1. Introduction

The global supply chain and manufacturing systems are undergoing a significant transformation with the advent of Industry 4.0. While this shift is often associated with large corporations, it is important to recognize that small- and medium-sized enterprises (SMEs) also play a crucial role in the global economy [

1,

2]. SMEs are not just bystanders but indispensable contributors to innovation and sustainability improvements. Their adoption of Industry 4.0 technologies presents a unique set of challenges. This study delves into the trends of the Fourth Industrial Revolution, smart manufacturing, logistics, and sustainability of SMEs, as well as the barriers and enablers of adoption, to contribute to the current research on this issue.

Industry 4.0 is a term used to describe the fusion of IoTs, AI, sophisticated robots, and cloud computing with industry. These systems are intelligent enough to carry and distribute data among cyber-physical systems to make predictions and even make autonomous decisions. Consequently, they greatly affect production and distribution systems [

2,

3]. Industrialization 4.0 offers small and medium-scale enterprises an opportunity to increase productivity and enhance their competitiveness in the larger world markets [

4]. These are all technologies that are necessary for tackling the very issues of climate change and resource scarcity, two of the biggest global issues, via waste reduction and improved resource efficiency. IoT and AI decrease absenteeism and real-time visibility enables the tracking of supply chains [

5,

6]. Despite the use of technology in this sector, it is usually constrained by limited funding for projects. To increase the adoption of these technologies, specific approaches, including government subsidies, industry partnerships, and tailored financing options, should be incorporated [

7].

Based upon the research of Mittal et al. [

8], some factors influencing the adoption of Industry 4.0 in export-oriented companies included technical capabilities, system flexibility, software infrastructure, human resource competency, and market pressure, with the last of these acting as moderating variables that improve the adoption process.

Technology-oriented Industry 4.0 advancements include additive manufacturing, robotics, blockchain, IoT, and digital twins. Industry 4.0 reengineers the processes by fully utilizing all the technologies and making the right decisions [

9,

10]. Automating the manufacturing and logistics channels is becoming possible. The IoT devices monitor the condition of the working assets, and the supply chain is improved with trust and confidentiality through blockchain [

11]. However, these technologies are not being widely implemented by SMEs compared with larger businesses because of resource and technical limitations. This is why many corporations invest in R & D, while in the case of sales strategies for SMEs, the timing has been vital since they do not have that financial strength [

4]. In addition, the scanty technical support and the absence of skilled employees in SMEs do not improve the situation either. Research shows that only 30 percent of the SMEs in developed economies have utilized the practices of Industry 4.0 as opposed to 70 percent of larger enterprises [

8,

10]. Such contrasts prove the necessity of policies and financial measures to ensure increased technology use in SMEs.

Industry 4.0 technology is used in smart manufacturing to build a productively resilient, adaptive, and sustainable production ecosystem. One of the features that are based on IoT sensors and AI algorithms is based on predictive maintenance. This helps identify the problems that can lead to the failure of machine components beforehand, hence less downtime and less cleaning costs [

6,

12]. Moreover, manufacturers can develop and test them using digital twins, virtual copies of natural systems that can be created without leaving the office [

13]. Smart logistics also improves the supply chain by leveraging IoT, AI, and blockchain. Industry 4.0 technologies have a transformative effect on SMEs. For example, AI systems can continuously monitor supply chain transactions and identify the most cost-efficient route during deliveries [

14]. These technologies are revolutionary and need to be implemented in SMEs. For instance, predictive maintenance systems reduced downtime for German electronics SME manufacturers by 30% [

6]. As with IoT trackers, they have helped SME logistics in India go from on-time delivery of 80% to 100% [

8,

14]. Therefore, smart technologies are being used in SMEs to increase productivity and customer satisfaction [

15,

16,

17].

Supply chain management requires the Fourth Industrial Revolution technologies to be used for sustainability to be achieved successfully. This contrasts with predictive maintenance, energy consumption, materials waste, eco designs, and circular economy targets [

18,

19,

20]. For example, factories can utilize digital twins to create virtual models of the product, allowing them to engage in testing and prototyping with significantly reduced resource costs and environmental impact. Based on this, Zheng et al. [

21] argue that blockchain strengthens responsibility by allowing the tracing of goods to prove their ‘ethical sourcing’ and comply with sustainability standards. The IoTs provide a way to improve the sustainability of various businesses by providing advanced information to optimize resources and reduce gasses pumped into the environment [

14]. However, firms can also use these technologies to decrease waste and carbon emissions generated and improve their overall operational processes.

Furthermore, even with the alleged limited resources, Industry 4.0 technologies are very beneficial to the application of sustainability practices by small and medium enterprises (SMEs). For instance, modeling is used in some enterprise sectors, such as the food and drink industries, where waste and resource management are important factors. These are examples of bridging the relationship between Industry 4.0 technologies and the indicators of global sustainability development goals.

Different types of constraints, such as funding, organizational, and technical constraints, make it hard for small and medium enterprises to embed Industry 4.0 technologies fully. Still, the main hurdles for adoption in small and medium enterprises [

5,

8] are costs related to technology or lack of access to borrowing. Liao, Hu et al. have also highlighted poor infrastructure and a lack of skilled personnel [

4]. As some of the technical impediments, sophisticated technologies are transferred into systems that fail to disperse the power that cannot be provided to the SMEs. Organizational issues and change resistance lead to deadened leadership with no innovations [

6]. Furthermore, policy and regulatory barriers have been pointed out, including the poor clarity in requirements of technology adoption policies and the lack of government support regarding these industries to invest in Industry 4.0 technologies fully [

14]. For instance, rising barriers include shifting government policies, increasing technical assistance, risk sharing, and initiatives aimed at helping small and medium businesses transition to Industry 4.0. However, it is worth overcoming for small and medium enterprises to employ complex supply chain management techniques [

22].

While many researchers have focused on Industry 4.0 technology, little consideration has been given to the conditions and hurdles the typical SME faces. Obstacles such as insufficient finances and technical skills are not discussed in enough detail, and research into the effects of Industry 4.0 technologies on SME supply chain sustainability in developing countries is lacking. Additionally, previous research has failed to account for the role of government policy or external support in SMEs’ adoption of smart technologies in supply chain management [

23].

Therefore, this research seeks to fill this research gap by investigating the adoption of Industry 4.0 by SMEs, focusing on the specific conditions faced by SMEs that influence their decisions to adopt the technologies and success in doing so. The study offers insight into how SMEs can improve the success of adopting Industry 4.0 technologies and what barriers they may face, especially in developing countries. Finally, this study identifies the advantages and difficulties of adopting Industry 4.0 from an SME-centric perspective.

