Mitigation of Global Climate Change through Genetic Improvement of Resin Production from Resinous Pines: The Case of Pinus halepensis in Greece

Abstract

1. Introduction

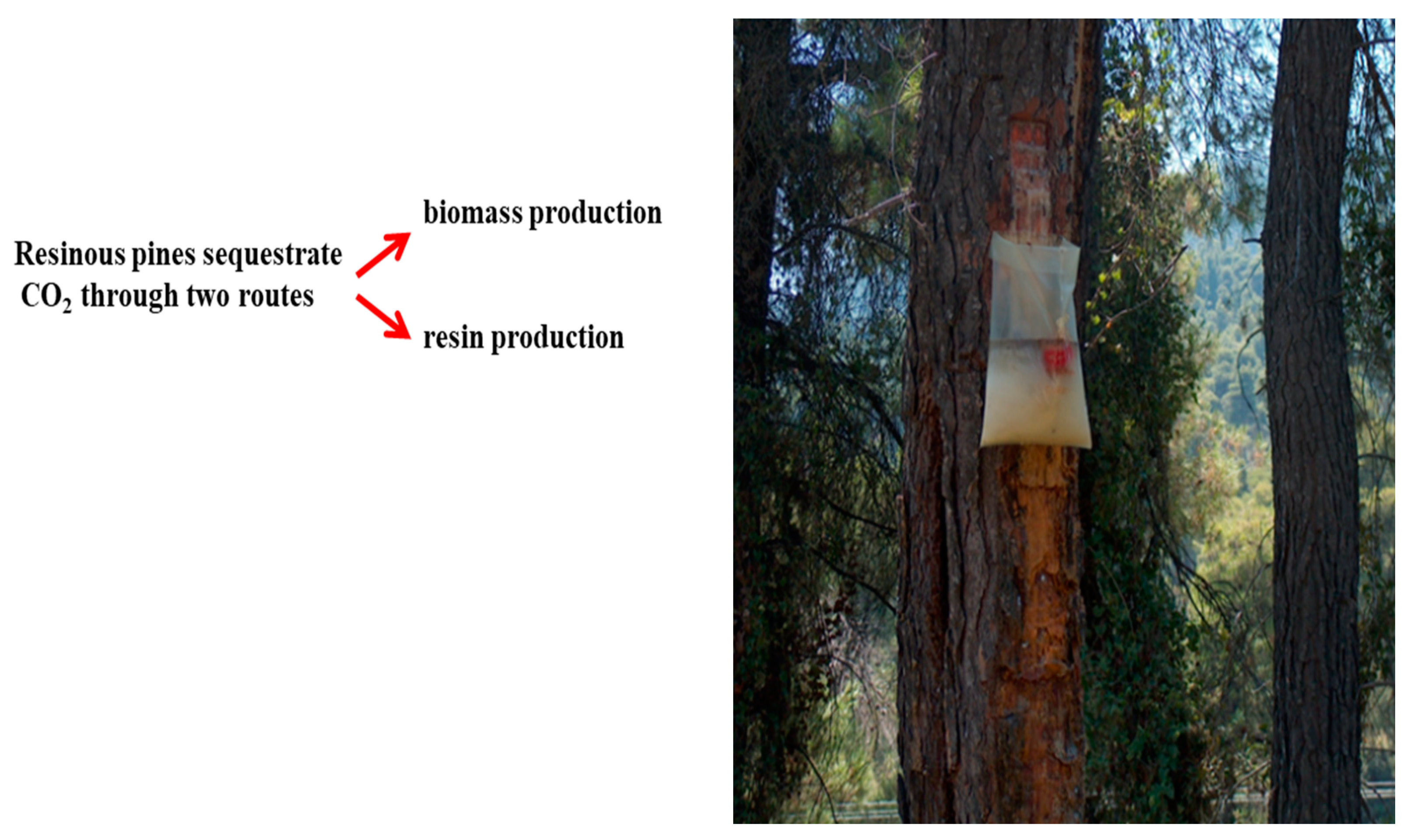

2. Pinus Species and Their Valuable Byproduct “Oleoresin”

3. Production of Oleoresin from P. halepensis Trees

