Case Study on Dynamic Identification of Overburden Fracture and Strong Mine Pressure Mechanism of Isolated Working Face Based on Microseismic Clustering

Abstract

:1. Introduction

2. Working Face Conditions and Microseismic Monitoring Data

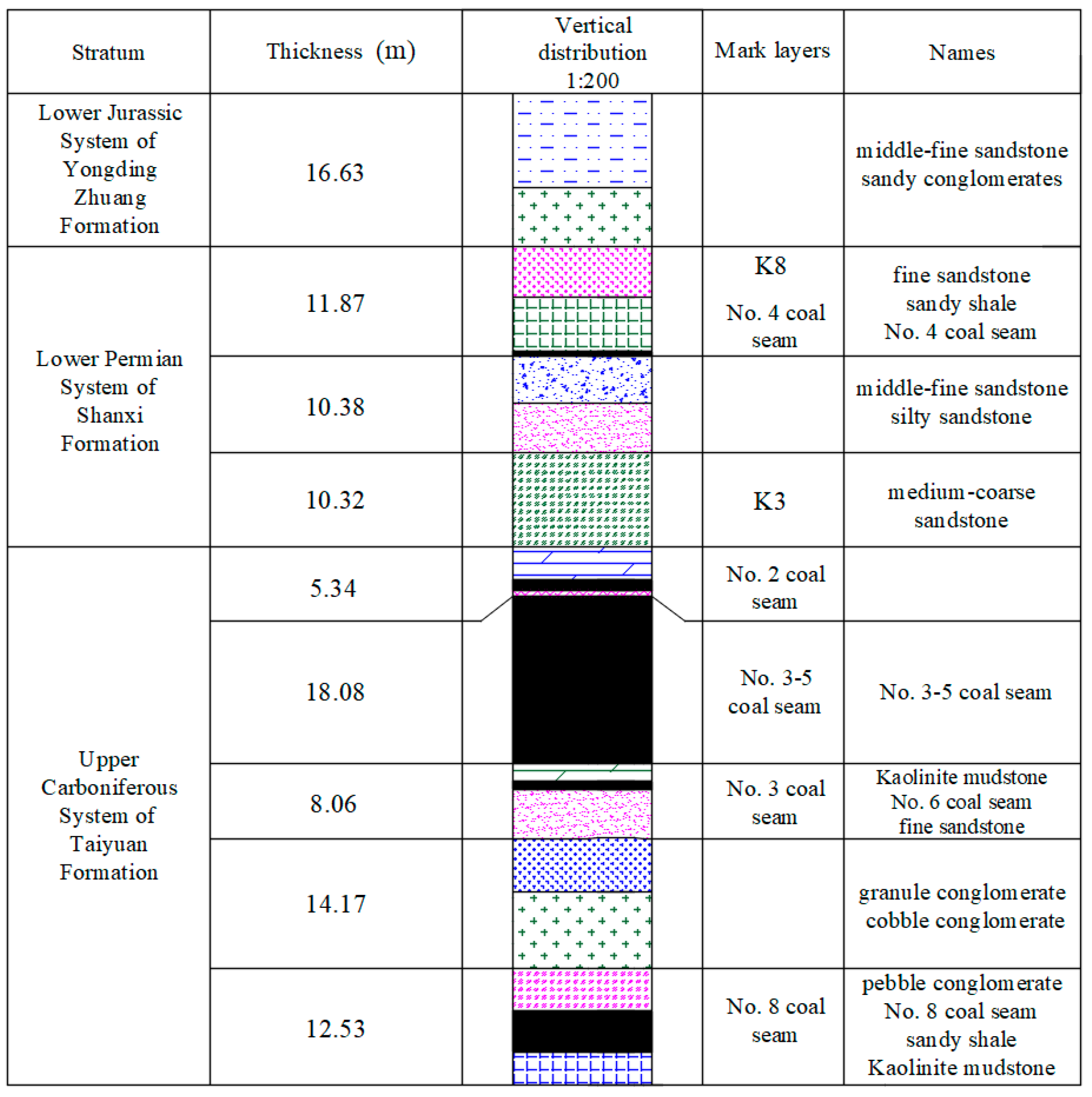

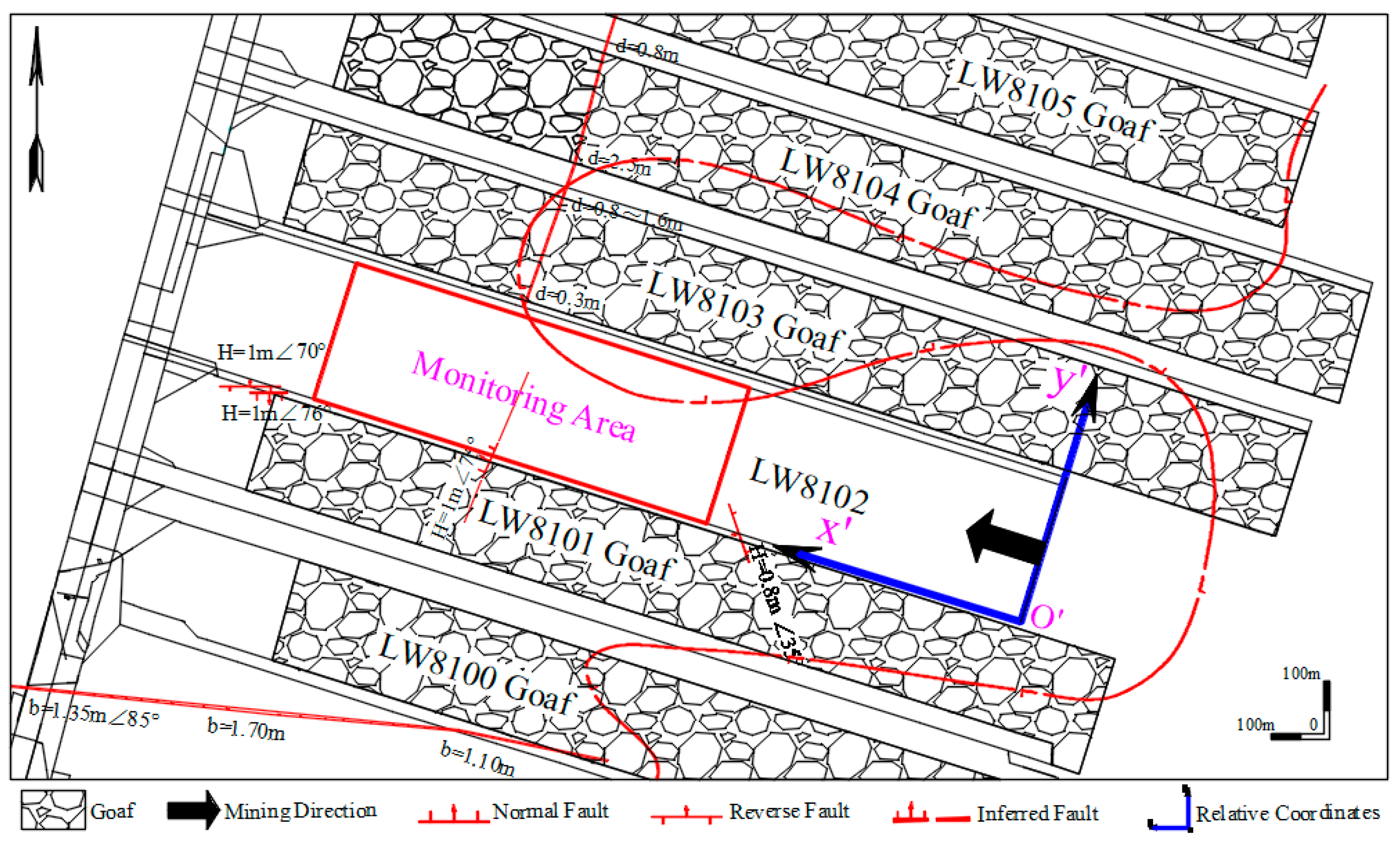

2.1. Working Face Conditions

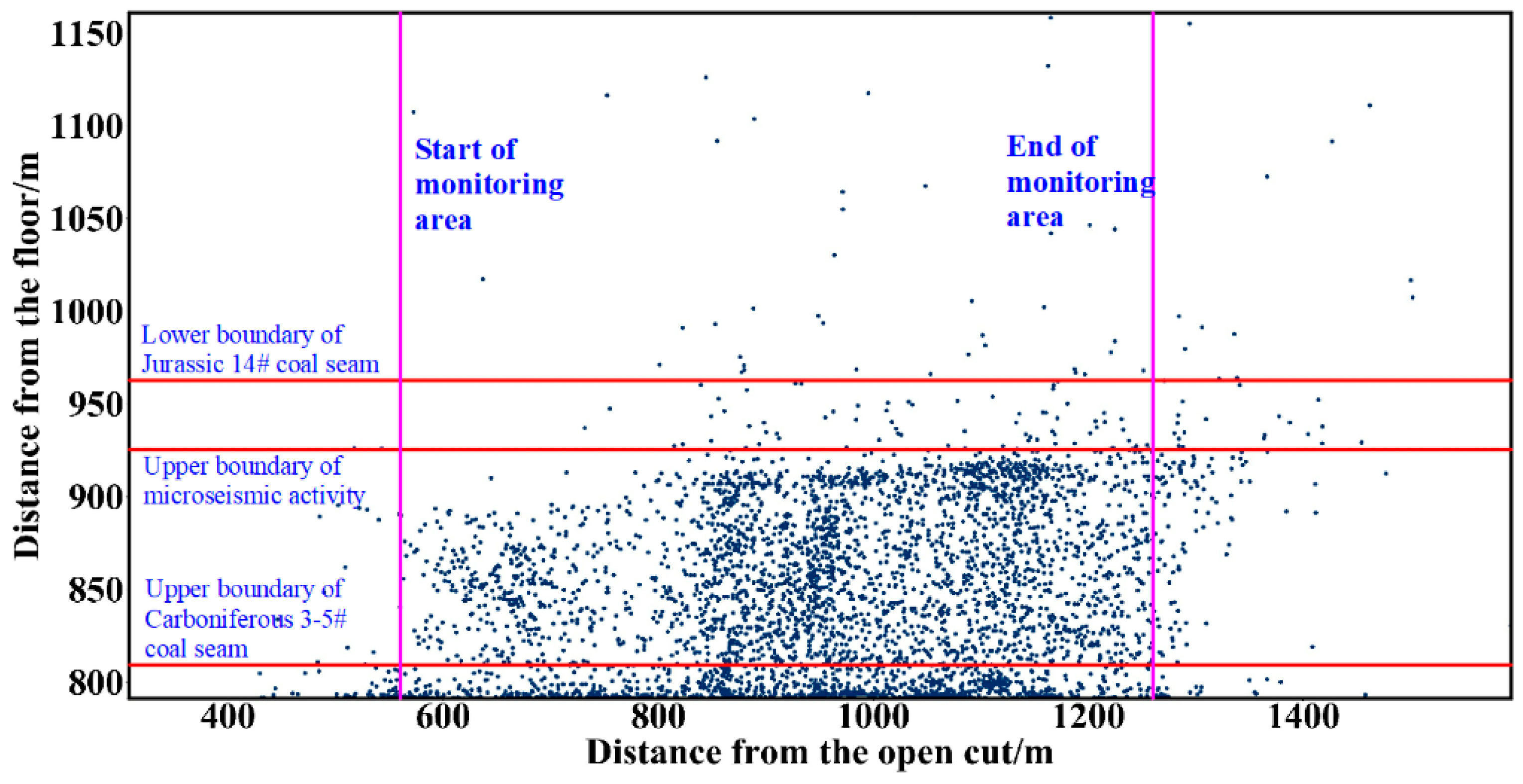

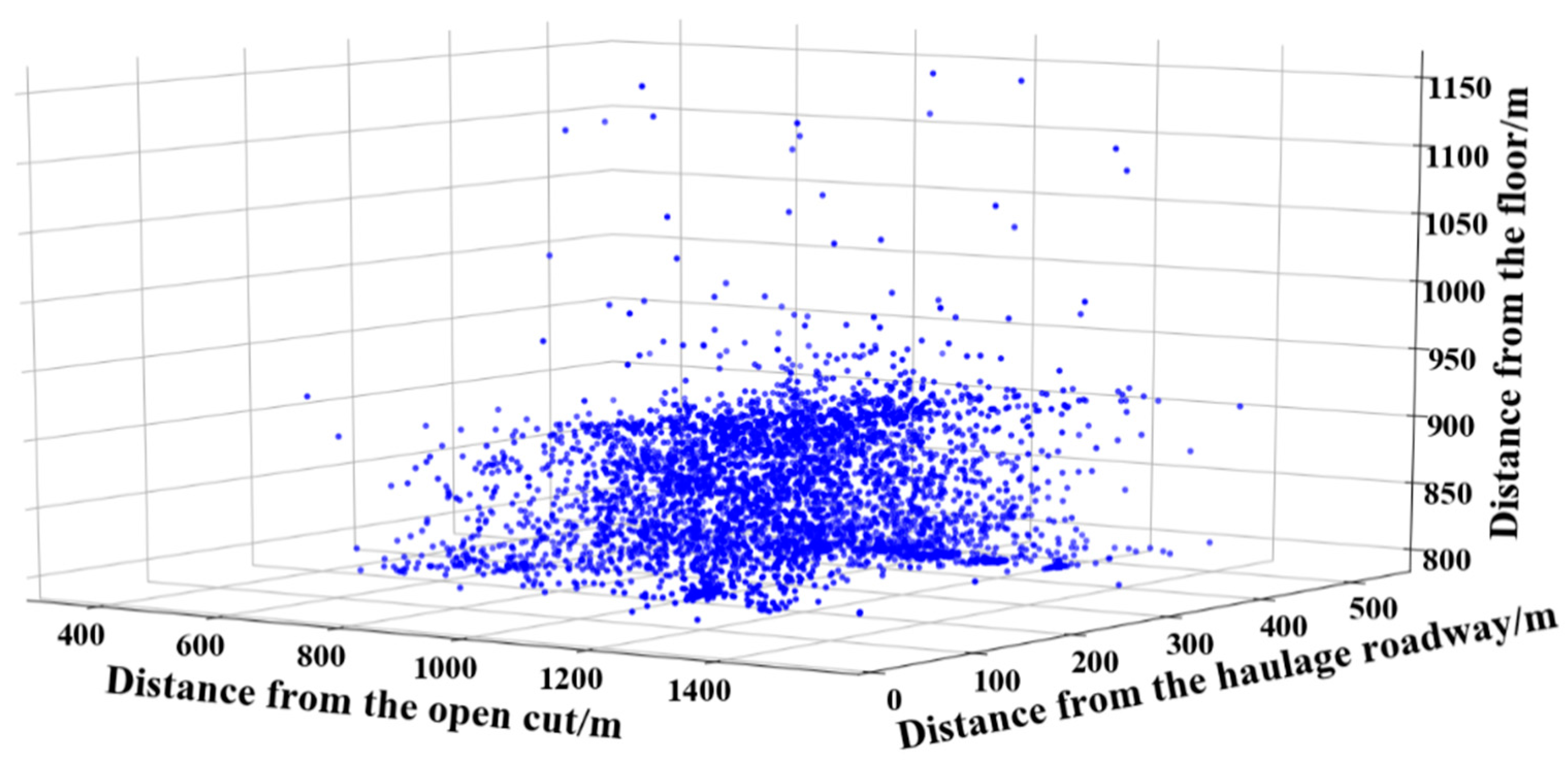

2.2. Microseismic Monitoring Data

3. Spatial and Temporal Clustering of Microseismic Events

3.1. Clustering Algorithm Principle

| Algorithm 1. k-means clustering algorithm |

| Input: sample set ; |

