1. Introduction

In emerging nations, the agricultural supply chain has undergone tremendous transformations [

1,

2]. In both developed and developing countries, the nature of food consumption has switched from a minimal diet to increased quality organic food, such as vegetables, fruits, dairy products, etc. [

3]. Companies are changing their production and distribution methods to reduce food waste in the supply chain in response to customer quality demands [

4,

5,

6]. Presently, companies are using cutting-edge innovation intimately connected to eco-efficiency, which entails minimizing negative environmental impacts by cutting back on resource use, pollution output, and trash accumulation [

7]. Integrating software is the greatest way to prevent food, financial, and other resource waste. System improvements have enabled businesses to monitor sales, monitor stock, control production, prevent waste, improve food quality and safety, and identify waste areas [

8].

Knowing why food waste occurs is essential to preventing it in the first place. Despite various studies attempting to define and offer a framework for food loss, the explanations are specific to the location. However, most food or agricultural supply chain losses occur in the production and post-harvest stages [

8].

It is possible to separate the supply chain management (SCM) system into two parts: strategic and operational [

9]. Customers, suppliers, and logistics are part of strategic supply chain management (SCM) [

10]. On the other hand, operational SCM focuses on streamlining processes and enhancing customer service [

8]. In recent years, there has been a lot of interest in Supply Chain Management, and several operational studies have taken place.

The concept of sustainable supply chain management (SSCM) is receiving considerable interest from researchers throughout the world. It not only helps businesses to integrate corporate social responsibility (CSR) principles into their operations [

10] but also increases their ability to achieve efficiency in logistics and resource consumption [

11]. On top of all that, Sustainable supply chain management aids in the achievement of UN Sustainable Development Goals [

12], particularly the triple-bottom-line concept, which focuses on economic, social, and environmental well-being at the same time. Borowski and Patuk [

10] also mentioned similar arguments in their study. The food supply chain (FSC) refers to the entire food activities, from the farm to the table. According to Yadav et al. [

13], FSC has five stages, that is, (1) production of Agri-products by farmers, (2) processors, (3) distributors, (4) retailers, and (5) end consumers. Each stage has a unique value to the final product. Each stakeholder experience different issues at their end in managing their activities.

Hunger affects 12 percent of the world’s population, and almost half of all vegetables, root crops, and fruits across the globe get wasted in moving from farmers to end consumers [

14]. A significant portion of food gets wasted at every stage. Many studies have tried identifying food waste causes and quantifying them at different levels. It is considered that the majority of food or agricultural supply chain losses occur during the production, processing, and post-harvest stages [

8]; 24 percent of food is wasted during production, 24 percent after harvest, and 35 percent during eating, according to Xue et al. [

15]. As a result, over 80% of the food is compromised during these three stages.

The losses in the postharvest supply chain are a common problem for any country facing food insecurity. The rapidly enlarging population in developing countries needs to alleviate hunger and mile nutrition better. The same has been included in the United Nations Sustainable Development Goals that by 2030, the world must minimize food loss to fifty percent. Much importance has been given to reducing food loss on consumers’ end. However, scant attention is paid to food loss in the post-harvest stage [

8], especially in developing countries. Pakistan is an agricultural country, and most of its revenue is generated from the agricultural sector. Vegetables and fruits have great importance in Pakistan’s rural and urban areas because they contribute ample carbohydrate portions to the diets of millions of Pakistanis [

15].

Despite Pakistan’s vast agricultural territory and a suitable climate, 49 percent of the country’s population is malnourished, according to a United Nations assessment. Post-harvest treatment waste is responsible for more than 16 percent of this malnutrition [

16]. To deal with the issues, drastic measures have been put in place worldwide. However, this issue is still present to a dangerous extent in Pakistan. Agriculture growth in Pakistan was negative (−0.7 percent) for the first time in 2015, as farmers determined that squandering their time was better than producing less. Until they reach the final customer, foods in Pakistan are in danger of 30 to 50 percent deterioration [

17]. Large-scale wastages have increased the cost of production, making it more expensive than in neighboring countries. Therefore, the paper poses the question: “What are the main causes of damage in the supply chain of perishable agricultural goods in Pakistan that lead to food waste?”

