1. Introduction

In the process of urban development, buildings in the process of either construction or use have consumed massive amounts of resources and energy [

1]. The life span of buildings, from their initial design, construction, and use to their demolition and abandonment, is usually no more than 60 years, but it has become one of the major sources of waste and greenhouse gas emissions in urban development [

2,

3]. In fact, most countries and regions do not have a complete “disassembly” method for the classification of construction waste, thus they usually use a destructive “demolition” method. Therefore, among these construction wastes, except for metal materials and relatively intact items, which are of a higher recycling value, other parts are almost buried underground or incinerated. However, in the concept of the circular economy (CE) [

4], it is hoped that more countries will be able to extend the service life of materials as much as possible and increase the reuse value of waste in the process of recycling and reuse. Therefore, in order to use building waste more efficiently, the classification of the building’s construction methods and materials needs to be undertaken before it is demolished, along with the accurate calculation of the amount of materials. Urban mining uses material flow calculation to provide a method for the reuse of construction waste [

5]. Urban minerals are how natural resources are stored in cities, and through mining, these resources can be dismantled, classified, and reused. The calculation of urban mining is divided into two methods: top-down and bottom-up methods, both of which can be used to calculate the stock of urban minerals in a relatively macroscopic manner. [

6]. Under the concept of the CE, there are also studies of material passports [

7] and material reuse methods [

8]. In this context, the relevant studies from various perspectives have put forward methodology and feasibility studies on the recycling of construction waste. However, these studies are mainly in the perspectives of engineering, technology, and statistics, and are rarely discussed in the discipline of architectural design [

9].

At present, there are two categories of research on the recycling mode in the construction field: one is to solve the problem of reuse and recycling [

10] in the process of design by establishing a material bank to utilize recycled materials and to optimize construction manners through the method of prototype design at the level of “Upstream Innovation”; the other is “Downstream Innovation”, and it is also the main focus of this paper. The authors first investigate, classify, calculate, and evaluate the building category and component type of the buildings whose life span is complete or is about to expire, and then put forward the feasibility of reuse [

11] in order to eliminate and diminish the existing urban construction waste.

Some researchers have not only considered the construction modes, recycling value, impacts on the environment, and reuse possibility, but have also assessed the recycling value of products and elements. Nevertheless, in their studies, the main structure of the building is not disassembled (decomposition according to component types), rather demolished (a destructive smash), and in the latter method the waste is recycled according to its value [

12]. Others classify construction waste materials according to the building type (such as a steel structure, RC structure, brick-concrete structure, etc.) to obtain a calculation coefficient of the material content through the statistics and the sorting of a large number of data of the same type of buildings, and to calculate the overall content of the different types of materials of the whole building by using the floor area of the building [

13,

14]. Based on such a research logic, although more accurate average data can be obtained by expanding the data from more buildings, the research content barely includes the uniqueness [

15] of each building resulted from architectural design, and the uniqueness would impact on the data accuracy and reference value.

The design phase may influence over 80% of environmental factors [

16], and the influence will accompany the whole life cycle of a building [

17]. Therefore, whether it is an upstream innovation or downstream innovation, not only the entire life cycle of a building needs to be considered but also the different steps such as the installation, dismantling, recycling, repair, and reuse of buildings should be considered from the perspective of design by using a reversible design approach to think about how buildings can be reused. At the initial stage of the building project, the architect designs the type, construction mode, and spatial function of the building according to its site use, planning conditions, and functions as well as the aesthetic needs, so that the building would be unique in addition to the fulfillment of the aforementioned needs, but the architect did not consider how the building should be dismantled, nor how the building could be reused. Stewart Brand once put forward the theory of building layers and mentioned the life cycles and possible changes in the different layers of a building [

18], providing a theoretical foundation for building disassembly. Since different design methods could affect the disassembly, recycling, and reuse methods of buildings when their life cycles are due, the recycling potential compared with the value of the material itself also varies. With differences in space and structural design in almost every building, if we want to reduce the negative impact in the process of demolition and reuse and to improve the recycling potential of waste, it is necessary to carry out a layer classification and structural restoration to obtain more accurate and reliable statistics of the building waste for buildings whose life spans complete due or are about to reach this point, which would provide an effective basis for the subsequent recycling and reuse methods.