| Clustering number of clusters |

| Process: |

| Randomly select numbers from Sample set as the initial mean vector |

| 2. repeat |

| Let |

| for do |

| Calculate the distance between the sample and each mean vector |

| The nearest mean vector determines the cluster labeling of : |

| Categorize the sample into the corresponding cluster: ; |

| end for |

| for do |

| Calculate the new mean vector: |

| if then |

| Update the current mean vector from to |

| else |

| Keep the current mean vector unchangeable |

| end if |

| end for |

| until the current mean vector keeps the same |

| Output: clusters are divided into . |

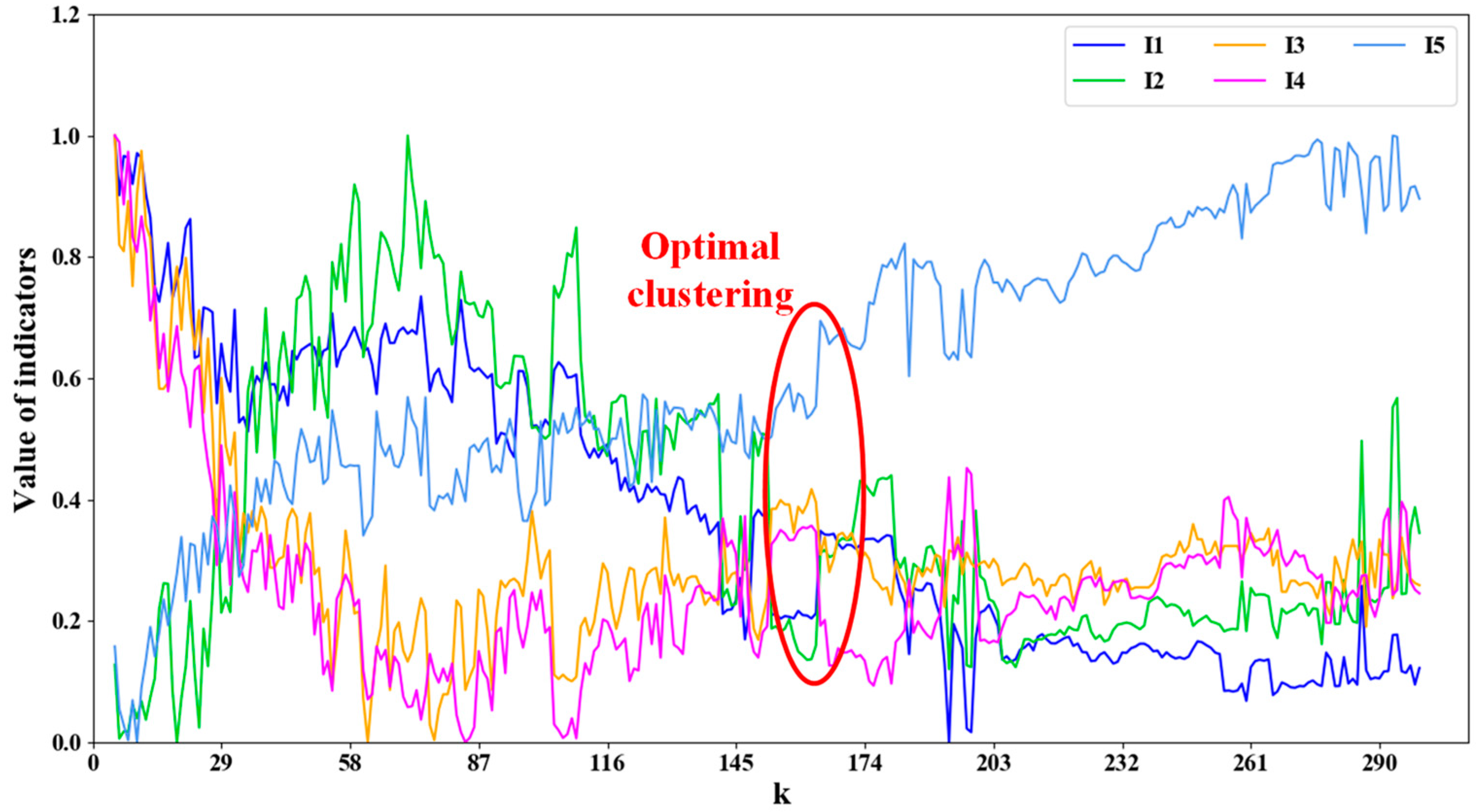

