1. Introduction

Acoustics is the science concerned with the production, control, transmission, reception, and effects of sound. The term is derived from the Greek akoustos, meaning “heard”.

Pierre Gassendi (†1655, a French philosopher, astronomer, and mathematician), as early as 1635, was the first to measure the speed of sound (with an accuracy of 25%), using firearms; he assumed that it was invariable relative to the pitch of the tone [

1]. At the end of the 17th century (1694), Joseph Sauveur (†1716, a French mathematician and physicist), in cooperation with Étienne Loulié (1654–1702), laid the foundations of “the science of sound”. Souveur J. was the first to apply the concept of acoustics to sound science (1701). In 1802, Ernst E.F. Chladni (†1716, a German physicist and musician) published a book called “Die Akustik” [

2], which can be considered the first comprehensive work on acoustics. John Tyndall (†1893, an Irish physicist) was the author of the book “Lectures on Sound” (1867) [

3], which influenced the teaching of acoustics at universities. His goal was to make acoustics interesting to all people. John William Strutt (†1919, a British physicist), aka Lord Rayleigh, was the author of two volumes of “The Theory of Sound” [

4,

5]. This book is still sought after by acoustics engineers. Wallace Clement Sabine (†1919, an American physicist) was a pioneer in architectural acoustics. He was the first to take quantitative measurements of the acoustics in a room [

6]. In 1913, George Fabyan (1867–1936) gave impetus to Sabine W.C. to build Riverbank Acoustical Laboratories, which in 1918 became the first independent globally recognized laboratory to examine construction acoustics [

7]. Wallace C. Sabine died shortly after it was built. In 1919, Fabyan G., asked Paul Earls Sabine (†1958, an American acoustician) to take over as director of Riverbank Labs. He summarized the results of his work in the book “Acoustics and Architecture”, published in 1932 [

8].

In the present age, the acoustic properties of materials play an increasing role in designing and addressing the regulation of unwanted noise and vibration [

9,

10] in several industries, such as the construction and automotive sectors. The detection of acoustic properties is therefore extremely important [

11,

12]. Designing and improving an environment that would be acceptable from the point of view of acoustics is directly linked to the selection of suitable building materials and the techniques for their use [

13,

14].

Desarnaulds V. et al. (2005) [

15] described traditional insulating materials which are widely used in construction acoustics for their sustainable properties. These materials are either natural such as cotton, cellulose, hemp, etc., or recycled, for example, rubber, cork, glass, textiles, and others. McGinnes C. et al. (2005) [

16] pointed out that natural materials such as straw are advantageous for use as building materials because of their accessibility, ease of preparation, and, last but not least, they are environmentally friendly. In a series of measurements, they showed that the absorption coefficients of this natural material have similar, if not comparable, values to other highly absorbent materials (e.g., mineral wool and glass fibres). This claim was refuted in 2017 by D’Alessandro F. et al. [

17]; a wall made of straw bales is a bad sound insulator, especially at low frequencies, and therefore does not meet the requirements of building regulations. The authors of these scientific articles [

18,

19,

20] investigated how additions of natural materials affect the properties of high-strength concrete. White M.J. (2009) [

21] assessed transmission loss and wavelength on samples of crushed limestone and gravel. Vigran T.E. (2012) [

22] also used both assessment methods in his research. He concluded that, within numerical accuracy, both of these methods provide the same results. Aly O.A.A. et al. (2014) [

23] investigated materials such as plastic bottle caps and cardboard egg boxes, which can be used to build an eco-friendly acoustic room (soundless chamber) that increases speech clarity, and also to obtain better conditions in multimedia studies. Niresh J. et al. (2015) [

9] looked in detail at the different methods of measuring the acoustic characteristics of materials used to control noise in the automotive industry. They argued that one of the factors that influences the purchase of a car is precisely noise. Noise control in the car is essential because it increases passenger comfort, making long-distance travel less fatiguing. Xinwu X. et al. studied the possibilities of using recycled natural or synthetic polymers from waste rubber in the production of acoustic materials for their good acoustic properties, (2018) [

24]. Bhingare N.H. et al. (2019) [

25] described the characteristics of natural fibres and waste (recycled) material. Natural materials are an effective alternative to synthetic ones due to their low cost and lower environmental impact. Akiwate D. et al. (2019) [

26] examined the acoustic properties of porous materials produced by 3D printing. Labašová E. and Ďuriša R. (2019) [

27] evaluated the sound absorption coefficient for various single-layer and two-layer materials (cork, felt, polyethylene). Gumanová V. et al. [

28] and Moravec M. et al. [

29,

30] also devoted themselves to similar research.