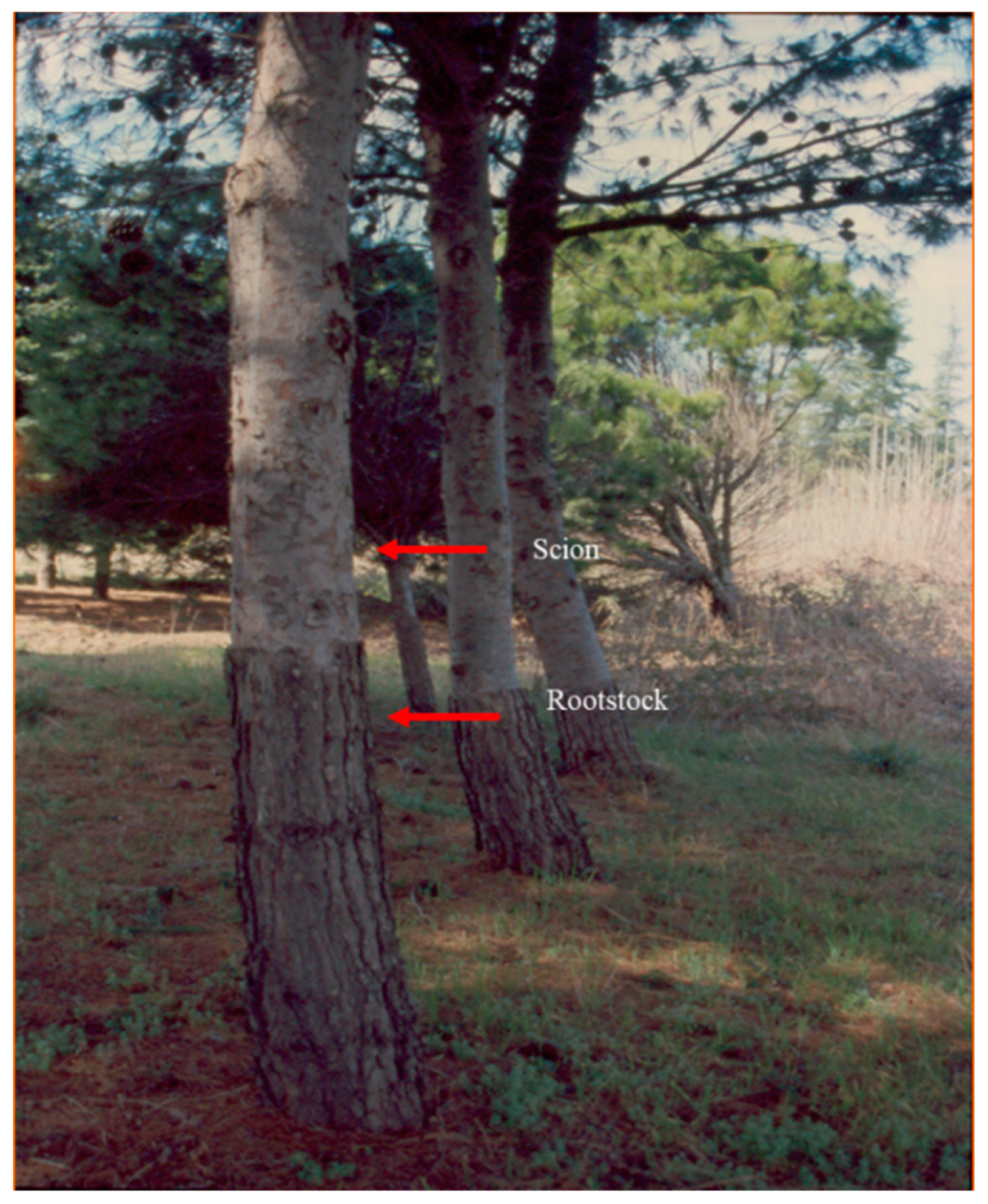

4. Use of Highly Resin-Yielding Genotypes of P. halepensis to Mitigate the Greenhouse Effect

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. Climate Action. Available online: https://www.un.org/en/climatechange/what-is-climate-change (accessed on 21 February 2023).