However, small and medium enterprises often face resource constraints, a lack of qualified personnel, and integration challenges when integrating Industry 4.0 technologies. Nevertheless, these technologies can substantially improve the performance and sustainability of their operations. However, SMEs trying to adapt to these technologies virtually do not realize such desirable benefits. A considerable body of literature overlooks the requirements and constraints that characterize SMEs, especially concerning sustainable supply chain management (SSCM). This gap calls for a detailed study of the factors that prevent and encourage Industry 4.0 in the small and medium enterprises sector (SMEs).

This study aims to:

Investigate how Industry 4.0 technologies impact smart manufacturing and logistics in SMEs.

Evaluate the sustainability benefits SMEs can achieve through technology adoption.

Identify the barriers and enablers of Industry 4.0 adoption in SMEs.

The issues surrounding SMEs adopting Industry 4.0 technologies must be solved to promote economic growth. This study contributes to formulating practical policies to improve these SMEs’ competitiveness and sustainability by advancing the comprehension of the obstacles and the sources of acceptance. The results will help policymakers, industry actors, and SMEs utilize the potential of Industry 4.0 technologies for innovations and sustainability in global supply chains. For policymakers, this research will serve to identify critical areas for policy interventions and guide the design of policies to address the needs of SMEs. For industry actors and SMEs, this study provides valuable insight into adopting advanced technologies and highlights strategies for easing their adoption.

2. Literature Review

Manufacturing and logistics industries are emerging as key beneficiaries of Industry 4.0, underlined by such cutting-edge technologies as artificial intelligence, the Internet of Things, and blockchain [

24]. These technologies contribute to the improvement of SMEs and facilitate sustainable development [

25]. However, the implementation of IT for SMEs continues to be a slow process since they lack resources and expertise compared to large firms [

26]. Specifically, by adopting Industry 4.0, European SMEs have achieved enhanced performance and sustainable business benefits like reducing costs and energy [

27]. As is typical with most innovative approaches, using digital transformation strategies is not without any hindrances, such as lack of capital and adequate technical expertise [

28].

These applications, such as AI with predictive maintenance applications, demonstrated an improved range of 20–30% on the downtime for manufacturing firms [

29]. AI also improves supply chain management and operational efficiency [

30]. However, adoption is not universal because of the high implementation costs and the scarcity of skillful employees. To manage these challenges, it is necessary to bring affordable AI solutions and workforce training [

31].

IoT embraces smart, connected, associated sensible-grade operations that help the supply chain’s resource identification, connection, and performance optimization [

32]. For instance, Indian SMEs have reported an 80% improvement in delivery accuracy using IoT. It also extends its applicability to inventory control, production tracking, and energy preservation. Nonetheless, the IoT implementation faces security concerns regarding data provision, high costs, and technical difficulties. The solutions are government subsidization, standardized IoT reference architectures, and architectures for IoT adoption strategies [

33].

Blockchain technology also helps to drive ethical sourcing and meet regulatory requirements of transparency, security, and accounts [

34]. Florida SME food and beverage companies employ blockchain to ensure traceability and enhance client relations. Blockchain creates partnerships by creating secure data transactions, although its protractstructure and costs are still challenges. Eliminating the complexity surrounding blockchain can help enhance its diffusion, and fostering collaboration with others should be implemented to improve the diffusion for blockchain among SMEs.

Industry 4.0 technologies contribute to sustainability through the triple bottom line (TBL) framework: it must also consider the ecological (environmental), social, and economic repercussions. AI and IoT decrease carbon footprints, energy consumption, and wastage, while blockchain increases social sustainability by assuring reasonable procurement standards and following them strictly in the supply chain. Economic sustainability includes finding source cost savings due to predictive analysis models and potential supply chain optimization. The synergistic impacts are observed when several technologies are enacted in SMEs simultaneously.

Obstacles like funding issues, lack of technical skills, and culture change have remained core issues in adopting Industry 4.0 programs. Organizational lock-in, particularly in more defined industries, aggravates these problems. Some of the challenges faced by the SME may include the following: lack of capital, lack of technical know-how, and high training costs; this can be solved by the support provided by the government through grants, taxes, and subsidized training. Country strategies such as Industry 4.0 in Germany and Smart Nation in Singapore show where state assistance for SME growth in developing nations can be found.

The partnership is greatly important in spreading Industry 4.0 technologies to SMEs [

31]. Integration with technology suppliers, other big companies, and research institutions enhances the availability of otherwise unattainable resources for SMEs [

32]. There are complex cooperative innovation spaces, such as start-ups and technology districts like Silicon Valley and Bavaria, and combined years of practice. These models also aim to ensure that SMEs are not left out of the digital change processes [

33].

Industry 4.0 technologies offer a unique radical chance for SMEs to update productivity, integrate sustainable standards, and survive and develop in the current and future environment. However, they are constrained by financial limitations, lack of skills and competency among key human capital, and resistance from organizational bureaucracies. The following issues arise: policymakers, industry leaders, and academic institutions have a role in creating the necessary enabling environment to address these challenges. When deployed properly, AI, IoT, and blockchain contribute closely to the innovation of small businesses, control of production results, and meeting sustainability goals for continued market relevance. The conceptual framework of the study is presented below in

Figure 1.

Hypotheses in the Study

The adoption of Industry 4.0 technologies (AI, IoT, blockchain) positively impacts operational efficiency in SMEs.

Financial, technical, and organizational constraints significantly hinder SMEs’ adoption of Industry 4.0 technologies.

Government policies, financial incentives, and partnerships positively impact the relationship between adoption and sustainability outcomes.

3. Materials and Methods

3.1. Theoretical Relevance

This study is based on an integrated theoretical framework that draws from key theories in technology adoption, business resilience, and sustainability. The Technology Acceptance Model (TAM) suggests that the perceived ease of use and usefulness of new technologies drive their adoption, which, in the case of SMEs, explains how technologies like IoT and AI can be adopted to ensure business continuity and efficiency [

26]. The Resource-Based View (RBV) posits that firms use their internal resources and capabilities to gain a competitive advantage, which is especially relevant as SMEs leverage Industry 4.0 technologies such as IoT to improve energy efficiency and sustainability [

27]. Additionally, the Diffusion of Innovations (DOI) theory, developed by Rogers, provides a framework for understanding how new technologies spread across organizations, offering insights into the barriers SMEs face when adopting Industry 4.0 and the strategies to overcome these challenges, including those related to infrastructure and resource limitations [

28]. This theoretical foundation presented in

Table 1 underpins the study’s exploration of how SMEs can overcome adoption challenges to improve resilience and sustainability by integrating advanced technologies.

3.2. Research Design

This study is meticulously designed, incorporating a cross-sectional, quantitative approach that is particularly suitable for evaluating the effect of Industry 4.0 technologies, namely AI, IoT, and blockchain, on sustainability outcomes in supply chain management.

