Performances of the Soil–Bentonite Cutoff Wall Composited with Geosynthetic Clay Liners: Large-Scale Model Tests and Numerical Simulations

Abstract

1. Introduction

2. Materials

2.1. Soil Properties

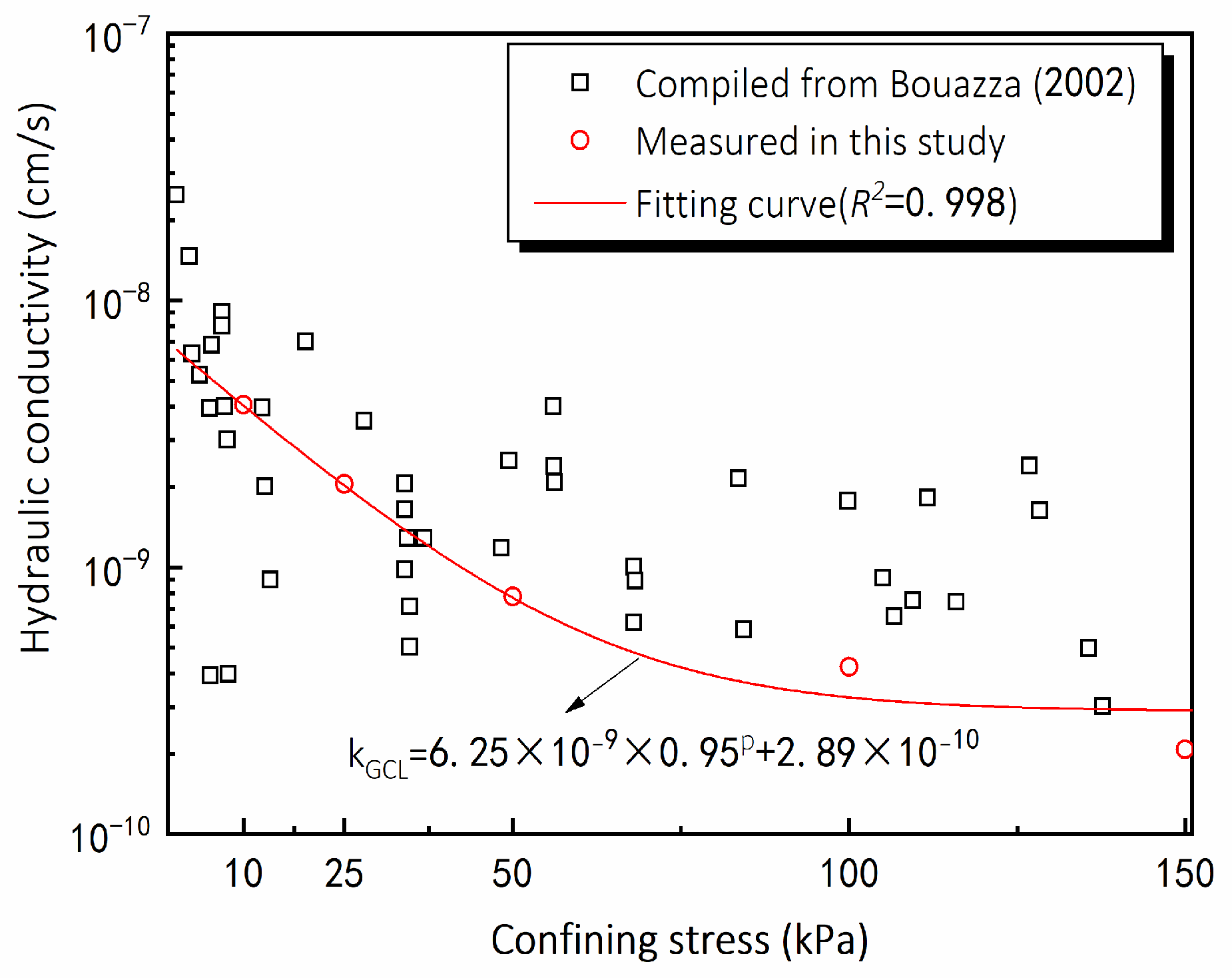

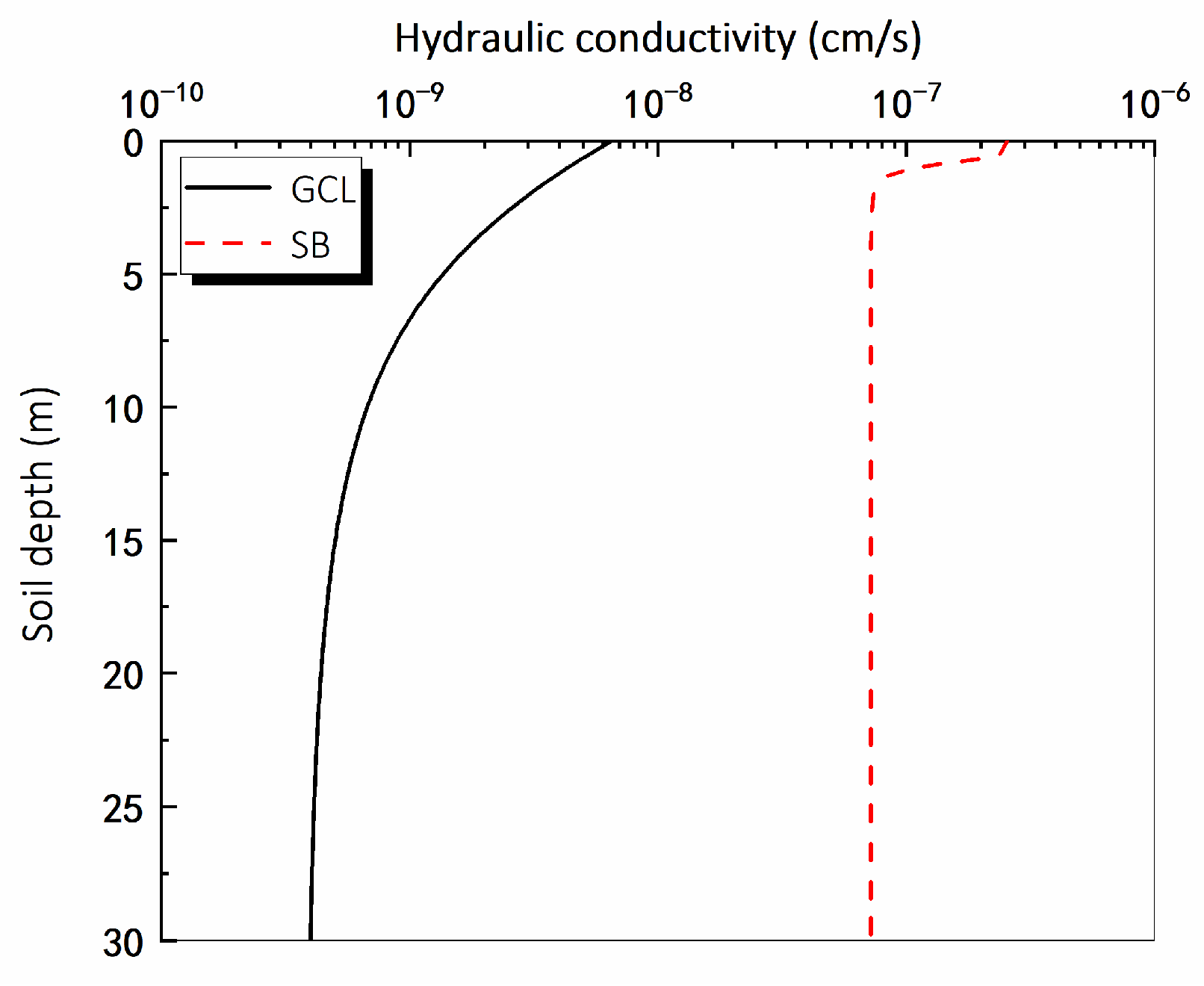

2.2. Hydraulic Conductivity of the GCL

3. Large-Scale Model Testing on the GCL Overlap

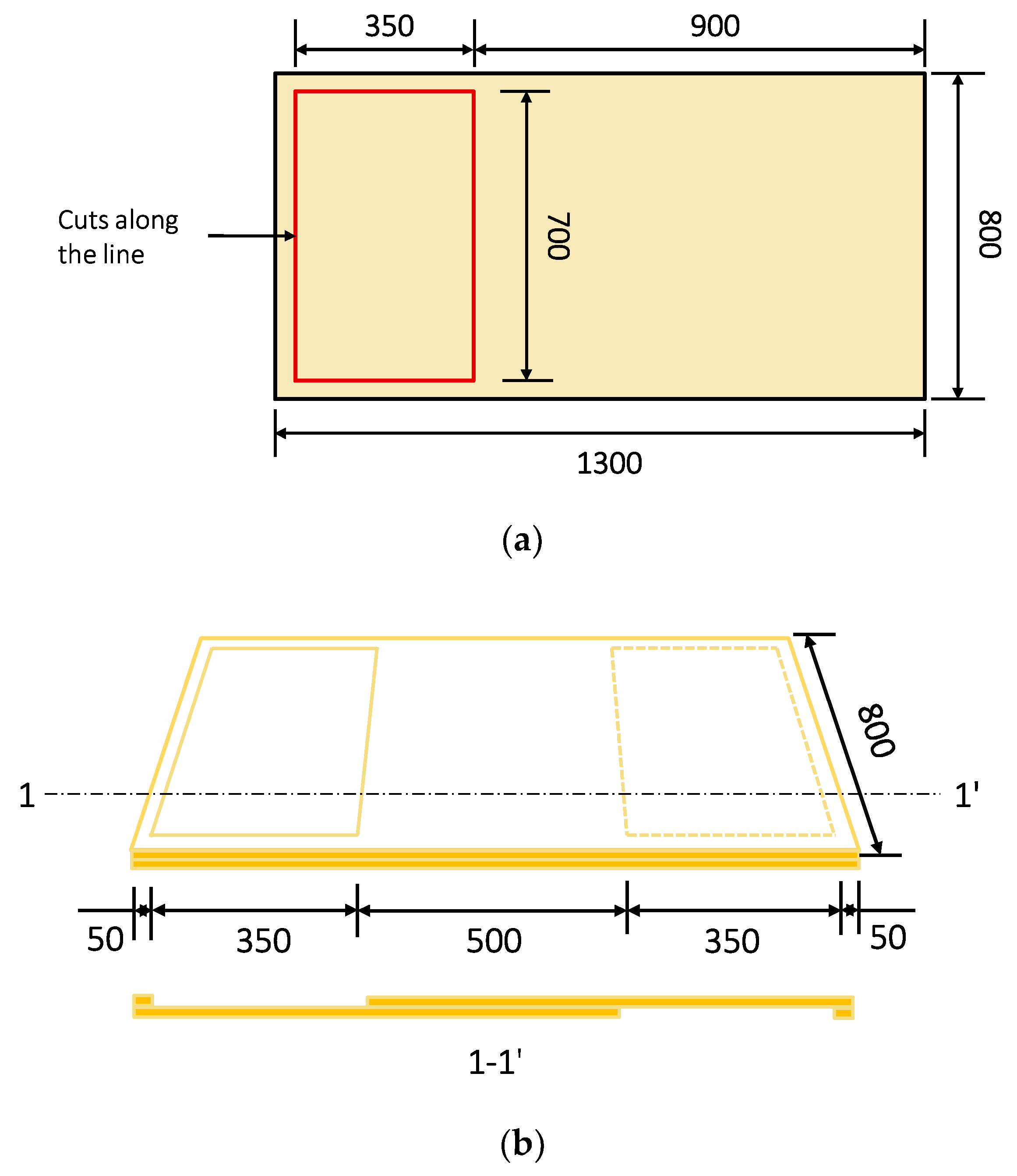

3.1. Test Program

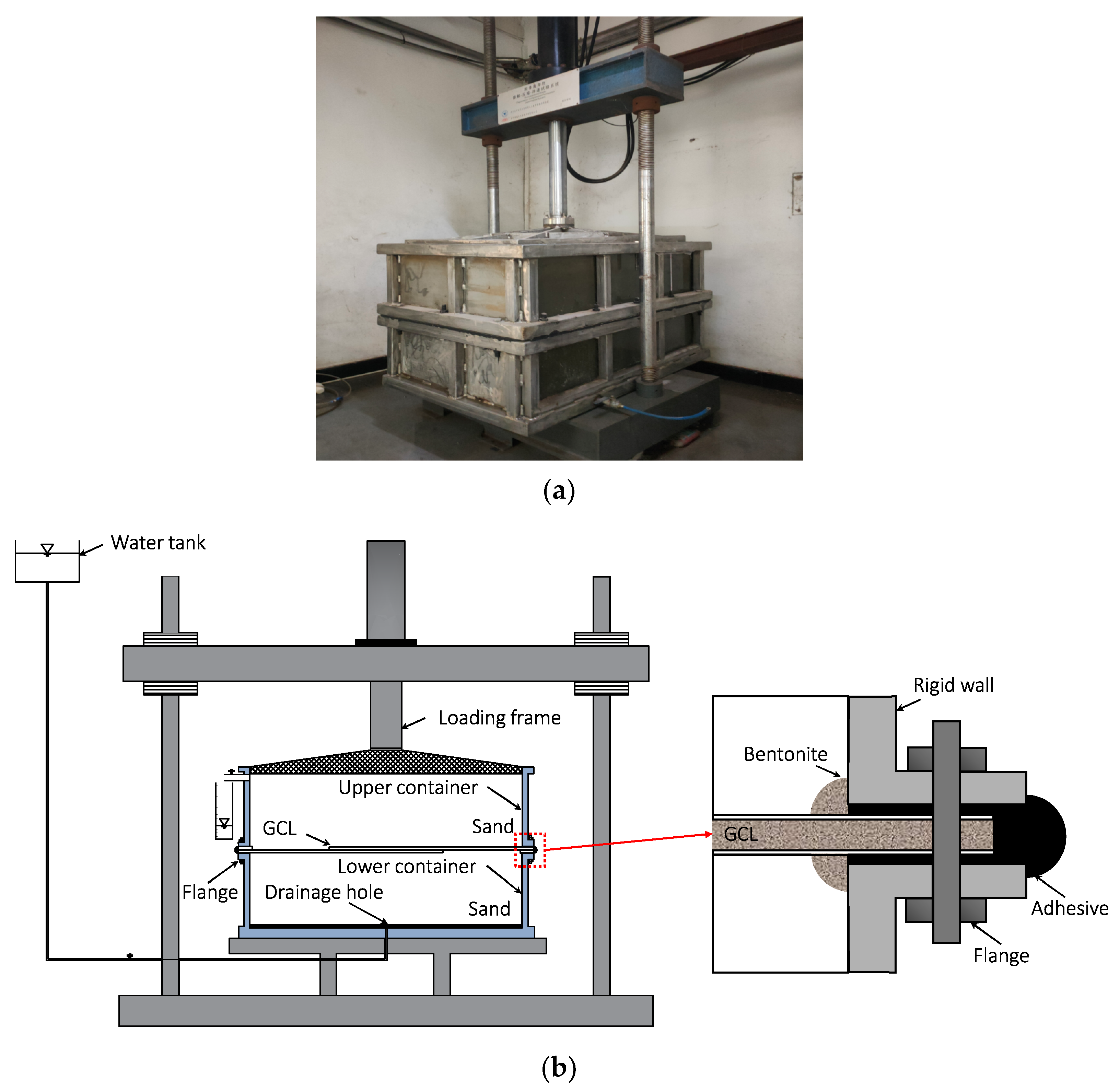

3.2. Testing Apparatus

3.3. Test Setup and Procedures

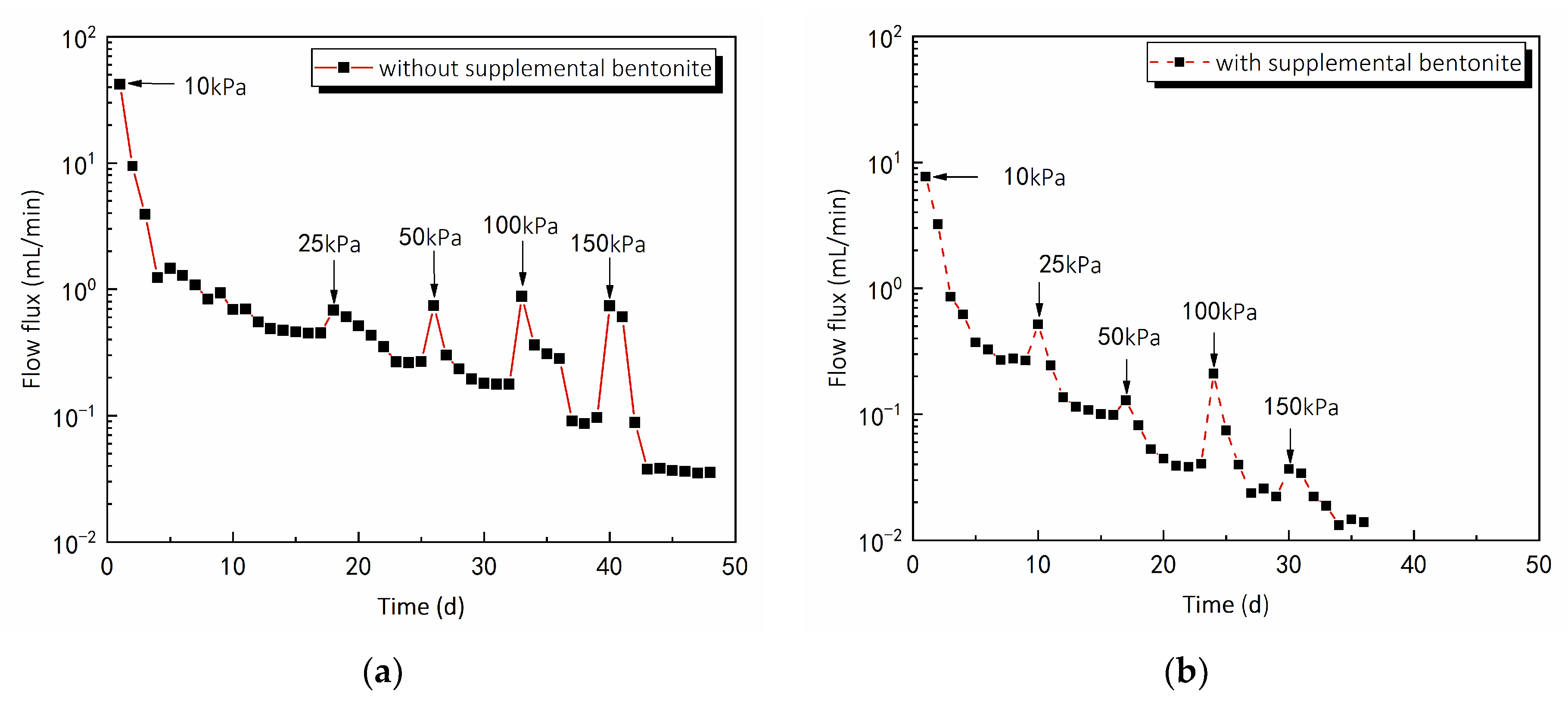

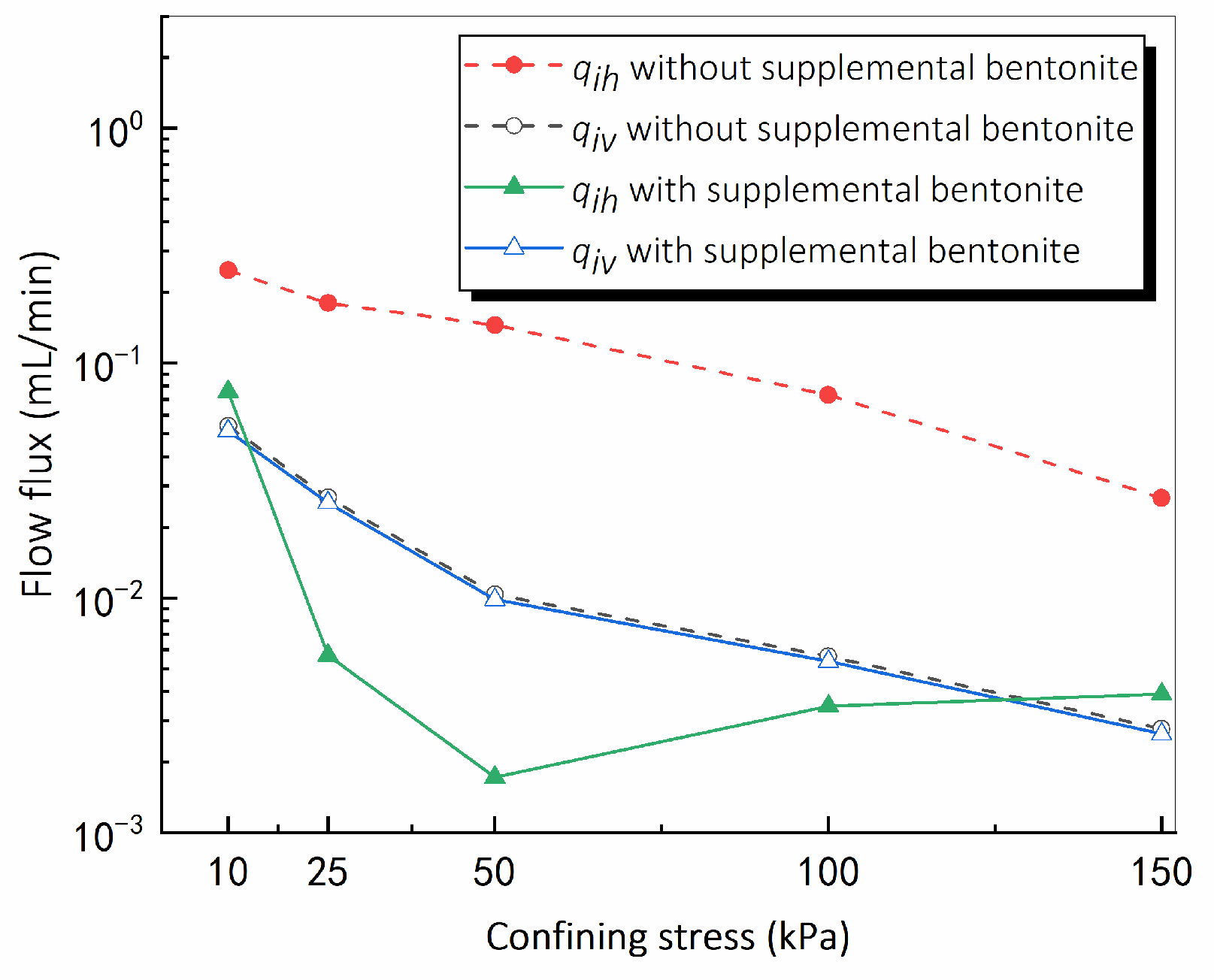

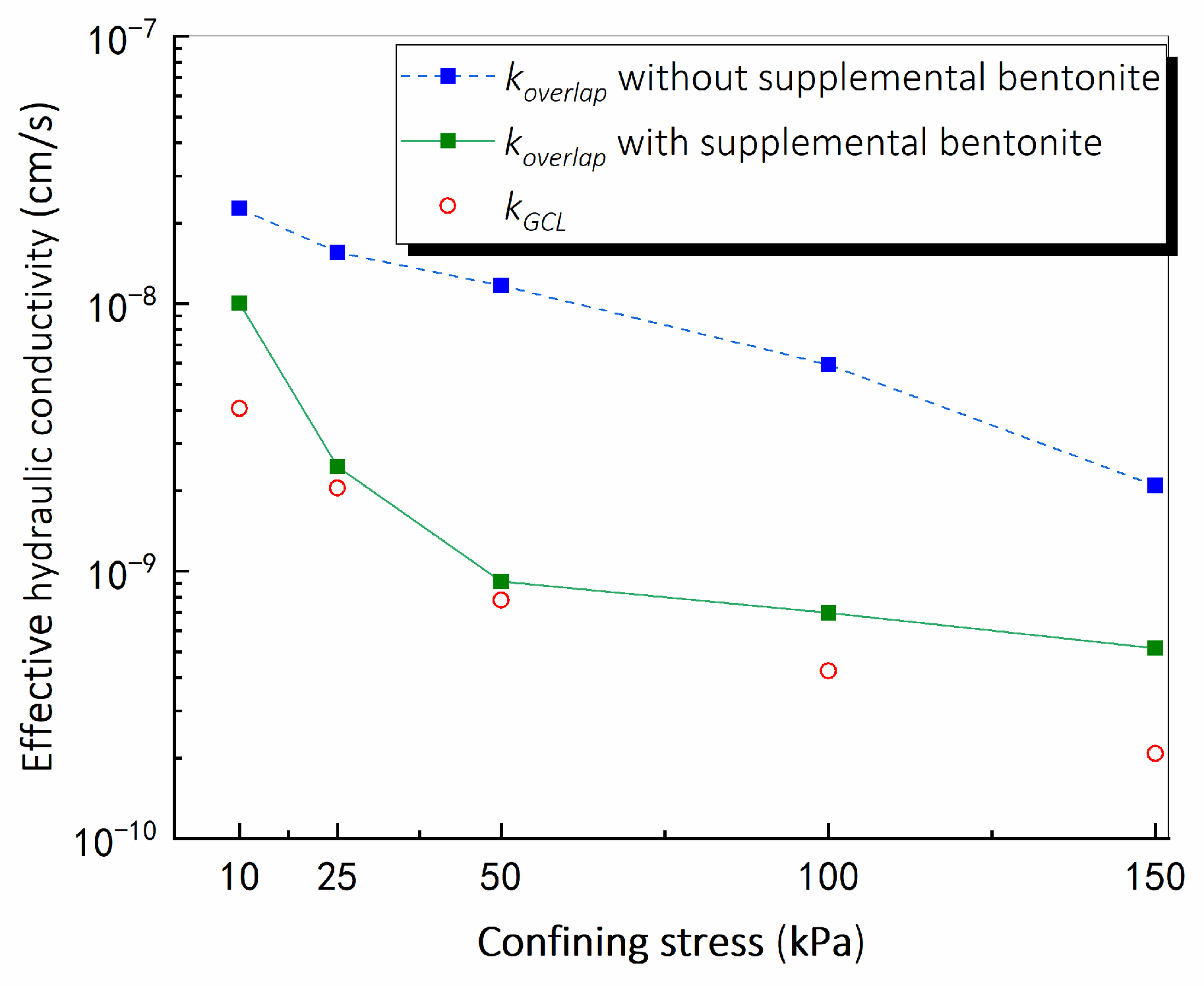

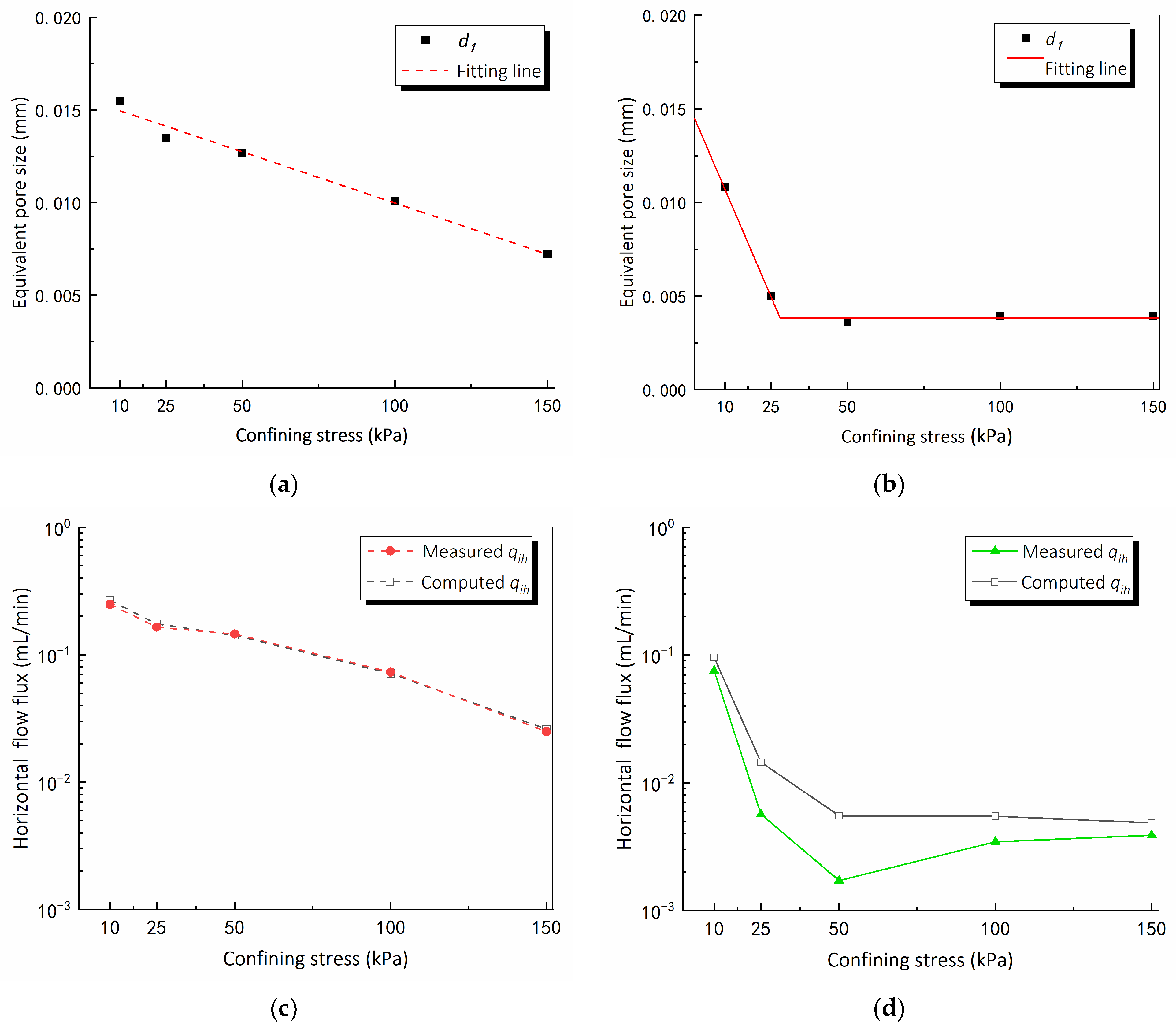

3.4. Flow Flux through the Overlapped GCL Panels

4. Numerical Modeling of the Soil–Bentonite Cutoff Wall Connected with the GCL

