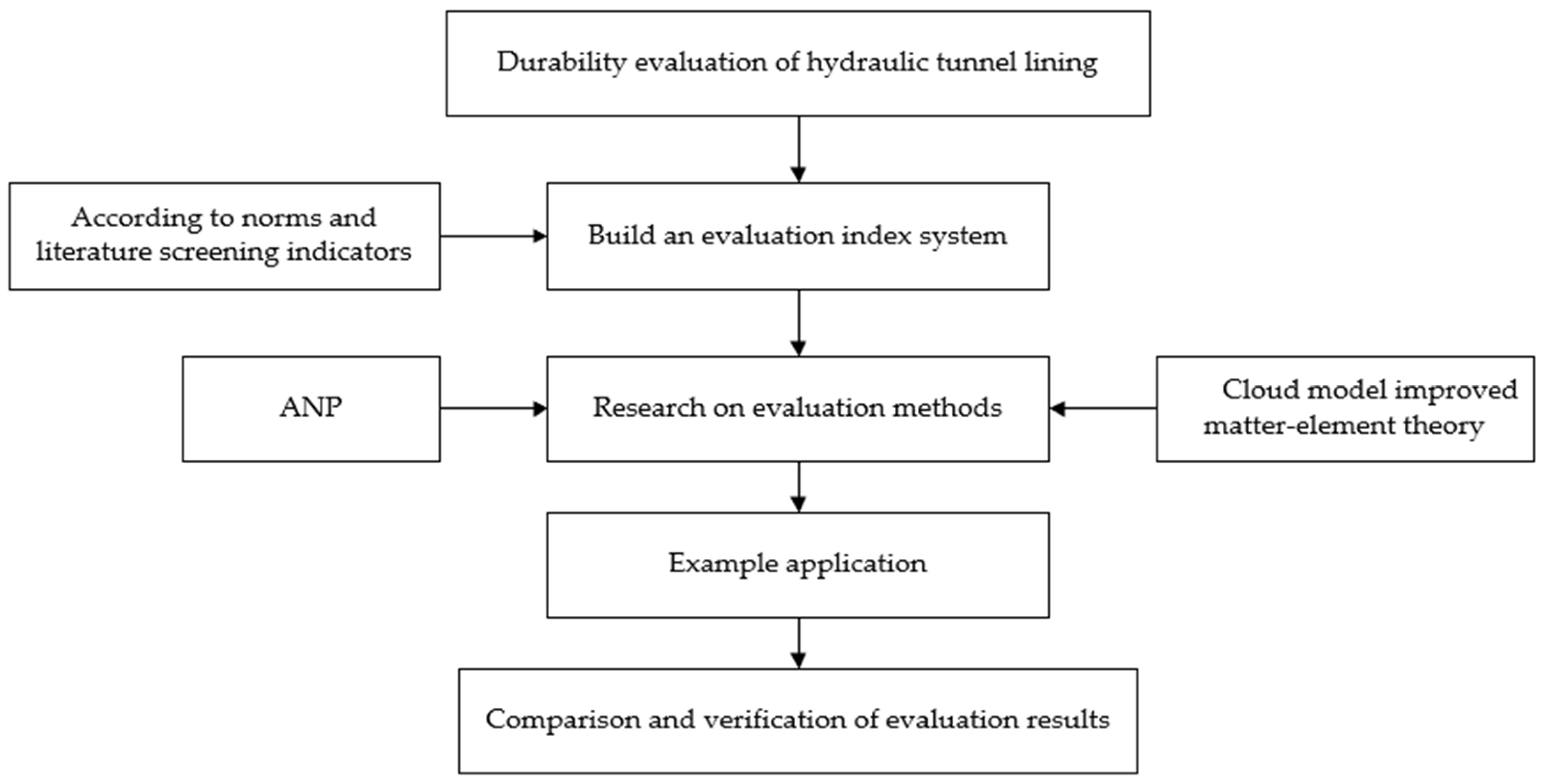

Evaluation of Hydraulic-Tunnel-Lining Durability Based on ANP and Cloud-Model-Improved Matter–Element Theory