The cross-sectional paradigm, which collects data on various organizations simultaneously, allows for a comprehensive exploration of the relationships between technology adoption and sustainability variables. This design was selected for its ability to produce robust and consistent results while addressing most of the research aims. Using quantitative techniques, variables are measured objectively, ensuring high confidence in the study’s findings. This design is ideal for studying the adoption of the level of Industry 4.0 technologies and their respective impact on tangible sustainability measures such as the carbon footprint and the level of effectiveness in terms of waste.

3.3. Population and Sampling

This study is a significant exploration of small- to medium-sized enterprises (SMEs) across different industries, focusing on those presently using or anticipating 4.0 technologies such as AI, IoT, or blockchain, including manufacturing, retail, logistics, and transportation. These SMEs were selected based on their crucial role within the global value chains and their capacity to harness modern technologies even in resource-constrained environments. Three hundred firms were chosen through purposive sampling, ensuring a comprehensive representation across industries, firm sizes, and levels of technological adoption. They included and excluded criteria used in this research, including firms with defined and measurable sustainability parameters and engaged in some aspects of 4th Industrial Technology. In contrast, the exclusion criteria included firms with less information and multinational corporations with different endowments of resources. This sampling approach enabled the study to gather applicable information regarding the growing trends of technology and its impacts on sustainability from the real experiences of the SMEs with clear evidence of the existing challenges and opportunities in pursuit of sustainability using proprietary technologies offered by the SMEs.

3.4. Data Sources

The data for this study were obtained from a diverse range of primary and secondary sources. Online surveys were conducted with selected SMEs to collect the primary data, particularly involving decision-makers and sustainability officers. Their roles in the organizations ensure that the data collected are reliable and valid, as they comprehensively understand their firm’s technological adoption and sustainability practices. The company reports traded publications and other metrics and databases on sustainability that were available in the public domain, which provided the basis for the secondary data. By combining these sources, the study achieved holistic coverage of the relevant data, ensuring a comprehensive understanding of the topic and minimizing the risk of missing information.

3.5. Data Collection Tools and Methods

Data were primarily gathered through structured and closed-ended questions that focused on the level of the adoption of AI, IoT, and blockchain on a one to five scale. The sustainability performance indicators assessed in the survey included carbon emissions, effective waste mitigation, and circular economy approaches. Such questions were classified and standardized into adoption measures, sustainability results, and organizational characteristics for easy comparison. The respondents’ survey answers were cross-checked against company reports and other relevant and applicable public information sources. This dual strategy, which consists of responses from SMEs and independent data from the internet, added to the reliability and completeness of the dataset while reducing the chances of hyperdata or underreporting.

This study’s survey instrument was structured into three sections to comprehensively capture data on adopting Industry 4.0 technologies, organizational characteristics, and sustainability outcomes. Standardized responses were ensured, and a 5-point Likert scale (1 = Strongly Disagree, 5 = Strongly Agree) was used for a quantitative analysis. The first section was focused on technology adoption items: “Our organization is actively using AI for predictive maintenance”, and “Blockchain is used to increase transparency of supply chain operations”. These questions were designed to measure the degree to which the firms incorporated advanced technologies into processing activities. Details are mentioned in

Appendix A.

In the second section, sustainability outcomes were assessed through ideas expressing ‘Our organization has reduced its carbon emissions by at least 10% over the past years’ or ‘The way we control our waste management processes is consistent with circular economy practice’. These items captured tangible sustainability improvement induced by technology adoption. The third section addressed organizational factors, asking inquiries like “Our organization has sufficient skilled staffers to install Industry 4.0 technologies” or “Our organization has sufficient cash for the expenses of transforming itself to Industry 4.0”. This section tried to identify internal enablers and inhibitors to technology adoption. The structured approach meant a holistic evaluation of the variables in question.

Qualitative validations were conducted through semi-structured interviews and focus groups to complement the quantitative findings. Interviews with sustainability officers, technology managers, and decision-makers explored barriers, strategies, and perceptions regarding adopting Industry 4.0 technologies such as AI, IoT, and blockchain. Key questions included, “What challenges do you face in adopting these technologies?” and “How have they influenced your organization’s sustainability goals?” Focus groups facilitated discussions among SMEs across sectors, allowing participants to share experiences and best practices. These qualitative methods provided valuable insights, enriching the study’s contextual understanding and enhancing the validity of its quantitative findings.

3.6. Data Preprocessing

For the study, the preprocessing steps were precise and rigid so the data could be credible and processed with powerful machine learning algorithms. Another important part was handling missing data using the Expectation-Maximization (EM) algorithm and multiple imputations. The data quality improved due to the role played by the EM algorithm in its unbiased approach and preservation of statistical relationships; as such, its contribution improved the study’s credibility. The normalization of the features was also important to bring the variables into some range so that the machine learning models that are especially sensitive to the scale or size of the variables, e.g., gradient boosting and neural networks, would have consistent results.

Dimensionality reduction through RFE was a powerful technique for selecting the most useful variables for prediction.

Figure 2 below shows how RFE can improve model functioning speed while adding value by eliminating unnecessary features without hurting forecast accuracy. This emphasis on RFE’s efficiency and accuracy should instill confidence in its application in the study.

RFE is preferred for this study because it considers more factors than simple relevance to the study. RFE eliminates irrelevant or redundant features that do not significantly interact with other selected variables.

3.7. Data Analysis

The first stage of the analysis involved descriptive statistics. These summary statistics briefly summarize the variables’ average, dispersion, and distribution values. Quantile regression was used as a tool for an inferential analysis to explain how technology adoption affects sustainability performance differently at different levels of technology adoption. In addition, machine learning models such as extreme gradient boosting (XGBoost: Python 3.0) were employed to identify the most critical factors that influence the end sustainability performance and to recommend them in descending order of importance. To achieve this, a Random Forest with SHAP values was used to clarify how different variables impact sustainability performance. Finally, the study employed GANS, a powerful tool, to conduct a scenario analysis. This comprehensive approach reassures the thoroughness of the study, as it allows for estimating anticipated sustainability outcomes given different policies and other organizational parameters. These methods made it possible to place the interrelationship between Industry 4.0 technologies and the achieved sustainability outcomes in context.

Triangulation was performed to augment credibility by the integration of numerous methods of the data analysis. The comparison of LDA-derived topic distributions and sentiment analysis results revealed common themes, such as the role of resource challenges and technological sustainability. This translates to a strong commitment to resource and technological sustainability. Secondly, secondary data sources such as industry reports and publicly accessible sustainability metrics were used to substantiate findings concerning the potential advantages of Industry 4.0 technologies. This methodological triangulation supports the study’s conclusions. Yet, in further studies, the need for independent validation to make these results more generalizable and internally valid is recognized.