Peng C. et al. (1998) [

31] and Tan K.N. (2010) [

32] described using an impedance tube with two microphones. The impedance tube was used by Suhanek M. et al. in their experimental studies (2008) [

33]. Pierre J. et al. (2013) [

34], Koruk H. (2014) [

35], Tan W.H. et al. (2015) [

36], and Neto B.N. et al. (2018) [

37] all carried out experimental analyses of the variation in the sound absorption coefficient for measurements on the impedance tube.

This article focuses on analysing the results of measurements of acoustic properties of bulk recycled materials and comparing them with compact materials of the same material composition. The production of compact panels is costly because it requires a chemical binder and a time-consuming production process. The price of these binders is quite high, which increases the price of the resulting product. Likewise, the material composition of these additives is also a problem from an environmental point of view, as they are substances with hazardous properties. These are disadvantages that could eliminate the use of recycled bulk materials. The article also describes the design of test cartridges for measuring the acoustic properties of materials, so that the measurement of acoustic properties can be carried out by means of an impedance tube. The aim of the article is to assess the suitability of recycled bulk materials for sound-insulating applications and products. There is great potential for the creation of suitable materials usable in sound-insulating applications in the automotive industry (production waste or end-of-life vehicle waste).

2. Materials and Methods

2.1. Test Cartridges for Measuring Acoustic Properties of Materials

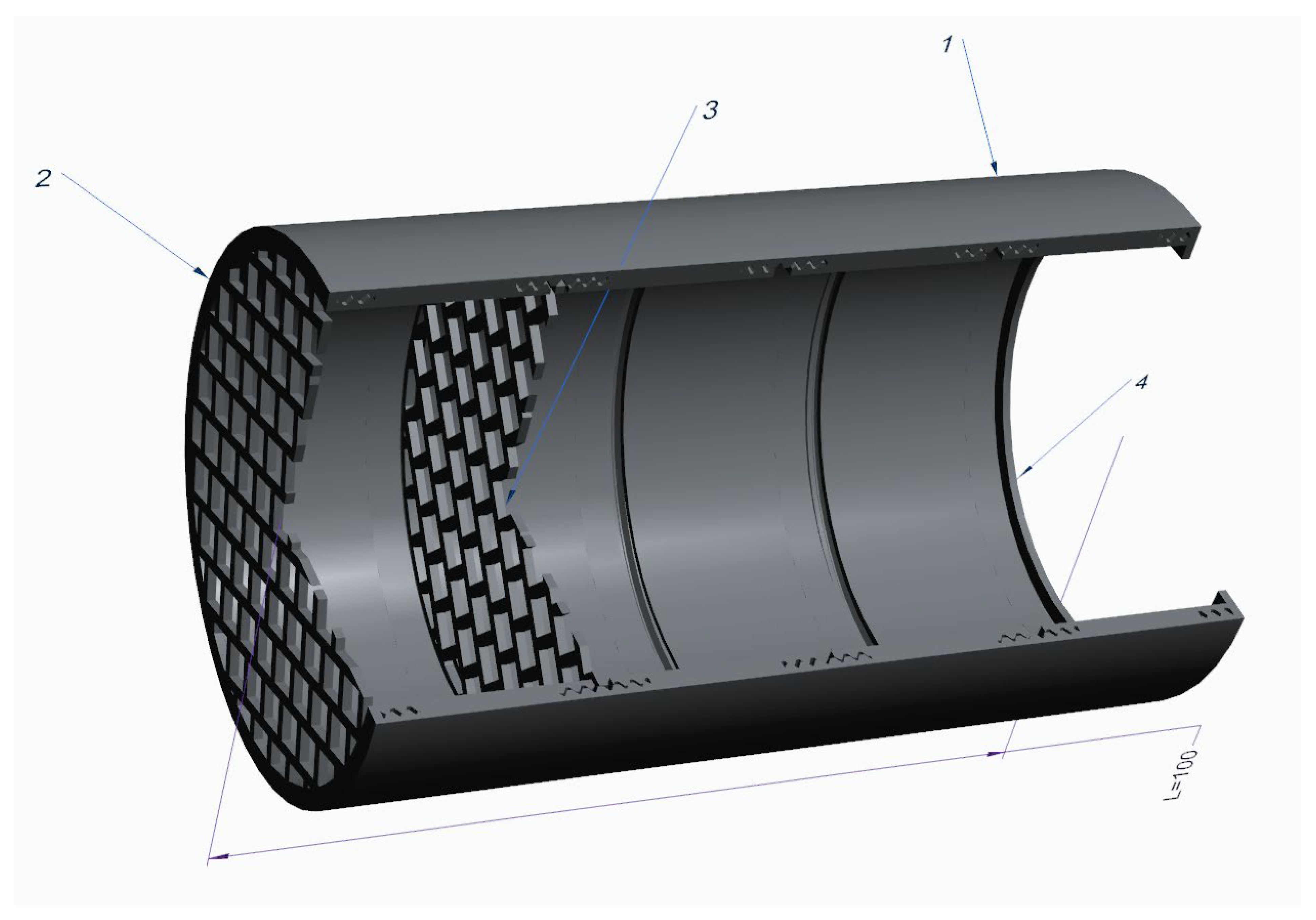

For the purposes of this research, the team of researches designed and developed test cartridges (Capsule1, Capsule2) to measure the acoustic properties of materials obtained by recycling from scrapped cars. The test cartridges were designed to be applicable to measuring the acoustic properties of the bulk, granular, and compact materials in the BSWA SW433 impedance tube.