Abstract

:1. Introduction

2. Hydraulic Tunnel Lining Durability Evaluation Index System

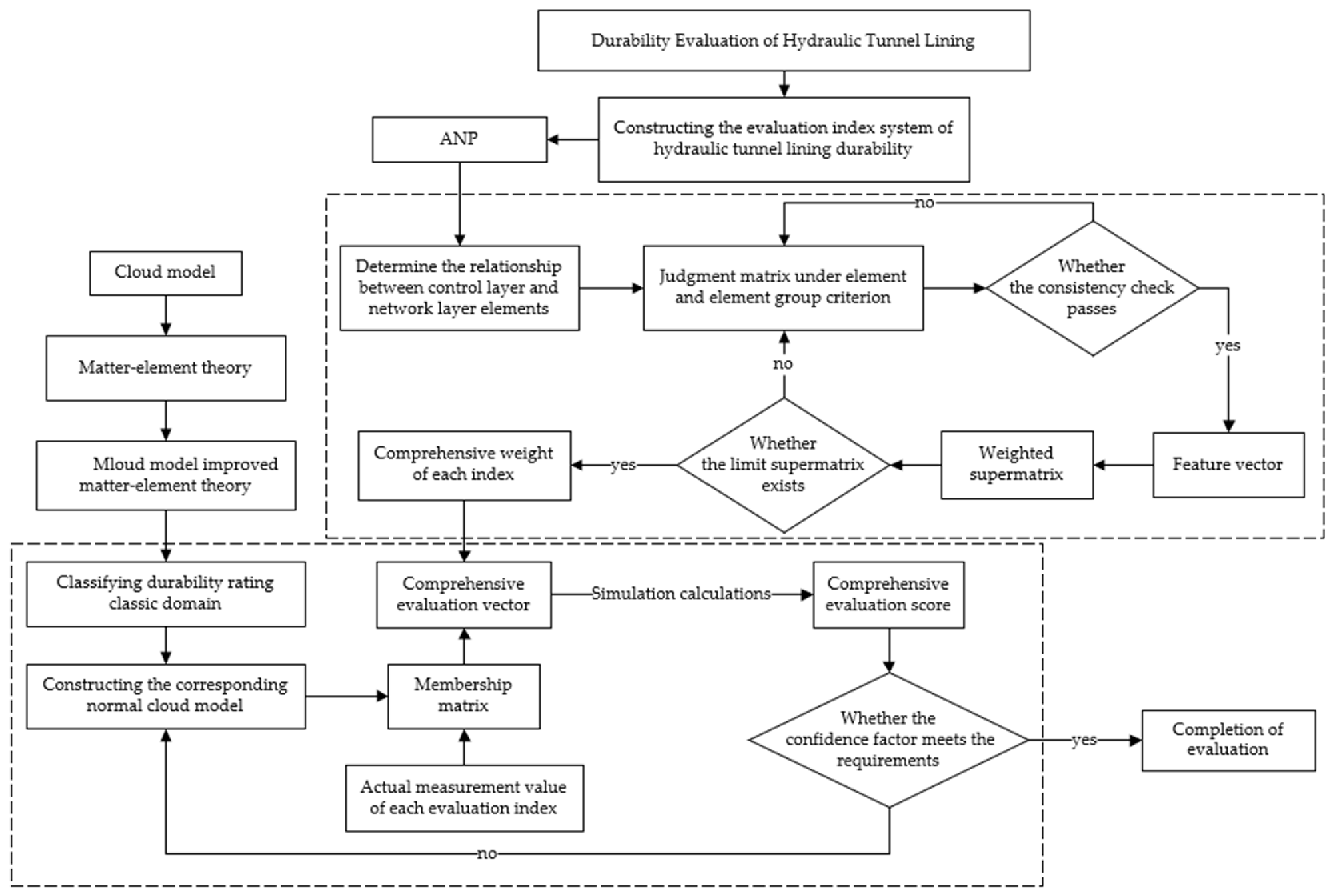

3. Evaluation Methods

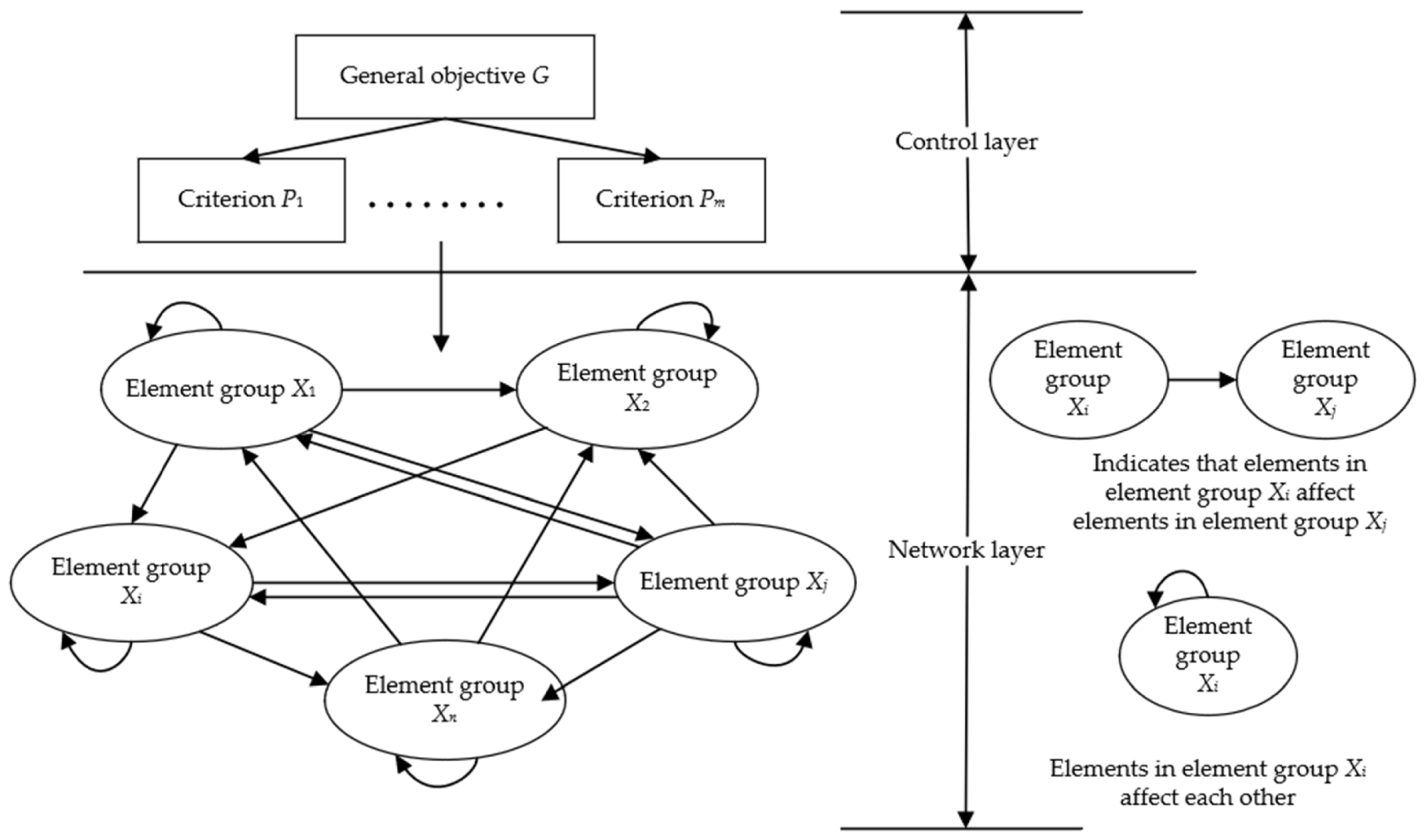

3.1. The Analytic Network Process

3.2. Cloud-Model-Improved Matter–Element Theory

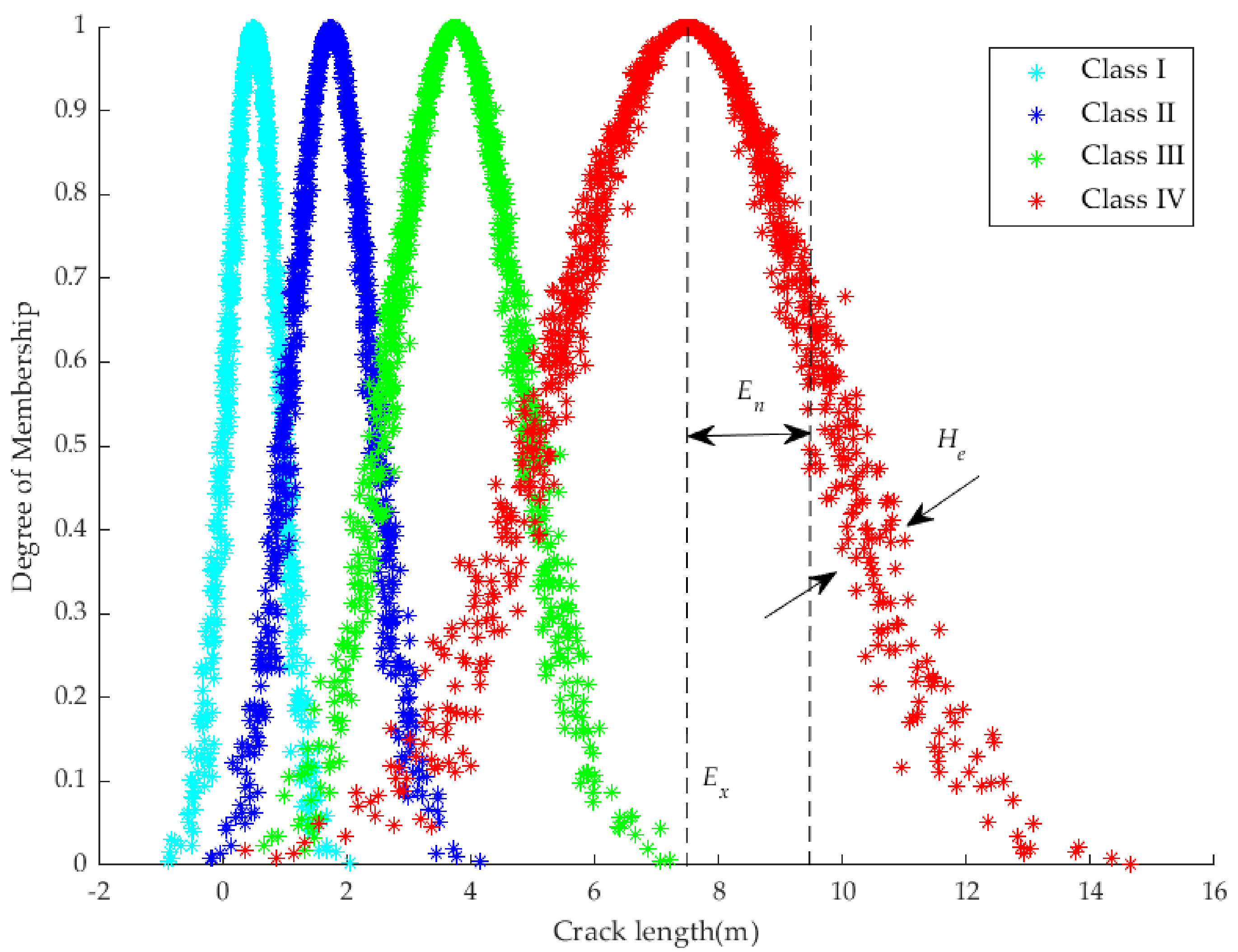

3.2.1. Transforming Matter–Element Model with Cloud Model