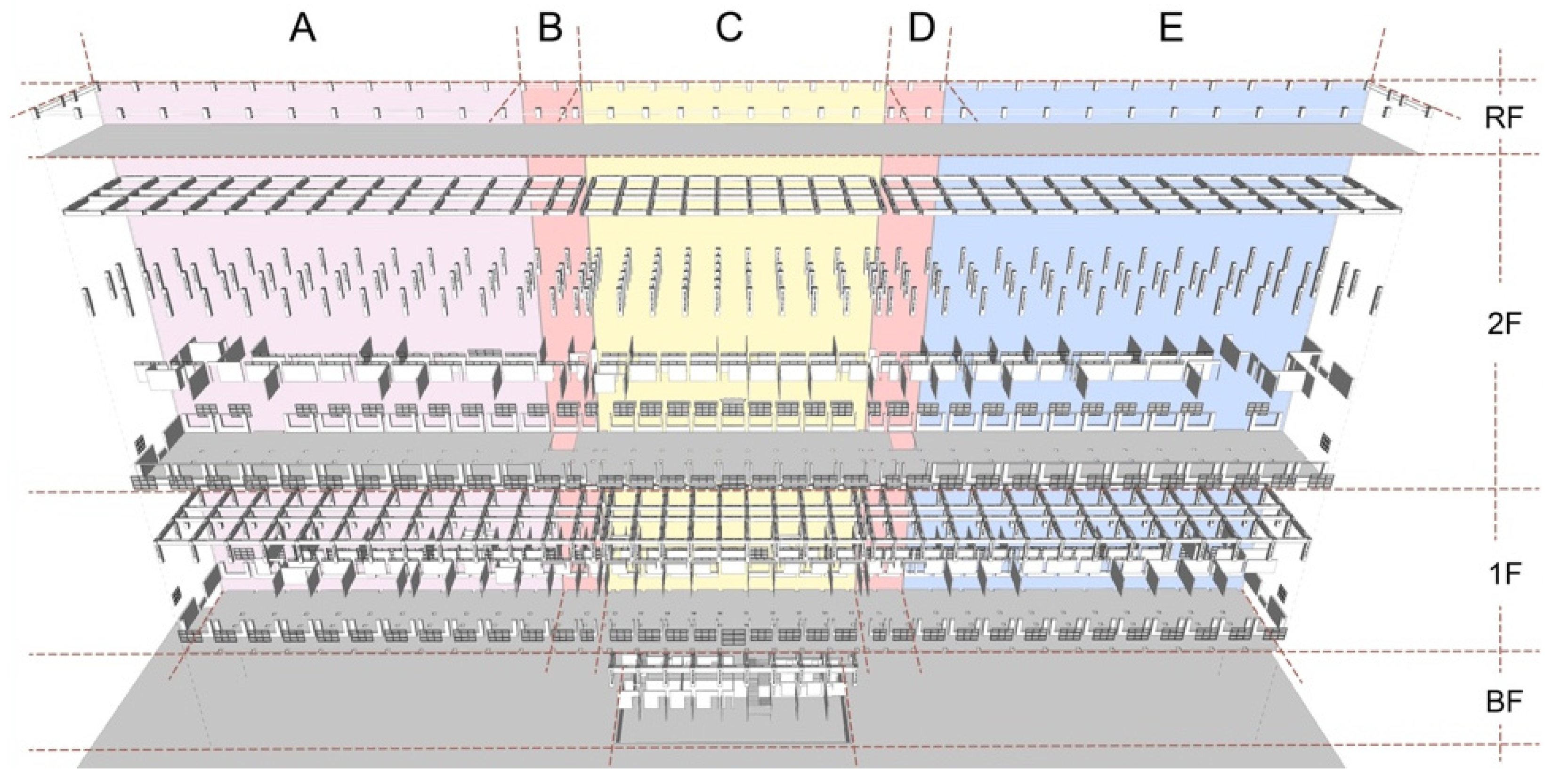

The Taiwan Contemporary Culture Laboratory (TCCLab), located at Ren’ai Road, Da’an District, Taipei, was originally the headquarters of the Taiwan air force. The TCCLab consists of 42 buildings in total, of which 32 buildings are about to reach or have exceeded their service life of 50 years. This study employs an office building built in 1973 in the TCCLab as the subject of the study (

Figure 1). The whole building is 139.4 m long, 13 m wide, and 7.4 m high. It has two floors above the ground and a total construction area of 3624 square meters, constructed with concrete frames and brick walls. The entire building is well preserved, organized, and has a complete structural appraisal report and the relevant documents, which is conducive to carrying out the research work. From the perspective of the architectural design, this building is analyzed and disassembled, and a more accurate urban mineral stock of the building is to be calculated according to the 3D digital model and on-site verification. Taking this office building as an example, the disassembly and calculation framework of brick–concrete office buildings is established to improve the feasibility of the recycling and reuse of urban building resources (materials) [

19,

20]. As the buildings with a service life of more than 50 years in Taiwan are mainly RC structures, this study has a representative significance for the disassembly and reuse of buildings in the future. This study takes the buildings that have reached or are about to reach the end of their life cycle as the subject of study and puts forward a more accurate inventory and the reuse method of the construction waste from the perspective of architectural design. The results provide a basis for more extensive urban mining and the establishment of material passports [

21].