The design of the cartridges was important for several reasons. The first reason is that the sample of bulk or granular materials cannot be placed directly in the measuring equipment. The second is that, if necessary, we can place different types of bulk or compact materials in the cartridge at the same time, or simulate the state of the bulk/air gap/compact granular material, etc. Without the design of such cartridges, such a measurement would not be possible, since the impedance tube is structurally limited for measuring only solid materials. The last reason is that there is currently production of filling equipment through which we will test the material examined at different pressures and, in this way, change the porousness of the measured sample, whether regarding glass, rubber shreds, or textile components. In this case, the test cartridge will not only serve for the measurement itself, but also as an auxiliary filling device.

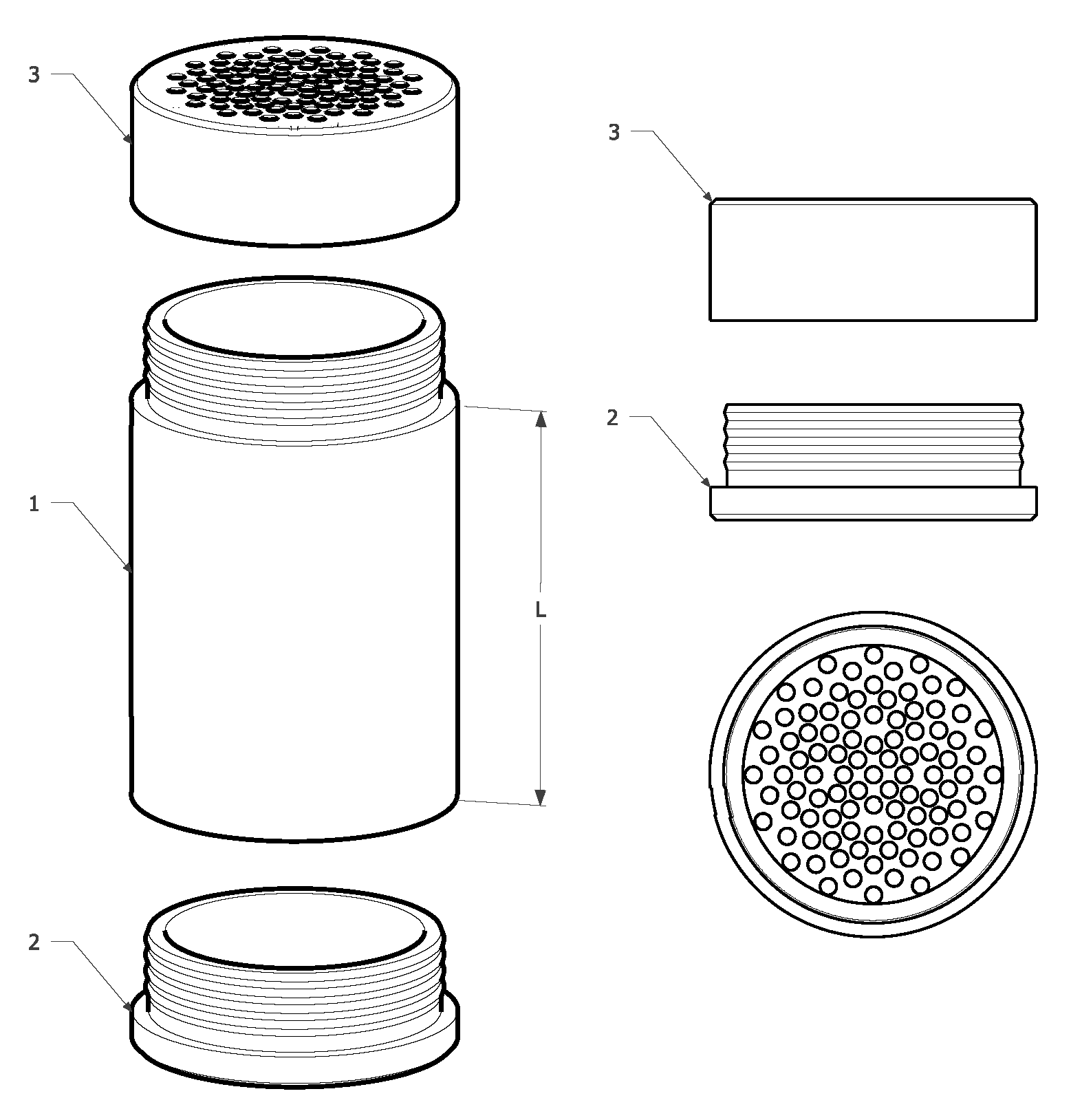

Two options for test cartridges were developed: using a CNC machining device (Capsule1; see

Figure 1, left) or 3D printing (Capsule2; see

Figure 1, right).