3.2. Selection of Spatio-Temporal Features and Determination of the Optimal k-Value

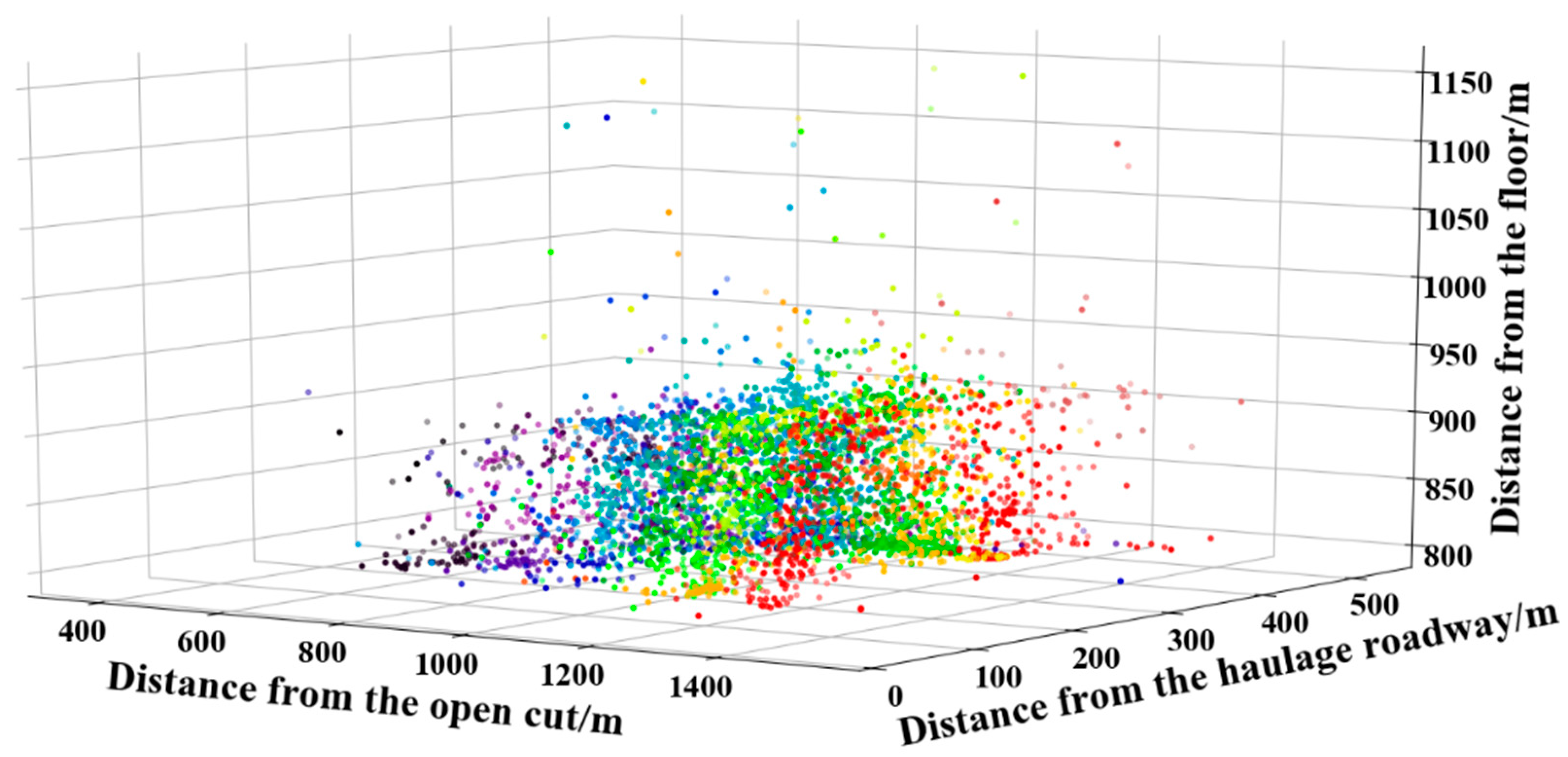

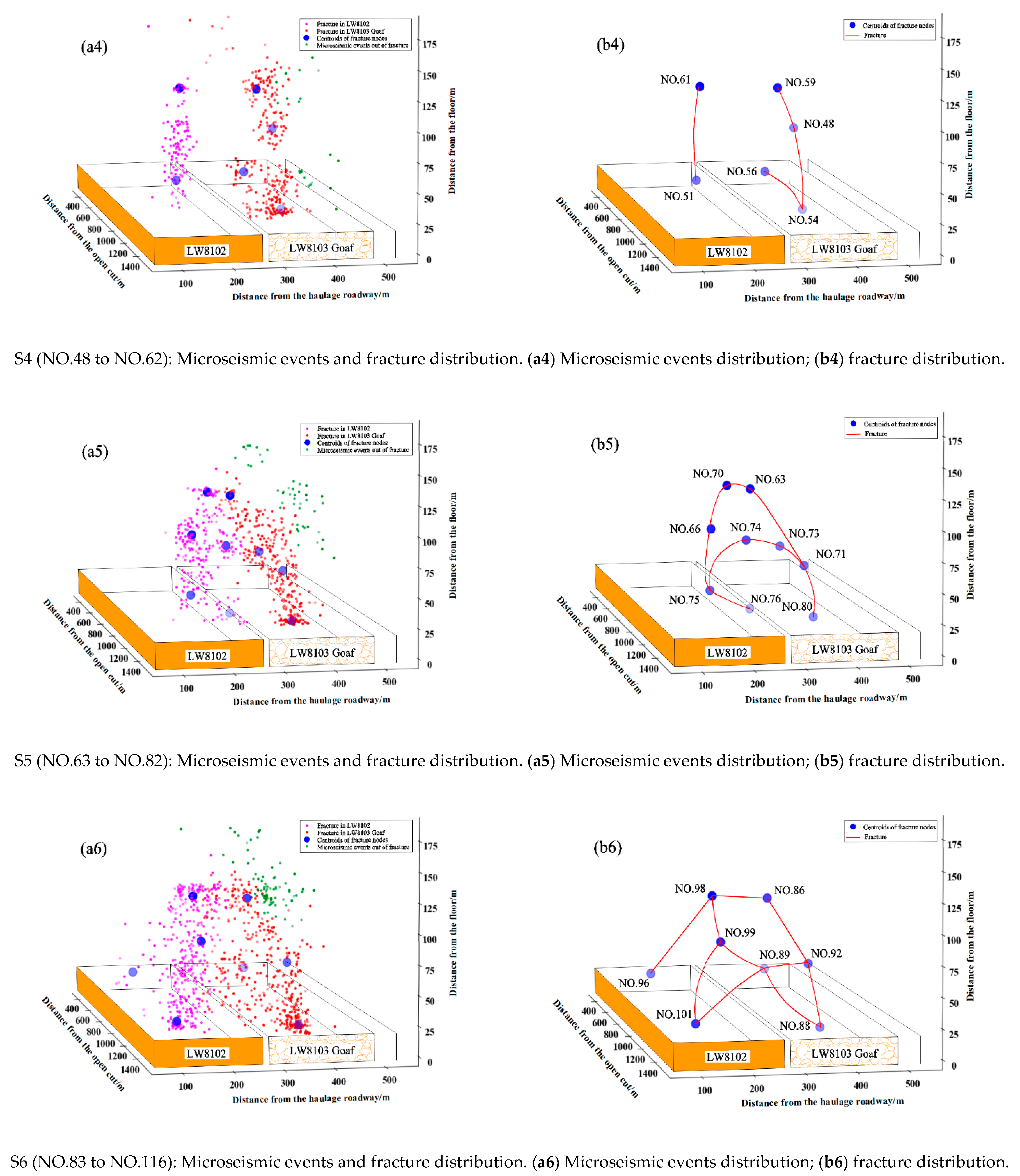

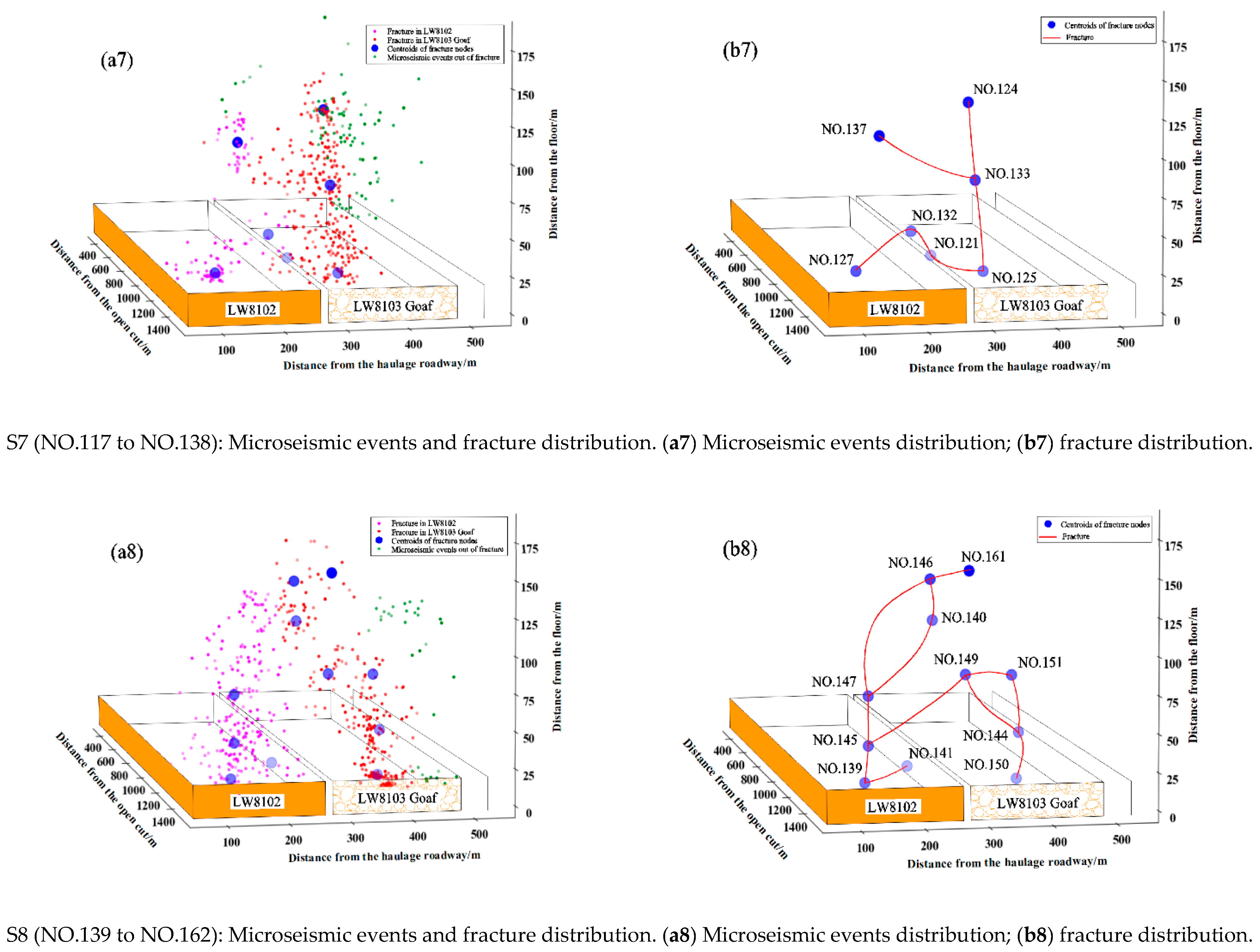

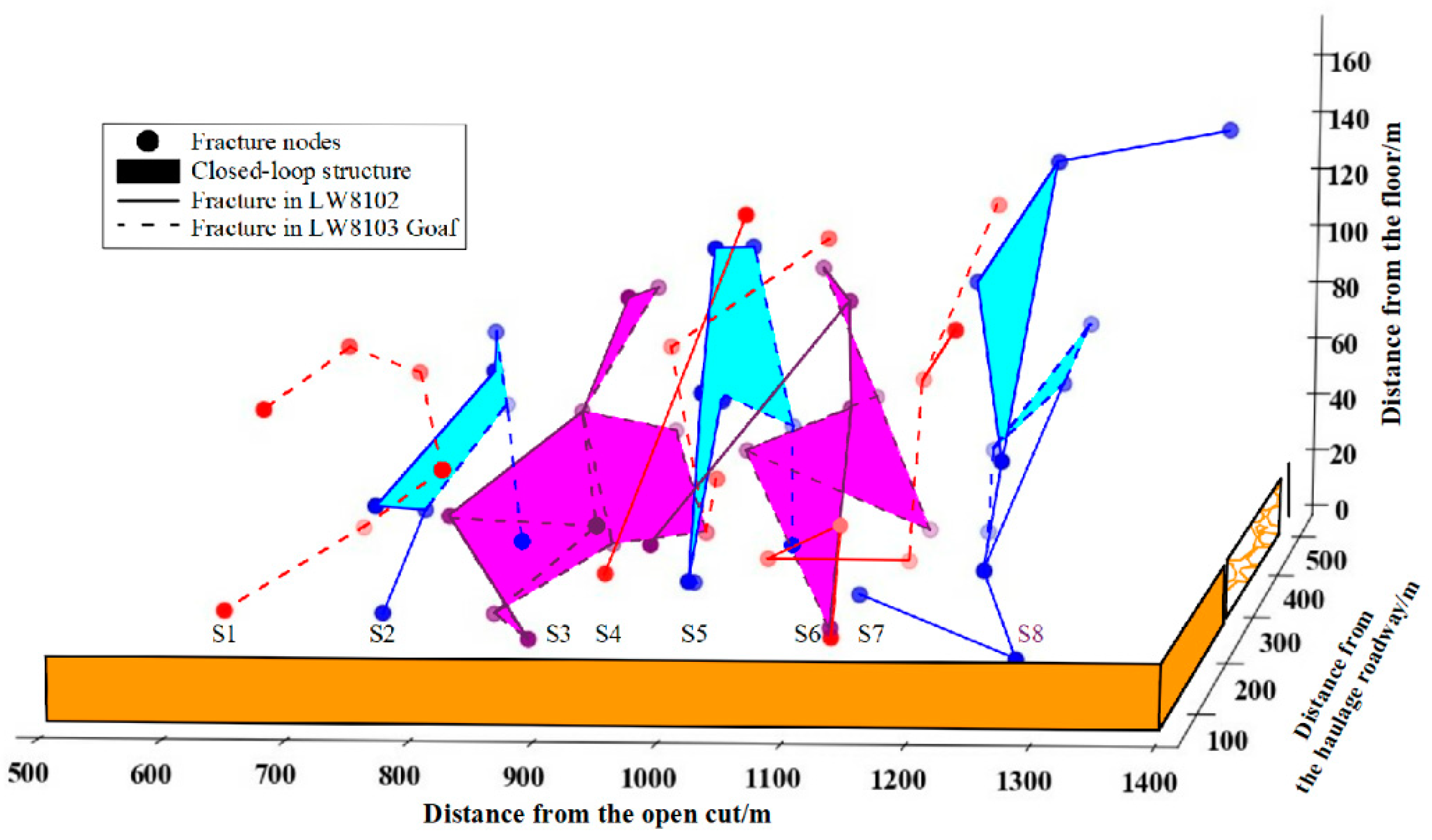

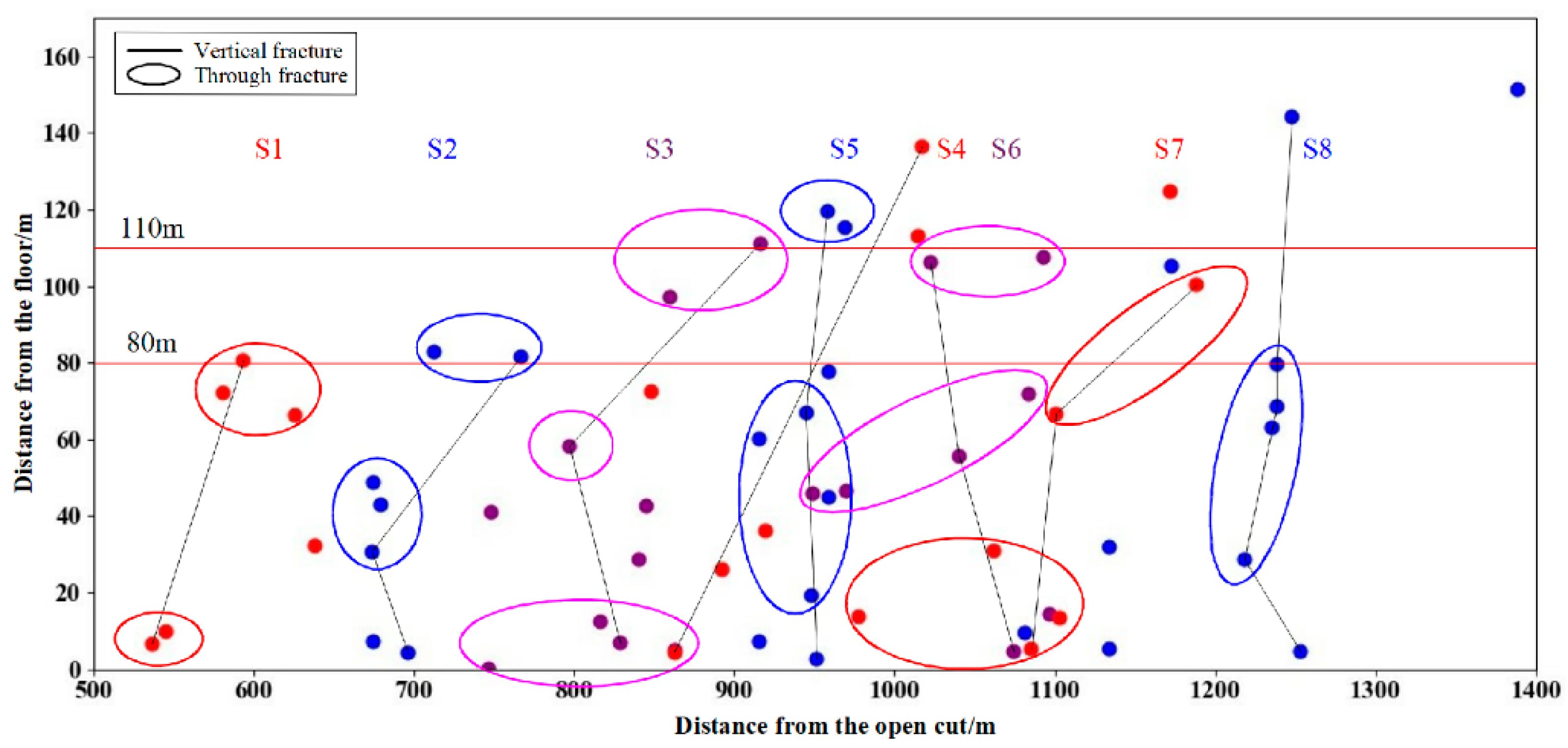

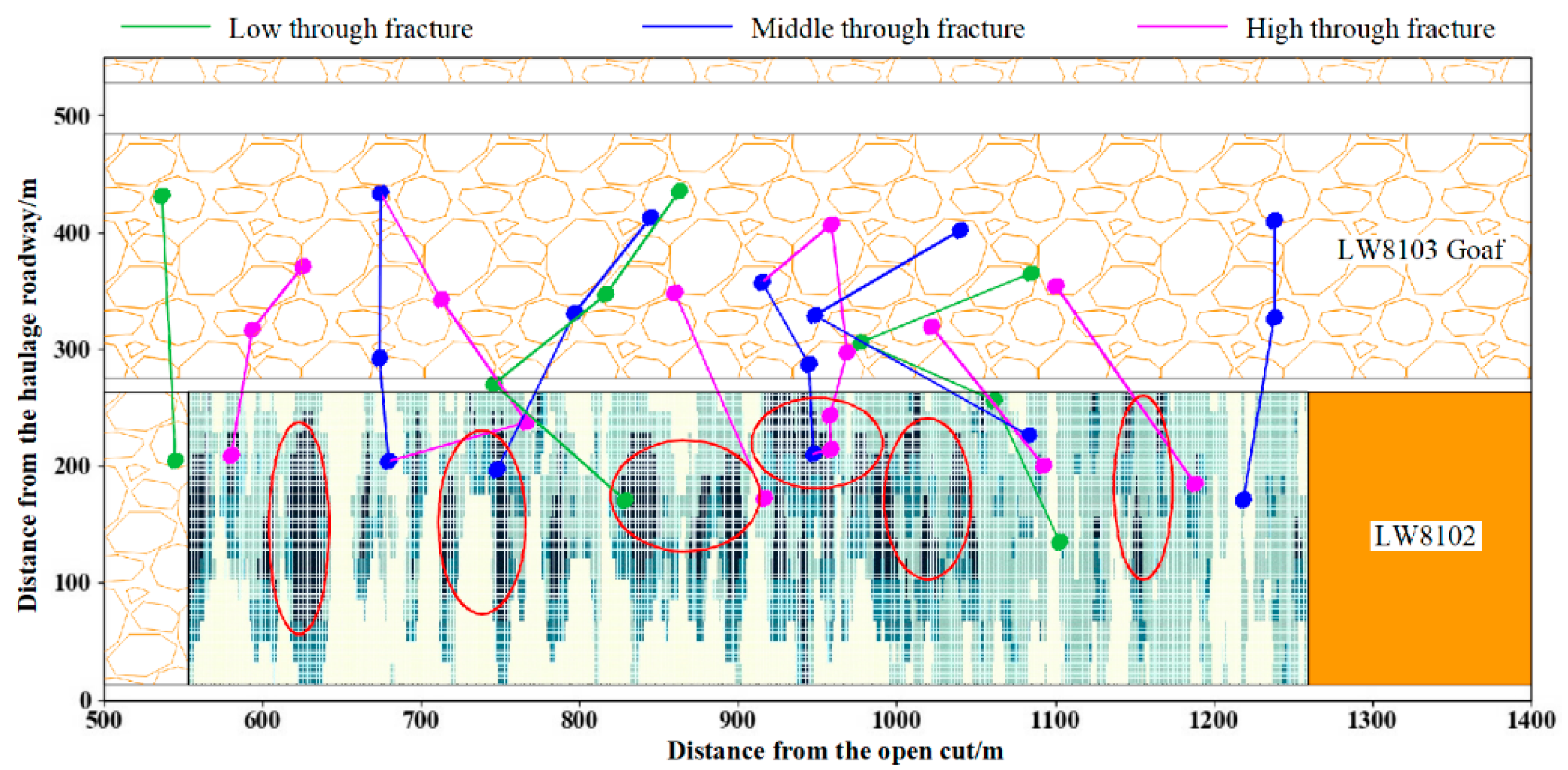

4. Dynamic Identification and Distribution Patterns of Overburden Fractures

5. Mine Pressure Mechanism Based on Overburden Fractures

6. Conclusions

7. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, J.X.; Liu, C.Y.; Yu, B.; Lu, Y. Strong strata pressure caused by hard roof group structure breaking and supporting strength determination. J. Univ. Sci. Technol. Beijing 2014, 36, 576–583. