Theoretical Analysis of Ultimate Main Span Length for Arch Bridge

Abstract

1. Introduction

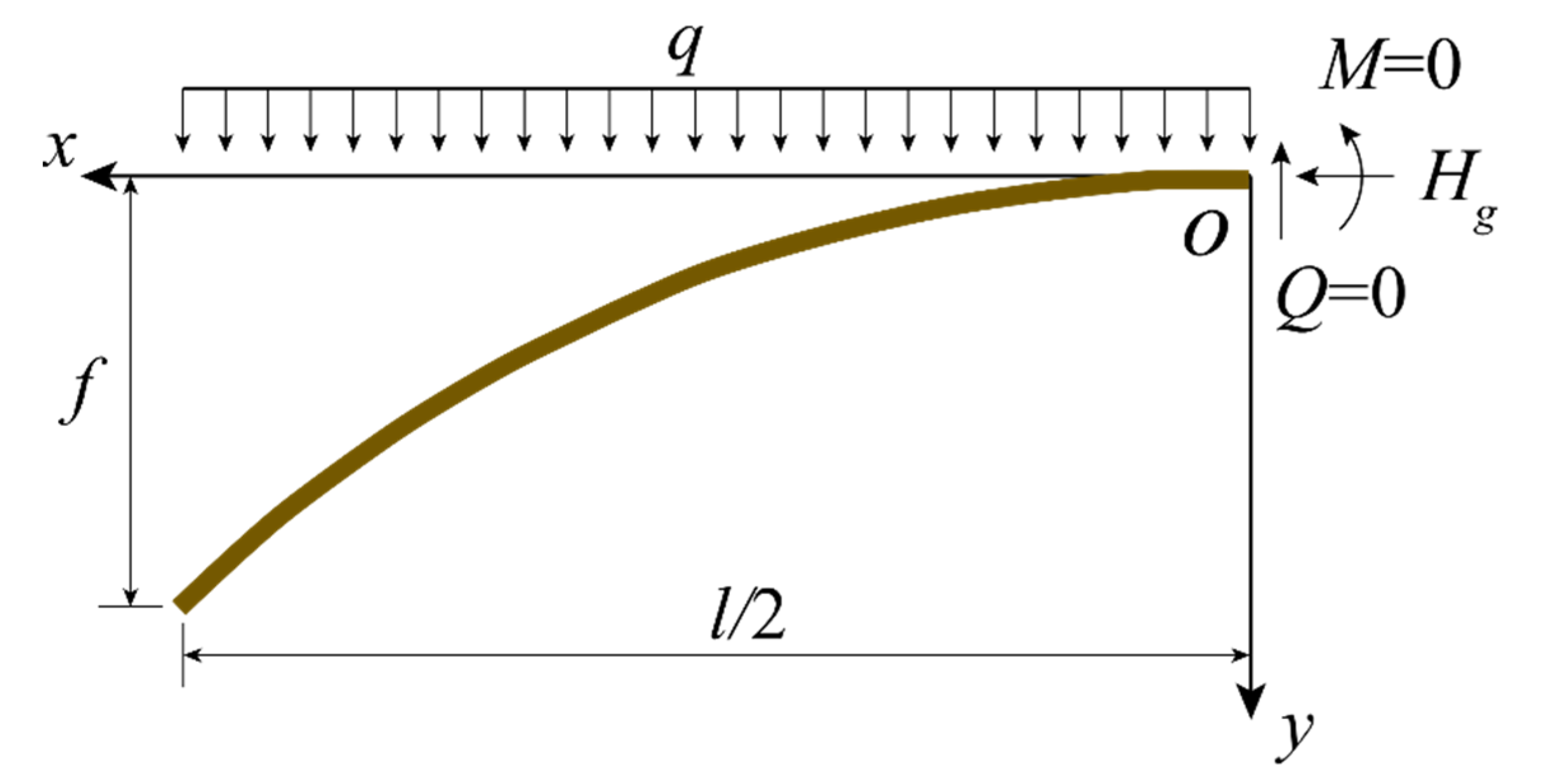

2. Parabolic Arch Axis

2.1. Strength Condition

2.2. Stability Conditions

2.2.1. In-Plane Stability

2.2.2. Out-of-Plane Stability

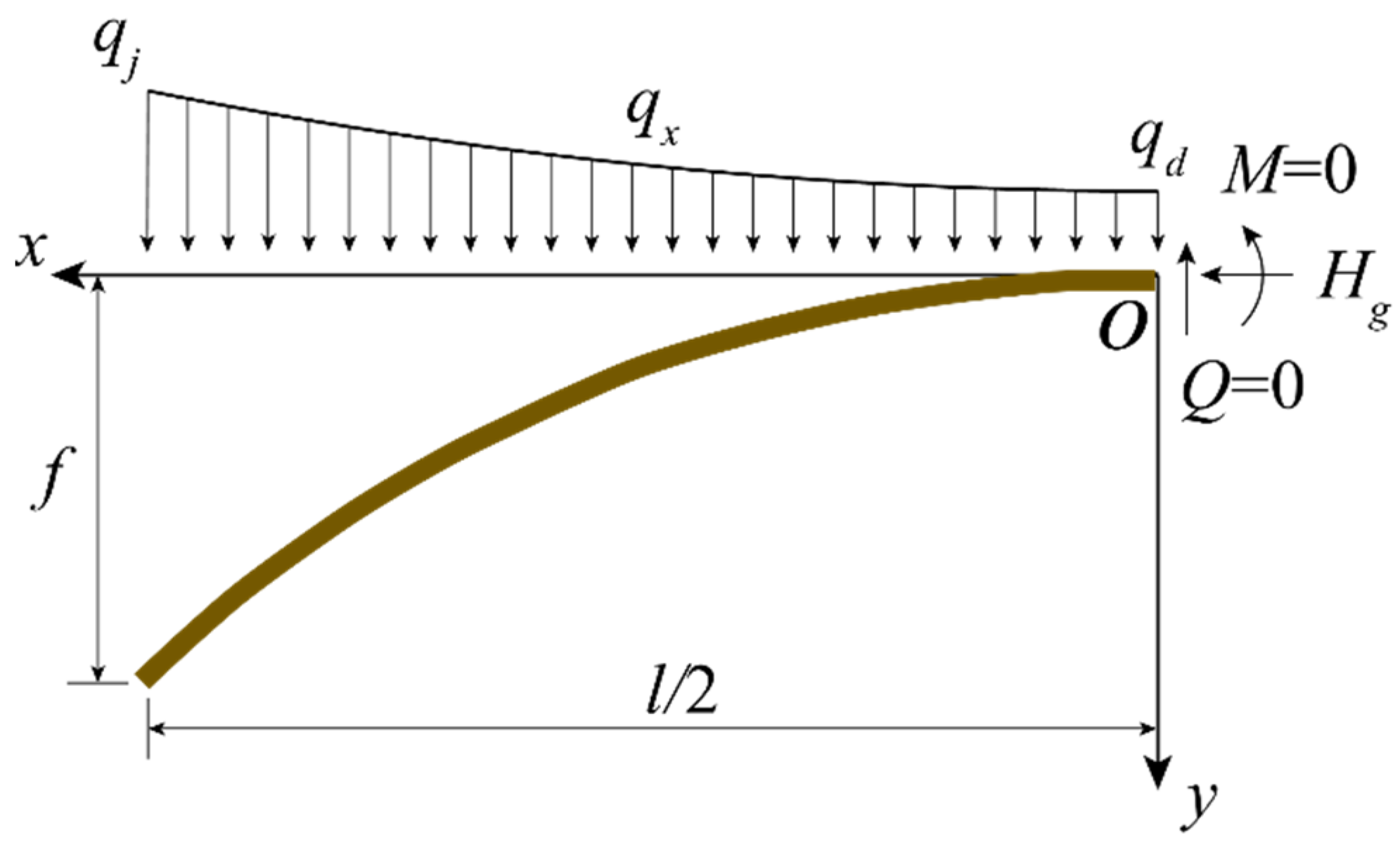

3. Catenary Arch Axis

