1. Introduction

Broiler production has been the fastest growing sector in animal production worldwide over the past decades, driven by the increasing demand for animal-sourced foods by the rapid population growth, [

1] and a change in dietary preferences [

2,

3]. In 2020, the world broiler meat production exceeded 100 million tonnes [

4]. Broilers grow fast with a high efficiency compared to other farm animals, because they consume relatively little feed per kg of produced kg of meat compared to, for example, pigs and cattle [

5]. Broiler meat is consumed across cultural and religious communities [

6]. However, citizens and consumers, particularly in developed countries such as those in Europe, are increasingly concerned about the living conditions of intensely farmed chickens and the health and welfare problems encountered in densely populated broiler houses with flocks of 20,000 birds and more [

7].

These houses offer very little structural orientation for the birds [

8]. The animals can freely move on a flat, usually concrete floor covered with litter material, such as chopped straw or wood chips, peat or something similar [

9]. They are offered feed and water from automatic feeding systems. A ventilation system combined with a heating system provides ambient indoor temperatures for optimal growth rates. In this barren environment [

10] with high stocking density, typical production diseases, often addressed as technopathies or cumulative disorders, such as lameness or foot pad dermatitis (FPD) [

11] and deep skin dermatitis as well as sudden cardiac death [

12], culminate in the last week of the production cycle.

To avoid or ease these problems that impair the welfare of the birds [

13] various measures and attempts have been undertaken [

14,

15,

16,

17,

18,

19,

20]. These problems can seriously affect productivity, with animal losses and degraded meat quality. Initially, research was carried out to mainly address factors of nutrition [

14,

15], but in recent years, attention has been paid more and more to housing conditions [

16,

17]. Due to their fast growth combined with low activity, the animals easily develop lameness and other pathologies, such as FPD, particularly in combination with wet litter [

18]. Consequently, birds may suffer from pain and their well-being and health status are reduced, which also results in economic losses for the farmers [

19,

20].

A solution, or at least an improvement, was seen in the so-called “environmental enrichment”, which has been defined as “an improvement in the biological functioning of captive animals resulting from modifications to their environment” [

21]. It has been shown in previous studies that environmental enrichment can be used to target problems of low complexity of structure and can therefore increase animal welfare [

8,

22,

23,

24]. It is part of the natural behaviour of birds and broiler chickens to be eager to climb and sit on perches or other structures off the ground [

25,

26,

27]. This is presumably related to the wildlife strategy of their ancestors to avoid predators [

26,

28]. Elevated structures allow species-specific behaviours and the broilers have the possibility to choose several different seating positions [

29]. These elements and activities may tackle the well-known problem in conventional chicken houses, i.e., the chickens are inactive for approximately 80% of their time [

30,

31] when not eating or drinking. Movement and choosing several different seating positions can help to distribute the load on the foot pads, while also help to increase muscle activity [

32] and reduce lameness [

24,

33] and FPD [

34].

Enrichment options, which have been under research in recent years, are higher places such as small elevated perforated or non-perforated floors, perches [

22,

27] and straw bales [

35], which trigger activity and direct pecking behaviour to straw stems. However, not every tested enrichment element suits the purpose perfectly [

36]. Some recent studies have shown that straw bales, for example, while being well-accepted for seating broilers, can also lead to an increase in FPD [

20,

37].

A common difficulty in assessing animal welfare in commercial broiler flocks is their often large numbers of birds [

38]. Modern technology can offer new options of real-time monitoring of not only the birds, but also the climate and everything related to the animals’ environment. Especially the high data density generated by this monitoring as well as the possible earlier detection of irregularities could contribute to higher animal welfare [

39,

40]. Nevertheless, it has to be taken into consideration that these systems could also be used for increasing productivity in addition to the main focus of improving animal welfare [

39]. The focus of animal welfare evaluations has often been on “outcome” measures [

40], but the climate also has a considerable influence on animal welfare as well as animal health [

41]. Thus, a more intensive monitoring can also contribute to improve environmental conditions.