- Cooper, C.F. Carbon storage in managed forests. Can. J. For. Res. 1983, 13, 155–166. [Google Scholar] [CrossRef]

- Rodrigues-Corrêa, K.C.S.; Lima, J.C.; Fett-Neto, A.G. Pine oleoresin: Tapping green chemicals, biofuels, food protection, and carbon sequestration from multipurpose trees. Food Ener. Secur. 2012, 1, 81–93. [Google Scholar] [CrossRef]

- Andersen, B.G.; Borns, H.W., Jr. The Ice Age World: An Introduction to Quaternary History on Research, 2nd ed.; Scandinavian University Press: Oslo, Norway, 1997; p. 208. ISBN 978-8200376835. [Google Scholar]

- Petit, J.R.; Jouzel, J.; Raynaud, D.; Barkov, N.I.; Barnola, J.-M.; Basile, I.; Bender, M.; Chappellaz, J.; Davis, M.; Delaygue, G.; et al. Climate and atmospheric history of the past 420,000 years from the Vostok ice core, Antarctica. Nature 1999, 399, 429–436. [Google Scholar] [CrossRef]

- NASA. Global Climate Change: Vital Signs of the Planet. Available online: https://climate.nasa.gov/vital-signs/carbon-dioxide/ (accessed on 10 March 2023).

- Lal, R. Carbon sequestration. Phil. Trans. R. Soc. B Biol. Sci. 2008, 363, 815–830. [Google Scholar] [CrossRef] [PubMed]

- NASA. Earth Data, Open Access for Open Science. Available online: https://www.earthdata.nasa.gov/learn/pathfinders/greenhouse-gases-data-pathfinder (accessed on 20 December 2022).

- WMO (World Meteorological Organization). State of Global Climate 2021, WMO Provisional Report; WMO: Geneva, Switzerland, 2021; p. 47. [Google Scholar]

- Abbass, K.; Qasim, M.Z.; Song, H.; Murshed, M.; Mahmood, H.; Younis, I. A review of the global climate change impacts, adaptation, and sustainable mitigation measures. Environ. Sci. Poll. Res. 2022, 29, 42539–42559. [Google Scholar] [CrossRef]

- Sedjo, R.A.; Wisniewski, J.; Sample, A.V.; Kinsman, J.D. The economics of managing carbon via forestry: Assessment of existing studies. Environ. Resour. Econ. 1995, 6, 139–165. [Google Scholar] [CrossRef]

- Montagnini, F.; Nair, P.K.R. Carbon sequestration: An underexploited environmental benefit of agroforestry systems. Agrofor. Syst. 2004, 61, 281–295. [Google Scholar]

- White, T.L.; Adams, W.T.; Neale, D.B. Forest Genetics; CABI Publishing: Wallingford, UK, 2007; p. 682. [Google Scholar]

- Jacob, K. Forests change the climate. Max Planck Res. 2020, 4, 79–85. [Google Scholar]

- Dafis, S. The Forests of Greece; The Goulandris Museum of Natural History: Thessaloniki, Greece, 2010; p. 192. (In Greek) [Google Scholar]

- Rodrigues-Corrêa, K.C.S.; Sausen, T.L.; Rocha, F.S.; Fett-Neto, A.G. Oleoresin yield and carbon stocks in tapped subtropical Pinus elliottii forests. In From Genomes to Intergration and Delivery, Proceedings of IUFRO Tree Biotechnology Conference 2011, Arraial d’Ajuda, Bahia, Brazil, 26 June–2 July 2011; BioMed Central: London, UK, 2011; Volume 5, (Suppl. 7), p. 100. Available online: http://www.biomedcentral.com/1753-6561/5/S7/P100 (accessed on 6 April 2023).

- Papajannopoulos, A.D.; Song, Z.Q.; Liang, Z.Q.; Spanos, J.A. GC-MS analysis of oleoresin of three Greek pine species. Eur. J. Wood Wood Prod. 2001, 59, 443–446. [Google Scholar] [CrossRef]

- Roberds, J.H.; Strom, B.L.; Hain, F.P.; Gwaze, D.P.; McKeand, S.E.; Lott, L.H. Estimates of genetic parameters for oleoresin and growth traits in juvenile loblolly pine. Can. J. For. Res. 2003, 33, 2469–2476. [Google Scholar] [CrossRef]

