Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

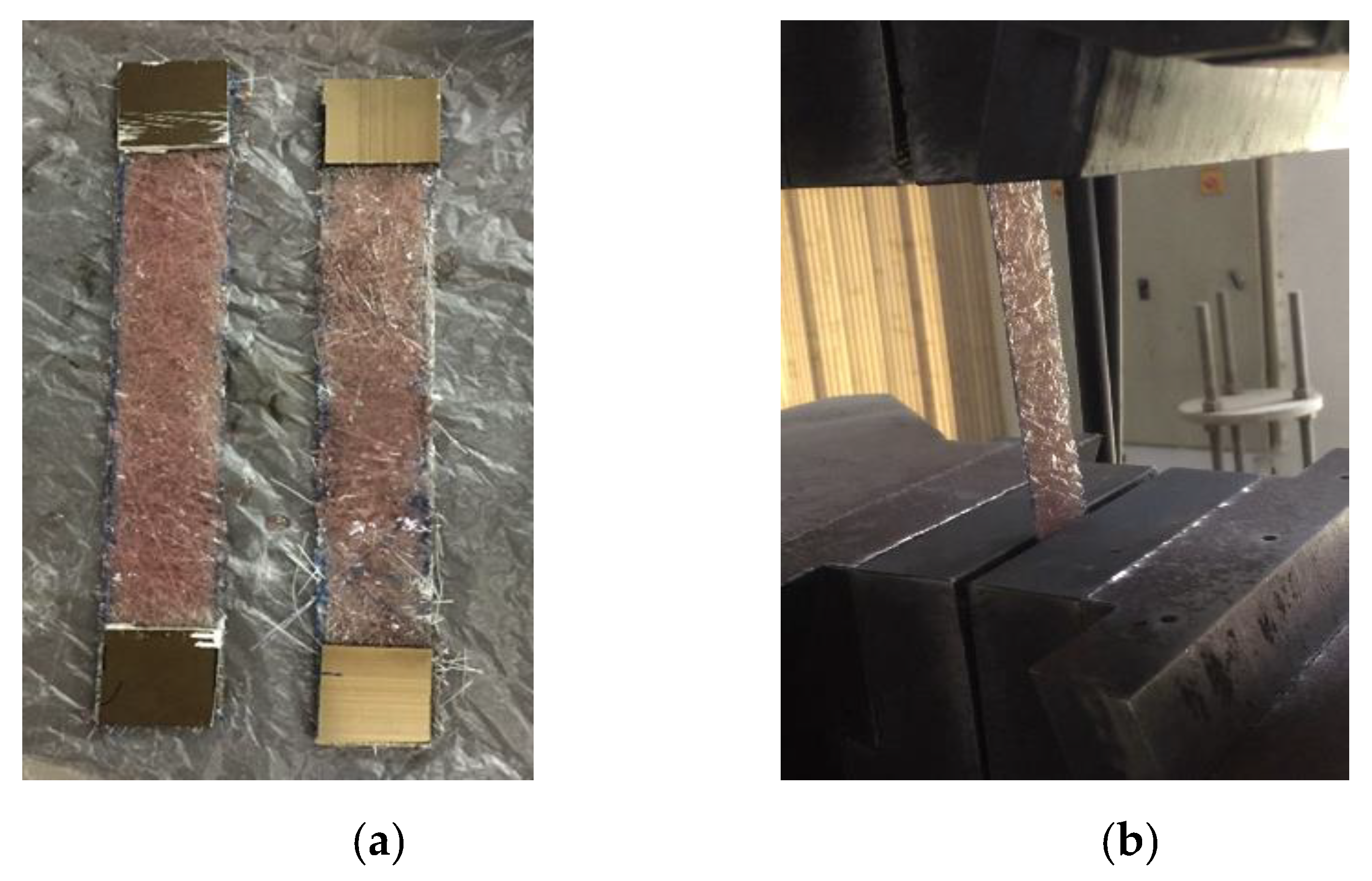

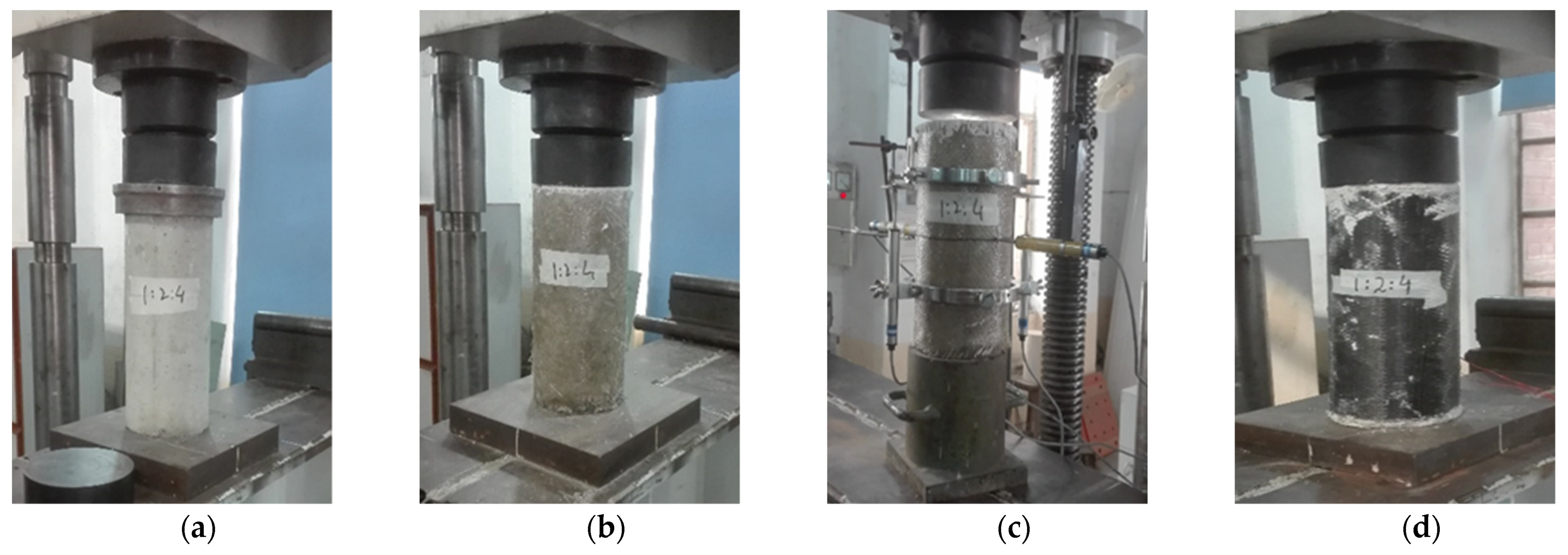

2.2. Specimen Preparation and Testing

