Construction of Control Charts to Help in the Stability and Reliability of Results in an Accredited Water Quality Control Laboratory

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of the Study

2.2. Methods

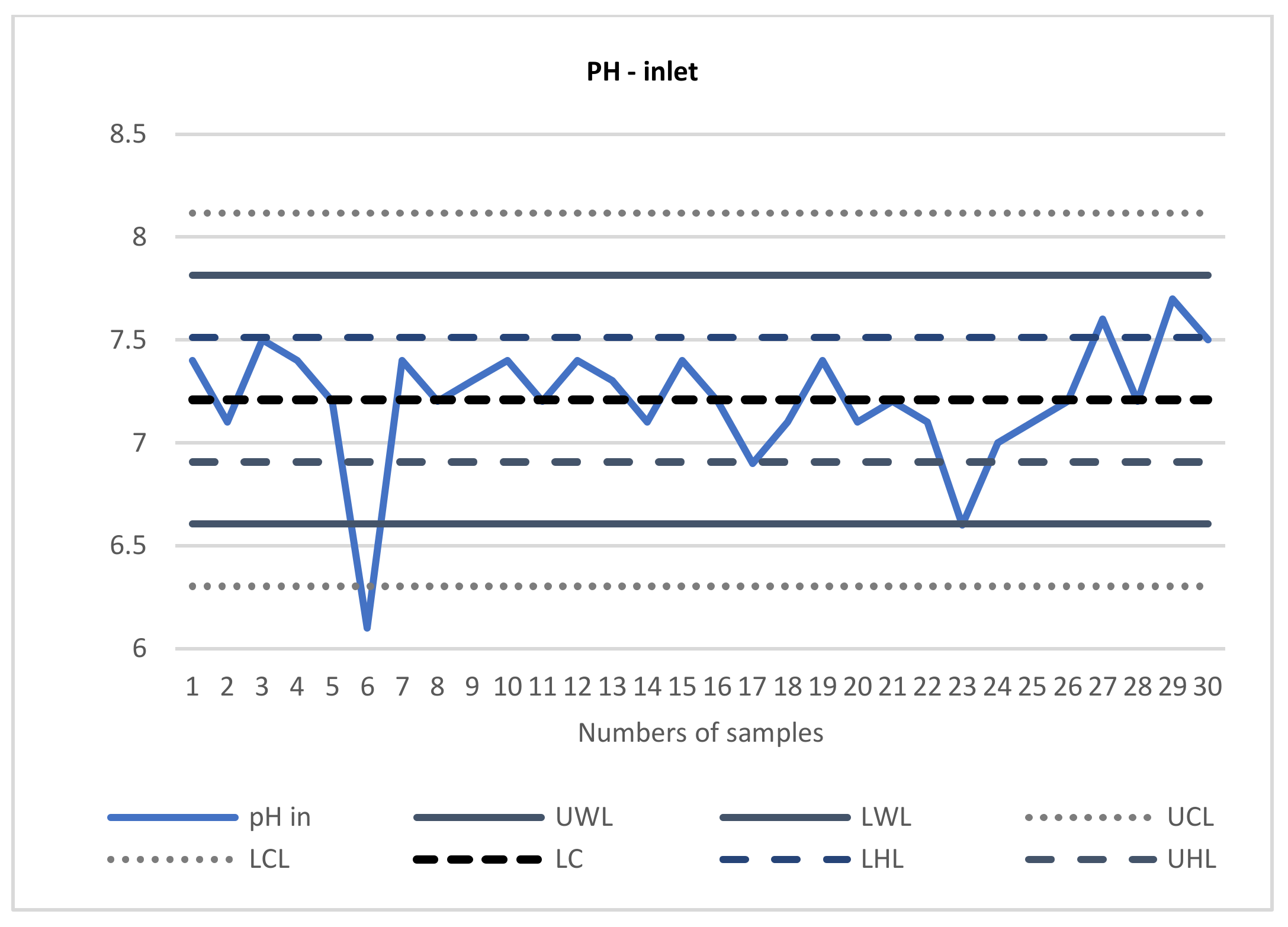

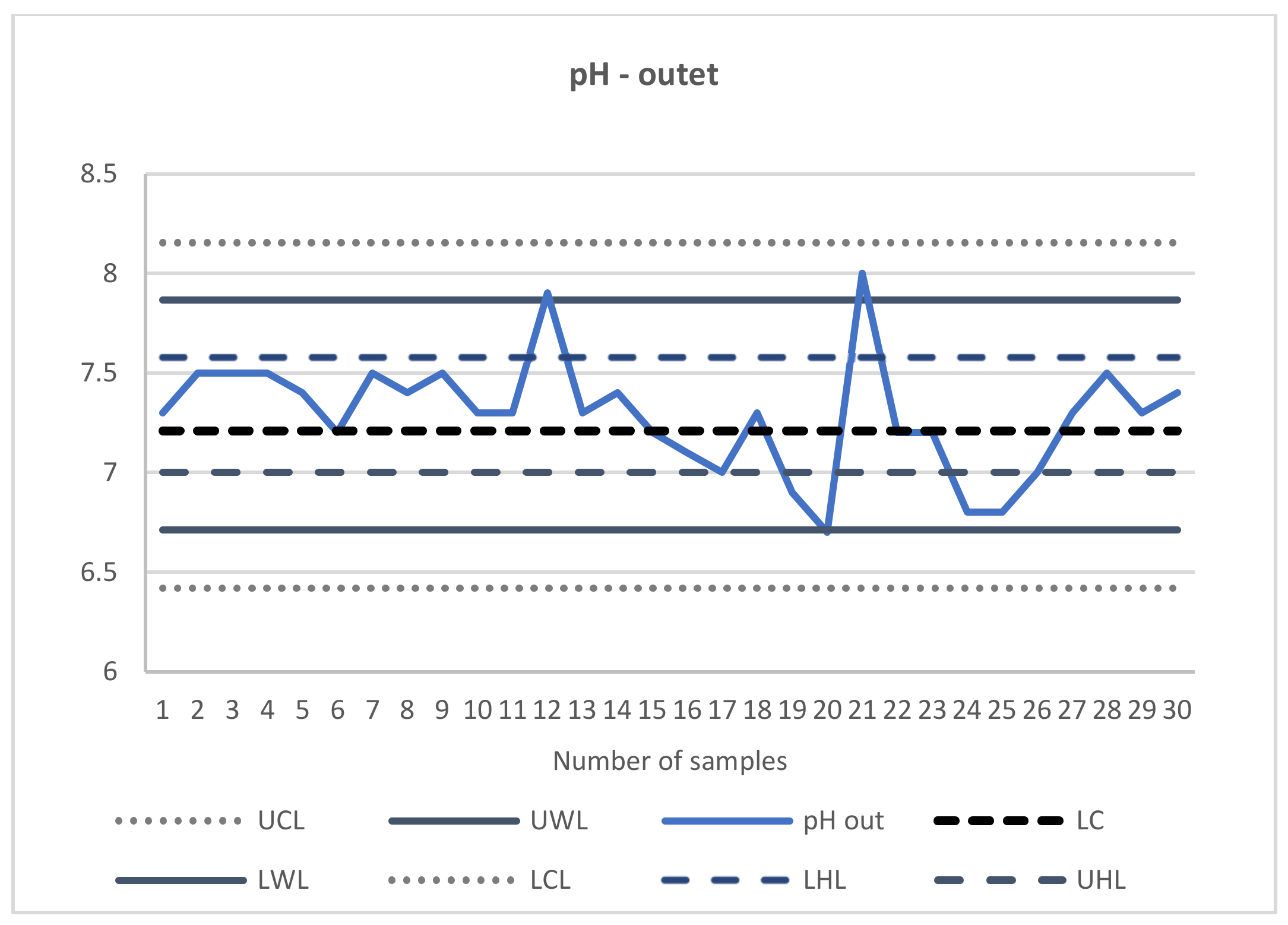

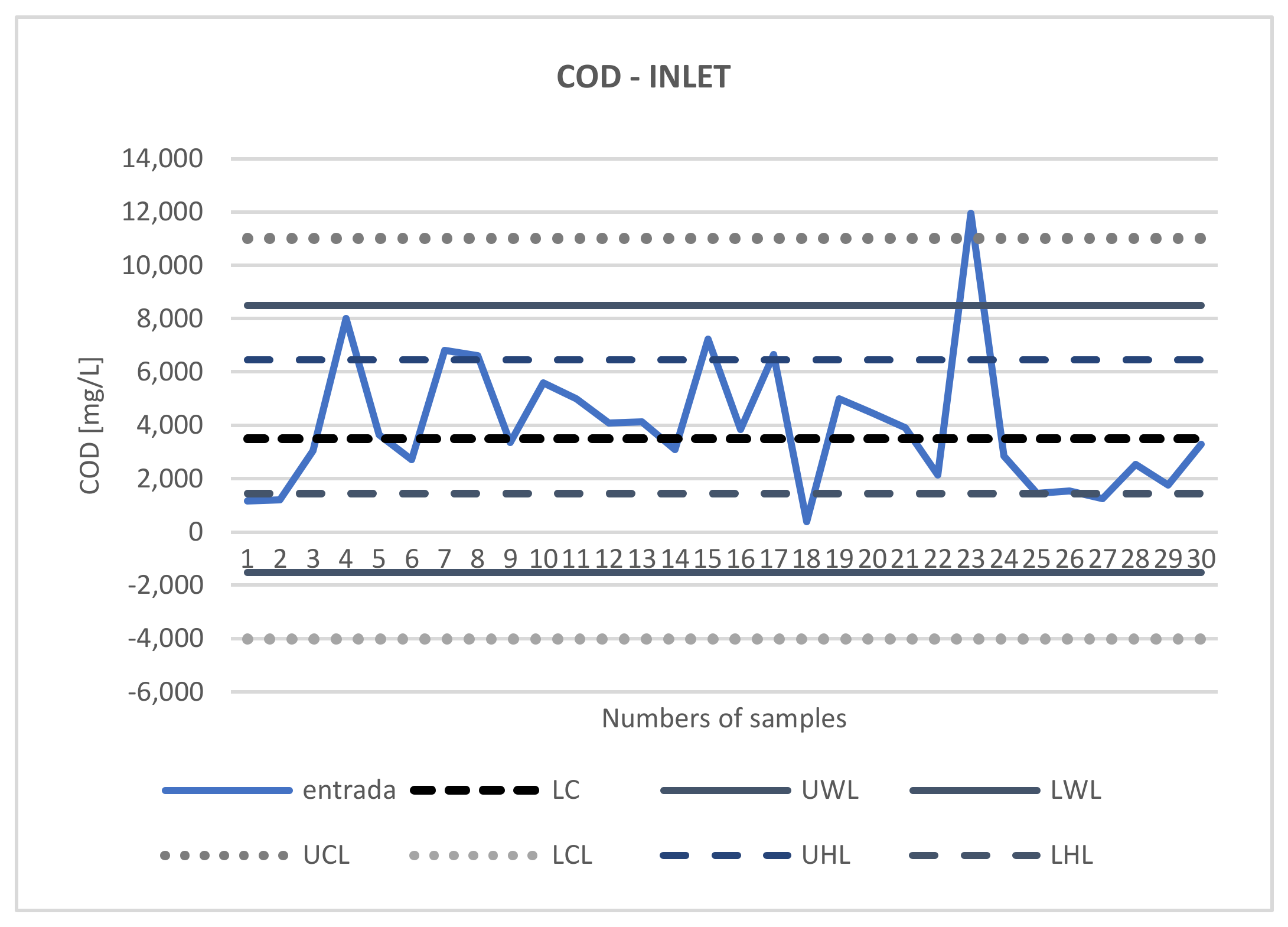

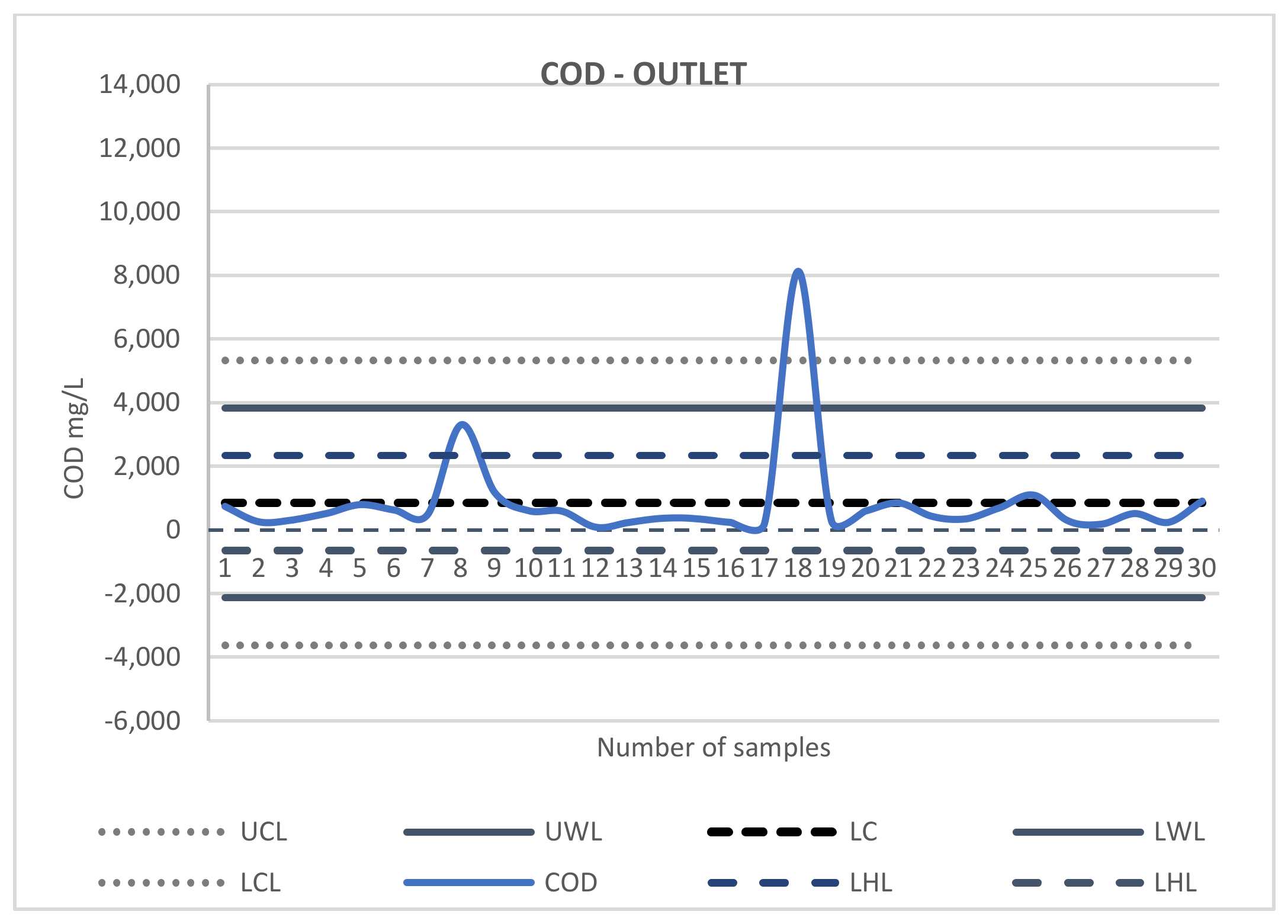

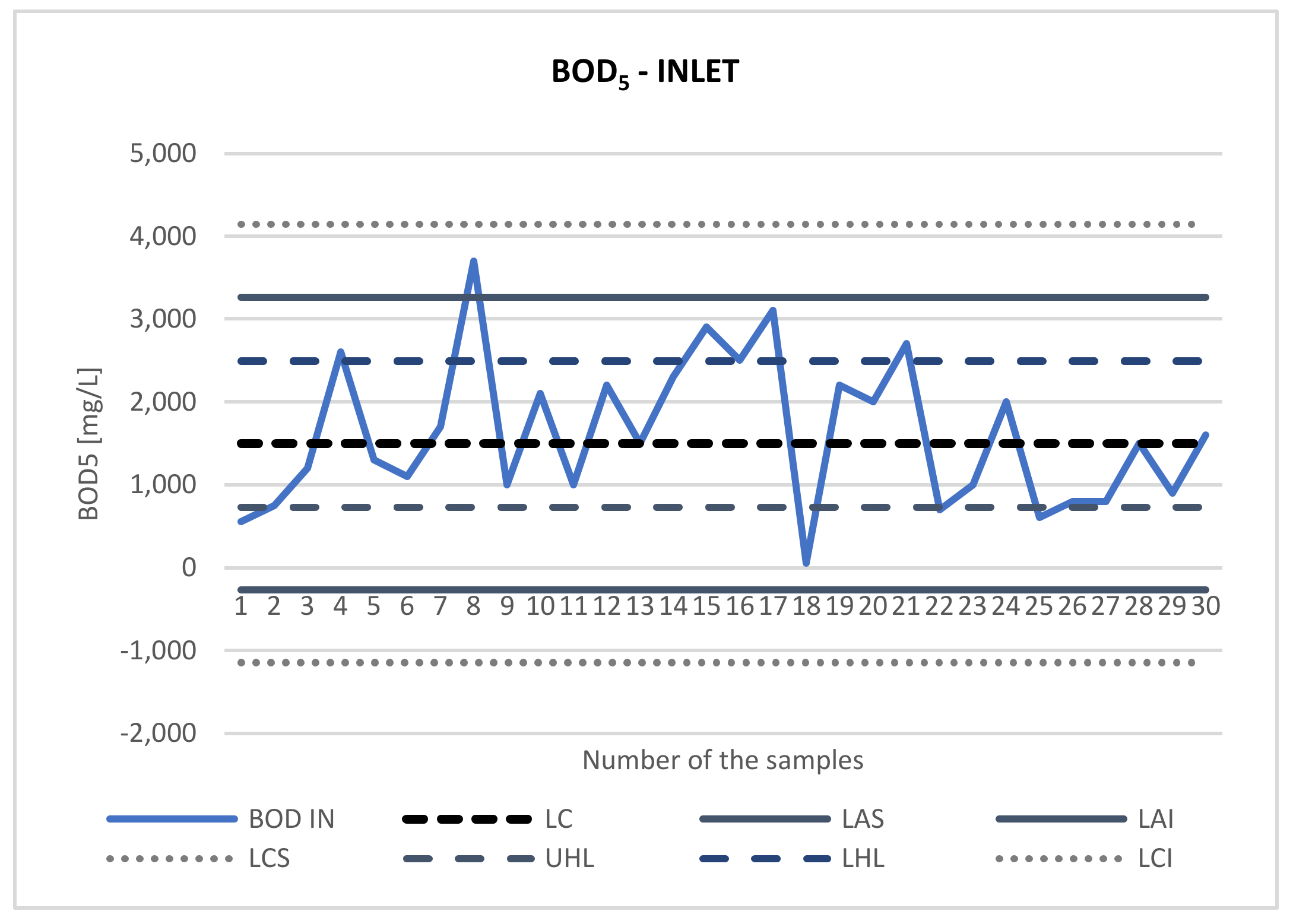

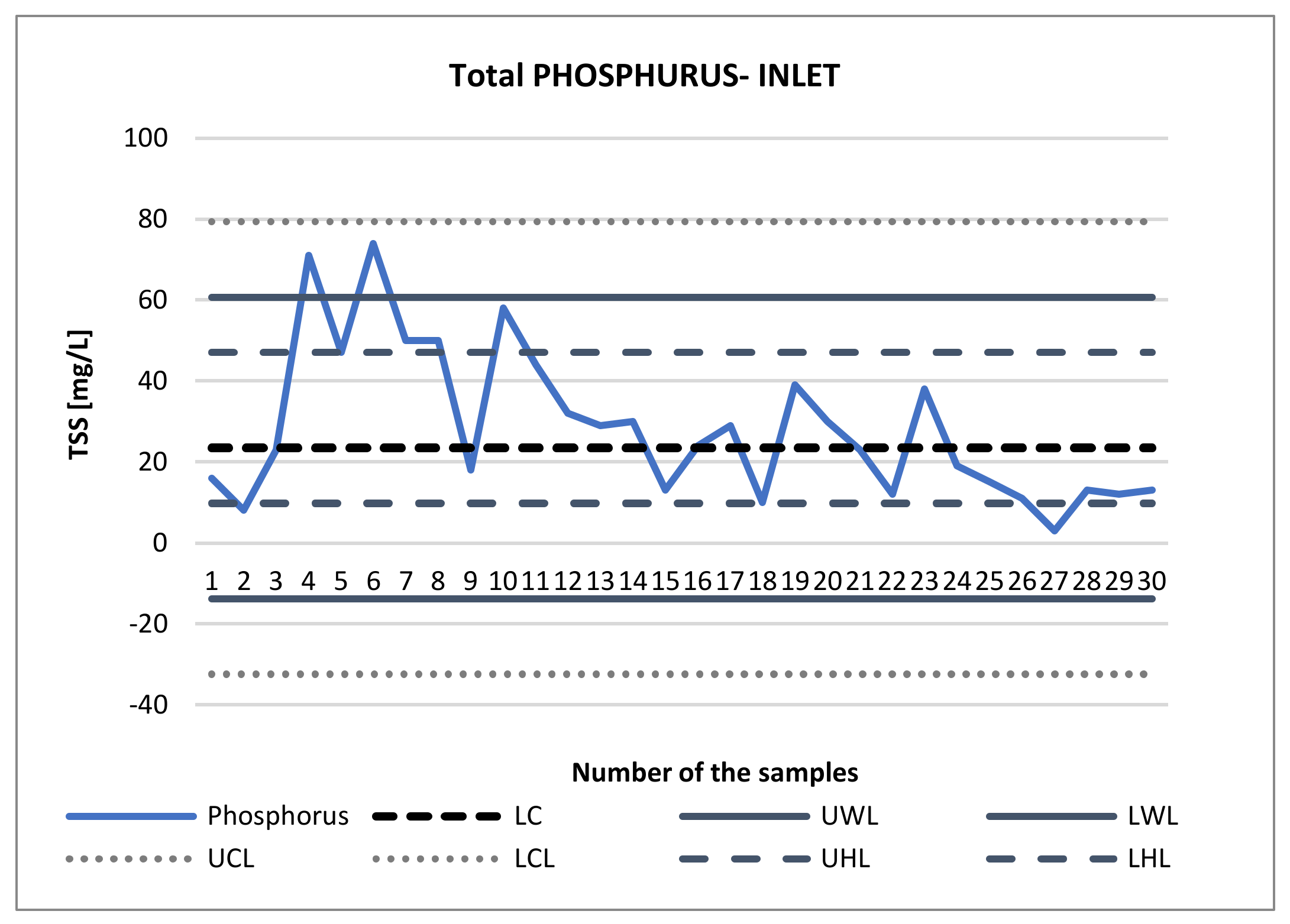

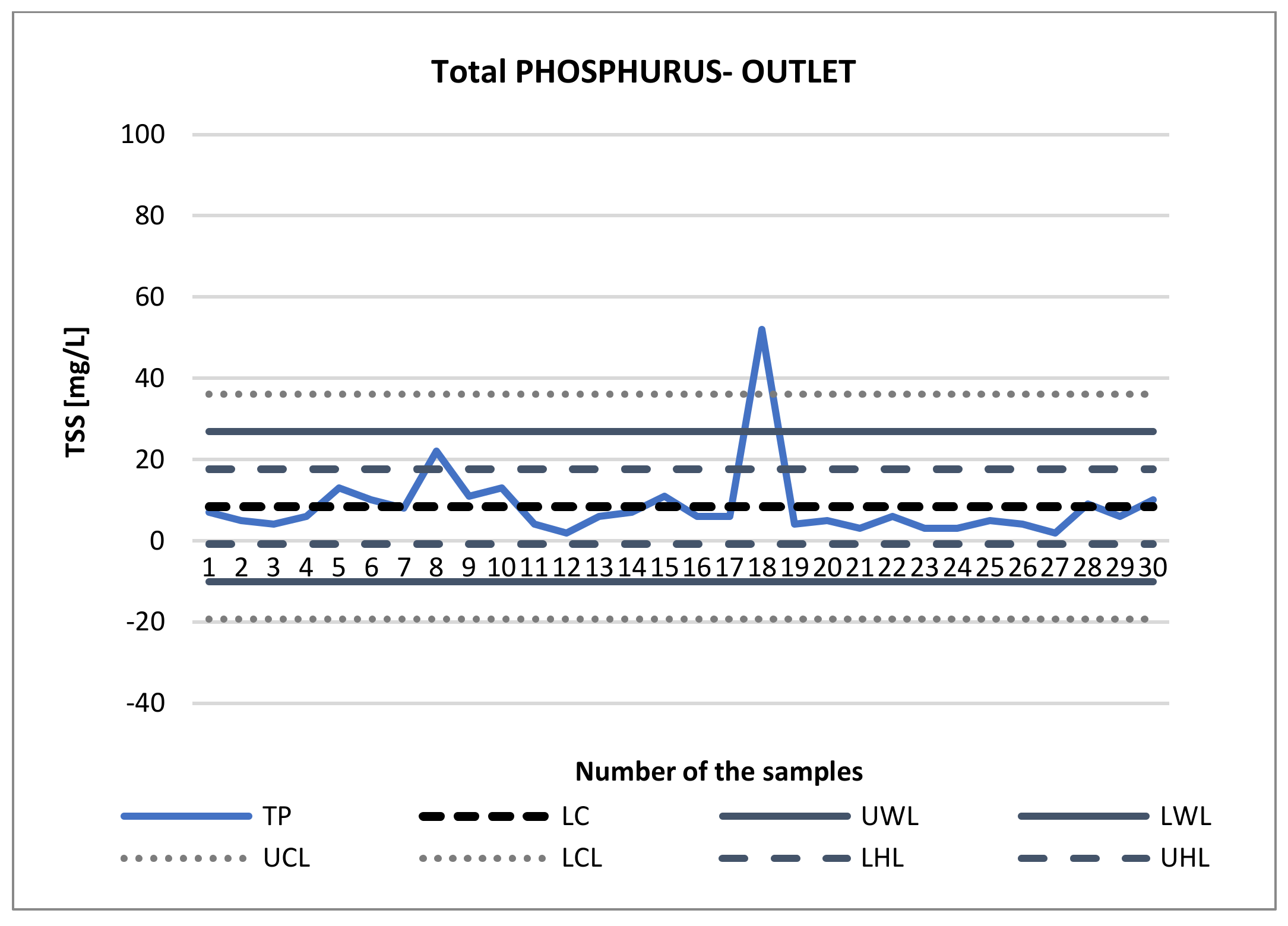

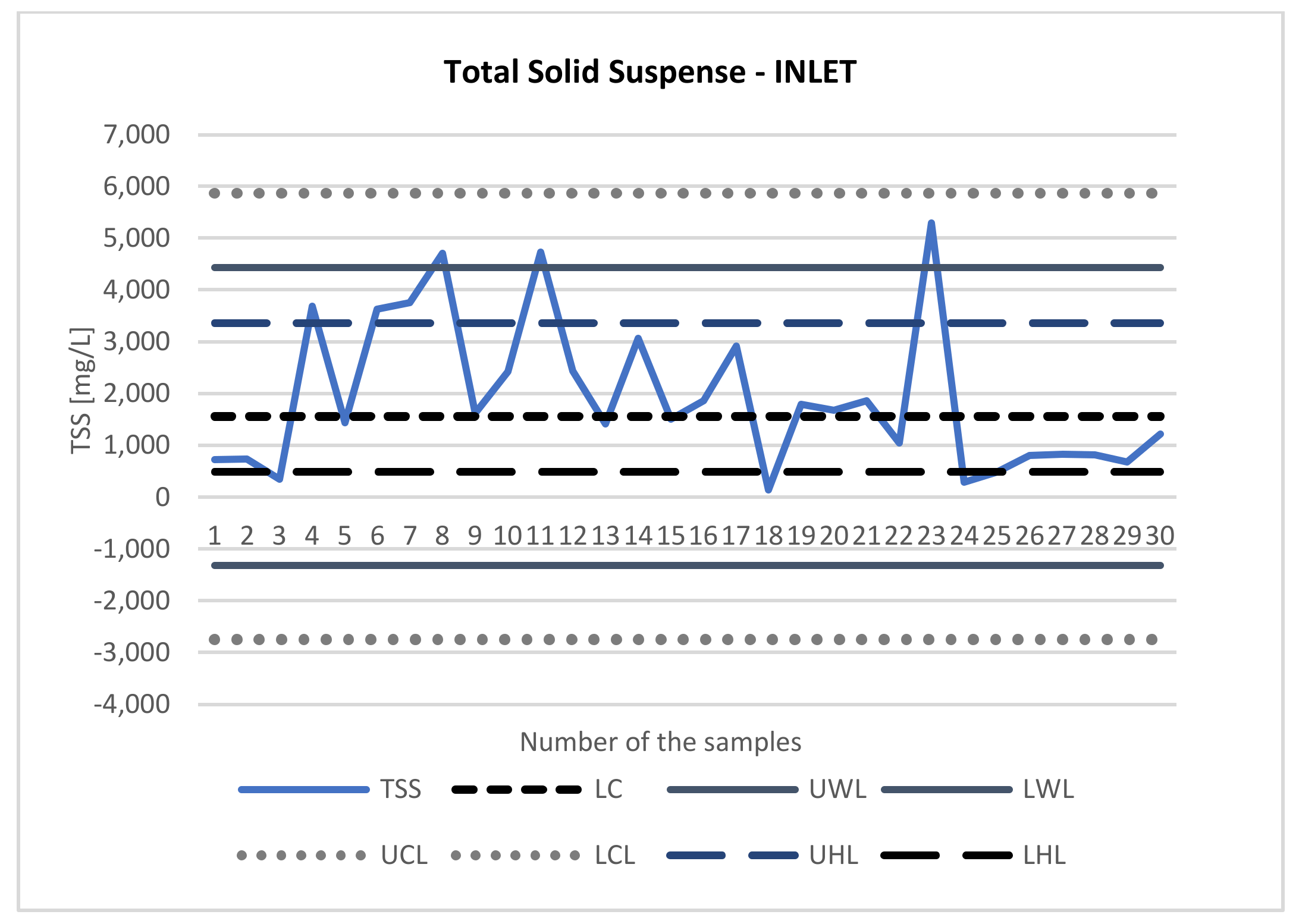

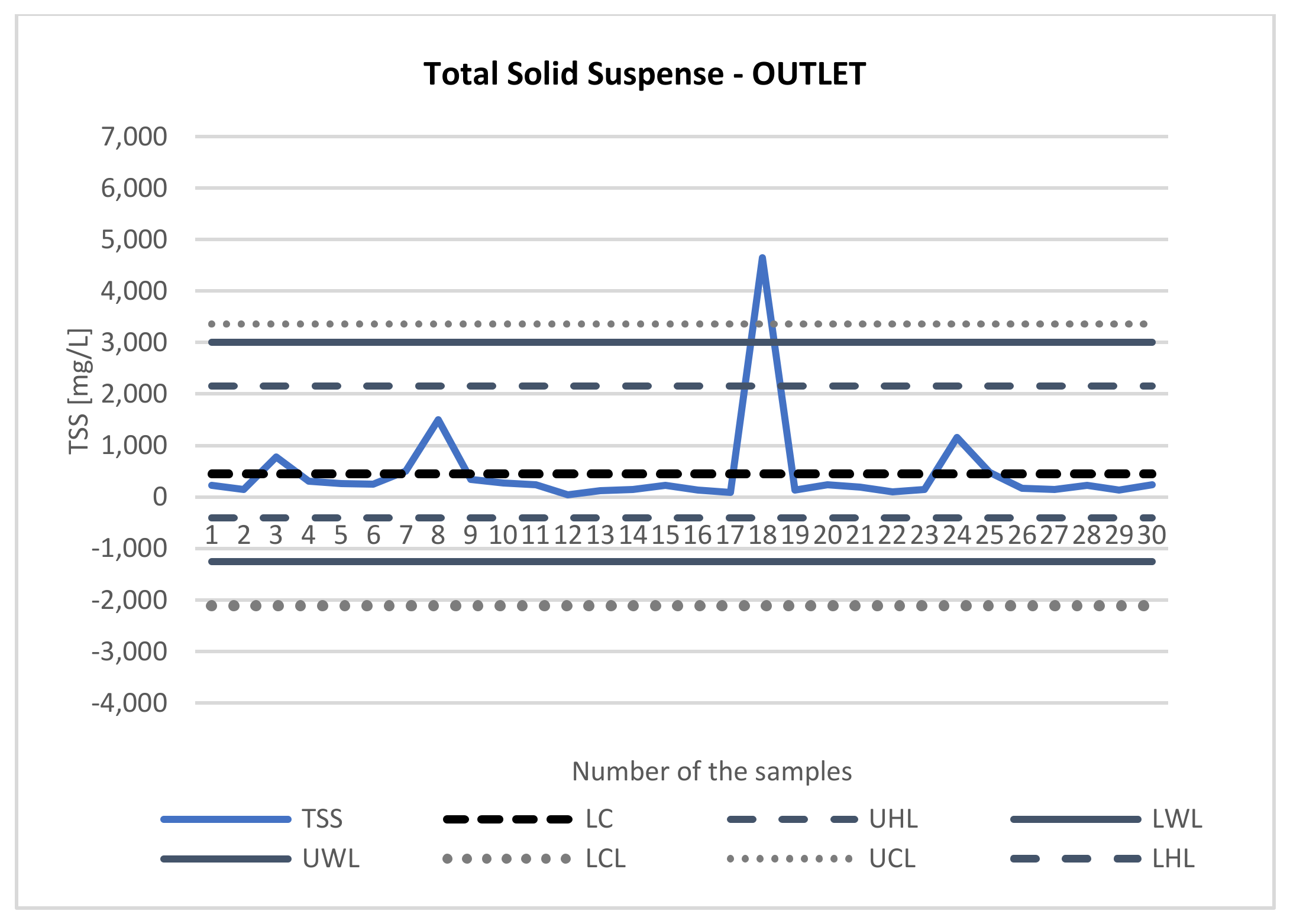