Both test cartridges are designed to expand the possibilities of laboratory measurements of the selected acoustic descriptors, namely sound absorption coefficient (α) and sound transmission loss (R).

2.1.1. Production of the Test Cartridge Using a CNC Machine (Capsule1)

The test cartridge (Capsule1) was manufactured in five lengths of 20, 50, 75, 100, and 120 mm, modifiable for use in different dimensions (

Figure 2). The body of the cartridge is made of aluminium, with its subsequent finish (anodic oxidation). An important part of the production of test cartridges is the perforated sieves, which prevent the emptying of bulk material; this was used for the purpose of this research (Capsule1). The materials studied were measured and compared for the two test cartridges we developed (Capsule1, Capsule2).

2.1.2. Production of the Test Cartridge (Capsule2) by 3D Printing

Currently, a large number of types or technologies of 3D printing are available on the market. In general, 3D printing is an additive method of production, where the successive application and binding of material in layers produces the resulting structure according to the design on the computer (

Figure 3). With 3D printing, we can quickly and easily make models of different sizes and shapes with suitable mechanical properties.

Since this research focuses on measuring and designing new materials from selected recycled parts from scrapped vehicles, namely used tyres (ground rubber), glass (fractions ≥ 1 mm), textiles (fibrous materials), etc., it was necessary to design and manufacture suitable auxiliary equipment to meet our requirements.

The test cartridges of this type were manufactured using a PRUSA i3 MK3 3D printer. PLA and PETG filaments were used for printing. PLA is one of the most versatile materials and is a biodegradable material that is increasingly used in industry. PETG is more durable, stronger, and can handle larger impacts. PLA was used for the production of the internal sieves and outer joins. PETG was used for the other parts of the test cartridge.

In the case of 3D printing, cylinder lengths of 25 and 50 mm were selected, modifiable for different resulting lengths. In the case of a cartridge printed on a 3D printer, internal sieves of 1 mm thickness were also produced to redistribute individual cylinders; in this way, different types of bulk materials can be put into one cartridge. If necessary, an air bubble or compact material can be placed between them.

2.2. Acoustic Metric

The following acoustic quantities were evaluated and measured to evaluate the acoustic properties of the materials: sound absorption coefficient α (dimensionless); sound reduction index

R (dB) [

38].

2.2.1. Measurement of the Sound Absorption Coefficient

The sound absorption coefficient is used to evaluate the sound absorption efficiency of materials. It is a dimensionless quantity defined as the ratio of the intensity of the sound wave absorbed by the given material (

I) to the sound intensity of the wave reaching the given material (

I0) [

38]:

The size of the sound absorption coefficient is located in the interval . Material that completely absorbs all the acoustic energy reaching it is characterized by a sound absorption coefficient of α = 1.

The effect factor in the perpendicular impact of acoustic waves is then determined from the following relationship [

38]:

where

r is the acoustic pressure reflection factor,

rr is the real component of the acoustic pressure reflection factor, and

ri is the imaginary component of the sound pressure reflector.

The sound pressure reflection factor is given by [

38]

where

H12 is the transmission function between locations 1 and 2,

HI is the transmission function for the falling wave itself,

HR is the transmission function for reflecting wave,

k0 is the comprehensive wave number,

x1 is the distance between the sample and more distant microphone, and

i is the imaginary unit.

2.2.2. Measurement of the Sound Reduction Index

The sound reduction index is the value given in decibels (dB) based on the ratio of the sound wave reaching the front of the sound-absorbing material to the sound wave transmitted back. Thus, the sound reduction index represents the damping properties of the material, where the greater the value of sound reduction index, the more attenuated the sound and the better the dampening properties of the material. The method of measuring the sound reduction index in an impedance tube involves decomposing the broadband stationary signal into the arriving and reflected components at the front of the test sample and the transferred and reflected component at the back of the test sample.

In addition to the type of material, the sound reduction index particularly depends on the frequency of mechanical oscillation, the thickness of the material, the size of the inertia load, the structure of the material (e.g., volume of pores, pore size and shape, etc.), temperature, etc.

