Preparation and Characterization of Black Seed/Cassava Bagasse Fiber-Reinforced Cornstarch-Based Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Film

2.3. Characterization of Prepared Films

2.3.1. Physical and Morphological Analysis

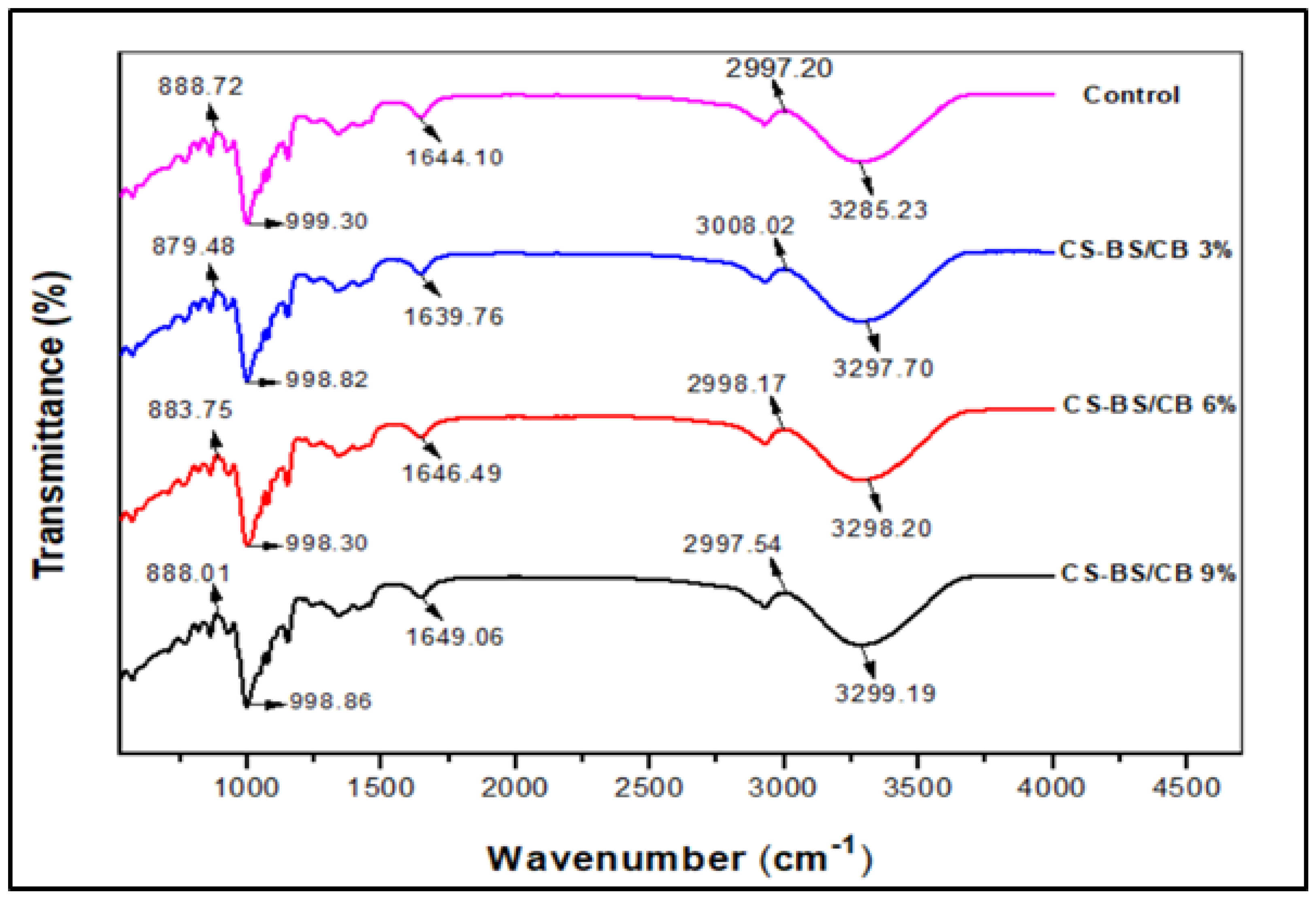

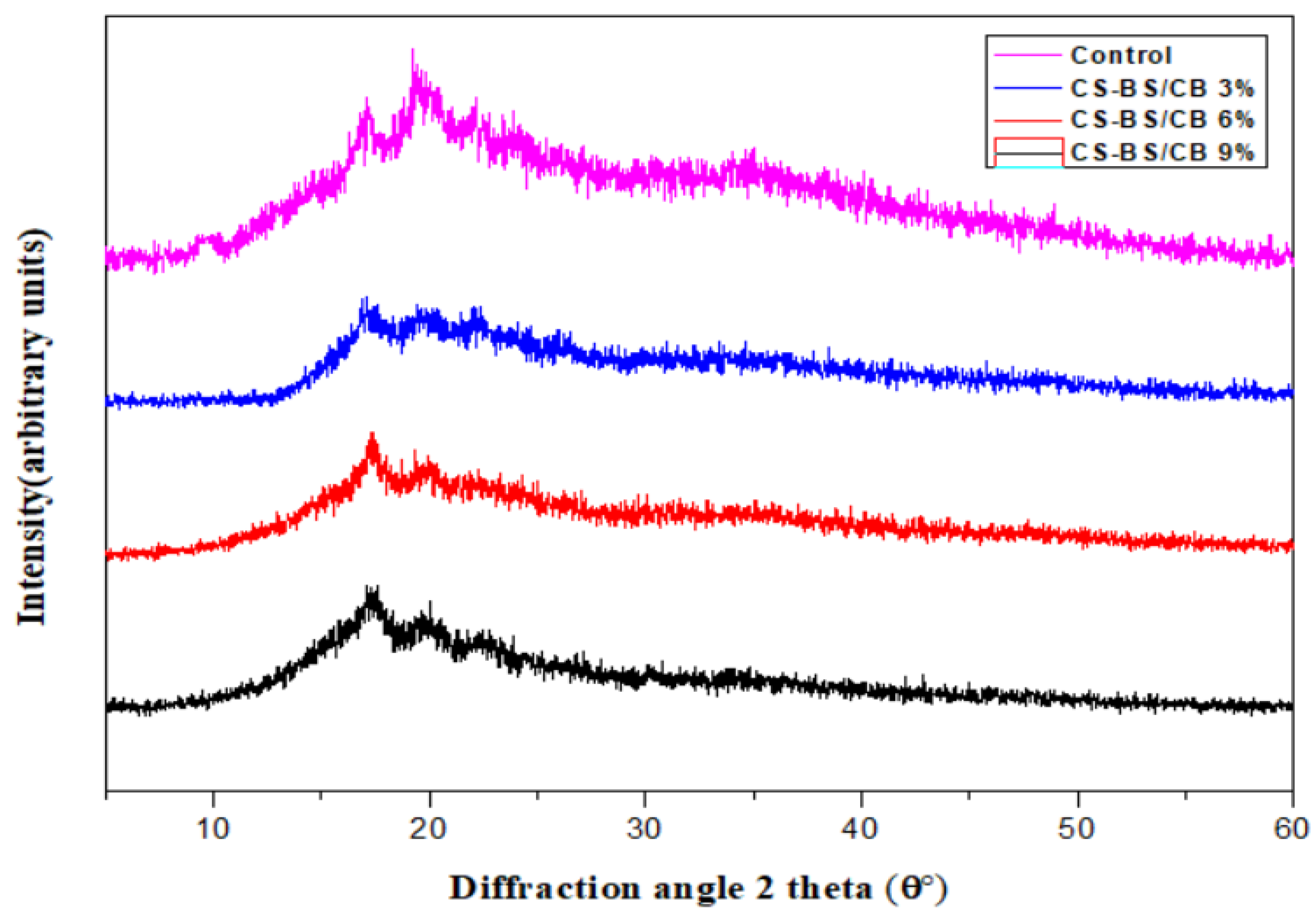

2.3.2. Surface Functional Groups and X-ray Diffraction Analysis

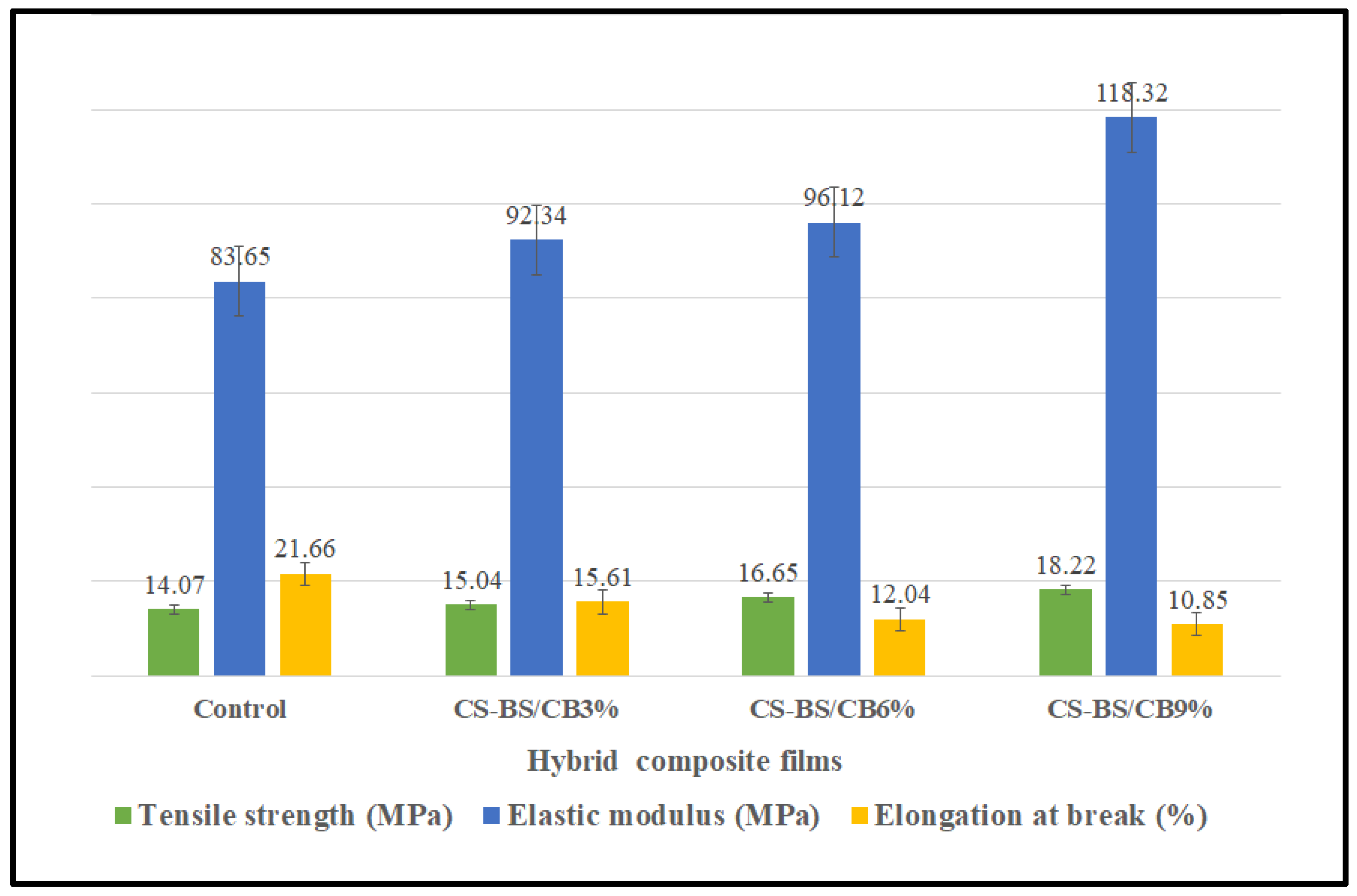

