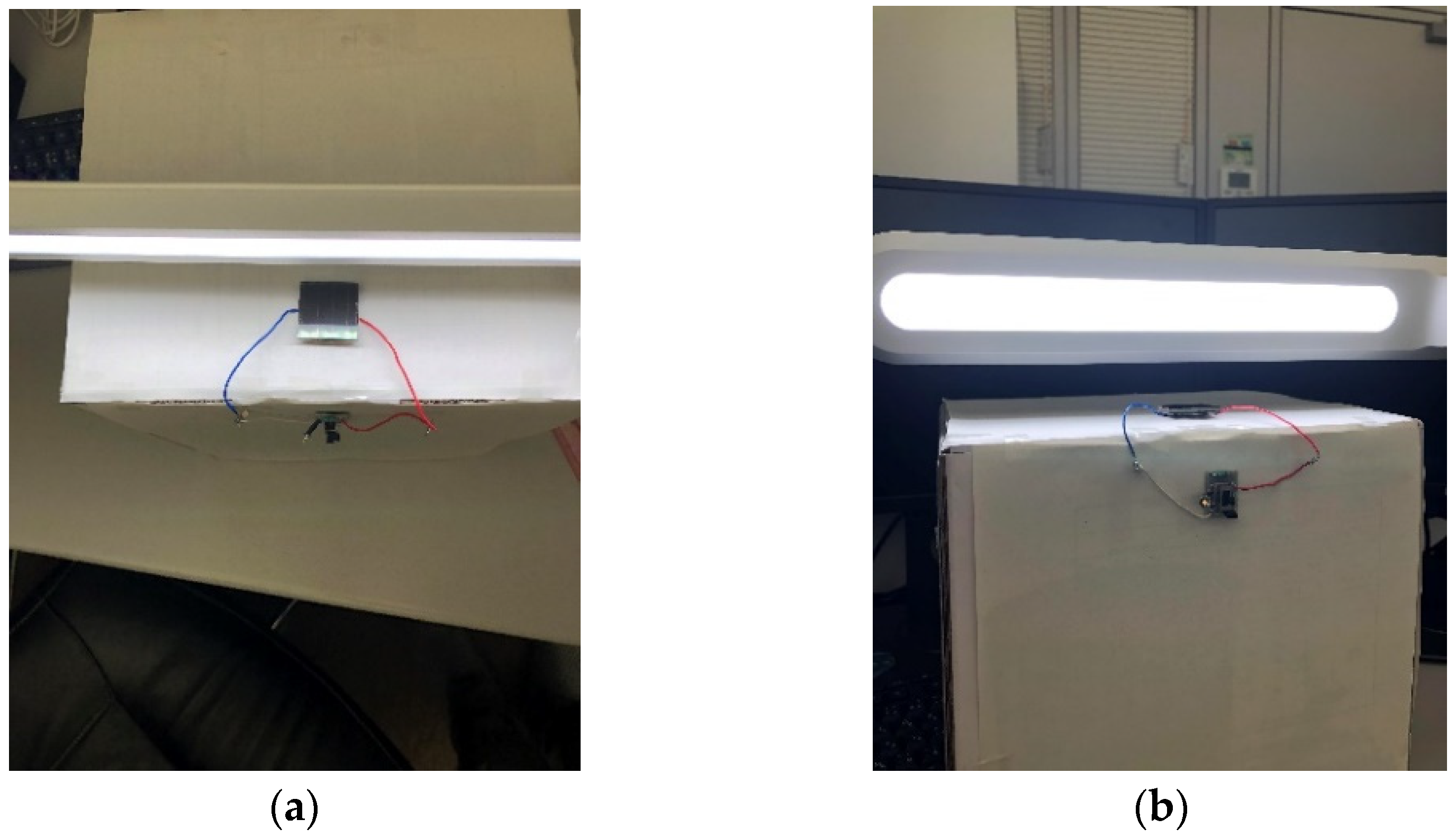

2.2. Experimental Methods

3. Results and Discussions

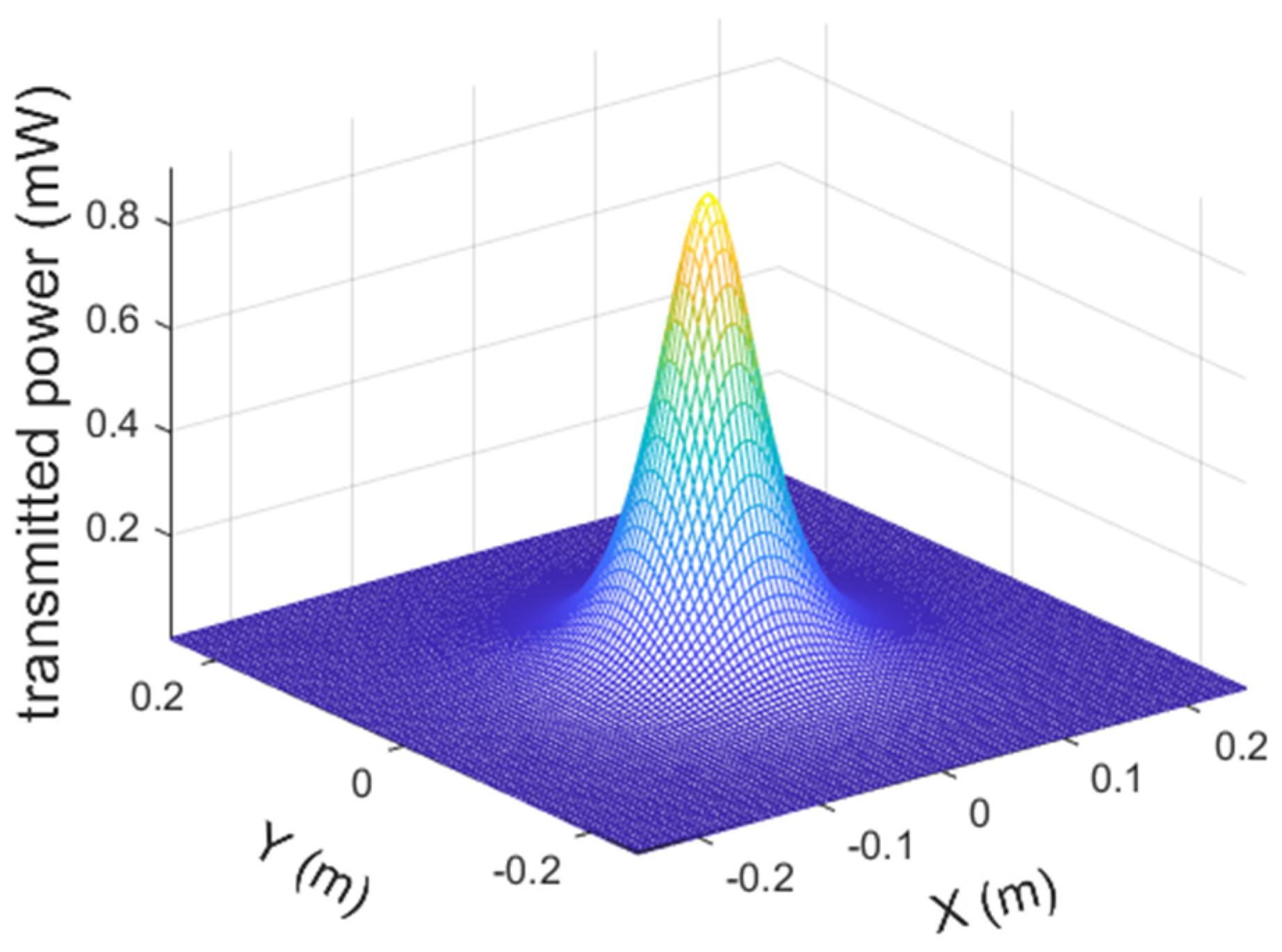

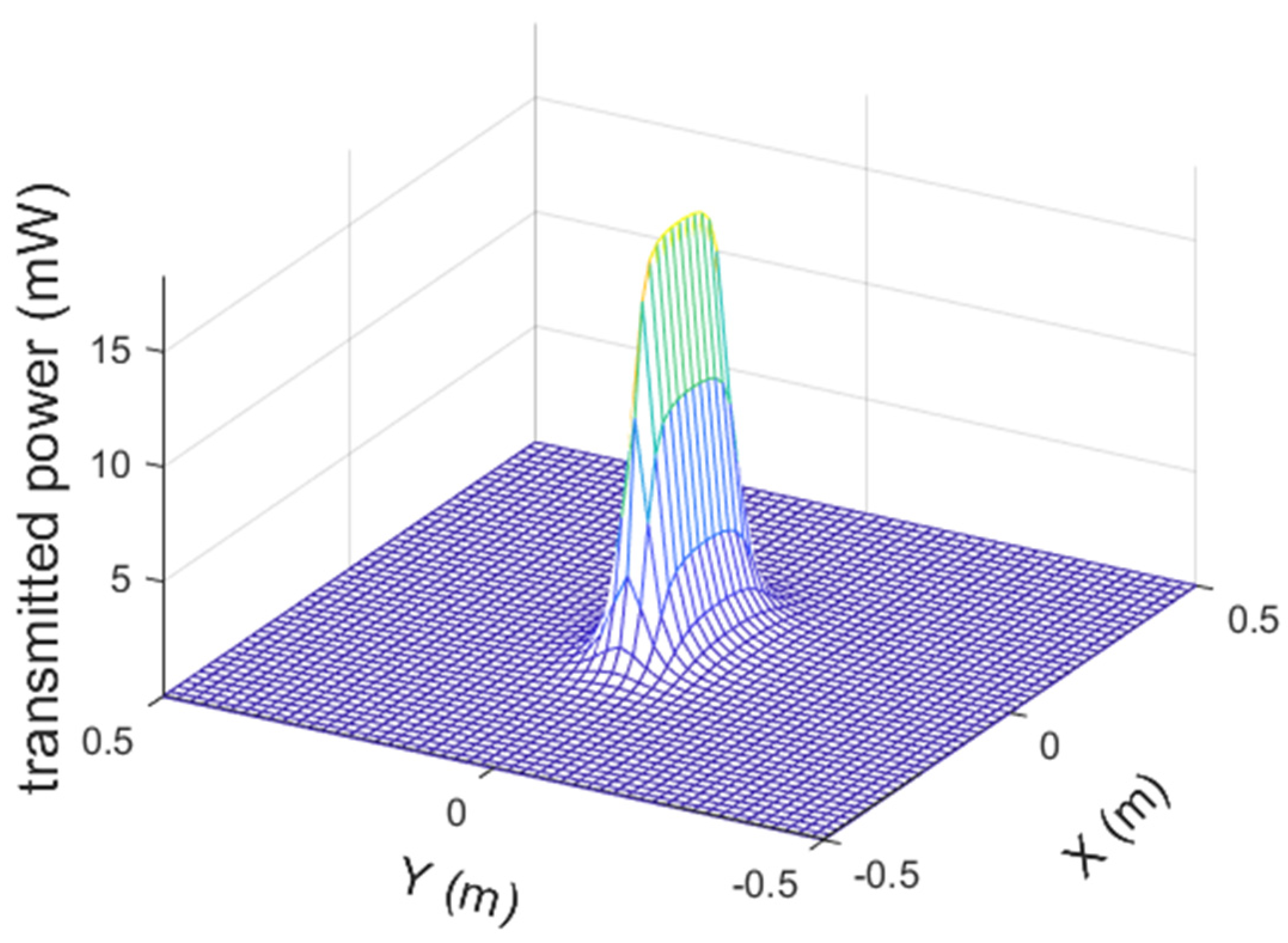

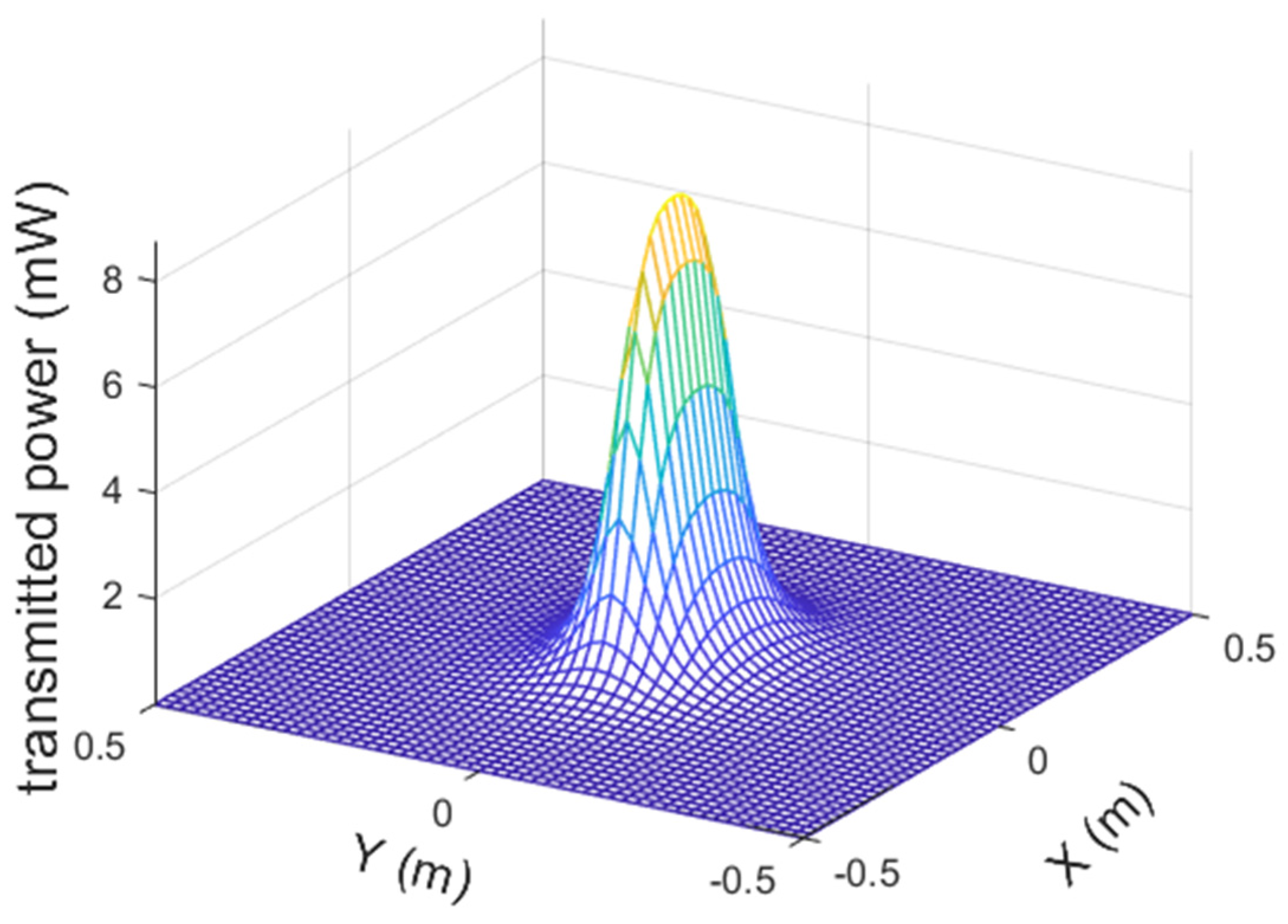

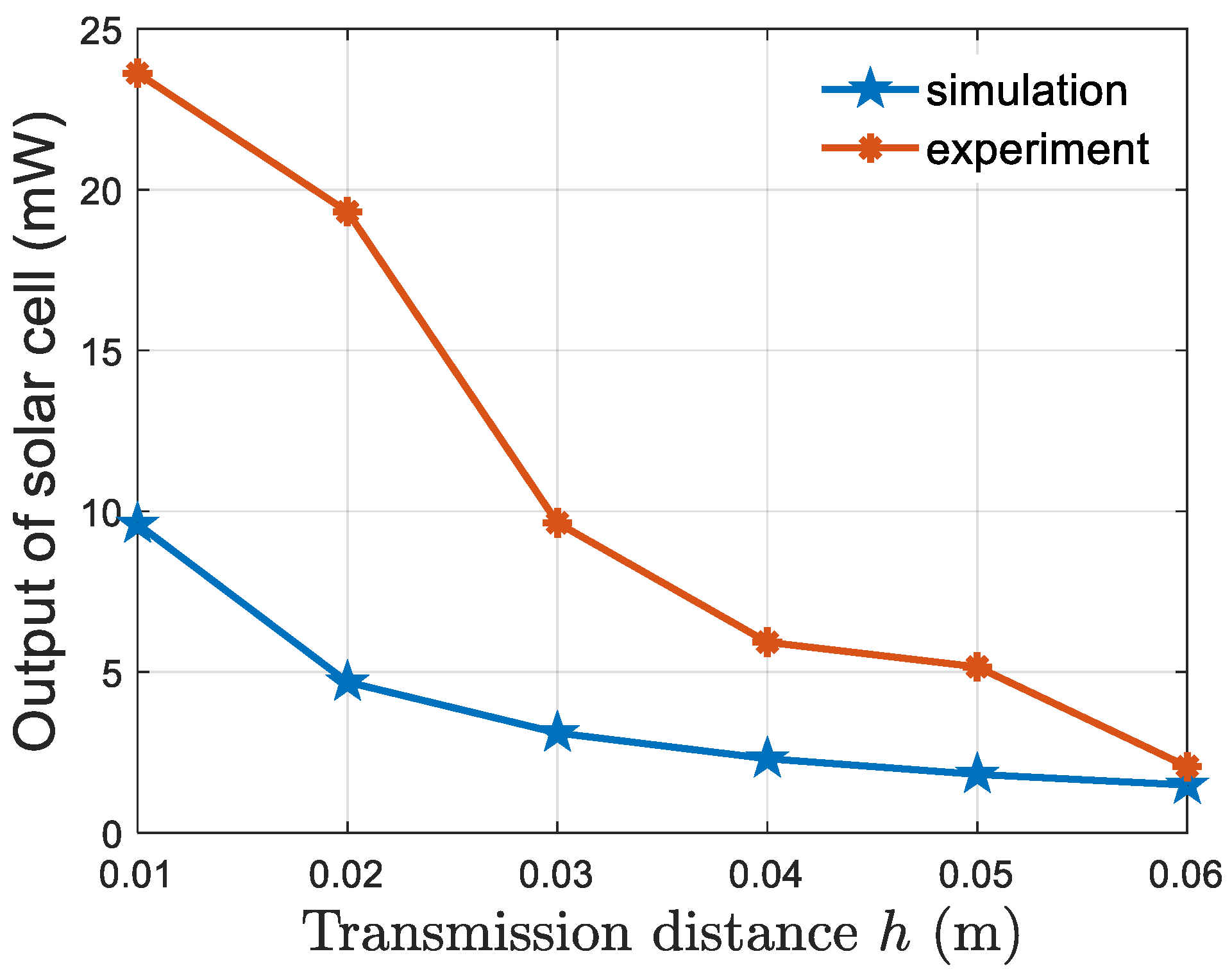

3.1. Simulation Results

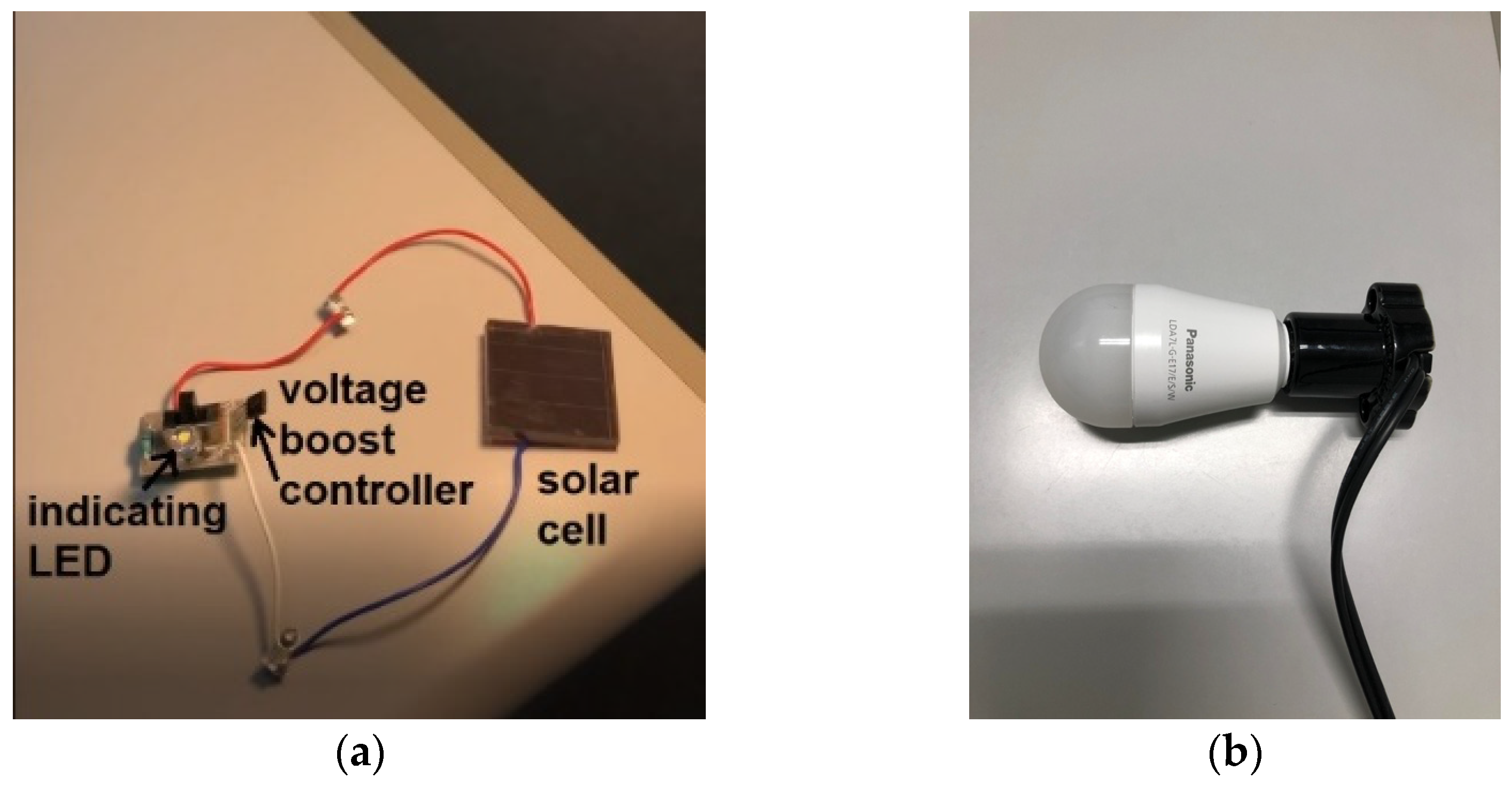

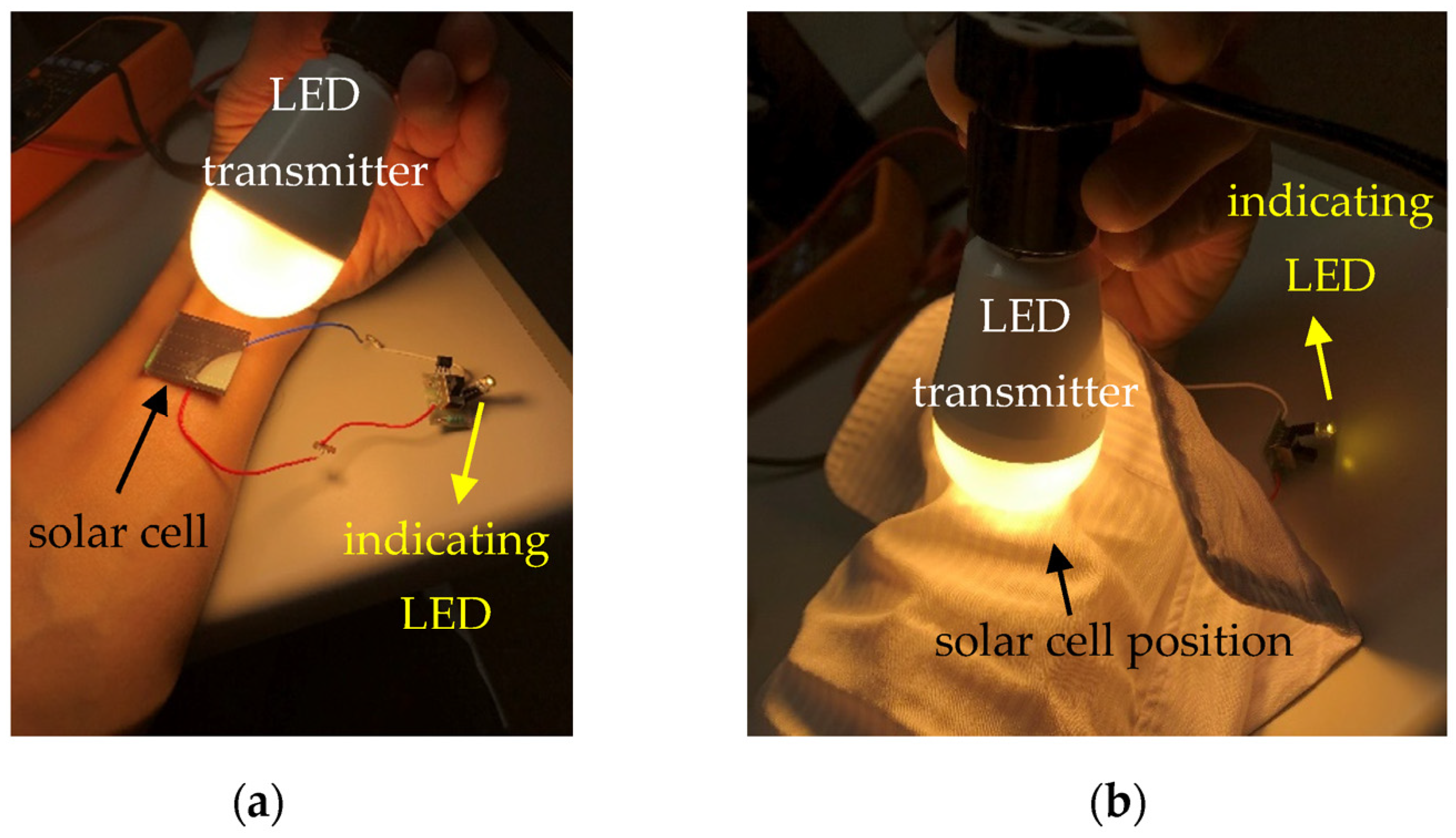

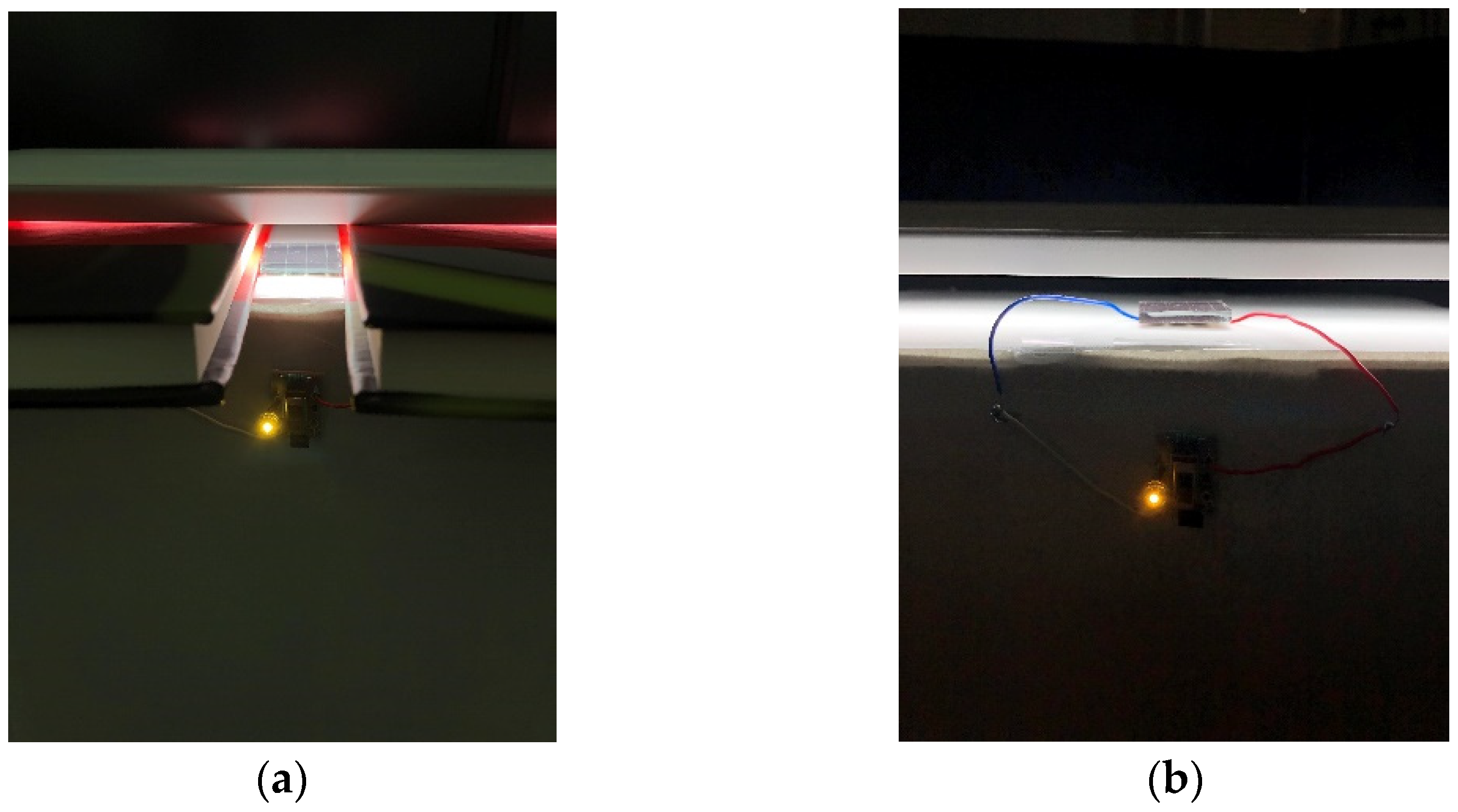

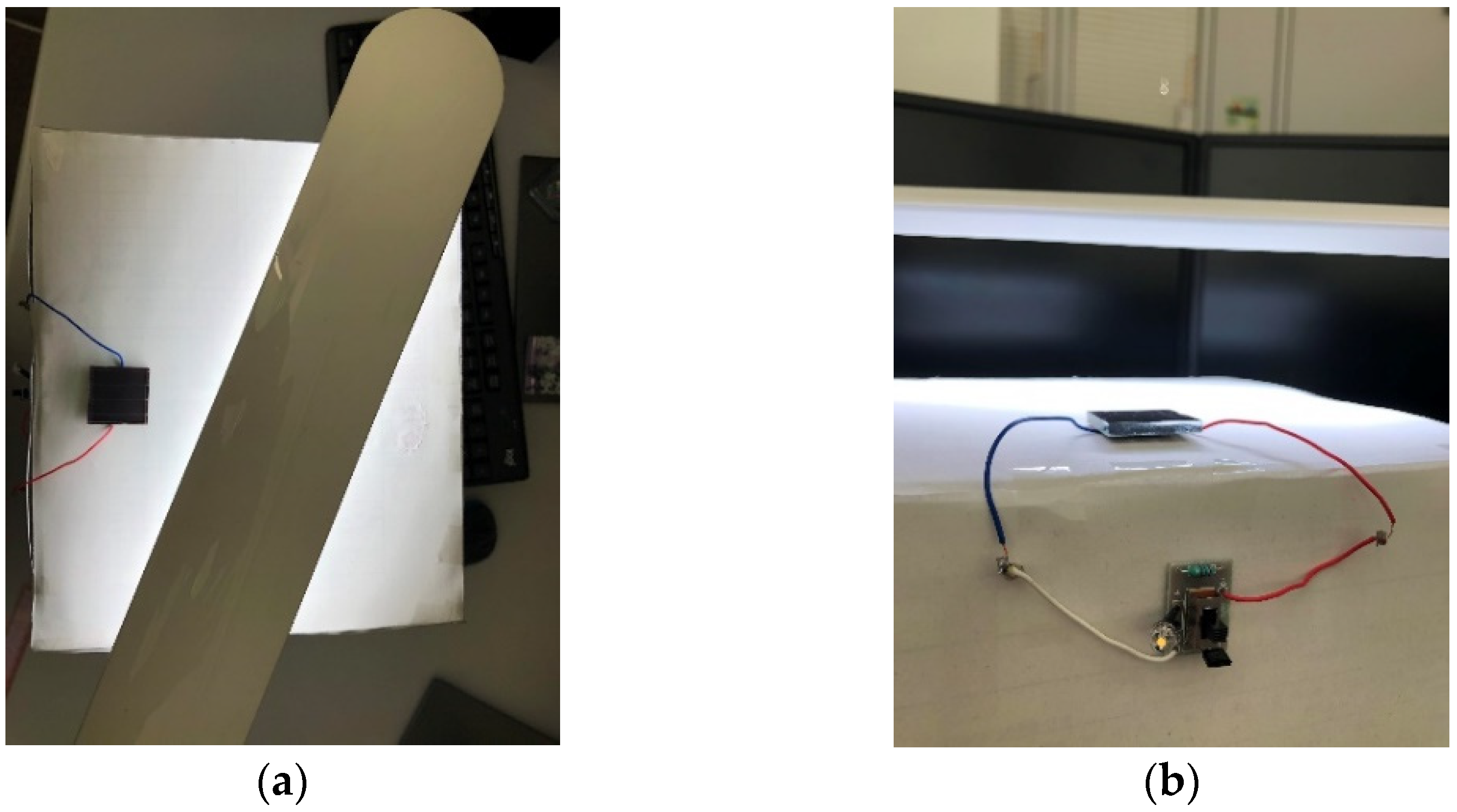

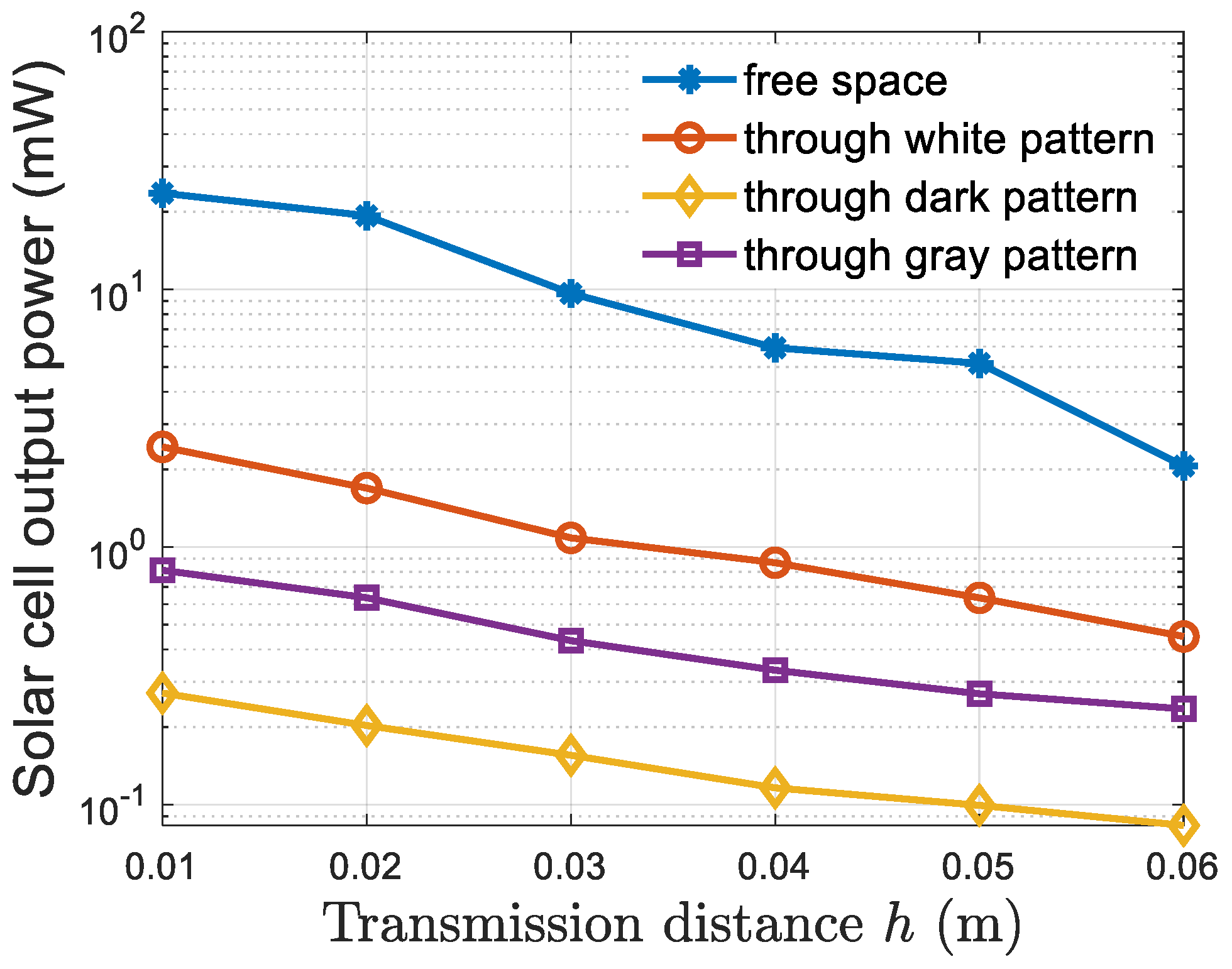

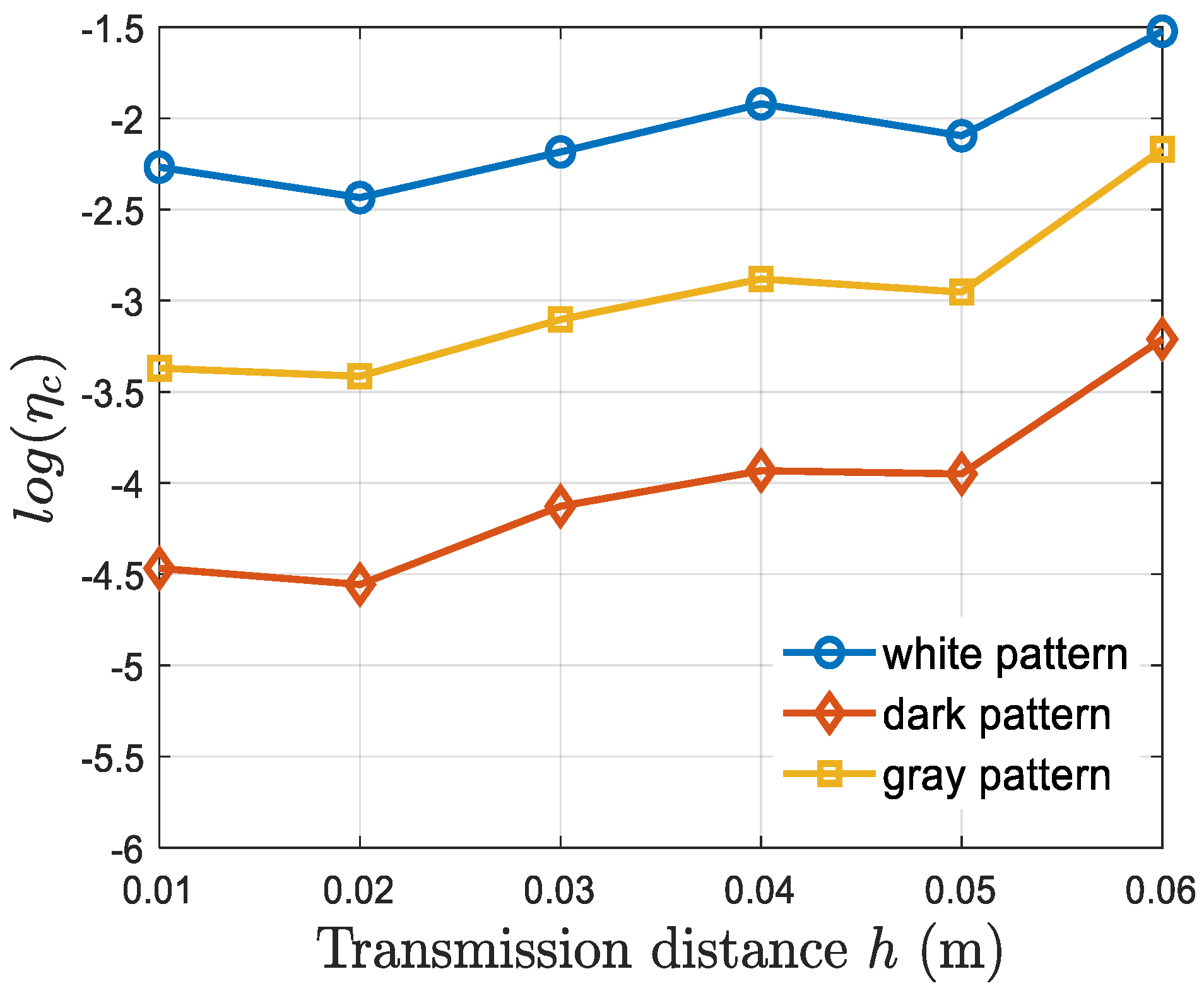

3.2. Experimental Results

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kubicek, J.; Fiedorova, K.; Vilimek, D.; Cerny, M.; Penhaker, M.; Janura, M.; Rosicky, J. Recent