The sound reduction index can be calculated from the following relationship [

38]:

where

Wi is the force of the incident wave coming towards the test sample and

Wt is the force of the transmitted wave leaving the test sample.

2.3. Description of the Tested Material Samples

Sound absorption materials are widely used in many noise control applications.

Noise control can be carried out using two basic methods: active and passive. Active methods are much more costly and complex compared to passive methods. Passive methods mainly use porous materials such as foam, glass, and mineral wool, etc., either alone or with the addition of composite materials. Such materials, for example, are used in the automotive industry as door, trunk, and roof or floor fillers to insulate road noise. In construction, they are used as wall cladding, for the construction of partitions, etc. For the purpose of noise control, materials should be evaluated on the basis of their acoustic properties.

The choice of materials for this research was conditioned by the possibilities and laboratory equipment of our workplace and also the materials’ use in practice as insulating and noise-absorbing materials. Based on the materials and their physical and mechanical properties, the following materials were selected and used for the experiment:

Tyre wear, mechanical damage, storage conditions, and ageing are among the most common factors in which the tyre is removed and becomes waste. By recycling tyres, we acquire usable fragments, where from an ecological point of view, we can reduce waste and landfills of material while giving the recycled material new possibilities for practical use. Textiles in a car account for up to 2–2.5% of its total weight, which is 23–26 kg, and by 2025, it is expected to increase up to 35 kg. In the production of a new car, up to 2.5–4 kg of technical waste is generated.

Rubber and textile bulk materials have been selected for our research purposes for the following reasons:

the significant potential for these types of waste to arise;

the existing processors and recycling companies for these materials, ensuring the availability of quality feedstock;

the assumption that rubber and textile materials have relatively good acoustic parameters, given that these materials are already used in the production of compact acoustic panels.

Aluminium test cartridges (Capsule1) developed in our workplace were used to measure the acoustic properties of bulk materials from scrapped cars. Three size fractions of recycled rubber granules (Fraction1, Fraction2, Fraction3) and a mixture of textile material were measured. For the purpose of comparing the acoustic properties of the bulk materials, standard available products were used (compact panel made of recycled rubber and insulating board made of recycled textiles). A compact panel made of recycled rubber and an insulating board made of recycled textiles were produced with the use of different types of binders. Binders are required, and there is a subsequent process of compaction and pressing at high temperature. Textile components are joined with a single-component expanding polyurethane glue. Rubber granulate materials are joined with epoxy-based glue.

Samples with a diameter of 60 mm were taken from the panels so that they could be used for the measurement of acoustic properties in the impedance tube.

Recycled rubber material from recycled car tyres comes in three size fractions. Textile recycled material comes from the interior of the car covers, acoustic fillings, carpets, and hardened textiles. The main components of these textiles are synthetic fibres, which are 80% polypropylene (PP) and polyethersulfone (PES). The remaining 20% share is made up of natural fibres consisting of cotton, flax, and possibly industrial hemp. The composition of the recycled and chopped textile material is the same as the compact recycled textile material that was supplied by the manufacturer of compact textile panels. The ratio of individual textile components is constant.

Granular bulk materials are characterized by the dimensions and shape of grains. The characteristics of each test sample are given in

Table 1.

2.4. Measurement Equipment

Several measurement methods have been developed to determine the sound absorption coefficient, but one of the most commonly used is measurement on an impedance tube [

39]. The impedance tube has an advantage over other measurement methods due to its compactness, low price, and relatively fast possibilities of obtaining the desired results. Compared to the sound chamber, the impedance tube requires diametrically smaller samples of the test material.

For the measurement of selected types of recycled materials, the BSWA SW433 impedance tube was used in a configuration with two microphones; it had a length of 500 mm, an internal diameter of 60 mm, and a frequency range from 100–2500 Hz (

Figure 4). The other components of the measurement technique were a 4-channel MC3242 data collection analyser (0~20 kHz), a PA50 (50 W) metering power amplifier for powering the speaker in the impedance tube, a PC with VA-Lab4 software, the necessary cabling, an impedance tube (100 Hz–6.4 kHz; model SW433), and their connections. Acoustic parameters, namely the sound absorption coefficient (α) and sound reduction index (R), were measured using the transformation function method in accordance with STN EN ISO 10534-2 (730537) [

40].

For each sample measured, 5 repeated measurements were made, and the resulting values were averaged. During measurement, the test cartridges were filled with bulk material, which was placed inside without applying additional pressure to this material.

For the assessment of the impact of the test cartridge on the measurement results, comparative measurements of the empty test cartridge and of the absorbent or reflective material were made.

The average values of the accompanying parameters of microclimatic conditions during measurement are given in

Table 2.

