Analysis of Dynamic Deformation Response of Closely Spaced Square Footings on Geogrid-Reinforced Sand under Cyclic Loading

Abstract

1. Introduction

2. Experimental

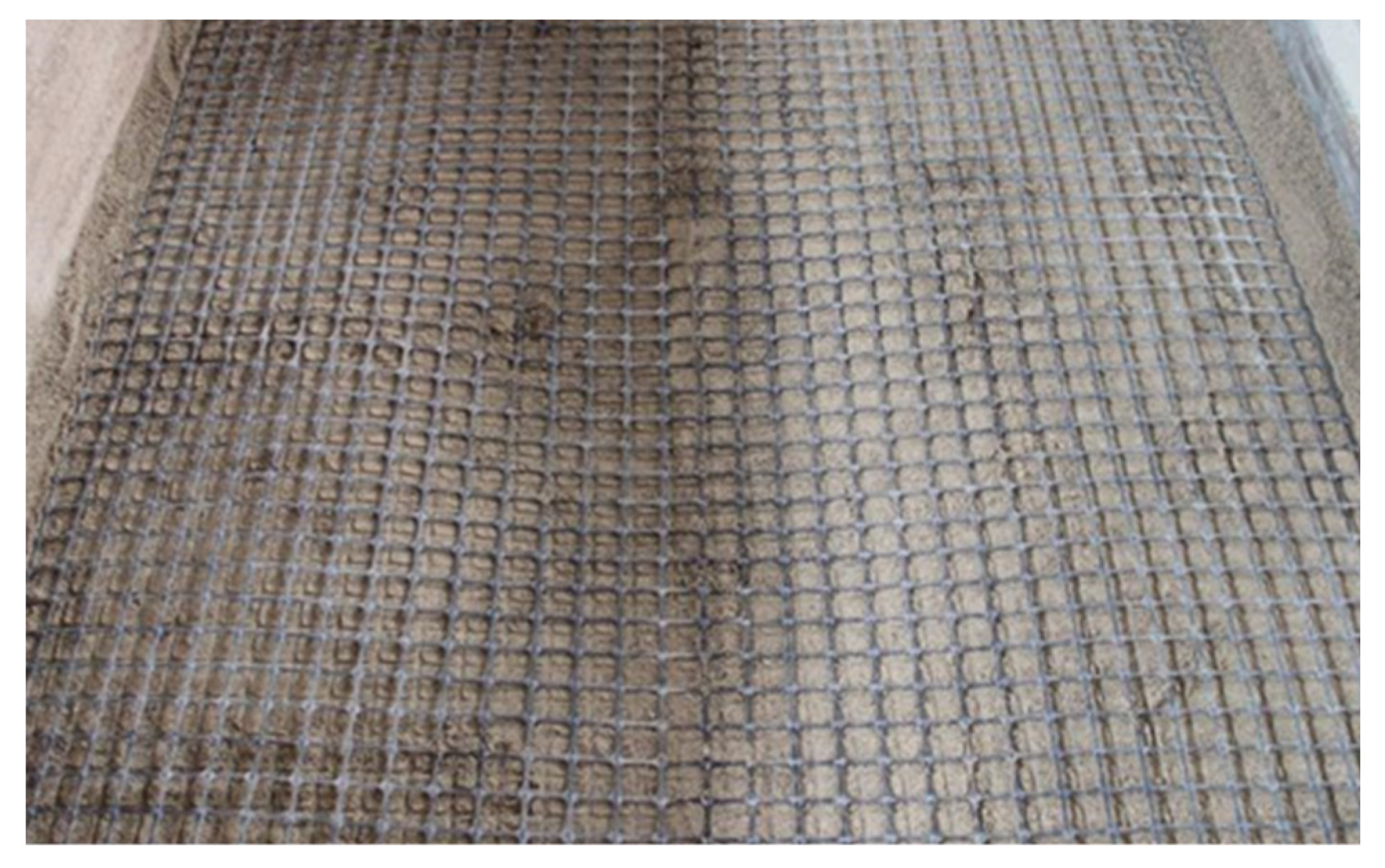

2.1. Test Materials

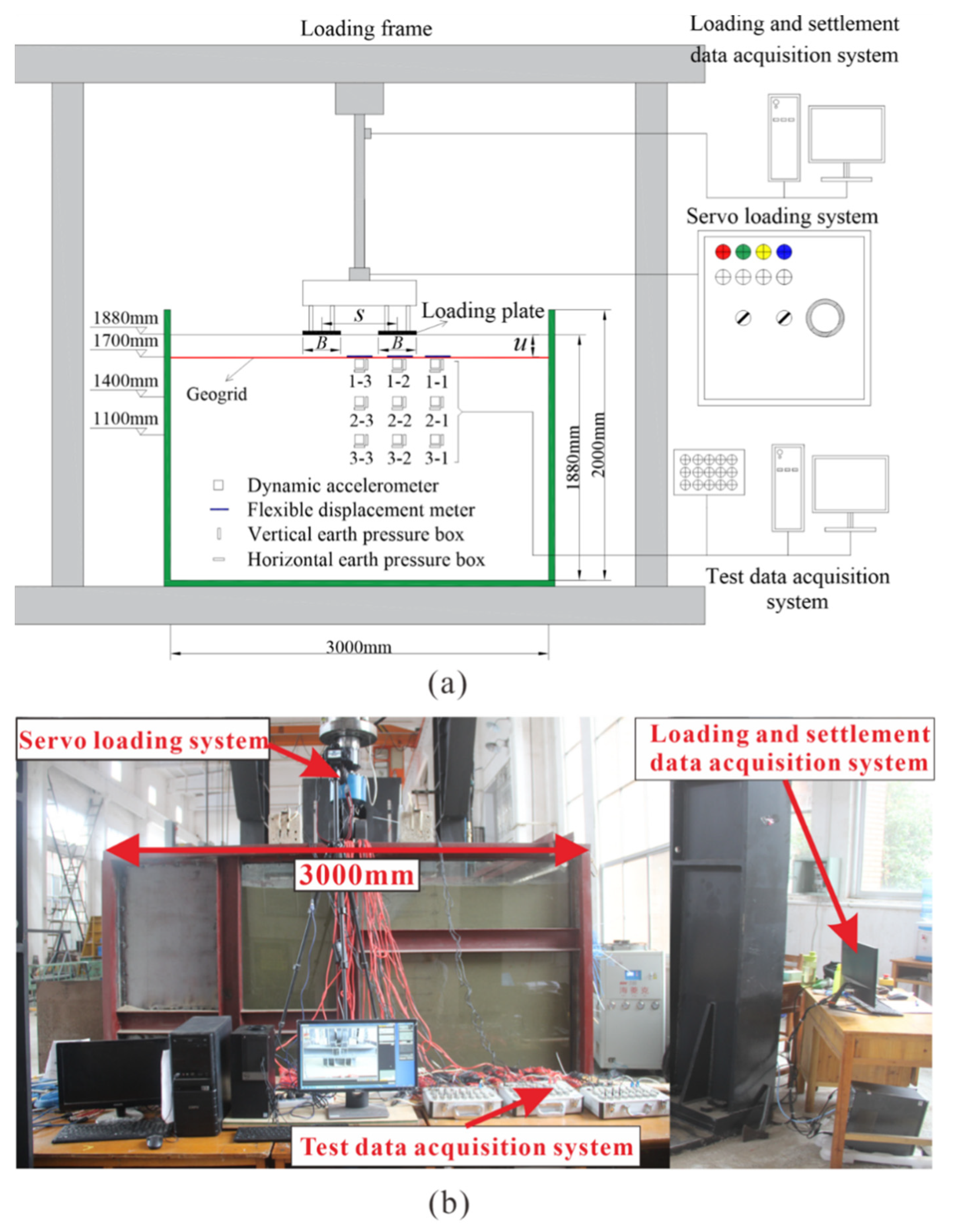

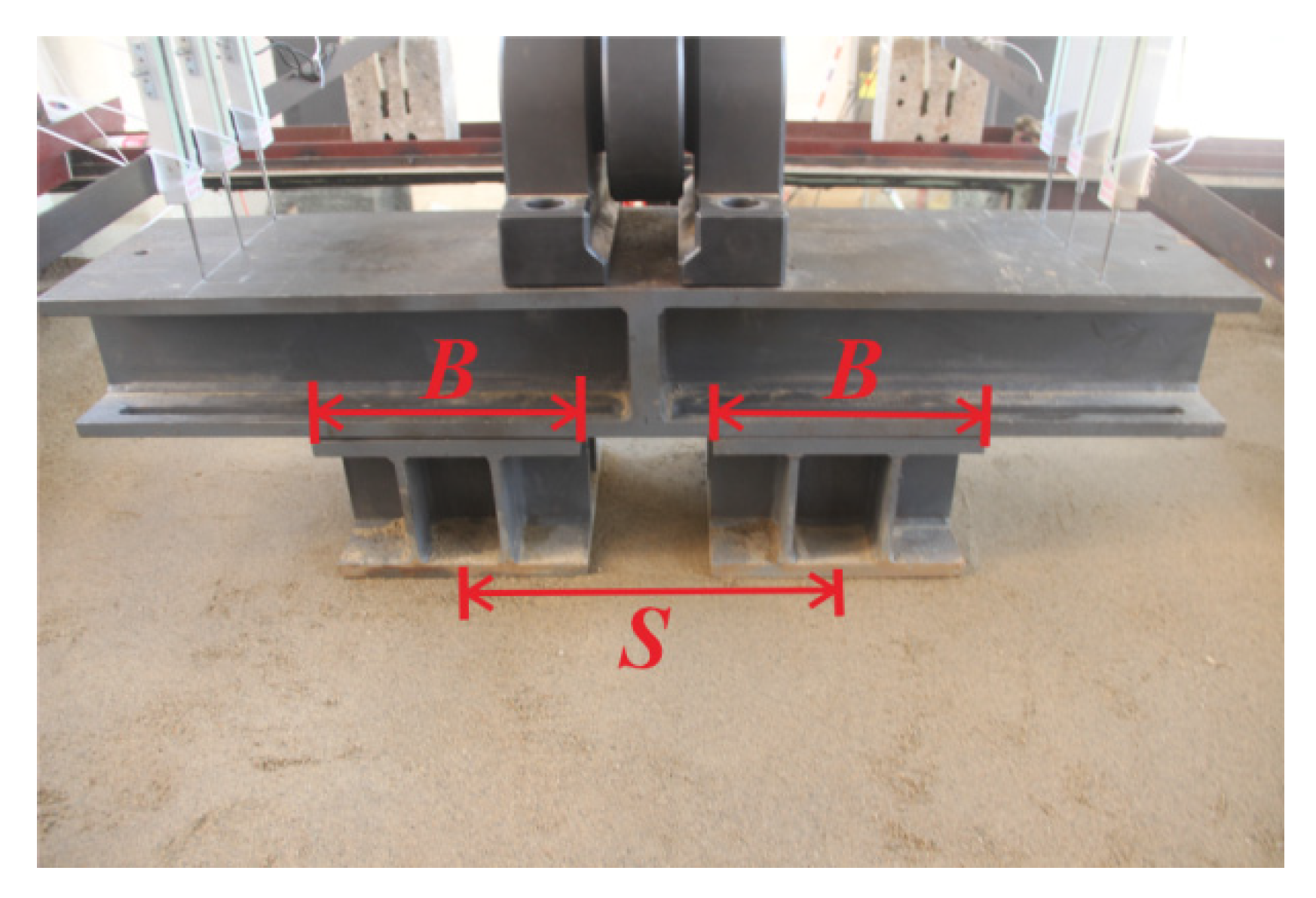

2.2. Test Device

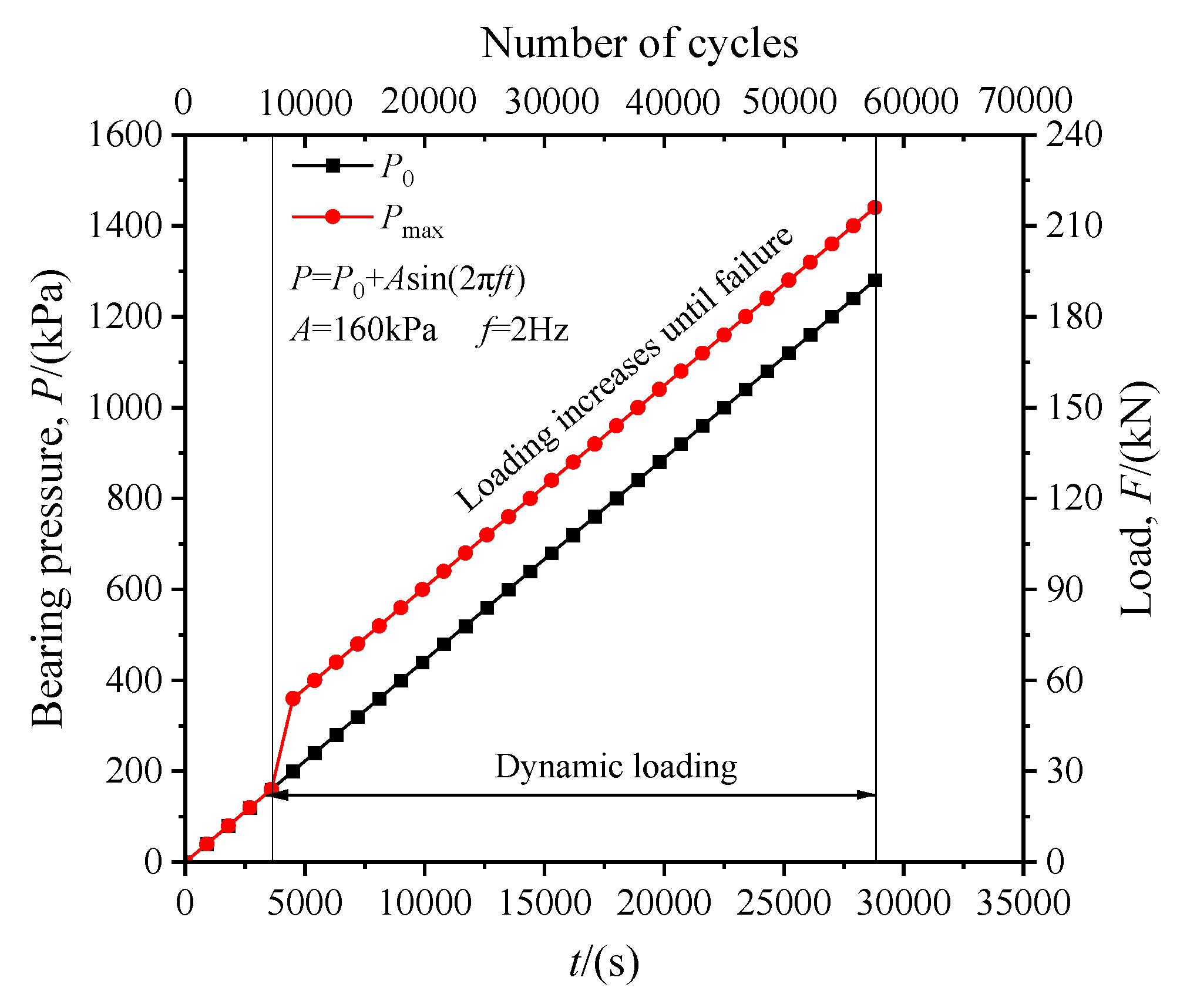

2.3. Test Scheme

2.4. Test Procedure

3. Test Results and Analysis

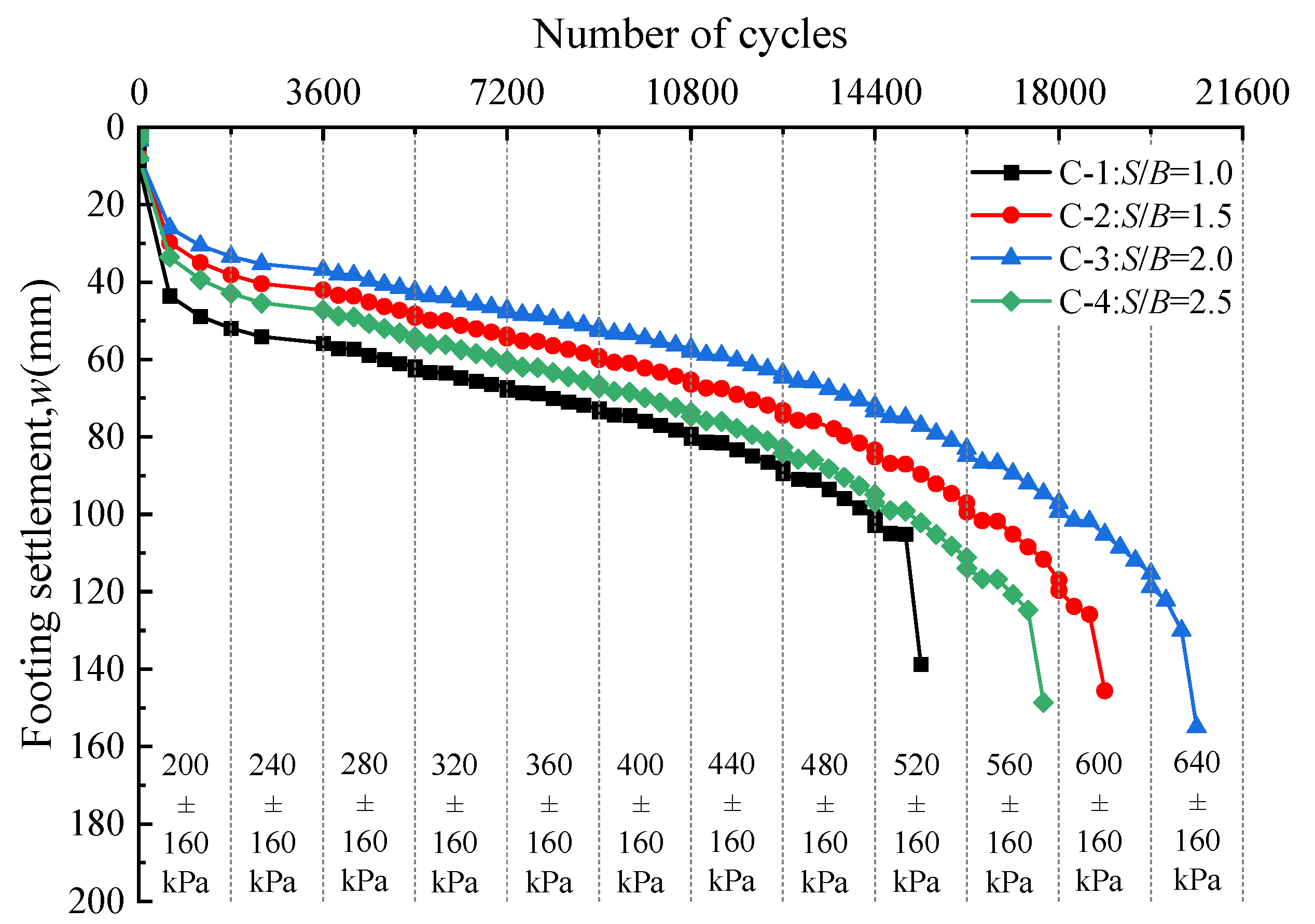

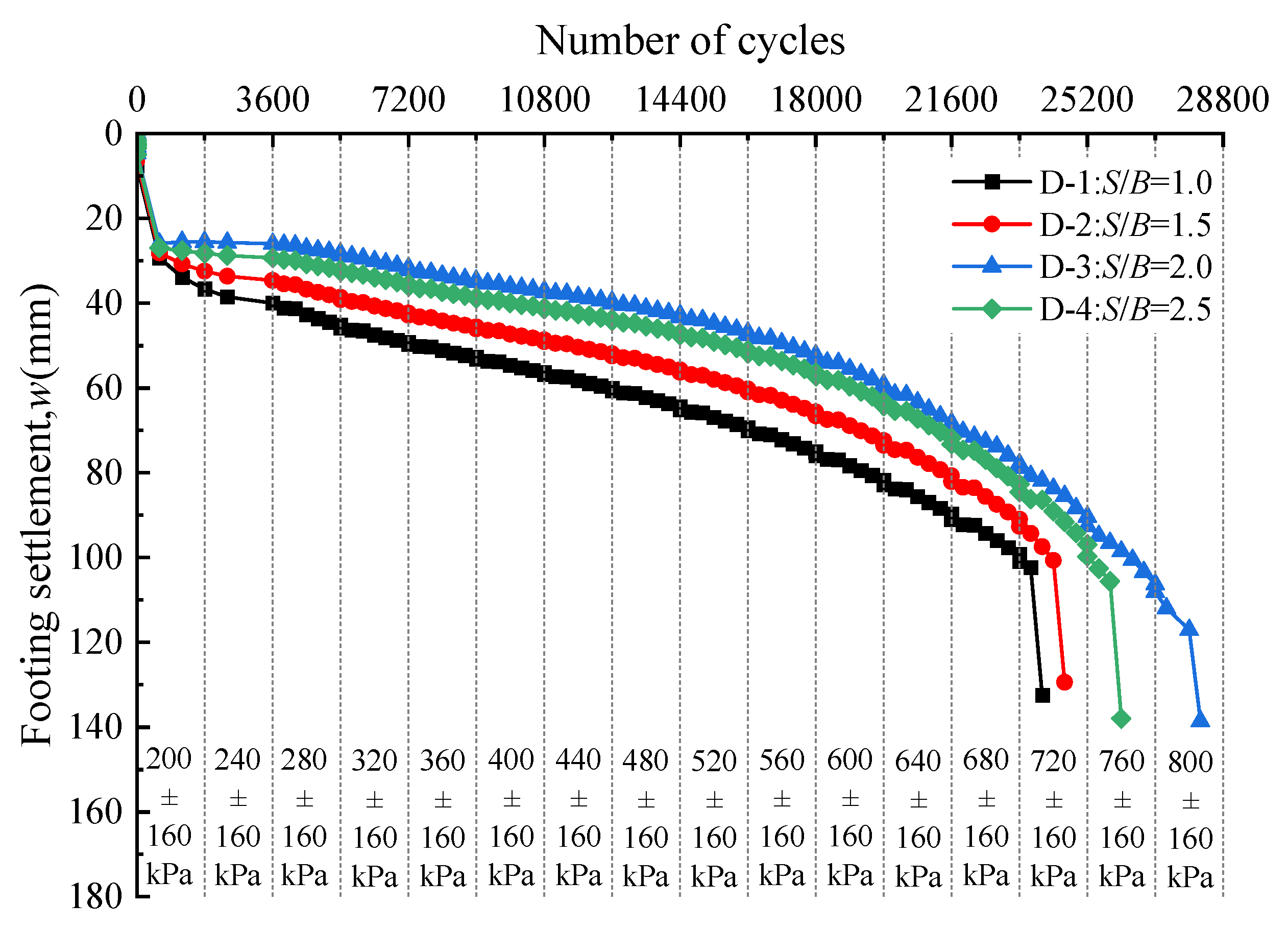