3.2.2. Cloud-Model Parameters

3.2.3. Degree of Membership of Evaluation Index

3.2.4. Durability-Class Calculation

4. Example Application and Analysis

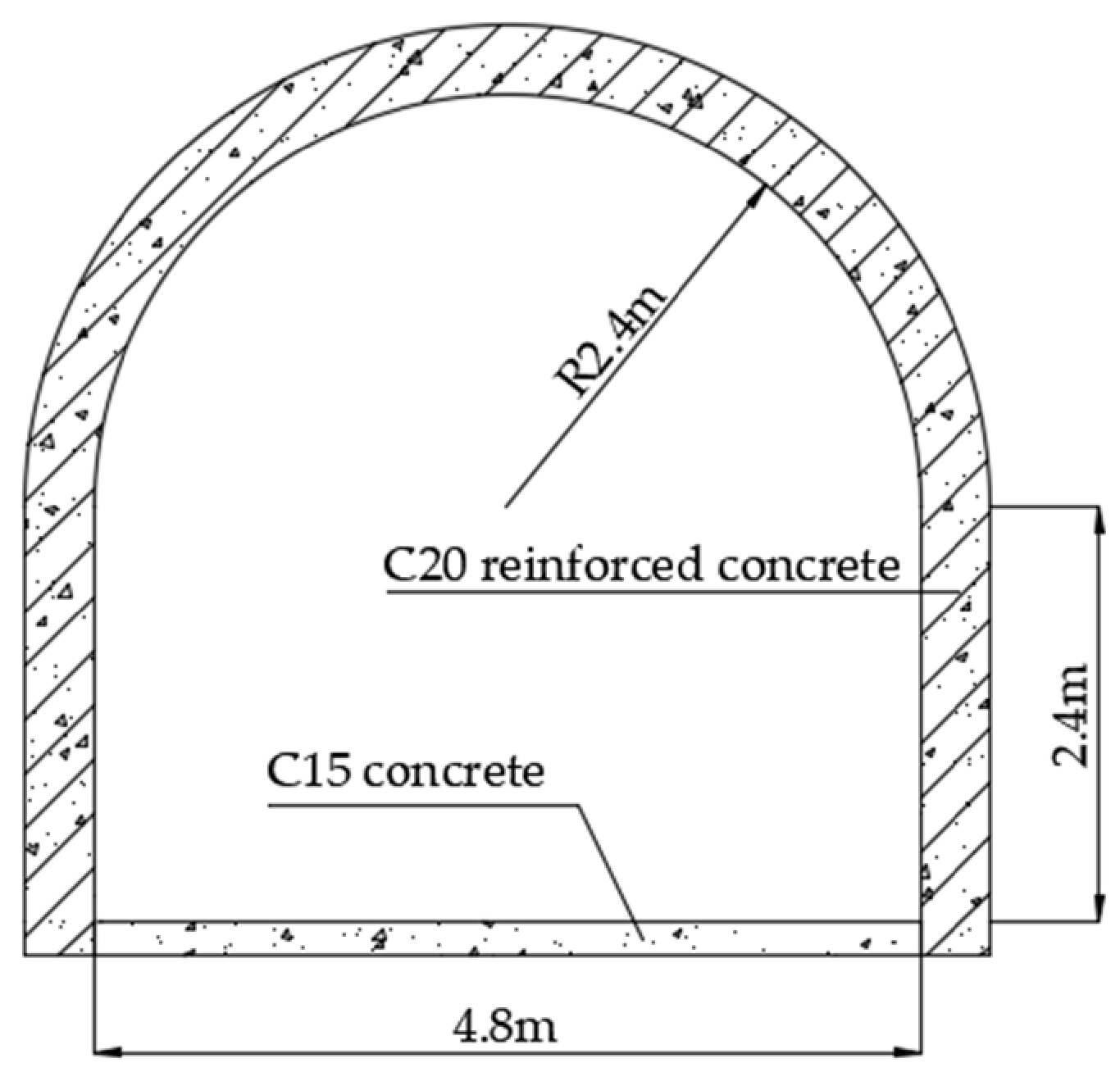

4.1. Engineering Background

4.2. Determination of Evaluation-Index Weights

4.3. Durability Evaluation of Example

5. Conclusions and Outlook

- (1)