3.8. Reliability and Validity Test

Cronbach’s alpha values are given in

Table 2 for variables evaluating Industry 4.0 adoption and sustainability. The values above the 0.07 threshold indicate acceptable but moderate reliability. The IoT Adoption Level (0.0910) and Waste Management Efficiency (0.0846) exhibit the highest reliability, suggesting stronger internal consistency in measuring these constructs. Other variables, such as the Ethical Sourcing Score (0.0834) and Circular Economy Practices (0.0815), also show reliability conducive to practical applications. These findings highlight the importance of consistent item design for reliable data interpretation, underpinning decision-making processes, and strategic advancements in technology adoption and sustainability practices for SMEs.

4. Results

This section presents the study’s findings.

Table 3 below shows the descriptive statistics of the study variables. The table provides an overview of the current levels of the adoption of Industry 4.0 technologies, highlighting the degree to which SMEs have adopted these technologies.

Table 3 also highlights the preexisting conditions in the SME and establishes a baseline against which to compare the metrics.

The descriptive statistics in

Table 3 underscore the potential impact of advanced technologies on sustainability metrics. The use of AI, IoT, and blockchain technologies, estimated to be around 0.50, indicates that sample organizations underutilize these technologies. However, the wide standard deviations and maximum values in the near-one range suggest some usage, with a few organizations utilizing the technologies almost completely. This variability highlights that technology adoption is not uniform across the industry, likely influenced by the size of organizations and the nature of the industry.

The dependent variables reflect positive trends in sustainability. A typical reduction in the carbon footprint stood at 54.76 units and can range anywhere between 28.88 and 79.68 units, meaning that an organization can impact the environment to varying degrees. Ethical Sourcing Scores’ mean is 3.28, while Waste Management Efficiency is 54.99 percent. These results show a targeted but limited progression; other circular economies reportedly have a mean adoption of 55.43 percent. These results demonstrate the implementation of sustainability practices; however, they also highlight the urgent need for better waste management and circularity. Annual revenue and years of sustainability initiatives are also essential factors. Higher revenues (mean: USD 171.61 million) will likely be a benchmark for advanced technology adoption, and advanced technology will be provided. Organizations with long-lasting sustainability initiatives (mean: 5.65 years) might have altered maturity in environmental initiatives and overall organization. The information underscores the importance of policy assistance and organizational features as determinants of sustainable results. It reinforces the rationale for designing specific approaches to overcome adoption gaps and enhance sustainability-related performance.

The results depicted in

Table 4 underscore a significant correlation between the adoption of AI, IoT, and blockchain technology and a noteworthy baseline reduction in the carbon footprint. The highly substantial coefficient of 43.58 on the constant term (

p-value = 0.000) indicates a significant decrease in the carbon footprint across organizations, irrespective of technology adoption. The positive associations between carbon footprint reduction and the adoption of AI (coefficient = 3.93) and IoT (coefficient = 3.46), with

p values less than 0.001 (0.001 and 0.000, respectively), validate the statistical significance of these independent variables. Notably, blockchain adoption has a more pronounced influence on sustainability outcomes than traditional social media adoption, with a coefficient of (1.46) and a

p-value of 0.003. While these findings are encouraging, they are accompanied by wide confidence intervals, indicating a degree of uncertainty about the precision of these estimates. The results suggest a positive correlation between carbon footprint reduction and technology adoption, but the influence of other factors cannot be ruled out. This underscores the need for further research to validate these relationships.

According to the XGBoost model and as demonstrated in

Figure 3, technology adoption levels determine sustainability outcomes, which can be ranked in importance. The index of importance for blockchain is 0.395, meaning that it is the most important technology when improving issues such as ethical sourcing and transparency. This implies that using blockchain technologies, such as creating a digital ledger for every transaction in the supply chain, to ensure accountability and traceability in the supply chain is critical in improving the sustainability of practices. Following closely behind blockchain, IoT adoption, with a score of 0.311, plays a crucial role in improving resource allocation and real-time monitoring. These findings also underscore the significant role of IoT in waste minimization, offering hope for more efficient resource management in the practices of a circular economy. While AI adoption may have a slightly lower importance score (0.293), it remains a significant factor, particularly in predictive maintenance and operational efficiency. The relatively similar importance scores suggest that the true power of these technologies lies in their integration. When all three are utilized, the potential to maximize sustainability outcomes is immense, offering a promising future for sustainable practices. The implications of the findings underscore the importance of concentrating on blockchain and IoT, with AI as a supporting factor, to enable the organization to achieve comprehensive sustainable goals. Plans should be centered around these technologies, ensuring that their effects complement each other, thereby maximizing the results.

Figure 4 presents the various patterns of the diffusion of the adoption of AI, IoT, and blockchain technologies among the respondents. Some of the negative observations, alongside the extensive range, imply that there are distinct levels of the integration of these technologies by various organizations. High positive values refer to those organizations that have integrated these technologies, and such efficiency improvement changes in the sustainability picture where waste would be minimized should be expected. However, negative values may infer that organizations cannot invest in those areas for operational or financial reasons, highlighting the potential for economic incentives to enhance sustainability and offer hope for the future.

Conversely, figures related to cross-border primary deficits present a more nuanced narrative with positive and negative indicators. The adoption rate of technologies like blockchain shows a high variation, suggesting that they are adopted in specific niches driven by ethical sourcing and transparency needs. In contrast, the rise and fall of IoT and AI technologies reflect the dynamic nature of their adoption as the operational efficiencies they promise begin to influence their diffusion.

These findings indicate that technology diffusion among the surveyed organizations is uneven, with each organization facing unique challenges. While some organizations successfully leverage advanced technologies, others may struggle to keep up. In such cases, targeted support in the form of financial incentives or policy measures could be instrumental in helping these organizations enhance their sustainability performance.

The data in

Figure 5 provides insights into the relationships between sustainability outcomes and various factors across four dimensions: the Ethical Sourcing Score, Carbon Footprint Reduction, Waste Management Efficiency, and Circular Economy Practices. These metrics allow for understanding how organizations perform relative to multiple sustainability initiatives.

The fact that values across all selected variables vary greatly implies that the outcomes are not uniform across organizations and that it is likely that there are different levels of technological adoption, organizational size, or government support. For instance, an example of such improvement would be a higher value for Carbon Footprint Reduction and Circular Economy Practices (e.g., 0.548 and 0.765, respectively), demonstrating innovative progress of the organizations in decreasing the unfavorable impact on the environment and applying the circular principles. Negative values (−0.519 in Carbon Footprint Reduction) indicate a pressing need for targeted intervention in underperforming organizations, emphasizing the urgency and necessity of action.

The Ethical Sourcing Score has positive and negative values, reflecting an unequal application of transparent and responsible sourcing practices. A negative value indicates a need for improvement in the organization’s ethical sourcing practices. Similarly, like Waste Management Efficiency, the range in this metric indicates that some organizations are more skilled at strategically maximizing resource use, while negative values demonstrate that other organizations struggle.

