Energy Efficiency Engagement Training in SMEs: A Case Study in the Automotive Sector

Abstract

:1. Introduction

2. Literature Review

2.1. SMEs in Automotive Supply Chain

- -

- Original equipment manufacturers (OEMs): companies involved in the design, marketing and assembly of the final product;

- -

- Tier 1 suppliers: companies working close to the OEMs, producing mainly automotive-grade hardware, doors, bumpers, brakes, wheels, gearboxes, powertrain, transmission and steering systems, etc.

- -

- Tier 2 suppliers: companies supplying electrical and/or electronic machinery and equipment, metal products, communication machinery and equipment, bearing assemblies and pumping units not directly to OEMs;

- -

- Tier 3 suppliers: supply raw materials (metals, plastics and glass).

2.2. Importance of Energy Efficiency for SMEs in Automotive Sector

2.3. VR in Training

3. Materials and Methods

3.1. E2DRIVER Methodology and Training Phases

3.2. Virtual Reality Training System

4. Results

4.1. Energy, Economic and Environmental Impact

4.2. Organizational, Behavioral and Sociocultural Impact

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- INDUCE. Towards a Sustainable Agro-Food Industry: Capacity Building Programmes in Energy Efficiency. Available online: https://www.induce2020.eu/ (accessed on 1 May 2022).

- Millan, G.; Llano, E.; Globisch, J. Increasing Energy Efficiency in the Food and Beverage Industry: A Human-Centered Design Approach. Sustainability 2020, 12, 7037. [Google Scholar] [CrossRef]

- European Parliament. EED. Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency. J. Eur. Union 2012, 315, 1–56. [Google Scholar]

- European Parliament. Directive 2018/2002/EU amending Directive 2012/27/EU on Energy Effciency. Eur. Union 2018, 328, 210–230. [Google Scholar]

- European Comission. Energy Eficiency Targets, The 2030 Targets. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficiency-targets-directive-and-rules/energy-efficiency-targets_en#the-2030-targets (accessed on 3 May 2022).