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BOD5 | Biological oxygen demand |

| CL | Centre line |

| COD | Chemical oxygen demand |

| LCL | Lower control line |

| LHL | Lower helpline |

| LWL | Lower warning line |

| TP | Total phosphorus |

| TSS | Total solid suspense |

| UCL | Upper control line |

| UHL | Upper helpline |

| UWL | Upper warning line |

| WFD | Water framework directive |

References

- Costa, A.F.B.; Epprecht, E.K.; Carpinetti, L.C.R. Controle Estatístico da Qualidade, 2nd ed.; Atlas: São Paulo, Brazil, 2010. [Google Scholar]

- Perez, V.V.; Diacenco, A.A.; Paulista, P.H. Análise das Sete Ferramentas Estatísticas da Qualidade Utilizadas nos Sistemas Produtivos. Rev. Univap 2016, 22, 807. [Google Scholar] [CrossRef][Green Version]

- Samohyl, R.W. Controle Estatístico de Qualidade; Elsevier: São Paulo, Brazil, 2009. [Google Scholar]

- Ramos, E.M.L.S. Aperfeiçoamento e Desenvolvimento de Ferramentas do Controle Estatístico da Qualidade—Utilizando Quartis Para Estimar o Desvio Padrão. Ph.D. Thesis, Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2003. [Google Scholar]

- Corrêa, H.; Corrêa, C.A. Administração da Produção e Operações: Manufatura e Serviços: Uma Abordagem Estratética; Atlas: São Paulo, Brazil, 2008. [Google Scholar]