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, H.W.; Fu, X.; Yu, B.; Huo, B. Study of the cylindrical shell structural characteristic of the hard overlying strata of extra thick coal seam and its application. J. China Univ. Min. Technol. 2017, 46, 1226–1230. (In Chinese) [Google Scholar] [CrossRef]

- Yu, B.; Yang, J.X.; Gao, R. Mechanism and technology of roof collaborative controlling in the process of Jurassic and Carboniferous coal mining in Datong mining area. J. China Univ. Min. Technol. 2018, 47, 486–493. (In Chinese) [Google Scholar] [CrossRef]

- Zhu, W.B.; Yu, B. Breakage form and its effect on strata behavior of far field key stratum in large space stope. Coal Sci. Technol. 2018, 46, 99–104. (In Chinese) [Google Scholar] [CrossRef]

- Gao, R.; Yu, B.; Meng, X.B. Study on the mechanism of strong strata behavior influenced by overlying coal pillar and control technology of ground fracturing. J. Min. Saf. Eng. 2018, 35, 324–331. (In Chinese) [Google Scholar] [CrossRef]

- Yu, B.; Liu, C.Y.; Liu, J.R. Mechanism and control technology of pressure occurence in roadway with extra thickness and mechanized caving coal seam in Datong mining area. Chin. J. Rock Mech. Eng. 2014, 33, 1863–1872. (In Chinese) [Google Scholar] [CrossRef]