The aim of this study is to test, characterise and improve possible options to offer environmental enrichment in broiler houses. The focus in this paper is to evaluate the influence of environmental enrichment on animal welfare and growth performance with the help of an FAS. The large amount of continuously measured climate data were analysed to evaluate the effects of possible higher numbers of birds in enriched areas. By collecting litter samples, the influence of the environmental enrichment on litter quality was evaluated. Moisture was the main focus, as it has an influence on the condition of the foot pads [

42]. Furthermore, the foot pads of individual animals were scored in order to investigate the influence of the environmental enrichment and to give an estimate of the impairment of the well-being of the birds resulting from these injuries.

2. Materials and Methods

2.1. Animals and Diets

2.1.1. Animals

In this study, broilers were raised as hatched in a barn on the Farm for Education and Research in Ruthe, University of Veterinary Medicine Hannover, Foundation, Hannover, Germany. Chicks of the same age and genetics (Ross 308) were distributed randomly between two groups (control group = CG and trial group = TG) on the same day and at the same time. The broilers were housed for 6 fattening runs, with each run having a control and trial group consisting of 8100 birds each. With 16,200 birds in each fattening group, a total number of 97,200 birds were housed in this trial. The length of each of the 6 fattening runs was 33 days.

2.1.2. Diets

The birds were fed ad libitum and had free access to water. A commercial pelleted diet (MEGA Tierernährung GmbH & Co. KG, Visbek, Germany), based on wheat and soybean meal, was offered in a three-phase feeding programme (

Table 1). The first phase was the “starter diet”, which was offered until d 7 of life, and then exchanged for the “grower I diet”. After d 20 of life, “grower II” was introduced, which was fed until d 29, and finally the “finisher diet” was fed until d 33.

2.2. Experimental Design and Housing

The broilers were raised for 33 days in two separate, but identically designed, broiler houses at the same time under controlled environmental housing conditions. The barn for each group was 30 m long and 16 m wide.