- According to the damage mechanism of hydraulic tunnel linings, the 16 evaluation indices, such as the crack-length, crack-width, and crack-depth ratio, arch-leakage status; sidewall-leakage status, freezing status, and pH value, are divided into four element groups: lining cracks, water leakage, lining-structure deterioration, and lining-material deterioration, forming a scientific hydraulic tunnel lining durability evaluation index system;

- (2)

- Feedback exists between the hydraulic tunnel lining durability evaluation indices, and on the basis of multiexpert scoring, the ANP is used to calculate the weights of each index, which reduces the subjectivity and one-sidedness in the calculation process and obtains the durability index weights that suit the actual situation. The weights of each evaluation index were obtained by calculation, and the first three were the crack width (0.1297), crack length (0.1198), and deformation speed (0.1197);

- (3)

- The cloud-model-improved matter–element theory combines the advantages of the cloud model and matter–element theory, fully considers the randomness and fuzziness in the evaluation process, and provides a new method for hydraulic tunnel lining durability evaluation. The lining durability classes of five sections of the Nawei Tunnel were obtained as III, II, II, II, and III using the method of this paper, which matched with the calculation results of the improved G2-antientropy weight method and unconfirmed measurement theory, thus verifying its accuracy and scientificity.

- (1)

- The material and structural forms of hydraulic tunnel linings are diverse, and a more complete durability evaluation index system needs to be established for different forms of hydraulic tunnel linings;

- (2)

- The feedback among the hydraulic tunnel lining durability evaluation indices may be asymmetric, and it is necessary to modify the ANP to further reflect the actual situation and improve the accuracy of the indice weights;

- (3)

- The classification criteria of the durability classes and the reasonableness of the durability score have a great influence on the evaluation results. The classification of the durability classes in this paper was obtained on the basis of a large amount of literature, and they are applicable to most shapes and sizes of tunnels, but in order to expand their application, more in-depth and detailed research is still needed to improve the comprehensiveness and objectivity of the evaluation results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arends, B.J.; Jonkman, S.N.; Vrijling, J.K.; van Gelder, P.H.A.J.M. Evaluation of tunnel safety: Towards an economic safety optimum. Reliab. Eng. Syst. Saf. 2005, 90, 217–228. [Google Scholar] [CrossRef]

- Jin, N.G.; Tang, L.; Fu, C.Q.; Jin, X.Y. Risk Analysis of Tunnel Lining Using Fault Tree Theory and Entropy Measurement. In Proceedings of the 2009 WRI World Congress on Computer Science and Information Engineering, Los Angeles, CA, USA, 31 March–2 April 2009; pp. 207–212. [Google Scholar]

- Jifei, W.; Hongwei, H.; Xiongyao, X.; Yadong, X. Risk assessment of voids behind the lining of mountain tunnels. In GeoFlorida 2010: Advances in Analysis, Modeling & Design; American Society of Civil Engineers: Reston, VA, USA, 2010; pp. 2319–2328. Available online: https://ascelibrary.org/doi/abs/10.1061/41095(365)235 (accessed on 14 September 2022).

- Wang, Y.; Liu, B.; Qi, Y. A Risk Evaluation Method with an Improved Scale for Tunnel Engineering. Arab. J. Sci. Eng. 2017, 43, 2053–2067. [Google Scholar] [CrossRef]

- Qi, Y.; Jin, C.; Gong, L. Safety assessment of water diversion tunnel diseases based on ANP-grey correlation TOPSIS method. Chin. J. Water Resour. Water Eng. 2019, 30, 143–149. [Google Scholar]

- Qiu, W.; Liu, Y.; Lu, F.; Huang, G. Establishing a sustainable evaluation indicator system for railway tunnel in China. J. Clean. Prod. 2020, 268, 122150. [Google Scholar] [CrossRef]

- Xu, J.; Xu, H.; Sun, R.; Zhao, X.; Cheng, Y. Seismic risk evaluation for a planning mountain tunnel using improved analytical hierarchy process based on extension theory. J. Mt. Sci. 2020, 17, 244–260. [Google Scholar] [CrossRef]

- Han, W.; Jiang, Y.; Li, N.; Koga, D.; Sakaguchi, O.; Chen, H. Safety evaluation and failure behavior of degraded tunnel structure with compound diseases of voids and lining defects. Arab. J. Geosci. 2021, 14, 1531. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P.; Makul, N. Effect of sludge water from ready-mixed concrete plant on properties and durability of concrete. Cem. Concr. Compos. 2006, 28, 441–450. [Google Scholar] [CrossRef]

- Jeon, J.-K.; You, J.-O.; Moon, J.-H. Durability evaluation of tunnel lining concrete reinforced with nylon fiber. J. Korea Concr. Inst. 2008, 20, 487–493. [Google Scholar]

- Abbas, S. Structural and Durability Performance of Precast Segmental Tunnel Linings. 2014. Available online: https://ir.lib.uwo.ca/etd/1865/ (accessed on 14 September 2022).

- Li, K.; Li, Q.; Wang, P.; Fan, Z. Durability assessment of concrete immersed tube tunnel in Hong Kong-Zhuhai-Macau sea link project. In Proceedings of the 27th Concrete Institute of Australia Conference, Melbourne, Australia, 30 August–2 September 2015; pp. 1016–1024. [Google Scholar]

- Akula, P.; Hariharan, N.; Little, D.N.; Lesueur, D.; Herrier, G. Evaluating the Long-Term Durability of Lime Treatment in Hydraulic Structures: Case Study on the Friant-Kern Canal. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 431–443. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, H.; Zhang, H. Durability evaluation of highway tunnel lining structure based on matter element extension-simple correlation function method-cloud model: A case study. Math. Biosci. Eng. 2021, 18, 4027–4054. [Google Scholar] [CrossRef]

- Zhang, H.; Qian, C. Durability evaluation of beam-slab wharf based on extension theory. J. Zhejiang Univ. Technol. 2022, 50, 90–94. [Google Scholar]

- Liu, Y.; Tang, C.; Wang, P.; Guan, Y.; Wang, S. Study on disease mechanism and theoretical quantification method of tunnel structure. Adv. Civ. Eng. 2019, 2019, 4398524. Available online: https://www.hindawi.com/journals/ace/2019/4398524/ (accessed on 14 September 2022). [CrossRef]

- Bergeson, W.; Ernst, S.L. Tunnel Operations, Maintenance, Inspection, and Evaluation (TOMIE) Manual; Federal Highway Administration: Washington, DC, USA, 2015. Available online: https://rosap.ntl.bts.gov/view/dot/42887 (accessed on 14 September 2022).

