Pellets from Lignocellulosic Material Obtained from Pruning Guava Trees: Characterization, Energy Performance and Emissions

Abstract

1. Introduction

2. Materials and Methods

2.1. Collection and Availability of Biomass

2.2. Material Preparation

2.3. Physical and Chemical Characterization of Biomass

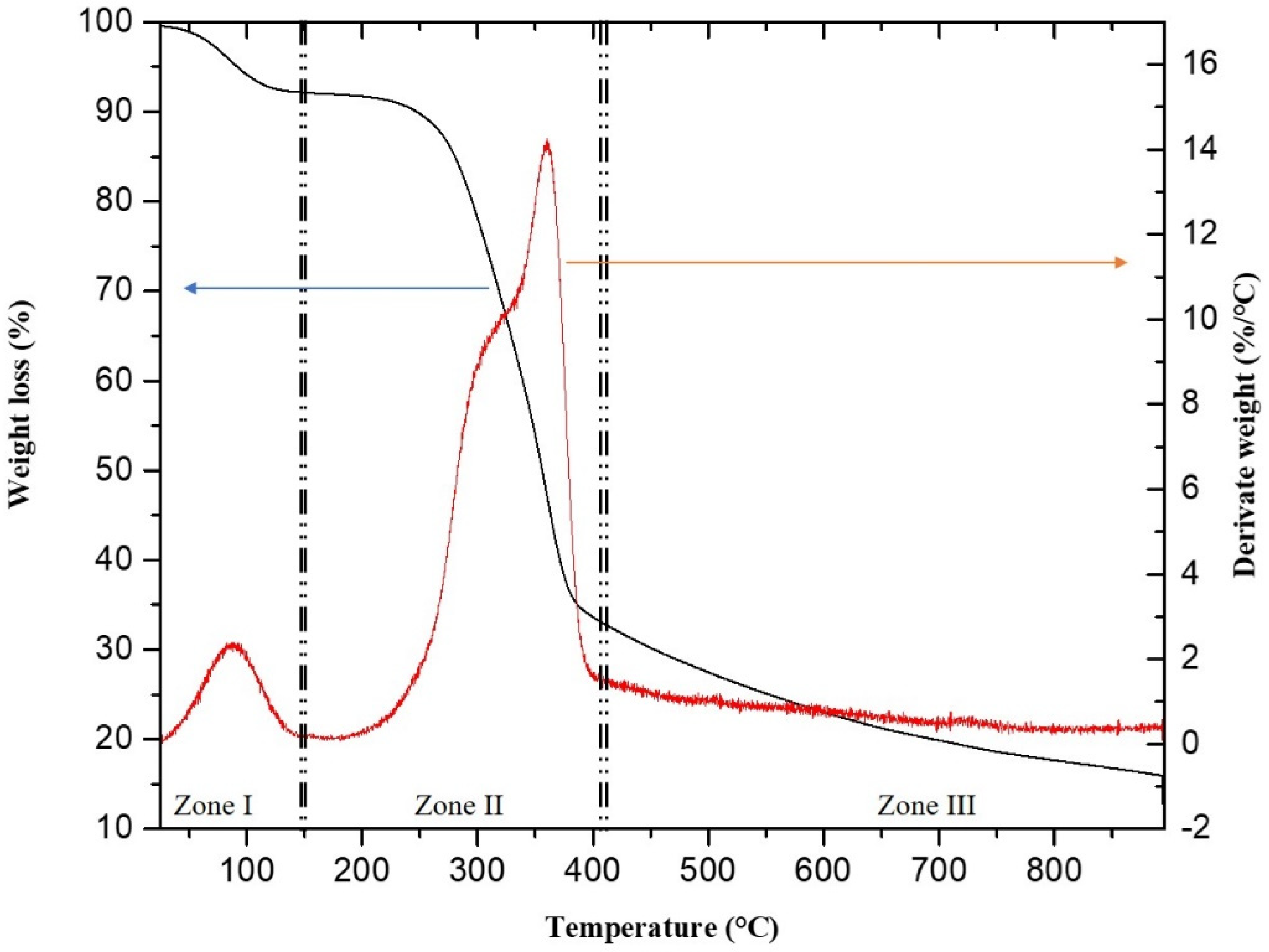

2.4. Thermogravimetric Analysis

2.5. Manufacture and Characterization of Pellets

2.6. Energy Performance and Greenhouse Gases Produced by the Combustion of Pellets

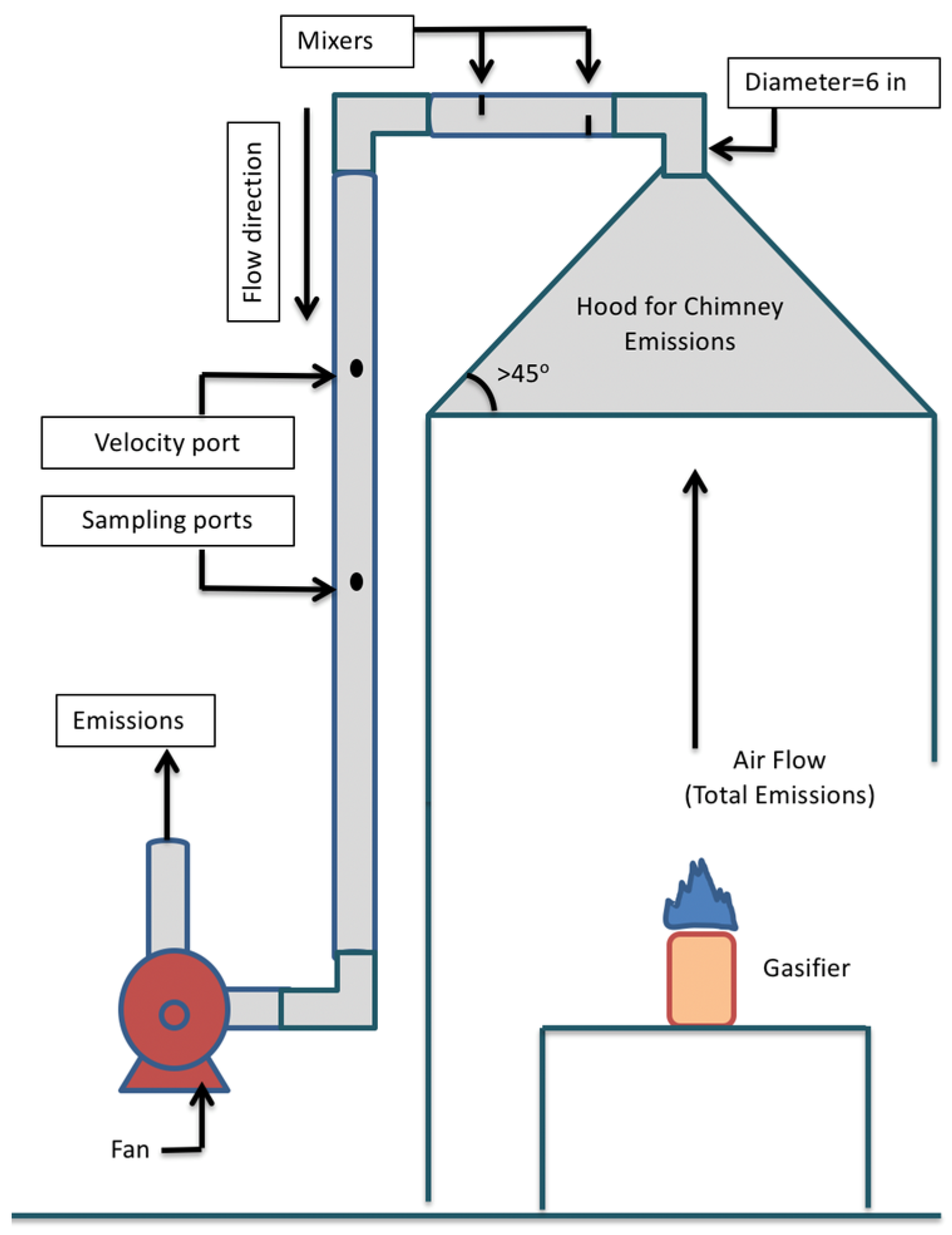

2.6.1. Particulate Matter

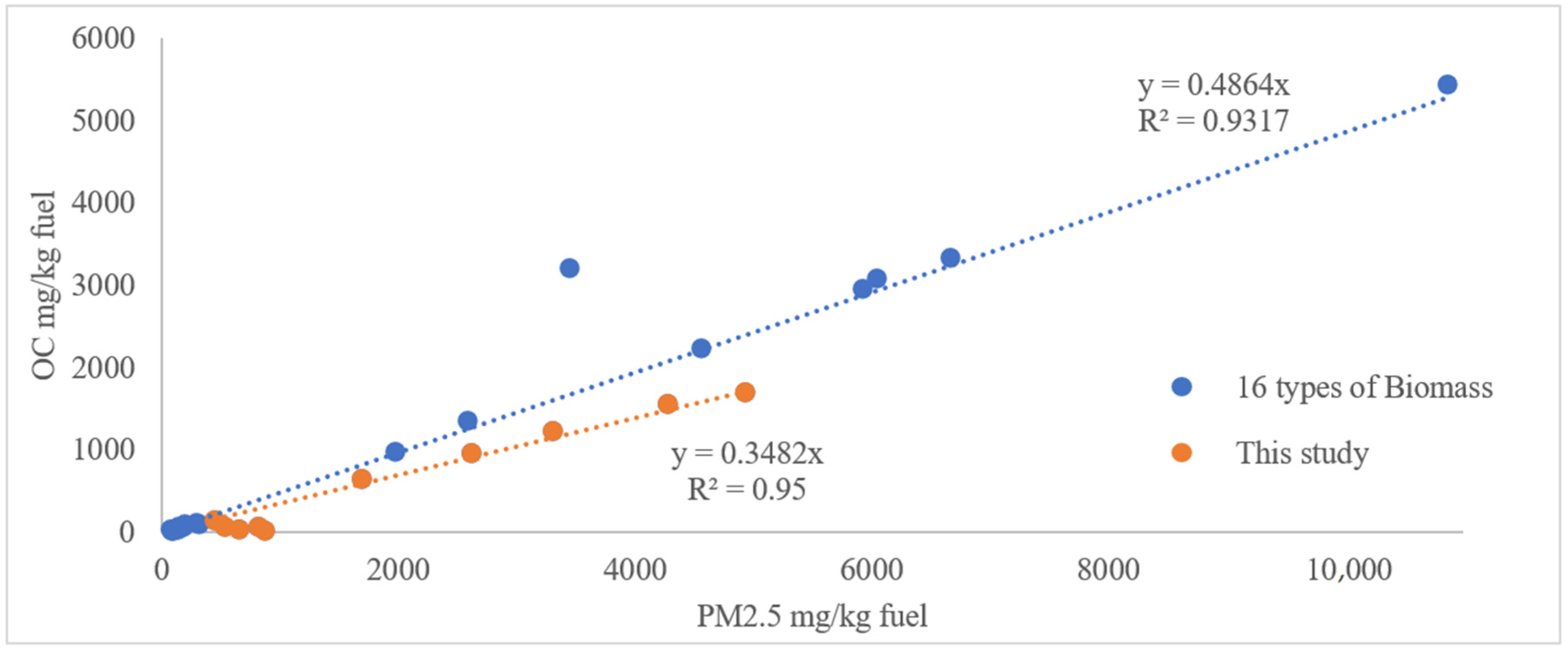

2.6.2. Organic and Elemental Carbon

2.6.3. Carbon Monoxide and Dioxide

2.6.4. Methane and Short Chain Hydrocarbons

3. Results and Discussion

3.1. Applied Survey

3.2. Characterization of Selected Biomass Samples

3.2.1. Moisture Content

3.2.2. Chemical Analysis

3.2.3. Proximate Analysis

3.2.4. Ultimate Analysis

3.2.5. Ash Microanalysis

3.3. Thermal Behavior: TGA and DTG Analysis