- Cunningham, A. Pine resin tapping techniques used around the world. In Pine Resin: Biology, Chemistry and Applications; Fett-Neto, A.G., Rodrigues-Corrêa, K.C.S., Eds.; Research Signpost: Kerala, India, 2012; pp. 1–8. ISBN 978-81-308-0493-4. [Google Scholar]

- Scaltsoyiannes, A.V.; Tsaktsira, M.; Karanikas, C.; Mitras, D.; Scaltsoyiannes, V.A.; Scaltsoyiannes, A.A.; Karkabunas, S.; Kontargiris, E.; Dima, Ι.; Tsanaktsidis, Κ.; et al. Genetic improvement of Aleppo pine (Pinus halepensis Mill.) oleoresin production—Application of the oleoresin and its derivatives on: (a) Climate change, (b) Pharmacology and (c) Quality of the liquid fuels (diesel). In Proceedings of the 17th Conference of the Hellenic Forestry Society, Argostoli Kefalonia, Greece, 4–5 October 2015; pp. 24–52. [Google Scholar]

- Karanikas, C.; Walker, V.; Scaltsoyiannes, A.; Compte, G.; Betrand, C. High vs. low yielding oleores in Pinus halepensis Mill. trees. GC terpenoids profiling as diagnostic tool. Ann. For. Sci. 2010, 67, 412–419. [Google Scholar] [CrossRef]

- Susaeta, A.; Peter, G.F.; Hodges, A.W.; Carter, D.R. Oleoresin tapping of planted slash pine (Pinus elliottii Engelm. var. elliottii) adds value and management flexibility to landowners in the southern United States. Biom. Bioen. 2014, 68, 55–61. [Google Scholar] [CrossRef]

- Bohlmann, J.; Keeling, C.I. Terpenoid biomaterials. Plant J. 2008, 54, 656–669. [Google Scholar] [CrossRef] [PubMed]

- Tsanaktsidis, C.G.; Favvas, E.P.; Scaltsoyiannes, A.A.; Christidis, S.G.; Katsidi, E.X.; Scaltsoyiannes, A.V. Natural resins and their application in antifouling fuel technology. Part I: Improving the physicochemical properties of diesel fuel using natural resin polymer as a removable additive. Fuel Process. Technol. 2013, 114, 135–143. [Google Scholar] [CrossRef]

- Tsanaktsidis, C.G.; Favvas, E.P.; Tzilantonis, G.T.; Scaltsoyiannes, A.V. A new fuel (D-BD-J) from the blending of conventional diesel, biodiesel and JP8. Fuel Process. Technol. 2014, 127, 66–71. [Google Scholar] [CrossRef]

- Tsanaktsidis, C.G.; Scaltsoyiannes, A.V.; Katsidi, E.X.; Christidis, S.G.; Tzilantonis, G.T. Use of natural resin to reduce water content in diesel fuel. Chem. Technol. Fuels Oils 2014, 49, 497–501. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, C. Reduction of Salmonella enterica contamination on grape tomatoes by washing with thyme oil, thymol, and carvacrol as compared with chlorine treatment. J. Food Protect. 2010, 73, 2270–2275. [Google Scholar] [CrossRef]

- Ravishankar, S.; Zhu, L.; Reyna-Granados, J.; Law, B.; Joens, L.; Friedman, M. Carvacrol and cinnamaldehyde inactivate antibiotic-resistant Salmonella enterica in buffer and on celery and oysters. J. Food Protect. 2010, 73, 234–240. [Google Scholar] [CrossRef]

- Behr, A.; Johnen, L. Myrcene as a natural base chemical in sustainable chemistry: A critical review. Chem. Sustain. Chem. 2009, 2, 1072–1095. [Google Scholar] [CrossRef]

- Mercier, B.; Prost, J.; Prost, M. The essential oil of turpentine and its major volatile fraction (α- and β-pinenes): A review. Int. J. Occup. Med. Environ. Health 2009, 22, 331–342. [Google Scholar] [CrossRef]

- Marzec, K.M.; Reva, I.; Fausto, R.; Malek, K.; Proniewicz, L.M. Conformational space and photochemistry of α-terpinene. J. Phys. Chem. A 2010, 114, 5526–5536. [Google Scholar] [CrossRef] [PubMed]