To evaluate and compare the sound absorption coefficient (α) and sound transmission loss (R) parameters, we used basic statistical methods and hypothesis testing methods [

41,

42]. Verifying the normality of the variable was performed using the Shapiro–Wilk test. A parametric single-selection

t-test or a non-parametric paired Wilcoxon test was used to pair dependent variables. To compare k-dependent variables, the Friedman test was used, which is non-parametric and similar to the single-factor ANOVA for dependent variables. When testing statistical hypotheses, the decision to reject or adopt a null hypothesis was made using the

p-value. If the

p-value was lower than the specified level of significance α, we rejected the null hypothesis in favour of an alternative hypothesis. If the

p-value was equal to or greater than the selected significance level α, we did not reject the null hypothesis.

3. Results

For the purposes of comparison with the acoustic properties of the processed flowing materials, the initial step was to design and develop test cartridges so that measurements of acoustic parameters could be made using the impedance tube.

Subsequently, a series of measurements of the acoustic properties of the bulk materials were carried out and compared to those for compact materials. On the basis of the measurements and analyses carried out, the suitability of these materials for sound-insulation applications was assessed.

3.1. Results of the Measurement of Etalon Samples

Based on measurements of acoustic properties of etalon samples of sound and reflective material and their comparison with measurements of an empty cartridge, we can conclude that the contribution of the cartridge itself to the results of measurements is minimal. Since the test cartridge is made of acoustically perfectly reflective material, using this cartridge improves the results of the sound reduction index measurement to a minimal level. In contrast, when measuring sound absorbance, it worsens the results since aluminium is a material with a very low sound absorbency value (see

Figure 5).

Bulk material will always be used in acoustic applications in combination with an outer layer, as bulk material cannot be used without outer packaging due to its nature. When measuring acoustic properties, the test cartridge represents the form of the outer packaging. Against this background, we can consider the results of measurements of acoustic properties of bulk materials using a test cartridge to be objective, as the contribution of the test cartridge is minimal and, in practical applications, the bulk material will still be enclosed in a form of outer packaging that has similar characteristics to the test cartridge developed by us.

A graphical representation of the average values of the coefficient of sound absorption, or the sound reduction index of the standard samples over the whole frequency range, is shown in

Figure 5.

3.2. Results from the Measurement of Materials Based on Recycled Rubber Granules

In the measuring of acoustic properties, four samples based on rubber granules were evaluated. One sample was made of a compact panel made of recycled rubber material. A further three samples were made of recycled rubber in a bulk form with different fraction sizes.

Rubber material is generally characterized by its good absorbency and lower attenuation. This is confirmed by the measurements made. The main objective of the measurements was to compare the properties of bulk rubber recycled materials with a compact rubber panel, which is ordinarily produced commercially. Based on the measurements made, we can conclude that the coefficient of sound absorption of the bulk materials compared to the compact rubber sample reached higher values. This is mainly due to the fact that in the bulk materials, there is an absorption of sound not only by the material itself, but by the contribution of the air gaps between individual rubber particles. The value of the coefficient of sound absorption for all four samples increased with increasing frequency, reaching maximum values in the frequency band 630–1250 Hz.

When measuring the sound reduction index, the best values were expected to be achieved by a compact rubber sample. Almost identical values were achieved by bulk rubber granules with the smallest fraction size (8–15 dB). Bulk materials with larger fractions already displayed significantly lower sound reduction index (3–6 dB) values compared to compact rubber and the smallest fraction of bulk rubber. In this case, the lower sound reduction index values are due precisely to the non-compactness of the bulk rubber granulates with larger fractions. The sound reduction index of all four samples increased slightly with an increasing frequency up to 1250 Hz. A graphical representation of the average values of the coefficient of sound absorption, or the sound reduction index for different types of recycled rubber over the whole frequency range, is shown in

Figure 6.

The best sound absorption index values in the 100–800 Hz frequency band were achieved by the sample with the smallest fractions of rubber granulate. In the 1000 and 1250 Hz frequency bands, samples with larger fractions achieved the best parameters.

The better features of the sound absorption coefficient for bulk Fraction1 and Fraction2 were achieved by combining the size of the grains of the rubber granulate and the size of the air gaps which are the best able to absorb sound waves with frequencies of 1000–1250 Hz. Damping of lower frequencies requires higher volumetric mass (density); for this reason, recycled rubber granules with bulk (Fraction3) achieved better sound absorption coefficient values for lower frequency bands.

We used testing methods to compare the measured values. The normality of sample sets was verified using the Shapiro–Wilk test. For each set, we tested “The null hypothesis is that the sample distribution is normal”. If the p-value was less than the significance level α, then the null hypothesis was rejected (the distribution is non-normal). In the event of measurements of the coefficient of sound absorption, only the recycled rubber—bulk (Fraction3) set did not display the normal distribution (p-value = 0.0006 < α). On the other hand, in the case of the sound reduction index, we did not reject the null hypothesis of normal distribution across the frequency range.