3.1. Loading Settlement Response

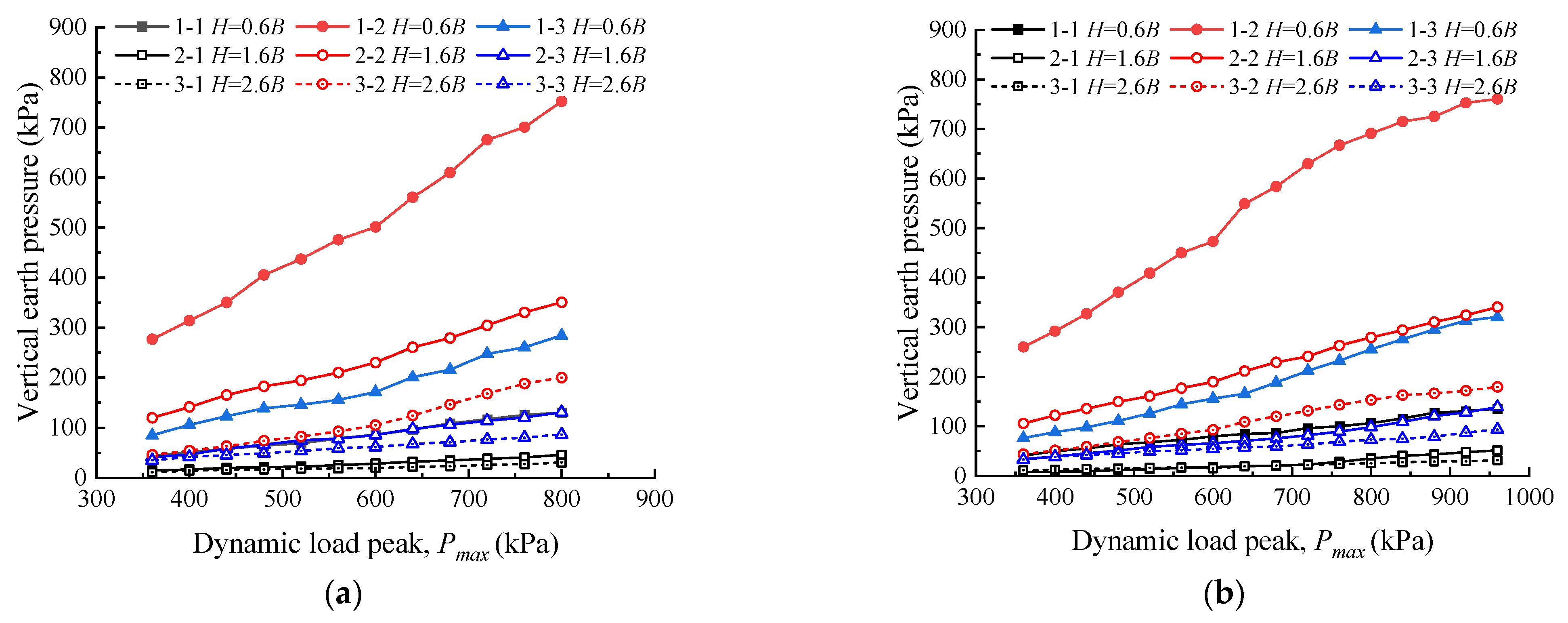

3.2. Earth Pressure Response

3.3. Strain in Geogrid under Foundation Loading

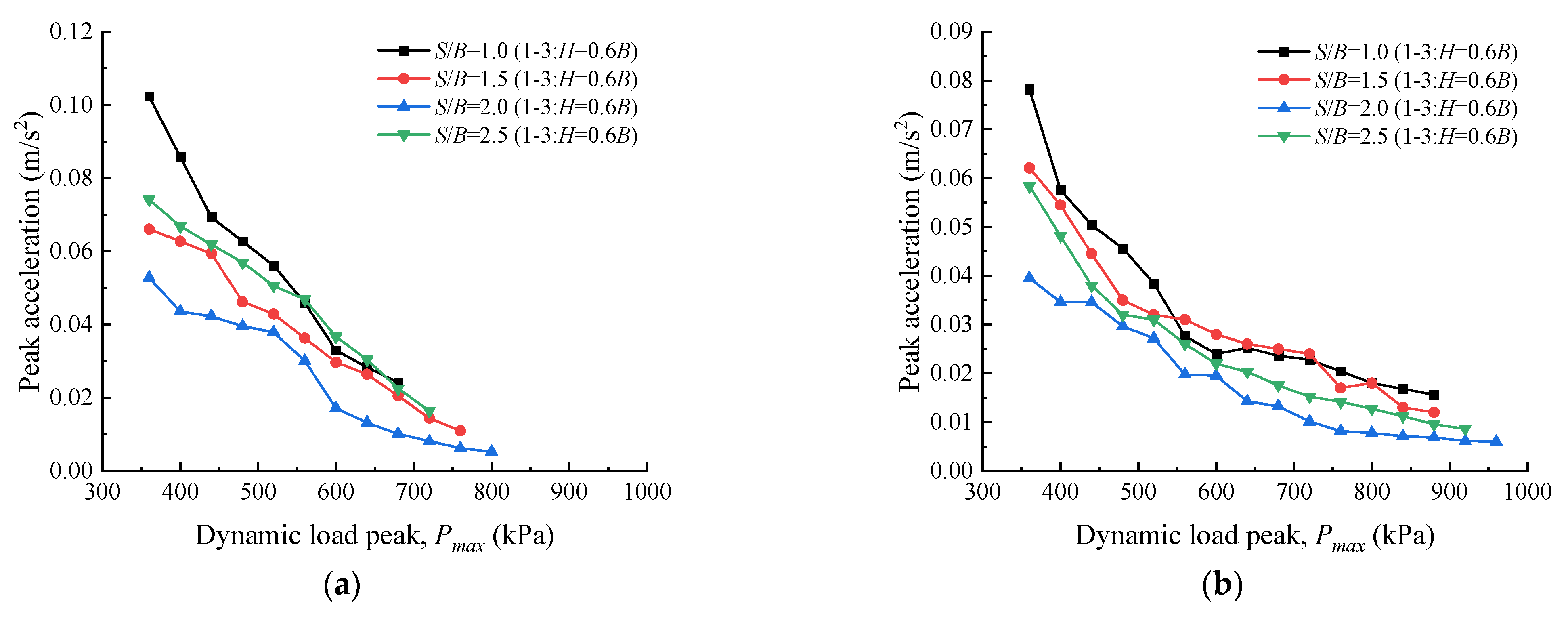

3.4. Acceleration Response

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Saha Roy, S.; Deb, K. Interference effect of closely spaced footings resting on granular fill over soft clay. Int. J. Geomech. 2019, 19, 04018181. [Google Scholar] [CrossRef]

- Swain, A.; Ghosh, P. Experimental study on dynamic interference effect of two closely spaced