- Zulak, K.G.; Bohlmann, J. Terpenoid biosynthesis and specialized vascular cells of conifer defense. J. Integr. Plant Biol. 2010, 52, 86–97. [Google Scholar] [CrossRef] [PubMed]

- Adams, T.B.; Gavin, C.L.; McGowen, M.M.; Waddell, W.J.; Cohen, S.M.; Feron, V.J.; Marnett, L.J.; Munro, I.C.; Portoghese, P.S.; Rietjens, I.M.C.M.; et al. The FEMA GRAS assessment of aliphatic and aromatic terpene hydrocarbons used as flavor ingredients. Food Chem. Toxicol. 2011, 49, 2471–2494. [Google Scholar] [CrossRef] [PubMed]

- da Silva, A.C.R.; Lopes, P.M.; de Azevedo, M.M.B.; Costa, D.C.M.; Alviano, C.S.; Alviano, D.S. Biological activities of α-pinene and β-pinene enantiomers. Molecules 2012, 17, 6305–6316. [Google Scholar] [CrossRef] [PubMed]

- Rudbäck, J.; Bergström, M.A.; Börje, A.; Nilsson, U.; Karlberg, A.-T. α-Terpinene, an antioxidant in tea tree oil, autoxidizes rapidly to skin allergens on air exposure. Chem. Res. Toxicol. 2012, 25, 713–721. [Google Scholar] [CrossRef]

- Nerio, L.S.; Olivero-Verbel, J.; Stashenko, E. Repellent activity of essential oils: A review. Bioresour. Technol. 2010, 101, 372–378. [Google Scholar] [CrossRef]

- Peng, X.; Zhao, Y.; Liang, X.; Wu, L.; Cui, S.; Guo, A.; Wang, W. Assessing the quality of RCTs on the effect of β-elemene, one ingredient of a Chinese herb, against malignant tumors. Contemp. Clin. Trials 2006, 27, 70–82. [Google Scholar] [CrossRef]

- Yao, Y.-Q.; Ding, X.; Jia, Y.-C.; Huang, C.-X.; Wang, Y.-Z.; Xu, Y.-H. Anti-tumor effect of beta-elemene in glioblastoma cells depends on p38 MAPK activation. Cancer Lett. 2008, 264, 127–134. [Google Scholar] [CrossRef]

- Adio, A.M. (-)-trans-β-Elemene and related compounds: Occurrence, synthesis, and anticancer activity. Tetrahedron 2009, 65, 5145–5159. [Google Scholar] [CrossRef]

- Belletti, N.; Kamdem, S.S.; Tabanelli, G.; Lanciotti, R.; Gardini, F. Modeling of combined effects of citral, linalool and beta-pinene used against Saccharomyces cerevisiae in citrus-based beverages subjected to a mild heat treatment. Int. J. Food Microbiol. 2010, 136, 283–289. [Google Scholar] [CrossRef]

- Vidakovic, M. Conifers: Morphology and Variation; Graficki Zavod Hrvatske: Zagreb, Croatia, 1991; p. 755. [Google Scholar]

- Ministry of Agriculture of Greece. Results of the First National Forest Inventory; General Directorate of Forests and Natural Environment Development and Protection: Athens, Greece, 1992; p. 134. Available online: https://dasarxeio.com/2020/11/27/89385/ (accessed on 20 December 2022). (In Greek)

- Tsoumis, G. Harvesting Forest Products; Stobart Davies Ltd.: Pontyclerc, UK, 1992; p. 159. ISBN 085442 055 X. [Google Scholar]

- Padilla, F.M.; Vidal, B.; Sánchez, J.; Pugnaire, F.I. Land-use changes and carbon sequestration through the twentieth century in a Mediterranean mountain ecosystem: Implications for land management. J. Εnviron. Μanag. 2010, 91, 2688–2695. [Google Scholar] [CrossRef] [PubMed]

- Karanikas, C. Selection and Biochemical Analysis of High-Yielding Oleoresin Genotypes of Pinus halepensis Mill.—Qualitative and Quantitative Oleoresin Analysis. Ph.D. Thesis, Aristotle University, Thessaloniki, Greece, 2008; p. 284. Available online: http:/hdl.handle.net/10442/hedi/20675 (accessed on 6 April 2023). [CrossRef]

