Abstract

In this study, locally produced recycled fine aggregate from concrete demolition waste was investigated for potential replacement of sand in new concrete mixes. Tests for the waste material included visual examination, chemical composition, grain size distribution, specific gravity, and fineness modulus. Tests on the incorporated recycled fine aggregate in new concrete mixes involved tests of the hardened plain concrete product. In total, eight concrete mixes were considered, of which four had low cement content with 30 MPa target strength, and the other four had high cement content with 55 MPa target strength. For each cement content, the four concrete mixes incorporated fine aggregate replacement ratios of 0% (control), 25%, 50%, and 100%. The hardened concrete tests involved cubes, cylinders, and prisms. The tests addressed compressive strength, tensile strength, and modulus of rupture in accordance with the relevant ASTM standards. In all cases, the average of two tested samples at the age of 28 days was considered. Results of the study showed that the recycled fine aggregate has some cementitious properties, which is capable of hardening when mixed with water and left to dry, even without adding cement from exterior sources. All tested concrete specimens made with recycled fine aggregate exhibited compressive and tensile strengths at least equal to 75% that of the control specimens that contained natural fine aggregate. However, for concrete mixes utilizing low cement content that can yield a compressive strength around 30 MPa with natural aggregate, replacement of 25% or 100% of the natural fine aggregate by weight with locally produced recycled fine aggregate from crushed old concrete can match and often exceeds the compressive and tensile strength of concrete made with virgin aggregate.

1. Introduction

In a world of depleting resources, increasing population, and rapid urbanization, the challenge to meet the world demands for goods and services continues to grow. This requires expansion of existing infrastructure and growth in new housing development, which requires increased demand for construction. Concrete is the most produced material in the world, in which it amounts to around 25 billion tons yearly and with components mainly consisting of aggregate [1]. One of the components of concrete is sand, which is referred to as fine aggregate, and it makes up around 25–40% of the concrete by mass. Due to the high amounts of sand mining that occurs, officials are concerned about the possible negative impacts of such activities on the environment. The United Nations estimates around 40–50 billion tons of sand is extracted annually [2,3], of which 20% is used solely for the production of concrete [4].

Mining of sand from streams greatly impacts the environment by causing erosion, shrinking deltas, modifying land-use, raising air pollution levels, contaminating groundwater reserves, and increasing the risk of climate-related disasters. The UN Environment Programme (UNEP) has identified ten strategic recommendations to prevent future crisis in sand mining, of which two promote sustainability through efficient use of resources, scaling up regenerative solutions and embracing circularity [5]. According to Bendixen et al. [6], the construction industry is responsible for around 39% of energy-related CO2 emissions, which can be significantly reduced through recycling of aggregate and also reducing the demand for sand mining.

The worldwide crisis of sand might come as a surprise to some due to the large amounts of sand available in deserts; however, this type of sand is unsuitable for most applications including the construction industry. This is mainly due the round and soft surface of desert sand which results in poor interlocking between particles, which forces a country such as the United Arab Emirates to import river sand (RS) from as far as Australia [2].

Another world problem that requires attention is the handling and management of continuously increasing wastes, which raises concerns about the consequences of improper disposal of waste on the environment. Concrete structures are often demolished after some time to be replaced by newer ones or in some cases as a result of excessive damage due to natural disasters. The demolished wastes are normally disposed of in landfills, which is an unsustainable way of handling demolition wastes. In recent years, recycling concrete has become more popular and accepted as an alternative source for sand and gravel. The recycling of demolition wastes is meant to reduce the dependance on imported raw material which will reduce CO2 emissions resulting from material transportation and from material extraction as well [3]. While recycling concrete produces sand and gravel that is used in the construction industry, the recycled coarse aggregate and recycled sand are often limited to lower-grade construction applications such as subbases, roads, and sidewalks [2]. Although the use of recycled sand and gravel is growing year by year, it remains as an inconsistent source of material since fresh concrete is produced at a much higher rate than recycling [3]. Previous studies have shown the significant effect of the source, physical characteristics, and mechanical properties of fine aggregate on the strength and workability of concrete [7].

A similar study was conducted by Ju et al. [8], in which five different replacement ratios were considered, namely 0%, 15%, 30%, 50%, and 100%. The prepared mixes were tested at several stages (3, 7, 28, and 190 days) to study the effect of curing time. In addition, two different concrete compressive strengths were considered. It was found that as the replacement ratio increased, the compressive strength of recycled fine aggregate (RFA) concrete decreased by approximately 30% and 10% for normal strength concrete and high strength concrete, respectively. Further, it was found that irrespective of the curing time and RFA, the relation between the splitting tensile strength and the compressive strength of concrete made with recycled material was similar to that of concrete made with natural aggregate.