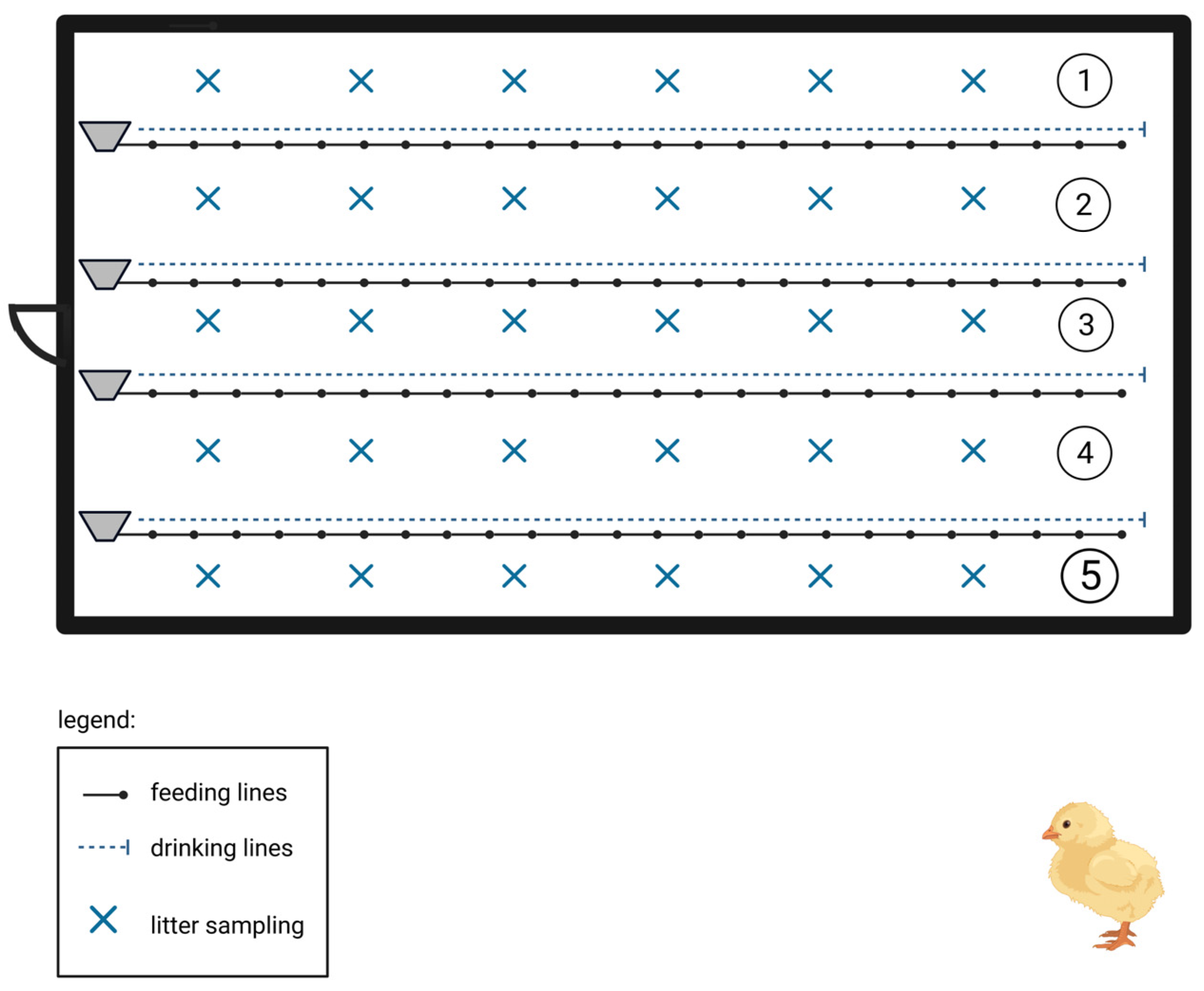

The feed was provided in four conventional feeding lines (Big Dutchman International GmbH, Vechta, Germany) with four conventional water lines (LUBING Maschinenfabrik Ludwig Bening GmbH & Co. KG, Barnstorf, Germany) next to them (

Figure 1). The water lines were equipped with drinking nipples (LUBING Maschinenfabrik Ludwig Bening GmbH & Co. KG).

Figure 1 shows an overview of the barn and the different areas.