3. Results

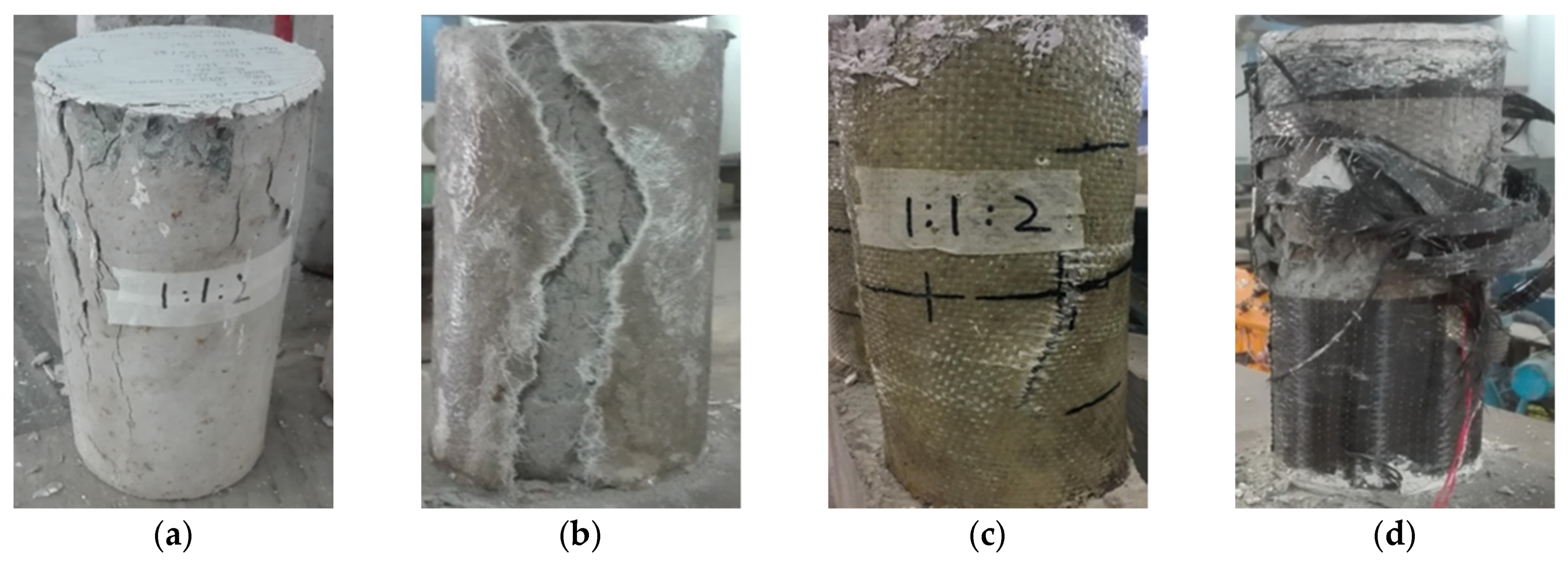

3.1. Observed Failure Pattern

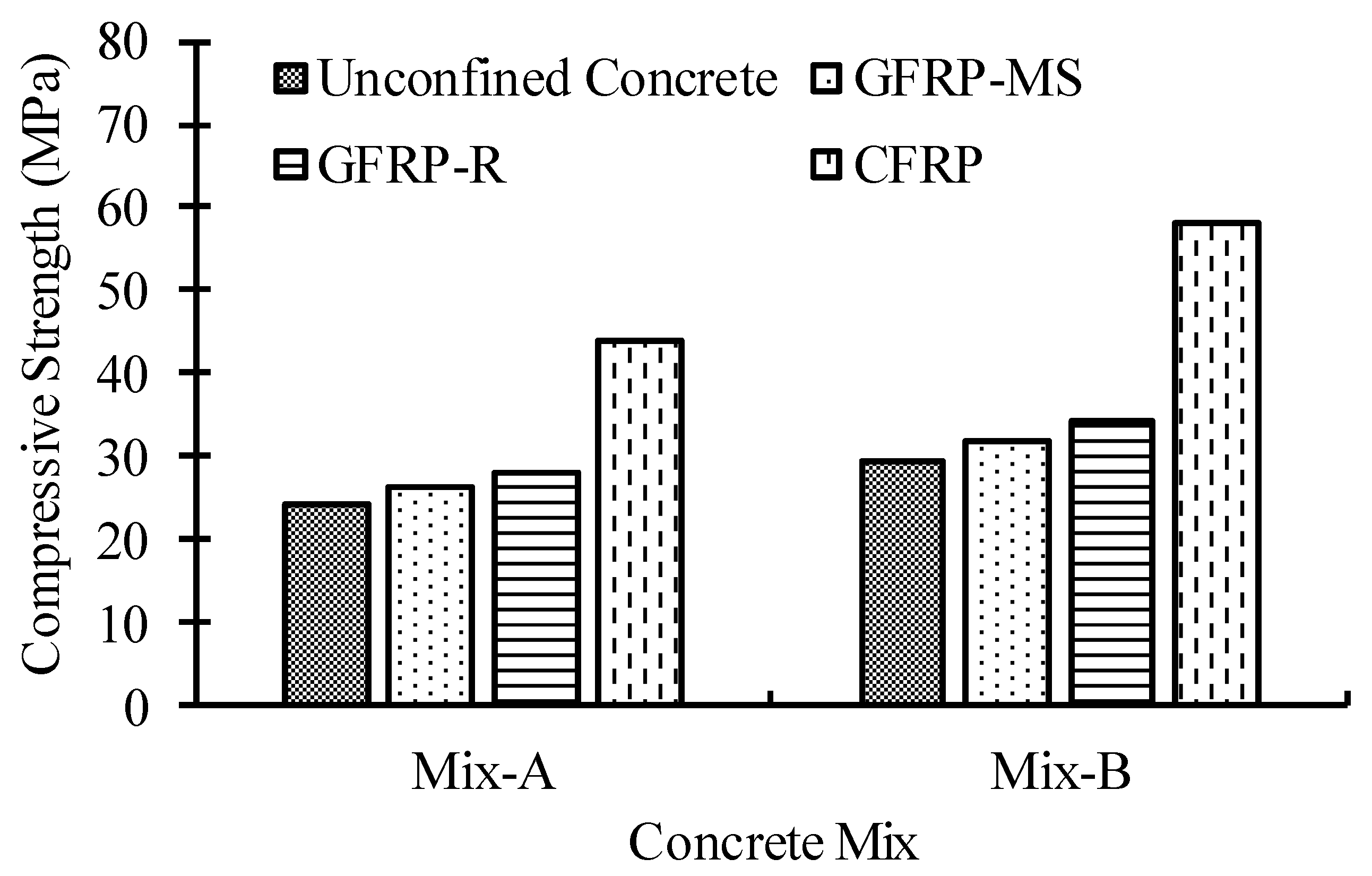

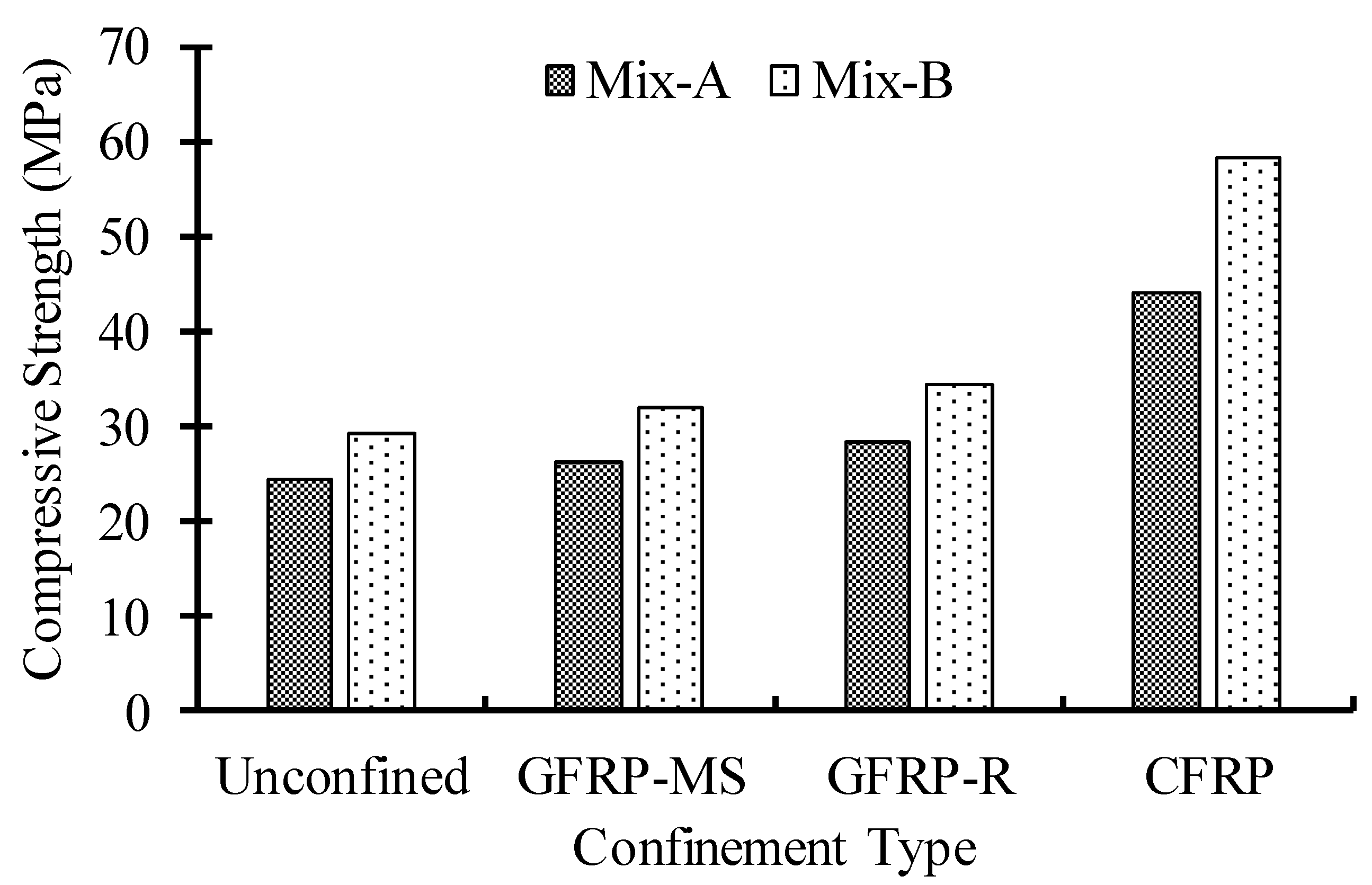