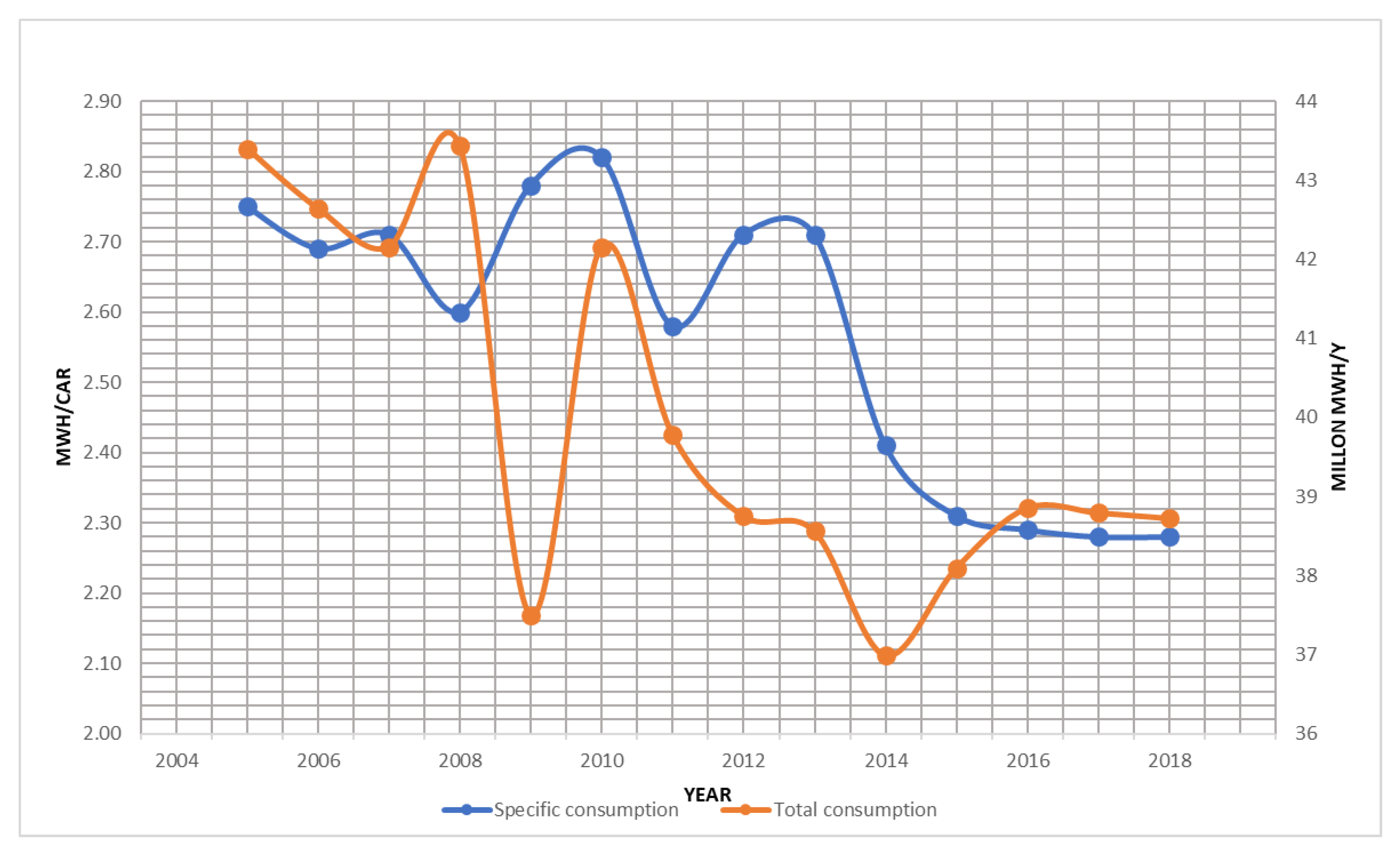

- European Automobile Manufacturers Association. Driving Mobility for Europe. Energy Consumption During Car Production in the EU. ACEA. October 2021. Available online: https://www.acea.auto/figure/energy-consumption-during-car-production-in-eu/ (accessed on 3 May 2022).

- Lorenzo, M. El Periódico. Economía. Europa Dejó de Producir Más de Vuatro Millones de Coches en 2020. Available online: https://www.elperiodico.com/es/economia/20210314/europa-dejo-producir-cuatro-millones-coches-2020-11578312 (accessed on 3 May 2022).

- European Association of Automotive Suppliers. What You Should Know about Parts and Components. Available online: https://clepa.eu/wp-content/uploads/2018/03/CLEPA-DNA_infographic-A4_FLYER_V14_PRESS-final_SMALL.pdf (accessed on 5 May 2022).

- Fidalgo Blanco, A.; Sein-Echaluce, M.; Garcia-Peñalvo, F. Ontological Flip Teaching: A Flip Teaching model based on knowledge management. Univers. Access Inf. Soc. 2018, 17, 475–489. [Google Scholar] [CrossRef]

- European Comission. Internal Market, Industry, Entrepreneurship and SMEs. SME Fefinition. Available online: https://single-market-economy.ec.europa.eu/smes/sme-definition_en (accessed on 21 July 2022).

- POLITO.E2DRIVER. Training on Energy Audits as an Energy Efficiency Driver for the Automotive Sector. Deliverable 2.1. Benchmarking Baseline Report. 2019, pp. 9, 27. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- POLITO.E2DRIVER. Training on Energy Audits as an Energy Efficiency Driver for the Automotive Sector. Deliverable 2.1. Benchmarking Baseline Report. 2019, pp. 10, 14. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- Goudillat, P.F.; Antonopoulos, I.S.; Dri, M.; Canfora, P.; Traverso, M. JRC Science for Policy Report. Best Environmental Management Practice for the Car Manufacturing Sector. 2017, pp. 17–18. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- De Becker, K.; Miroudot, S. Mapping Global Value Chains. OECD Publ. 2013, 159, 24–28. [Google Scholar] [CrossRef]

- Govindan, S.; Azevedo, S.; Cravalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef] [Green Version]

- Brunnermeier Smita, B.; Martin Sheila, A. Interoperability Cost Analysis of the U.S. Automotive Supply Chain. Research Triangle Institute. In Interoperability Cost Analysis of the U.S. Automotive Supply Chain; Insight Drive Innovation GEP: Clark, NJ, USA, 1999. [Google Scholar]

- European Association of Automotive Suppliers. What You Should Know about Parts and Components. 2017. Available online: CLEPA-DNA_infographic-A4_FLYER_V14_PRESS-final_SMALL.pdf (accessed on 21 July 2022).