RC structures were widely used in the 20th century and are also the main building types that need to be updated in more developed areas in the world. RC frame structures dominated the houses built in Taiwan in the mid and late 20th century. However, in the construction of some houses, sea sand (containing sodium chloride) was used, which caused a corrosion to the internal steel bars. In addition, there are occasional earthquakes in Taiwan, so many buildings do not reach 50 years of age before the end of their life cycle. According to the data of the European Union, the demolition of old buildings will account for 30% of carbon dioxide emissions and 40% of solid waste [

22]. Otherwise, they have to be abandoned. However, the maintenance of a building’s structure is challenging, and the ratio of a repair cost to the cost of a new construction reaches 28%. Most RC-structured buildings in Taiwan are faced with the problem how to prolong their service time.

2. Methodology

In order to obtain the urban mineral content of buildings more accurately and reuse the construction waste more effectively at the end of the life cycle of buildings, this research takes the TCCLab office building as the research object. Based on the architectural design method, the researchers sought out the spatial function, construction sequence, structural form, and construction type of the whole office building. Meanwhile, a detailed 3D model was established to simulate the forward construction sequence of the office building. According to the theory of building stratification by Steward Brand, the reverse dismantling method of buildings and the framework of building waste reuse are put forward. The establishment of a feasible reverse disassembly method can further change the current status of urban mining which reuses and recycles the exclusively valuable elements of construction waste. Based on the reverse disassembly principle, the framework is divided into four parts: the project information, shearing layers, material bank, and recycling, with an emphasis of a hierarchical order of disassembly (from stuff which occupies a building to the site), as well as the correlation between the information flow and materials flow. In this process, the information flow of the material bank allows for the material flow information of the disassembly and recycling to be connected and exchanged (

Figure 2).