4.1. Mathematical Formulation

4.2. Model Calibration

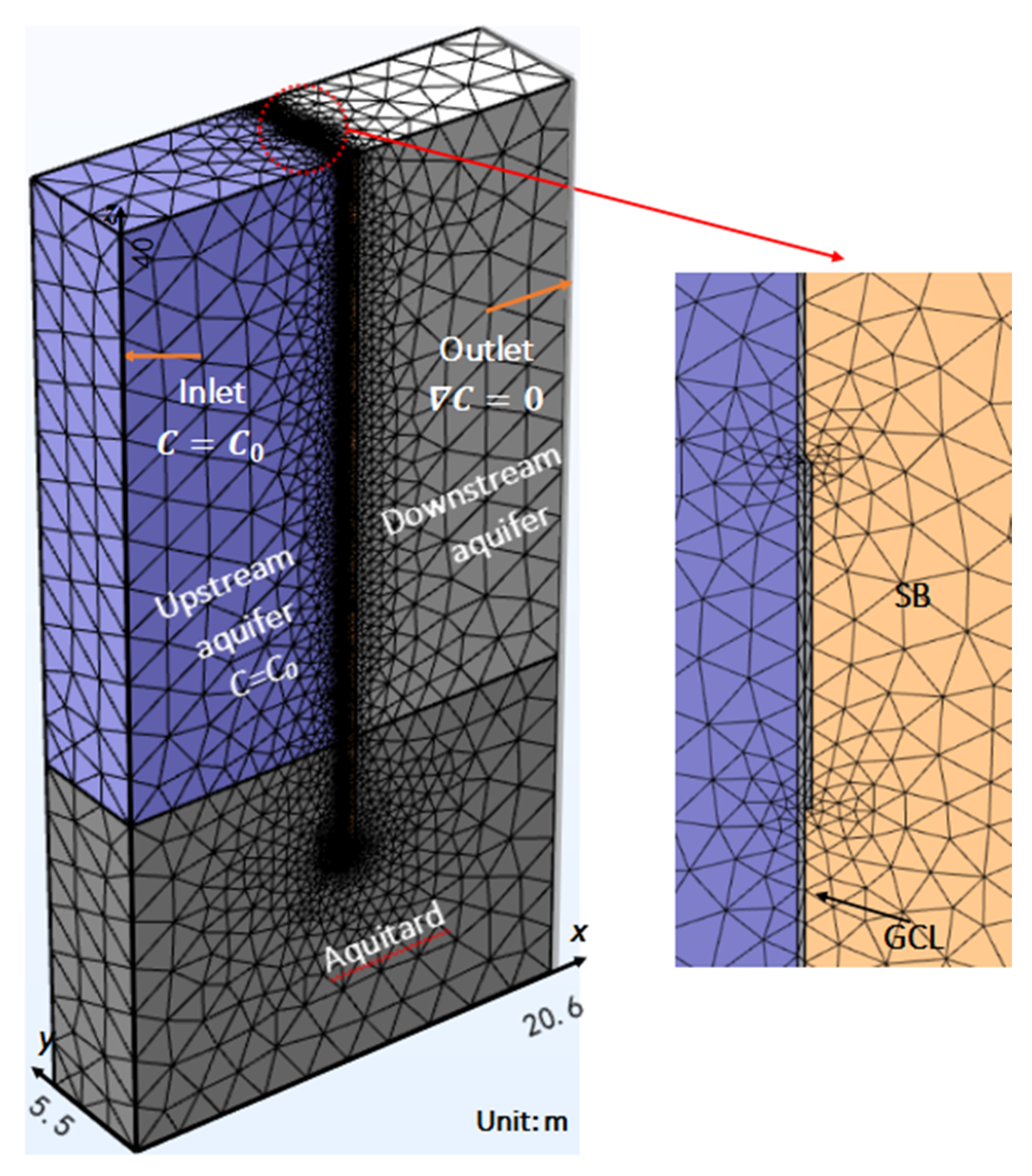

4.3. Finite Element Model Features

4.4. Parameters

4.5. Results and Discussions

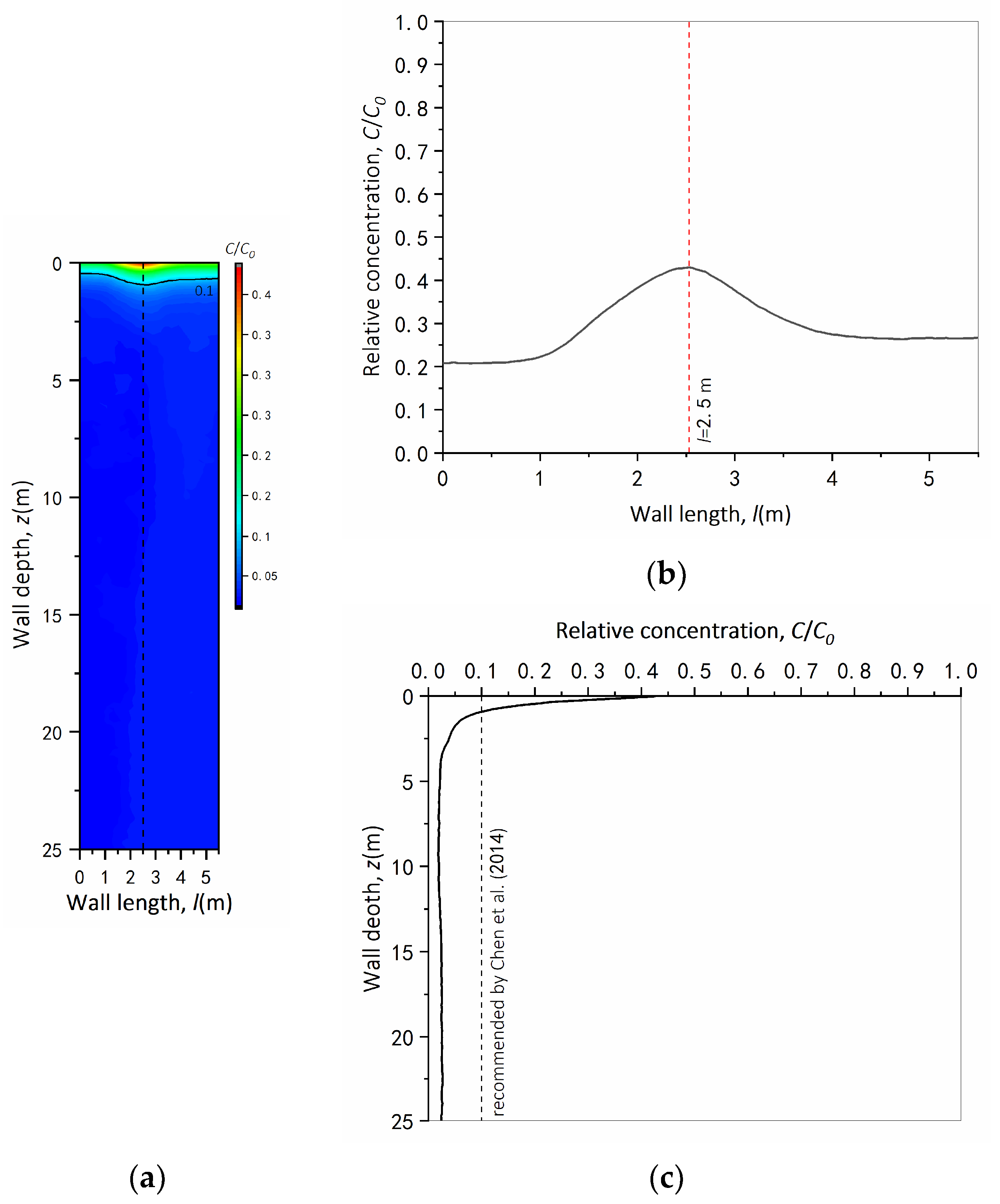

4.5.1. Relative Concentration in the GCL–SB Composite Cutoff Wall with Supplemental Bentonite at the Overlap

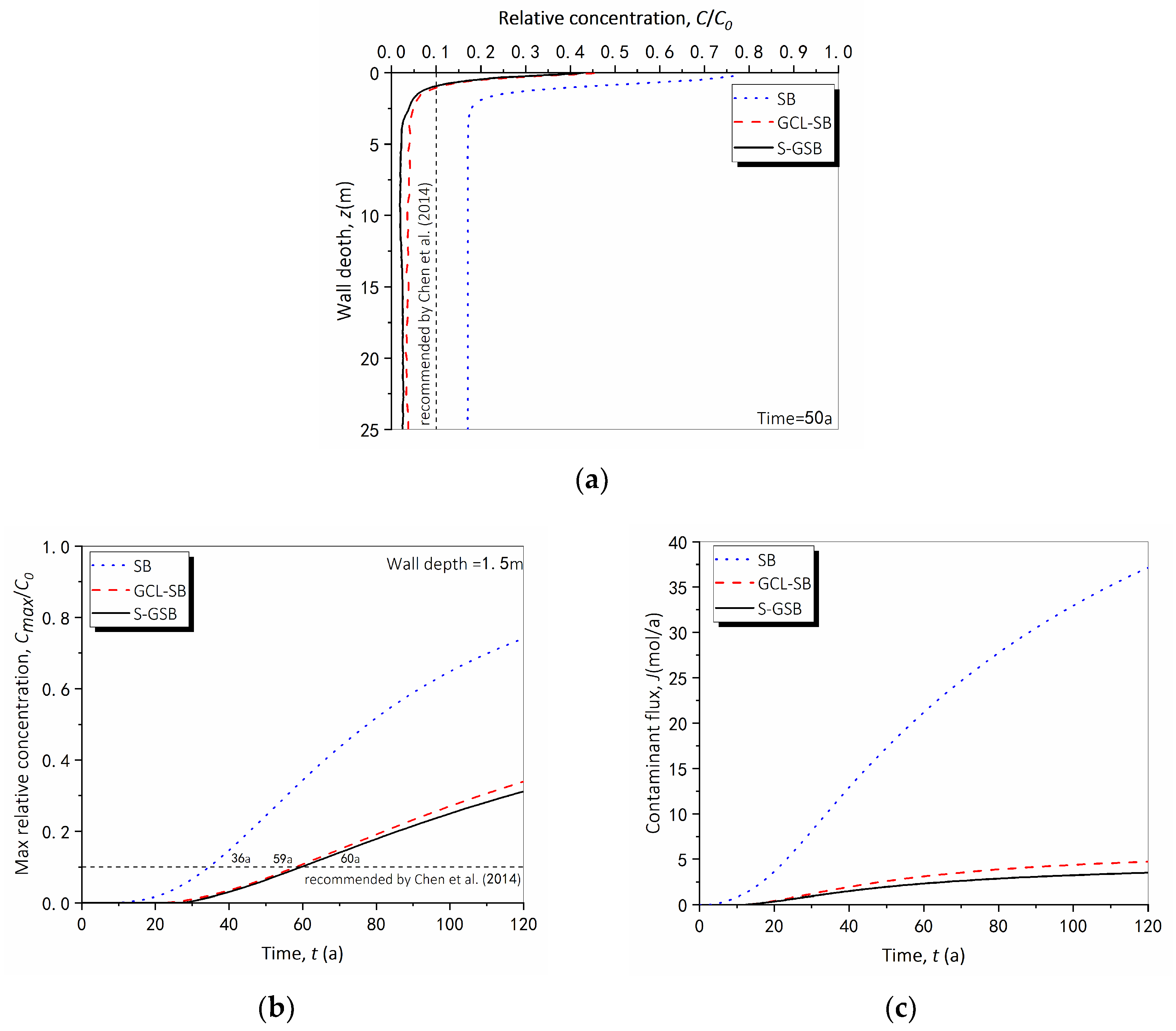

4.5.2. Effects of Supplemental Bentonite Applied at the GCL Overlap

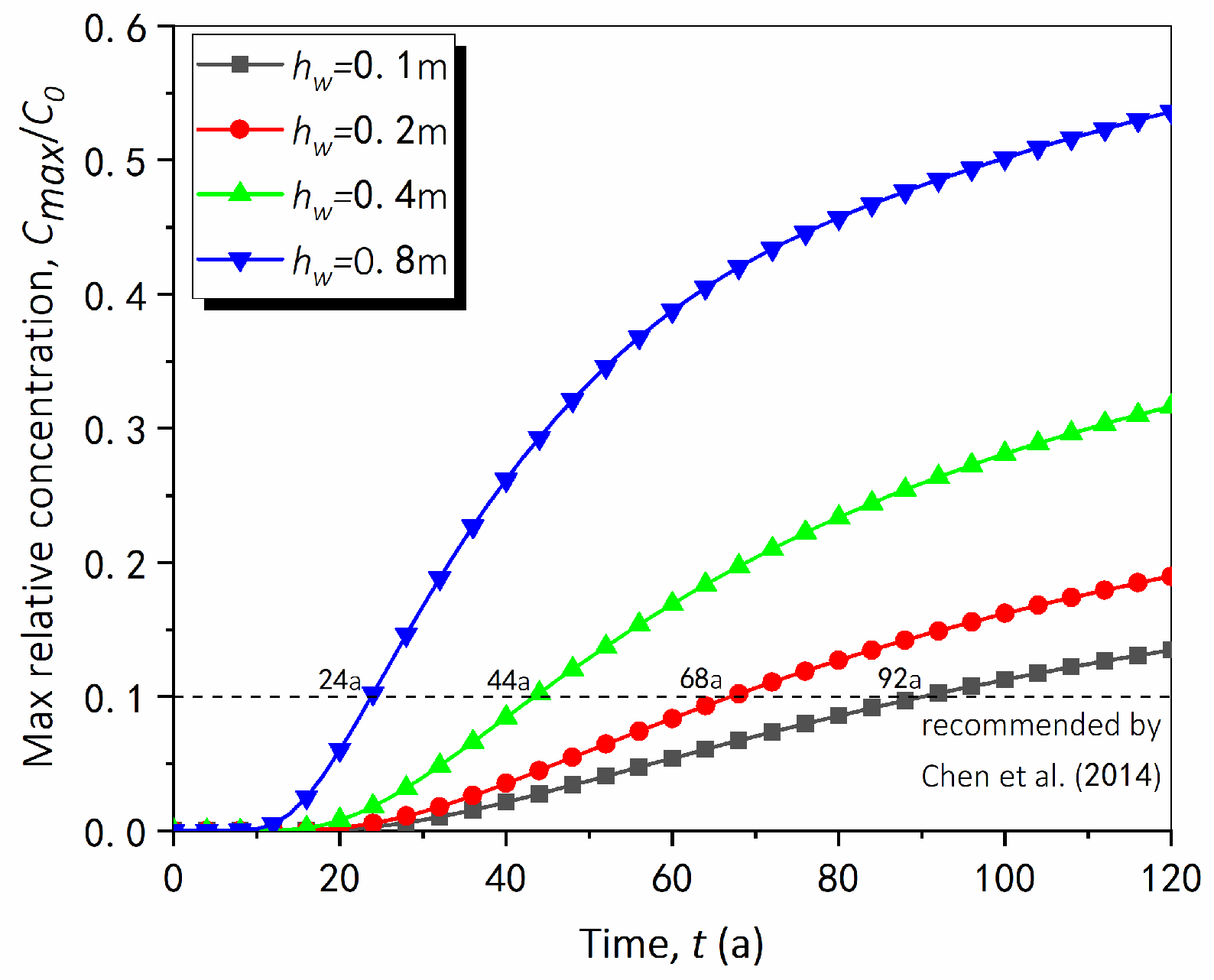

4.5.3. Effects of Hydraulic Head Applied at the GCL Overlap

5. Conclusions

- (1)

- Compared with the flexible wall permeameter, the developed apparatus with an internal dimension of 1.2 m × 0.7 m can guarantee full field-scale GCL overlap to be tested. The edge effect of the permeameter