The findings underscore the need to develop strategies specifically to fill those performance gaps. Organizations with better sustainability outcomes can be seen as benchmarks, providing a clear path for improvement. At the same time, underperformers may need assistance in technology adoption, resource optimization, and policy incentives to achieve improved performance across all dimensions. This guidance can provide a sense of support and direction for underperforming organizations.

Figure 6 is the network analysis of the variables or key determinants responsible for the performance in achieving sustainable results; it is the visual presentation of these relationships of dependencies with each other. For example, sustainability metrics, carbon footprint reduction, Circular Economy Practices, and waste management are connected to AI_Adoption_Level, IoT_Adoption_Level, or Blockchain_Adoption_Level nodes that are crucial when establishing these connections. Annual_Revenue and Sustainability_Initiative_Years are important because they play a role in technological integration and sustainability performance. Firms with higher revenue and those involved in more extensive engagement in sustainability initiatives tend to integrate technology more effectively, resulting in superior sustainability performance. The Ethical Sourcing Score result’s high density of relationships suggests that firms depend heavily on a blockchain that improves transparency and accountability. The figure depicts that when you optimize one dimension, like IoT_Adoption_Level, it automatically gives better performance in the other areas, like waste management or circular practices. This ripple effect underscores the significance of addressing sustainability performance within an integrated framework. It also highlights the potential of technology to enhance sustainability, offering a promising path for future progress. These key nodes should be strengthened through future interventions to maximize impact.

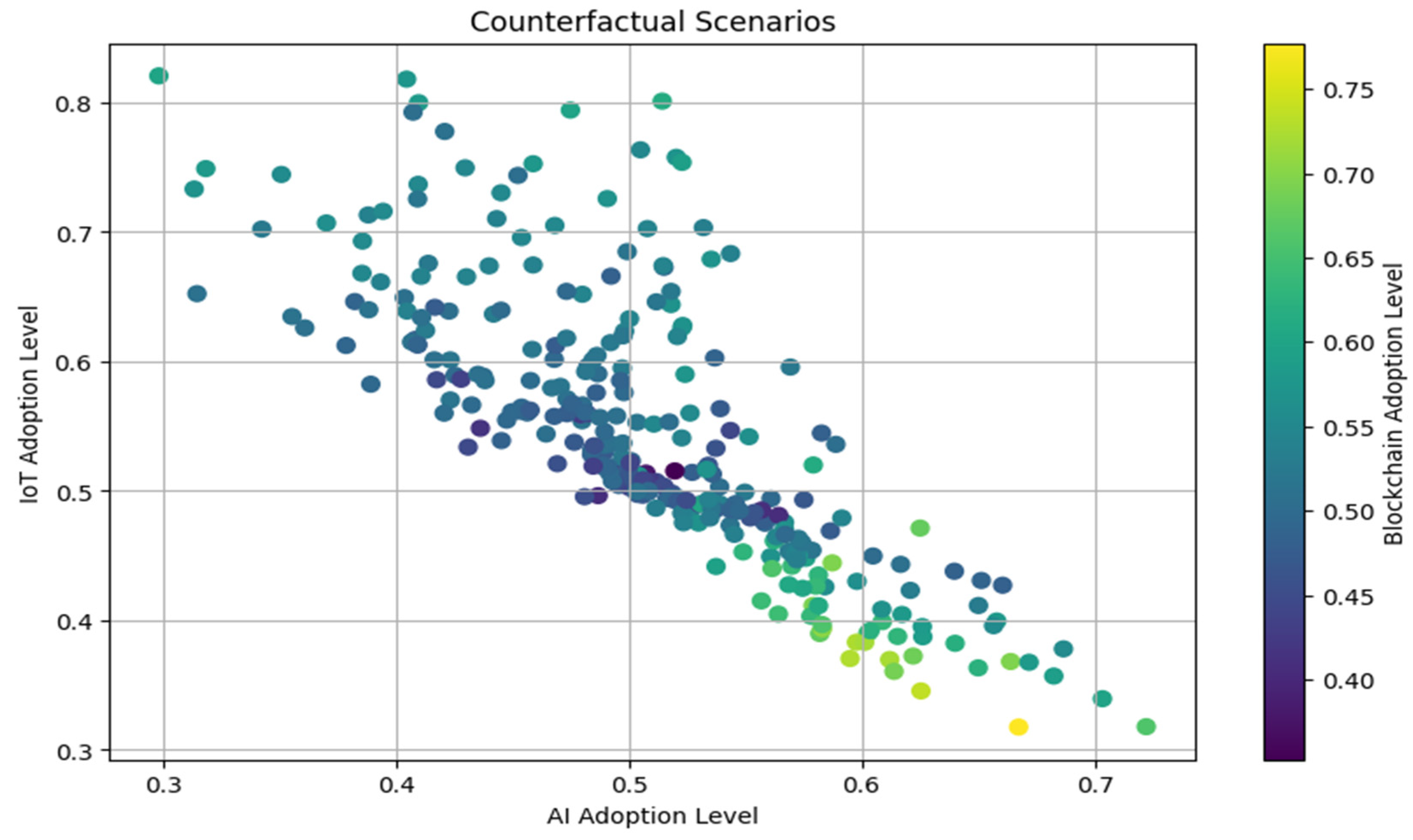

The scatter plot in

Figure 7 is a crucial visual representation of the relationship between the levels of the adoption of AI, IoT, and blockchain technology. The scatter plot from the counterfactual analysis also tends to deepen understanding. The inverse relationship between AI and IoT, espoused by the two sets of focal points, indicates that many firms choose to invest in AI or IoT due to budgetary or capacity possibility, but not both. This highlights that there must be a more comprehensive and integrated approach to adopting technologies. The color gradient in the scatter plot, showing the degree of the adoption of blockchain, is one of the critical variables in the analysis. It indicates that there are clusters of organizations that are generally advanced in the adoption of AI as well as IoT and that are also advanced in the adoption of blockchain technology (yellow shades). This means that these managers perceive the adoption of blockchain as just part of the adoption of other advanced technologies. In contrast, a lower adoption of blockchain technology (dark purple) is seen in a wider range of AI and IoT adopters, demonstrating that adopting blockchain technology is more selective and not automatically considered standard in technology deployment approaches.

It is interesting to note that the adoption of blockchain technologies is higher amongst those with high degrees of AI adoption and low degrees of IoT adoption, which indicates that the adoption of blockchain is part and parcel of the adoption of AI technologies. Additionally, greater dispersion in the figure’s upper portions corresponds to higher levels of IoT adoption, as compared to the right side of the figure, corresponding with high levels of AI adoption. This indicates that AI adoption is higher than IoT integration, with most companies in the sample demonstrating high levels of AI adoption and moderate to low levels of IoT integration.