Trends, Construction, and Applications of Smart Textiles and Clothing for Monitoring of Health Activity: A Comprehensive Multidisciplinary Review. IEEE Rev. Biomed. Eng. 2022, 15, 36–60. [Google Scholar] [CrossRef]

- Wangatia, L.M.; Yang, S.; Zabihi, F.; Zhu, M.; Ramakrishna, S. Biomedical electronics powered by solar cells. Curr. Opin. Biomed. Eng. 2020, 13, 25–31. [Google Scholar] [CrossRef]

- Zhao, J.; Ghannam, R.; Htet, K.O.; Liu, Y.; Law, M.-K.; Roy, V.A.L.; Michel, B.; Imran, M.A.; Heidari, H. Self-Powered Implantable Medical Devices: Photovoltaic Energy Harvesting Review. Adv. Healthc. Mater. 2020, 9, 2000779. [Google Scholar] [CrossRef]

- Dinis, H.; Mendes, P. A comprehensive review of powering methods used in state-of-the-art miniaturized implantable electronic devices. Biosens. Bioelectron. 2021, 172, 112781. [Google Scholar] [CrossRef]

- Lee, G.-H.; Moon, H.; Kim, H.; Lee, G.H.; Kwon, W.; Yoo, S.; Myung, D.; Yun, S.H.; Bao, Z.; Hahn, S.K. Multifunctional materials for implantable and wearable photonic healthcare devices. Nat. Rev. Mater. 2020, 5, 149–165. [Google Scholar] [CrossRef]

- Machura, P.; Li, Q. A critical review on wireless charging for electric vehicles. Renew. Sustain. Energy Rev. 2019, 104, 209–234. [Google Scholar] [CrossRef]