3.4. Characterization of Pellets Samples

3.4.1. Moisture Content

3.4.2. Particle Density

3.4.3. Bulk Density

3.4.4. Impact Resistance

3.4.5. Heating Value

3.5. Energy Performance and Greenhouse Gases Produced by the Combustion of Pellets

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García, C.A.; Riegelhaupt, E.; Masera, O. Introducción. In Estado del Arte de la Bioenergía en México, Red Temática de Bioenergía (RTB) del CONACYT; García-Bustamante, C.A., Masera, O., Eds.; Imagia Comunicación: Guadalajara, Mexico, 2016; pp. 9–14. [Google Scholar]

- Sovacool, B.K. How long will it take? Conceptualizing the temporal dynamics of energy transitions. Energy Res. Soc. Sci. 2016, 13, 202–215. [Google Scholar] [CrossRef]

- Burke, M.J.; Stephens, J. Energy democracy: Goals and policy instruments for sociotechnical transitions. Energy Res. Soc. Sci. 2017, 33, 35–48. [Google Scholar] [CrossRef]

- Hernández, J.C.A. Ley de Transición Energética, México. 2015. Available online: http://bibliodigitalibd.senado.gob.mx/handle/123456789/2315 (accessed on 26 January 2021).

- Rennkamp, B.; Haunss, S.; Wongsa, K.; Ortega, A.; Casamadrid, E. Competing coalitions: The politics of renewable energy and fossil fuels in Mexico, South Africa and Thailand. Energy Res. Soc. Sci. 2017, 34, 214–223. [Google Scholar] [CrossRef]

- Moran, P.; Goggins, J.; Hajdukiewicz, M. Super-insulate or use renewable technology? Life cycle cost, energy and global warming potential analysis of nearly zero energy buildings (NZEB) in a temperate oceanic climate. Energy Build. 2017, 139, 590–607. [Google Scholar] [CrossRef]

- Wang, C.; Chang, Y.; Zhang, L.; Pang, M.; Hao, Y. A life-cycle comparison of the energy, environmental and economic impacts of coal versus wood pellets for generating heat in China. Energy 2017, 120, 374–384. [Google Scholar] [CrossRef]

- Van Dael, M.; Lizin, S.; Swinnen, G.; Van Passel, S. Young people’s acceptance of bioenergy and the influence of attitude strength on information provision. Renew. Energy 2017, 107, 417–430. [Google Scholar] [CrossRef]