- Ge, S.; Gao, W.; Wang, Y.; Xie, Y.; Chen, X.; Wang, S. A Review of Research on Disease, Evaluation and Treatment of Traffic Shield Tunnels in my country. Chin. J. Civ. Eng. 1–11. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=TMGC2022040100A&uniplatform=NZKPT&v=wy60cmNGWEz7N6KGDze-6g6elo7B9YmqmIUXMDXO9eVkznCztyXfUTM902gQC0k0 (accessed on 14 September 2022).

- Wu, Z.; Yang, L.; Shi, B.; Mo, Y. Study on the influence of crack on the durability of tunnel segments using fuzzy evaluation. Chin. J. Undergr. Space Eng. 2007, 3, 224–228. [Google Scholar]

- Tang, L.; Li, H.; Xie, Y.; Song, R.; Fu, X. Crack detection and safety classification evaluation of hydraulic tunnel lining. Water Conserv. Hydropower Technol. 2018, 49, 135–141. [Google Scholar] [CrossRef]

- Zhiqiang, Z.; Mansoor, Y.A. Evaluating the strength of corroded tunnel lining under limiting corrosion conditions. Tunn. Undergr. Space Technol. 2013, 38, 464–475. [Google Scholar] [CrossRef]

- Yoo, C. Effect of water leakage in tunnel lining on structural performance of lining in subsea tunnels. Mar. Georesour. Geotechnol. 2017, 35, 305–317. [Google Scholar] [CrossRef]

- Chen, J.; Deng, X.; Luo, Y.; He, L.; Liu, Q.; Qiao, X. Investigation of microstructural damage in shotcrete under a freeze–thaw environment. Constr. Build. Mater. 2015, 83, 275–282. [Google Scholar] [CrossRef]

- Berezhnoi, D.; Balafendieva, I.; Sachenkov, A.; Sekaeva, L. Modelling of deformation of underground tunnel lining, interacting with water-saturated soil. IOP Conf. Ser. Mater. Sci. Eng. 2016, 158, 012018. [Google Scholar] [CrossRef]

- Li, B.; Lei, M.; Li, W. Influence of operating highway tunnel diseases on the safety of lining structures. Chin. J. Railw. Sci. Eng. 2011, 8, 40–45. [Google Scholar] [CrossRef]

- Usman, M.; Galler, R. Long-term deterioration of lining in tunnels. Int. J. Rock Mech. Min. Sci. 2013, 64, 84–89. [Google Scholar] [CrossRef]

- Wang, G.; Zhu, K. Research on hydraulic tunnel disease diagnosis based on fuzzy neural network. Chin. J. Undergr. Space Eng. 2009, 5, 201–206. [Google Scholar]

- Saaty, T.L. What is the analytic hierarchy process. In Mathematical Models for Decision Support; Springer: Berlin/Heidelberg, Germany, 1988; pp. 109–121. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. The analytic network process. In Decision Making with the Analytic Network Process; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–40. Available online: https://link.springer.com/chapter/10.1007/978-1-4614-7279-7_1 (accessed on 14 September 2022).

- Cai, W. An Overview of Extenics. In Systems Engineering Theory and Practice; 1998; pp. 77–85. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFD9899&filename=XTLL801.017&uniplatform=NZKPT&v=sUt7xjfRZbhWCHiXl-iAVvAL3oPrRm5NUQkfBVLHjMM5A1nYbEEG6i3faNI2VmXy (accessed on 14 September 2022). [CrossRef]

- Li, D.; Liu, C.; Du, Y.; Han, X. Uncertain Artificial Intelligence. Chin. J. Softw. 2004, 1583–1594. Available online: http://www.jos.org.cn/jos/article/abstract/20041101?st=search (accessed on 14 September 2022).

- Li, D. Uncertainty in Knowledge Representation. China Eng. Sci. 2000, 73–79. Available online: https://www.engineering.org.cn/ch/article/20001018 (accessed on 14 September 2022).

- Li, D.; Meng, H.; Shi, X. Affiliate Cloud and Affiliate Cloud Generator. Comput. Res. Dev. 1995, 15–20. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFD9495&filename=JFYZ506.002&uniplatform=NZKPT&v=uht02ElFREMrOIOwOltNXHX8fTTr5QEu0-ykvshtyy11nzN9j3eJeA5xggq2mqrg (accessed on 14 September 2022).

- Wang, L. The Theory and Algorithm of Analytic Network Process. In System Engineering Theory and Practice; 2001; pp. 44–50. Available online: https://www.sysengi.com/CN/10.12011/1000-6788(2001)3-44 (accessed on 14 September 2022).

- Li, D.; Liu, C. On the Universality of the Normal Cloud Model. China Eng. Sci. 2004, 28–34. Available online: https://www.engineering.org.cn/ch/article/20040806 (accessed on 14 September 2022).

- Li, R.; Su, H. Power Quality Comprehensive Evaluation Model Based on Extensible Cloud Theory. Autom. Electr. Power Syst. 2012, 36, 66–70. [Google Scholar]

- Tu, S.; Zhao, Z.; Deng, M.; Wang, B. Safety risk assessment of blasting construction of high rock slope engineering based on cloud-physical element coupling model. Saf. Environ. Eng. 2021, 28, 102–108. [Google Scholar] [CrossRef]

- Lu, L.; Jin, C.; Gong, L.; Qi, Y.; Wang, J.; He, S. Structural Safety Evaluation of Diversion Tunnels Based on Improved G2-AEW-UMT Model. Chin. J. Water Resour. Water Eng. 2020, 31, 172–178. [Google Scholar]

- Lu, L. Lining Disease Analysis and Safety Status Evaluation of Water Diversion Tunnels in Cold Regions. Master’s Thesis, Lanzhou Jiaotong University, Lanzhou, China, 2021. [Google Scholar]

- Hao, W.; Wei, X. Durability assessment of concrete girder bridges in alpine regions based on grey correlation. Chin. J. Saf. Environ. 2021, 21, 1889–1897. [Google Scholar] [CrossRef]

- Albitar, M.; Ali, M.M.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Mater. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Q/CR 405.2-2019; Assessment Standard for Structure Deterioration of Railway Bridge and Tunnel—Part 2: Tunnel; China State Railway Group Co., Ltd.: Beijing, China, 2019.

- Luo, X.; Xia, C. Current Situation and Problems of Tunnel Disease Classification. Chin. J. Undergr. Space Eng. 2006, 877–880. Available online: https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFD2006&filename=BASE200605039&uniplatform=NZKPT&v=snlLeqZSi1OtlCxiyTKjuy8jRcUq_-rpdi4Sr4Pj3we0akzRKCfD9T23fqGpIIwi (accessed on 14 September 2022).