In reverse disassembly, it is on the contrary to the construction sequence. In the study, it is found that the first part to be disassembled is also the one with the shortest life cycle, which is easier to replace, move, and change. This point is also illustrated in Steward Brand’s architectural stratification theory. The first layer to be disassembled is the stuff which is included in different functional spaces, which is usually the last element to be put into the building. It has a wide variety, a comparatively shorter service time, and is easy to change. The second layer has to do with the services. It refers to the power system, air conditioning system, fire protection system, and network system (not equipped in the buildings of an earlier time). This layer does not tend to change, unless the spatial function changes. The following layers to be disassembled are the space and skin. After the building is designed and built, the user’s demand for the space function would change, or the building needs to be renovated and transformed after a period of service. Such changes occur relatively late, so the disassembly of the space and skin is in an intermediate stage in the whole process. Next is the structure, which is the most significant part of a building and is often designed to be relatively sturdy. Therefore, in this study, structure components are also classified and numbered in detail in order to prolong their service life span through the disassembly. The last layer is to reorganize the site and try to restore its original and natural state as much as possible.

As shown in

Table 1, this study classifies the elements of the different layers. First, the spatial location and the item names of different elements are illustrated in the table; second, the author divides the storage types of these elements into three categories: product, components, and materials, which is conducive to searching in the building material bank according to the needs of use in the future; third, the ways of reuse and dismantled materials are classified; and finally, according to the characteristics of each element, a redesign and reproduction are needed. This table follows the reverse dismantling sequence and considers the transfer of information flow by the building material bank at the front end and the specific use of the material flow at the back end. In the future, a data collation and attribute identification can be carried out through the building materials bank to determine the next reuse method. In this way, whether it is an individual (a direct use) or a manufacturing (remanufacturing) use, the elements can be selected according to their needs. In order to improve the recycling value of construction waste, this study classifies the elements of the different layers and determines the future reuse mode through a sorting of the data and an identification of the attributes in the building material bank. In this way, either individuals (a direct utilization) or manufacturers (remanufacturing) may select the elements according to their needs, resulting in the improvement of the reuse value of construction waste.

It is hoped that through a specific classification and information disclosure, this research will make it possible for users’ needs to determine the value of the old building’s components. It is the users’ needs instead of the material value of the components (the value of metals and complete articles is usually higher) or the interests of demolition contractors that decide whether this material should be recycled or not.

3. Results

In the research process, the authors demonstrated that the reverse dismantling method, as well as the material classification and reuse framework, could more accurately obtain the content of construction waste, thereby improving the reuse possibility of construction waste. First, the authors consulted and analyzed the original design drawings of the TCCLab office building based on the forward construction sequence of the architectural design and also established a specific 3D digital model based on construction survey data to simulate the structural mode, spatial layout, and structure (including the reinforcement ratio) of the whole building. Second, each step of the reverse disassembly was assumed according to the forward construction process. By classifying and numbering the main components and elements of the building, the contents of the concrete, reinforcement, wood, and cement mortar in the main part of the building were calculated in detail. Third, with the assistance of the 3D digital model, an on-site investigation of the building was carried out, and the number of doors, windows, and other elements were counted, so as to eliminate the influence of the missing and damaged parts on the final calculation results. Finally, a data comparison of the two different calculation methods was made, i.e., the bottom-up (a rough estimate) and disassembly classification method (specific), to discuss the feasibility of accurately obtaining urban minerals and recycling construction waste in the future.

Through a preliminary data analysis, a detailed 3D digital model simulation, as well as an on-site investigation, the TCCLab office building was determined to be a RC structure. The forward construction process of the building can be divided into 6 steps: (1) the excavation of the foundation and the concrete pouring; (2) binding the beams, pillars and floor reinforcement, and erecting the formwork and pouring the concrete; (3) creating internal partitions; (4) installing the water and electricity facilities as well as the door and window components; (5) interior decoration; and (6) the indoor furniture layout. With a reference to the forward construction sequence, the original architectural drawings, and the investigation reports, this study applied 3D digital modeling technology to restore the three-dimensional model of the TCCLab office building (

Figure 3).