Researchers have paid little attention to the strategic aspects of the supply chain, despite the growing importance of sustainable development and strategic elements of food enterprises. Similarly, earlier research has concentrated on SCM from a broad standpoint. The integrative vision of the food supply chain, particularly in terms of strategy, network design, and information systems, has received little consideration. Literature also reveals that prior research on SCM has primarily concentrated on industrialized nations while growing Asian economies have received minimal attention. Each food industry is different, especially from developing and developed regions’ perspectives. Therefore, it is difficult to anticipate the findings of developed regions to be the same for underdeveloped and developing regions.

This study focuses on the secondary sources of damage that the FSC process causes to agricultural products. While the world fights COVID-19-related challenges, most of the world faces a significant lack of fresh organic foods [

18]. Specifically, this study will shed light on the role of supply chain strategy, network design, and information systems in countering the food waste issue in the FSC. The research is significant for (a) Optimizing the existing supply chain of perishable items, (b) Increasing food security in Pakistan, and (c) Decrease in damages to agricultural produces. Understanding the issues within FSC and concentrating on increasing productivity is vital in this situation. The current study follows the quantitative approach to achieve its objectives, and the findings of the current study will explicitly help individuals liked to the food industry, such as farmers, transporters, companies, and related stakeholders, to understand how they can capitalize on supply chain strategy, network design, and information system to counter the ever-increasing food crisis and minimize waste in the food supply chain network. The next sections discuss the literature relevant to the studied variables with hypotheses development, methodology, result and discussion, and conclusion with theoretical and practical implications.

2. Literature Review

SCM is a broad topic that researchers have examined from various angles in the last several years. One notable field of SCM is sustainability in it. It has been a decade of steadily increasing research and practical implementation in this particular field. Sustainable supply management as handling capital flows, information, materials, and cooperation between companies. It considers goals from all three dimensions of sustainable development (i.e., economic, environmental, and social). It is specifically the cooperation of partners in the whole chain. The definition of the supply chain emphasizes the importance of recognizing the legitimate needs of the supply chain’s stakeholders.

Several stages in the FSC refer to the movement of agricultural products from their source to their final destination in the food chain. Before products can be distributed to different retailers, a raw product must first be produced and then processed at the distribution stage. Retailers sell their goods to consumers, who then purchase them. These stakeholders include farmers, suppliers, consumers, distributors, non-governmental organizations, national and international agricultural bodies, government agencies, and allied institutions [

19]. Running the various FSC activities is challenging for each stakeholder, and many issues can arise during the procedure. Financial and human resources shortages, pesticides and fertilizers, raw materials and other inputs, information-sharing challenges, the threat of burglary, and transportation difficulties are only some examples of the issues faced by farmers [

20].

Furthermore, intermediaries also face difficulties because of the highly perishable nature of agricultural produce, lack of information, and inconsistent supply and demand for agricultural products. Consumers are concerned about product quality, safety, price fluctuations, and a lack of standardization in agricultural products. Many intermediaries account for various processes, making AFSC an advanced and complex network. There is also an expectation that the AFSC of today can provide various options for the consumer, ranging from processed food to fresh produce. Additional stress on natural resources such as water, energy, and land is being placed on them due to an ever-increasing global demand for food resulting in increased market volatility [

21]. Sustainable production and distribution are important and timely issues [

20]. Many developed and developing countries still mainly rely on the food industry as their primary source of employment. However, food waste is a significant obstacle to a long-term food supply.

The agricultural product supply chain has changed dramatically in developing countries during the last few years. Due to economic growth, people in both developed and developing countries can afford better quality of life [

22], such as vegetables, fruits, and dairy products. Developing countries are altering their food production and delivery methods in response to customer demand for higher-quality products. AFSC is unique among SC activities because it deals with perishable goods while bringing together a diverse group of stakeholders. Supply chains play a crucial role in the global food system and are often called its skeleton. Achieving the United Nations’ second sustainable development goal of eradicating world hunger by giving food to everyone, ensuring food security, and enhancing nutrition are all made possible by this initiative. As a result, a comprehensive strategy including all FSC components is required for success in this endeavor. This goal necessitates major efforts to reduce food waste.