- Li, S.; Mi, C.C. Wireless Power Transfer for Electric Vehicle Applications. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 4–17. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Chapman, A. The potential contributions of universal and ubiquitous wireless power transfer systems towards sustainability. Int. J. Sustain. Eng. 2021, 14, 1780–1790. [Google Scholar] [CrossRef]

- Moon, E.; Barrow, M.; Lim, J.; Lee, J.; Nason, S.R.; Costello, J.; Kim, H.S.; Chestek, C.; Jang, T.; Blaauw, D.; et al. Bridging the “Last Millimeter” Gap of Brain-Machine Interfaces via Near-Infrared Wireless Power Transfer and Data Communications. ACS Photon. 2021, 8, 1430–1438. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Seo, J.; Jung, D.; Lee, T.; Ju, H.; Han, J.; Kim, N.; Jeong, J.; Cho, S.; Seol, J.H.; et al. Active photonic wireless power transfer into live tissues. Proc. Natl. Acad. Sci. USA 2020, 117, 16856–16863. [Google Scholar] [CrossRef]

- Wuthibenjaphonchai, N.; Haruta, M.; Sasagawa, K.; Tokuda, T.; Carrara, S.; Ohta, J. Wearable and Battery-Free Health-Monitoring Devices with Optical Power Transfer. IEEE Sens. J. 2021, 21, 9402–9412. [Google Scholar] [CrossRef]

- Kumamoto, Y.; Isaac, N.; Fujita, K.; Ando, J.; Kawat, S. Optical Techniques for Future Pacemaker Technology. In Modern Pacemakers—Present and Future; INTECH Open Access Publisher: London, UK, 2011. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Tumen-Ulzii, G.; Matsushima, T.; Adachi, C. Performance Analysis of a Perovskite-Based Thing-to-Thing Optical Wireless Power Transfer System. IEEE Photon. J. 2022, 14, 6213208. [Google Scholar] [CrossRef]

- Nguyen, D.H.; Matsushima, T.; Qin, C.; Adachi, C. Toward Thing-to-Thing Optical Wireless Power Transfer: Metal Halide Perovskite Transceiver as an Enabler. Front. Energy Res. 2021, 9, 679125. [Google Scholar] [CrossRef]

- Waghule, T.; Singhvi, G.; Dubey, S.K.; Pandey, M.M.; Gupta, G.; Singh, M.; Dua, K. Microneedles: A smart approach and increasing potential for transdermal drug delivery system. Biomed. Pharmacother. 2019, 109, 1249–1258. [Google Scholar] [CrossRef]

- Indermun, S.; Luttge, R.; Choonara, Y.E.; Kumar, P.; du Toit, L.C.; Modi, G.; Pillay, V. Current advances in the fabrication of microneedles for transdermal delivery. J. Control. Release 2014, 185, 130–138. [Google Scholar] [CrossRef] [PubMed]

- Bai, W.; Kuang, T.; Chitrakar, C.; Yang, R.; Li, S.; Zhu, D.; Chang, L. Patchable micro/nanodevices interacting with skin. Biosens. Bioelectron. 2018, 122, 189–204. [Google Scholar] [CrossRef]

- Wu, H.; Yang, G.; Zhu, K. Materials, Devices, and Systems of On-Skin Electrodes for Electrophysiological Monitoring and Human–Machine Interfaces. Adv. Sci. 2021, 8, 2001938. [Google Scholar] [CrossRef] [PubMed]