2.3.3. Mechanical Properties

2.3.4. Thermal Properties

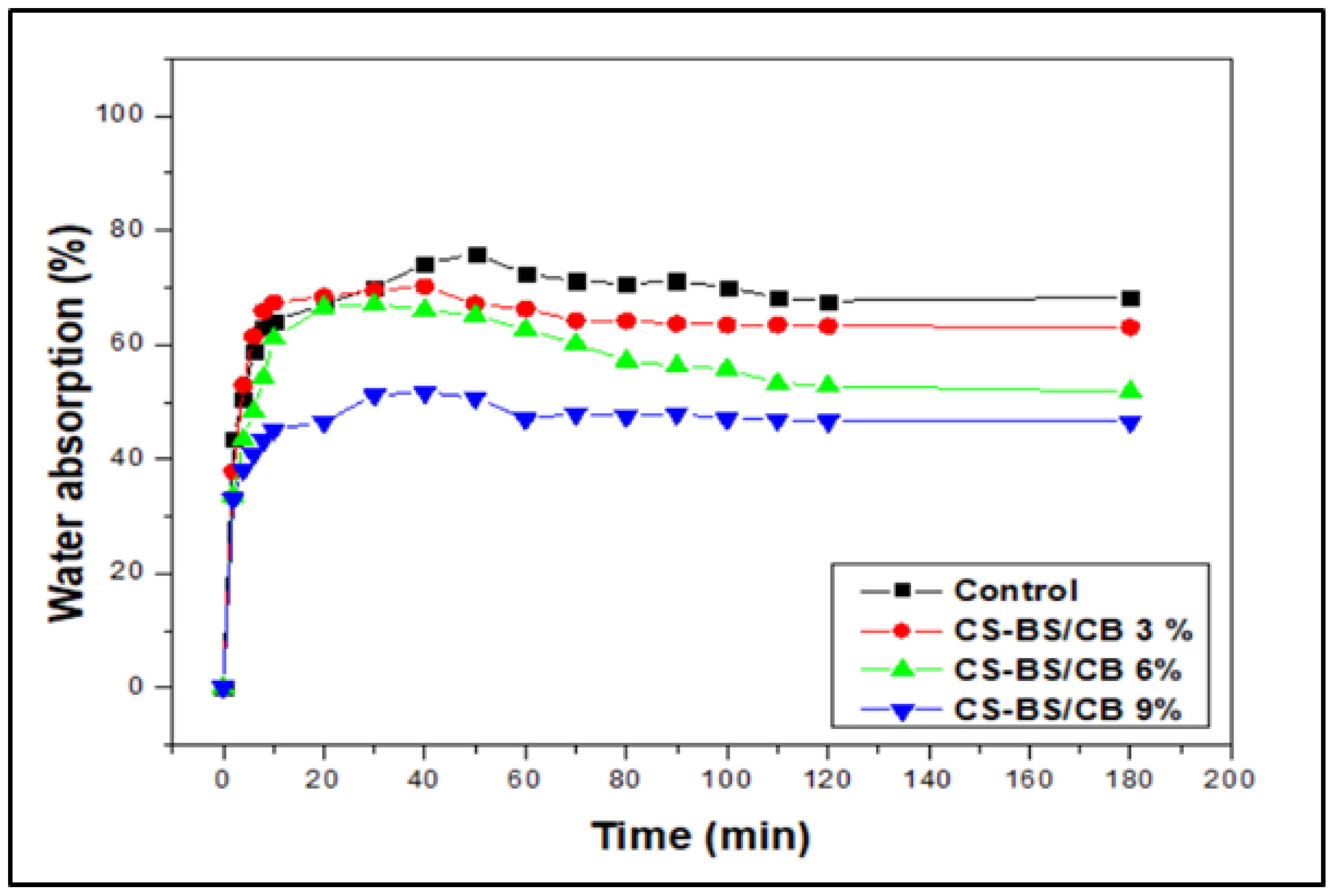

2.3.5. Water Absorption and Soil Burial Test

2.4. Statistical Analyses

3. Results and Discussion

3.1. Physical and Morphological Analysis

3.2. Surface Functional Groups

3.3. X-ray Diffraction (XRD)

3.4. Mechanical Properties

3.5. Thermal Properties

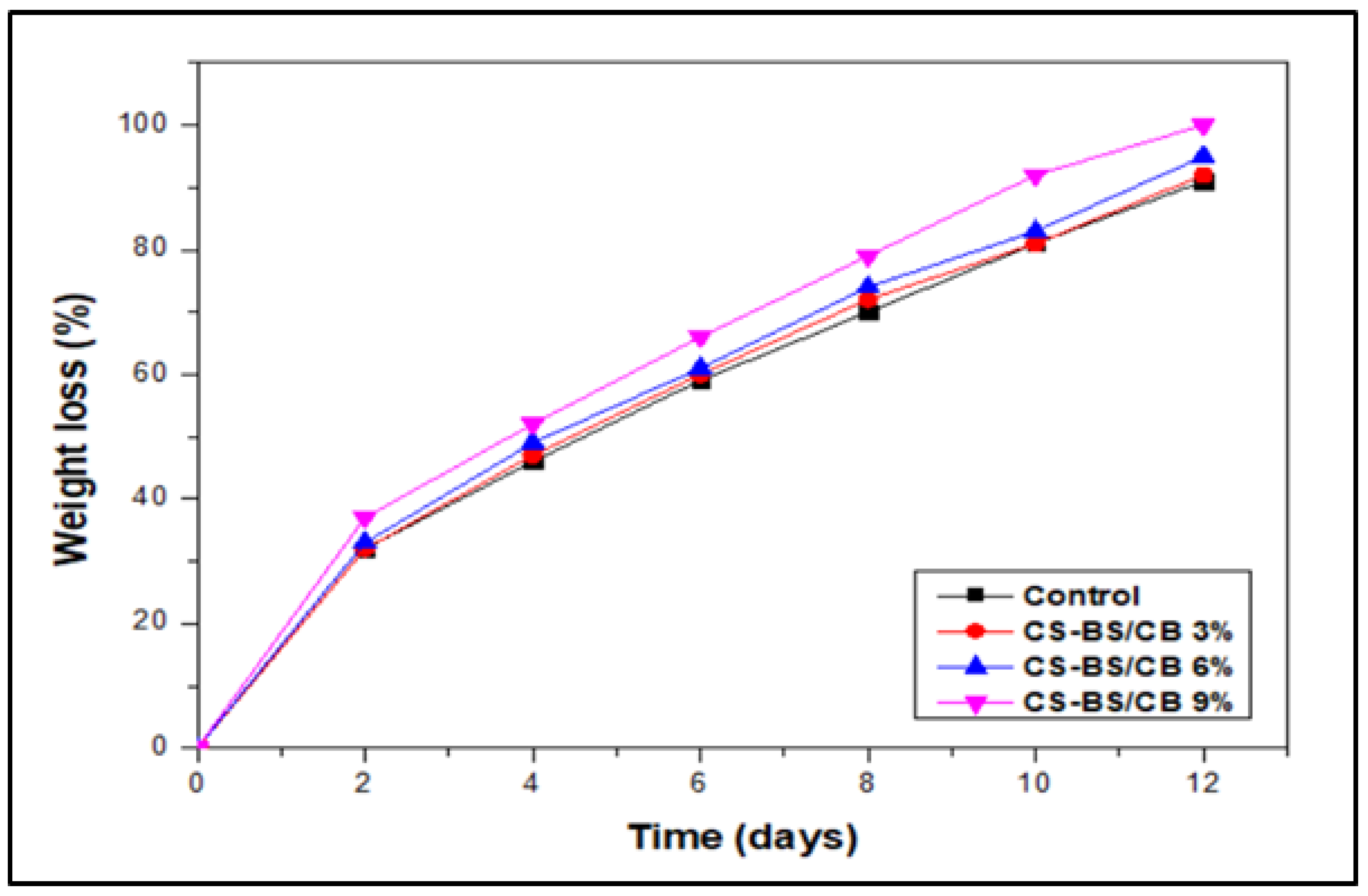

3.6. Water Absorption and Soil Burial Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Florencia, V.; López, O.V.; García, M.A. Exploitation of by-products from cassava and ahipa starch extraction as filler of thermoplastic corn starch. Compos. Part B Eng. 2020, 182, 107653. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.; Khalina, A.; Ilyas, R.; Zainudin, E. Thermal, flammability, and antimicrobial properties of arrowroot (Maranta arundinacea) fiber reinforced arrowroot starch biopolymer composites for food packaging applications. Int. J. Biol. Macromol. 2022, 213, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Zentou, H.; Abidin, Z.Z.; Yunus, R.; Biak, D.R.A.; Issa, M.A. Optimization and modeling of the performance of polydimethylsiloxane for pervaporation of ethanol−water mixture. J. Appl. Polym. Sci. 2020, 138, 50408. [Google Scholar] [CrossRef]