Nebiyu et al. [9] carried out an experimental study to investigate the feasibility of using recycled fine aggregate (RFA) in concrete mixes. In their study, the authors studied the effect of partial replacement of fine natural aggregates. It was found that the workability of mixes without admixture increases as the replacement ratio of RFA increases and vice versa for mixes with admixture. Furthermore, the compressive strength of concrete decreases as the replacement ratio of RFA increases. It was also concluded that even if there is a decrease in compressive strength as the replacement ratio of RCFA increases, it is possible to replace NS up to 20% without an admixture and up to 50% with an admixture for the production of C-25 concrete without a significant compressive strength loss from the control mix. The same findings were confirmed by another research by Revilla-Cuesta et al. [10], in which a replacement ratio of 50% resulted in an acceptable reduction of strength, and it was recommended that the replacement ratio be limited to 25% to comply with service requirements regarding deformability.

In another study by Cao et al. [4], the strength and workability of mortar made using RFA were studied. It was found that at the same water to binder ratio, the mortar using the recycled S-sand (S for sandstone) shows worse workability than that using R-sand (R for river sand) but a slight increase of water to binder ratio or the addition of a water reducer agent improves not only the workability but also the mechanical properties. The compressive strength is reduced due to ASR (alkali silica reaction); however, it was found that as the ASR progresses, the strength is restored.

Kirthika et al. [11] studied the performance of concrete prepared with partial replacement of RS with RFA, and the result shows that the developed mix design uses lesser quantities of cement and fine aggregates. It was concluded that replacement of about 30% RS by RFA was optimum. Furthermore, the increases in compressive, flexural, and splitting tensile strengths and modulus of elasticity at 56 days were 11.0%, 9.7%, 3.8%, and 4.0%, respectively. Other research with similar findings has been conducted on the use of RFA for the production of new concrete to assess the compressive strength [12,13,14], modulus of elasticity [8,15,16], creep and shrinkage [17,18,19], and durability [20,21].

A literature search on the subject revealed that most of the published research focuses more on the potential use of recycled concrete coarse aggregate [22,23,24,25,26] than fine aggregate. Moreover, the findings obtained for a specific recycled material could be dependent on the location and source of the waste. Therefore, to use a certain recycled fine aggregate in new concrete mixes for structural applications requires extensive analysis of batches of the material because of its variability and sensitivity to its origin. The objective of this study is to evaluate the properties of RFA produced locally and to investigate the possibility of replacing natural fine sand in concrete with recycled fine concrete aggregate. This is achieved by considering different loading conditions through testing and by comparing the mechanical properties of concrete made with recycled fine aggregate with those of concrete made with natural sand.

2. Problem Statement and Research Significance

Most of the available desert sand is not readily suitable for construction purposes without treatment because the grains are finer in size and smoother on the surface. The production of concrete has extensively utilized RS as an alternative to desert sand, which over the years has imposed a heavy environmental toll on the planet. Furthermore, the waste generated from the demolition of existing concrete structures, requires a lot of manpower to handle and takes up a substantial space in landfills. Concrete made from recycled aggregate supports many sustainability initiatives because it saves landfill space, manages construction waste in an eco-friendlier manner, reduces the need for aggregate mining, and decreases pollution resulting from mining natural aggregate. However, due to inadequate development in the area of testing and specifications concerning concrete produced with recycled aggregate, the use of recycled aggregate concrete (RAC) is still limited. This creates a need for further research and improvements on the subject.

3. Experimental Program

A review of research and practical efforts on recycled concrete in countries that are part of the Gulf Cooperation Council was published in 2011 [27]. Since then, a lot of work has been accomplished with regard to green concrete construction due to encouragement and support by government and municipalities. In this study, the recycled fine aggregate used in concrete was processed by the Beeah’s Waste Management facility [28] in Sharjah, UAE. To assess the mechanical properties of concrete produced using this material, 8 concrete mixes were produced, in which the parameters considered were the natural sand replacement ratio and the cement content. The replacement ratios of fine aggregates considered for this study were 0% (control mix), 25%, 50%, and 100%. For each of those replacement ratios, two cement contents were considered, a low cement content mix with a water-to-cement ratio of 0.58 that targeted 30 MPa compressive strength and a high cement content mix with a water-to-cement ratio corresponding to 0.37 that aimed at 55 MPa compressive strength. In total, two 150 mm cubes, four 150 mm diameter by 300 mm height cylinders, and two 500 mm long prisms with 100 mm square cross-section were cast and tested to determine the compressive and tensile properties of the produced concrete.