3.1. Strength Condition

3.2. Stability Conditions

3.2.1. In-Plane Stability

3.2.2. Out-of-Plane Stability

4. Theoretical Ultimate Span Length

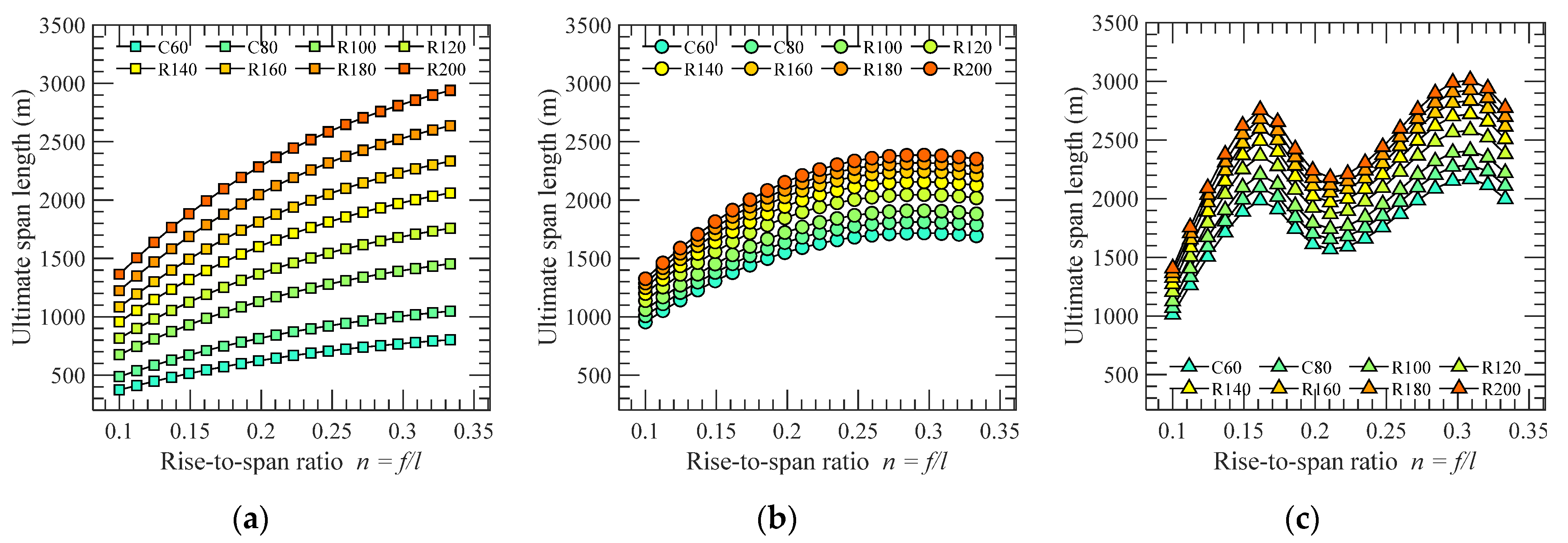

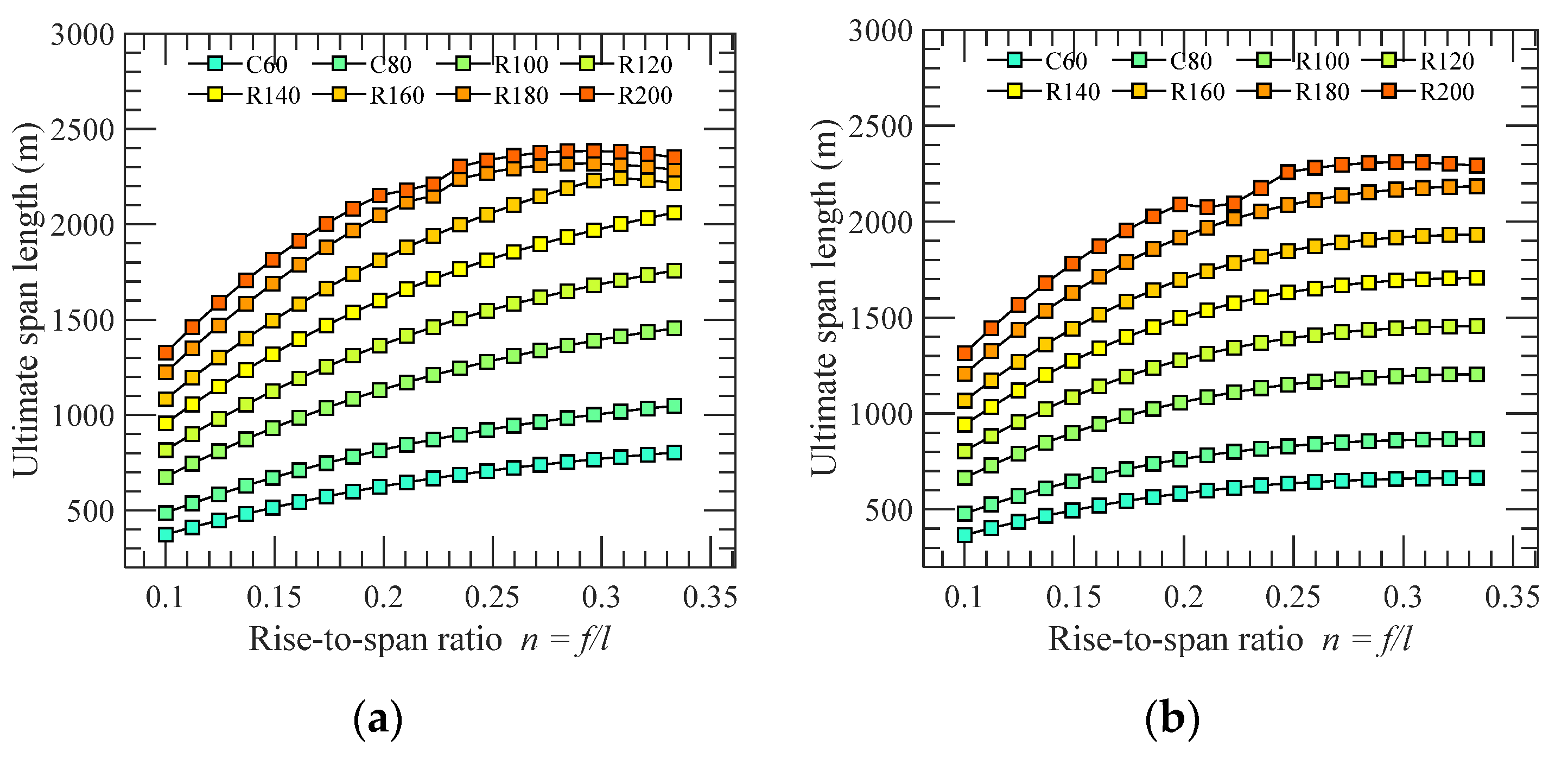

4.1. Concrete Arch Bridge

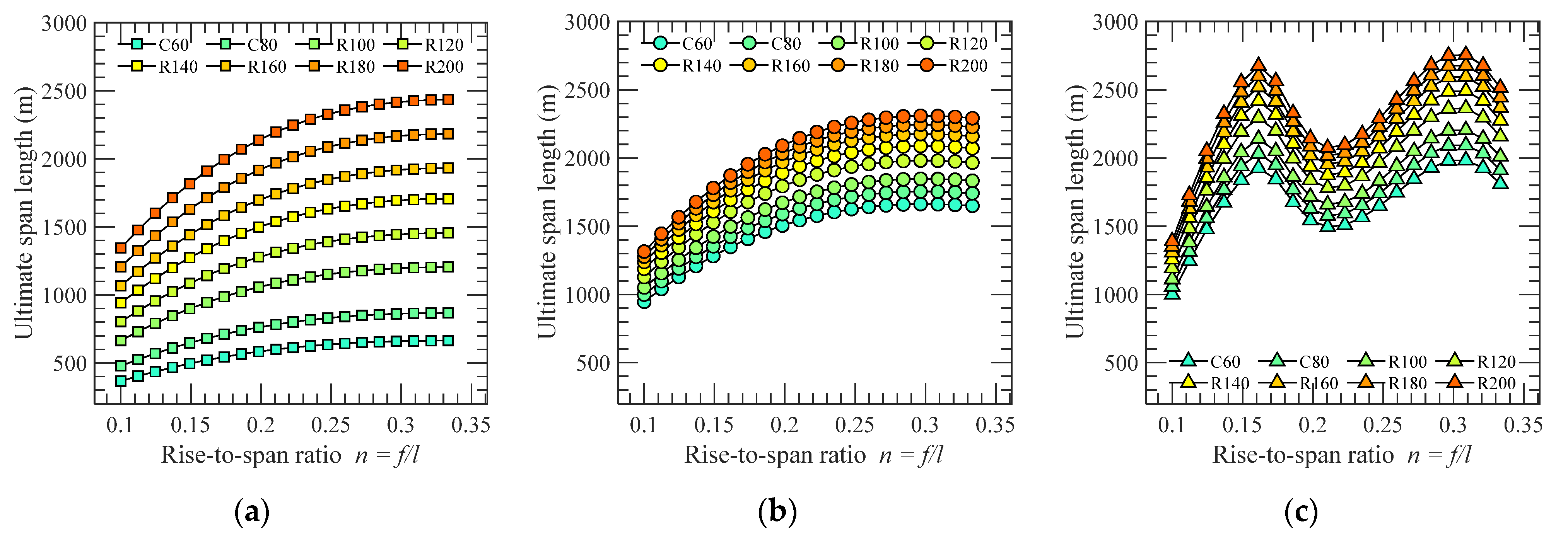

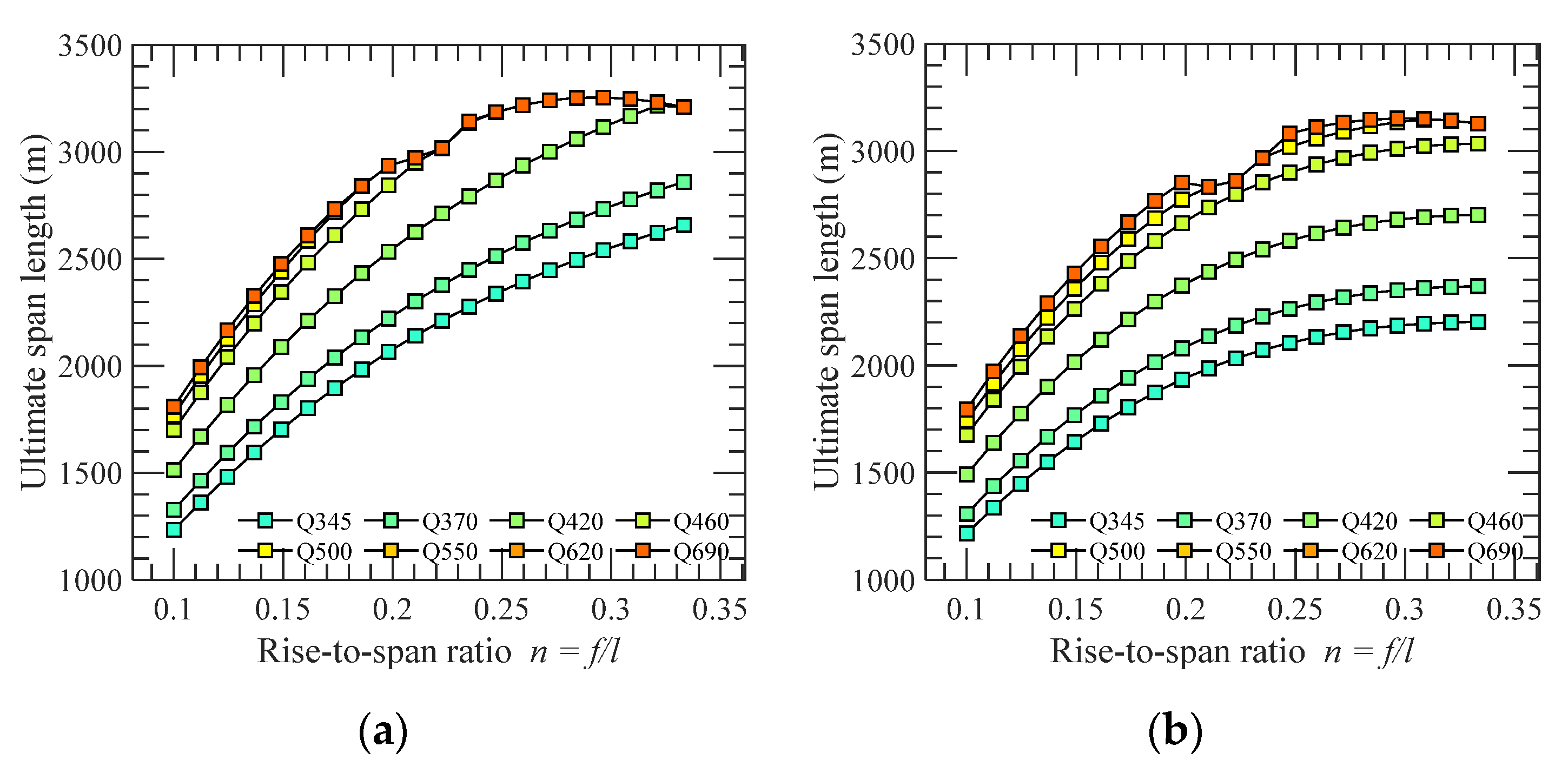

4.2. Steel Arch Bridge

5. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, N.; Dai, G.L.; Yan, B.; Liu, K. Recent development of design and construction of medium and long span high-speed railway bridges in China. Eng. Struct. 2014, 74, 233–241. [Google Scholar] [CrossRef]

- Cheng, J. Optimum design of steel truss arch bridges using a hybrid genetic algorithm. J. Constr. Steel Res. 2010, 66, 1011–1017. [Google Scholar] [CrossRef]

- Liu, J.P.; Chen, B.C.; Li, C.; Zhang, M.J.; Mou, T.M.; Tabatabai, H. Recent application of and research on concrete arch bridges in China. Struct. Eng. Int. 2022. [Google Scholar] [CrossRef]

- Thrall, A.P.; Billington, D.P. Bayonne Bridge: The Work of Othmar Ammann Master Builder. J. Bridge Eng. 2008, 13, 635–643. [Google Scholar] [CrossRef]

- Zheng, J.L.; Du, H.L.; Mu, T.M.; Liu, J.; Qin, D.; Mei, G.; Tu, B. Innovations in design, construction, and management of Pingnan Third Bridge—The largest-span arch bridge in the world. Struct. Eng. Int. 2022, 32, 134–141. [Google Scholar] [CrossRef]

