Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil

Abstract

:1. Introduction

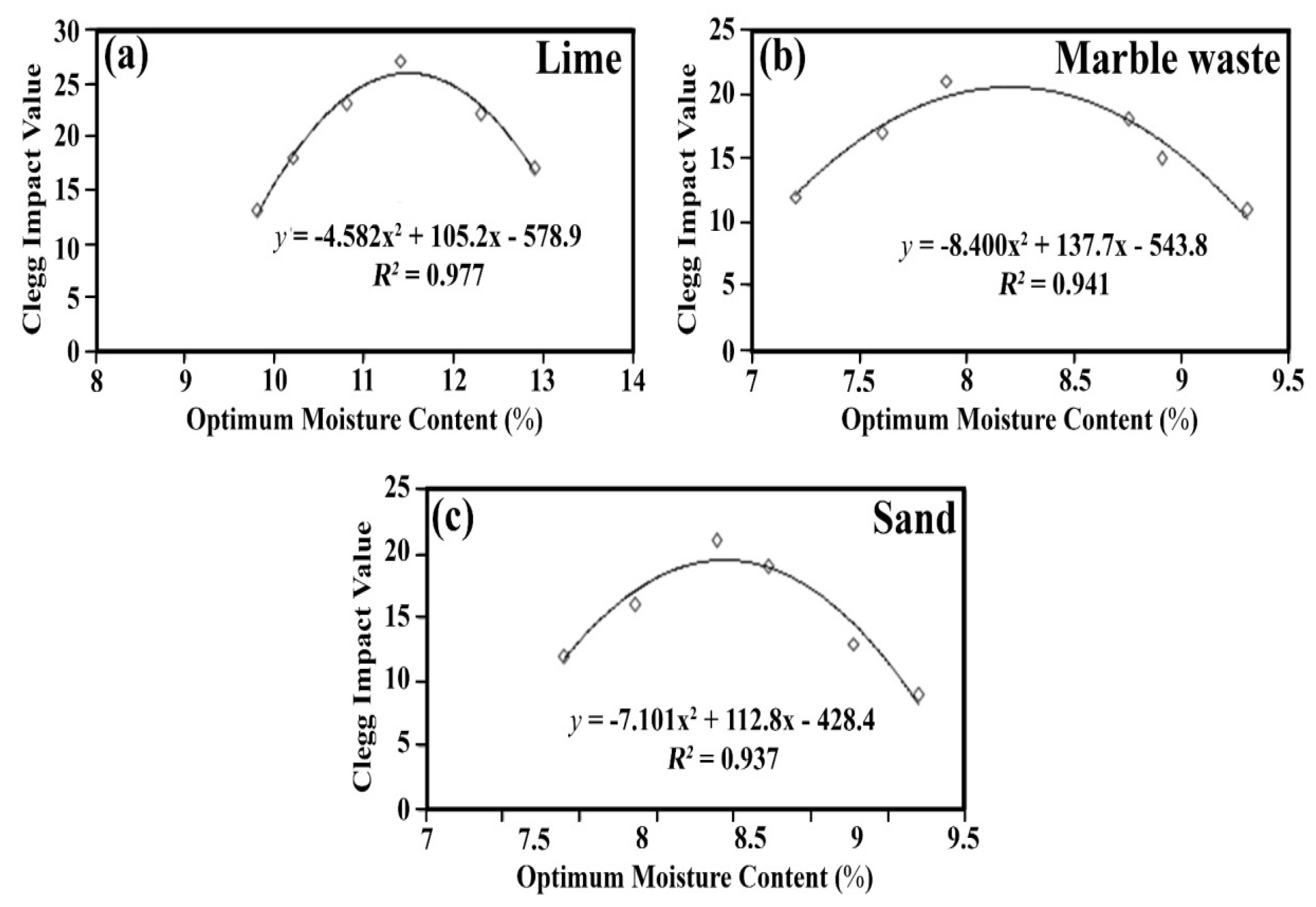

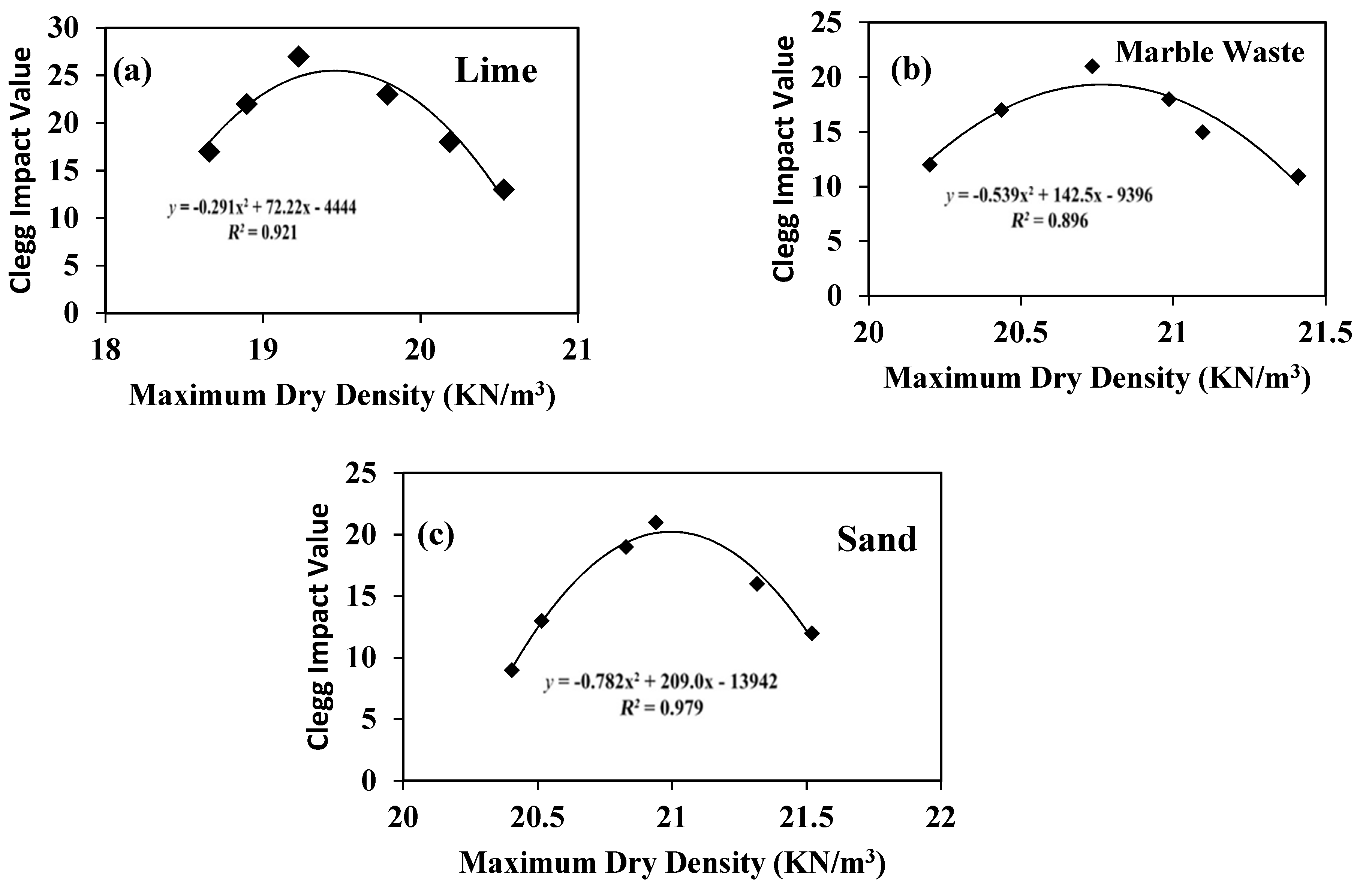

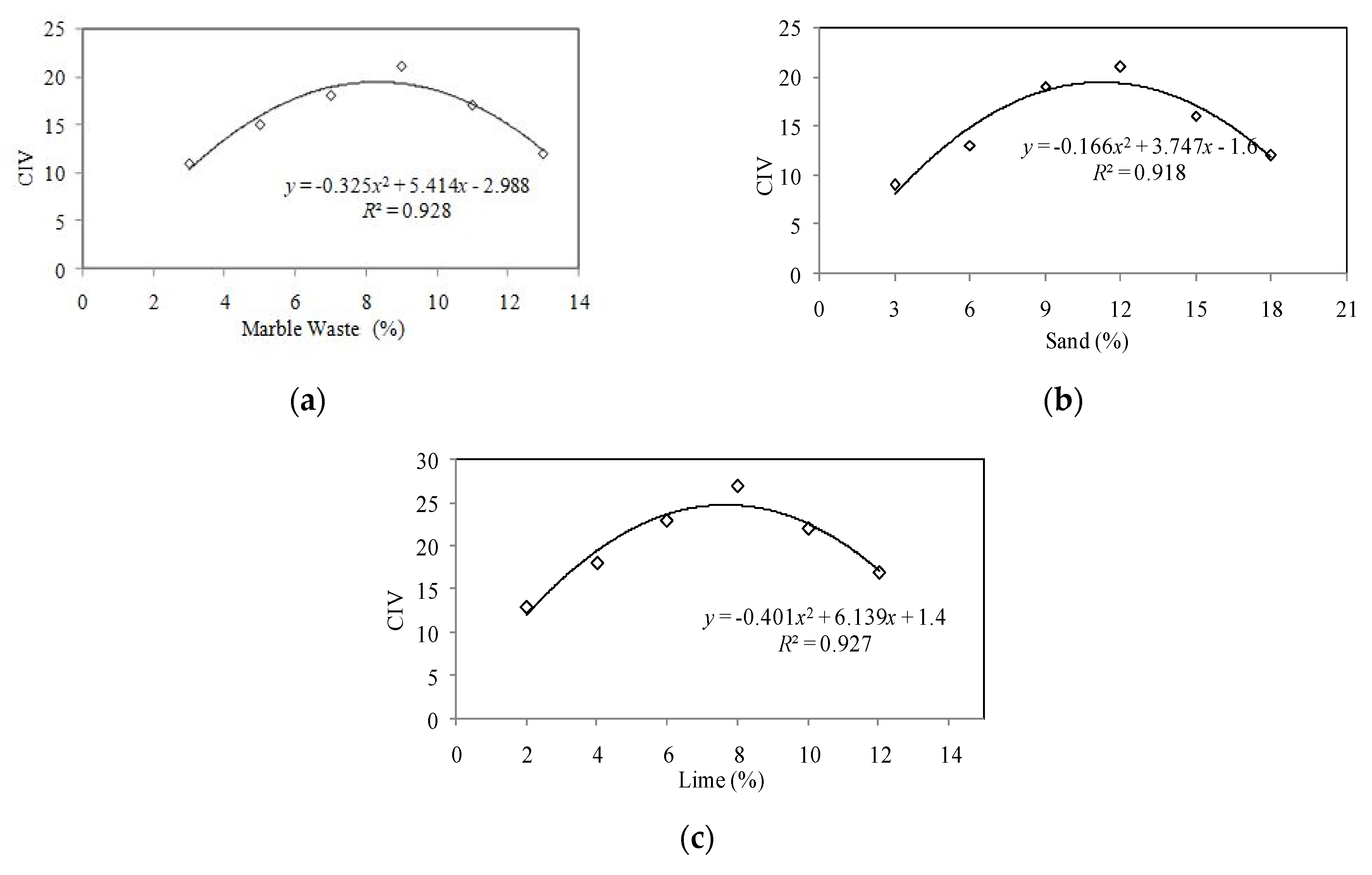

- To study the effect of optimum moisture content, maximum dry density, and different percentages of conventional modifiers on MR and Clegg Impact Value.