- Rizal, S.; Olaiya, F.; Saharudin, N.; Abdullah, C.; Olaiya, M.K.; Haafiz, M.M.; Yahya, E.; Sabaruddin, F.; Ikramullah; Khalil, H.P.S.A. Isolation of Textile Waste Cellulose Nanofibrillated Fibre Reinforced in Polylactic Acid-Chitin Biodegradable Composite for Green Packaging Application. Polymers 2021, 13, 325. [Google Scholar] [CrossRef]

- Abotbina, W.; Sapuan, S.M.; Ilyas, M.T.H.; Alkbir, M.F.M.; Ilyas, R.A. Development and Characterization of Cornstarch-Based Bioplastics Packaging Film Using a Combination of Different Plasticizers. Polymers 2021, 13, 3487. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Aisyah, H.A.; Asyraf, M.R.M.; Hassan, S.A.; Zainudin, E.S.; Sapuan, S.M.; Sharma, S.; Bangar, S.P.; Jumaidin, R.; et al. Natural Fiber-Reinforced Polylactic Acid, Polylactic Acid Blends and Their Composites for Advanced Applications. Polymers 2022, 14, 202. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Zuhri, M.Y.M.; Norrrahim, M.N.F.; Misenan, M.S.M.; Jenol, M.A.; Samsudin, S.A.; Nurazzi, N.M.; Asyraf, M.R.M.; Supian, A.B.M.; Bangar, S.P.; et al. Natural Fiber-Reinforced Polycaprolactone Green and Hybrid Biocomposites for Various Advanced Applications. Polymers 2022, 14, 182. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Aisyah, H.A.; Nordin, A.H.; Ngadi, N.; Zuhri, M.Y.M.; Asyraf, M.R.M.; Sapuan, S.M.; Zainudin, E.S.; Sharma, S.; Abral, H.; et al. Natural-Fiber-Reinforced Chitosan, Chitosan Blends and Their Nanocomposites for Various Advanced Applications. Polymers 2022, 14, 874. [Google Scholar] [CrossRef]

- Abotbina, W.; Sapuan, S.; Sultan, M.; Alkbir, M.; Ilyas, R. Extraction, Characterization, and Comparison of Properties of Cassava Bagasse and Black Seed Fibers. J. Nat. Fibers 2022, 1–14. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Tawakkal, I.S.M.A.; Ilyas, R.A. Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites. Nanotechnol. Rev. 2021, 10, 431–442. [Google Scholar] [CrossRef]

- Syafiq, R.M.O.; Sapuan, S.M.; Zuhri, M.Y.M.; Othman, S.H.; Ilyas, R.A. Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films. Nanotechnol. Rev. 2022, 11, 423–437. [Google Scholar] [CrossRef]

- Nazrin, A.; Sapuan, S.M.; Zuhri, M.Y.M.; Tawakkal, I.S.M.A.; Ilyas, R.A. Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites. Nanotechnol. Rev. 2021, 11, 86–95. [Google Scholar] [CrossRef]

- Surya, I.; Olaiya, N.; Rizal, S.; Zein, I.; Sri Aprilia, N.A.; Hasan, M.; Yahya, E.B.; Sadasivuni, K.K.; Abdul Khalil, H.P.S. Plasticizer enhancement on the miscibility and thermomechanical properties of polylactic acid-chitin-starch composites. Polymers 2020, 12, 115. [Google Scholar] [CrossRef] [PubMed]

- Ganguly, S.; Maity, T.; Mondal, S.; Das, P.; Das, N.C. Starch functionalized biodegradable semi-IPN as a pH-tunable controlled release platform for memantine. Int. J. Biol. Macromol. 2017, 95, 185–198. [Google Scholar] [CrossRef] [PubMed]

- Goldshtein, J.; Margel, S. Synthesis and characterization of polystyrene/2-(5-chloro-2H-benzotriazole-2-yl)-6-(1,1- dimethylethyl)-4-methyl-phenol composite microspheres of narrow size distribution for UV irradiation protection. Colloid Polym. Sci. 2011, 289, 1863–1874. [Google Scholar] [CrossRef]

- Ganguly, S.; Mondal, S.; Das, P.; Bhawal, P.; Maity, P.P.; Ghosh, S.; Dhara, S.; Das, N.C. Design of psyllium-g-poly(acrylic acid-co-sodium acrylate)/cloisite 10A semi-IPN nanocomposite hydrogel and its mechanical, rheological and controlled drug release behaviour. Int. J. Biol. Macromol. 2018, 111, 983–998. [Google Scholar] [CrossRef]

- Medina, D.D.; Goldshtein, J.; Margel, S.; Mastai, Y. Enantioselective Crystallization on Chiral Polymeric Microspheres. Adv. Funct. Mater. 2007, 17, 944–950. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H.; Entezami, A.A. Improving the barrier and mechanical properties of corn starch-based edible films: Effect of citric acid and carboxymethyl cellulose. Ind. Crops Prod. 2011, 33, 229–235. [Google Scholar] [CrossRef]

- Abotbina, W.; Sapuan, S.M.; Sulaiman, S.; Ilyas, R.A. Review of corn starch biopolymer. In Proceedings of the 7th Postgraduate Seminar on Natural Fibre Reinforced Polymer Composites; Institute of Tropical Forest and Forest Products (INTROP), Universiti Putra Malaysia: Serdang, Malaysia, 2020; Volume 2020, pp. 37–40. [Google Scholar]