Additionally, the greatest density and cluster of points is in the middle of the figure, indicating that these companies employ moderate levels of AI and IoT. Some of the darkest points are in this area, which suggests that these companies also employ blockchains the least.

This presents an image wherein the adoption of these three technologies can be competing. While blockchain adoption is higher as the level of AI adoption increases, the simultaneous adoption of IoT and AI technologies seems to “crowd out” blockchain adoption, most likely due to cost issues. There is likely to be some overlap in the technological infrastructure needed to engage with AI at an advanced level and blockchain technologies. At the same time, IoT integration may require a distinct infrastructure set from both.

This investigation underscores the potential for future policies and strategies to encourage the integration of technological progress. Integrating AI, IoT, and blockchain in collaboration at the organizational level will likely significantly boost sustainability objectives and operational efficiency. This promising observation should foster hope, as it suggests that the future of technology adoption is bright and full of potential for maximal effects.

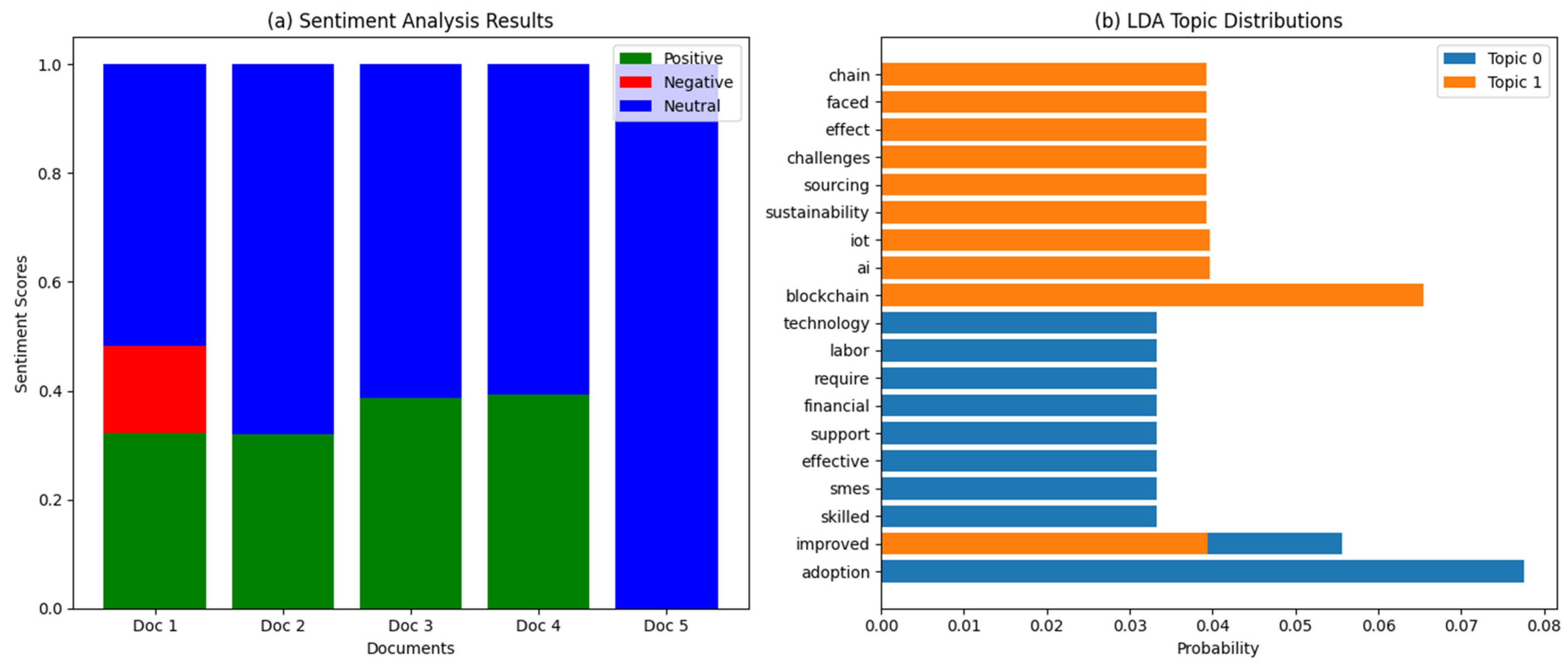

Figure 8 presents two analyses: Sentiment Analysis Results,

Figure 8a,b LDA Topic Distributions.

Figure 8a shows the sentiment analysis of five textual documents, where most sentiment is neutral, with small positive contributions, and almost no negative sentiment. This implies that the qualitative content of these documents is mostly descriptive or analytical and has no subjective polarizing emotional language. A positive sentiment demonstrates some optimism about certain things; a negative sentiment focuses on problems or things to be concerned about, like a barrier to adopting technology. Two Latent Dirichlet Allocation (LDA) generated topics with topic distributions are shown in

Figure 8b. Terms including “support”, “effective”, and “skilled” are emphasized in topic 0, which suggests operational efficiency and resource constraints. In topic 1, the focus is on terms such as “blockchain”, “sustainability”, and “AI”, which indicate technological emphasis and moral implications during supply chain improvements. Together, the combined findings point to the dominance of neutral narratives focused on technological sustainability and resource challenges, along with a call for targeted interventions to reduce adoption barriers and improve resource optimization to achieve the optimum implementation outcome of Industry 4.0.