- González-Velasco, J. Energías Renovables; Editorial Reverté: Barcelona, Spain, 2009. [Google Scholar]

- Velázquez-Martí, B. Aprovechamiento de la Biomasa para uso Energético, 2nd ed.; Editorial Reverté: Barcelona, Spain, 2018. [Google Scholar]

- Sovacool, B.K.; Bergman, N.; Hopkins, D.; Jenkins, K.E.; Hielscher, S.; Goldthau, A.; Brossmann, B. Imagining sustainable energy and mobility transitions: Valence, temporality, and radicalism in 38 visions of a low-carbon future. Soc. Stud. Sci. 2020, 50, 642–679. [Google Scholar] [CrossRef]

- SENER. Balance Nacional de Energía 2018. 2019. Available online: https://www.gob.mx/cms/uploads/attachment/file/528054/Balance_Nacional_de_Energ_a_2018.pdf) (accessed on 28 May 2020).

- Riegelhaupt, E. Biocombustibles sólidos. In Estado del Arte de la Bioenergía en México, Red Temática de Bioenergía (RTB) del CONACYT; García-Bustamante, C.A., Masera, O., Eds.; Imagia Comunicación: Guadalajara, Mexico, 2016; pp. 23–33. [Google Scholar]

- SIAP. El Poder de la Guayaba. 2019. Available online: http://www.gob.mx/siap/articulos/el-poder-de-la-guayaba (accessed on 11 May 2021).

- PFC. Guayaba. Rica en Sabor y Propiedades. 2020. Available online: http://www.gob.mx/profeco/articulos/guayaba-rica-en-sabor-y-propiedades?idiom=es (accessed on 11 May 2021).

- Damián-Nava, A.; González-Hernández, V.A.; Sánchez-García, P.; Peña-Valdivia, C.B.; Livera-Muñoz, M.; Brito-Guadarrama, T. Crecimiento y fenología del Guayabo (Psidium guajava L.) cv. “Media-china” en Iguala, Guerrero. Rev. Fitotecn. Mex. 2004, 4, 349–358. [Google Scholar]

- González-Gaona, E.; Padilla-Ramírez, J.S.; Reyes-Muro, L.; Perales-de la Cruz, M.A.; Esquivel-Villagrana, F. Guayaba su Cultivo en México. Libro Técnico No 1; Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias, Centro de Investigación Regional Norte Centro, Campo Experimental Pabellón: México, Mexico, 2002.

- Rahim, N.; Gomes, D.J.; Watanabe, H.; Rahman, S.R.; Chomvarin, C.; Endtz, H.P.; Alam, M. Antibacterial activity of Psidium guajava leaf and bark against multidrug-resistant Vibrio cholerae: Implication for cholera control. Jpn. J. Infect. Dis. 2010, 63, 271–274. [Google Scholar]

- Dakappa, S.S.; Adhikari, R.; Timilsina, S.S.; Sajjekhan, S. A review on the medicinal plant Psidium guajava Linn. (myrtaceae). J. Drug Deliv. Ther. 2013, 3, 162–168. [Google Scholar] [CrossRef]

- Braga, T.V.; das Dores, R.G.R.; Ramos, C.S.; Evangelista, F.C.G.; Tinoco, L.M.D.S.; Varotti, F.D.P.; Carvalho, M.D.G.; Sabino, A.D.P. Antioxidant, Antibacterial and Antitumor Activity of Ethanolic Extract of the Psidium guajava Leaves. Am. J. Plant Sci. 2014, 5, 3492–3500. [Google Scholar] [CrossRef]

- Camarena-Tello, J.C.; Rocha-Guzmán, N.E.; Gallegos-Infante, J.A.; González-Laredo, R.F.; Pedraza-Bucio, F.E.; López-Albarrán, P.; Herrera-Bucio, R.; Rutiaga-Quiñones, J.G. Chemical composition of biomass generated in the guava tree pruning. EXCLI J. 2015, 14, 204–212. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Jiménez, M.R.; Rocha-Guzmán, N.E.; Rutiaga-Quiñones, J.G.; Medrano-Núñez, D.; Rojas-Contreras, J.A.; González-Laredo, R.F.; Gallegos-Infante, J.A. Polyphenolic Profile, Sugar Consumption and Organic Acids Generation along Fermentation of Infusions from Guava (Pisidium guajava) by the Kombucha Consortium. Recent Res. Sci. Technol. 2018, 10, 16–22. [Google Scholar] [CrossRef][Green Version]

- You, D.-H.; Park, J.-W.; Yuk, H.-G.; Lee, S.-C. Antioxidant and tyrosinase inhibitory activities of different parts of guava (Psidium guajava L.). Food Sci. Biotechnol. 2011, 20, 1095–1100. [Google Scholar] [CrossRef]