Due to non-compliance with the normality condition throughout the frequency range, we used the non-parametric Friedman test (significance level α = 0.05) to compare the coefficient of sound absorption, which is suitable for comparing dependent sets. The result of the testing shows that the value of the coefficient of sound absorption depends on the type of recycled rubber (p-value < α). We used the non-parametric paired Wilcoxon text, or the parametric paired t-test, to determine which types of recycled rubber show statistically significant differences. The paired comparison shows that recycled rubber—bulk (Fraction3) has sound absorption coefficient values which differ significantly from those of other sample types.

We used a paired t-test to determine which types of recycled rubber show statistically significant differences in the sound reduction index. The sound reduction index values were shown to be comparable for the recycled rubber—compact and recycled rubber—bulk (Fraction3) pair and the recycled rubber—bulk (Fraction1) and recycled rubber—bulk (Fraction2) pair.

3.3. Results from the Measurement of Recycled Textile Materials

For measuring the acoustic properties of recycled textile materials, two samples were evaluated. One was made of compact recycled textile material and the other was prepared from the same recycled chopped textile material.

Based on the measurements made on the coefficient of sound absorption, we can conclude that the compact textile material achieved better parameters in the frequency bands of 100–500 Hz and 1600–2500 Hz. Bulk textile material achieved better absorption parameters in the frequency band 500–1250 Hz, reaching maximum values for the coefficient of sound absorption at a frequency of 800 Hz.

Based on the measurement results for the sound reduction index, compact textile material has better properties throughout the frequency band. This result could be assumed as the bulk mass of the compact material is 4 times higher than the bulk mass of the bulk textile material, which greatly affects the acoustic properties of the materials. The values of the sound reduction index increased with increasing frequency for both samples evaluated. The maximum values were reached at the highest-rated frequency, 2500 Hz.

The graphical representation of the average values of the coefficient of sound absorption, or the sound reduction index for two types of textile samples over the whole frequency range, is shown in

Figure 7.

The graphs show that the values of the coefficient of sound absorption and the sound reduction index vary depending on the type of textile material examined. The sound reduction index shows that for a sample of bulk textile material, the sound reduction index value is on average 55% lower than for a sample of compact material. This difference varies from 50% to 60% depending on the frequency.

4. Discussion

This article evaluates the possibilities of using recycled and granular materials in sound insulation applications in terms of their acoustic properties. Several authors have addressed this issue previously.

The research conducted by authors Borelli D. and Schenone C. [

43] was focused on the experimental analysis of the acoustic properties of vulcanized rubber crumbs, obtained by the shredding of used tires. Additionally, their performance as sound-absorbing material in lined ducts and dissipative silencers was studied. The comparison between the performances of ducts lined with traditional sound absorbing materials (rock wool, granular clay) and the rubber crumbs evidenced, in general, a worse effectiveness of the recycled material, except for frequencies lower than 400 Hz, where it performs even better. These results are also in line with our research findings, where granular materials achieved very similar acoustic properties to traditional sound insulation materials.

Sikora J. et al. [

44] focused on research into the acoustic properties of two groups of materials. The first group included granular polypropylene, gravelite, and foamed polystyrene. The second included rubber granulate and quartz sand, similarly for mineral wool “granulate”. Both groups of granular materials may be applied in practice. Granulates with narrow-band absorption within the frequency range of 500–2000 Hz may be very useful as extra sound-absorbing layers in panels and elements of wall acoustic screens, resulting in an increase in single-number quantities. The present authors have great hopes for rubber granulates, especially considering that they are obtained from production waste and used rubber products. They may be found in the form of granulates, but also as plates made from laminated rubber granulate. This type of rubber layer may be applied in elements of wall noise protection, resulting in increased acoustic insulation.

In [

45], two types of recycled insulating panels were investigated, composed of waste paper and textile fibres, joined by glue, with a total thickness of 12 mm and 20 mm, respectively. Experimental measurements were carried out in order to evaluate both thermal and acoustic performance. The experimental results were compared with the thermal and acoustic properties of traditional insulating systems. In terms of environmental impact, the panel composed of waste paper and textile fibres caused relatively large energy consumption and a high potential for global warming. Even when the panel was composed of recycled materials such as waste paper and polyethylene fibres, the sample presented a high density that determined a highly functional unit. A further reduction of the embodied energy and of the global warming potential could be obtained by modifying the manufacturing process: the introduction of recycled glues and the development of lighter solutions will allow the panels to be more competitive in terms of embodied energy and GHG emissions. These authors point to a higher environmental load in the production of acoustic panels, mainly due to the use of adhesives.