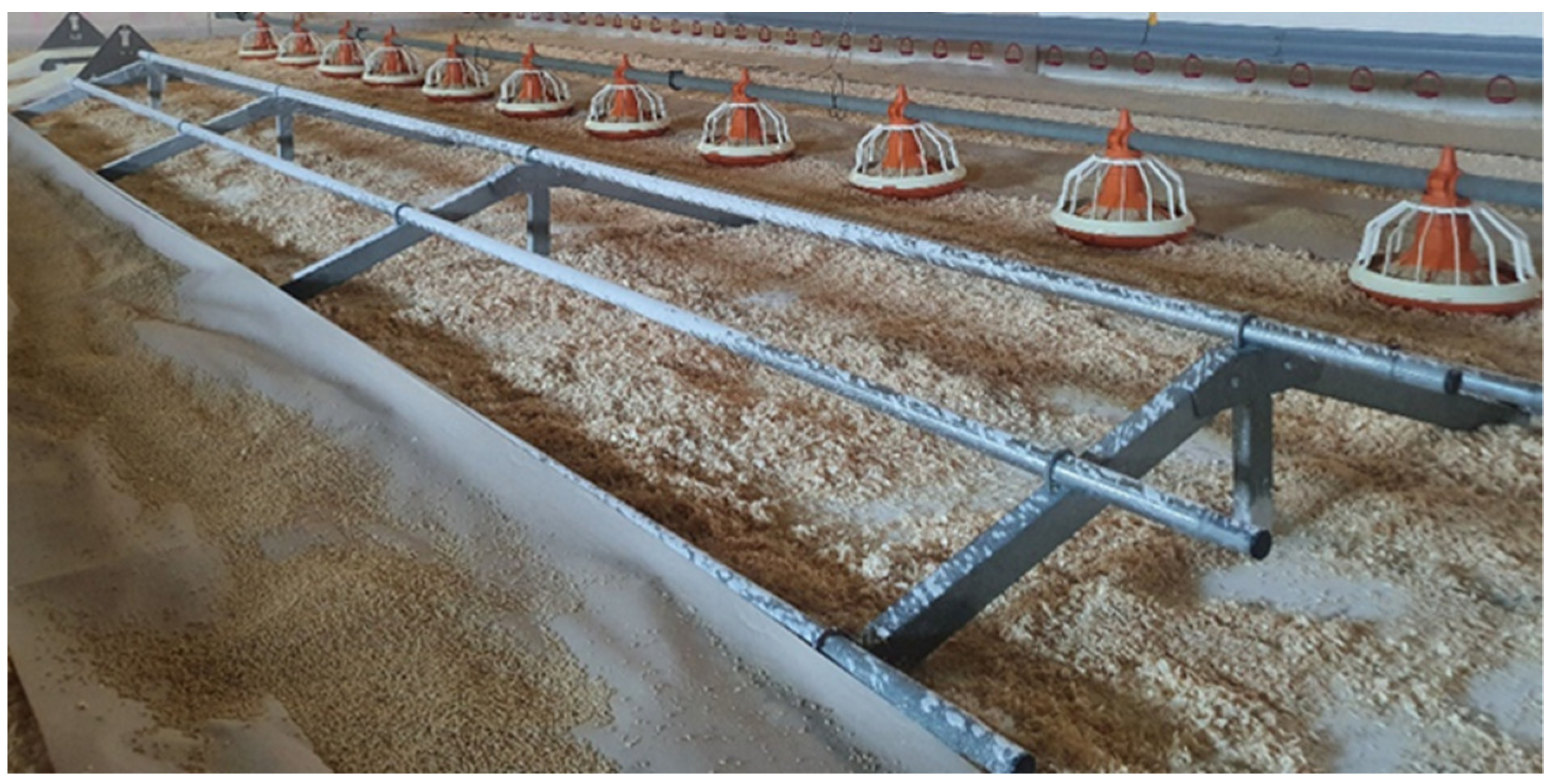

The chicks were housed on a litter composed of conventional wood shavings (GOLDSPAN®, Goldspan GmbH and Co. KG, Goldenstedt, Germany).

The light programme was 24 h light at d 0. At d 1, the light was turned off from 23:00 to 03:00, and at d 2 from 22:00 to 04:00. From d 3 onwards, the dark period was between 21:00 and 05:00. After d 21, the dark period was shortened to the period from 22:00 until 04:00.

The air temperature at d 1 was 33.5 °C and was successively lowered gradually until d 33 to 23 °C. The barn was heated with a gas air-heating system. The air temperature was measured with temperature and humidity sensors, which were used to control the negative pressure ventilation system.

The birds were vaccinated via the drinking water at d 12 against Newcastle Disease (Poulvac ND Hitchner B1; Zoetis Deutschland GmbH, Berlin, Germany), at d 18 against Gumboro (AviPro Precise, Elanco Animal Health, Bad Homburg, Germany) and at d 20 against infectious bronchitis with the virus strain Ma5 (Nobilis IB Ma5, Intervet Deutschland GmbH, Unterschleißheim, Germany).