- Hindi, S.S.Z. Contribution of Parent Wood to the Final Properties of the Carbonaceous Skeleton via Pyrolysis. Int. J. Sci. Eng. Investig. 2012, 1, 9–12. [Google Scholar]

- Ibe, C.; Jacobs, C.C.; Imo, C.; Osuocha, K.U.; Okoronkwo, M.U. Evaluation of the Antioxidant Activities of Psidium guajava and Aloe vera. Br. J. Pharm. Res. 2014, 4, 397–406. [Google Scholar] [CrossRef]

- Lucas, E.; Olorunnisola, A.; Adewole, N. Preliminary Evaluation of Guava (Psidium guajava L.) Tree Branches for Truss Fabrication in Nigeria. Agr. Eng. Int. CIGR J. 2006, 8, 1–10. [Google Scholar]

- Ivanova, T.; Mendoza Hernández, A.H.; Bradna, J.; Fernández Cusimamani, E.; García Montoya, J.C.; Armas Espinel, D.A. Assesment of guava (Psidium guajava L.) wood biomass for briquettes’ Production. Forests 2018, 9, 613. [Google Scholar] [CrossRef]

- EN ISO 18134–3 (2016); Solid Biofuels. Determination of Moisture Content. Oven Dry Method. Part 3: Moisture in General Analysis Sample. European Standard. CEN European Committee for Standarization: Madrid, Spain, 2016; p. 11.

- Goering, H.K.; Van Soest, P.J. Forage Fiber Analyses (Apparatus, Reagents, Procedures and Some Applications); USDA-ARS Agricultural Handbook 379; US Government Printing Office: Washington, DC, USA, 1970; p. 20.

- EN ISO 18122 (2016); Solid Biofuels. Determination of Ash Content. European Standard. CEN European Committee for Standarization: Madrid, Spain, 2016; 12p.

- EN ISO 18123 (2016); Solid Biofuels. Determination of the Content of Volatile Matter. European Standard. CEN European Committee for Standarization: Madrid, Spain, 2016; 15p.

- Rotz, L.; Giazzi, G. Characterization of Pharmaceutical Products by the Thermo Scientific FLASH 2000 Elemental Analyzer; Thermo Fischer Scientific: Milan, Italy, 2012. [Google Scholar]

- Arcibar-Orozco, J.; Josue, D.-B.; Rios-Hurtado, J.C.; Rangel-Mendez, J.R. Influence of iron content, surface area and charge distribution in the arsenic removal by activated carbons. Chem. Eng. J. 2014, 249, 201–209. [Google Scholar] [CrossRef]

- UNE-EN 15103. Determinación de la Densidad a Granel; Asociación Española de Normalización y Certificación (AENOR): Madrid, España, 2010. [Google Scholar]

- Richards, S. Physical testing of fuel briquettes. Fuel Process. Technol. 1990, 25, 89–100. [Google Scholar] [CrossRef]

- UNE-EN 14918. Determinación del Poder Calorífico; Asociación Española de Normalización y Certificación (AENOR): Madrid, España, 2010. [Google Scholar]

- ISO/TR 19867-3. Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols—Part 3: Voluntary Performance Targets for Cookstoves Based on Laboratory Testing; KEBS Centre: Nairobi, Kenya, 2018. [Google Scholar]

- Johnson, M.; Edwards, R.; Frenk, C.A.; Masera, O. In-field greenhouse gas emissions from cookstoves in rural Mexican households. Atmos. Environ. 2008, 42, 1206–1222. [Google Scholar] [CrossRef]

- Ruiz-García, V.M.; Edwards, R.D.; Ghasemian, M.; Berrueta, V.M.; Princevac, M.; Vázquez, J.C.; Johnson, M.; Masera, O.R. Fugitive Emissions and Health Implications of Plancha-Type Stoves. Environ. Sci. Technol. 2018, 52, 10848–10855. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, R.C.; Brenes-Peralta, L.; Jiménez-Morales, M.F. Evaluación técnica de dos métodos de compostaje para el tratamiento de residuos sólidos biodegradables domiciliarios y su uso en huertas caseras. Rev. Tecnol. Marcha 2016, 29, 25–32. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Ivanova, T.; Havrland, B.; Hutla, P.; Muntean, A. Drying of cherry tree chips in the experimental biomass dryer with solar collector. Res. Agric. Eng. 2012, 58, 16–23. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood-Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 1983. [Google Scholar]

- ISO 17225-2; Solid Biofuels—Fuel Specifications and Clases—Part 2: Graded Wood Pellets. SIS: Stockholm, Sweden, 2014.