As

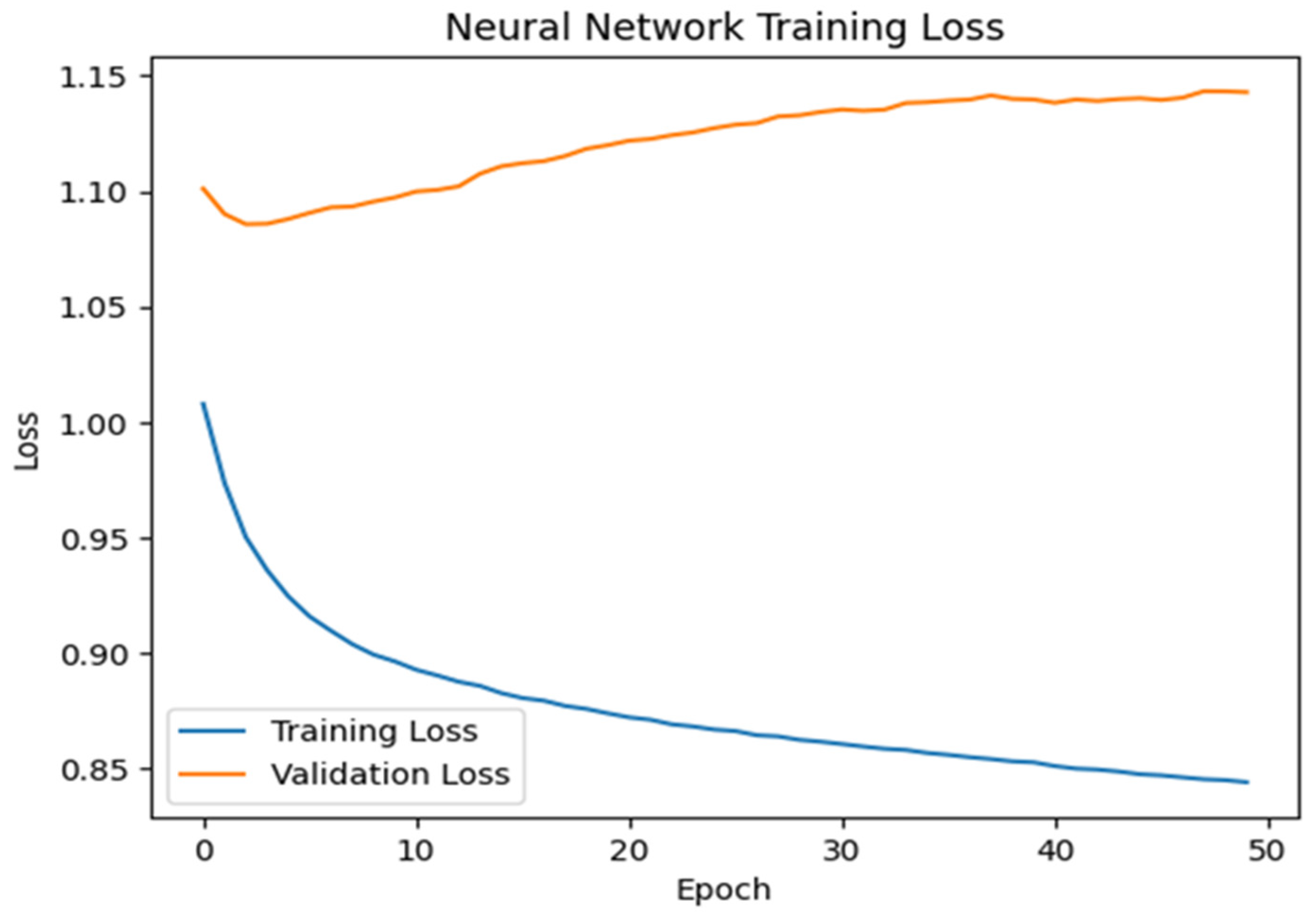

Table 5 shows, the performance of the Random Forest model is far from satisfactory for training or test datasets. On the training set, the model produces an extremely low MSE (0.013) and a very high R

2 Score (0.964), showing a good fit to the training data, and these good results follow from the fact that the model is very simple and handles both column and row features equally well. However, on the test set, its performance suffers severely, with a greater MSE (0.105) and lower R

2 Score (0.707), which indicates overfitting. This means that training data have noise and patterns, and the model knows how to capture those things but then fails to generalize them well to unseen data. This shows that regularization, cross-validation, and careful hyperparameter tuning are necessary to make the final model more reliable.

Figure 9 shows how Industry 4.0 technologies can facilitate SME sustainability and how a Recursive Feature Elimination with Cross Validation (RFECV) analysis can help identify the most significant variables. It coincides with the study’s reliance on advanced techniques such as Recursive Feature Elimination (RFE) to ensure that models ignore unimportant predictors and concentrate on significant predictors like IoT, the adoption levels of AI, and blockchain.

The figure illustrates the validity of this study’s objective of obtaining robust and interpretable machine learning models given an optimal subset of features. This approach maximizes the model’s predictive power and minimizes the risk of overfitting or underfitting. This directly correlates with practical implications for SMEs regarding actionable insights regarding which technologies or adoption factors have the greatest impact on sustainability outcomes, such as waste reduction, carbon footprint minimization, and ethical sourcing improvement. The orange line similarly has a high degree of inconsistency, with a sharp dip at three features but a recovery at four and five features, suggesting sensitivity to feature combinations or potential overfitting. However, the pink line shows an upward trend, which means the accuracy increases with the number of features selected for the experiments. Similarly, the yellow line has a large drop at two features but eventually improves as more features are added, showing its dependence on more features to perform optimally. On the other hand, the blue line stands out for its stability, as it exhibits minimal fluctuations in accuracy as the number of selected features increases, hinting at its robustness. In contrast, the number of features chosen influences other lines.

The analysis focuses on the few highly relevant ones that guarantee resource efficiency and interpretability—relevant to SMEs with limited technical and resource capabilities who cannot cope successfully with Industry 4.0 challenges. This analysis corroborates the study’s focus on utilizing advanced computational techniques to generate valuable and actionable recommendations for SME policymaking and implementation.

5. Discussion

The research findings on adopting Industry 4.0 technologies like AI, IoT, and blockchain within SMEs and the impacts on sustainability standards are very useful. Considering previous studies and the literature available about technology adoption and SMEs, these findings are important in the context of technological adoption in SMEs. The research first highlights the power of Industry 4.0 technologies in advancing sustainability metrics, as shown by several previous studies, such as Haddud et al. [

6] and Zhong et al. [

14], proving that IoT and AI can significantly boost operational efficiency in manufacturing and logistics, e.g., maintenance and resource allocation. This research confirms these findings and shows that AI and IoT are negatively associated with carbon emissions and significantly affect waste management. Earlier studies have shown that the promising impact of IoT on the environmental footprint has been proven, as it can help to monitor and optimize resource utilization.

According to the survey, blockchain technology can contribute to transparency and responsibility in supply chains. These findings are consistent with those of Zheng et al. [

21], who highlighted the use of blockchain to guarantee security during negotiations and ethical behavior in business. This research stresses that any SME seeking innovative and sustainable strategies for ethical sourcing and low carbon emissions must adopt blockchain technologies. The assertion of these benefits of blockchain is further solidified in this analysis of the importance index. More specifically, it posits that the higher the blockchain system’s integration level, the higher the company’s overall sustainability efficiency [

22].

At the same time, the need is highlighted to highlight that despite such positive outcomes, Industry 4.0 technology diffusion for a diverse SME cross-section is still uneven. Further findings indicate major technological use disparities, demonstrating financial, technical, and organizational constraints. Both Liao et al. [

4] and Kamble et al. [

5] also observed that limited resources, an incompetent workforce, and limited infrastructure are some of the main contributors to SMEs’ slow adoption of such advanced technologies. Furthermore, the study underscores the fact that the position of SMEs needs to be strengthened, and the challenges they face must be defeated with the help of specific assistance such as financial support and state laws. This confirms earlier suggestions made by Mittal et al. [

8], who pointed out the need for specific approaches to improve technology usage in SMEs.