- Park, S.; Shin, Y.; Oh, Y.; Ahn, S. A guideline on condition assessment of existing old railway tunnels. Tunn. Undergr. Space Technol. 2006, 21. Available online: https://trid.trb.org/view/789091 (accessed on 14 September 2022). [CrossRef]

| Parameter | Meaning | Parameter | Meaning |

|---|---|---|---|

| R(N, C, V) | Matter–element model | w | Global-weight vector |

| D | Quantitative domain | Combined-weight vector | |

| I | Qualitative language values in D | Ex | Expectation |

| x | Actual measurement value | En | Entropy |

| Degree of membership of x to I | He | Hyperentropy | |

| G | General objective | Tmin | Minimum value of the constraint interval |

| m | Number of elements in the criterion layer | Tmax | Maximum value of the constraint interval |

| n | Number of network-layer-element groups | k | Hyperentropy-constant value |

| N | Number of network-layer elements | Normal random number with En as expectation value | |

| Ps | Criterion-layer elements | d | Standard-normal-distribution random numbers |

| Xi | Network-layer-element group | E | The intersection of two clouds |

| Xj-l | Network layer element group elements | F | The union of two clouds |

| Normalized eigenvectors of Xi judgment matrix under Xj-l criterion | U | Membership matrix | |

| Wij | Matrix of supermatrix subblocks composed of normalized eigenvectors | B | Comprehensive-evaluation vector |

| Ws | Supermatrix under the criterion Ps | r | Comprehensive-evaluation score |

| aj | Normalized eigenvectors of the judgment matrix of each element group under Xj criterion | bj | The element in the comprehensive-evaluation vector (B) |

| aij | Weighting factor | hj | Assigned score of durability class (j) |

| A | Weighting matrix | Ex,r | Expectation of comprehensive-evaluation score |

| Weighted supermatrix subblock | t | Number of simulation calculations | |

| Weighted supermatrix under the criterion Ps | En,r | Standard deviation of comprehensive-evaluation score | |

| wij | , reflecting the one-step dominance of element i over element j | Confidence factor | |

| Limit supermatrix |

| Scale | Meaning |

|---|---|

| 1 | The elements have the same importance as the element being compared. |

| 3 | The element is slightly more important than the element being compared. |

| 5 | The element is significantly more important than the element being compared. |

| 7 | The element is more strongly important than the element being compared. |

| 9 | The element is extremely more important than the element being compared. |

| 2, 4, 6, 8 | The middle value of the above adjacent judgments. |

| Countdown | The significance of the above elements when swapped with the elements being compared. |

| Pile Segment | Notable Characteristics |

|---|---|

| 4 + 247.01~4 + 281.6 | The bottom plate is seriously damaged, with 5~10 cm pits (the deepest is 21 cm). The concrete-surface layer below the water-crossing surface of the sidewall is seriously peeling off, and the concrete aggregate is exposed. |

| 4 + 362~4+402 | There are many cracks in the bottom plate. |

| 4 + 757.5~4 + 797 | The water leakage is serious. Concrete cracks are developed in the range of 3.3~4.3 m on the left wall, the length is 1~4 m, and most of them are closed. There are white precipitates in the cracks, of which the 0.2 m water leakage on the right wall of 4 + 773 is dripping. |

| 5 + 071~5 + 135 | The water leakage on the two walls is serious. There are water-leakage points in the range of 0~4.3 m, mostly at the junction of the vault and side wall, and especially the 5 + 120 full-arch seepage, which is dripping. |

| 6 + 240~6 + 346.26 | The frost-heave damage of the bottom plate is serious, and there are many cracks. The concrete surface is mostly pitted and honeycombed, which seriously falls off. |

| X1-1 | X1-2 | X1-3 | X2-1 | X2-2 | X2-3 | X2-4 | X3-1 | X3-2 | X3-3 | X3-4 | X3-5 | X4-1 | X4-2 | X4-3 | X4-4 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1-1 | 1 * | 1 | 1 | 1 | 1 | 1 | −2 | −2 | −2 | 1 | 0 | 0 | 1 | 1 | −2 | 0 |

| X1-2 | 1 | 1 | 1 | 1 | 1 | 1 | −2 | −2 | −2 | 1 | 0 | 0 | 1 | 1 | 1 | 0 |

| X1-3 | 1 | 1 | 1 | 0 | 0 | 0 | −2 | −2 | −2 | 1 | 0 | 2 | 1 | 1 | 1 | 0 |

| X2-1 | 1 | 1 | 0 | 0 | 0 | 2 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 1 | 0 |

| X2-2 | 1 | 1 | 0 | 0 | 0 | 2 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 1 | 0 |

| X2-3 | 1 | 1 | 0 | −2 | −2 | 0 | 2 | 2 | 0 | 0 | 2 | 2 | 0 | 0 | 0 | 2 |

| X2-4 | 2 | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 2 | 2 | 2 | 0 |

| X3-1 | 2 | 2 | 2 | 0 | 0 | −2 | 0 | 0 | 0 | 2 | −2 | −2 | 0 | 1 | 0 | −2 |

| X3-2 | 2 | 2 | 2 | 1 | 1 | 0 | 1 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 |

| X3-3 | 1 | 1 | 1 | −2 | −2 | 0 | 0 | −2 | −2 | 0 | 1 | 1 | −2 | −2 | 0 | 0 |

| X3-4 | 0 | 0 | 0 | 0 | 0 | -2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 0 |

| X3-5 | 0 | 0 | −2 | 0 | 0 | −2 | 0 | 2 | 0 | 1 | 1 | 1 | 1 | 2 | 1 | 0 |

| X4-1 | 1 | 1 | 1 | 0 | 0 | 0 | −2 | 0 | 0 | 2 | 1 | 1 | 0 | 0 | −2 | −2 |

| X4-2 | 1 | 1 | 1 | 0 | 0 | 0 | −2 | 1 | 0 | 2 | −2 | −2 | 0 | 0 | −2 | −2 |

| X4-3 | 2 | 1 | 1 | 1 | 1 | 0 | −2 | 0 | 0 | 0 | −2 | 1 | 2 | 2 | 1 | 0 |

| X4-4 | 0 | 0 | 0 | 0 | 0 | −2 | 0 | 2 | 0 | 0 | 0 | 0 | 2 | 2 | 0 | 1 |

| E1 | E2 | E3 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | a1 | X1 | X2 | X3 | X4 | a1 | X1 | X2 | X3 | X4 | a1 | |