- Oh, S.-C.; Hildreth, A.J. Estimating the Technical Improvement of Energy Efficiency in the Automotive Industry—Stochastic and Deterministic Frontier Benchmarking Approaches. Energies 2014, 7, 6196–6222. [Google Scholar] [CrossRef] [Green Version]

- Galitsky, C.; Worrell, E. Energy Efficiency Improvement and Cost Saving Opportunities for the Vehicle Assembly Industry: An ENERGY STAR Guide for Energy and Plant Managers. Technical Report. 2008. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- European Automobile Manufacturers Association. The Automobile Industry Pocket Guide 2019–2020. Available online: ACEA_Pocket_Guide_2019-2020.pdf (accessed on 22 July 2022).

- Clark, J. Why Should You Care about Virtual Reality in Marketing? Forbes 2017. Available online: www.forbes.com/sites/forbesagencycouncil/2017/10/02/why-should-you-care-about-virtual-reality-in-marketing/#414db3c464c4 (accessed on 21 December 2017).

- Van Kerrebroeck, H.; Brengman, M.; Willems, K. Escaping the crowd: An experimental study on the impact of a virtual reality experience in a shopping mall. Comput. Hum. 2017, 77, 437–450. [Google Scholar] [CrossRef]

- Merchant, Z.; Goetz, E.; Cifuentes, L.; Keeney-Kennicutt, W.; Davis, T. Effectiveness of virtual reality-based instruction on students’learning outcomes in K-12 and higher education: Ameta-analysis. Comput. Educ. 2014, 70, 29–40. [Google Scholar] [CrossRef]

- Nagendran, M.; Gurusamy, K.; Aggarwal, R.; Loizidou, M.; Davidson, B. Virtual realitytraining for surgical trainees in laparoscopic surgery. Cochrane Database Syst. 2013, 1, 1465–1858. [Google Scholar]

- Jung, T.; Tom Dieck, M.; Lee, H.; Chung, N. Effects of virtual reality and augmented reality on visitor experiences in Museum. In Information and Communication Technologies in Tourism 2016: Proceedings of the International Conference, Bilbao, Spain, 2–5 February 2016; Inversini, A., Schegg, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 621–635. [Google Scholar]

- Düking, P.; Holmberg, H.-C.; Sperlich, B. The potential usefulness of virtual reality systemsfor athletes: A short SWOT analysis. Front. Physiol. 2018, 9, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Jalo, N.; Johansson, I.; Kanchiralla, F.; Thollander, P. Do Energy Efficiency Networks Help Reduce Bariers to Energy Efficiency?—A Case Study of a Regional Swedish Policy Program for Industrial SMEs. ScienceDirect. 2021. Available online: https://www.sciencedirect.com/science/article/pii/S136403212100856X (accessed on 20 May 2022).

- European Union. Article 8—Directives of Energy Efficiency of UE 2012/27 / UE (UE EED). December 2012. Available online: https://www.boe.es/doue/2012/315/L00001-00056.pdf (accessed on 23 June 2022).

- CIRCE. E2DRIVER. Training on Energy Audits as an Energy Efficiency Driver for the Automotive Sector. Deliverable 4.4. In ; pp. Methodology and Training Material Report. p. 39, 45. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- Buttussi, F.A.; Chittaro, L.B. A comparison of procedural safety training in three conditions: Virtual reality headset, smartphone, and printed materials. IEEE Trans. Learn. Technol. 2021, 14, 1–15. [Google Scholar] [CrossRef]

- Lovreglio, R.A.; Duan, X.; Rahouti, A.; Phipps, R.; Nilsson, D. Comparing the effectiveness of fire extinguisher virtual reality and video training. Virtual Real. 2021, 25, 133–145. [Google Scholar] [CrossRef]

- Lamberti, F.; De Lorenzis, F.; Pratticò, F.G.; Migliorini, M. An immersive virtual reality platform for training CBRN operators. Annu. Comput. Softw. Appl. Conf. (COMPSAC) 2021, 45, 133–137. [Google Scholar]

- Conges, A.; Evain, A.; Benaben, F.; Chabiron, O.; Rebiere, S. Crisis management exercises in virtual reality. In Proceedings of the IEEE Conference on Virtual Reality and 3D User Interfaces Abstracts and Workshops (VRW), Atlanta, GA, USA, 22 March 2020; pp. 87–92. [Google Scholar]