3.1. Tests and Procedures

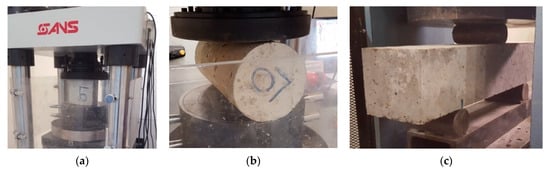

Several tests were performed to compute the compressive strength and tensile strength of the concrete. The compressive strength was determined by testing cubes and cylinders in compression, in accordance to BS EN 12390 [29] and ASTM C39 [30], respectively. Cubes were tested with 2 smooth surfaces on the top and bottom, while the cylinders were capped with a steel top containing a neoprene sheet to reduce the stress concentrations that could emerge due to the roughness of the top surface of the cylinder. During the tests, the compressive load gradually increased at a rate of 0.25 MPa/s until failure was reached. The tensile strength of the concrete was determined through the split cylinder tensile test in accordance with ASTM C496 [31] standard. The test is performed by testing a cylinder placed on its side and applying loading along the length of the cylinder. Lastly, the modulus of rupture (also known as flexural strength) of the concrete was identified through the three-point bending test performed on the prism specimens following the ASTM D790 [32] standard. All specimens were cast and tested at the American University of Sharjah structural laboratory and cured for 28 days prior to carrying out the experiments. The test setup of each test is presented in Figure 1.

Figure 1.

Test setup for (a) compressive (b) tensile and (c) flexural tests.

3.2. Material

In this study, four types of aggregate were utilized, which are natural coarse aggregate (NAC), natural crushed sand, natural dune sand, and recycled fine aggregate (RFA) from crushed old concrete, which is shown in Figure 2. The specific gravity of the recycled fine aggregates (RFA) was determined and compared to that of the natural fine aggregates (dune sand). The test used to determine the specific gravity was in accordance with ASTM D854 [33]. The average specific gravity of the RFA turned out to be 2.595, which is 0.31% greater than the average specific gravity of the dune sand, 2.587. The small difference between the specific gravities suggests that replacing the fine aggregates by weight does not greatly impact the volume of the mix.

Figure 2.

Recycled fine aggregate obtained from Beeah.

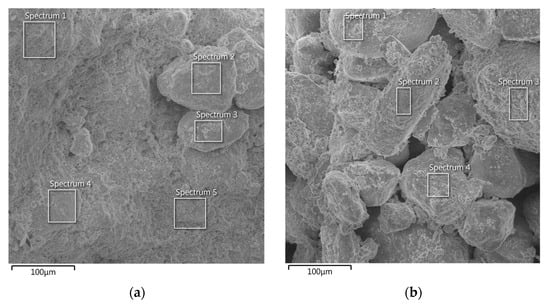

Using a scanning electron microscope (SEM), the cement content of the hardened RFA was determined through chemical composition analysis which was accomplished by energy dispersive spectroscopy (EDS). The sample was mixed with 22.5% of water and left to dry for 28 days and then observed by SEM. The SEM scanned the sample at two different positions in which multiple spectrums were considered for the EDS analysis, as shown in Figure 3.

Figure 3.

SEM images of RFA (a) position 1, (b) position 2.

It should be noted that the main chemical composition of Portland cement contains several compounds such as Tricalcium Silicate (C3S), Dicalcium Silicate (C2S), and Tetracalcium Aluminoferrite (C4AF). The results obtained from the EDS analysis on the RFA sample were summarized in Table 1, and by examining the content of the samples, it can be seen that there are large concentrations of Calcium, Oxygen, and Silicon which are the key elements for the compounds found in Portland cement. This proves that the recycled sand sample may contain some cementitious properties. However, the existence of cement in the sample does not prove that the sample has binding properties. Therefore, a simple test method was devised to determine whether or not the RFA sample has cementitious properties that can solidify after drying when mixed with water and, if the outcome is positive, to quantify the contribution of the binding material towards strength.

Table 1.

Chemical composition of RFA sample by weight percentage.

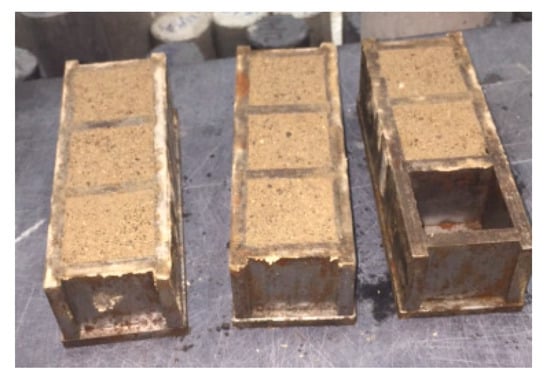

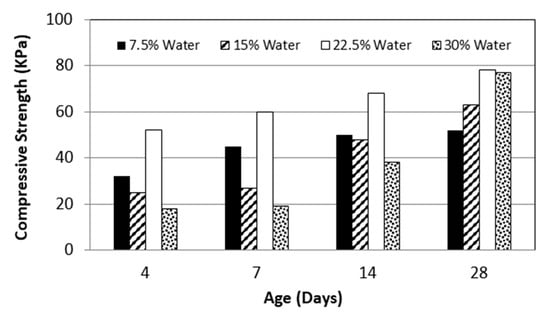

To assess the influence of cementitious properties possessed by the RFA on the compressive strength, 50 mm cubes of wet fine aggregate samples were prepared by adding different percentages of water to them: 7.5%, 15%, 22.5%, and 30% by weight. For each water content, a total of eight cubes were cast and tested at 4, 7, 14, and 28 days. Figure 4 shows the 50 mm cubes of the RFA in the form prior to demolding and testing

Figure 4.