- Mitras, D. Selection, Identification and Cloning of High Resin Yielding Pinus halepensis Mill. Genotypes. Ph.D. Thesis, Aristotle University, Thessaloniki, Greece, 2011; p. 172. Available online: http:/hdl.handle.net/10442/hedi/26219 (accessed on 6 April 2023). [CrossRef]

- Tsaktsira, M.; Karanikas, C.; Mitras, D.; Zhelev, P.; Scaltsoyiannes, A. Genetic analysis of selected high-yielding oleoresin trees of Aleppo pine (Pinus halepensis Mill.). For. Ideas 2022, 28, 420–433. [Google Scholar]

- Zobel, B.; Talbert, J. Applied Forest Tree Improvement; John Wiley & Sons: New York, NY, USA, 1984; p. 505. ISBN 9780471096825. [Google Scholar]

- Schiller, G.; Conkle, M.T.; Grunwald, C. Local differentiation among Mediterranean populations of Aleppo pine in their isoenzymes. Silvae Gen. 1986, 35, 11–19. [Google Scholar]

- Scaltsoyiannes, A.; Panetsos, K.; Economou, A.; Tsoulpha, P. Micropropagation of the pine hybrid Pinus brutia (Ten.) × Pinus halepensis (Mill.) by culturing interfascicular shoots. Ann. Sci. For. 1994, 51, 175–182. [Google Scholar] [CrossRef]

- Korol, L.; Madmony, A.; Riov, Y.; Schiller, G. Pinus halepensis × Pinus brutia subsp. brutia hybrids? Identification using morphological and biochemical traits. Silvae Gen. 1995, 44, 186–190. [Google Scholar]

- Gomez, A.; Alia, R.; Bueno, M.A. Genetic diversity of Pinus halepensis Mill. populations detected by RAPD loci. Ann. For. Sci. 2001, 58, 869–875. [Google Scholar] [CrossRef]

- Gomez, A.; Aravanopoulos, F.A.; Bueno, M.A.; Alia, R. Linkage of random amplified polymorphic DNA markers in Pinus halepensis Mill. Silvae Gen. 2002, 51, 196–201. [Google Scholar]

- Aravanopoulos, F.A.; Panetsos, K.P.; Scaltsoyiannes, A. Genetic structure of Pinus brutia stands exposed to wild fires. Plant Ecol. 2004, 171, 175–183. [Google Scholar] [CrossRef]

- Scaltsoyiannes, A. Identification by isozyme gene markers of European pine species used for ornamental purposes. Prop. Ornam. Plants 2004, 4, 42–46. [Google Scholar]

- Yi, M.; Zhang, L.; Cheng, Z.; Hu, R.; Gao, Y.; Jin, C.; Yuan, S.; Sun, S.; Lai, M. Identification of key genes for oleoresin biosynthesis in high and low oleoresin-yielding slash pine based on transcriptome analysis. Forests 2022, 13, 1337. [Google Scholar] [CrossRef]

- Hanover, J.W. Genetics of terpenes. I. Gene control of monoterpene levels in Pinus monticola Dougl. Heredity 1966, 21, 73–84. [Google Scholar] [CrossRef]

- Peters, W.J. Variation in oleoresin yielding potential of selected slash pines. For. Sci. 1971, 17, 306–307. [Google Scholar]

- Squillace, A.E. Inheritance of monoterpene composition in cortical oleoresin of slash pine. For. Sci. 1971, 17, 381–387. [Google Scholar] [CrossRef]

- McReynolds, R.D.; Kossuth, S.V.; Clements, R.W. Gum naval stores methodology. In Naval Stores; Zinkel, D.F., Russel, J., Eds.; Pulp Chemical Association: New York, NY, USA, 1989; pp. 82–122. [Google Scholar]