The amount of food thrown out or uneaten is commonly thought of as food loss or waste. This phenomenon is well-documented in the literature, though. An investigation by Chauhan et al. [

23] found that five distinct types of waste can be categorized as “food loss”, “food disparity”, “food surplus”, or “food waste”. The notions of food loss and food waste are distinct. Irani et al. [

24] define food loss as any loss that occurs during the food’s primary supply chain, from planting to processing. However, food waste happens later and is usually caused by consumer behavior.

About a third of all global food production goes to waste because of either food loss or waste. According to the United Nations, consumer food waste is predicted to be twice as great as the food waste generated at the farm level [

25]. Many of the world’s population still suffers from hunger and malnutrition [

26]. Food waste is responsible for a fifth of all agricultural water usage and a yearly economic loss of

$940 billion. Corrado and Sala [

26] also examined the food waste supply chain. Globally, people throw away around 389 kg of food per year, from 158 to 298 kilos in the EU, accounting for 25 percent of all food purchased by households in the European Union.

Worldwide, food waste of 1.3 billion tons results from an inefficient food supply chain [

25]. China is covered in the literature in the same way; 188 million Chinese are food insecure, causing the country to throw away

$32 billion of food yearly. A staggering

$165 billion is lost yearly in the United States due to the waste of 40% of the food produced. Almost a quarter of all families in India have gone a day without food in the past year [

27]. All along the supply chain, food is wasted in developed and developing countries, but the reasons vary. The majority of food losses in developing nations occur at the harvesting level. Food surplus and consumer behavior are the primary causes of this issue in developed regions. An inefficient market system and poor infrastructure are all factors that contribute to food waste in underdeveloped countries, where the vast majority of food is lost before it even reaches the customer [

28].

Household food waste creation is not significantly different amongst high, middle, and low-income countries. A lack of sufficient infrastructure, market systems, and proper infrastructure is mostly blamed for pre-consumer food losses in underdeveloped nations [

15]. The great majority of food waste is a result of post-consumer losses. The term “post-consumer” refers to food products purchased and consumed by consumers. Agri-products that fall short of industry standards directly result from defective planting materials and antiquated cultural procedures used during harvest, storage, and transportation [

29]. Insufficient infrastructure and facilities mean that Agri-products cannot be packaged or processed properly before being sold [

30].

Pakistan’s fertile land is excellent for growing a wide variety of crops. However, the government must still import billions of dollars’ worth of vegetables and other items from more than a hundred countries, which raises the dollar’s value and contributes to the trade imbalance [

31]. Pakistan ranks 73rd in the world’s food security index despite having a bumper crop of wheat, rice, and sugarcane. Every third child in Pakistan suffers from malnutrition, putting their physical and mental health at risk. The mother’s malnutrition is to blame for the death of one in five newborns. Food loss is a major contributor to this problem. Pakistan’s food production has exceeded 325 million tons, while post-harvest losses have exceeded 36 million tons.

2.1. Role of Strategy in Food Supply Chain

As a key component of SCM, the strategy makes actions easier, and managers are better positioned to compete in the market [

32]. It manages the exchange of data and the coordination of supply chain activities between buyers and sellers. According to Accrosi et al. [

20], supply chain strategy coordinates strategic cooperation among product development decision-makers worldwide. Systematic cost-benefit analysis and operational module trade-offs are part of this approach. Modern organizations can adapt to any situation because of their flexible strategy [

33]. Every level of the supply chain is guided by a supply chain strategy [

13].

Sustainable food and nutrition need for a wide range of populations are a major challenge for food and nutrition policymakers of the 21st century. Sustainable food supply chains necessitate innovative [

34] and technologically advanced agriculture and processing technologies, smart packaging, transparent warehousing, transportation systems, and optimal operations that maximize synergies across these systems [

35]. It would be disastrous for businesses to include sustainability issues in their plans without considering the strategic implications. Consequently, the food industry must define reasonable goals or performance indicators to assist decision-making. The literature and theories on supply chain management have shown that initiatives tend to only focus on chain fragments when attempting to improve the chain’s performance. As a result, a more comprehensive strategy is required in practice.