- Norfarhana, A.; Ilyas, R.; Ngadi, N. A review of nanocellulose adsorptive membrane as multifunctional wastewater treatment. Carbohydr. Polym. 2022, 291, 119563. [Google Scholar] [CrossRef]

- Bangar, S.P.; Harussani, M.; Ilyas, R.; Ashogbon, A.O.; Singh, A.; Trif, M.; Jafari, S.M. Surface modifications of cellulose nanocrystals: Processes, properties, and applications. Food Hydrocoll. 2022, 130, 107689. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Harussani, M.; Hakimi, M.; Haziq, M.; Atikah, M.; Asyraf, M.; Ishak, M.; Razman, M.; Nurazzi, N.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Haris, N.I.N.; Hassan, M.Z.; Ilyas, R.; Suhot, M.A.; Sapuan, S.; Dolah, R.; Mohammad, R.; Asyraf, M. Dynamic mechanical properties of natural fiber reinforced hybrid polymer composites: A review. J. Mater. Res. Technol. 2022, 19, 167–182. [Google Scholar] [CrossRef]

- Ahmad, M.F.; Ahmad, F.A.; Ashraf, S.A.; Saad, H.H.; Wahab, S.; Khan, M.I.; Ali, M.; Mohan, S.; Hakeem, K.R.; Athar, M.T. An updated knowledge of Black seed (Nigella sativa Linn.): Review of phytochemical constituents and pharmacological properties. J. Herb. Med. 2021, 25, 100404. [Google Scholar] [CrossRef] [PubMed]

- Barkah, N.N.; Wiryawan, K.G.; Retnani, Y.; Wibawan, W.T.; Wina, E. Physicochemical properties of products and waste of black seed produced by cold press method. IOP Conf. Ser. Earth Environ. Sci. 2021, 756, 012025. [Google Scholar] [CrossRef]

- Abotbina, W.; Sapuan, S.M.; Ilyas, M.T.H.; Alkbir, M.F.M.; Ilyas, R.A.; Harussani, M.M. A Short Review on Black Seed Fibre (Nigella Sativa) Reinforced. In Proceedings of the 8th Postgraduate Seminar on Natural Fibre Composites 2022; Institute of Tropical Forest and Forest Products (INTROP), Universiti Putra Malaysia: Serdang, Malaysia, 2022; pp. 14–17. [Google Scholar]

- Younus, H. Molecular and Therapeutic Actions of Thymoquinone: Actions of Thymoquinone; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9789811088001. [Google Scholar]

- Ahmad, R.; Ahmad, N.; Shehzad, A. Solvent and temperature effects of accelerated solvent extraction (ASE) coupled with ultra-high pressure liquid chromatography (UHPLC-DAD) technique for determination of thymoquinone in commercial food samples of black seeds (Nigella sativa). Food Chem. 2019, 309, 125740. [Google Scholar] [CrossRef]

- Vedove, T.M.; Maniglia, B.C.; Tadini, C.C. Production of sustainable smart packaging based on cassava starch and anthocyanin by an extrusion process. J. Food Eng. 2020, 289, 110274. [Google Scholar] [CrossRef]

- Travalini, A.P.; Lamsal, B.; Magalhães, W.L.E.; Demiate, I.M. Cassava starch films reinforced with lignocellulose nanofibers from cassava bagasse. Int. J. Biol. Macromol. 2019, 139, 1151–1161. [Google Scholar] [CrossRef]

- Farias, F.O.; Jasko, A.C.; Colman, T.A.D.; Pinheiro, L.A.; Schnitzler, E.; Barana, A.C.; Demiate, I.M. Characterisation of Cassava Bagasse and Composites Prepared by Blending with Low-Density Polyethylene. Braz. Arch. Biol. Technol. 2014, 57, 821–830. [Google Scholar] [CrossRef]

- Shojaee-Aliabadi, S.; Hosseini, H.; Mohammadifar, M.A.; Mohammadi, A.; Ghasemlou, M.; Ojagh, S.M.; Hosseini, S.M.; Khaksar, R. Characterization of antioxidant-antimicrobial κ-carrageenan films containing Satureja hortensis essential oil. Int. J. Biol. Macromol. 2013, 52, 116–124. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2020, 9, 200–211. [Google Scholar] [CrossRef]

- Kumaravel, S.; Hema, R.; Lakshmi, R. Production of Polyhydroxybutyrate (Bioplastic) and its Biodegradation by Pseudomonas Lemoignei and Aspergillus Niger. E-J. Chem. 2010, 7, S536–S542. [Google Scholar] [CrossRef]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Thermal, mechanical, and physical properties of seaweed/sugar palm fibre reinforced thermoplastic sugar palm Starch/Agar hybrid composites. Int. J. Biol. Macromol. 2017, 97, 606–615. [Google Scholar] [CrossRef] [PubMed]

- Lodha, P.; Netravali, A.N. Characterization of interfacial and mechanical properties of “green” composites with soy protein isolate and ramie fiber. J. Mater. Sci. 2002, 37, 3657–3665. [Google Scholar] [CrossRef]

- Diyana, Z.; Jumaidin, R.; Selamat, M.; Ghazali, I.; Julmohammad, N.; Huda, N.; Ilyas, R. Physical Properties of Thermoplastic Starch Derived from Natural Resources and Its Blends: A Review. Polymers 2021, 13, 1396. [Google Scholar] [CrossRef]