- Westbrook, J.W.; Resende, M.F.R., Jr.; Munoz, P.; Walker, A.R.; Wegrzyn, J.L.; Nelson, C.D.; Neale, D.B.; Kirst, M.; Huber, D.A.; Gezan, S.A.; et al. Association genetics of oleoresin flow in loblolly pine: Discovering genes and predicting phenotype for improved resistance to bark beetles and bioenergy potential. New Phytol. 2013, 199, 89–100. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, J.; Luan, Q. Genetic and correlation analysis of oleoresin chemical components in slash pine. Gen. Mol. Res. 2016, 15, gmr.15038982. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Shen, L.; Hou, Q.; Zhou, Z.; Mei, L.; Zhao, H.; Wen, X. Identification of genes and metabolic pathways involved in resin yield in masson pine by integrative analysis of transcriptome, proteome and biochemical characteristics. Int. J. Mol. Sci. 2022, 23, 11420. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Li, Y.; Zhang, Y.; Diao, S.; Luan, Q.; Jiang, J. Genetic analysis and elite tree selection of the main resin components of slash pine. Front. Plant Sci. 2023, 14, 1079952. [Google Scholar] [CrossRef]

- Ditoras, N. Inheritance of Gum Yielding Ability of Pinus halepensis Mill. Ph.D. Thesis, Aristotle University, Thessaloniki, Greece, 1989; p. 147. Available online: https://hdl.handle.net/10442/hedi/1040 (accessed on 6 April 2023). (In Greek). [CrossRef]

- Roberds, J.H.; Strom, B.L. Repeatability estimates for oleoresin yield measurements in three species of the southern pines. For. Ecol. Manag. 2006, 228, 215–224. [Google Scholar] [CrossRef]

- Gonçalves, P.d.S.; Bortoletto, N.; Martins, A.L.M.; da Costa, R.B.; Gallo, P.B. Genotype-environment interaction and phenotypic stability for girth growth and rubber yield of Hevea clones in São Paulo State, Brazil. Gen. Mol. Biol. 2003, 26, 441–448. [Google Scholar] [CrossRef]

- Panetsos, K.; Scaltsoyiannes, A.; Alizoti, P. Effect of genotype and cutting type on the vegetative propagation of the pine hybrid Pinus brutia (Ten.) × Pinus halepensis (Mill.). Ann. Sci. For. 1994, 51, 447–454. [Google Scholar] [CrossRef]

- Economou, A.S. From macrocutting rooting to microplant establishment: Key points to consider for maximum success in woody plants. Acta Hort. 2013, 988, 43–46. [Google Scholar] [CrossRef]

| Management Type | Sequestration of C (tn of C/ha/year) | Sequestration of CO2 (tn of CO2/ha/year) |

|---|---|---|

| Wood biomass production from natural stands of P. halepensis (density 400 trees/ha) | 0.69 (0.55 * × 2.5 m3/ha ** × 0.5 ***) | 2.53 (0.69 × 44 ÷ 12) |

| Resin production from natural stands of P. halepensis (2.5 kg resin/tree) (density 400 trees/ha) | 0.77 (1 tn/ha × 0.7717 ****) | 2.82 (0.77 × 44 ÷ 12) |

| Resin production from commercial plantations of genetically improved P. halepensis (20 kg resin/tree) (density 500 trees/ha) | 7.72 (10 tn/ha × 0.7717) | 28.31 (7.72 × 44 ÷ 12) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsaktsira, M.; Tsoulpha, P.; Economou, A.; Scaltsoyiannes, A. Mitigation of Global Climate Change through Genetic Improvement of Resin Production from Resinous Pines: The Case of Pinus halepensis in Greece. Sustainability 2023, 15, 8052. https://doi.org/10.3390/su15108052

Tsaktsira M, Tsoulpha P, Economou A, Scaltsoyiannes A. Mitigation of Global Climate Change through Genetic Improvement of Resin Production from Resinous Pines: The Case of Pinus halepensis in Greece. Sustainability. 2023; 15(10):8052. https://doi.org/10.3390/su15108052

Chicago/Turabian StyleTsaktsira, Maria, Parthena Tsoulpha, Athanasios Economou, and Apostolos Scaltsoyiannes. 2023. "Mitigation of Global Climate Change through Genetic Improvement of Resin Production from Resinous Pines: The Case of Pinus halepensis in Greece" Sustainability 15, no. 10: 8052. https://doi.org/10.3390/su15108052

APA StyleTsaktsira, M., Tsoulpha, P., Economou, A., & Scaltsoyiannes, A. (2023). Mitigation of Global Climate Change through Genetic Improvement of Resin Production from Resinous Pines: The Case of Pinus halepensis in Greece. Sustainability, 15(10), 8052. https://doi.org/10.3390/su15108052