- Bosnjak, A.; Kennedy, A.; Linares, P.; Borges, M.; McLaughlin, J.; Escalona, O.J. Performance assessment of dry electrodes for wearable long term cardiac rhythm monitoring: Skin-electrode impedance spectroscopy. In Proceedings of the 2017 39th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Jeju, Republic of Korea, 11–15 July 2017; pp. 1861–1864. [Google Scholar] [CrossRef]

- Shetti, N.P.; Mishra, A.; Basu, S.; Mascarenhas, R.J.; Kakarla, R.R.; Aminabhavi, T. Skin-Patchable Electrodes for Biosensor Applications: A Review. ACS Biomater. Sci. Eng. 2020, 6, 1823–1835. [Google Scholar] [CrossRef]

- Zhao, J.; Ghannam, R.; Law, M.-K.; Imran, M.A.; Heidari, H. Photovoltaic Power Harvesting Technologies in Biomedical Implantable Devices Considering the Optimal Location. IEEE J. Electromagn. RF Microw. Med. Biol. 2020, 4, 148–155. [Google Scholar] [CrossRef]

- Shi, Q.; Dong, B.; He, T.; Sun, Z.; Zhu, J.; Zhang, Z.; Lee, C. Progress in wearable electronics/photonics—Moving toward the era of artificial intelligence and internet of things. Infomat 2020, 2, 1131–1162. [Google Scholar] [CrossRef]

- Lister, T.; Wright, P.A.; Chappell, P.H. Optical properties of human skin. J. Biomed. Opt. 2012, 17, 0909011–09090115. [Google Scholar] [CrossRef]

- Jacques, S.L. Optical properties of biological tissues: A review. Phys. Med. Biol. 2013, 58, R37–R61. [Google Scholar] [CrossRef]

- Ash, C.; Dubec, M.; Donne, K.; Bashford, T. Effect of wavelength and beam width on penetration in light-tissue interaction using computational methods. Lasers Med. Sci. 2017, 32, 1909–1918. [Google Scholar] [CrossRef]

- Mignon, C.; Tobin, D.J.; Zeitouny, M.; Uzunbajakava, N.E. Shedding light on the variability of optical skin properties: Finding a path towards more accurate prediction of light propagation in human cutaneous compartments. Biomed. Opt. Express 2018, 9, 852–872. [Google Scholar] [CrossRef] [PubMed]

- Anderson, R.R.; Parrish, J.A. Optical Properties of Human Skin. In The Science of Photomedicine. Photobiology; Regan, J.D., Parrish, J.A., Eds.; Springer: Boston, MA, USA, 1982; pp. 147–194. [Google Scholar] [CrossRef]

- Nguyen, D.H. Optical Wireless Power Transfer for Clothing-Covered Wearables. In Proceedings of the 2022 7th International Conference on Intelligent Informatics and Biomedical Science (ICIIBMS), Nara, Japan, 24–26 November 2022; pp. 222–226. [Google Scholar] [CrossRef]

- Nguyen, D.H. Optical Wireless Power Transfer Toward Applications in Implanted and Wearable Devices. In Proceedings of the 33rd International Photovoltaic Science and Engineering Conference (PVSEC-33), Nagoya, Japan, 13–17 November 2022. [Google Scholar]

- Komine, T.; Nakagawa, M. Fundamental analysis for visible-light communication system using LED lights. IEEE Trans. Consum. Electron. 2004, 50, 100–107. [Google Scholar] [CrossRef]

- Tong, J.K.; Huang, X.; Boriskina, S.V.; Loomis, J.; Xu, Y.; Chen, G. Infrared-Transparent Visible-Opaque Fabrics for Wearable Personal Thermal Management. ACS Photon. 2015, 2, 769–778. [Google Scholar] [CrossRef]

- Yamashita, I.; Tsukuma, K. Light scattering by residual pores in transparent zirconia ceramics. J. Ceram. Soc. Jpn. 2011, 119, 133–135. [Google Scholar] [CrossRef]

- Mayerhöfer, T.G.; Pahlow, S.; Popp, J. The Bouguer-Beer-Lambert Law: Shining Light on the Obscure. ChemPhysChem 2020, 21, 2029–2046. [Google Scholar] [CrossRef]

- Song, K.; Han, J.H.; Lim, T.; Kim, N.; Shin, S.; Kim, J.; Choo, H.; Jeong, S.; Kim, Y.-C.; Wang, Z.L.; et al. Subdermal Flexible Solar Cell Arrays for Powering Medical Electronic Implants. Adv. Health Mater. 2016, 5, 1572–1580. [Google Scholar] [CrossRef]

- Huang, J.; Golubović, D.S.; Koh, S.; Yang, D.; Li, X.; Fan, X.; Zhang, G.Q. Degradation Mechanisms of Mid-Power White-Light LEDs Under High-Temperature–Humidity Conditions. IEEE Trans. Device Mater. Reliab. 2015, 15, 220–228. [Google Scholar] [CrossRef]

- Kaushal, H.; Kaddoum, G. Optical Communication in Space: Challenges and Mitigation Techniques. IEEE Commun. Surv. Tutor. 2017, 19, 57–96. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Output power | 20 mW |

| Semi-angle at half power | 70 deg |

| FOV | 60 deg |

| Received Power | Power Density | |

|---|---|---|

| Free-space | 67 mW | 107.2 μW/mm2 |

| Under-clothing | 28.3 mW | 45.28 μW/mm2 |

| Charging Time through Different Color Patterns (Minutes) | |||

|---|---|---|---|

| Distance (cm) | White | Dark | Gray |

| 1 | 5 (daily), 15 (full) | 35 (daily), 102 (full) | 13 (daily), 38 (full) |

| 2 | 7 (daily), 21 (full) | 46 (daily), 135 (full) | 17 (daily), 48 (full) |

| 3 | 10 (daily), 29 (full) | 59 (daily), 172 (full) | 22 (daily), 64 (full) |

| 4 | 12 (daily), 36 (full) | 78 (daily), 227 (full) | 29 (daily), 83 (full) |

| 5 | 16 (daily), 46 (full) | 90 (daily), 262 (full) | 34 (daily), 98 (full) |

| 6 | 20 (daily), 60 (full) | 107 (daily), 312 (full) | 40 (daily), 116 (full) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, D.H. Optical Wireless Power Transfer for Implanted and Wearable Devices. Sustainability 2023, 15, 8146. https://doi.org/10.3390/su15108146

Nguyen DH. Optical Wireless Power Transfer for Implanted and Wearable Devices. Sustainability. 2023; 15(10):8146. https://doi.org/10.3390/su15108146

Chicago/Turabian StyleNguyen, Dinh Hoa. 2023. "Optical Wireless Power Transfer for Implanted and Wearable Devices" Sustainability 15, no. 10: 8146. https://doi.org/10.3390/su15108146

APA StyleNguyen, D. H. (2023). Optical Wireless Power Transfer for Implanted and Wearable Devices. Sustainability, 15(10), 8146. https://doi.org/10.3390/su15108146