- To establish correlation between MR and Clegg Impact Value

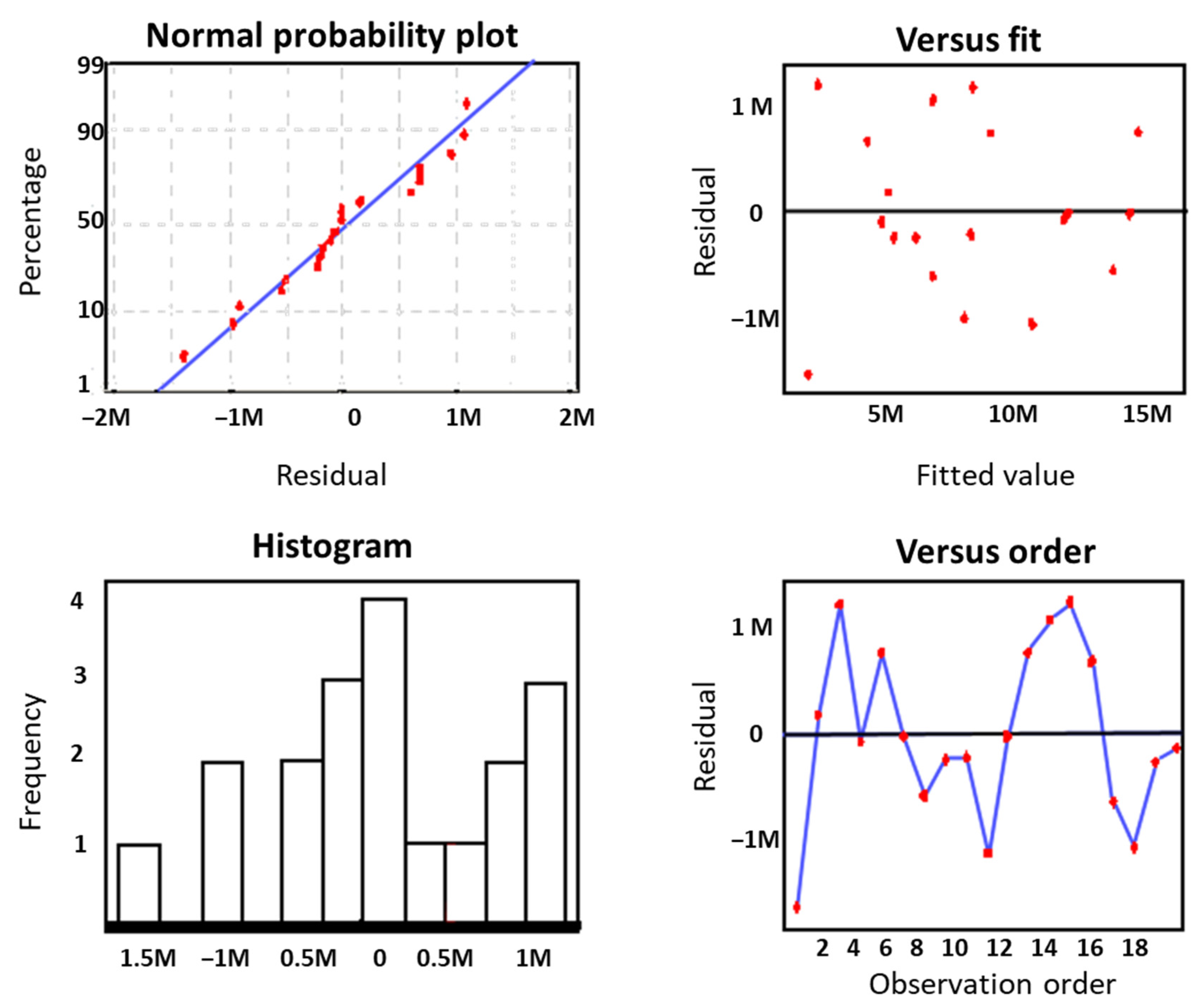

- To develop the regression model between MR and other variables involved in the study.