Sample preparation of wet recycled fine aggregate.

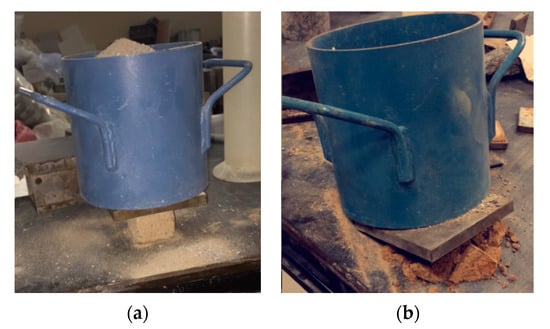

On the day of testing, the cubes are removed from the molds and are placed on a table. Due to the expected low strength of the hardened RFA, a manual testing procedure is carried out on the samples to determine the compressive strength. The test setup consisted of a thick metal plate placed on the top of the RFA cube, a bucket mounted on the plate, and sand slowly poured inside the container until collapse, as shown in Figure 5. When failure occurs, the mass of the sand, container, and plate are weighed, and the stress is computed by dividing the weight of all three components by the area of the cube’s contact surface. The maximum load supported by the 50 mm cubes prior to crushing varied depending on the age of the cubes at the time of testing and the amount of added water.

Figure 5.

Testing the binding properties of RFA: (a) before failure, (b) at collapse.

Figure 6 shows the results of compressive strength of the samples at the age of 4, 7, 14, and 28 days for the four percentages of water mixed with RFA (7.5%, 15%, 22.5%, and 30%) after drying. As expected, the results demonstrate an increase in the compressive strength with time. An interesting finding is that there is an optimum amount of water that results in the maximum strength, which for the tested sample was 22.5%. This is because on the one hand, adding little water may not be enough to activate the un-hydrated cement, and on the other hand, using a lot of water keeps the extra amount within the sand. The 22.5% of water gives the maximum compressive stress at failure compared to the other percentages of water for all tests that were conducted at different days. Although these results are not very precise, they show that the fine aggregate has some cementitious binding properties that can contribute towards the compressive strength when used in a new concrete mix.

Figure 6.

Effect of time on compressive strength of hydrated recycled sand.

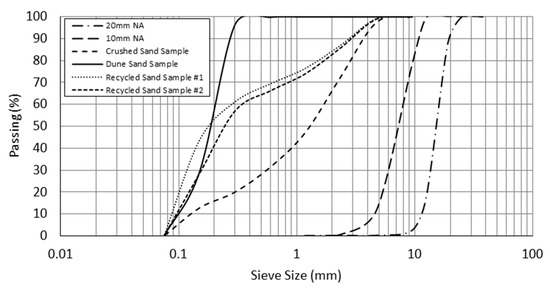

3.3. Sieve Analysis

Two samples from the RFA were taken along with samples from the natural dune sand and natural crushed sand. A sieve analysis was carried out, and the results are plotted in Figure 7. The fineness modulus was computed in accordance with the ASTM C33 [34] standard. The fineness moduli for two samples of the recycled fine sample was 1.90 and 1.63. The dune sand reported a fineness modulus of 0.74 and the crushed sand’s fineness modulus was 3.18. This means that the gradation of RFA lies in between the crushed sand and dune sand, which provides a good distribution of particle sizes.

Figure 7.

Sieve analysis results of the coarse and fine aggregates used in the study.

3.4. Mixing Proportions

The two control concrete mixes without recycled material were designed to achieve compressive strengths of 30 MPa and 55 MPa for low and high cement content, respectively. A summary of the mix proportions is presented in Table 2. Note that for the coarse aggregate, 35% of the quantity by weight consisted of 10 mm aggregate and the remaining 65% comprised 20 mm aggregate. The source of the natural fine aggregate was 35% dune sand and 65% crushed sand. In this study, the replacement of fine aggregate with RFA followed the same proportions for the dune and crushed sand. The water-cement ratios for the low and high cement content concretes were equal to 0.58 and 0.37, respectively. Since the fine aggregate from demolition waste includes particle sizes in between those of crushed and dune sand, the recycled sand fraction in the concrete mixes that utilize recycled material in this study replaces both types of sand by an equal percentage. For example, for a 50% fine aggregate replacement ratio, the recycled sand replaces 50% of the crushed sand and 50% of the dune sand in the control mix.