Moreover, the study contributes to understanding the interactions of different technologies, even in economies at various development stages. The results demonstrate that the simultaneous use of AI, IoT, and blockchain technology generates a multiplier effect on sustainability. This comprehensive perspective supports Müller et al. [

13]. The so-called benefits of Industry 4.0 technologies should not be taken as the benefits of using individual technologies; instead, using several technologies provides benefits. The network analysis performed for this study also graphically depicts these synergies that would be apparent in practice; that is, advances made in one technology can benefit others, thereby enhancing the sustainability outcomes in other metrics.

However, the research also underscores the urgent need for further study. The study findings reveal a level of uncertainty in the precision of some measures due to the large sizes of confidence intervals. This echoes earlier studies that emphasized the necessity for more empirical research to validate the long-term effects of these technologies on SMEs’ performance. The literature gap in this study regarding the determinant role of government policies in technology adoption further underscores the need for future studies to explore the relationship between the regulatory environment and the technology adoption process.

The research outcomes underscore the importance of Industry 4.0 technologies to small and medium enterprises (SMEs) and their sustainability agenda. This is particularly significant given the differing nature of these technologies, which refers to their diverse applications and potential impacts. As prior research suggests, this study verifies that implementing AI, IoT, and blockchain in every organization’s operation increases its chances of being more environmentally sustainable through fewer carbon emissions and better waste disposal. Haddud et al. [

6], and Zhong et al. [

14] showed that IoT and AI can transform manufacturing processes through predictive maintenance and optimize resource use, which the current analysis corroborates. The results also show a positive relationship between the two variables. Therefore, these technological advancements increase the efficiency of the business’s day-to-day operations.

The alignment of these findings with those advanced by Zheng et al. [

21] indicates the significance of the blockchain in facilitating ethical sourcing and transparency in the supply chain by reducing instances of fraud using secure transactions. This study substantiates those claims by demonstrating that higher blockchain adoption levels correlate with improved sustainability measures, thus making it possible for SMEs to vouch for ethical standards when conducting business operations. Given these advantages, the barriers to the growth of SMEs mentioned in the research are quite low. In this regard, SMEs faced ‘limited resources’ as pointed out by Liao et al. [

4] and Kamble et al. [

5], who were unable to gain sufficient technical knowledge. Focusing on this central issue, the current study broadens the understanding of the topic by discussing these factors in more detail and providing more support for the results indicating the existence of a gap in technology adoption, as other studies have done, in the form of policies and financial incentives.

Furthermore, the evidence of synergies involving AI, IoT, and blockchain implies that such harmonized use of technology can enhance the sustainability advantages propounded by Müller et al. [

13], who state that the core advantages of Industry 4.0 strategies would be associated with using these technologies in an integrated manner. Hence, this research enriches the current literature by offering examples of compounded benefits related to technology adoption in more than one context.

5.1. Limitations and Future Directions

The findings of the study indicated that the implementation of Industry 4.0 technologies, a term that refers to the current trend of automation and data exchange in manufacturing technologies, such as AI, IoT, and blockchain, in small- and medium-sized enterprises (SMEs), is a complicated dynamic. For instance, AI integration leads to a rise in blockchain adoption, but the integration of IoT and AI results in a drop in blockchain adoption due to the complex and expensive coordination and integration of multiple technological infrastructures. However, this finding is inconsistent with other studies that have argued that there is a more ‘synergistic’ relationship between these technologies in propelling innovation and sustainability in SMEs. For example, Luthra and Mangla [

24] assert that the confluence of AI, IoT, and blockchain may complement each other to boost overall supply chain efficiencies and sustainability without engendering significant infrastructure conflicts. This reinforces the belief that these technologies can strengthen each other and facilitate smarter, more transparent, top-performing operations when combined correctly. Stock and Seliger [

25] also argue that SMEs can use Industry 4.0 technologies to minimize environmental impact and improve operations without significant loss of Augmentation through IA, IoT, or blockchain adoption.

On the other hand, the study indicates that high costs and resource constraints in SMEs can act as barriers to adopting IoT and AI, leading to further barriers in blockchain, as the survey discovered. These findings challenge more optimistic views of prior research, which suggested these technologies could be seamlessly integrated. The implications are that the challenges of simultaneously adopting AI, IoT, and blockchain may be steeper for SMEs, which often endure financial and operational constraints that larger organizations can more readily solve. However, the study also extends the growing body of literature on adopting Industry 4.0 advanced technologies in SMEs by focusing on the complexity of adoption and the conflicts between these advanced technologies as they are introduced simultaneously. This finding thus suggests that the general adoption of the different types of AI, IoT, and blockchain in SMEs needs to be viewed within a broader spectrum of advantages and disadvantages and should not simply be regarded as a necessity for future development. Adopting a wider perspective is crucial to fully understanding these technologies’ implications.

In conclusion, Industry 4.0 technologies significantly impact the sustainability of organizations in the African context while also contributing to the growing literature on the challenges faced by SMEs. The research advocates for integrated approaches that involve funding, policies, and the overall adoption of technologies. The results align with previous studies and provide new perspectives that can inform policy or strategy formulation. This underscores the importance of comprehensive strategies and joint activities to accelerate the transformation of SMEs to Industry 4.0.

5.2. Theoretical and Practical Implications

Using the theoretical framework, this study aims to contribute to understanding how Industry 4.0 technologies can be integrated into small- and medium-sized enterprises (SMEs) to promote sustainability. It contributes to existing knowledge in the SME adoption of emerging technologies, such as AI, IoT, and blockchain. The findings advance technology adoption and innovation theories in addressing SMEs’ barriers to technology adoption, specifically fiscal limitations and technological inadequacy. The study focuses on the intersection of sustainability and digital transformation. It offers new insights into how these advanced technologies can help SMEs boost operational efficiency, save money, and significantly contribute towards sustainable development goals. Further contributing to the field of sustainable business practices across manufacturing and logistics, which are important contributors to SMEs, this research also deepens the understanding of the impact that technological advancements can have in these contexts.

From a practical perspective, the study highlights the importance of targeted initiatives to assist SMEs in adopting advanced technologies. It provides a roadmap for how SMEs can capitalize on the benefits of key Industry 4.0 technologies to enhance their manufacturing processes and logistics. The study also underscores the potential benefits of AI, IoT, and blockchain implementation, such as improved operational efficiency, cost savings, and sustainability, through better resource and material management, waste reduction, and energy optimization. Additionally, the research identifies common challenges SMEs face, including high initial investment and the need for skilled labor, and offers potential solutions based on strategic acquisitions, partnerships, and capacity building. Policymakers and business leaders can use these findings to develop targeted initiatives that assist SMEs in adopting these technologies, thereby securing more sustainable supply chains and gaining a competitive edge. The study also emphasizes enabling digital transformation in SMEs through initiatives like financial incentives, training programs, and infrastructure development to fully harness Industry 4.0 for sustainability.