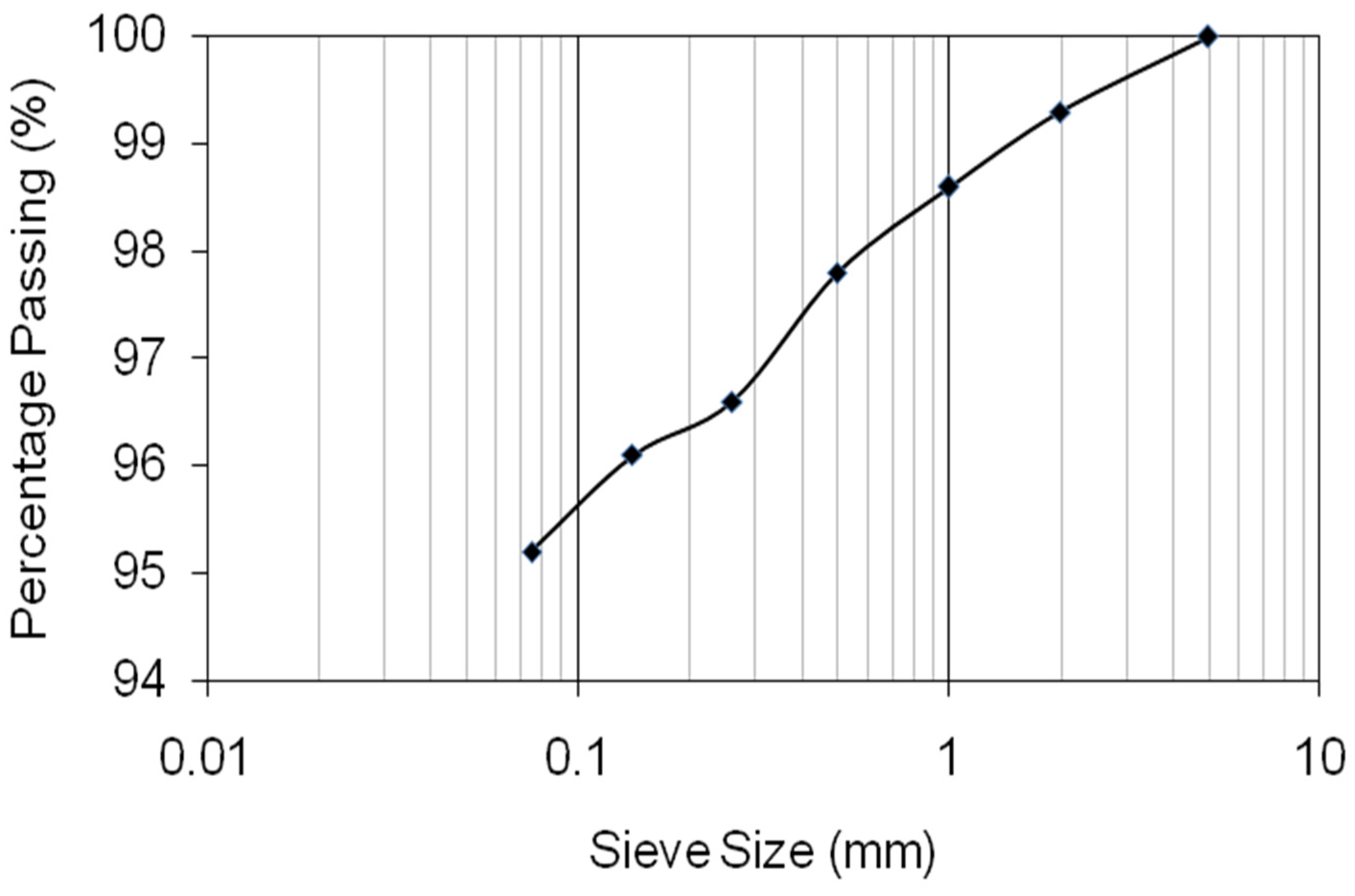

2. Materials and Methods

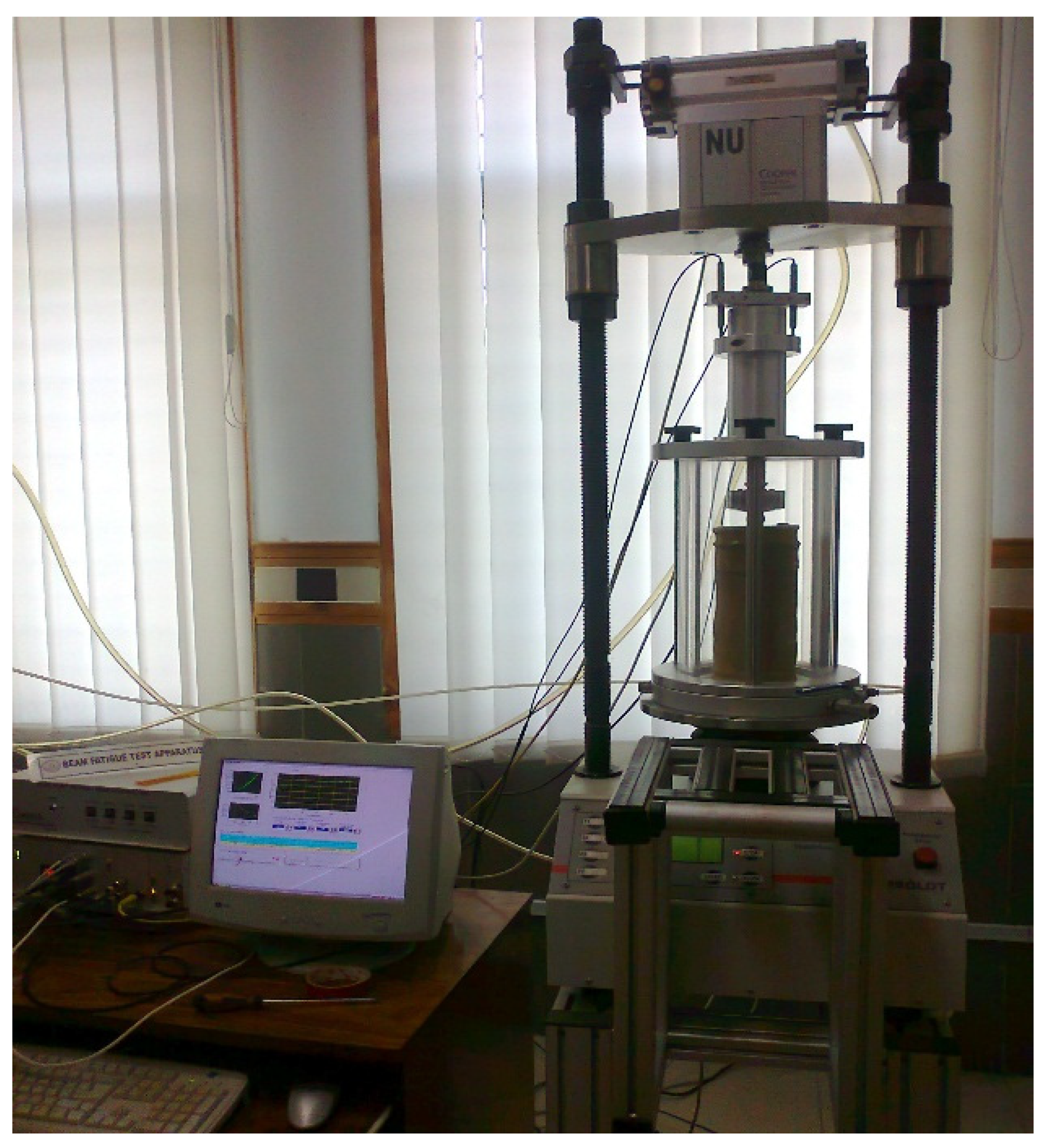

2.1. Assessment of Soil Stiffness

2.2. Data Modeling

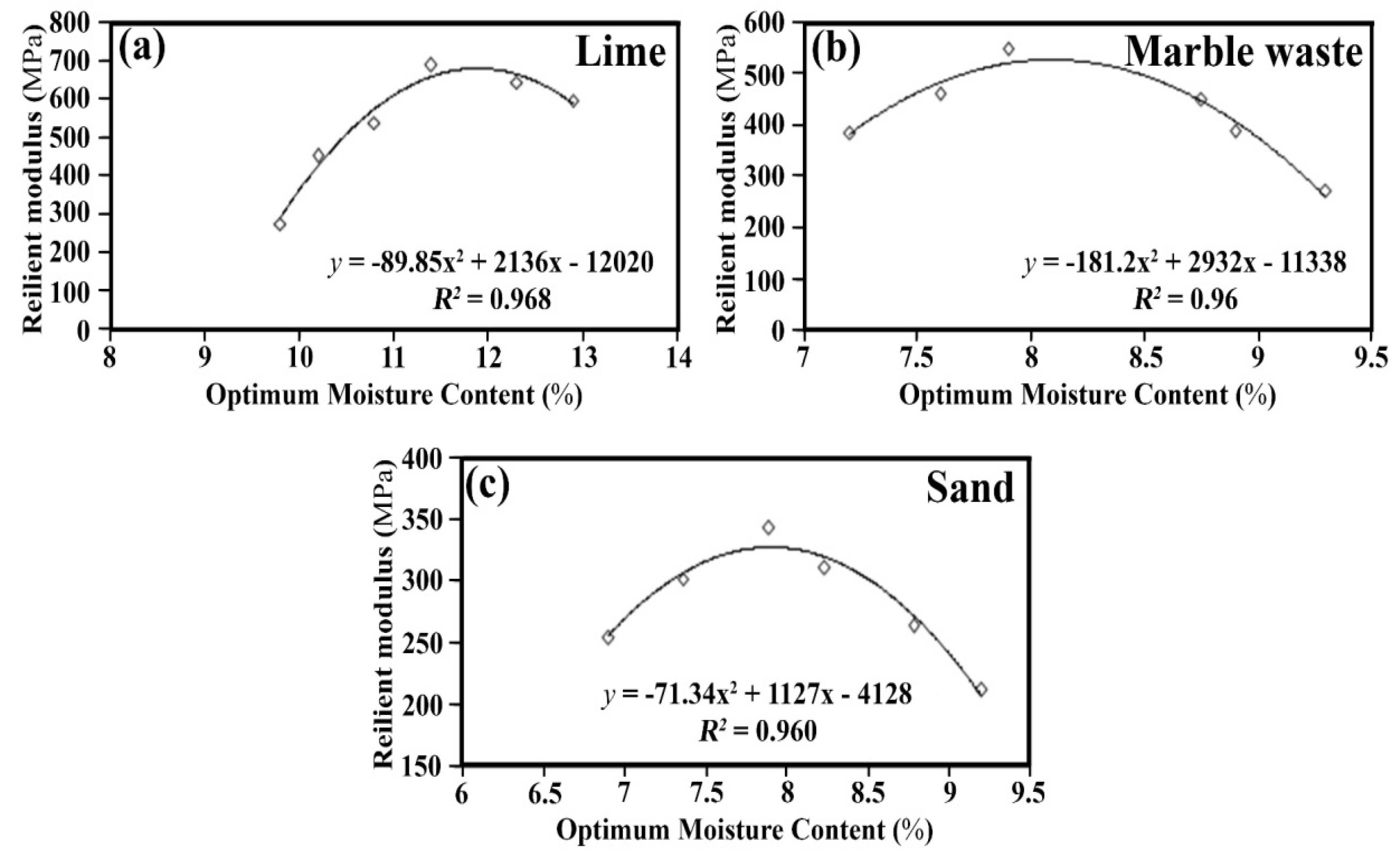

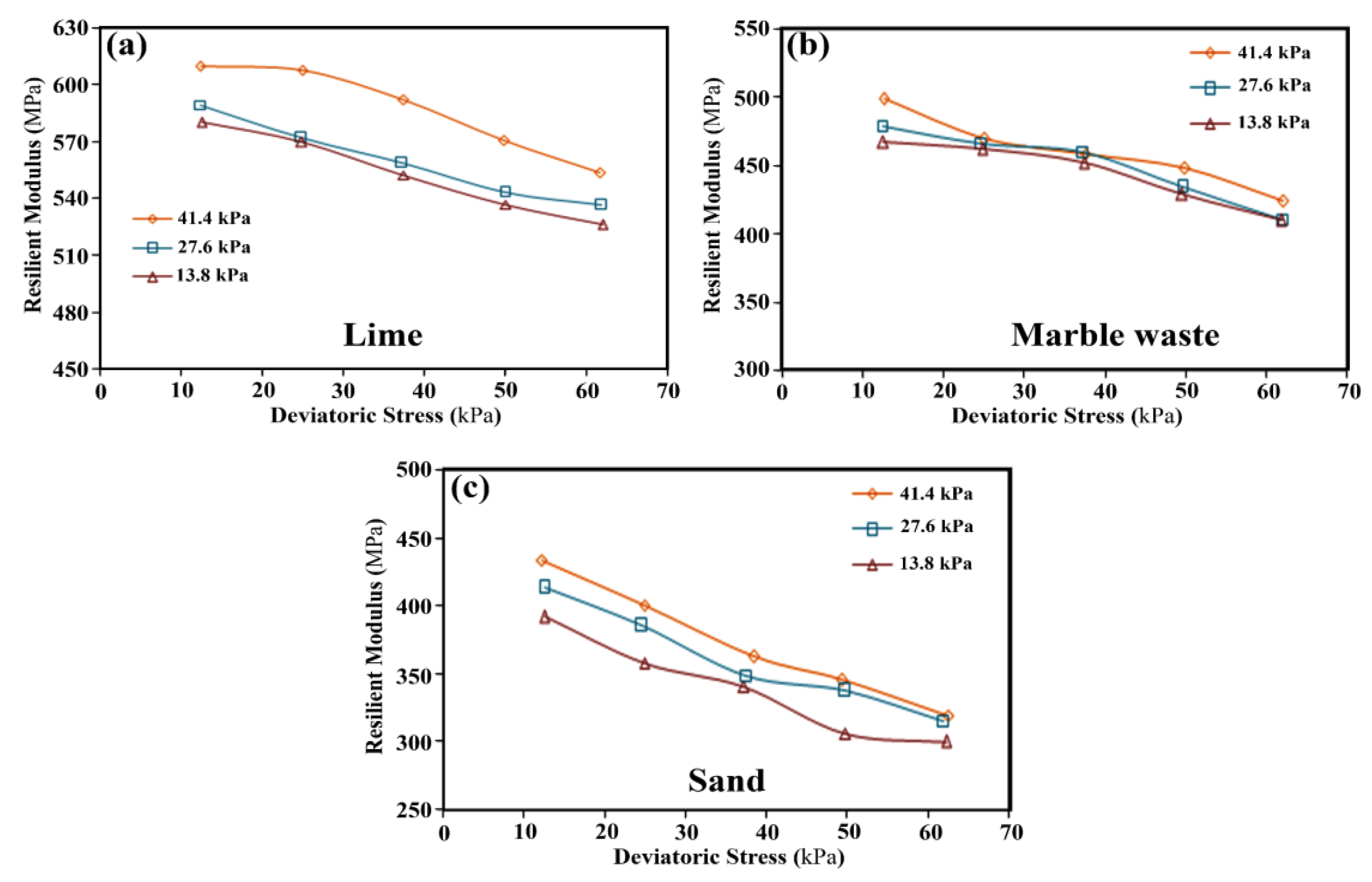

3. Results and Discussion

3.1. Data Modeling

3.2. Regression Model

4. Conclusions

- All of the modifiers improved the stiffness of weak subgrade soil, but lime proved to be the most significant modifier because it improved the stiffness properties better than marble waste and sand.

- It is observed that the increment in percentages of lime and sand caused a drop in the value of maximum dry density of the soil samples, but the increment in marble waste percentage has enhanced the dry density of soil samples up to a certain extent and then decreased afterwards. With increasing the percentage of sand and marble waste, optimum moisture content decreased, but increase in lime percentage has increased the optimum moisture content. This significant increase in moisture content is due to its fineness, so the moisture sensitivity of subgrade soils can be dramatically affected by lime stabilization