Similar research was carried out by Buratti C. et al. [

46], who investigated as many as three types of recycled sound-absorbing panels, composed of waste paper, textile, and wool fibres. An experimental analysis was carried out in order to evaluate both acoustic performance and the Life Cycle Assessment. The best performance was obtained for the material made of wool scraps and waste paper; its acoustic performance was comparable to conventional extruded polystyrene, with a significantly lower environmental impact. The authors pointed to the good acoustic properties of recycled materials and lower environmental impacts based on life cycle assessment results.

In 2021, Svoboda J. et al. [

47] conducted research focused on lightening the concrete mixture; this was achieved by replacing aggregate with rubber granulate from waste tyres in cement composites, which places this mixture in the category of lightweight concrete. The workability of this mixture containing rubber granulate can be controlled using a plasticizing or super-plasticizing additive. Cement composites containing recycled rubber from waste tyres show better sound insulation properties at a layer thickness of 10 mm at frequencies of 125 and 2000 Hz; at a sample thickness of 30 mm at frequencies of 125, 500, and 2000 Hz; and at a sample thickness of 50 mm at frequencies of 125, 500, and 2000 Hz when compared to the comparative sample containing natural aggregate. From the above research, it is clear that the application of recycled granular materials is also possible when substituted and mixed with other materials.

5. Conclusions

An acoustically suitable material may be considered to be one which has significant properties of absorbency or reflectivity. Sound is best absorbed by voluminous, soft, and porous materials. Conversely, sound energy is mainly reflected by hard materials with a smooth surface that cannot oscillate.

The application of such materials is envisaged in the implementation of structures of noise walls, or other sound and thermal insulation products. Noise-reducing walls are currently used to reduce traffic and industrial noise directly in the production process. The structures of noise-reducing walls can be very diverse. The basis is an external perforated covering surface, between which is placed one or more layers of absorbent material (e.g., based on mineral wool, glass fibres, etc.). A typical noise-absorption barrier consists mainly of a perforated cover plate surrounding porous absorbent materials and air gaps. There are many materials that are part of cars over their lifetime which are difficult to make further use of (textiles, airbags, glass, tyres, etc.). They could be suitable for the production of sound-absorbing elements. In general, it is possible to produce several options for sound-absorbing elements. The production and preparation of these recycled materials into the final product phase applicable to the production of noise walls is very demanding in terms of technological processes. Special technology is often needed for the treatment of these materials, and the need to add binders is also an important problem. The addition of these binders ultimately makes the production of these materials too expensive and is also often harmful to the environment.

One possible solution for the use of recycled granular (but also chopped, sheared, torn, and crushed) materials in acoustic applications without the use of binders is the application of these materials to noise walls in the form of bulk material. A prerequisite for such an application is the suitable structure of the noise panel and suitable application of bulk material with subsequent compaction.

Based on measurements of the acoustic properties of recycled bulk and textile materials, it is clear that the acoustic properties of these materials are comparable to compact materials. The acoustic properties of bulk materials can be further improved by increasing their bulk mass by using additional pressure when filling these materials into specific applications. The assessment of the impact of bulk mass and pressure increase in filling these materials into test cartridges will be the subject of further research. In addition, acoustic properties can be varied by mixing individual size fractions. From the above, it is clear that by applying bulk recycled materials to sound insulation, one can achieve values comparable to acoustic panels made of recycled materials, and also to traditionally used materials.

A great advantage of the application of bulk materials is their price. The production of panels with recycled materials is costly and time consuming. To combine individual grains and pieces of materials, different types of binders are required, and there is a subsequent process of compaction and pressing at high temperature. The price of these binders greatly increases the price of the final product. Another problem with the production of such compact panels is the chemical composition of these additives, showing a number of dangerous properties. For these economic and also ecological reasons, it is precisely the application of suitable rubber and textile-based recycled materials to sound insulation that is highly suitable, since the acoustic properties of these materials are also of high standard, and their high variability is also an advantage based on the requirements of their application to specific conditions.

The present authors focused on research and comparison of acoustic properties of recycled compact materials with various recycled bulk materials that could be applied in the core of the sound-insulating panel, as a substitute for the traditional sound-insulating materials currently used. Based on the results of research on the acoustic properties of bulk recycled materials and comparing them with compact materials, we can conclude that the acoustic properties of bulk recycled rubber and textile materials achieve very good values, which enables them to be used in a wide range of applications.

Recycled bulk materials have industrial applications in the cores of sound-insulating panels, as cavity-filling in building walls in assembled houses, and in the cores in noise barriers and prefabricated dividing constructions.

The advantages of using such recycled bulk materials in acoustic (but also potentially thermal insulation) applications, such as noise walls, compared to commercial materials are a combination of very light material, high physical and chemical stability, low cost, and very good acoustic properties.