- Nazmy, A.S. Stability and lode-carrying capacity of three-dimensional long-span steel arch bridges. Comput. Struct. 1997, 65, 857–868. [Google Scholar] [CrossRef]

- Salonga, J.; Gauvreau, P. Comparative study of the proportions, form, and efficiency of concrete arch bridges. J. Bridge Eng. 2014, 19, 04013010. [Google Scholar] [CrossRef]

- Tang, M.C. Super-long span bridges. Struct. Infrastruct. Eng. 2017, 13, 722–730. [Google Scholar] [CrossRef]

- Ge, Y.J. Challenge and development of long-span arch bridges in statics, dynamics and aerodynamics. In Proceedings of the ARCH 2019: 9th International Conference on Arch Bridges, Porto, Portugal, 2–4 October 2019. [Google Scholar]

- Zheng, J.L.; Wang, J.J. Concrete-Filled Steel Tube Arch Bridges in China. Engineering 2018, 4, 143–155. [Google Scholar] [CrossRef]

- Azzara, R.M.; Falco, A.D.; Girardi, M.; Pellegrini, D. Ambient vibration recording on the Maddalena Bridge in Borgo a Mozzano (Italy): Data analysis. Ann. Geophys. 2017, 60, S0441. [Google Scholar] [CrossRef]

- Lin, Y.P.; Zhang, Z.H.; Ma, B.; Zhou, L. Lupu arch bridge, Shanghai. Struct. Eng. Int. 2004, 14, 24–26. [Google Scholar] [CrossRef]

- Järvenpää, E.; Jutila, A. Ultimate spans and optimal rise relations of steel arches. In Proceedings of the IABSE Congress, New York, NY, USA, 4–6 September 2019. [Google Scholar]

- Wang, X.C. Study on the reasonable arch axis of long-span concrete-filled steel tubular arch bridge. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2019. [Google Scholar]

- Xia, M.; Liu, H. Disquisition of limitation span of arch bridge. Transp. Sci. Technol. 2005, 12, 39–42. [Google Scholar]

- Xia, M. Analysis of ultimate carrying capacity for long-span fixed arch bridge with thrust. Ph.D. Thesis, Tongji University, Shanghai, China, 2005. [Google Scholar]

- Li, X.H.; Chen, B.C. Development of long span arch bridges. World Bridge 2007, 1, 9–12. [Google Scholar]

- Wang, J. The Study of Ultimate Spans for Steel Arch Bridges. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2012. [Google Scholar]

- Zhao, H.D. Analysis on the ultimate span of railway concrete deck type arch bridges. High Speed Railw. Technol. 2017, 8, 29–32. [Google Scholar]

- Chen, B.C.; Liu, J.P. Review of construction and technology development of arch bridges in the world. J. Traffic Transp. Eng. 2020, 20, 27–41. [Google Scholar]

- Čandrlić, V.; Radić, J.; Gukov, I. Research of Concrete Arch Bridges up to 1000 m in Span. In Proceedings of the 4th International Conference on Arch Bridge, Advances in Assessment, Structural Design and Construction, Barcelona, Spain, 17–19 November 2004. [Google Scholar]

- Zheng, J.; Wang, J.J.; Mou, T.M.; Feng, Z.; Han, Y.; Qin, D. Feasibility study on design and construction of concrete filled steel tubular arch bridge with a span of 700 m. Strateg. Study Chin. Acad. Eng. 2014, 16, 33–37. [Google Scholar]

- Shao, X.D.; He, G. Conceptual design and feasibility study of an 800 m scale steel-UHPC composite truss arch bridge. China J. Highw. Transp. 2020, 33, 73–82. [Google Scholar]

- Shao, X.D.; He, G.; Shen, X.J.; Zhu, P.; Chan, Y. Conceptual design of 1000 m scale steel-UHPFRC composite truss arch bridge. Eng. Struct. 2021, 226, 111430. [Google Scholar] [CrossRef]

- CCCC Highway Consultants Co., Ltd. General Specification for Design of Highway Bridges and Culverts: JTG D60-2015; China Communication Press: Beijing, China, 2015. [Google Scholar]

- Xiang, H.F.; Liu, G.D. Stability and Vibration of Arch Structures; China Communication Press: Beijing, China, 1991. [Google Scholar]

- CCCC Highway Consultants Co., Ltd. Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts: JTG 3362-2018; China Communication Press: Beijing, China, 2018. [Google Scholar]

- Hunan University. Technical Specifications for Reactive Powder Concrete Structures: DBJ43/T 325-2017; China Architecture & Building Press: Beijing, China, 2017. [Google Scholar]

- CCCC Highway Consultants Co., Ltd. Specifications for Design of Highway Steel Bridges: JTG D64-2015; China Communication Press: Beijing, China, 2015. [Google Scholar]

