Bond Performance of CFRP/Steel Double Strap Joint at Elevated Temperatures

Abstract

1. Introduction

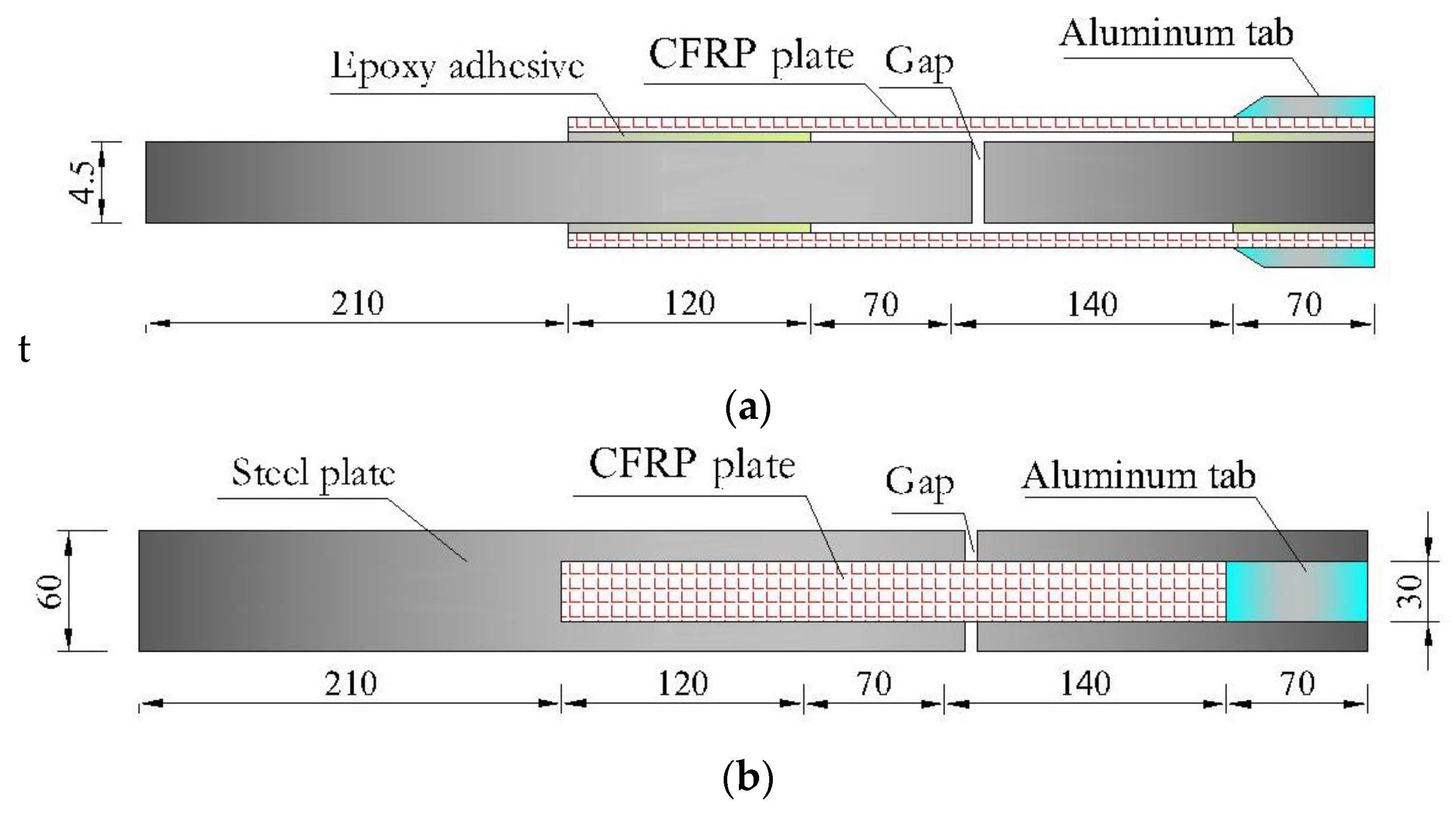

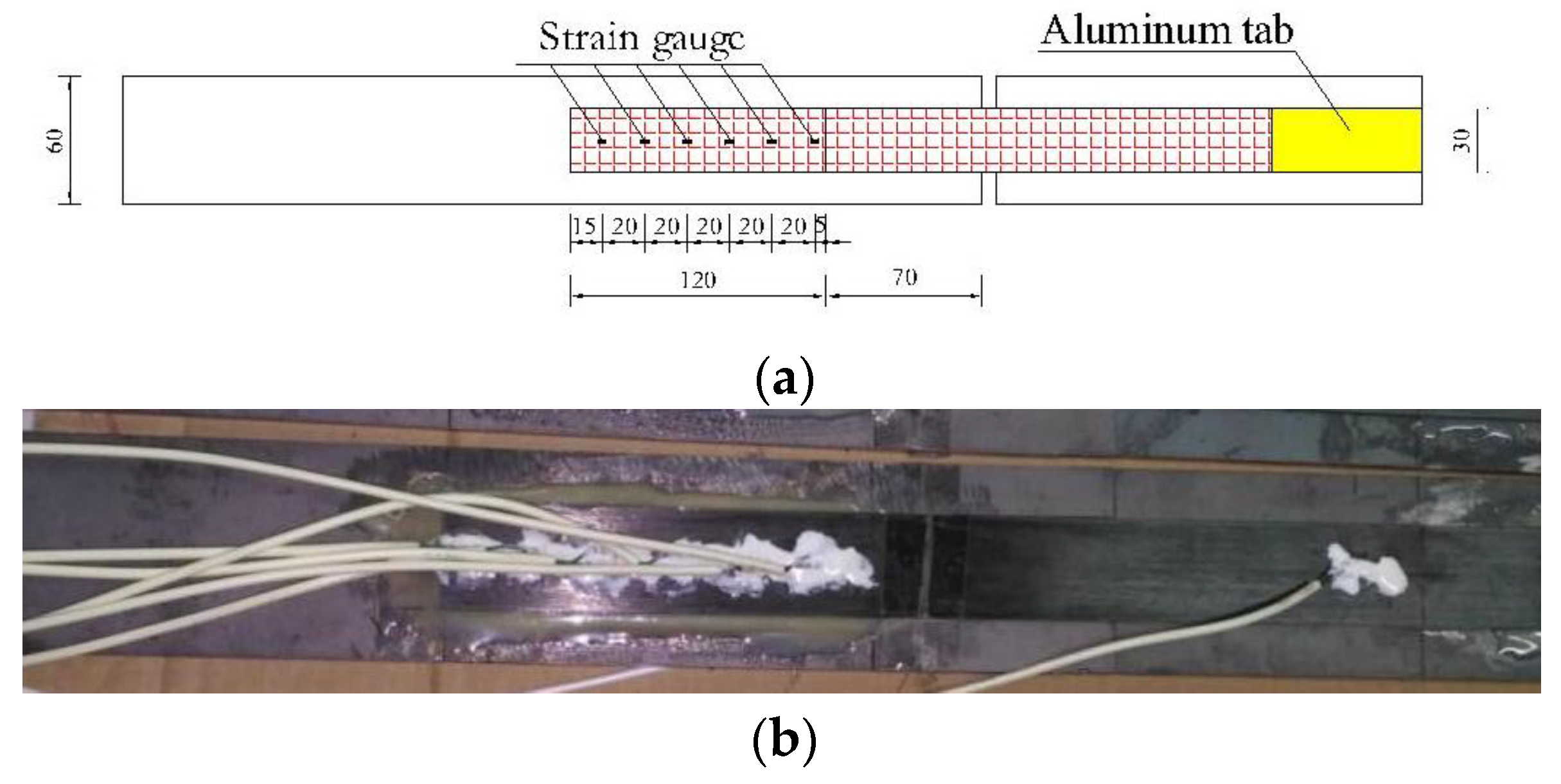

2. Experimental Program

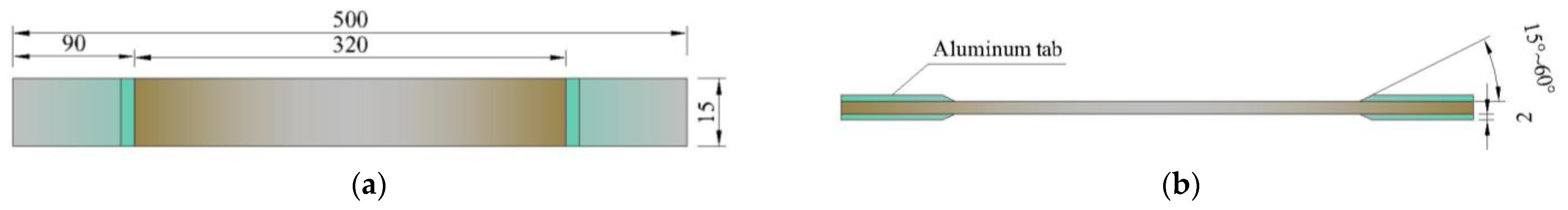

2.1. Material Properties

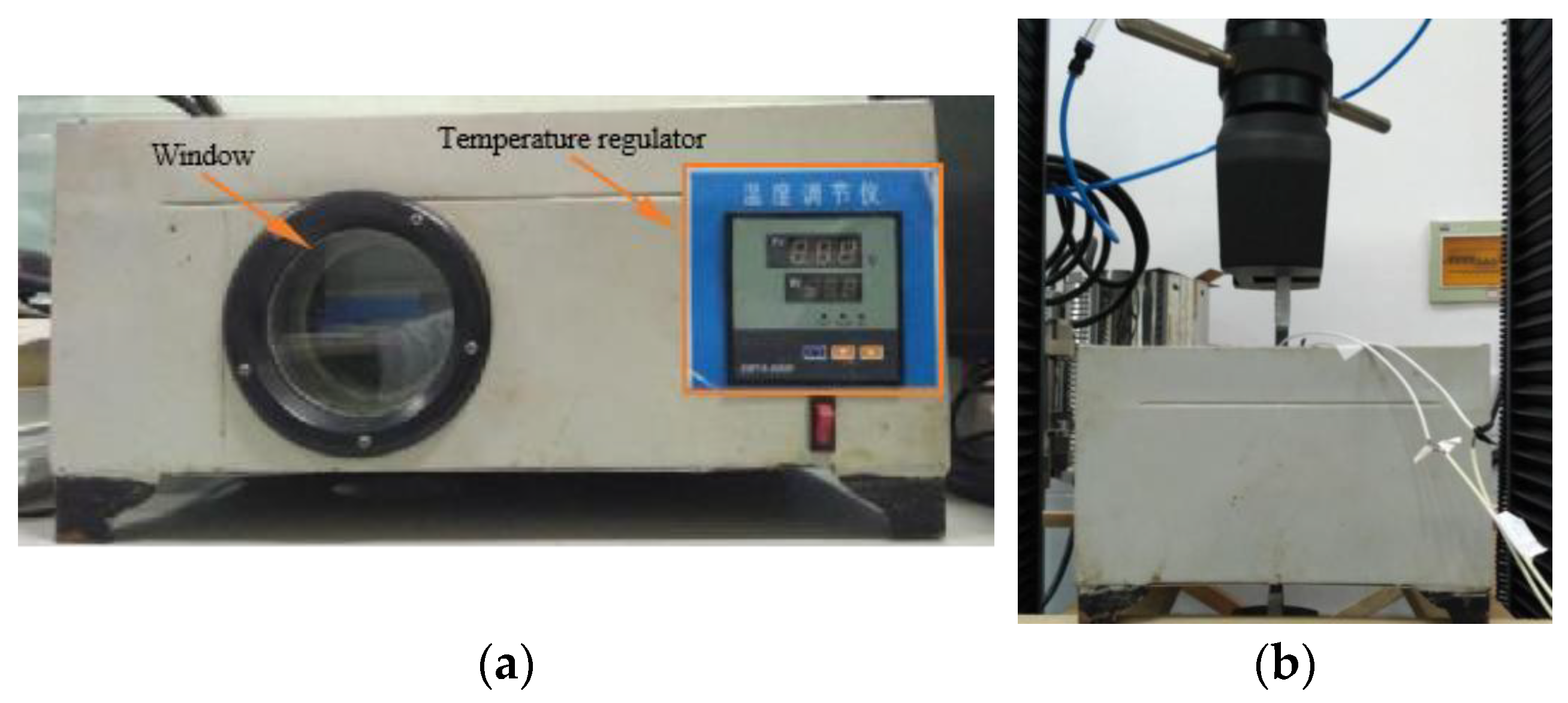

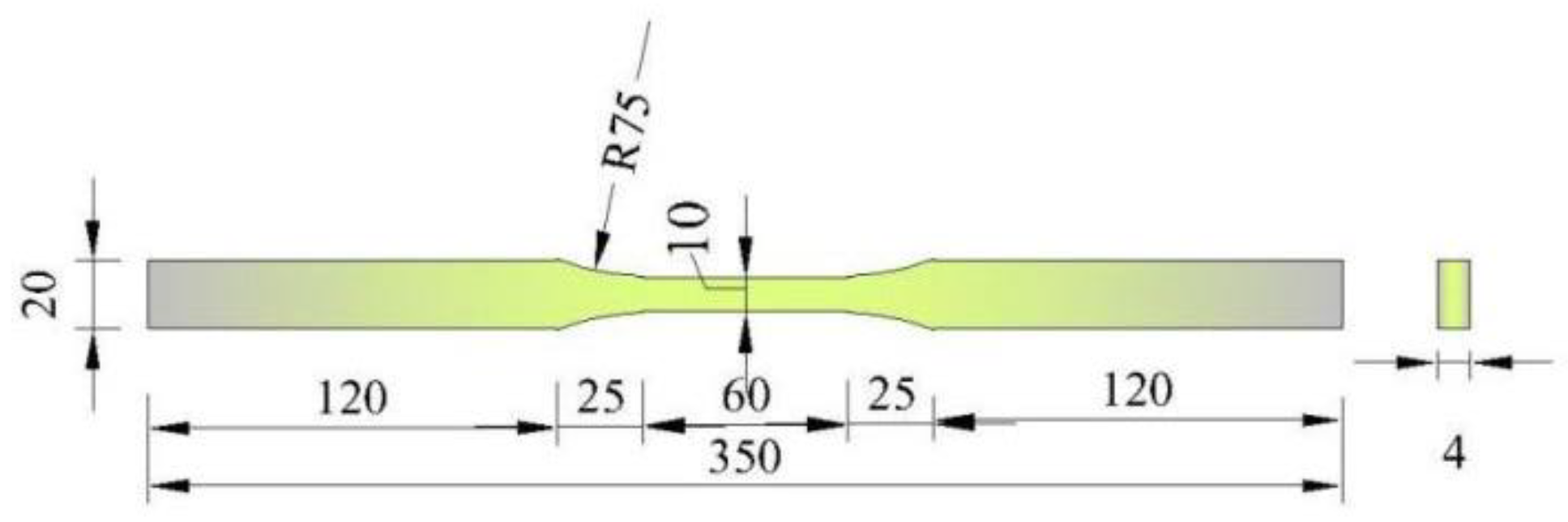

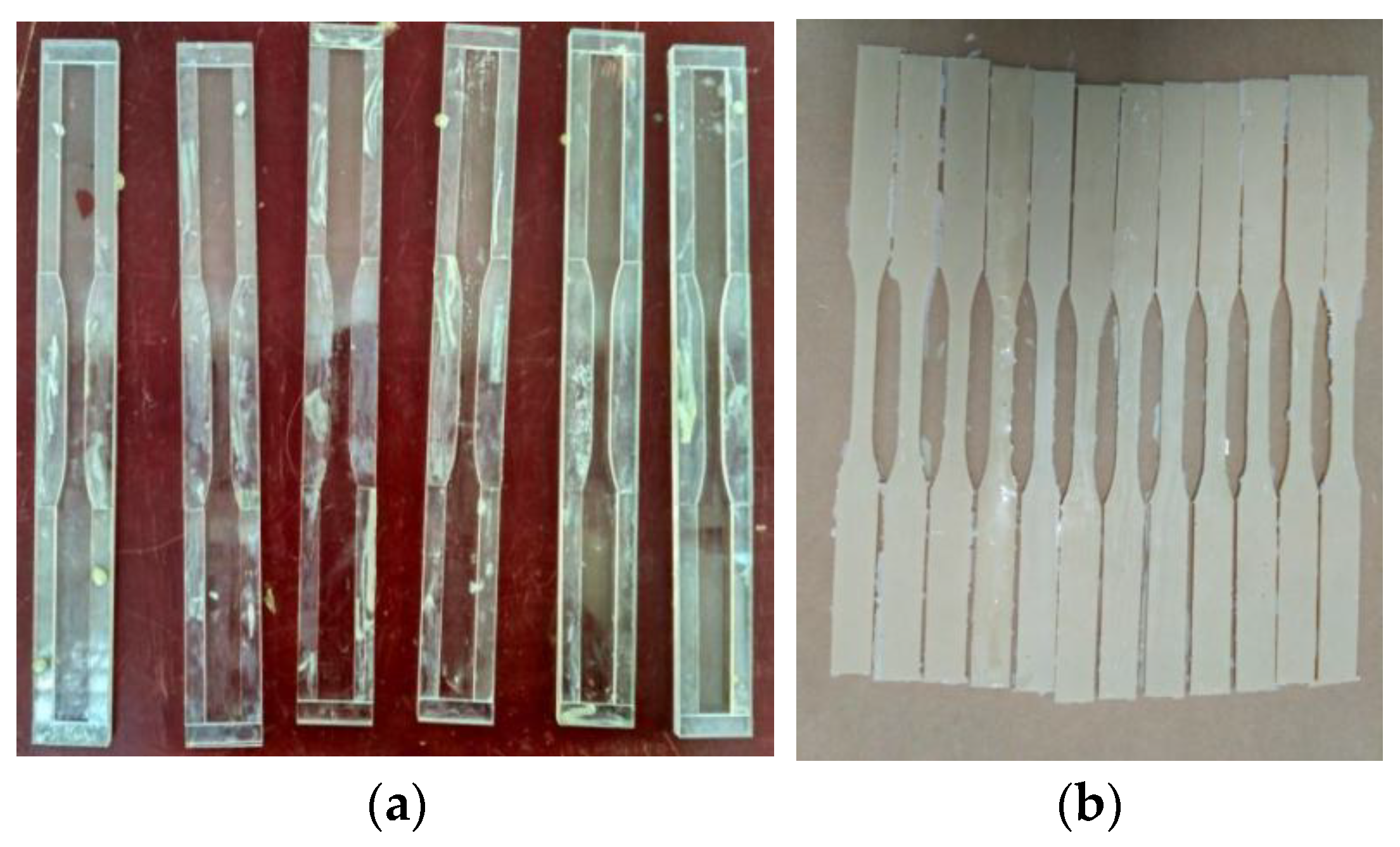

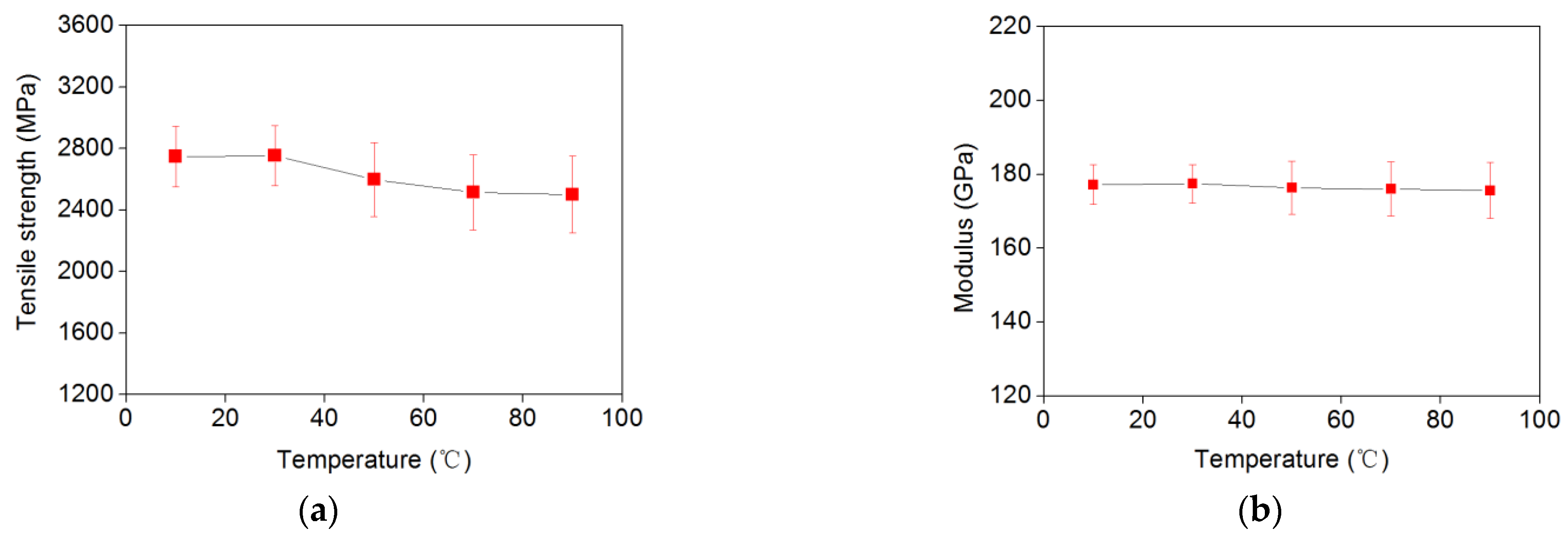

2.2. Material Testing of CFRP Plates under Elevated Temperatures

2.3. Material Testing of Epoxy Adhesive under Elevated Temperatures

2.4. Bond Testing of CFRP/Steel Double Strap Joint under Elevated Temperatures