2.3. Experimental Treats

2.3.1. Environmental Enrichment

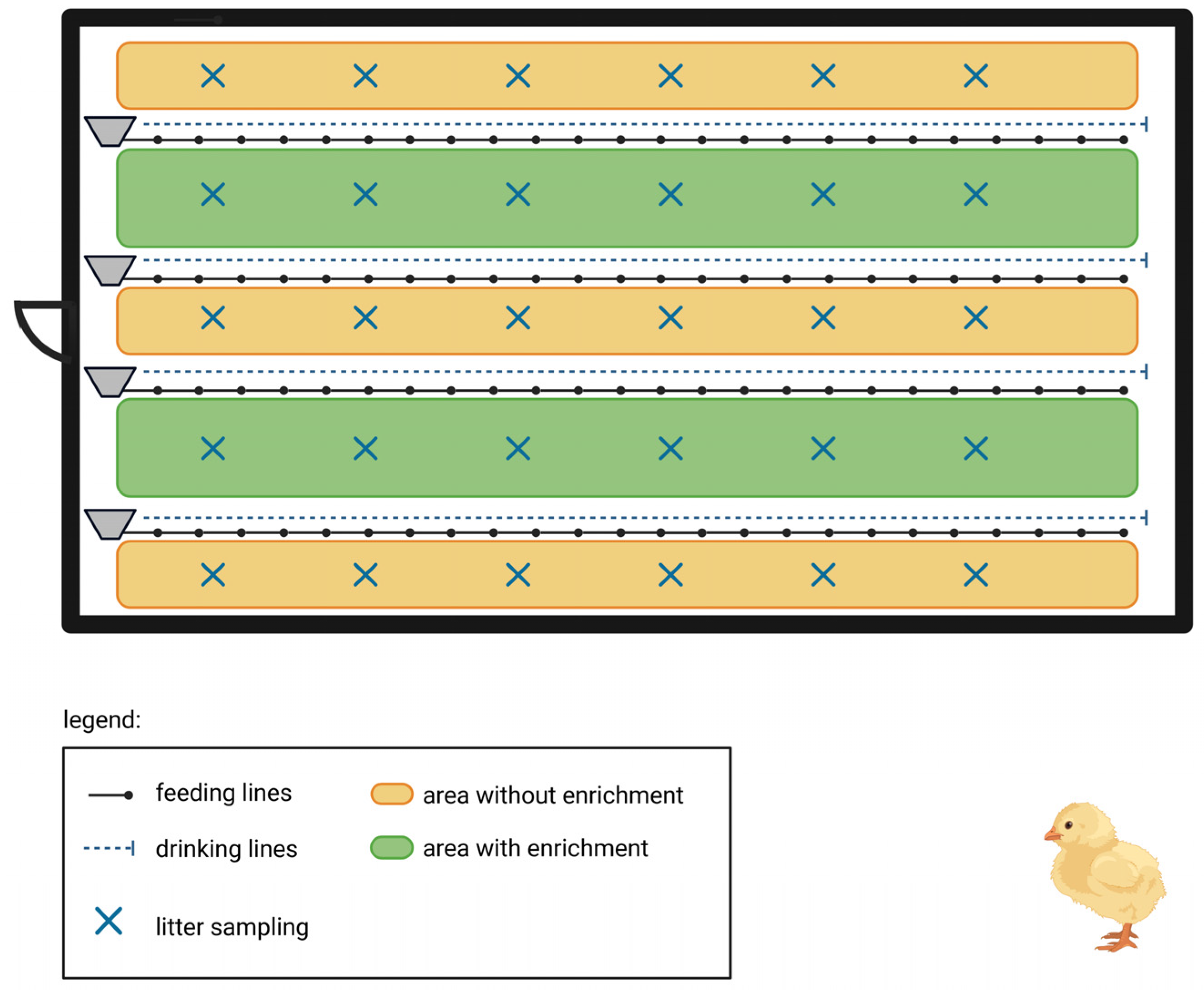

During the trial, three different types of environmental enrichment were used (

Figure 2,

Figure 3 and

Figure 4). The first type was the so-called “A-Reuter” (Big Dutchman International GmbH, Vechta, Germany). It consisted of five round perches made of metal, which were mounted on a triangular framework. The dimensions of the perches and, therefore, the whole construction were 5.60 m long by 1.40 m wide.

The second environmental enrichment used was the “Hybrid” (Hölscher + Leuschner GmbH & Co. Kg, Emsbüren, Germany), which was a combination of perches and elevated planes. It consisted of two elevated planes on each side, which were accessible via two ramps, each on either side. Both were 248 mm wide and 1012 mm long. The planes were connected via three perches, each of which was 1.5 m in length. Two perches were mounted under the planes, leaving a space of 992 mm between the inner edges of the planes. The third perch was mounted above the planes and had a triangular framework to hold it. All perches were aligned at right angles towards the planes. The perches were 52 mm wide and 78 mm high, with a rounded top part.