- China Iron and Steel Association. Structural Steel for Bridge: GB/T 714-2015; Standards Press of China: Beijing, China, 2015. [Google Scholar]

- Fang, G.S.; Pang, W.; Zhao, L.; Xu, K.; Cao, S.; Ge, Y. Tropical-Cyclone-Wind-Induced Flutter Failure Analysis of Long-Span Bridges. Eng. Fail. Anal. 2022, 132, 105933. [Google Scholar] [CrossRef]

- Hu, X.N.; Fang, G.S.; Yang, J.Y.; Zhao, L.; Ge, Y. Simplified models for uncertainty quantification of extreme events using Monte Carlo technique. Reliab. Eng. Syst. Saf. 2023, 230, 108935. [Google Scholar] [CrossRef]

- Fang, G.S.; Wei, M.M.; Zhao, L.; Xu, K.; Cao, S.; Ge, Y. Site- and building height-dependent design extreme wind speed vertical profile of tropical cyclone. J. Build. Eng. 2022, 62, 105322. [Google Scholar] [CrossRef]

- Wang, X.W.; Mazumder, R.K.; Salarieh, B.; Salman, A.M.; Shafieezadeh, A.; Li, Y. Machine learning for risk and resilience assessment in structural engineering: Progress and future trends. J. Struct. Eng. 2022, 148, 03122003. [Google Scholar] [CrossRef]

- Pang, Y.; Wang, X. Cloud-IDA-MSA conversion of fragility curves for efficient and high-fidelity resilience assessment. J. Struct. Eng. 2021, 147, 04021049. [Google Scholar] [CrossRef]

- Zhong, J.; Ni, M.; Hu, H.; Yuan, W.; Yuan, H.; Pang, Y. Uncoupled multivariate power models for estimating performance-based seismic damage states of column curvature ductility. Structures 2022, 36, 752–764. [Google Scholar] [CrossRef]

- Khedmatgozar Dolati, S.S.; Mehrabi, A.; Khedmatgozar Dolati, S.S. Application of Viscous Damper and Laminated Rubber Bearing Pads for Bridges in Seismic Regions. Metals 2021, 11, 1666. [Google Scholar] [CrossRef]

- Khedmatgozar Dolati, S.S.; Mehrabi, A. Review of available systems and materials for splicing prestressed-precast concrete piles. Structures 2021, 30, 850–865. [Google Scholar] [CrossRef]

| No. | Year of Completion | Years of Record | Bridge Name | Main Span (m) | Rate of Increase | Material | Country |

|---|---|---|---|---|---|---|---|

| 1 | 605 | 695 | Zhaozhou Bridge | 37.5 | —— | Stone | China |

| 2 | 1300 | 41 | Maddalena Bridge [11] | 38 | 1.3% | Stone | Italy |

| 3 | 1341 | 15 | Diable Bridge | 45 | 18.4% | Stone | Italy |

| 4 | 1356 | 21 | Castelvecchio Bridge | 49 | 8.9% | Stone | Italy |

| 5 | 1377 | 500 | Trezzo Bridge * | 72 | 46.9% | Stone | Italy |

| 6 | 1877 | 7 | Maria Bridge | 160 | 122.2% | Cast iron | Portugal |

| 7 | 1884 | 2 | Garabit Bridge | 165 | 3.1% | Cast iron | France |

| 8 | 1886 | 12 | Dom Luís Bridge | 172.5 | 4.5% | Cast iron | Portugal |

| 9 | 1898 | 18 | Upper Steel Bridge * | 256 | 48.4% | Steel truss | USA |

| 10 | 1916 | 15 | Hell Gate Bridge | 298 | 16.4% | Steel truss | USA |

| 11 | 1931 | 46 | Bayonne Bridge [2] | 504 | 69.1% | Steel truss | USA |

| 12 | 1977 | 26 | New River Gorge Bridge | 518 | 2.8% | Steel truss | USA |

| 13 | 2003 | 6 | Lupu Bridge [12] | 550 | 6.2% | Steel box | China |

| 14 | 2009 | 11 | Chaotianmen Bridge [4] | 552 | 0.4% | Steel truss | China |

| 15 | 2020 | —— | Pingnan 3rd Bridge [3] | 575 | 4.2% | CFST * | China |

| Researcher | Year | Material | Arch Axis | Rise-Span Ratio | Material Grade | Ultimate Span (m) | Method | Condition |

|---|---|---|---|---|---|---|---|---|

| Xia [15,16] | 2005 | Concrete | Parabolic | 1/4 | C60 | 481 | Theoretical analysis | Strength and in-plane stability, solid-web rectangular arch section. An ultimate span reduction coefficient of 0.75 is used for only considering the self-weight of the main arch. |