Table 2.

Concrete mix proportions.

4. Results and Discussion

The experimental results of the compressive and tensile tests of the hardened specimens are presented in this section. All tests were conducted after 28 days of curing. Due to the small volume of concrete within each batch, the average of two samples was considered appropriate for the study. The mass density of the concrete was in the range of 2457–2387 kg/m3 for the mix with low cement content and 2461–2407 kg/m3 for the mix with high cement content, with the lower density values associated with the concrete that utilized larger amount of recycled fine aggregate. Results of the cube compressive strength, cylinder compressive strength, cylinder split tensile strength, and prism flexural strength are presented in Table 3. Analysis and discussion of the results follows in the next sections.

Table 3.

Summary of results of all mechanical tests.

4.1. Compressive Strength

Compressive strength of concrete is one of the most important characteristics of the material. It is impacted by the proportion of mix, properties of aggregates, time and quality of curing, and the amount of water. Experience has shown that the compressive strength has a significant effect on the performance characteristics of the mixture and the overall quality of the finished product.

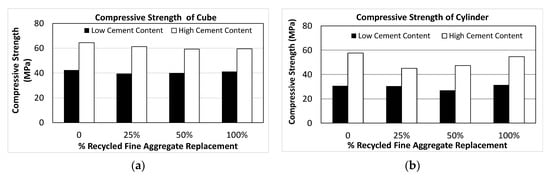

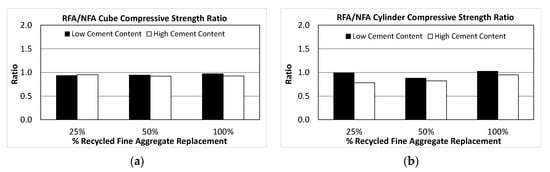

In this section, the results of the cylinder and cube compressive strength of the natural and recycled concrete are presented for the two considered concrete mixes. Figure 8 shows the compressive strength of cubes and cylinders, and Figure 9 shows the corresponding normalized results with respect to the control mix.

Figure 8.

Compressive strength of: (a) cubes, (b) cylinders.

Figure 9.

Normalized compressive strength of: (a) cubes, (b) cylinders.

The results show that replacing natural fine aggregates with locally produced recycled ones yielded concrete that is comparable with concrete produced to natural sand in terms of compressive strength. There were slightly less variations observed in the strength of the cube compared to that of the cylinder across the different replacement ratios, which is in agreement with previous studies on natural concrete [35]. For the lower strength concrete mixes, the addition of RFA did not greatly affect the compressive strength of the concrete for different percentages of fine aggregate replacement ratios, resulting in a 5% average reduction in cube strength and 3.7% average reduction in cylinder strength. The cube-to-cylinder strength ratios for the recycled concrete ranging 1.30–1.48 were comparable to that of the natural concrete (1.38).

For the higher strength concrete mixes, there were larger reductions in compressive strength with the addition of RFA, equal to 6.7% for the cubes and 15% for the cylinders. More specifically, the drops in cylinder strength for the high cement concrete mix when incorporating RFA were 22%, 18%, and 5.2% for the 25%, 50%, and 100% fine aggregate replacement ratios, respectively. The cube-to-cylinder strength ratios for the recycled concrete varied over a wide range (1.09–1.36) and were inconsistent with that of the natural concrete (1.12).

The addition of RFA has two opposing effects on the concrete compressive strength: on the one hand, the quality of the recycled product is not as high as the natural aggregate, which has a negative effect, and on the other hand, it contains some binding properties, which has a positive influence. These two conflicting aspects affect the strength of the concrete in different ways, depending on the percentages of RFA and the amount of cement in the mix.

Based on the observed results, the use of RFA in low strength concrete mixes averaging around 30 MPa cylinder compressive strength seems feasible, especially for replacement ratios of 25% and 100%.

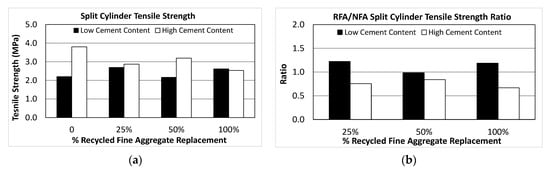

4.2. Tensile Strength by Split Cylinder

The splitting tensile cylinder test is performed on concrete to determine its tensile strength, which is important for concrete members that can be negatively impacted by significant crack formation. In this section, the results of the split cylinder strength of the natural and recycled concrete are presented in Figure 10 for each replacement ratio and cement content mix. It can be seen that replacing natural sand with RFA resulted in similar or improved tensile strength of the concrete for mixes with lower cement content. However, the effect of adding RFA to the mixes with high cement ratio caused inferior tensile strength (16–33% reduction from the natural concrete), irrespective of the percentages of replacement. The tensile strength of concrete with lower cement content made with RFA was on average 13% higher than mixes made entirely of natural aggregate, but 15% lower for mixes having higher cement content.