- A strong relationship exists (R2 > 0.9) between the MR determined from triaxial testing and CIV from Clegg impact test. The linear regression model shows that MR is a function of CIV, OMC, Filler type and MDD. Moreover, all the predictive techniques forecast the resilient modulus from other test parameters with good accuracy, but local linear regression better estimates the results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuhlman, T.; Farrington, J. What is sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef] [Green Version]

- Teltayev, B.B.; Liu, J.; Suppes, E.A. Distribution of temperature, moisture, stress and strain in the highway Pacпpeдeлeниe тeмпepaтypы, влaжнocти, нaпpяжeний и дeфopмaций в aвтoмoбильнoй дopoгe. Mag. Civ. Eng. 2018, 83, 202–213. [Google Scholar]

- Zhou, C.; Huang, B.; Drumm, E.C.; Shu, X.; Dong, Q.; Udeh, S. Seasonal resilient modulus inputs for Tennessee soils and their effects on asphalt pavement performance. In Proceedings of the Transportation Research Board 92nd Annual Meeting, Washington, DC, USA, 13–17 January 2013. [Google Scholar]

- Sadrossadat, E.; Heidaripanah, A.; Osouli, S. Prediction of the resilient modulus of flexible pavement subgrade soils using adaptive neuro-fuzzy inference systems. Constr. Build. Mater. 2016, 123, 235–247. [Google Scholar] [CrossRef]

- Trivedi, J.S.; Nair, S.; Iyyunni, C. Optimum utilization of fly ash for stabilization of sub-grade soil using genetic algorithm. Procedia Eng. 2013, 51, 250–258. [Google Scholar] [CrossRef] [Green Version]

- Al-Rawas, A.A.; Goosen, M.F.A. Expansive soils: Recent advances in characterization and treatment. Proc. Monogr. Eng. Water Earth Sci. 2006, 130, 391–402. [Google Scholar]

- Шaшкин, К.Г.; Улыбин, А.В. Soil stabilization and foundation restoration using an expandable polyurethane resin Стaбилизaция гpyнтoв и вoccтaнoвлeниe фyндaмeнтa c иcпoльзoвaниeм pacшиpяющeйcя пoлиypeтaнoвoй cмoлы. Mag. Civ. Eng. 2018, 82, 68–80. [Google Scholar]

- Sol-Sánchez, M.; Castro, J.; Ureña, C.G.; Azañón, J.M. Stabilisation of clayey and marly soils using industrial wastes: pH and laser granulometry indicators. Eng. Geol. 2016, 200, 10–17. [Google Scholar] [CrossRef]