machine foundations. Can. Geotech. J. 2015, 53, 196–209. [Google Scholar] [CrossRef]

- Stuart, J.G. Interference between foundations, with special reference to surface footings in sand. Geotechnique 1962, 12, 15–22. [Google Scholar] [CrossRef]

- Reddy, E.S.; Borzooei, S.; Reddy, G.N. Interference between adjacent footings on sand. Int. J. Adv. Eng. Res. Stud. 2012, 1, 95–98. [Google Scholar]

- Graham, J.; Raymond, G.P.; Suppiah, A. Bearing capacity of three closely-spaced footings on sand. Geotechnique 1984, 34, 173–181. [Google Scholar] [CrossRef]

- Das, P.E.; AS, F.; Braja, M.; Puri, V.K.; Neo, B.K. Interference effects between two surface footings on layered soil. Transp. Res. Rec. 1993, 1406, 34–40. [Google Scholar]

- Kumar, J.; Ghosh, P. Upper bound limit analysis for finding interference effect of two nearby strip footings on sand. Geotech. Geol. Eng. 2007, 25, 499–507. [Google Scholar] [CrossRef]

- Kumar, J.; Bhoi, M.K. Interference of two closely spaced strip footings on sand using model tests. J. Geotech. Geoenviron. Eng. 2009, 135, 595–604. [Google Scholar] [CrossRef]