| Catenary | 1/4 | C60 | 451 | |||||

| Steel | Parabolic | 1/4 | Q345 | 916 | ||||

| Catenary | 1/4 | Q345 | 860 | |||||

| Li [17] | 2007 | Concrete | Catenary | 1/5 | C100 | 590 | Numerical simulation of arch | Strength and stability conditions |

| Steel | Catenary | 1/5 | Q460 | 660 | ||||

| Wang [18] | 2012 | Steel | Parabolic | 1/4 | Q420 | 866 | Numerical simulation of arch | Strength and stability conditions |

| Catenary | 1/5.5 | Q420 | 818 | |||||

| Zhao [19] | 2017 | Concrete | Parabolic | 1/4 | C60 | 540 | Theoretical analysis | Strength and in-plane stability conditions. An ultimate span reduction coefficient of 0.62 is used for only considering the self-weight of the main arch. |

| Tang [8] | 2017 | Steel | Catenary | 1/5.5 | — | 5000 | Theoretical analysis | Strength, the allowable stress of steel is 420 MPa |

| Wang [14] | 2019 | CFST | Catenary | 1/4 | Q420/C80 | 821 | Numerical simulation of full bridge | Strength, stiffness and stability conditions |

| Järvenpää and Jutila [13] | 2019 | Steel | Parabolic | 1/2.31 | — | 6250 | Theoretical analysis | Strength condition, the allowable stress of steel is 500 MPa |

| Catenary | 1/2.96 | — | 8284 |

| n | 1/3 | 1/4 | 1/5 | 1/6 | 1/7 | 1/8 | 1/9 | 1/10 |

|---|---|---|---|---|---|---|---|---|

| ζ | 1.167 | 0.962 | 0.797 | 0.576 | 0.495 | 0.452 | 0.425 | 0.406 |

| Arch Axis | Strength lmax1 | In-Plane Stability lmax2 | Out-of-Plane Stability lmax3 |

|---|---|---|---|

| Parabola | |||

| Catenary |

| Grade | C60 | C80 | R100 | R120 | R140 | R160 | R180 | R200 |

|---|---|---|---|---|---|---|---|---|

| fd (MPa) | 26.5 | 34.6 | 48.0 | 58.0 | 68.0 | 77.0 | 87.0 | 97.0 |

| E (×104 MPa) | 3.60 | 3.80 | 4.00 | 4.29 | 4.52 | 4.71 | 4.86 | 5.00 |

| Grade | Q345 | Q370 | Q420 | Q460 | Q500 | Q550 | Q620 | Q690 |

|---|---|---|---|---|---|---|---|---|

| fd (MPa) | 265 | 285 | 325 | 365 | 380 | 420 | 460 | 520 |

| Grade | C60 | C80 | R100 | R120 | R140 | R160 | R180 | R200 |

|---|---|---|---|---|---|---|---|---|

| Parabolic arch axis lmax (m) | 627 | 819 | 1136 | 1372 | 1609 | 1822 | 2058 | 2161 |

| Catenary arch axis lmax (m) | 586 | 766 | 1062 | 1283 | 1505 | 1704 | 1925 | 2099 |

| Grade | Q345 | Q370 | Q420 | Q460 | Q500 | Q550 | Q620 | Q690 |

|---|---|---|---|---|---|---|---|---|

| Parabolic arch axis lmax (m) | 2077 | 2233 | 2547 | 2860 | 2948 | 2948 | 2948 | 2948 |

| Catenary arch axis lmax (m) | 1942 | 2089 | 2382 | 2675 | 2785 | 2865 | 2865 | 2865 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Deng, Z.; Fang, G.; Ge, Y. Theoretical Analysis of Ultimate Main Span Length for Arch Bridge. Sustainability 2022, 14, 17043. https://doi.org/10.3390/su142417043

Zhang X, Deng Z, Fang G, Ge Y. Theoretical Analysis of Ultimate Main Span Length for Arch Bridge. Sustainability. 2022; 14(24):17043. https://doi.org/10.3390/su142417043

Chicago/Turabian StyleZhang, Xianxiong, Zhuozhang Deng, Genshen Fang, and Yaojun Ge. 2022. "Theoretical Analysis of Ultimate Main Span Length for Arch Bridge" Sustainability 14, no. 24: 17043. https://doi.org/10.3390/su142417043

APA StyleZhang, X., Deng, Z., Fang, G., & Ge, Y. (2022). Theoretical Analysis of Ultimate Main Span Length for Arch Bridge. Sustainability, 14(24), 17043. https://doi.org/10.3390/su142417043