- Dimitris, D.; Meng, X.G. Utilization of fly ash for stabilization/solidification of heavy metal contaminated soils. Eng. Geol. 2003, 70, 377–394. [Google Scholar]

- Onyelowe, K.C. Review on the role of solid waste materials in soft soils reengineering. Mater. Sci. Energy Technol. 2019, 2, 46–51. [Google Scholar] [CrossRef]

- Castro-Fresno, D.; Movilla-Quesada, D.; Vega-Zamanillo, Á.; Calzada-Pérez, M.A. Lime Stabilization of bentonite sludge from tunnel boring. Appl. Clay Sci. 2011, 51, 250–257. [Google Scholar] [CrossRef]

- Bekhiti, M.; Trouzine, H.; Rabehi, M. Influence of waste tire rubber fibers on swelling behavior, unconfined compressive strength and ductility of cement stabilized bentonite clay soil. Constr. Build. Mater. 2019, 208, 304–313. [Google Scholar] [CrossRef]

- Singh, K.; Arora, V.K. Stabilization of Plastic Soil using Marble Dust, Rice Husk and Fly Ash. Int. J. Adv. Technol. Eng. Sci. 2019, 5, 276–281. [Google Scholar]

- Yadav, A.K.; Gaurav, K.; Kishor, R.; Suman, S.K. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2017, 10, 254–261. [Google Scholar] [CrossRef]

- Ali, R.; Khan, H.; Shah, A.A. Expansive soil stabilization using marble dust and bagasse ash. J. Sci. Res. 2014, 3, 2812–2816. [Google Scholar]

- Gelsefidi, S.; Alireza, S.; Mohammad, M.S.; Hasan, B.M. Application of nanomaterial to stabilize a weak soil. In Proceedings of the 7th International Conference on Case Histories in Geotechnical Engineering, Chicago, IL, USA, 29 April–4 May 2013; pp. 1–8. [Google Scholar]

- Patel, M.A.; Patel, H.S. A review on effects of stabilizing agents for stabilization of weak soil. Civ. Environ. Res. 2012, 2, 1–7. [Google Scholar]

- Kumar, J.K.; Kumar, V.P. Soil stabilization using E-waste: A retrospective analysis. Mater. Today Proc. 2020, 22, 691–693. [Google Scholar] [CrossRef]

- Solanki, P.; Zaman, M.; Muraleetharan, K.K.; Timm, D. Evaluation of resilient moduli of pavement layers at an instrumented section on I-35 in Oklahoma. Road Mater. Pavement Des. 2009, 10, 167–188. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Leong, M. Resilient moduli of demolition wastes in geothermal pavements: Experimental testing and ANFIS modelling. Transp. Geotech. 2021, 29, 100592. [Google Scholar] [CrossRef]

- Plati, C.; Cliatt, B. A sustainability perspective for unbound reclaimed asphalt pavement (RAP) as a pavement base material. Sustainability 2019, 11, 78. [Google Scholar] [CrossRef] [Green Version]

- Ikeagwuani, C.C.; Nwonu, D.C.; Nweke, C.C. Resilient modulus descriptive analysis and estimation for fine-grained soils using multivariate and machine learning methods. Int. J. Pavement Eng. 2021, 22, 1–16. [Google Scholar] [CrossRef]

- Ghorbani, B.; Yaghoubi, E.; Arulrajah, A. Thermal and mechanical characteristics of recycled concrete aggregates mixed with plastic wastes: Experimental investigation and mathematical modeling. Acta Geotech. 2021, 16, 1–16. [Google Scholar] [CrossRef]

- Nazzal, M.D.; Tatari, O. Evaluating the use of neural networks and genetic algorithms for prediction of subgrade resilient modulus. Int. J. Pavement Eng. 2013, 14, 364–373. [Google Scholar] [CrossRef]

- Al-Joulani, N. Effect of stone powder and lime on strength, compaction and CBR properties of fine soils. Jordan J. Civ. Eng. 2012, 6, 1–16. [Google Scholar]

- Agrawal, V.; Gupta, M. Expansive soil stabilization using marble dust. Int. J. Earth Sci. Eng. 2011, 4, 59–62. [Google Scholar]

- Nazzal, M.D.; Mohammad, L.N. Estimation of resilient modulus of subgrade soils using falling weight deflectometer. Transp. Res. Rec. 2010, 2186, 1–10. [Google Scholar] [CrossRef]

- Ji, R.; Siddiki, N.; Nantung, T.; Kim, D. Evaluation of resilient modulus of subgrade and base materials in Indiana and its implementation in MEPDG. Sci. World J. 2014, 2014, 372838. [Google Scholar] [CrossRef]

- Kim, D.; Kim, J.R. Resilient behavior of compacted subgrade soils under the repeated triaxial test. Constr. Build. Mater. 2007, 21, 1470–1479. [Google Scholar] [CrossRef]

- Oh, J.H.; Fernando, E.G.; Holzschuher, C.; Horhota, D. Comparison of resilient modulus values for Florida flexible mechanistic-empirical pavement design. Int. J. Pavement Eng. 2012, 13, 472–484. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Hago, A.; Al-Sarmi, H. Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. Build. Environ. 2005, 40, 681–687. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Taha, R.; Nelson, J.D.; Beit Al-Shab, T.; Al-Siyabi, H. A comparative evaluation of various additives used in the stabilization of expansive soils. Geotech. Test. J. GTJODJ ASTM 2002, 25, 199–209. [Google Scholar]

- Little, D.N.; Males, E.H.; Prusinski, J.R.; Stewart, B. Cementitious stabilization. In Transportation in the New Millennium: Perspectives from TRB Standing Committees; Committee A2J01; Committee on Cementitious Stabilization. TRB; National Research Council: Washington, DC, USA, 2000. [Google Scholar]

- Prusinski, J.R.; Bhattacharja, S. Effectiveness of portland cement and lime in stabilizing clay soils. In Transportation Research Record 1652; TRB; National Research Council: Washington, DC, USA, 1999; pp. 215–222. [Google Scholar]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Choksi, R.; Mishra, C.; Patel, N. Pursuance of waste marble powder to improve soil stabilization. Int. Res. J. Eng. Technol. 2018, 5, 1695–1698. [Google Scholar]

- Cary, C.E.; Zapata, C.E. Resilient modulus for unsaturated unbound materials. Road Mater. Pavement Des. 2011, 12, 615–638. [Google Scholar] [CrossRef]

- Perry, J.; MacNeil, D.J.; Wilson, P.E. The uses of lime in ground engineering: A review of work undertaken at the Transport Research Laboratory. In Lime Stabilisation: Proceedings of the Seminar Held at Loughborough University Civil & Building Engineering Department on 25 September 1996; Thomas Telford Publishing: London, UK, 1996; pp. 27–45. [Google Scholar]

- Biczysko, S.J. Long-term performance of lime stabilised road subgrade. In Lime Stabilisation: Proceedings of the Seminar Held at Loughborough University Civil & Building Engineering Department on 25 September 1996; Thomas Telford Publishing: London, UK, 1996; pp. 62–74. [Google Scholar]