3. Experimental Results and Discussion

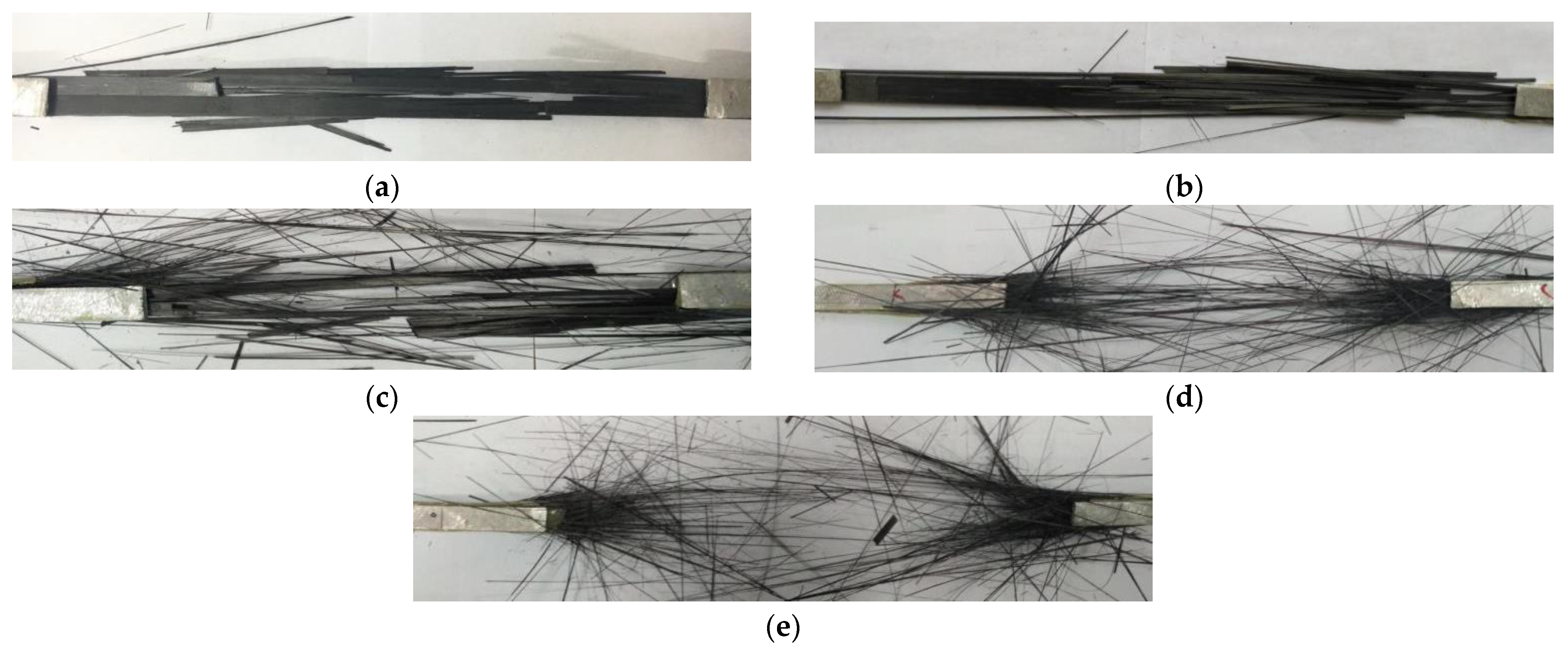

3.1. Effect of Elevated Temperatures on the Properties of CFRP Plates

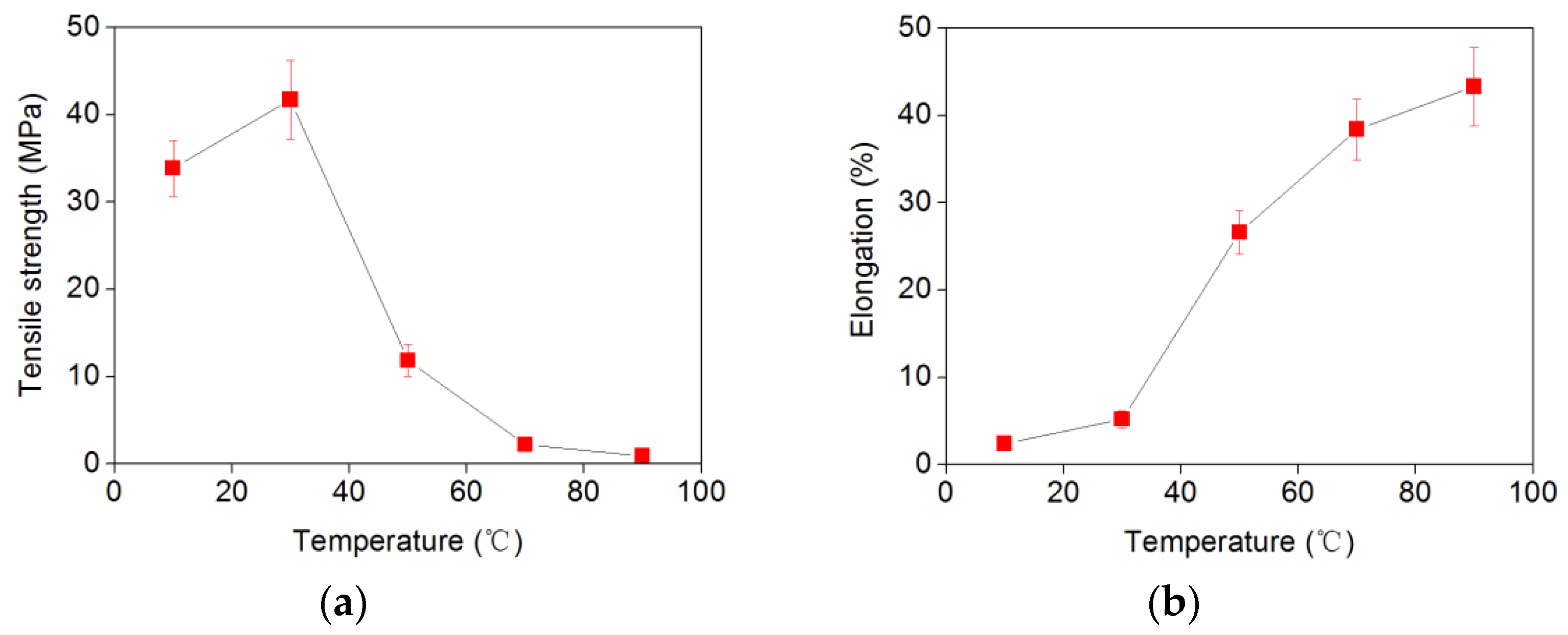

3.2. Effect of Elevated Temperatures on the Properties of Epoxy Adhesive

3.3. Effect of Elevated Temperatures on the Properties of CFRP/Steel Double Strap Joint

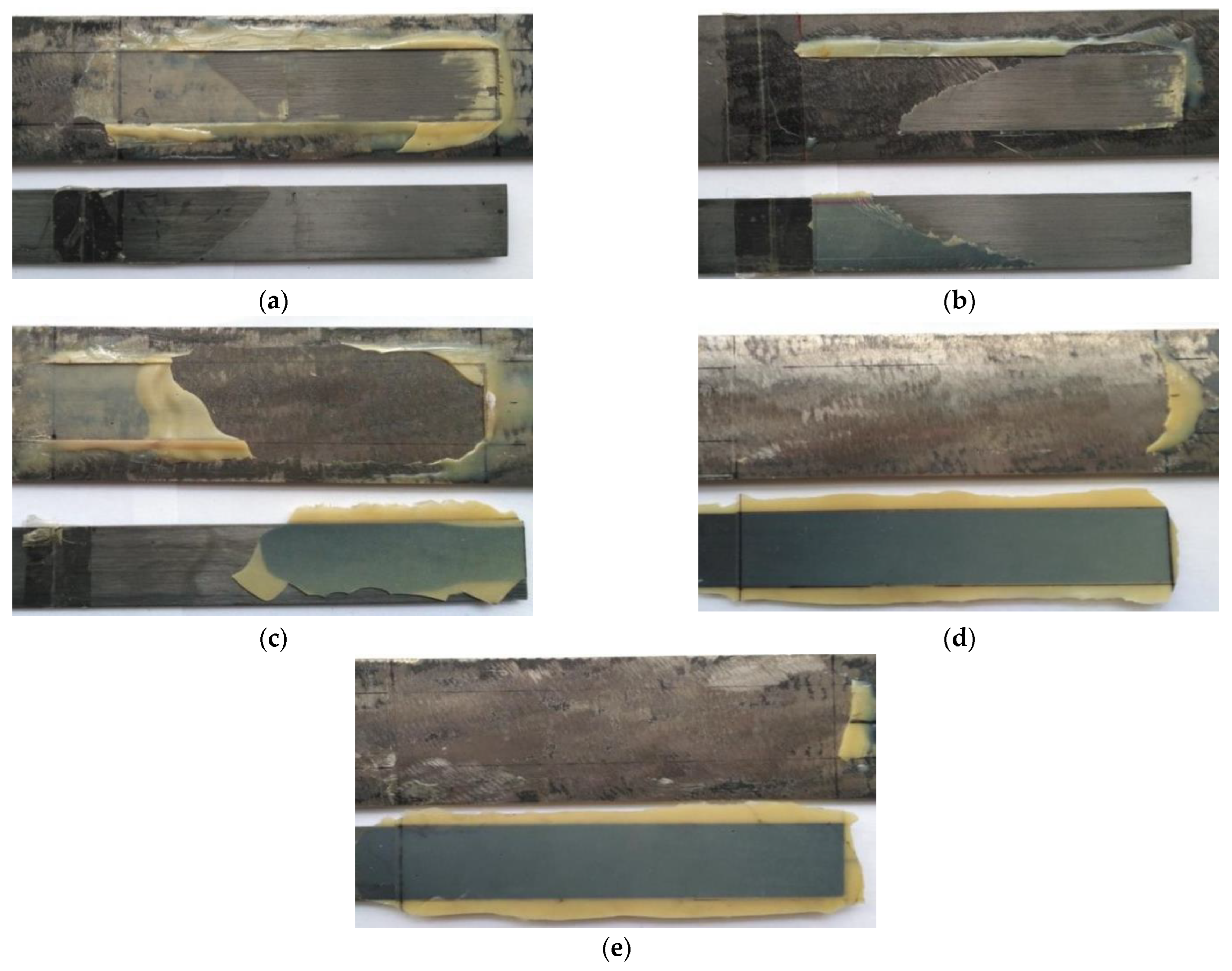

3.3.1. Failure Mode

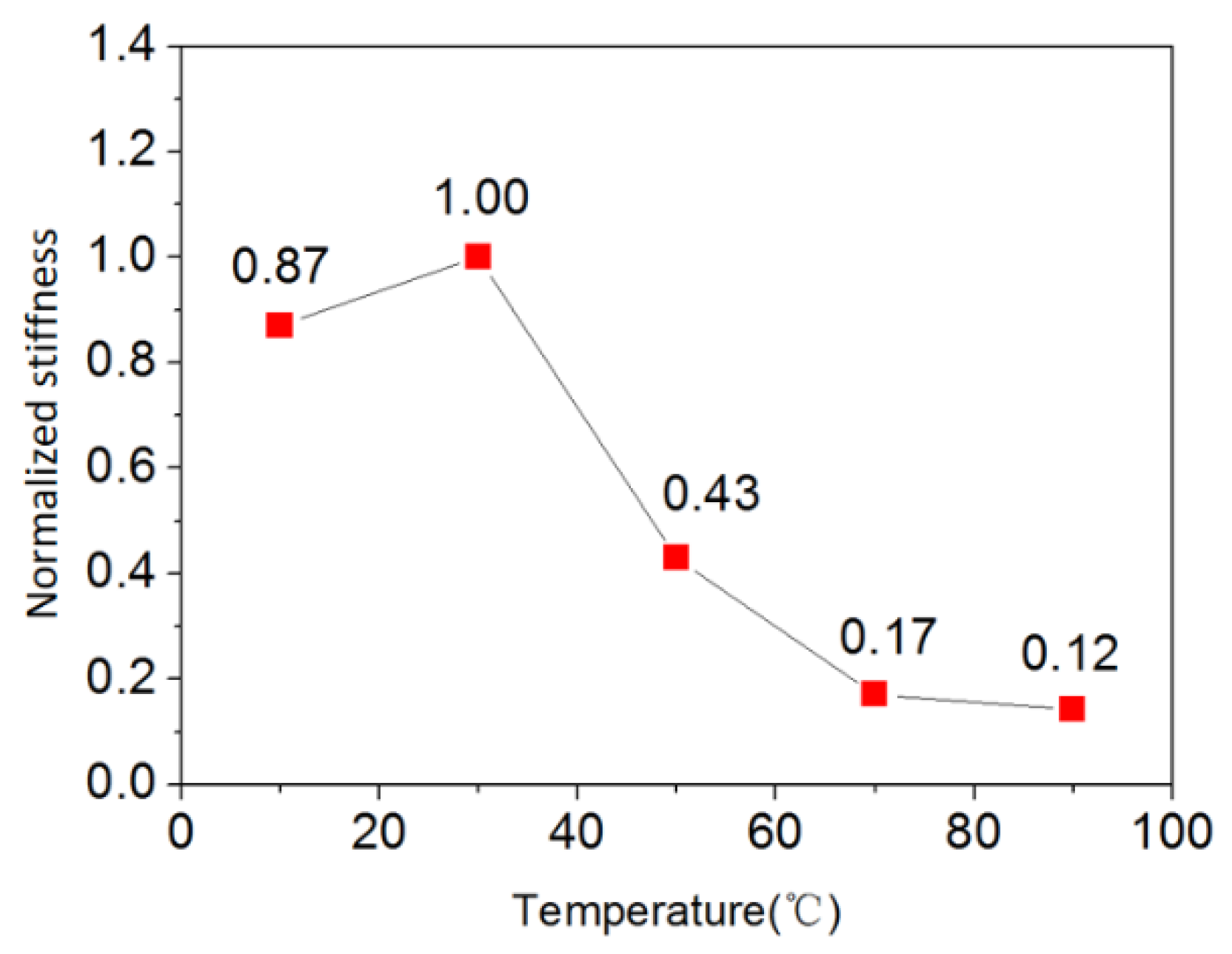

3.3.2. Joint Stiffness

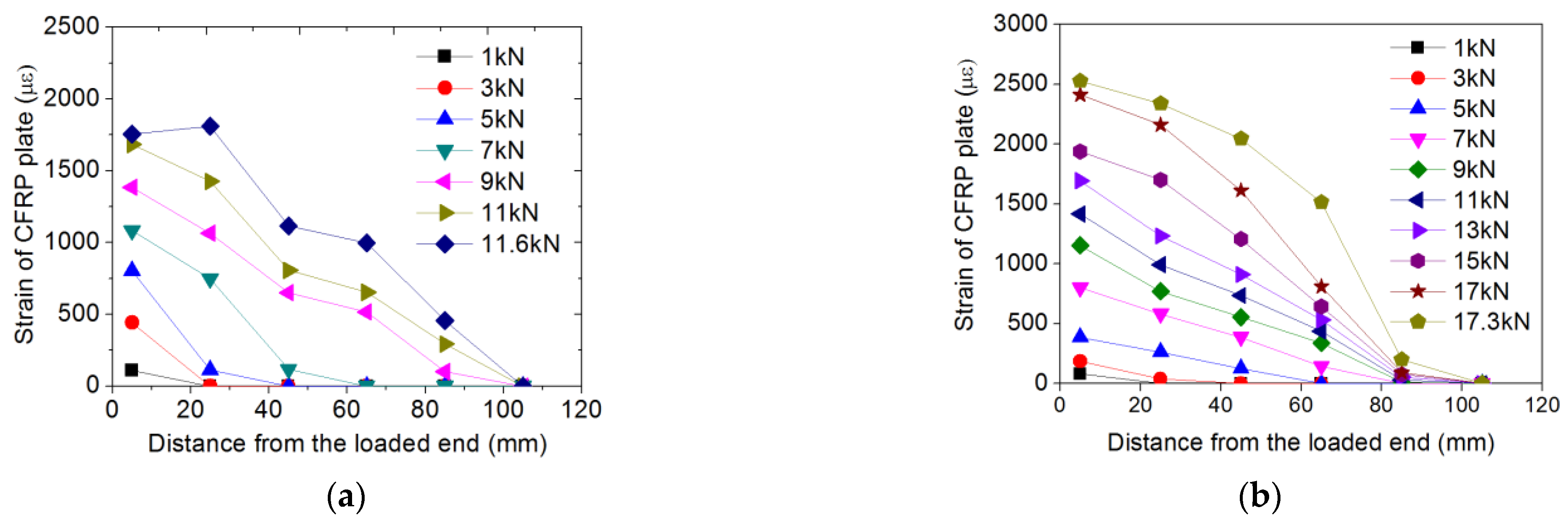

3.3.3. Strain Distribution

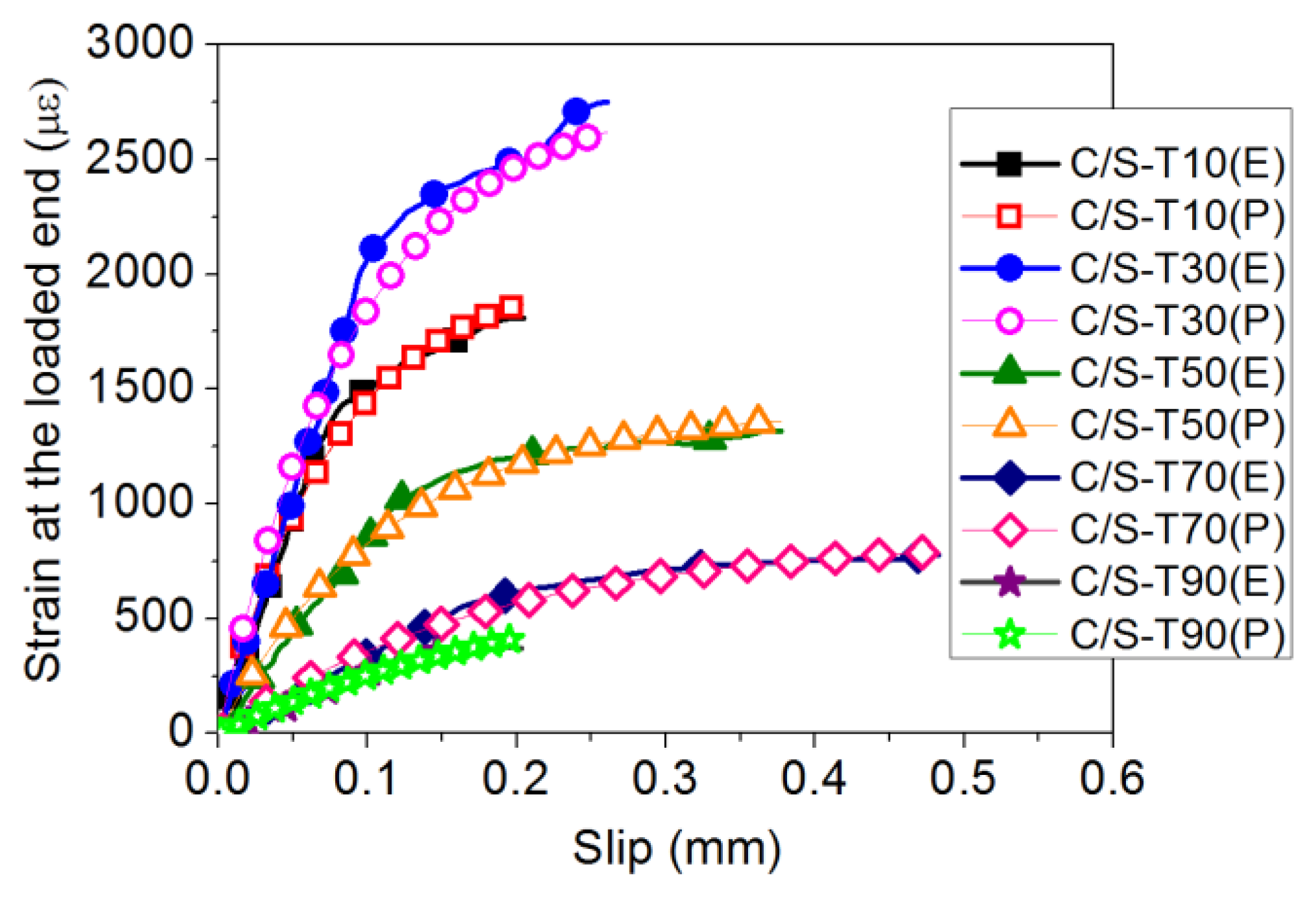