- Rutiaga-Quiñones, J.G.; Pintor-Ibarra, L.F.; Orihuela-Equihua, R.; González-Ortega, N.; Ramírez-Ramírez, M.A.; Carillo-Parra, A.; Carrillo-Ávila, N.; Navarrete-García, M.A.; Ruíz-Aquino, F.; Rangel-Méndez, J.R.; et al. Characterization of Mexican waste biomass relative to energy generation. BioResources 2020, 15, 8529–8553. [Google Scholar] [CrossRef]

- Vassileva, C. Contents, modes of occurrence and origin of chlorine and bromine in coal. Fuel 2000, 79, 903–921. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. A new approach for the combined chemical and mineral classification of the inorganic matter in coal. 1. Chemical and mineral classification systems. Fuel 2009, 88, 235–245. [Google Scholar] [CrossRef]

- Martínez-Pérez, R.; Pedraza-Bucio, F.E.; Orihuela-Equihua, R.; López-Albarrán, P.; Rutiaga-Quiñones, J.G. Calorific value and inorganic material of ten Mexican wood species. Wood Res. 2015, 60, 281–292. [Google Scholar]

- Ngangyo-Heya, M.; Foroughbahchk-Pournavab, R.; Carrillo-Parra, A.; Rutiaga-Quiñones, J.G.; Zelinski, V.; Pintor-Ibarra, L.F. Calorific Value and Chemical Composition of Five Semi-Arid Mexican Tree Species. Forests 2016, 7, 58. [Google Scholar] [CrossRef]

- Pintor-Ibarra, L.F.; Carrillo-Parra, A.; Herrera-Bucio, R.; López-Albarrán, P.; Rutiaga-Quiñones, J.G. Physical and chemical properties of timber by-products from Pinus leiophylla, P. montezumae and P. pseudostrobus for a bioenergetic use. Wood Res. 2017, 62, 849–861. [Google Scholar]

- Cárdenas-Gutiérrez, M.A.; Correa-Méndez, F.; Pedraza-Bucio, F.E.; Carrillo-Parra, A.; Herrera-Bucio, R.; López-Albarrán, P.; Rutiaga-Quiñones, J.G. Chemical components of the branches of six hardwood species. Wood Res. 2018, 63, 795–808. [Google Scholar]

- Ruiz-Aquino, F.; Ruiz-Ángel, S.; Feria-Reyes, R.; Santiago-García, W.; Rutiaga-Quiñones, J.G. Wood chemical composition of five tree species from Oaxaca, Mexico. BioResources 2019, 14, 9826–9839. [Google Scholar] [CrossRef]

- UNE-EN 14961-1. Especificaciones y Clases de Combustibles. Parte 1: Requisitos Generales; Asociación Española de Normalización y Certificación (AENOR): Madrid, España, 2011. [Google Scholar]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Van Lith, S.C.; Alonso-Ramírez, V.; Jensen, P.A.; Frandsen, F.J.; Glarborg, P. Release to the Gas Phase of Inorganic Elements during Wood Combustion. Part 1: Development and Evaluation of Quantification Methods. Energy Fuels 2006, 20, 964–978. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. The Pellets Handbook: The Production and Thermal Utilization of Biomass Pellets; Earthscan: Abingdon, UK, 2010. [Google Scholar]

- Werkelin, J.; Lindberg, D.; Boström, D.; Skrifvars, B.-J.; Hupa, M. Ash-forming elements in four Scandinavian wood species part 3: Combustion of five spruce samples. Biomass Bioenergy 2011, 35, 725–733. [Google Scholar] [CrossRef]

- Kumar, M.; Sabbarwal, S.; Mishra, P.; Upadhyay, S. Thermal degradation kinetics of sugarcane leaves (Saccharum officinarum L.) using thermo-gravimetric and differential scanning calorimetric studies. Bioresour. Technol. 2019, 279, 262–270. [Google Scholar] [CrossRef]

- Gašparovič, L.; Koreňová, Z.; Jelemenský, L. Kinetic study of wood chips decomposition by TGA. Chem. Pap. 2010, 64, 174–181. [Google Scholar] [CrossRef]

- Setter, C.; Silva, F.; Assis, M.; Ataíde, C.; Trugilho, P.; Oliveira, T. Slow pyrolysis of coffee husk briquettes: Characterization of the solid and liquid fractions. Fuel 2019, 261, 116420. [Google Scholar] [CrossRef]

- Flores, J.J.A.; Quiñones, J.G.R.; Rodríguez, M.L.; Vera, J.V.A.; Valencia, J.E.; Martínez, S.J.G.; Montesino, F.M.; Rosas, A.A. Thermal Degradation Kinetics and FT-IR Analysis on the Pyrolysis of Pinus pseudostrobus, Pinus leiophylla and Pinus montezumae as Forest Waste in Western Mexico. Energies 2020, 13, 969. [Google Scholar] [CrossRef]

- Koppejan, J.; Van Loo, S. The Handbook of Biomass Combustion and Co-Firing; Earthscan: London, UK, 2012. [Google Scholar]

- Tumuluru, J.S.; Sokhansanj, S.; Lim, C.J.; Bi, T.; Lau, A.; Melin, S.; Sowlati, T.; Oveisi, E. Quality of Wood Pellets Produced in British Columbia for Export. Appl. Eng. Agric. 2010, 26, 1013–1020. [Google Scholar] [CrossRef]