| X1 | 1 | 1/2 | 2 | 3 | 0.2995 | 1 | 1/2 | 3 | 4 | 0.3358 | 1 | 1/2 | 3 | 4 | 0.3056 |

| X2 | 2 | 1 | 2 | 2 | 0.3889 | 2 | 1 | 2 | 3 | 0.4004 | 2 | 1 | 4 | 5 | 0.4918 |

| X3 | 1/2 | 1/2 | 1 | 2 | 0.1881 | 1/3 | 1/2 | 1 | 3 | 0.1777 | 1/3 | 1/4 | 1 | 2 | 0.1248 |

| X4 | 1/3 | 1/2 | 1/2 | 1 | 0.1235 | 1/4 | 1/3 | 1/3 | 1 | 0.0862 | 1/4 | 1/5 | 1/2 | 1 | 0.0778 |

| CR * | 0.0536 | 0.0789 | 0.0181 | ||||||||||||

| E1 | E2 | E3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1-1 | X1-2 | X1-3 | X1-1 | X1-2 | X1-3 | X1-1 | X1-2 | X1-3 | ||||

| X1-1 | 1 | 2 | 3 | 0.5396 | 1 | 3 | 4 | 0.6250 | 1 | 3 | 3 | 0.6000 |

| X1-2 | 1/2 | 1 | 2 | 0.2970 | 1/3 | 1 | 2 | 0.2385 | 1/3 | 1 | 1 | 0.2000 |

| X1-3 | 1/3 | 1/2 | 1 | 0.1634 | 1/4 | 1/2 | 1 | 0.1365 | 1/3 | 1 | 1 | 0.2000 |

| CR | 0.0088 | 0.0176 | 0.0000 | |||||||||

| E1 | E2 | E3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X2-1 | X2-2 | X2-3 | X2-1 | X2-2 | X2-3 | X2-1 | X2-2 | X2-3 | ||||

| X2-1 | 1 | 2 | 4 | 0.5584 | 1 | 1 | 3 | 0.4286 | 1 | 2 | 3 | 0.5278 |

| X2-2 | 1/2 | 1 | 3 | 0.3196 | 1 | 1 | 3 | 0.4286 | 1/2 | 1 | 3 | 0.3325 |

| X2-3 | 1/4 | 1/3 | 1 | 0.1220 | 1/3 | 1/3 | 1 | 0.1429 | 1/3 | 1/3 | 1 | 0.1396 |

| CR | 0.0176 | 0.0000 | 0.0516 | |||||||||

| E1 | E2 | E3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| X4-1 | X4-2 | X4-1 | X4-2 | X4-1 | X4-2 | ||||

| X4-1 | 1 | 3 | 0.7500 | 1 | 2 | 0.6667 | 1 | 3 | 0.7500 |

| X4-2 | 1/3 | 1 | 0.2500 | 1/2 | 1 | 0.3333 | 1/3 | 1 | 0.2500 |

| CR | 0.0000 | 0.0000 | 0.0000 | ||||||

| Index | Weight | Sequence | Index | Weight | Sequence |

|---|---|---|---|---|---|

| X1-1 | 0.1198 | 2 | X3-2 | 0.0145 | 15 |

| X1-2 | 0.1297 | 1 | X3-3 | 0.1197 | 3 |

| X1-3 | 0.0823 | 6 | X3-4 | 0.0876 | 5 |

| X2-1 | 0.0640 | 7 | X3-5 | 0.0993 | 4 |

| X2-2 | 0.0430 | 11 | X4-1 | 0.0469 | 10 |

| X2-3 | 0.0496 | 8 | X4-2 | 0.0309 | 13 |

| X2-4 | 0.0159 | 14 | X4-3 | 0.0477 | 9 |

| X3-1 | 0.0376 | 12 | X4-4 | 0.0116 | 16 |

| Durability Class | Durability Status | Qualitative Determination Basis |

|---|---|---|

| I | Normal | Material and structure functions slightly damaged or intact, and these damages have no effect on the water delivery and do not need to be repaired. |

| II | Basically normal | Materials and structural functions are basically intact, and there is basically no impact on the water transmission, but minor repairs are required. |

| III | Reaching the durability limit | The durability cannot meet the applicability requirements, which may endanger the safety of the water transmission, and the necessary preparations and measures should be taken. |

| IV | Reaching the bearing-capacity limit | The durability cannot meet the safety requirements, which will endanger the safety of the water transmission, and enforcement measures must be taken. |

| First-Level Indices (Element Group) | Secondary Indices (Element) | Durability Classes | |||

|---|---|---|---|---|---|

| I | II | III | IV | ||

| Lining cracks (X1) | Crack length (X1-1) (m) | (0,1] | (1,2.5] | (2.5,5] | (5,10] |

| Crack width (X1-2) (mm) | (0,0.2] | (0.2,0.3] | (0.3,0.4] | (0.4,0.8] | |

| Crack depth/lining thickness (X1-3) | (0,0.3] | (0.3,0.5] | (0.5,0.7] | (0.7,1] | |

| Water leakage (X2) | Arch-leakage status (X2-1 1) | (0,1] | (1,2] | (2,3] | (3,4] |

| Sidewall-leakage status (X2-2 2) | (0,1] | (1,3] | (3,4] | (4,6] | |

| Freezing status (X2-3 3) | (0,1] | (1,2] | (2,3] | (3,4] | |

| pH value (X2-4) | (6,14] | (5,6] | (4,5] | (0,4] | |

| Lining-structure deterioration (X3) | Insufficient thickness/design thickness, (X3-1) | (0,0.01] | (0.01,0.1] | (0.1,0.5] | (0.5,1] |

| Depth of void behind (X3-2) (mm) | (0,50] | (50,100] | (100,500] | (500,1000] | |

| ) | (0,1] | (1,3] | (3,10] | (10,20] | |

| Spalling diameter (X3-4) (mm) | (0,50] | (50,75] | (75,150] | (150,300] | |

| Spalling depth (X3-5) (mm) | (0,6] | (6,12] | (12,25] | (25,50] | |

| Lining-material deterioration (X4) | Actual strength/design strength (X4-1) | (0.8,1] | (0.5,0.8] | (0.3,0.5] | (0,0.3] |