- Ghazavi, M.; Lavasan, A.A. Interference effect of shallow foundations constructed on sand reinforced with geosynthetics. Geotext. Geomembr. 2008, 26, 404–415. [Google Scholar] [CrossRef]

- Ghosh, P.; Kumar, S. Interference effect of two nearby strip surface footings on cohesionless layered soil. Int. J. Geotech. Eng. 2011, 5, 87–94. [Google Scholar] [CrossRef]

- Lavasan, A.A.; Ghazavi, M. Behavior of closely spaced square and circular footings on reinforced sand. Soils Found. 2012, 52, 160–167. [Google Scholar] [CrossRef]

- Roy, S.S.; Deb, K. Effect of aspect ratio of footing on behavior of two closely-spaced footings on geogrid-reinforced sand. Geotext. Geomembr. 2020, 48, 443–453. [Google Scholar]

- Naderi, E.; Hataf, N. Model testing and numerical investigation of interference effect of closely spaced ring and circular footings on reinforced sand. Geotext. Geomembr. 2014, 42, 191–200. [Google Scholar] [CrossRef]

- Dehkordi, P.F.; Ghazavi, M.; Ganjian, N.; Karim, U.F.A. Effect of geocell-reinforced sand base on bearing capacity of twin circular footings. Geosynth. Int. 2019, 26, 224–236. [Google Scholar] [CrossRef]

- Vivek, P.; Ghosh, P. Dynamic interaction of two nearby machine foundations on homogeneous soil. In Proceedings of the GeoCongress 2012: State of the Art and Practice in Geotechnical Engineering, Oakland, CA, USA, 25–29 March 2012; pp. 21–30. [Google Scholar]

- ASTM D2487-17; Standard Practice for Classifification of Soils for Engineering Purposes (Unifified Soil Classifification System). ASTM International: West Conshohocken, PA, USA, 2017.