- Artemio, C.P.; Maginot, N.H.; Serafín, C.-U.; Rahim, F.P.; Guadalupe, R.Q.J.; Fermín, C.-M. Physical, mechanical and energy characterization of wood pellets obtained from three common tropical species. PeerJ 2018, 6, e5504. [Google Scholar] [CrossRef] [PubMed]

- Núñez-Retana, V.D.; Escobedo-Bretado, M.A.; Ruiz-Aquino, F.; Quiñones-Reveles, M.; Carrillo-Parra, A. Efecto del contenido de humedad sobre pellets de aserrín de madera de Pinus spp. Rev. Mex. Agrosistemas 2019, 6, 136–144. [Google Scholar]

- Camps, M.M.; Marcos, M.F. Los Biocombustibles; Ediciones Mundi-Prensa: Madrid, Spain, 2008. [Google Scholar]

- DIN 51731. Test of Solid Fuels—Compressed Untreated Wood—Requeriments and Testing; German Institut for Standarization, Beuth Verlag: Berlin, UK, 1996. [Google Scholar]

- Núñez-Retana, V.D.; Wehenkel, C.; Vega-Nieva, D.J.; García-Quezada, J.; Carrillo-Parra, A.; Retana, N.; Nieva, V.; Quezada, G.; Parra, C. The Bioenergetic Potential of Four Oak Species from Northeastern Mexico. Forests 2019, 10, 869. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Radomiak, H. Possibility of the Utilization of Waste Glycerol as an Addition to Wood Pellets. Waste Biomass Valorization 2019, 10, 2193–2199. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Recent developments concerning pellet combustion technologies—A review of Austrian developments. In Proceedings of the 2nd World Conference on Pellets, Swedish Bioenergy Association, Jönköpping, Sweden, 30 May–1 June 2006. [Google Scholar]

- Peng, J.; Wang, J.; Bi, X.T.; Lim, C.J.; Sokhansanj, S.; Peng, H.; Jia, D. Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 2015, 129, 168–173. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; Protásio, T.D.P. Comparative Energy Properties of Torrefied Pellets in Relation to Pine and Elephant Grass Pellets. BioResources 2018, 13, 2898–2906. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an effective binder for making torrefied pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.; Boardman, R.D. Review: A review on biomass torrefaction process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Balasubramanian, R. Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 2014, 113, 1315–1322. [Google Scholar] [CrossRef]

- WHO. WHO Guidelines for Indoor Air Quality: Household Fuel Combustion; World Health Organization: Geneva, Switzerland, 2014; Available online: https://apps.who.int/iris/handle/10665/141496 (accessed on 14 May 2021).

- Quiñones-Reveles, M.; Ruiz-García, V.; Ramos-Vargas, S.; Vargas-Larreta, B.; Masera-Cerutti, O.; Ngangyo-Heya, M.; Carrillo-Parra, A. Assessment of Pellets from Three Forest Species: From Raw Material to End Use. Forests 2021, 12, 447. [Google Scholar] [CrossRef]

- Thompson, R.J.; Li, J.; Weyant, C.L.; Edwards, R.; Lan, Q.; Rothman, N.; Hu, W.; Dang, J.; Dang, A.; Smith, K.R.; et al. Field Emission Measurements of Solid Fuel Stoves in Yunnan, China Demonstrate Dominant Causes of Uncertainty in Household Emission Inventories. Environ. Sci. Technol. 2019, 53, 3323–3330. [Google Scholar] [CrossRef] [PubMed]

| Biomass Type | HHV (MJ/kg) | Carbon Content (%) | Reference |

|---|---|---|---|

| Pruning biomass of guava trees | 19.37 ± 0.22 | 46.83% | (this study) |

| Guava pellets | 19.52 ± 0.38 | (this study) | |

| Pruning biomass of guava trees | 18.42 | 49.65 | [25] |

| Pine sawdust | 19.7 to 19.9 | 49.5 to 50.8 | [45] |

| Persian lime branches | 19.80 | 49.1 to 49.9 | [45] |

| Orange branches | 19.83 | [45] | |

| Hardwood felling residues | 19.5 to 20.0 | 50.0 to 50.6 | [70] |

| Pellets for heating applications in the commercial or industrial sector | 18.0 to 20.0 | - | [70] |

| Device | T-LUD (Wood Gas) | Three Stone Stove | ||

|---|---|---|---|---|

| Fuel Type | Guava Pellets | Arbutus xalapensis (with Bark) * | Juniperus deppeana Pellets (without Bark) * | White Oak Firewood |