Many supply chain partners have divergent interests in shifting from transforming the old supply chain to one that is more environmentally friendly. The food supply chain has many enablers that must be understood if sustainability is achieved and strategies are required. For example, sustainable food supply chain management has developed a sustainable product design framework to support reusable packaging design and reduce waste in food supply chains. The traditional single-use packaging solution is compared to the multi-use packaging solution through a life cycle assessment on a catering chain case. The research shows that green packaging has environmental advantages [

36] but can have a negative financial impact on some chain partners. Grocery stores help legitimize sustainable practices in the dairy industry. The research uses institutional theory to study the behavior of dominant retailers in supporting energy reduction in the food supply. The results of interviews with various stakeholders have led to the conclusion that adopting sustainable practices may compromise economic gains and require collaborative approaches to encourage sustainable practices in supply chains to be drawn.

A Supply chain strategy helps integrate sustainability goals into operations and network designs. It helps firms achieve cost-effective supply operations, improve customer service, reduce waste, minimize environmental impact, and gain a competitive advantage. Supply chain strategy alignment of people and processes is difficult. It is necessary to redefine and reclassify responsibilities to emphasize changing destinations, simplifying processes, and developing new skills. As a result, SC performance is enhanced by redeploying underperforming components. An adequate Sustainable supply chain management system plans the capacity to manage raw materials and deliver products and services [

37].

Asset utilization efficiency, a company’s competitiveness, and profitability are key indicators of an organization’s success. Strategy and performance are linked in the supply chain. However, establishing a link between a sustainable supply chain and an organization’s performance is still difficult. When multiple supply chain partners must be successfully integrated, many internal and external factors must be considered. Industrial operations include purchasing, selling, exchanging, and exchanging information with supply chain partners and different stakeholders. In developing nations, firms integrate supply chain strategy into their overall business strategy to improve organizational performance [

14] and stakeholders’ satisfaction.

However, this conclusion is unproven from the perspective of emerging markets. Several studies [

11,

13] have recently examined how the supply chain can affect organizational operations. These studies recommended concentrating on supply chain strategy to address today’s global challenges. Large corporations in developed countries face particular challenges due to strategy. As a result, many nations in developing countries cannot utilize automated techniques. They must rely on a strategic plan to ensure quality, customer satisfaction, and growth. The following hypothesis is proposed (see