- Engineering Geology Handbook Compilation Committee. Engineering Geology Handbook, 4th ed.; Architecture and Building Press: Beijing, China, 2007; pp. 218–224. (In Chinese) [Google Scholar]

- Wang, J.Q.; Zhang, L.L.; Xue, J.F.; Tang, Y. Load-settlement response of shallow square footings on geogrid-reinforced sand under cyclic loading. Geotext. Geomembr. 2018, 46, 586–596. [Google Scholar] [CrossRef]

- Wang, J.Q.; Zhang, L.L.; Tang, Y.; Huang, S.B. Influence of reinforcement-arrangements on dynamic response of geogrid-reinforced foundation under repeated loading. Constr. Build. Mater. 2021, 274, 122093. [Google Scholar] [CrossRef]

- China Academy of Building Research. GB50007-2011 Code for Design of Builiding Foundation; Architecture and Building Press: Beijing, China, 2011; pp. 124–126. (In Chinese) [Google Scholar]

- Qian, Y.; Han, J.; Pokharel, S.K.; Parsons, R.L. Stress analysis on triangular-aperture geogrid-reinforced bases over weak subgrade under cyclic loading: An experimental study. Transp. Res. Rec. 2011, 2204, 83–91. [Google Scholar] [CrossRef]

- Adams, M.T.; Collin, J.G. Large model spread footing load tests on geosynthetic reinforced soil foundations. J. Geotech. Geoenviron. Eng. 1997, 123, 66–72. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Jha, J.N.; Gill, K.S. Laboratory investigation of bearing capacity behaviour of strip footing on reinforced flyash slope. Geotext. Geomembr. 2010, 28, 393–402. [Google Scholar] [CrossRef]

- Suku, L.; Prabhu, S.S.; Babu, G.S. Effect of geogrid-reinforcement in granular bases under repeated loading. Geotext. Geomembr. 2017, 45, 377–389. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Longitudinal ultimate tensile strength (kN/m) | 31.4 |

| Transverse ultimate tensile strength (kN/m) | 32.5 |

| Longitudinal yield elongation (%) | 13.4 |

| Transverse yield elongation (%) | 13.6 |

| Tensile strength at 2% elongation in the longitudinal direction (kN/m) | 13.7 |

| Tensile strength at 2% elongation in the transverse direction (kN/m) | 14.0 |

| Tensile strength at 5% elongation in the longitudinal direction (kN/m) | 24.3 |

| Tensile strength at 5% elongation in the transverse direction (kN/m) | 24.7 |

| Aperture size (mm × mm) | 40 × 40 |

| Type of Foundation | Test Series | S/B | Geogrid Layout Type | f (Hz) | A (kPa) | P0 (kPa) | N | L (m) | u (m) |

|---|---|---|---|---|---|---|---|---|---|

| unreinforced | C-1 | 1 | Level layout | 2 | 160 | 200 | - | - | - |

| C-2 | 1.5 | - | - | - | |||||

| C-3 | 2 | - | - | - | |||||

| C-4 | 2.5 | - | - | - | |||||

| Geogrid-reinforced | D-1 | 1 | 1 | 9.3B | 0.6B | ||||

| D-2 | 1.5 | 1 | 9.3B | 0.6B | |||||

| D-3 | 2 | 1 | 9.3B | 0.6B | |||||

| D-4 | 2.5 | 1 | 9.3B | 0.6B |

| Measurement Position | Vertical Earth Pressure of Unreinforced Sand Foundation/kPa | Vertical Earth Pressure of Reinforced Sand Foundation/kPa | Vertical Earth Pressure Reduction Ratio/% |

|---|---|---|---|

| 1-1 | 126 | 100 | 26% |

| 2-1 | 41 | 28 | 46% |

| 3-1 | 27 | 24 | 13% |

| 1-2 | 701 | 667 | 5% |

| 2-2 | 331 | 263 | 26% |

| 3-2 | 188 | 143 | 31% |

| 1-3 | 261 | 232 | 13% |

| 2-3 | 121 | 89 | 36% |

| 3-3 | 80 | 69 | 16% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Qi, H.; Lin, Z.; Tang, Y. Analysis of Dynamic Deformation Response of Closely Spaced Square Footings on Geogrid-Reinforced Sand under Cyclic Loading. Sustainability 2023, 15, 438. https://doi.org/10.3390/su15010438

Wang J, Qi H, Lin Z, Tang Y. Analysis of Dynamic Deformation Response of Closely Spaced Square Footings on Geogrid-Reinforced Sand under Cyclic Loading. Sustainability. 2023; 15(1):438. https://doi.org/10.3390/su15010438

Chicago/Turabian StyleWang, Jiaquan, Hangxiang Qi, Zhinan Lin, and Yi Tang. 2023. "Analysis of Dynamic Deformation Response of Closely Spaced Square Footings on Geogrid-Reinforced Sand under Cyclic Loading" Sustainability 15, no. 1: 438. https://doi.org/10.3390/su15010438

APA StyleWang, J., Qi, H., Lin, Z., & Tang, Y. (2023). Analysis of Dynamic Deformation Response of Closely Spaced Square Footings on Geogrid-Reinforced Sand under Cyclic Loading. Sustainability, 15(1), 438. https://doi.org/10.3390/su15010438