- Simonet, B. Quality control in qualitative analysis. TrAC Trends Anal. Chem. 2005, 24, 525–531. [Google Scholar] [CrossRef]

- Mohammad, R. BOD, COD, and TSS Predictions from DO measurement results for the Surabaya River, Indonesia. J. Civ. Eng. Plan. Des. 2022, 1, 1–7. [Google Scholar]

- Orssatto, F.; Boas, M.A.V.; Nagamine, R.; Uribe-Opazo, M.A. Shewhart’s control charts and process capability ratio applied to a sewage treatment station. Eng. Agríc. Jaboticabal 2014, 34, 770–779. [Google Scholar] [CrossRef]

- Śliz, P.; Piotr, B. Assessment of the stability and reliability of the water treatment plant in Nowy Sącz using control cards. J. Water Land Dev. 2022, 251–256. [Google Scholar] [CrossRef]

- Turuta, T.B. Aplicação de Cartas de Controle como Ferramenta de Melhoria Frente às Dificuldades Operacionais de Laboratórios Acreditados na ABNT NBR ISO/IEC 1705. Master’s Thesis, Instituto de Química de São Carlos da Universidade de São Paulo, São Carlos, Brazil, 2015. [Google Scholar]

- Zan, T.; Wang, M.; Fei, R.Y. Pattern Recognition for Control Charts Using AR Spectrum and Fuzzy ARTMAP Neural Network. Adv. Mater. Res. 2010, 97–101, 3696–3702. [Google Scholar] [CrossRef]