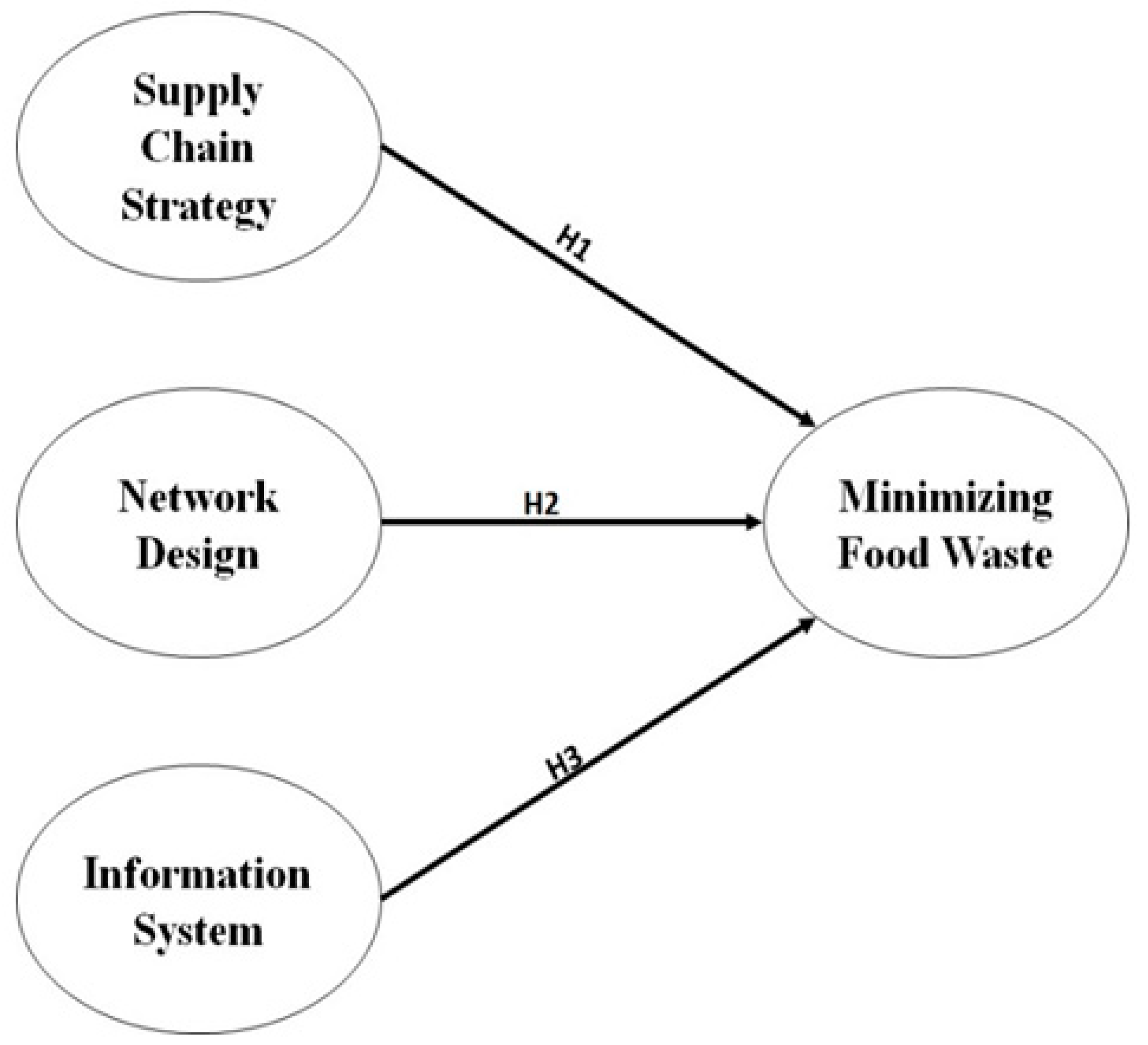

Figure 1):

Hypothesis 1 (H1). Strategy in the supply chain plays a significant role in reducing waste in the food supply chain.

2.2. Role of Network Design and Food Supply Chain

Adapting supply chain strategy and network design to assess and encourage sustainable behavior. If an organization does not restructure to meet its stated goals, its entire strategy will be questioned. The supplier’s network design must meet the production requirements of producers. Suppliers should choose factors that affect price, delivery, and quality [

37]. Network design configuration theory focuses on providing valuable and effective products to customers. When optimizing supply chain material flow, it uses supply chain network design to identify the number of manufacturing plants and distribution locations and their capacities [

38].

Network design directly affects supply chain location, quality [

39] and related party performance [

40]. As a result, supply chain network design challenges manufacturing and distribution personnel [

41]. The supply chain relies on a cost-effective system interacting with customers. Conversely, supply chain network design significantly impacts SCM decisions that impact organizational performance and all supply chain strategy decisions. Yadav et al. [

13] define supply chain networks offer, assembling, and distributing products to clients.

The previous study on network design of supply chains has primarily concentrated on economic issues, with little attention given to the importance of SD [

34]. Nagurney [

42] reworked the supply chain network design’s capabilities and operational product and gave a framework for finding appropriate values. While each manager’s role is essential, the supply chain design is not yet determined. According to Lin and Wang [

40], supply disruptions cause inventory and sales losses. Supply chain network design impacts supply chain processes and minimizes disruptions, impacting the firm’s overall operations. Improved supply chain network design reduces operational dysfunctionalities and improves organizational performance. For example, recent research has shown that different supply chain network design techniques significantly influence process improvement [

42,

43]. Developed countries can afford to spend more money on automating their businesses, which leads to greater financial and operational results. However, this effect is understudied in developing nations. So, the following hypotheses are proposed:

Hypothesis 2 (H2). Network design in the food supply chain plays a significant role in reducing waste in the food supply chain.