cell is reduced, and the loss of bentonite near edges due to the cut can be avoided. Additionally, the specimen is placed between two containers and sealed at the edge of 50 mm with adhesive and flanges such that the leakage of water through the container wall can be avoided;

- (2)

- A negative relationship is demonstrated between the effective hydraulic conductivity and the confining stress of the GCL overlap. As the confining stress increases from 10 to 150 kPa, the effective hydraulic conductivity decreases from 10−8 to 10−9 cm/s. Furthermore, the addition of supplemental bentonite paste with a water-to-bentonite ratio of 19:1 contributes to reducing the effective hydraulic conductivity by 60% compared with that for a GCL overlap with no bentonite;

- (3)

- The breakthrough time for the vertical barrier was 64% longer by using GCLs in comparison with that of the SB wall. The breakthrough is made for the entire SB wall while at the shallow 0.9 m depth for the composite wall with bentonite at the overlap after 50 years. Considering that the depth of the groundwater table is generally greater than 1 m, the GCL–SB composite cutoff wall will exhibit a good performance in containing groundwater contaminants in the field;

- (4)

- For engineering practice, it is recommended to extend the breakthrough time of the GCL–SB composite cutoff wall to 92 years by applying supplemental bentonite paste with a water-to-bentonite ratio of 19:1 at the GCL overlap and reducing the difference in the hydraulic head to 0.1 m between the inboard and outboard sides of the barrier.