- Hadian, H.; Rahimifard, A. Multivariate statistical control chart and process capability indices for simultaneous monitoring of project duration and cost. Comput. Ind. Eng. 2019, 130, 788–797. [Google Scholar] [CrossRef]

- Wagner, I.; Breil, P. The role of ecohydrology in creating more resilient cities. Ecohydrol. Hydrobiol. 2013, 13, 113–134. [Google Scholar] [CrossRef]

- Reilly, M.; Cooley, A.P.; Tito, D.; Tassou, A.S.; Theodorou, M.K. Electrocoagulation treatment of dairy processing and slaughterhouse wastewaters. Energy Procedia 2019, 161, 343–351. [Google Scholar] [CrossRef]

- Bustillo-Lecompte, C.; Mehrvar, M. Slaughterhouse wastewater: Treatment, management and resource recovery. In Physico-chemical Wastewater Treatment and Resource Recovery; Farooq, R., Ahmad, Z., Eds.; IntechOpen: Rijeka, Croatia, 2017; pp. 153–174. [Google Scholar]

- Tirado, L.; Gökkuş, Ö.; Brillas, E.; Sirés, I. Treatment of cheese whey wastewater by combined electrochemical processes. J. Appl. Electrochem. 2018, 48, 1307–1319. [Google Scholar] [CrossRef]

- Slavov, A.K. General characteristics and treatment possibilities of dairy wastewater—A review. Food Technol. Biotechnol. 2017, 55, 14–28. [Google Scholar] [CrossRef] [PubMed]