- Ma, C.C.; Li, T.B.; Zhang, H.; Jiang, Y.P.; Song, T. A method for numerical simulation based on microseismic information and the interpretation of hard rock fracture. J. Appl. Geophys. 2019, 164, 214–224. [Google Scholar] [CrossRef]

- Niitsuma, H. Acoustic emission/Microseismic technique: Review of research in the 20th century and future aspects. In Proceedings of the 15th International Acoustic Emission Symposium (IAES15), Tokyo, Japan, 11–14 September 2000; pp. 109–125. [Google Scholar] [CrossRef]

- Reyes-Montes, J.M.; Young, R.P. Interpretation of fracture geometry from excavation induced microseismic events. In Proceedings of the International Symposium of the International-Society-for-Rock-Mechanics, Liege, Belgium, 9–12 May 2006. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Ranjith, P.G.; Gao, F.; Xie, H.; Wang, J. Changes in microstructure and mechanical properties of low-permeability coal induced by pulsating nitrogen fatigue fracturing tests. Rock Mech. Rock Eng. 2022, 55, 7469–7488. [Google Scholar] [CrossRef]

- Xue, Y.; Ranjith, P.; Chen, Y.; Cai, C.; Gao, F.; Liu, X. Nonlinear mechanical characteristics and damage constitutive model of coal under CO2 adsorption during geological sequestration. Fuel 2023, 331, 125690. [Google Scholar] [CrossRef]