The whole office building has a length of 139.4 m, and such a length during construction requires extra structural joints for earthquake resistance and for the prevention of thermal expansion and cold contraction. Therefore, the whole building is divided into five parts, i.e., the A, B, C, D, and E in

Figure 3. The overall layout extends from the central core functional area to both sides, making the whole building a symmetrical composition. Due to the different spatial functions of each floor, the number of components varies. Among them, the roof layer has no beams, doors, windows, or walls, but only 80 pillars and 1813.5 square meters of floor; the basement layer has no windows, and it has 56 pillars, 50 beams, 24 doors, 28 walls, and 474.1 square meters of floor. The number of components obtained in each floor provides the basis for the subsequent calculation of the total amount of materials. According to the number of components obtained on the different floors, the authors provide a basis for the calculation of the total amount of materials in the following (

Table 2). In addition to this, with reference to the detailed structural investigation report, accurate statistics of the pillars, beams, doors, windows, walls, and floors of each floor were collected, which benefits a more precise calculation of the content of concrete, red bricks, steel, wood, aluminum, glass, and cement mortar in the building.

The digital model completely simulates the structures (including the protective layers and rebar), partition walls, doors, and windows of the building. However, they might change in the actual use process, such as in the case of decoration, loss, damage, modification, etc. Moreover, in order to test and compare the accuracy of the digital model, this study conducts a field investigation on the TCCLab office building (

Figure 4). In the investigation, we first confirmed the accuracy of the building drawings that had been referred to in the early stage of the study and verified the composition mode and size of the reinforcement and the thickness of the decorative surface wrapped outside the structure according to some damaged walls, which further ensures the accuracy of our simulation results. Second, we noticed that the positions of three columns and several compartment walls had changed (different from the original architectural drawings) over time, as users’ space needs had changed. Meanwhile, we observed the damaged part of the partition wall and discovered that it is made of red bricks. Finally, the actual quantity, size, and materials of the sanitary products, bookcases, newspaper clips, stairs, guardrails, and other items in the building were verified and recorded, and those damaged, lost, and unidentified parts were excluded in the record.

This office building has not been used and maintained for a long time, and the basement does not meet the safety requirements, so an on-site underground investigation was not allowed. At the same time, due to the massive number of items in the building, the authors mainly verified the size, quantity, and structural mode of the pillars, beams, doors, windows, walls, and floors of the building, and recorded those items with comparatively good conditions. Beyond that, the whole building is symmetrical in the X-axis and Y-axis directions. That is, part A and part E, part B, and part D are the same, and both sides of the A/B/C/D/E corridor are the same. In addition, the component dimensions of the same floor are consistent, and the component dimensions of the different floors vary. This reduces tremendous work for the subsequent calculation of the material quantity and the classification of the construction and reuse methods.