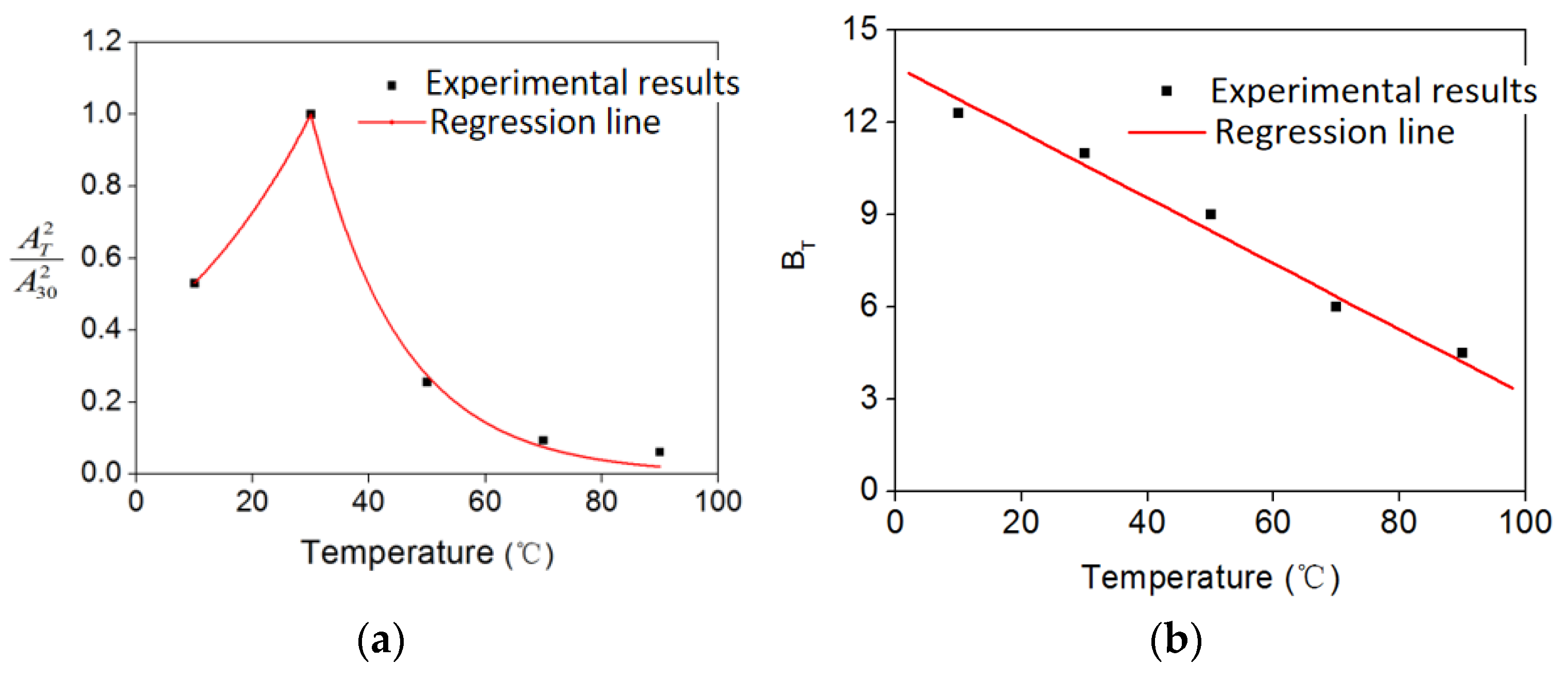

3.3.4. Bond–Slip Curves

4. Conclusions

- (1)

- Elevated temperatures had a slight effect on the mechanical performance of CFRP plates. The tensile strength had no change from 10 to 30 °C, while it decreased slightly from 30 to 90 °C. The modulus of the CFRP plates experienced a very slight decrease when the temperature increased from 10 to 90 °C.

- (2)

- The mechanical properties of epoxy adhesive were sensitive to temperature. The tensile strength increased from 10 to 30 °C, but had a significant decrease from 30 to 90 °C, while the elongation increased when the temperature was below 30 °C, beyond which the elongation increased significantly.