- De Lorenzis, F.; Pratticò, F.G.; Lamberti, F. HCP–VR: Training first responders through a virtual reality application for hydrogeological risk management. Int. Conf. Hum. Comput. Interact. Theory Appl. (HUCAPP) 2022, 6, 273–280. [Google Scholar]

- Pratticó, F.G.; Lamberti, F. Towards the adoption of virtual reality training systems for the self-tuition of industrial robot operators: A case study at KUKA. Comput. Ind. 2021, 129, 103446. [Google Scholar] [CrossRef]

- CIRCE. E2DRIVER. Training on energy audits as an Energy Efficiency Driver for the automotive sector. Deliverable 5.2. Best Practices Guideline and Recommendations for the Automotive Sector. Zaragoza, Spain. 2022, pp. 10–11. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- Javied, T.; Rackow, T.; Franke, J. Implementing energy management system to increase energy efficiency in manufacturing companies. Procedia CIRP 2015, 26, 156–161. [Google Scholar] [CrossRef] [Green Version]

- ISO. ISO 50001-2018: Energy Management Systems—Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2018; p. 47. [Google Scholar]

- POLITO. E2DRIVER. Training on Energy Audits as an Energy Efficiency Driver for the Automotive Sector. Deliverable 2.1. Benchmarking Baseline Report; Torino, Italy. 2021, pp. 12, 15. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- FRAUNHOFER. E2DRIVER. Training on Energy Audits as an Energy Efficiency Driver for the Automotive Sector. Deliverable 5.1. Overall Evaluation Report of E2DRIVER Capacity Building Programme. Freiburg, Germany. 2022, pp. 36–37. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- POLITO. E2DRIVER. Training on Energy Audits as an Energy Efficiency Driver for the Automotive Sector. Deliverable 2.1. Benchmarking Baseline Report. Torino, Italy. 2021, pp. 38–39. Available online: http://e2driver.eu/ (accessed on 5 May 2022).

- European Commission; Eurostat. Small and Medium-Sized Enterprises: An Overview; Eurostat Press Centre: Luxembourg, 2018; pp. 1–2. [Google Scholar]

| Impact | Value/Enterprise | Unit |

|---|---|---|

| Investment | 129,108 | EUR |

| Energy savings (final energy) | 697,540 | kWh |

| Electricity | 376,987 | kWh |

| Natural gas | 320,552 | kWh |

| Energy savings (primary energy) | 1123,147 | kWh |

| Energy costs avoided | 59,324 | EUR |

| Electricity costs avoided | 49,125 | EUR |

| Natural gas costs avoided | 10,199 | EUR |

| Greenhouse gas (GHG) avoided (EU electricity mix) | 127,310 | kgCO2 |

| GHG avoided due to electricity | 95,378 | kgCO2 |

| GHG avoided due to natural gas | 76,933 | kgCO2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Millán, G.; Rqiq, Y.; Llano, E.; Ballestín, V.; Neusel, L.; Durand, A.; Tröger, J.; Lamberti, F.; De Lorenzis, F.; Repetto, M. Energy Efficiency Engagement Training in SMEs: A Case Study in the Automotive Sector. Sustainability 2022, 14, 10504. https://doi.org/10.3390/su141710504

Millán G, Rqiq Y, Llano E, Ballestín V, Neusel L, Durand A, Tröger J, Lamberti F, De Lorenzis F, Repetto M. Energy Efficiency Engagement Training in SMEs: A Case Study in the Automotive Sector. Sustainability. 2022; 14(17):10504. https://doi.org/10.3390/su141710504

Chicago/Turabian StyleMillán, Gema, Yassine Rqiq, Erudino Llano, Víctor Ballestín, Lisa Neusel, Antoine Durand, Josephine Tröger, Fabrizio Lamberti, Federico De Lorenzis, and Maurizio Repetto. 2022. "Energy Efficiency Engagement Training in SMEs: A Case Study in the Automotive Sector" Sustainability 14, no. 17: 10504. https://doi.org/10.3390/su141710504

APA StyleMillán, G., Rqiq, Y., Llano, E., Ballestín, V., Neusel, L., Durand, A., Tröger, J., Lamberti, F., De Lorenzis, F., & Repetto, M. (2022). Energy Efficiency Engagement Training in SMEs: A Case Study in the Automotive Sector. Sustainability, 14(17), 10504. https://doi.org/10.3390/su141710504