- Little, D.N. Stabilization of Pavement Subgrades and Base Courses with Lime; Lime Association of Texas: McGregor, TX, USA, 1995. [Google Scholar]

- Sabat, A.K.; Nanda, R.P. Effect of marble dust on strength and durability of Rice husk ash stabilised expansive soil. Int. J. Civ. Struct. Eng. 2011, 1, 939–948. [Google Scholar]

- Bansal, H.; Sidhu, G.S. Influence of Waste Marble Powder on Characteristics of Clayey Soil. Int. J. Sci. Res. 2016, 5, 82–87. [Google Scholar]

- Muthu Kumar, M.; Tamilarasan, V.S. Experimental study on expansive soil with marble powder. Int. J. Eng. Trends Technol. 2015, 22, 504–507. [Google Scholar] [CrossRef]

- Yilmaz, F.; Yurdakul, M. Evaluation of marble dust for soil stabilization. Acta Phys. Pol. A 2017, 132, 710–711. [Google Scholar] [CrossRef]

- Khoury, N.; Brooks, R.; Zaman, M.M.; Khoury, C.N. Variations of resilient modulus of subgrade soils with postcompaction moisture contents. Transp. Res. Rec. 2009, 2101, 72–81. [Google Scholar] [CrossRef]

- Chen, W.-B.; Feng, W.-Q.; Yin, J.-H. Effects of water content on resilient modulus of a granular material with high fines content. Constr. Build. Mater. 2020, 236, 117542. [Google Scholar] [CrossRef]

- Rahman, M.M.; Gassman, S.L. Moisture effect of subgrade resilient modulus on pavement rutting. In Proceedings of the Transportation Research Board 97th Annual Meeting, Washington, DC, USA, 7–11 January 2018. [Google Scholar]

- Velasquez, R.A.; Marasteanu, M.O.; Hozalski, R.M. Investigation of the effectiveness and mechanisms of enzyme products for subgrade stabilization. Int. J. Pavement Eng. 2006, 7, 213–220. [Google Scholar] [CrossRef]

- Moazami, D.; Yusoff, Z.M.; Muni, R.; Hamid, H. Effect of stabilizers on stiffness modulus of soil layers: A review. Int. J. Phys. Sci. 2013, 8, 1602–1610. [Google Scholar]

- Solanki, P.; Khoury, N.N.; Zaman, M.M. Engineering Properties of Stabilized Subgrade Soils for Implementation of the AASHTO 2002 Pavement Design Guide; Federal Highway Administration: Washington, DC, USA, 2009. [Google Scholar]

- Li, D.; Selig, E.T. Resilient modulus for fine-grained subgrade soils. J. Geotech. Eng. 1994, 120, 939–957. [Google Scholar] [CrossRef]

- Fairbrother, S.; McGregor, R.; Aleksandrov, I. Development of a correlation equation between Clegg impact values and california bearing ratio for In-field strength assessment of forest road subgrades. In Proceedings of the 33th Annual Meeting of the Council on Forest Engineering: Fueling the Future, Auburn, AL, USA, 6–9 June 2010. [Google Scholar]

- Gulen, S.; McDaniel, R.S. Use of Clegg Hammer for Compaction Control; The National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1990. [Google Scholar]

- Saberian, M.; Li, J.; Nguyen, B.T.; Setunge, S. Estimating the resilient modulus of crushed recycled pavement materials containing crumb rubber using the Clegg impact value. Resour. Conserv. Recycl. 2019, 141, 301–307. [Google Scholar] [CrossRef]

| Sr. No. | Description | Results |

|---|---|---|

| 1 | Liquid Limit (%) | 26 |

| 2 | Plasticity Index | 11 |

| 3 | Moisture content (%) | 9.4 |

| 4 | Maximum Dry density (g/cc) | 2.13 |

| 5 | Specific gravity | 2.50 |

| Sequence Number | Confining Pressure, σ3 (Pa) | Maximum Axial Stress, σd (kPa) | Cyclic Stress, σcd (kPa) | Contact Stress, σd (kPa) | Number of Load Applications |

|---|---|---|---|---|---|

| Conditioning | 41.37 | 27.58 | 24.82 | 5.51 | 500–1000 |

| 1 | 41.37 | 13.79 | 12.41 | 6.89 | 100 |

| 2 | 41.37 | 27.58 | 24.82 | 1.38 | 100 |

| 3 | 41.37 | 41.37 | 37.23 | 2.75 | 100 |

| 4 | 41.37 | 55.16 | 49.64 | 4.14 | 100 |

| 5 | 41.37 | 68.94 | 62.05 | 5.51 | 100 |

| 6 | 27.58 | 13.79 | 12.41 | 6.89 | 100 |

| 7 | 27.58 | 27.58 | 24.82 | 2.75 | 100 |

| 8 | 27.58 | 41.37 | 37.23 | 4.14 | 100 |

| 9 | 27.58 | 55.16 | 49.64 | 5.51 | 100 |

| 10 | 27.58 | 68.94 | 62.05 | 6.89 | 100 |

| 11 | 13.79 | 13.79 | 12.41 | 1.37 | 100 |

| 12 | 13.79 | 27.58 | 24.82 | 2.75 | 100 |

| 13 | 13.79 | 41.37 | 37.23 | 4.14 | 100 |

| 14 | 13.79 | 55.16 | 49.64 | 5.51 | 100 |

| 15 | 13.79 | 68.95 | 62.05 | 6.89 | 100 |

| Mineral Composition of Clay (A-6) | |

| Mineral | Percentage |

| Illite | 37% |

| Kaolinite | 12% |

| Chlorite | 5% |

| Quartz | 45% |

| Hematite | 6% |

| Mineral Composition of Lime | |

| Mineral | Percentage |

| Calcite | 98.70% |

| Montmorillonite | - |

| Quartz | 1.30 |

| Dolomite | - |

| Mineral Composition of Marble | |

| Mineral | Percentage |

| Illite | 3.2% |

| Calcite | 90.35% |

| Chlorite | 0% |

| Quartz | 0% |

| Dolomite | 2.43% |

| Ankerite | 2.4% |

| Albite | 0.85% |

| Pyrite | 0.08% |

| Mineral Composition of Sand | |

| Mineral | Percentage |

| Calcite | 14.21% |

| Kaolinite | 7.89% |

| Quartz | 21.26% |

| Dolomite | 14.58% |

| Smectite | 9.10% |

| Halite | 7.99% |

| Lime (%) | Marble Waste (%) | Sand (%) |

|---|---|---|

| 2 | 3 | 3 |

| 4 | 5 | 6 |

| 6 | 7 | 9 |

| 8 | 9 | 12 |

| 10 | 11 | 15 |

| 12 | 13 | 18 |

| Lime (%) | Proctor Test | Marble Waste (%) | Proctor Test | Sand (%) | Proctor Test | |||