- Fritschen, R. Mining-Induced Seismicity in the Saarland, Germany. Pure Appl. Geophys. 2010, 167, 77–89. [Google Scholar] [CrossRef]

- Kozlowska, M.; Orlecka-Sikora, B.; Rudzinski, L.; Cielesta, S.; Mutke, G. Atypical evolution of seismicity patterns resulting from the coupled natural, human-induced and coseismic stresses in a longwall coal mining environment. Int. J. Rock Mech. Min. Sci. 2016, 86, 5–15. [Google Scholar] [CrossRef]

- Sato, K.; Fujii, Y. Induced seismicity associated with longwall coal mining. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1988, 25, 253–262. [Google Scholar] [CrossRef]

- Cao, W.; Durucan, S.; Cai, W.; Shi, J.-Q.; Korre, A.; Jamnikar, S.; Rošer, J.; Lurka, A.; Siata, R. The Role of Mining Intensity and Pre-existing Fracture Attributes on Spatial, Temporal and Magnitude Characteristics of Microseismicity in Longwall Coal Mining. Rock Mech. Rock Eng. 2020, 53, 4139–4162. [Google Scholar] [CrossRef]

- Woodward, K.; Wesseloo, J.; Potvin, Y. A spatially focused clustering methodology for mining seismicity. Eng. Geol. 2018, 232, 104–113. [Google Scholar] [CrossRef]

- Lasocki, S. Statistical short-term prediction in mining induced seismicity. In Proceedings of the 3rd International Symp on Rockbursts and Seismicity in Mines, Kingston, ON, Canada, 16–18 August 1993; pp. 211–216. [Google Scholar]

- Lj, J. Outbursts in Coal Mines; IEA Coal Research: London, UK, 1984. [Google Scholar]

- Yu, B.; Zhao, J.; Xiao, H.T. Case Study on Overburden Fracturing during Longwall Top Coal Caving Using Microseismic Monitoring. Rock Mech. Rock Eng. 2017, 50, 507–511. [Google Scholar] [CrossRef]

- Si, G.; Durucan, S.; Jamnikar, S.; Lazar, J.; Abraham, K.; Korre, A.; Shi, J.-Q.; Zavšek, S.; Mutke, G.; Lurka, A. Seismic monitoring and analysis of excessive gas emissions in heterogeneous coal seams. Int. J. Coal Geol. 2015, 149, 41–54. [Google Scholar] [CrossRef]

- Young, R.P.; Collins, D.S.; Hazzard, J.; Heath, A.; Pettitt, W.S.; Baker, C.; Billaux, D.; Cundall, P.; Potyondy, D.; Dedecker, F. Seismic Validation of 3-D Thermo-Mechanical Models for the Prediction of the Rock Damage around Radioactive Waste Packages in Geological Repositories-SAFETI; Final Report; European Commission Nuclear Science and Technology: 2005. Available online: https://cordis.europa.eu/project/id/FIKW-CT-2001-00200/reporting/it (accessed on 3 November 2022).

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Wang, H.; Cai, W.; Cao, A.Y. Rockburst characteristics in syncline regions and microseismic precursors based on energy density clouds. Tunn. Undergr. Space Technol. 2018, 81, 83–93. [Google Scholar] [CrossRef]

- Yu, G.; Cheng, G.; Li, L.; Tang, C.; Ren, B.; Han, Y. Preliminary Study on High-Energy and Low-Energy Microfracture Event Evolution Characteristics in the Development Process of Rock Failure. Geofluids 2020, 2020, 8880107. [Google Scholar] [CrossRef]

- Pang, H.D. Study of Micro Seismic Mode, Location of Rock Mass and Its Collapse Prediction. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2004. (In Chinese). [Google Scholar]

- Cheng, Y.H. Preventing Coal Bump by Appling Microseismic Locating Monitoring Technology in Longwallface. Ph.D. Thesis, Shandong University of Science and Technology, Qingdao, China, 2006. (In Chinese). [Google Scholar]

- Cai, W. Fault Rockburst Induced by Static and Dynamic Loads Superposition and Its Monitoring and Warning. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2015. (In Chinese). [Google Scholar]

- Zhou, Z.H. Machine Learning; Tsinghua University Press: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Li, Z.; Jia, L.; Su, B. Improved k-means algorithm for finding public opinion of mount emei tourism. In Proceedings of the 15th International Conference on Computational Intelligence and Security (CIS), Macao, China, 13–16 December 2019. [Google Scholar] [CrossRef]

| Dynamic Expansion Forms | LW8102 | LW8103 Goaf |

|---|---|---|

| Middle to both the ends | S2, S5 | S1, S2, S4, S8 |

| Both the ends to the middle | S6-1, S8 | S6, S7 |

| Low-lying to high-lying | S3, S4 | S3 |

| High-lying to low-lying | S6-2 | S5 |

| Dynamic Expansion Forms | High Level | Middle Level | Low Level | |

|---|---|---|---|---|

| vertical fractures arise first | both ends to the middle | S1, S2, S5 | —— | S3, S7 |

| LW8103 goaf to LW8102 | S6 | S3, S5 | —— | |

| LW8102 to LW8103 goaf | S3 | S8 | S1 | |

| through fractures arise first | middle to both the ends | S7 | S2, S6 | —— |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Liu, C.; Liu, J.; Yang, P.; Lu, S. Case Study on Dynamic Identification of Overburden Fracture and Strong Mine Pressure Mechanism of Isolated Working Face Based on Microseismic Clustering. Sustainability 2023, 15, 436. https://doi.org/10.3390/su15010436

Chen Y, Liu C, Liu J, Yang P, Lu S. Case Study on Dynamic Identification of Overburden Fracture and Strong Mine Pressure Mechanism of Isolated Working Face Based on Microseismic Clustering. Sustainability. 2023; 15(1):436. https://doi.org/10.3390/su15010436

Chicago/Turabian StyleChen, Yiqi, Changyou Liu, Jinrong Liu, Peiju Yang, and Shuo Lu. 2023. "Case Study on Dynamic Identification of Overburden Fracture and Strong Mine Pressure Mechanism of Isolated Working Face Based on Microseismic Clustering" Sustainability 15, no. 1: 436. https://doi.org/10.3390/su15010436

APA StyleChen, Y., Liu, C., Liu, J., Yang, P., & Lu, S. (2023). Case Study on Dynamic Identification of Overburden Fracture and Strong Mine Pressure Mechanism of Isolated Working Face Based on Microseismic Clustering. Sustainability, 15(1), 436. https://doi.org/10.3390/su15010436