- Bazrafshan, E.; Mostafapour, F.K.; Farzadkia, M.; Ownagh, K.A.; Mahvi, A.H. Slaughterhouse Wastewater Treatment by Combined Chemical Coagulation and Electrocoagulation Process. PLoS ONE 2012, 7, e40108. [Google Scholar] [CrossRef] [PubMed]

- Şengil, I.A.; Özacar, M. Treatment of dairy wastewaters by electrocoagulation using mild steel electrodes. J. Hazard. Mater. 2006, 137, 1197–1205. [Google Scholar] [CrossRef] [PubMed]

- Henning, E. Aperfeiçoamento e Desenvolvimento dos Gráficos Combinados Shewhart-CUSUM Binomiais, 2010.251f. Ph.D. Thesis, Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2010. [Google Scholar]

- Krzanowski, S.; Wałęga, A. Wykorzystanie Teorii Niezawodności i Statystycznej Kontroli Jakości do Oceny Eksploatacyjnej Oczyszczalni Ścieków. [The Use of the Theory of Reliability and Statistical Quality Control to Evaluate the Operational Evaluation of Sewage Treatment Plants]; Infrastruktura i Ekologia Terenów Wiejskich, nr 3/2/2006; Polska Akademia Nauk: Kraków, Poland, 2006; pp. 17–37. [Google Scholar]

- Krzanowski, S.; Waleça, A.; Pásmioka, I. Treatment of Wastewater from Selected Food Industry Plants; Wydawnictwo Kmisji Technicznej Infrastruktury Wsi PAN w Krakowie: Krakow, Poland, 2008. [Google Scholar]

- Andraka, D. Wykorzystanie Statystycznej Kontroli Jakości do Oceny Pracy Oczyszczalni Ścieków W: Problemy Gospodarki Wodno-Ściekowej w Rejonach Rolniczo-Przemysłowych [The Use of Statistical Quality Control to Evaluate the Operation of Sewage Treatment Plants]. In Problems of Water and Sewage Management in Agricultural and Industrial Regions]; Monografie Komitetu Inżynierii Środowiska PAN: Warsaw, Poland, 2005. [Google Scholar]

- Batista, L.T.; Franco, J.R.Q.; Fakury, R.H.; Porto, M.F.; Braga, C.M.P. Methodology for Determining Sustainable Water Consumption Indicators for Buildings. Sustainability 2022, 14, 5695. [Google Scholar] [CrossRef]

- Woodall, W.H.; Montgomery, D.C. Research Issues and Ideas in Statistical Process Control. J. Qual. Technol. 1999, 31, 376–386. [Google Scholar] [CrossRef]

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Młyński, D.; Bugajski, P.; Młyńska, A. Application of the Mathematical Simulation Methods for the Assessment of the Wastewater Treatment Plant Operation Work Reliability. Water 2019, 11, 873. [Google Scholar] [CrossRef]

- Nagendra, Y.; Rai, G. Optimum sample size and sampling interval for controlling the mean of non-normal variables. J. Am. Stat. Assoc. 1971, 66, 637–640. [Google Scholar] [CrossRef]

- Moore, P.G. Normality in Quality Control Charts. J. R. Stat. Soc. Ser. C 1957, 6, 171. [Google Scholar] [CrossRef]

- Ministério do Ambiente DIARIO DA REPUBLICA - 1. ª SERIE A, Nº 176, de 1998-08-01, Pág. 3676, Portugal. Decreto-Lei No 236/98; Ministério do Ambiente: Brasilia, Brazil, 1998; pp. 3676–3722.

- Emiídio, V.J.G. A Problemática do Fósforo nas Águas para Consumo Humano e Águas Residuais e Soluções para o Seu Tratamento; Universidade do Algarve: Algarve, Portugal, 2012. [Google Scholar]

- Luizi, R.P.S.L. Operação de Sistmas de Tratamento de Águas Residuais por Lamas Activadas com Arejamento Prolongado; Universidade Técnica de Lisboa: Lisboa, Portugal, 2012. [Google Scholar]

| Indicator | BOD5 | COD | TSS | TP |

|---|---|---|---|---|

| Reliability coefficient WN | 0.37 | 0.57 | 0.45 | 0.84 |

| Reduction Efficiency η (%) | 89 | 78 | 76 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira da Silva, F.M.; Silvério, K.S.; Castanheira, M.I.; Raposo, M.; Imaginário, M.J.; Simões, I.; Almeida, M.A. Construction of Control Charts to Help in the Stability and Reliability of Results in an Accredited Water Quality Control Laboratory. Sustainability 2022, 14, 15392. https://doi.org/10.3390/su142215392

Oliveira da Silva FM, Silvério KS, Castanheira MI, Raposo M, Imaginário MJ, Simões I, Almeida MA. Construction of Control Charts to Help in the Stability and Reliability of Results in an Accredited Water Quality Control Laboratory. Sustainability. 2022; 14(22):15392. https://doi.org/10.3390/su142215392

Chicago/Turabian StyleOliveira da Silva, Flávia Matias, Karina Santos Silvério, Maria Ivone Castanheira, Mariana Raposo, Maria José Imaginário, Isabel Simões, and Maria Adelaide Almeida. 2022. "Construction of Control Charts to Help in the Stability and Reliability of Results in an Accredited Water Quality Control Laboratory" Sustainability 14, no. 22: 15392. https://doi.org/10.3390/su142215392

APA StyleOliveira da Silva, F. M., Silvério, K. S., Castanheira, M. I., Raposo, M., Imaginário, M. J., Simões, I., & Almeida, M. A. (2022). Construction of Control Charts to Help in the Stability and Reliability of Results in an Accredited Water Quality Control Laboratory. Sustainability, 14(22), 15392. https://doi.org/10.3390/su142215392