2.3. Information Systems and Food Supply Chain

The supply chain must explain and demonstrate how an organization’s information system meets the needs of its stakeholders. Supply chain strategy can be restructured and integrated with sustainable development to achieve balanced growth and superior performance through information systems [

44]. To examine the advantages and capabilities of a diverse Sustainable supply chain management information system linked to an electronic data exchange marketplace, Beske et al. [

35] looked at how the SSC information system’s alternative scope can support organizational capabilities by finding a suitable empirical model. This mechanism aids in achieving the organization’s sustainable development goals by utilizing alternative resources.

FSC’s supply chain is inefficient because of information asymmetry, a lack of industrialization, and insufficient management [

45]. Most industrial companies’ increasing operational efficiency is a common goal [

46]. On the other hand, firms must consider integration when creating a new information system. Firms can identify and solve administrative issues that vary by industry with an effective information system [

47]. Changes in specific financial performance measures can predict the impact of supply chain strategy and information systems on discrete value chain components [

48]. The supply chain has multiple features, such as an information system, automatic information routing, active process monitoring, and multi-level supply chain management integration. These features ensure that the knowledge management and information system are adapted to match your organization’s requirements. Therefore, procurement, inventory management, and material handling rely heavily on the information system.

Consumers today are very concerned about sustainable practices and expect circularity in food supply chain design [

49].Qu and Liu [

48] used Delphi and Information System methodologies to model the difficulties of implementing a circular economy in the Indian Forest Service. According to the researchers, lack of “technology, techniques, farmer knowledge and awareness, and poor government policies” are the biggest obstacles to implementing a circular economy in the Indian food supply chain. Hsu et al. [

37] discussed a sustainable retail supply chain. They found that an important part of food safety and quality compliance can be achieved by ensuring farmers are involved in sourcing activities and receiving assistance from institutions. To determine the most common causes of food waste, Aramyan et al. [

1] examined the food supply networks in the United Kingdom. According to their findings, there is a variety of management practices that lead to food waste in supply chains. To reduce the environmental impact of food production along supply chains, this study offers new information on what needs to be done to address it. As a result of a collaborative effort toward integrated supply chain operations, the interactions between partners will be more sustainable.

In a study by Beske et al. [

35], most articles on collaboration in the supply chain painted a messy picture. Even though eight articles discuss Logistical Integration, there are only six articles that discuss Technological Integration. A total of 28 articles describes Enhanced Communication as an integral and important practice in their interactions with partners, which helps mitigate the latter. The information exchanged is of higher significance even with the goal of a transparent supply chain [

50,

51,

52]. Because a chain’s overall success is only as strong as its weakest link, it makes sense to work on strengthening relationships with existing partners. Changes to the supply chain can be brought about, among other things, through implementing knowledge sharing. According to six of the papers analyzed, focal firms often have to provide their suppliers with the information to produce the desired raw material (e.g., organic products). Some methods allow sharing of knowledge, such as Partner Development Programs and Partner Training.

Recent research shows that better information technology improves organizational performance. Modern technology allows organizations to innovate faster and produce more with fewer resources. It is possible to enhance organizational efficiency while also reducing environmental impact by implementing big data analytics, ERP systems, and related system management. Consideration of the best mixture for the company is critical. Instead, each firm must tailor the solutions to its specific situation. Since information systems are essential, their inclusion in long-term strategy seems inevitable. Based on the above discussion, the following hypothesis is proposed:

Hypothesis 3 (H3). Information system in the food supply chain plays a significant role in reducing waste in the food supply chain.

3. Methodology and Data Analysis

To accomplish the research objective, this study used an empirical technique. The study aims to learn about the function of supply chain components in minimizing waste in the food supply chain. This research is conducted in a developing nation (Pakistan) with limited real-time data and automation access. As a result, the ideal strategy contextualizes the study. The Securities and Exchange Commission of Pakistan’s list of Pakistani manufacturing companies was one of the study’s primary focuses, which is the target population of this research. A list of the top 48 companies was selected as a sample. It was decided to work with these companies because of the supply chain resources, the clarity of the organization’s structure, and the significance of both time and cost. Researchers adapted questionnaire items from previous studies. There were two sections in the first draught: section A sought demographic data from the responder, while section B comprised 23 items (items are provided in the

Appendix A). Nine academics and six supply chain industry specialists reviewed the items to see if any changes or improvements could be made. Researchers collected feedback from 51 managers to pilot test their modified draught. Internal consistency of constructs ranged from 0.76 to 0.91, meeting the minimal criteria of 0.7 set by Hair et al. [

53].