Figure 10.

Results of the split cylinder: (a) actual strength, (b) normalized strength.

Similar to the experimental findings of the compressive strength, the observed split cylinder test results support the merits of using RFA in low strength concrete mixes for all considered replacement ratios.

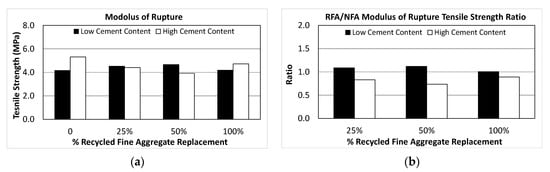

4.3. Tensile Strength by Modulus of Rupture

Modulus of rupture, also referred to as flexural strength, is another measure of the tensile strength of concrete that is particularly applicable to flexural members, such as beams or slabs. The results of the modulus of rupture from the three-point bending test of the prisms for all replacement ratios and cement contents are plotted in Figure 11. It can be noticed that for all RFA replacement ratios, the flexural strength of concrete was enhanced when the cement content is low, especially for the 25% and 50% ratios. On the other hand, for all replacement ratios incorporating a high cement content resulted in a maximum reduction of 25% of the flexural strength of concrete made with natural sand. On average, the flexural strength of concrete incorporating RFA was 7% higher and 18% lower than concrete mixes made with 100% natural sand having a lower and higher cement content, respectively.

Figure 11.

Modulus of rupture: (a) actual strength, (b) normalized strength.

Similar to the experimental outcomes of the compressive strength and split cylinder tensile tests, the modulus of rupture test results favor the use of RFA in concrete mixes utilizing smaller amounts of cement, for all considered replacement ratios.

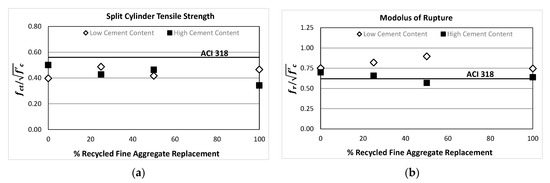

4.4. Relationship between Tensile and Compressive Strengths

In this section, the experimental results of the splitting tensile strength, fct, and modulus of rupture, fr, are discussed and compared with the concrete compressive strength and with the ACI 318 code predictive equations [36]. Experience has shown that the tensile strength of concrete is about 10 to 20% of the compressive strength, although the relationship between the two strengths is not linear. According to the ACI 318 code, fct and fr can be estimated for natural concrete as a function of the compressive strength, f′c.

in which fct, fr and f′c are all in MPa, and λ is a light-weight concrete factor that is equal to 1.0 for normal weight concrete.

Figure 12 presents the normalized tensile strength results with respect to the square-root of the compressive strength for both split cylinder and modulus of rupture tests for the considered replacement ratios. Moreover, shown in the figure are the ACI 318 code equations. Considering the large natural variation in tensile strength, examination of the experimental findings shows that ACI 318 code provides a somewhat reasonable approximation of fct and fr. While Equation (1) slightly overestimates the split cylinder strength, Equation (2) slightly underestimates the modulus of rupture. For the concrete mixes containing low cement content, the recycled concrete resulted in higher normalized tensile strength with respect to the square-root of the compressive strength when compared with the natural aggregate concrete. The opposite was observed for the high cement mixes. The reason for this finding is believed to be that the presence of cementitious material in the recycled sand overshadows the impurity of the product in concrete mixes containing a small amount of cement. On the other hand, mixes containing a large amount of cement are more affected by the negative influence of the impurity of the recycled sand than by the relatively small positive contribution of the cementitious properties. More tests on the subject are needed before firm conclusions are drawn on the relationship between the tensile and compressive strengths.

Figure 12.

Relationship between tensile and compressive strengths: (a) fct, (b) fr.

5. Summary and Conclusions

In this study, concrete mixes made with partial and full replacement of natural sand with locally produced recycled sand from old concrete demolition waste were tested, and the mechanical properties of the concrete were assessed. By testing the compressive and tensile properties of the concrete made with 0%, 25%, 50%, and 100% replacement, and considering low and high cement content, the following conclusions can be drawn:

- SEM scanning and testing of hardened recycled fine aggregate after wetting and drying revealed that the recycled aggregate contains traces of cement and has some binding properties. The strength of the product is due to the fact that the addition of water to the recycled sand activates some of the binding properties possessed by the traces of cementitious material that had not been hydrated earlier.

- Compressive strength test results on cube samples showed comparable strength of the concrete containing recycled fine aggregate to the one containing natural aggregate, irrespective of the cement content and replacement percentages. For cylinders, this conclusion is valid only for concrete mixes containing low cement content leading to compressive strength near 30 MPa and having replacement ratios of either 25% or 100%.