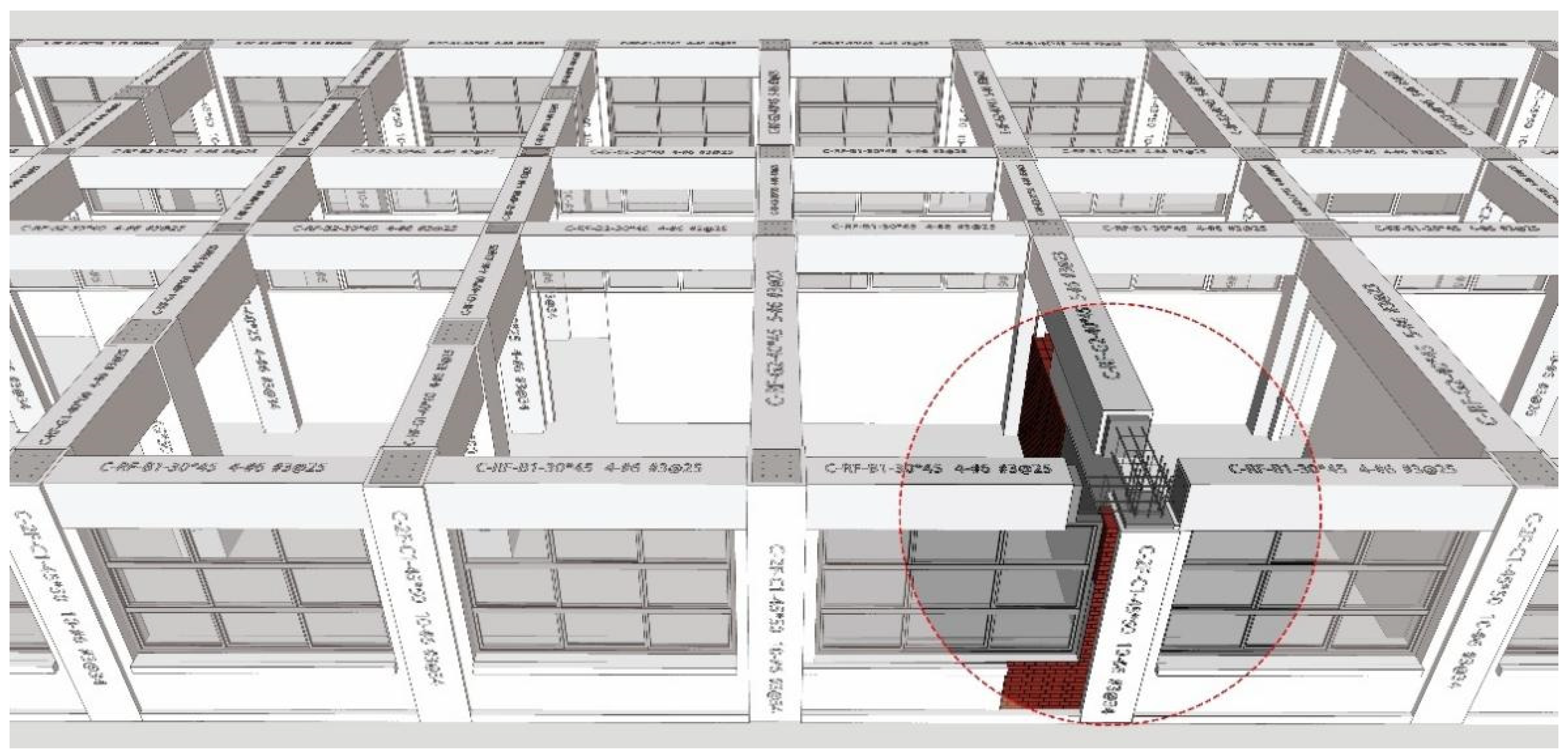

According to the results of the 3D simulation and field investigation, it was found that the size and reinforcement ratio of the beams and columns in different floors and positions are different. The authors have, respectively, coded the beams, columns, and other building components in different floors and positions, so as to facilitate the classified calculation and statistical analysis of the beams and columns on different floors. Since the building is divided into five parts for construction, they are, respectively, defined as: A\B\C\D\E, and the floors are divided into: RF\2F\1F\BF. Therefore, the coding principle is described as follows: X Block-X Floor-type-size-reinforcement model.

The established unified numbering method according to the 3D model is shown in

Figure 5: C-2F-C1-45*50-10#6-#3@34 stands for the pillar on the second floor of Block C of the building. Its lateral section size is 0.45 m × 0.5 m with 10 vertical rebars of a diameter of 0.0191 m (Refer to Taiwan CNS 560 Rebar Specifications), and the interval between the ring rebars is 0.34 m and their diameter is 0.00953 m. In

Table 3, the numbers of beams and columns for the different parts are listed. Because part A and part E and part b and part D are the same size, not all are listed in the table.