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rowe, R.K.; Abdelatty, K. Modelling of contaminant transport through a hole in the GMB. Can. Geotech. J. 2012, 49, 773–781. [Google Scholar] [CrossRef]

- Scalia, J.; Benson, C.H. Hydraulic Conductivity of Geosynthetic Clay Liners Exhumed from Landfill Final Covers with Composite Barriers. J. Geotech. Geoenviron. Eng. 2011, 137, 1–13. [Google Scholar] [CrossRef]

- Rouf, A.; Bouazza, A.; Singh, R.M.; Gates, W.P.; Rowe, R.K. Gas flow unified measurement system for sequential measurement of gas diffusion and gas permeability of partially hydrated geosynthetic clay liners. Can. Geotech. J. 2016, 53, 1000–1012. [Google Scholar] [CrossRef]

- Daniel, D.E.; Trautwein, S.J.; Goswami, P.K. Measurement of hydraulic properties of geosynthetic clay liners using a flow box. In Testing and Acceptance Criteria for Geosynthetic Clay Liners; ASTM International: West Conshohocken, PA, USA, 1997; pp. 196–207. [Google Scholar]

- Rowe, R.K.; Brachman, R.W.I.; Joshi, P. Hydraulic performance of overlapped geosynthetic clay liner seams requiring field-applied supplemental bentonite. J. Geotech. Geoenviron. Eng. 2016, 142, 4016067. [Google Scholar]

- Weerasinghe, I.A.; Gallage, C.; Dawes, L.; Kendall, P. Factors affecting the hydraulic performance of a geosynthetic clay liner overlap. J. Environ. Manag. 2020, 271, 110978. [Google Scholar] [CrossRef] [PubMed]

- Benson, C.H.; Jo, H.Y.; Abichou, T. Forensic analysis of excessive leakage from lagoons lined with a composite GCL. Geosynthet. Int. 2004, 11, 242–252. [Google Scholar] [CrossRef]

- Joshi, P.; Rowe, R.K.; Brachman, R.W. GCLs with factory-applied bentonite below geomembrane wrinkle. Environ. Geotech. 2017, 5, 263–270. [Google Scholar] [CrossRef]

- Rowe, R.K.; Brachman, R.W.; Hosney, M.S.; Take, W.A.; Arnepalli, D.N. Insight into hydraulic conductivity testing of geosynthetic clay liners (GCLs) exhumed after 5 and 7 years in a cover. Can. Geotech. J. 2017, 54, 1118–1138. [Google Scholar] [CrossRef]

- Rowe, R.K.; Brachman, R.W.; Take, W.A. Field measurements of overlap reductions for two reinforced fabric-encased geosynthetic clay liners (GCLs). Can. Geotech. J. 2018, 55, 631–639. [Google Scholar] [CrossRef]

- Petrov, R.J.; Rowe, R.K.; Quigley, R.M. Selected factors influencing GCL hydraulic conductivity. J. Geotech. Geoenviron. Eng. 1997, 123, 683–695. [Google Scholar] [CrossRef]