- Split cylinder tests demonstrated that recycled concrete mixes containing low cement content can match or exceed the tensile strength results of concrete mixes having natural sand, irrespective of the percentage of sand replacement.

- Modulus of rupture tests revealed that recycled concrete mixes containing low cement content can match the strength results of concrete mixes having natural sand, regardless of the amount of recycled sand replacement. For concrete mixes that have high cement content leading to compressive strength in the 45–55 MPa region, the addition of RFA can lead to reductions in the modulus of rupture as high as 25%.

Based on the above, it can be concluded that concrete made with partial replacement equal to 25% or 100% of natural sand with recycled fine aggregate produced by Sharjah-based plant Beeah, UAE, has comparable mechanical properties to concrete made with natural sand if the concrete has a cement content that can yield a concrete compressive strength of around 30 MPa. For concrete with a larger cement content leading to higher compressive strength, in the region of 50 MPa, the addition of RFA can reduce its strength by up to 25%.

6. Future Research

The authors recognize the importance of further research on the subject to pave the way for rational specification for recycled aggregate and concrete. To list a few potential areas, there is a need for developing concrete mix design procedures, studying recycled concrete at the micro-structure level, and investigating the durability aspect of such concrete, particularly in harsh environments.

Author Contributions

Formal analysis, S.W.T. and Y.A.; Investigation, S.W.T. and Y.A.; Methodology, S.W.T.; Supervision, S.W.T.; Writing—original draft, Y.A.; Writing—review & editing, S.W.T. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to recognize the financial support provided by Gulf Ecosystems Research Center and the Office of Sponsored Research at the American University of Sharjah, UAE. The work in this paper was supported, in part, by the Open Access Program from the American University of Sharjah. This paper represents the opinions of the authors and does not mean to represent the position or opinions of the American University of Sharjah.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

Special thanks are due to Arshi Faridi for helping with the sieve analysis and Mohamad Ansari for assisting with the testing of hardened concrete samples. The authors would also like to acknowledge Mustafa Al Safadi and Sara Qutob for their contribution in determining the chemical composition and conducting the binder content tests for the recycled fine aggregate.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Guo, M.; Hu, B.; Xing, F.; Zhou, X.; Sun, M.; Sui, L.; Zhou, Y. Characterization of the mechanical properties of eco-friendly concrete made with untreated sea sand and seawater based on statistical analysis. Constr. Build. Mater. 2020, 234, 117339. [Google Scholar] [CrossRef]

- Beiser, V. Why the World Is Running Out of Sand. BBC Future. 18 November 2019. Available online: https://www.bbc.com/future/article/20191108-why-the-world-is-running-out-of-sand (accessed on 21 May 2022).

- Laura Cole. How Ending Mining Would Change the World. BBC Future. 14 April 2022. Available online: https://www.bbc.com/future/article/20220413-how-ending-mining-would-change-the-world (accessed on 21 May 2022).

- Cao, Y.; Wang, Y.; Zhang, Z.; Wang, H. Recycled sand from sandstone waste: A new source of high-quality fine aggregate. Resour. Conserv. Recycl. 2022, 179, 106116. [Google Scholar] [CrossRef]

- Vander Velpen, A.; Smeets, A.; Torres, A.; Matheson, A.B.; Friot, D.; Franks, D.M.; Cuperus, G.; Yusuf, H.; van der Vegt, H.; Selby, I.; et al. Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis; GRID-Geneva, United Nations Environment Programme: Geneva, Switzerland, 2022. [Google Scholar]

- Bendixen, M.; Iversen, L.L.; Best, J.; Franks, D.M.; Hackney, C.R.; Latrubesse, E.M.; Tusting, L.S. Sand, gravel, and UN Sustainable Development Goals: Conflicts, synergies, and pathways forward. One Earth 2021, 4, 1095–1111. [Google Scholar] [CrossRef]

- Khouadjia, M.L.; Mezghiche, B.; Drissi, M. Experimental evaluation of workability and compressive strength of concrete with several local sand and mineral additions. Constr. Build. Mater. 2015, 98, 194–203. [Google Scholar] [CrossRef]

- Ju, M.; Park, K.; Park, W.-J. Mechanical behavior of recycled fine aggregate concrete with high slump property in normal- and high-strength. Int. J. Concr. Struct. Mater. 2019, 13, 61. [Google Scholar] [CrossRef]