- (3)

- Elevated temperatures had a pronounced effect on the mechanical performance of CFRP/steel double strap joints. Both the bond strength and stiffness increased from 10 to 30 °C, while they decreased from 30 to 90 °C.

- (4)

- The specimens under 10 °C showed an adhesive/steel interface debonding, whereas most specimens under 30 and 50 °C showed a mixed failure mode. When the temperature increased from 70 to 90 °C, the failure mode changed to adhesive/steel interface debonding.

- (5)

- The FRP strain distributions in the overlapping area at different levels of load were measured. The effective bond length increased with temperature. In addition, the strains in the CFRP plate decreased significantly with elevated temperature.

- (6)

- A predictive formula considering elevated temperatures is proposed based on the test results, and the predictions agree well with the test results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Teng, J.G.; Yu, T.; Fernando, D. Strengthening of steel structures with fiber-reinforced polymer composites. J. Constr. Steel Res. 2012, 78, 131–143. [Google Scholar] [CrossRef]

- Tafsirojjamana, T.; Dogar, A.U.R.; Liu, Y.; Manalo, A.; Thambiratnam, D.P. Performance and design of steel structures reinforced with FRP composites: A state-of-the-art review. Eng. Fail. Anal. 2022, 138, 106371. [Google Scholar] [CrossRef]

- Zheng, Z.H.; Du, Y.S.; Chen, Z.H.; Li, S.Y.; Niu, J.Q. Experimental and theoretical studies of FRP-Steel composite plate under static tensile loading. Constr. Build. Mater. 2021, 271, 121501. [Google Scholar] [CrossRef]

- Zeng, J.J.; Gao, W.Y.; Feng, L.F. Interfacial behavior and debonding failures of full-scale CFRP-strengthened H-section steel beams. Compos. Struct. 2018, 201, 540–552. [Google Scholar] [CrossRef]

- Akbar, I.; Oehlers, D.J.; Ali, M.S.M. Derivation of the bond–slip characteristics for FRP plated steel members. J. Constr. Steel Res 2010, 66, 1047–1056. [Google Scholar] [CrossRef]

- Fawzia, S.; Zhao, X.L.; Al-Mahaidi, R. Bond-slip models for double strap joints strengthened by CFRP. Compos. Struct. 2010, 92, 2137. [Google Scholar] [CrossRef]

- Al-Shawaf, A.; Al-Mahaidi, R.; Zhao, X.L. Effect of elevated temperature on bond behaviour of high modulus CFRP/steel double-strap joints. Aust. J. Struct. Eng. 2009, 10, 63–74. [Google Scholar] [CrossRef]

- ACI 440.2R-08; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute Rep.: Farmington Hills, MI, USA, 2008.