A detailed survey was initiated after the structures’ internal correctness was verified. All levels of management, from junior to senior, were asked to fill out the questionnaire. The five-point Likert scale was used, with one indicating strongly disagree and five indicating strongly agree. There were 211 usable responses out of 441 issued surveys. SPSS and Amos v.25 were used for the empirical and structural analyses. The Cronbach’s alpha value of 0.907% indicates that it meets Peterson’s [

54] threshold for credible data, which is 0.8 or above 3. The instrument’s reliability and validity were evaluated after establishing one-dimensionality, as recommended by Hinkin [

55]. Hair et al. [

53] state that factor loading can assess convergent validity and that the optimal loading value for well-established items is above 0.6. The minimal value for average variance extracted (AVE), according to Molina et al. [

56], should be more than 0.5 for all constructs.

Table 1 provides more information on the components’ number, loading, AVE values, and composite reliability. A discriminant validity test was used to ensure that all constructs were distinct from one another. Fornell and Larcker [

57] argued that the variance of constructs must be higher than other constructs to ensure discriminant validity. Similarly, if the square root values of AVE correlate strongly with other pair indicators, this is regarded as an additional indicator of discriminant validity. Hair et al. [

53] recommend that the correlation values of the independent variables should not exceed 0.9.

Table 2 represents the result of discriminant validity.

SEM’s strong assumptions have led researchers to use it for multiple regression. SEM has been extensively explored by Bollen [

58] and employing SEM in the current investigation looked like a sounder strategy. An improved and more rigorous technique for dealing with self-reported data sets is provided by CFA utilizing Amos, which is particularly useful for investigations proposing new constructs or measurement items. The value of R

2 was discovered to be 0.92, which indicates that the data is fine. The KMO test was performed to determine sample adequacy, and the resultant value of 0.931 was found to be effective with an above 0.6 recommended value [

59]. It was necessary to do a confirmatory factor analysis to establish that all of the found constructs have a single dimension underlying them. SPSS AMOS v.25 was used for this task. Chi-square/degree of freedom (CMIN/DF), standardized root means square residual (SRMR), adjusted goodness of fit index (AGFI), comparative fit index (CFI), normative fit index (NFI), the goodness of fit index (GFI), and Root Mean Square Error of Approximation (RMSEA).

Table 3 presents the findings for recommended indices for measurement and structural models, which significantly complied with recommended values.

4. Results and Discussion

Considering the increasing food and clean water challenges, the world realizes the need to follow practices that increase food production and ensure its safety and preservation. Nations are taking measures to minimize food waste at all levels, such as harvesting stage, post harvesting, transportation, storage, and consumption. A number of researchers have studied food waste from diverse perspectives, highlighting the importance of technology, transportation system, storage system, packaging design, training the individuals involved in the food chain, etc. This study focuses on the role of supply chain strategy, network design, and information systems in minimizing waste in the food supply chain. The structural equation modeling technique was used to investigate the suggested hypotheses. It is found that an effective supply chain strategy helps firms minimize waste in the food supply chain with a

p-value of 0.004 and 0.299 β value (see

Table 4). This led to the acceptance of H1, that is, “Strategy in the supply chain plays a significant role in reducing waste in the food supply chain”. This finding relates to the Fu et al. [

11] study highlighting the importance of supply chain strategy in agricultural firms’ operational performance. According to structural analysis, sampled companies’ food performance improved significantly due to an effective supply chain strategy. This indicates that sampled firms are effectively capitalizing on their strategy, which ultimately helps them minimize waste in their food supply chain. Supply chain strategy may also be a follow-up strategy for these companies, and they relate it to their entire business strategy to fulfill their short- and long-term goals. The findings show that organizations must operationalize and integrate their models cohesively to effectively capitalize on Sustainable supply chain management. The strategic choice theory claims that a firm’s operational and financial performance is directly influenced by its ability to choose various options and implement an effective strategy [

60]. However, Sustainable supply chain management’s goals cannot be achieved in its true spirit until organizations integrate all of its components and deploy them as a cohesive whole. There will be a need to increase the knowledge of industrial company management to employ their supply chain participation techniques, which will be a beneficial investment for long-term SC performance.