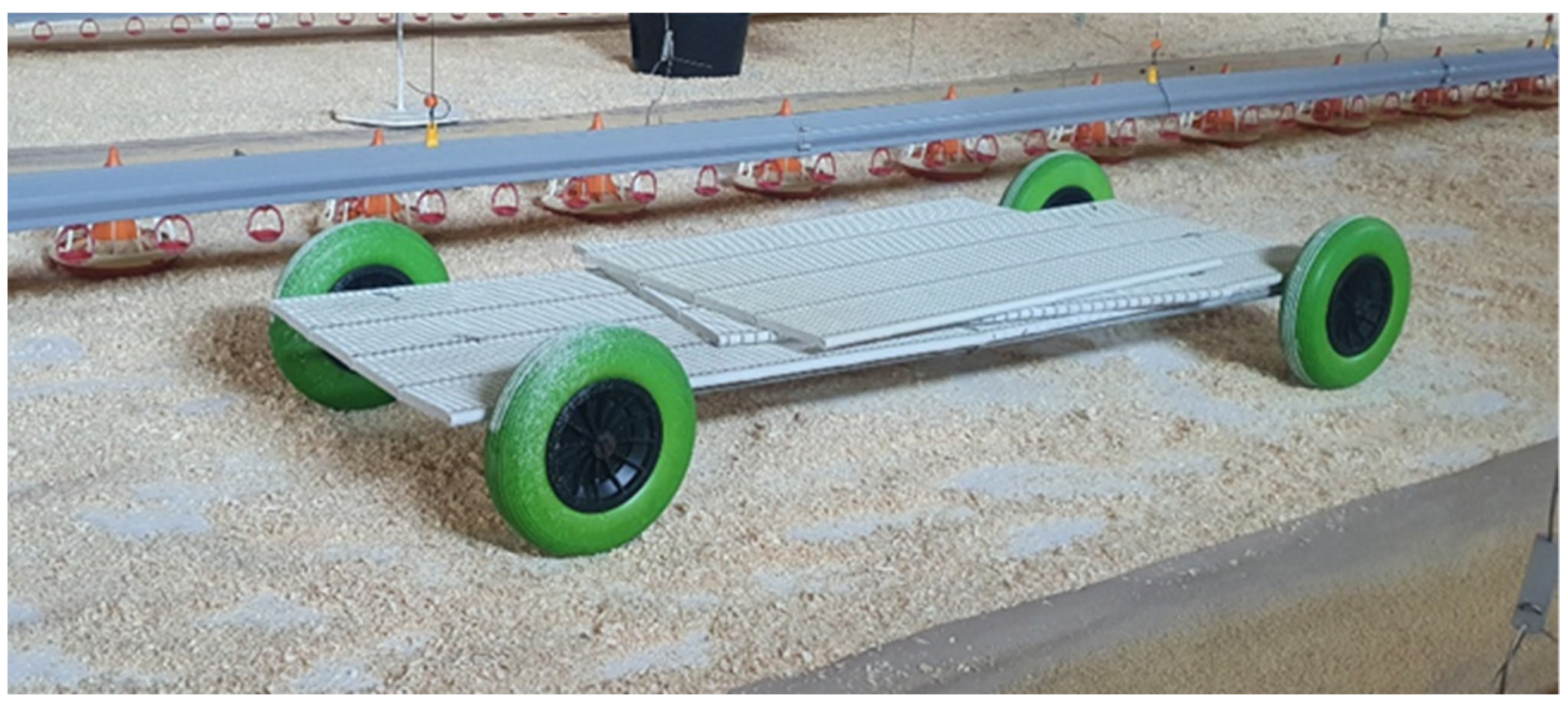

The third environmental enrichment was the “Plateau” as an elevated plane variant. It consisted of two grids mounted on a rectangular framework. The framework was supported by two carriage axles with two tyres each. Each grid had a length of 1.20 m and a width of 0.75 m, making the whole enrichment 2.40 m long. On both of the long sides, there was a ramp, also consisting of one of the grids.

During each trial run, all of the three different environmental enrichments were used and placed in three different positions within the barn: A, B and C. In each of the following trial runs, the positions of the enrichments were changed in a clockwise direction so that A became B, B became C and C became A. This was performed to exclude any negative effects of the positioning.