|---|---|---|---|---|---|---|---|---|

| OMC (%) | MDD (g/cc) | OMC (%) | MDD (g/cc) | OMC (%) | MDD (g/cc) | |||

| 2 | 9.8 | 2.09 | 3 | 9.3 | 2.23 | 3 | 9.2 | 2.08 |

| 4 | 10.2 | 2.06 | 5 | 8.9 | 2.30 | 6 | 8.78 | 2.02 |

| 6 | 10.8 | 2.02 | 7 | 8.75 | 2.30 | 9 | 8.23 | 1.97 |

| 8 | 11.4 | 1.96 | 9 | 7.9 | 2.36 | 12 | 7.89 | 1.92 |

| 10 | 12.3 | 1.92 | 11 | 7.6 | 2.21 | 15 | 7.36 | 1.90 |

| 12 | 12.9 | 1.90 | 13 | 7.2 | 2.20 | 18 | 6.9 | 1.89 |

| Parameters and Their Effects | Result Obtained from This Research | Justified from Previous Research |

|---|---|---|

| Effect of additives on OMC and MDD | OMC shows the same trend for marble waste and sand modifier; as the percentage of modifier increases, OMC tends to decrease. In case of waste lime, increase in modifier percentage causes an increase in OMC, whereas MDD decreases. MDD in case of marble waste increases up to a certain level and then decreases afterwards. For lime and sand, MDD decreases with increase in percentage of respective modifier. | Same effect on the OMC and MDD has been observed [41,42,43,44]. |

| Effect of Maximum Dry Density on Resilient Modulus | The MR values with lower water content higherthan those with high water contents. | The peak value of both CBR and MR was found on the dry side of optimum and at a dry density less than the maximum. Subgrade soil moisture condition has shown less significant influence on subgrade rutting if stabilized aggregate base layer is used instead of untreated granular base [45,46,47]. |

| Effect of Percentage Modifier on Resilient Modulus | The modifiers improved the stiffness of the soil up to a certain level. | The soil clay content and percent of fines appear to play an important role in the effectiveness of enzyme-based stabilizer treatment. The limited effectiveness of enzyme (for low clay content soil) appears to be due to its surfactant-like characteristics [48]. The research works [49,50] evaluated the effectiveness of different percentages of hydrated lime, class C fly ash (CFA), and cement kiln dust (CKD) as soil stabilizers. The CKD-stabilized specimens exhibited a higher increase in MR, and UCS values than the corresponding values of lime- and CFA-stabilized Specimens |

| Effect of deviatoric stress on Resilient Modulus | The relationship follows the ideal trends in case of all the three different confining pressures (decrease with increase in deviatoric stress). | MR decrease firstly and then remains constant with increasing the deviatoric stress [51]. MR decrease firstly and then increases with increasing the deviatoric stress. The effect of stress state is determined by equations relating resilient modulus at optimum moisture content to deviator stress so that the equation parameters represent the effect of soil type and its structure [46] |

| Effect of Maximum Dry Density Content on CIV | CIV and MDD values increased up to certainlevel and then CIV decreased while MDD goes increasing for further addition of modifier | Same trend has been observed for the analysis indicates a relatively strong correlation between CIV and CBR for forest subgrade soils [52]. Clayey and excessively wet soils have a significant negative impact on the correlation [53] |

| Effect of Concentration of Modifiers on CIV | It can be observed that impact value reaches its maximum by adding the modifier but onfurther addition, it reduces the strength | MR values are dependent of deviator and confining pressure, so in order to develop a relationship between the CIV and MR, resilient modulus should be written in the form of these stresses. Amount and size of the aggregates have remarkable effect of the resilient modulus. Fine additives can act as filler and damper to provide better interfacial bonding. Increase in the fine modifiers increases both CIV and MR values [54] |

| Filler Type | % Filler | MR (MPa) Measured in Lab | MR (MPa) Computed from Minitab Equation |

|---|---|---|---|

| Lime | 2 | 275.12 | 267.98 |

| 4 | 450.09 | 399.55 | |

| 6 | 537.27 | 540.64 | |

| 8 | 687.43 | 655.75 | |

| 10 | 642.62 | 643.47 | |

| 12 | 594.35 | 618.1 | |

| Marble Waste | 3 | 270.09 | 280.19 |

| 5 | 388.09 | 397.05 | |

| 7 | 447.57 | 493.73 | |

| 9 | 546.35 | 547.11 | |

| 11 | 459.15 | 427.43 | |

| 13 | 384.25 | 338.83 | |

| Sand | 3 | 212.06 | 160.33 |

| 6 | 264.25 | 235.41 | |

| 9 | 310.67 | 336.86 | |

| 12 | 342.78 | 386.5 | |

| 15 | 301.86 | 312.99 | |

| 18 | 254.41 | 259.51 |

| Filler Type | % Filler | MR (MPa) Calculated in Lab | MR (MPa) Computed from Regression Model |

|---|---|---|---|

| Lime | 2 | 275.12 | 314.46 |

| 4 | 450.09 | 438.26 | |

| 6 | 537.27 | 562.75 | |

| 8 | 687.43 | 662.74 | |

| 10 | 642.62 | 537.80 | |

| 12 | 594.35 | 413.44 | |

| Marble Waste | 3 | 270.09 | 265.20 |

| 5 | 388.09 | 363.88 | |

| 7 | 447.57 | 438.26 | |

| 9 | 546.35 | 512.88 | |

| 11 | 459.15 | 413.44 | |

| 13 | 384.25 | 289.81 | |

| Sand | 3 | 212.06 | 216.11 |

| 6 | 264.25 | 314.46 | |

| 9 | 310.67 | 463.10 | |

| 12 | 342.78 | 512.88 | |

| 15 | 301.86 | 388.64 | |

| 18 | 254.41 | 289.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaffar, S.T.A.; Muneeb Abid, M.; Khan, S.Z.; Jafri, T.; Rehman, Z.U.; Tariq, M.A.U.R.; Ng, A.W.M. Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil. Sustainability 2022, 14, 2493. https://doi.org/10.3390/su14052493

Jaffar STA, Muneeb Abid M, Khan SZ, Jafri T, Rehman ZU, Tariq MAUR, Ng AWM. Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil. Sustainability. 2022; 14(5):2493. https://doi.org/10.3390/su14052493

Chicago/Turabian StyleJaffar, Syed Taseer Abbas, Malik Muneeb Abid, Sikander Zaman Khan, Turab Jafri, Zia Ur Rehman, Muhammad Atiq Ur Rehman Tariq, and Anne W. M. Ng. 2022. "Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil" Sustainability 14, no. 5: 2493. https://doi.org/10.3390/su14052493

APA StyleJaffar, S. T. A., Muneeb Abid, M., Khan, S. Z., Jafri, T., Rehman, Z. U., Tariq, M. A. U. R., & Ng, A. W. M. (2022). Evaluation of Conventional and Sustainable Modifiers to Improve the Stiffness Behavior of Weak Sub-Grade Soil. Sustainability, 14(5), 2493. https://doi.org/10.3390/su14052493