- Nebiyu, W.M.; Nuramo, D.A.; Ketema, A.F. Experimental Study of Recycled Aggregate Concrete Produced from Recycled Fine Aggregate. In Lecture Notes of the Institute for Computer Sciences, Social-Informatics and Telecommunications Engineering, LNICST; Springer: Cham, Switzerland, 2022; Volume 412 LNICST, pp. 49–67. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of fine recycled concrete aggregate on the mechanical behavior of self-compacting concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K.; Chourasia, A. Performance of Recycled Fine-Aggregate Concrete Using Novel Mix-Proportioning Method. J. Mater. Civ. Eng. 2020, 32, 04020216. [Google Scholar] [CrossRef]

- Hu, J.; He, X.; Li, Q.; Bai, S. Experimental Study on the Influence of Specific Factors on the Compressive Strength of Recycled Fine Aggregate Concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 304, p. 052083. [Google Scholar] [CrossRef]

- Soni, N.; Shukla, D.K. Analytical study on mechanical properties of concrete containing crushed recycled coarse aggregate as an alternative of natural sand. Constr. Build. Mater. 2021, 266, 120595. [Google Scholar] [CrossRef]

- Leite, M.B.; Santana, V.M. Evaluation of an experimental mix proportion study and production of concrete using fine recycled aggregate. J. Build. Eng. 2019, 21, 243–253. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and durability properties of concrete based on recycled coarse and fine aggregates produced from demolished concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- da França, A.P.M.; da Costa, F.B.P. Evaluating the effect of recycled concrete aggregate and sand in pervious concrete paving blocks. Road Mater. Pavement Des. 2022. [Google Scholar] [CrossRef]

- Akono, A.T.; Chen, J.; Zhan, M.; Shah, S.P. Basic creep and fracture response of fine recycled aggregate concrete. Constr. Build. Mater. 2021, 266, 121107. [Google Scholar] [CrossRef]

- Chinzorigt, G.; Lim, M.K.; Yu, M.; Lee, H.; Enkbold, O.; Choi, D. Strength, shrinkage and creep and durability aspects of concrete including CO2 treated recycled fine aggregate. Cem. Concr. Res. 2020, 136, 106062. [Google Scholar] [CrossRef]

- Saha, S.; Rajasekaran, C. Strength and shrinkage properties of heat-cured fly ash-based geopolymer mortars containing fine recycled concrete aggregate. J. Test. Eval. 2020, 48. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, C.; Lehman, D.E.; Xiao, W.; Zheng, S.; Fan, B. Mechanical and durability behaviours of concrete made with recycled coarse and fine aggregates. Eur. J. Environ. Civ. Eng. 2017, 24, 171–189. [Google Scholar] [CrossRef]

- Bravo, M.; Duarte, A.P.C.; de Brito, J.; Evangelista, L.; Pedro, D. On the Development of a Technical Specification for the Use of Fine Recycled Aggregates from Construction and Demolition Waste in Concrete Production. Materials 2020, 13, 4228. [Google Scholar] [CrossRef]

- Kim, J. Influence of quality of recycled aggregates on the mechanical properties of recycled aggregate concretes: An overview. Constr. Build. Mater. 2022, 328, 127071. [Google Scholar] [CrossRef]

- Murali, G.; Vardhan, C.V.; Rajan, G.; Janani, G.J.; Jajan, N.S.; Sri, R.R. Experimental study on recycled aggregate concrete. Int. J. Eng. Res. Appl. 2012, 2, 407–410. [Google Scholar]

- Puthussery, J.V.; Kumar, R.; Garg, A. Evaluation of recycled concrete aggregates for their suitability in construction activities: An experimental study. Waste Manag. 2017, 60, 270–276. [Google Scholar] [CrossRef]

- Ahmed, S.; Alhoubi, Y.; Elmesalami, N.; Yehia, S.; Abed, F. Effect of recycled aggregates and treated wastewater on concrete subjected to different exposure conditions. Constr. Build. Mater. 2021, 266, 120930. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, Z. Mechanical properties of recycled concrete made with different types of coarse aggregate. Constr. Build. Mater. 2017, 134, 497–506. [Google Scholar] [CrossRef]

- Abdelfatah, A.S.; Tabsh, S.W. Review of research on and implementation of recycled concrete aggregate in the GCC. Adv. Civ. Eng. 2017, 2011, 567924. [Google Scholar] [CrossRef]

- Leading Environmental Management Company in UAE: Bee’ah. Available online: https://beeahgroup.com (accessed on 15 July 2022).

- BS EN 12390-1:2021; Testing Hardened Concrete Shape, Dimensions and Other Requirements for Specimens and Moulds. British Standard Institute: London, UK, 2021.

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C496-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C33-07; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2007.

- Graybeal, B.; Davis, M. Cylinder or cube: Strength testing of 80 to 200 MPa (11.6 to 29 ksi) ultra-high-performance fiber-reinforced concrete. ACI Mater. J. 2008, 105, 603. [Google Scholar]

- ACI CODE-318-19; Building Code Requirements for Structural Concrete and Commentary. ACI Committee 318: Farmington Hills, MI, USA, 2019.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).