2.3.2. Farmer-Assistant System

The Farmer-Assistant System (FAS) is a mobile, ceiling-based livestock robot that runs on rails attached to the ceiling of the barn. It consists of top and bottom boxes, which are connected by a telescope arm. The top part contains the battery, the engine, the driving wheels and the top camera, which provides an overview of the stall. The rails allow the robot to permanently circulate through the barn and monitor the broilers continuously. The bottom box is equipped with sensors, which permanently measure air temperature, relative humidity of the air, wind velocity, carbon dioxide (CO2), ammonia (NH3), light and noise 70 cm above the barn floor. It does not influence the behaviour of the birds. The robot delivers climate data for each square metre of the barn. The bottom box also contains one bottom and two side cameras for a more detailed monitoring of the broilers. All data are stored in a protected, cloud-based system mapped across the barn floor and presented to the farmers regularly in a daily report.

2.4. Measurements

2.4.1. Growth Performance and Slaughter Data

Individual bodyweight (BW) of 50 randomly selected birds per barn (for six runs) was measured at d 14, 21 and 28 of life (

Figure 5). Hanging scales (Veit electronics s.r.o., Brno, Czech Republic) were used to record the birds’ weight. At the slaughterhouse, the number of delivered birds was noted as well as their BW. After subtracting the discarded birds, an average slaughter weight was calculated. The slaughterhouse also scored the foot pads via a camera-based system according to the common FPD scoring (QS Qualität und Sicherheit GmbH, Bonn, Germany) at slaughter with scores 0, 1, 2 a and 2 b [

43].

2.4.2. Feed Conversion Ratio

The feed conversion ratio (FCR) was calculated by dividing the feed intake (kg) by the total BW (kg) of all birds for both the control and trial groups. The corrected FCR was calculated by using the corrected feed intake in kg. The corrected feed intake was obtained by subtracting the cumulative feed intake of the dead animals from the total feed intake. The cumulative feed intake of the dead animals was the sum of the daily feed intake of each animal up to the day of slaughter (d 33).

2.4.3. Litter Dry Matter

Litter samples to measure the dry matter (DM) content were collected at d 14, 21 and 28 of life (

Figure 5) from five different rows in each barn (in all six runs). The rows were defined in-between the outside walls and the next drinking line or in the area between feeding and drinking lines (

Figure 1). There were six points of sample collection in each row, resulting in thirty samples for each day. The litter was collected by taking all litter down to the ground with one hand at every spot (50 g). All samples were dried at 103 °C for the time needed to reach a constant weight and, afterwards, the DM was measured.

2.4.4. Foot Pad Dermatitis

The external examination of the foot pads (as an indicator of animal welfare) of the birds was performed for 50 randomly selected birds in each barn in all six runs at d 14, 21 and 28 (

Figure 5). The foot pads were examined for both feet and the FPD score was recorded looking at the central plantar area. To evaluate the FPD scores, a seven-point scale in accordance with Mayne et al. [

44] was used, which is described by

Table 2. Regarding this scoring, score 0 refers to no external signs of FPD. Score 3 marks the point where first necrotic areas may occur and where the central part of the foot pad is swollen, red and harder. The other scores relate, in increasing order, to the size of the necrotic areas up until score 7, which describes a foot pad in which half of it is covered in necrotic scales.

2.4.5. Carbon Dioxide and Ammonia in the Air

Carbon dioxide (CO2) and ammonia (NH3) and the other climate parameters were continuously measured in the air of the barn by the FAS during up to twenty rounds per day on average and for one square metre of the barn floor. Data collection stopped shortly before slaughter, resulting in around 100,000 individual values per run and parameter, in total 2 million pieces of data per day. From these individual values, daily means and weekly means were formed.

2.5. Statistical Analysis

Data analysis was performed using the statistical software package from SAS, Version 7.1 (SAS Inst., Cary, NC, USA). All measured data were analysed descriptively by sample size, mean values, confidence interval, standard deviation, minimum and maximum. The group comparisons as well as the area comparisons were performed by one-way analysis of variance (ANOVA) for independent samples. In general, the Ryan–Einot–Gabriel–Welsch multiple-range test (REGWQ) was used for multiple pairwise means comparisons between the groups. All statements of statistical significance were based on p < 0.05.