The impact of network design on food waste in the supply chain was also examined, which revealed significantly positive results with a

p-value of 0.012 and a β value of 0.287. Thus, the second hypothesis, that is, “Network design in the food supply chain plays a significant role in reducing waste in the food supply chain”, is also accepted. This finding advocates Yadav et al. [

13] study in which they highlighted the critical role of network design in the agro-food supply chain. Most companies in the sample are attempting to enhance their performance by adjusting their network design to match the strategic level used in SCM. Supply chain partners must collaborate on similar goals and visions to meet their goals, establishing structures and processes. Finally, the role of the information system was examined in the food waste in the food supply chain, which presented a significant positive impact result with 0.331 β and 0.002

p-values. So, the third hypothesis, that is, “Information system in the food supply chain plays a significant role in reducing waste in the food supply chain”, is also accepted. This finding supports Al-Wattar et al. [

44] study highlighting the critical role of information systems in the food industry from the purchasers’ perspective. This investigation also showed considerable gains in the organization’s capabilities to minimize food waste in the food supply chain when looking at information systems. This indicates that a company’s food waste control is improved when information systems are implemented effectively. Data quantification is a constant challenge for dynamic companies. The appropriate person may make the correct decision at the right moment with the support of an effective information system. Sampled companies are reaping the benefits of their information systems, boosting their operational performance concerning food waste management.

5. Theoretical Contributions, Practical Implications, and Limitations

This study investigates the influence of sustainable supply chain management components, namely network design, supply chain strategy, and information on minimizing waste in the food supply chain. The literature review indicates that most studies have focused on the supply chain concept of organizational performance. However, rare attention is paid to the studied constructs relating to food waste. Studying such a phenomenon becomes more important in an agricultural country facing a food crisis. Thus, this study enriches the rare literature on food waste and loss in FSC in Pakistan and highlights the importance of supply chain strategy, network design, and the critical role of information systems.

From the industrial perspective, managers must grasp the comprehensive approach to sustainable supply chain management, which is not normally associated with the supply chain department alone. Specifically, companies cannot meet their sustainability goals without adhering to supply chain sustainability principles. The finding suggests organizational management take a more rigorous strategic approach to Sustainable supply chain management by realizing the importance of a well-designed network, thoughtful technology solution, and a compliant organizational structure. When it comes to increasing the efficiency of organizations, industrial firms should focus on tools and methods, including improving pooled connections and forging alliances with suppliers, direct consumers, and the vast majority of others in the supply chain. With the use of decision-support tools and methods for reducing material and service costs and creating a technical supply chain system that supports many levels of decision-making, they must construct a supply chain network to minimize costs.

There are multiple limitations to this study. For instance, the current study’s scope is limited to Pakistan only. Future studies’ scope should also be widened to include data from other regions. The information gathered is subjective and does not consider official records such as yearly reports or other sources of factual information that could exist. By combining both forms of data, future research will be more useful. Future studies can also examine the causal relationship between antecedent factors, namely supply chain strategy, network design, and information.

6. Conclusions

Recent events have brought attention to the seriousness of food waste and its role in the quest for more sustainable food systems. In light of the COVID-19 pandemic’s ripple effects, manufacturers, retailers, and consumers are increasingly aware of the need to eliminate wasteful practices. The effects of food waste can be felt down the supply chain. Foods that farmers cannot sell cost them money. Food that spoils on the road is a waste of fuel. Retailers lose a lot of money if they do not sell their products. Tossing out food at the retail or consumer level is food waste. Food loss occurs early in the supply chain, such as during manufacture, processing, or transportation. Anywhere it happens, its effects will be severe.

In the current study, the authors highlighted the role of strategy, network design, and information systems in the food supply chain to minimize damage and waste. It is found that information system plays a critical role in minimizing food loss and waste in the food supply chain, followed by strategy and network design. Thus, individuals having a stake in the food supply chain system must pay attention to these concepts in the food supply chain to counter the food loss issue.