- Bai, Y.; Keller, T. Effects of thermal loading history on structural adhesive modulus across glass transition. Constr. Build. Mater. 2011, 25, 2162–2168. [Google Scholar] [CrossRef]

- Michels, J.; Widmann, R.; Czaderski, C.; Allahvirdizadeh, R.; Motavalli, M. Glass transition evaluation of commercially available epoxy resins used for civil engineering applications. Compos. Part B Eng. 2015, 77, 484–493. [Google Scholar] [CrossRef]

- Kodur, V.K.R.; Bisby, L.A.; Green, M.F. Preliminary guidance for the design of FRP-strengthened concrete members exposed to fire. J. Fire Prot. Eng. 2007, 17, 5–26. [Google Scholar] [CrossRef]

- Porter, M.L.; Harries, K. Future directions for research in FRP composites in concrete construction. J. Compos. Constr. 2007, 11, 252–257. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Durability of bonded FRP-to-steel joints: Effects of moisture, de-icing salt solution, temperature and FRP type. Compos. Part B Eng. 2017, 119, 153–167. [Google Scholar] [CrossRef]

- Stratford, T.J.; Bisby, L.A. Effect of Warm Temperatures on Externally Bonded FRP Strengthening. J. Compos. Constr. 2016, 16, 235–244. [Google Scholar] [CrossRef]

- Guo, D.; Zhou, H.; Wang, H.P.; Dai, J.G. Effect of temperature variation on the plate-end debonding of FRP-strengthened steel beams: Coupled mixed-mode cohesive zone modeling. Eng. Fract. Mech. 2022, 270, 108583. [Google Scholar] [CrossRef]

- Dong, K.; Hao, J.W.; Li, P.; Zhong, C.Q. A nonlinear analytical model for predicting bond behavior of FRP-to-concrete/steel substrate joints subjected to temperature variations. Constr. Build. Mater. 2022, 320, 126225. [Google Scholar] [CrossRef]

- Yao, M.X.; Zhu, D.J.; Yao, Y.M.; Zhang, H.A.; Mobasher, B. Experimental study on basalt FRP/steel single-lap joints under different loading rates and temperatures. Compos. Struct. 2016, 145, 68–79. [Google Scholar] [CrossRef]

- Teng, R.; Guo, Y.; Wang, H.; Zhao, Z.; Wang, X. Experimental study of bending interface characteristics of CFRP-strengthened long-span steel main beams at different temperatures. Eng. Struct. 2021, 235, 111932. [Google Scholar] [CrossRef]

- Zhou, H.; Fernando, D.; Torero, J.L.; Torres, J.P.; Maluk, C.; Emberley, R. Bond Behavior of CFRP-to-Steel Bonded Joints at Mild Temperatures: Experimental Study. J. Compos. Constr. 2020, 24, 04020070. [Google Scholar] [CrossRef]

- Nguyen, T.C.; Bai, Y.; Zhao, X.L.; Al-Mahaidi, R. Mechanical characterization of steel/CFRP double strap joints at elevated temperatures. Compos. Struct. 2011, 93, 1604–1612. [Google Scholar] [CrossRef]

- Chandrathilaka, E.R.K.; Gamage, J.C.P.H.; Fawzia, S. Mechanical characterization of CFRP/steel bond cured and tested at elevated temperature. Compos. Struct. 2019, 207, 471–477. [Google Scholar] [CrossRef]

- GB/T 3354-1999; Test Method for Tensile Properties of Oriented Fiber Reinforced Plastics. National Standard of the People’s Republic of China: Beijing, China, 1999.

- Li, X.J. Study on the Basic Mechanical Properties and Durabilities of FRP-Steel Composites Material. Ph.D. Thesis, Wuhan University, Wuhan, China, 2014. [Google Scholar]

- GB/T 228-2002; Metallic Materials-Tensile Testing at Ambient Temperature. National Standard of the People’s Republic of China: Beijing, China, 2002.

- GB/T 2567-2008; Test Methods for Properties of Resin Casting Body. National Standard of the People’s Republic of China: Beijing, China, 2008.

- Dai, J.G.; Ueda, T.; Sato, Y. Development of the nonlinear bond stress-slip model of fiber reinforced plastics sheet-concrete interfaces with a simple method. J. Compos. Constr. 2005, 9, 52–62. [Google Scholar] [CrossRef]

| Specimen ID | Number of Specimens | Temperature (°C) | Ultimate Load (kN) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| C-T10 | 6 | 10 | 49.48 | 2748 | 177.24 | 1.55 |

| C-T30 | 6 | 30 | 49.57 | 2754 | 177.45 | 1.54 |

| C-T50 | 6 | 50 | 46.76 | 2597 | 176.36 | 1.47 |

| C-T70 | 6 | 70 | 45.28 | 2515 | 176.03 | 1.43 |

| C-T90 | 6 | 90 | 45.02 | 2501 | 175.65 | 1.41 |

| Specimen ID | Number of Specimens | Temperature (°C) | Ultimate Load (N) | Tensile Strength (MPa) | Elastic Modulus (MPa) | Elongation (%) |

|---|---|---|---|---|---|---|

| A-T10 | 6 | 10 | 1354 | 33.85 | 4788 | 2.4 |

| A-T30 | 6 | 30 | 1669 | 41.72 | 5052 | 5.2 |

| A-T50 | 6 | 50 | 474 | 11.85 | — | 26.6 |

| A-T70 | 6 | 70 | 89 | 2.23 | — | 38.4 |

| A-T90 | 6 | 90 | 38 | 0.95 | — | 43.3 |

| Specimen ID | Temperature (°C) | Ultimate Load (kN) | Average Value (kN) | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |||

| C/S-T10 | 10 | 24.0 | 23.2 | 22.9 | 15.9 | 25.2 | 22.7 | 22.35 |

| C/S-T30 | 30 | 24.3 | 42.5 | 34.6 | 40.6 | 38.6 | 34.7 | 35.92 |

| C/S-T50 | 50 | 20.5 | 15.7 | 24.9 | 16.4 | 10.1 | 15.2 | 17.13 |

| C/S-T70 | 70 | 10.2 | 11. | 9.8 | 10.1 | 6.8 | 8.5 | 9.58 |

| C/S-T90 | 90 | 2.4 | 3.8 | 4.7 | 6.2 | 3.0 | 5.5 | 4.28 |

| Specimen ID | Temperature (°C) | A | B (mm−1) | R2 |

|---|---|---|---|---|

| C/S-T10 | 10 | 0.002027 | 12.589 | 0.988 |

| C/S-T30 | 30 | 0.002784 | 10.886 | 0.951 |

| C/S-T50 | 50 | 0.001411 | 8.849 | 0.984 |

| C/S-T70 | 70 | 0.000853 | 5.479 | 0.982 |

| C/S-T90 | 90 | 0.000690 | 4.589 | 0.969 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Chen, W.; Liu, C.; Li, N. Bond Performance of CFRP/Steel Double Strap Joint at Elevated Temperatures. Sustainability 2022, 14, 15537. https://doi.org/10.3390/su142315537

Liu Y, Chen W, Liu C, Li N. Bond Performance of CFRP/Steel Double Strap Joint at Elevated Temperatures. Sustainability. 2022; 14(23):15537. https://doi.org/10.3390/su142315537

Chicago/Turabian StyleLiu, Yuwen, Wei Chen, Chun Liu, and Na Li. 2022. "Bond Performance of CFRP/Steel Double Strap Joint at Elevated Temperatures" Sustainability 14, no. 23: 15537. https://doi.org/10.3390/su142315537

APA StyleLiu, Y., Chen, W., Liu, C., & Li, N. (2022). Bond Performance of CFRP/Steel Double Strap Joint at Elevated Temperatures. Sustainability, 14(23), 15537. https://doi.org/10.3390/su142315537

_Xie.png)