- Sangeetha, S.; Archit, R.; SathiaVelu, A. Phytochemical testing, antioxidant activity, HPTLC and FTIR analysis of antidiabetic plants Nigella sativa, Eugenia jambolana, Andrographis paniculata and Gymnema sylvestre. Res. J. Biotechnol. 2014, 9, 65–72. [Google Scholar]

- Ma, X.; Cheng, Y.; Qin, X.; Guo, T.; Deng, J.; Liu, X. Hydrophilic modification of cellulose nanocrystals improves the physicochemical properties of cassava starch-based nanocomposite films. LWT 2017, 86, 318–326. [Google Scholar] [CrossRef]

- Silva, M.L.T.; Brinques, G.B.; Gurak, P.D. Desenvolvimento e caracterização de bioplásticos de amido de milho contendo farinha de subproduto de broto. Braz. J. Food Technol. 2020, 23. [Google Scholar] [CrossRef]

- Huang, M.-F.; Yu, J.-G.; Ma, X.-F. Studies on the properties of Montmorillonite-reinforced thermoplastic starch composites. Polymer 2004, 45, 7017–7023. [Google Scholar] [CrossRef]

- Dias, A.B.; Müller, C.M.; Larotonda, F.D.; Laurindo, J.B. Mechanical and barrier properties of composite films based on rice flour and cellulose fibers. LWT 2011, 44, 535–542. [Google Scholar] [CrossRef]

- Salaberria, A.M.; Labidi, J.; Fernandes, S.C. Chitin nanocrystals and nanofibers as nano-sized fillers into thermoplastic starch-based biocomposites processed by melt-mixing. Chem. Eng. J. 2014, 256, 356–364. [Google Scholar] [CrossRef]

- da Rosa Zavareze, E.; Pinto, V.Z.; Klein, B.; El Halal, S.L.M.; Elias, M.C.; Prentice-Hernández, C.; Dias, A.R.G. Development of oxidised and heat–moisture treated potato starch film. Food Chem. 2012, 132, 344–350. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.A.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.; Zainudin, E.; Asrofi, M.; Atikah, M.S.N.; Huzaifah, M.R.M.; Radzi, A.M.; et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensive approach from macro to nano scale. J. Mater. Res. Technol. 2019, 8, 2753–2766. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Ibrahim, R.; Abral, H.; Ishak, M.; Zainudin, E.; Atikah, M.; Nurazzi, N.M.; Atiqah, A.; Ansari, M.; et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J. Mater. Res. Technol. 2019, 8, 4819–4830. [Google Scholar] [CrossRef]

- Syafri, E.; Yulianti, E.; Asrofi, M.; Abral, H.; Sapuan, S.M.; Ilyas, R.A.; Fudholi, A. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Edhirej, A.; Sapuan, S.M.; Jawaid, M.; Zahari, N.I. Preparation and characterization of cassava bagasse reinforced thermoplastic cassava starch. Fibers Polym. 2017, 18, 162–171. [Google Scholar] [CrossRef]

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Potential of using multiscale corn husk fiber as reinforcing filler in cornstarch-based biocomposites. Int. J. Biol. Macromol. 2019, 139, 596–604. [Google Scholar] [CrossRef]

- Hazrol, M.D.; Sapuan, S.M.; Zainudin, E.S.; Wahab, N.I.A.; Ilyas, R.A. Effect of Kenaf Fibre as Reinforcing Fillers in Corn. Polymers 2022, 14, 1590. [Google Scholar] [CrossRef]

- Othman, S.H.; Tarmiti, N.A.N.; Shapi’I, R.A.; Zahiruddin, S.M.M.; Tawakkal, I.S.M.A.; Basha, R.K. Starch/banana pseudostem biocomposite films for potential food packaging applications. BioResources 2020, 15, 3984–3998. [Google Scholar] [CrossRef]

- Hazrati, K.; Sapuan, S.; Zuhri, M.; Jumaidin, R. Preparation and characterization of starch-based biocomposite films reinforced by Dioscorea hispida fibers. J. Mater. Res. Technol. 2021, 15, 1342–1355. [Google Scholar] [CrossRef]

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of Sugar Palm-derived Cellulose Reinforcement on the Mechanical and Water Barrier Properties of Sugar Palm Starch Biocomposite Films. BioResources 2016, 11, 4134–4145. [Google Scholar] [CrossRef] [Green Version]

- López, O.; Versino, F.; Villar, M.; García, M. Agro-industrial residue from starch extraction of Pachyrhizus ahipa as filler of thermoplastic corn starch films. Carbohydr. Polym. 2015, 134, 324–332. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atiqah, A.; Atikah, M.S.N.; Syafri, E.; Asrofi, M.; et al. Thermal, Biodegradability and Water Barrier Properties of Bio-Nanocomposites Based on Plasticised Sugar Palm Starch and Nanofibrillated Celluloses from Sugar Palm Fibres. J. Biobased Mater. Bioenergy 2020, 14, 234–248. [Google Scholar] [CrossRef]

- López, O.V.; Ninago, M.; Lencina, M.M.S.; García, M.A.; Andreucetti, N.A.; Ciolino, A.E.; Villar, M.A. Thermoplastic starch plasticized with alginate–glycerol mixtures: Melt-processing evaluation and film properties. Carbohydr. Polym. 2015, 126, 83–90. [Google Scholar] [CrossRef]