| Rebar-section-loss rate (X4-2 (%)) | (0,3] | (3,10] | (10,25] | (25,100] | |

| Carbonization coefficient (X4-3 4) | (0,0.6] | (0.6,0.8] | (0.8,1] | (1,2] | |

| Shellfish thickness (X4-4) (mm) | (0,20] | (20,50] | (50,100] | (100,200] | |

| Durability Class | I | II | III | IV | |

|---|---|---|---|---|---|

| Evaluation Indices | Numerical Characteristics | ||||

| X1-1 | Ex | 0.500 | 1.750 | 3.750 | 7.500 |

| En | 0.425 | 0.637 | 1.062 | 2.123 | |

| He | 0.043 | 0.064 | 0.106 | 0.212 | |

| X1-2 | Ex | 0.100 | 0.250 | 0.350 | 0.600 |

| En | 0.085 | 0.042 | 0.042 | 0.170 | |

| He | 0.009 | 0.004 | 0.004 | 0.017 | |

| X1-3 | Ex | 0.150 | 0.400 | 0.600 | 0.850 |

| En | 0.127 | 0.085 | 0.085 | 0.127 | |

| He | 0.013 | 0.009 | 0.009 | 0.013 | |

| X2-1 | Ex | 0.500 | 1.500 | 2.500 | 3.500 |

| En | 0.425 | 0.425 | 0.425 | 0.425 | |

| He | 0.043 | 0.043 | 0.043 | 0.043 | |

| X2-2 | Ex | 0.500 | 2.000 | 3.500 | 5.000 |

| En | 0.425 | 0.849 | 0.425 | 0.849 | |

| He | 0.043 | 0.085 | 0.043 | 0.085 | |

| X2-3 | Ex | 0.500 | 1.500 | 2.500 | 3.500 |

| En | 0.425 | 0.425 | 0.425 | 0.425 | |

| He | 0.043 | 0.043 | 0.043 | 0.043 | |

| X2-4 | Ex | 10.000 | 5.500 | 4.500 | 2.000 |

| En | 3.397 | 0.425 | 0.425 | 1.699 | |

| He | 0.340 | 0.043 | 0.043 | 0.170 | |

| X3-1 | Ex | 0.005 | 0.055 | 0.300 | 0.750 |

| En | 0.004 | 0.038 | 0.170 | 0.212 | |

| He | 0.000 | 0.004 | 0.017 | 0.021 | |

| X3-2 | Ex | 25.000 | 75.000 | 300.000 | 750.000 |

| En | 21.231 | 21.231 | 169.851 | 212.314 | |

| He | 2.123 | 2.123 | 16.985 | 21.231 | |

| X3-3 | Ex | 0.500 | 2.000 | 6.500 | 15.000 |

| En | 0.425 | 0.849 | 2.972 | 4.246 | |

| He | 0.043 | 0.085 | 0.297 | 0.425 | |

| X3-4 | Ex | 25.000 | 62.500 | 112.500 | 225.000 |

| En | 21.231 | 10.616 | 31.847 | 63.694 | |

| He | 2.123 | 1.062 | 3.185 | 6.369 | |

| X3-5 | Ex | 3.000 | 9.000 | 18.500 | 37.500 |

| En | 2.548 | 2.548 | 5.520 | 10.616 | |

| He | 0.255 | 0.255 | 0.552 | 1.0616 | |

| X4-1 | Ex | 0.900 | 0.650 | 0.400 | 0.150 |

| En | 0.085 | 0.127 | 0.085 | 0.127 | |

| He | 0.009 | 0.013 | 0.009 | 0.013 | |

| X4-2 | Ex | 1.500 | 6.500 | 17.500 | 62.500 |

| En | 1.274 | 2.972 | 6.369 | 31.847 | |

| He | 0.127 | 0.297 | 0.637 | 3.185 | |

| X4-3 | Ex | 0.300 | 0.700 | 0.900 | 1.500 |

| En | 0.255 | 0.085 | 0.085 | 0.425 | |

| He | 0.026 | 0.009 | 0.009 | 0.043 | |

| X4-4 | Ex | 10.000 | 35.000 | 75.000 | 150.000 |

| En | 8.493 | 12.739 | 21.231 | 42.463 | |

| He | 0.849 | 1.274 | 2.123 | 4.246 | |

| Element Groups | Elements | Pile Segment | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| X1 | X1-1 (m) | 4.5 | 1 | 4 | 2 | 3.5 |

| X1-2 (mm) | 0.4 | 0.2 | 0.25 | 0.2 | 0.45 | |

| X1-3 | 5/12 | 1/8 | 1/3 | 1/3 | 5/12 | |

| X2 | X2-1 | 0.5 | 0.5 | 2.5 | 2.5 | 1.5 |

| X2-2 | 1.5 | 0.5 | 0.5 | 2.5 | 2.5 | |

| X2-3 | 1.5 | 0.5 | 0.5 | 2.5 | 2.5 | |

| X2-4 | 4.5 | 6 | 5.5 | 5.5 | 5 | |

| X3 | X3-1 | 7/12 | 1/4 | 5/12 | 1/3 | 1/2 |

| X3-2 (mm) | 400 | 50 | 150 | 200 | 350 | |

| ) | 4 | 1 | 2 | 2 | 4 | |

| X3-4 (mm) | 120 | 50 | 60 | 65 | 110 | |

| X3-5 (mm) | 21 | 6 | 13 | 12 | 19 | |

| X4 | X4-1 | 0.8 | 0.85 | 0.7 | 0.9 | 0.8 |

| X4-2 (%) | 15 | 10 | 20 | 19 | 18 | |

| X4-3 | 0.8 | 0.4 | 0.6 | 0.6 | 0.9 | |

| X4-4 (mm) | 20 | 5 | 5 | 10 | 20 | |

| Pile Segment | Expectation | Standard Deviation | Confidence Factor | Evaluation Results of the Method of [39] |

|---|---|---|---|---|

| 1 | 2.772 (III) | 0.057 | 0.021 | III |

| 2 | 1.580 (II) | 0.054 | 0.034 | II |

| 3 | 2.292 (II) | 0.057 | 0.025 | II |

| 4 | 2.225 (II) | 0.054 | 0.024 | II |

| 5 | 2.880 (III) | 0.051 | 0.018 | III |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Fan, C. Evaluation of Hydraulic-Tunnel-Lining Durability Based on ANP and Cloud-Model-Improved Matter–Element Theory. Sustainability 2022, 14, 11801. https://doi.org/10.3390/su141911801

Li Q, Fan C. Evaluation of Hydraulic-Tunnel-Lining Durability Based on ANP and Cloud-Model-Improved Matter–Element Theory. Sustainability. 2022; 14(19):11801. https://doi.org/10.3390/su141911801

Chicago/Turabian StyleLi, Qingfu, and Chuangshi Fan. 2022. "Evaluation of Hydraulic-Tunnel-Lining Durability Based on ANP and Cloud-Model-Improved Matter–Element Theory" Sustainability 14, no. 19: 11801. https://doi.org/10.3390/su141911801

APA StyleLi, Q., & Fan, C. (2022). Evaluation of Hydraulic-Tunnel-Lining Durability Based on ANP and Cloud-Model-Improved Matter–Element Theory. Sustainability, 14(19), 11801. https://doi.org/10.3390/su141911801