| Energy performance | ||||

| Dry fuel | 328 ± 20 | 360 ± 1 | 366 ± 10 | 629 ± 45 |

| Burn rate (g/min) | 13 ± 2 | 11 ± 1 | 9 ± 2 | 27 ± 7 |

| Thermal efficiency (%) | 20 ± 1 | 31 ± 3 | 30 ± 2 | 17 ± 1 |

| Available power (Kw) | 4 ± 1 | 3 ± 1 | 3 ± 1 | 8 ± 2 |

| Time (min) | 26 ± 2 | 34 ± 2 | 39 ± 6 | 24 ± 5 |

| Emission factors per kg of dry fuel consumed | ||||

| gCO2 | 859 ± 97 | 1247 ± 15 | 1140 ± 74 | 1127 ± 118 |

| gCO | 9 ± 2 | 9 ± 1 | 4 ± 1 | 39 ± 12 |

| mgCH4 | 426 ± 211 | 105 ± 11 | 105 ± 13 | 857 ± 324 |

| mgNMHC | 583 ± 66 | 263 ± 76 | 110 ± 57 | 1607 ± 794 |

| mgPM2.5 | 668 ± 181 | 315 ± 125 | 91 ± 22 | 3370 ± 1292 |

| mgEC | 124 ±132 | 133 ± 97 | 73 ±17 | 482 ± 168 |

| mgOC | 65 ± 51 | 101 ± 18 | 15 ± 3 | 1219 ± 426 |

| Emission rate per minute | ||||

| gCO2 | 11 ± 1 | 13 ± 1 | 11 ± 1 | 46 ± 12 |

| mgCO | 557 ± 24 | 95 ± 8 | 39 ± 5 | 1491 ± 178 |

| mgCH4 | 27 ± 2 | 1 ± 1 | 1 ± 1 | 34 ± 15 |

| mgNMHC | 7 ± 1 | 3 ± 1 | 1 ± 1 | 66 ± 40 |

| mgPM2.5 | 9 ± 3 | 3 ± 1 | 1 ± 1 | 128 ± 21 |

| mgEC | 2 ± 2 | 1 ±1 | 1 ± 0 | 18 ± 3 |

| mgOC | 1 ± 1 | 1 ± 1 | <1 ± 0 | 47 ± 7 |

| Emission factors per MJ consumed | ||||

| gCO2 | 49 ± 6 | 73 ± 1 | 63 ± 4 | 107 ± 1 |

| mgCO | 507 ± 133 | 514 ± 24 | 230 ± 53 | 3623 ± 834 |

| mgCH4 | 24 ± 12 | 6 ± 1 | 6 ± 1 | 82 ± 30 |

| mgNMHC | 33 ± 4 | 15 ± 4 | 6 ± 3 | 152 ± 72 |

| mgPM2.5 | 38 ± 10 | 18 ± 7 | 5 ± 1 | 315 ± 95 |

| mgEC | 7 ± 8 | 8 ± 6 | 4 ± 1 | 45 ± 12 |

| mgOC | 4 ± 3 | 6 ± 1 | 1 ± 0 | 114 ± 31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz-García, V.M.; Huerta-Mendez, M.Y.; Vázquez-Tinoco, J.C.; Alvarado-Flores, J.J.; Berrueta-Soriano, V.M.; López-Albarrán, P.; Masera, O.; Rutiaga-Quiñones, J.G. Pellets from Lignocellulosic Material Obtained from Pruning Guava Trees: Characterization, Energy Performance and Emissions. Sustainability 2022, 14, 1336. https://doi.org/10.3390/su14031336

Ruiz-García VM, Huerta-Mendez MY, Vázquez-Tinoco JC, Alvarado-Flores JJ, Berrueta-Soriano VM, López-Albarrán P, Masera O, Rutiaga-Quiñones JG. Pellets from Lignocellulosic Material Obtained from Pruning Guava Trees: Characterization, Energy Performance and Emissions. Sustainability. 2022; 14(3):1336. https://doi.org/10.3390/su14031336

Chicago/Turabian StyleRuiz-García, Víctor Manuel, Maritza Yunuen Huerta-Mendez, Juan Carlos Vázquez-Tinoco, José Juan Alvarado-Flores, Víctor Manuel Berrueta-Soriano, Pablo López-Albarrán, Omar Masera, and José Guadalupe Rutiaga-Quiñones. 2022. "Pellets from Lignocellulosic Material Obtained from Pruning Guava Trees: Characterization, Energy Performance and Emissions" Sustainability 14, no. 3: 1336. https://doi.org/10.3390/su14031336

APA StyleRuiz-García, V. M., Huerta-Mendez, M. Y., Vázquez-Tinoco, J. C., Alvarado-Flores, J. J., Berrueta-Soriano, V. M., López-Albarrán, P., Masera, O., & Rutiaga-Quiñones, J. G. (2022). Pellets from Lignocellulosic Material Obtained from Pruning Guava Trees: Characterization, Energy Performance and Emissions. Sustainability, 14(3), 1336. https://doi.org/10.3390/su14031336