- Tavares, K.M.; de Campos, A.; Mitsuyuki, M.C.; Luchesi, B.R.; Marconcini, J.M. Corn and cassava starch with carboxymethyl cellulose films and its mechanical and hydrophobic properties. Carbohydr. Polym. 2019, 223, 115055. [Google Scholar] [CrossRef]

- Ramírez, M.G.L.; Satyanarayana, K.G.; Iwakiri, S.; de Muniz, G.I.B.; Tanobe, V.; Flores-Sahagun, T.S. Study of the properties of biocomposites. Part, I. Cassava starch-green coir fibers from Brazil. Carbohydr. Polym. 2011, 86, 1712–1722. [Google Scholar] [CrossRef]

- Zoungranan, Y.; Lynda, E.; Dobi-Brice, K.K.; Tchirioua, E.; Bakary, C.; Yannick, D.D. Influence of natural factors on the biodegradation of simple and composite bioplastics based on cassava starch and corn starch. J. Environ. Chem. Eng. 2020, 8, 104396. [Google Scholar] [CrossRef]

- Anugrahwidya, R.; Armynah, B.; Tahir, D. Bioplastics Starch-Based with Additional Fiber and Nanoparticle: Characteristics and Biodegradation Performance: A Review. J. Polym. Environ. 2021, 29, 3459–3476. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef]

- Sabbah, M.; Altamimi, M.; Di Pierro, P.; Schiraldi, C.; Cammarota, M.; Porta, R. Black Edible Films from Protein-Containing Defatted Cake of Nigella sativa Seeds. Int. J. Mol. Sci. 2020, 21, 832. [Google Scholar] [CrossRef] [Green Version]

| Film | Fructose and Glycerol g/g Dry Starch | Starch g/180 mL Distilled Water | BS g/100 g of Dry Starch | CB g/100 g of Dry Starch |

|---|---|---|---|---|

| Control(CS/BS) | 0.3 | 10 | 9 | 0 |

| CS-BS/CB3% | 0.3 | 10 | 9 | 3 |

| CS-BS/CB6% | 0.3 | 10 | 9 | 6 |

| CS-BS/CB9% | 0.3 | 10 | 9 | 9 |

| Sample Name | MC (%) | Density (g/cm3) | Thickness (µm) | Solubility (%) |

|---|---|---|---|---|

| Control | 7.546 ± 0.6 | 1.34 ± 0.02 | 0.272 ± 0.01 | 34.23 ± 2.0 |

| CS-BS/CB3% | 6.813 ± 0.4 | 1.31 ± 0.07 | 0.274 ± 0.08 | 32.93 ± 1.4 |

| CS-BS/CB6% | 6.406 ± 0.2 | 1.29 ± 0.01 | 0.332 ± 0.05 | 32.45 ± 0.9 |

| CS-BS/CB9% | 6.026 ± 0.3 | 1.25 ± 0.06 | 0.35 ± 0.04 | 31.47 ± 1.1 |

| Polymer | Fiber | Plasticizer | TS | E | Reference |

|---|---|---|---|---|---|

| Cassava starch | Cassava bagasse (6 wt.%) | Fructose | 10.78 MPa | 3.19 mm | [49] |

| Corn starch | Corn Husk (8 wt.%) | Fructose | 12.84 MPa | 3.7% | [50] |

| Corn starch | Kenaf fiber (6 wt.%) | Sorbitol | 17.74 MPa | 48.79% | [51] |

| Cassava starch | Banana pseudostem powder (10 wt.%) | - | 16 MPa | 113.5% | [52] |

| Dioscorea hispida starch | Dioscorea hispida Fiber (6 wt.%) | Sorbitol | 9.29 MPa | 25.44% | [53] |

| Sugar palm starch | Sugar palm cellulose fiber (10 wt.%) | Glycerol and sorbitol | 19.68 MPa | 32.8% | [54] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abotbina, W.; Sapuan, S.M.; Ilyas, R.A.; Sultan, M.T.H.; Alkbir, M.F.M. Preparation and Characterization of Black Seed/Cassava Bagasse Fiber-Reinforced Cornstarch-Based Hybrid Composites. Sustainability 2022, 14, 12042. https://doi.org/10.3390/su141912042

Abotbina W, Sapuan SM, Ilyas RA, Sultan MTH, Alkbir MFM. Preparation and Characterization of Black Seed/Cassava Bagasse Fiber-Reinforced Cornstarch-Based Hybrid Composites. Sustainability. 2022; 14(19):12042. https://doi.org/10.3390/su141912042

Chicago/Turabian StyleAbotbina, Walid, S. M. Sapuan, R. A. Ilyas, M. T. H. Sultan, and M. F. M. Alkbir. 2022. "Preparation and Characterization of Black Seed/Cassava Bagasse Fiber-Reinforced Cornstarch-Based Hybrid Composites" Sustainability 14, no. 19: 12042. https://doi.org/10.3390/su141912042

APA StyleAbotbina, W., Sapuan, S. M., Ilyas, R. A., Sultan, M. T. H., & Alkbir, M. F. M. (2022). Preparation and Characterization of Black Seed/Cassava Bagasse Fiber-Reinforced Cornstarch-Based Hybrid Composites. Sustainability, 14(19), 12042. https://doi.org/10.3390/su141912042