- Yu, B.; El-Zein, A. Experimental investigation of the effect of airgaps in preventing desiccation of bentonite in geosynthetic clay liners exposed to high temperatures. Geotext. Geomembr. 2019, 47, 142–153. [Google Scholar] [CrossRef]

- Bostwick, L.; Rowe, R.K.; Take, W.A.; Brachman, R.W.I. Anisotropy and directional shrinkage of geosynthetic clay liners. Geosynth. Int. 2010, 17, 157–170. [Google Scholar] [CrossRef]

- Kevern, J.T. Evaluating permeability and infiltration requirements for pervious concrete. J. Test. Eval. 2015, 43, 544–553. [Google Scholar] [CrossRef]

- Brachman, R.W.; Rowe, R.K.; Take, W.A. Reductions in GCL overlap beneath an exposed geomembrane. J. Geotech. Geoenviron. Eng. 2018, 144, 04018094. [Google Scholar] [CrossRef]

- Estornell, P.; Daniel, D.E. Hydraulic Conductivity of Three Geosynthetic Clay Liners. J. Geotechn. Eng. 1992, 118, 1592–1606. [Google Scholar] [CrossRef]

- Didier, G.; Comeaga, L. Influence of initial hydration conditions on GCL leachate permeability. ASTM Spec. Tech. Publ. 1997, 1308, 181–195. [Google Scholar]

- Weerasinghe, I.; Gallage, C.; Dawes, L.; Kendall, P. Liquid flow mechanism at a geosynthetic clay-liner overlap. In Proceedings of the Geosynthetics Conference 2019, Houston, TX, USA, 9–13 February 2019; pp. 221–229. [Google Scholar]

- Li, Y.C.; Cleall, P.J.; Wen, Y.D.; Chen, Y.M.; Pan, Q. Stresses in soil–bentonite slurry trench cut-off walls. Géotechnique 2015, 65, 843–850. [Google Scholar] [CrossRef]

- Ruffing, D.G.; Evans, J.C.; Ryan, C.R. Strength and stress estimation in soil bentonite slurry trench cutoff walls using cone penetration test data. In Proceedings of the International Foundations Congress and Equipment Expo, San Antonio, TX, USA, 17–21 March 2015; Volume 256, pp. 2567–2576. [Google Scholar]

- BS 1377-2; Methods of Test for Soils for Civil Engineering Purposes—Part 2 Classification Tests. BSI: London, UK, 1990.

- JG/T 193-2006; Sodium Bentonite Geosynthetic Clay Liner. Standards Press of China: Beijing, China, 2006.

- GB/T 5005-2010; Specifications of Drilling Fluid Materials. Standards Press of China: Beijing, China, 2010.

- Zhu, B.; Wen, K.; Li, T.; Wang, L.; Kong, D. Experimental study on lateral pile–soil interaction of offshore tetrapod piled jacket foundations in sand. Can. Geotech. J. 2019, 56, 1680–1689. [Google Scholar] [CrossRef]

- Bouazza, A. Geosynthetic clay liners. Geotext. Geomembr. 2002, 20, 3–17. [Google Scholar] [CrossRef]

- Bolton, M.D. A Guide to Soil Mechanics; Macmillan Press: London, UK, 1991. [Google Scholar]

- Athanassopoulos, C.; Yuan, Z.; Trauger, R.J.; Goldenberg, M. Large-Scale Flow Testing through Seamed and Unseamed Samples of a Multi-Component Geosynthetic Clay Liner. In Current and Future Practices for the Testing of Multi-Component Geosynthetic Clay Liners; ASTM International: West Conshohocken, PA, USA, 2013; pp. 62–70. [Google Scholar]

- Tong, X.; Li, Y.C.; Ke, H.; Li, Y.; Pan, Q. In situ stress states and lateral deformations of soil–bentonite cutoff walls during consolidation process. Can. Geotech. J. 2020, 57, 139–148. [Google Scholar] [CrossRef]

- Zhan, L.T.; You, Y.Q.; Zhao, R.; Chen, C.; Chen, Y.M. Centrifuge modelling of lead retardation in soil—Bentonite cut-off walls. Int. J. Phys. Model. Geotech. 2022, 1–14. [Google Scholar] [CrossRef]

- Xie, H.; Lou, Z.; Chen, Y.; Jin, A.; Chen, P. An analytical solution to contaminant advection and dispersion through a GCL/AL liner system. Chin. Sci. Bull. 2011, 56, 811–818. [Google Scholar] [CrossRef]

- Yang, K.L. Experimental Study on Water Permeability of Waste Soil-Bentonite Backfill. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Chen, Y.M. A fundamental theory of environmental geotechnics and its application. Chin. J. Geotech. Eng. 2014, 36, 1–4. [Google Scholar]

| Mineral | Value |

|---|---|

| Montmorillonite (%) | 68.2 |

| Albite (%) | 23.4 |

| Calcite (%) | 6.3 |

| Quartz (%) | 2.1 |

| Parameter | Value |

|---|---|

| Specific gravity, Gs, (-) | 2.67 |

| Liquid limit, wL, (-) | 258% |

| Plastic limit, wP, (-) | 31% |

| Plasticity index, Ip, (-) | 227% |

| Particle < 0.075 mm, (-) | 90% |

| Swelling index in water, (mL/2 g) | 25 |

| Swelling index in CaCl2 solution, (mL/2 g) | 20.5 |

| Filtrate volume, (mL) | 12.6 |

| Soil Layer | nf (-) | Dd (m2/s) | Rd (-) |

|---|---|---|---|

| Aquifer | 0.5 | 5 × 10−10 | 1 |

| SB | 0.6 | 2.34 × 10−10 | 15 |

| GCL | 0.9 | 3 × 10−10 | 15 |

| Aquitard | 0.3 | 5 × 10−10 | 1 |

| Fracture | 1 | 5 × 10−10 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, L.-T.; Cao, L.-F.; Zhao, R.; Ding, Z.-H.; Xie, S.-P.; Chen, Y.-M. Performances of the Soil–Bentonite Cutoff Wall Composited with Geosynthetic Clay Liners: Large-Scale Model Tests and Numerical Simulations. Sustainability 2023, 15, 1886. https://doi.org/10.3390/su15031886

Zhan L-T, Cao L-F, Zhao R, Ding Z-H, Xie S-P, Chen Y-M. Performances of the Soil–Bentonite Cutoff Wall Composited with Geosynthetic Clay Liners: Large-Scale Model Tests and Numerical Simulations. Sustainability. 2023; 15(3):1886. https://doi.org/10.3390/su15031886

Chicago/Turabian StyleZhan, Liang-Tong, Lin-Feng Cao, Rui Zhao, Zhao-Hua Ding, Shi-Ping Xie, and Yun-Min Chen. 2023. "Performances of the Soil–Bentonite Cutoff Wall Composited with Geosynthetic Clay Liners: Large-Scale Model Tests and Numerical Simulations" Sustainability 15, no. 3: 1886. https://doi.org/10.3390/su15031886

APA StyleZhan, L.-T., Cao, L.-F., Zhao, R., Ding, Z.-H., Xie, S.-P., & Chen, Y.-M. (2023). Performances of the Soil–Bentonite Cutoff Wall Composited with Geosynthetic Clay Liners: Large-Scale Model Tests and Numerical Simulations. Sustainability, 15(3), 1886. https://doi.org/10.3390/su15031886