This study constructs a 3D digital model of the TCCLab office building according to the building’s forward construction sequence and detailed architectural drawings, then, a reverse dismantling method is used to establish a framework for the classification and reuse of the materials. The internal projects were verified and documented through our on-site surveys; they validate our simulation of the whole building. Based on the data accuracy of the research results, currently, only those items with a complete record were measured, including the beams, pillars, doors, windows, floors, and some other fixed and intact objects of the building at the ground level. As the building was built 48 years ago, there are varieties in the internal objects and ornaments, and most of the equipment and power systems used a hidden layout, which have changed in the long-term use of the building. In order to reflect the real measurable objects, the non-measurable elements are excluded at present.

This study takes the TCCLab office building as an example and compares the calculation results of the bottom-up method and the disassembly classification method proposed in this research. Bottom-up methods use the building area to multiply the material content coefficient per unit area of the different types of buildings to calculate one or more buildings to obtain the urban mineral content of the building. At present, the majority of the relevant research is based on the macro statistics of urban mineral resources, using the method of combining the geographic information (GIS) with the material quantity coefficient of the different types of buildings to estimate the total amount. Although it provides a basis for the use of urban mineral resources, the precision and accuracy require an improvement for a further application. For this data comparison, the coefficients for the different types of materials in

Table 4 [

23] and

Table 5 [

24] were calculated for the entire office building.

Because the reverse disassembly method allows us to fully consider the architectural differences caused by the design, it is found that the total urban minerals of the two-storied RC office building reach 3,504,510 kg. Compared with the original bottom-up calculation method, the result is 37.59% more accurate, totaling 2,110,460 kg. Among the minerals, the largest substance is steel (68.36%), followed by concrete (27.29%), brick (4.07%), aluminum (1.43%), and glass (1.3%). It can be seen from

Table 6 that the differences between the quantity of steel and red bricks calculated in this study and the average content of RC buildings in Taiwan are 100% and 200%, respectively. In terms of the content of concrete, glass, and aluminum, there are differences in varying degrees due to the detailed consideration of the actual use, with a total content difference of 37.59%. If the buildings that are about to reach the end of their life cycle are effectively recycled and reused, more accurate urban mining methods to optimize the calculation of construction waste and improve the utilization rate are critical.

4. Discussion

The urban mining method depicted in this paper is based on the professional perspective of architecture, with architectural design as the point of departure to restore the original state of the whole building. The paper comparatively puts forward a reverse disassembly method and a reuse framework according to the forward construction sequence of the building, in order to solve the problem of construction waste that takes up the largest proportion of solid waste. Only by obtaining a more accurate material classification and material content data before the building is demolished can these wastes be effectively used and turned into new components or materials for a redesign and remanufacturing. The main purpose of this research is to propose the disassembly classification method, and to demonstrate the accuracy of this method through an architectural case. Before that, the relevant research mainly focused on the urban mineral analysis based on material flow in the specialty of environmental engineering, which ignores the influence of architectural design, the construction mode, and material application on the statistical data. The authors use the professional knowledge of architecture to establish the disassembly classification method, which also reflects the necessity of professional architects to participate in the research work of the circular economy and urban mining.

In this study, we focus on the architectural design, construction mode, and material application from the perspective of architecture, and the calculated material content results are 37.59% more accurate than that of previous methods. On that basis, the recycling potential and reuse value of waste could be assessed more effectively. At the same time, reverse disassembly can provide a more detailed classification list of the building elements as well as the framework of the reuse methods. In addition, the disclosure of information data by the material bank may promote the integration of the “material flow” and “information flow” so that users can determine the recycling methods as well as the “direction” of the material flow.

This study explores RC buildings, which have the highest stock at present, and considers a variety of factors affecting the accuracy of the data. In the research process, in order to better count the construction waste and establish an effective framework, it was necessary to consider various statistical methods. For example, the researchers attempted to restore the original situation with 3D point cloud technology, and the amount of data turned out to be too large to be used effectively. Although the material content of different types of buildings can be obtained by collecting more samples, it is clear that there is an error between the average data and the actual data. If other relevant influencing factors could be added in the future, the accuracy and feasibility would be continuously improved.