3.2. Experimental Results of Unconfined and FRP Confined Concrete Specimens

3.2.1. Influence of Type of FRP Wraps

3.2.2. Influence of Different Concrete Mix Proportions

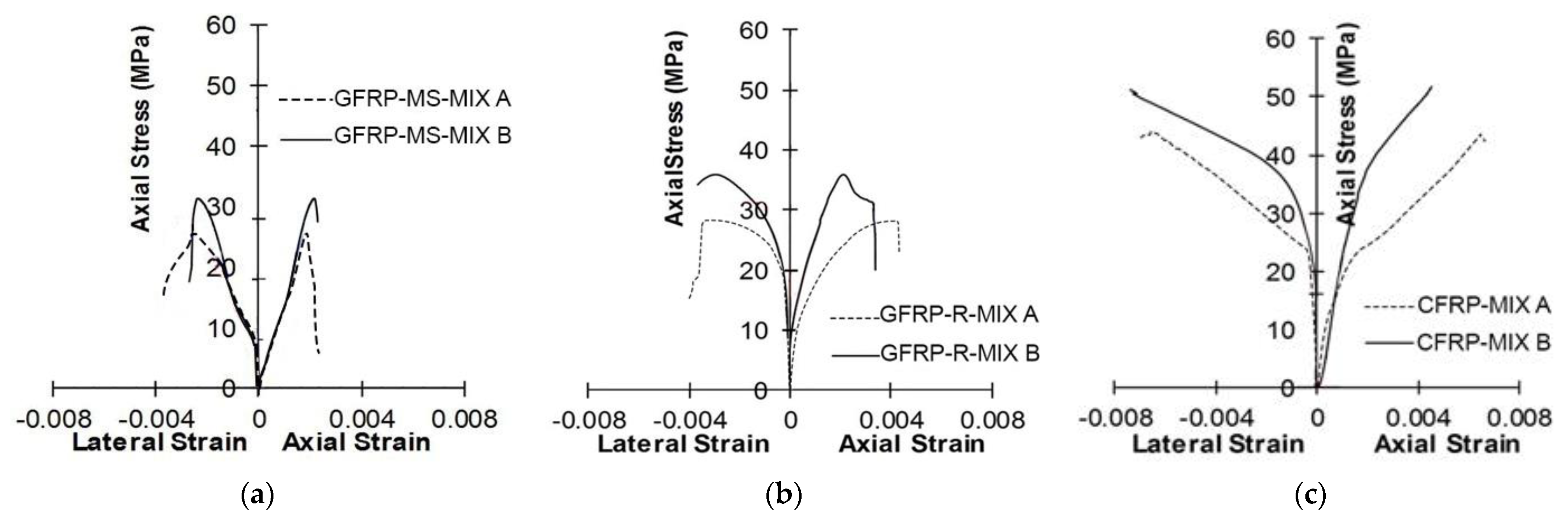

3.3. Axial Stress versus Strain Curves of FRP Confined Concrete

4. Analytical Approach

4.1. FRP Wrap Database

- The database was limited to the FRP wrapped specimens. The FRP tube specimens were excluded.

- The database comprises FRP confined concrete specimens with concrete compressive strengths between 17 and 55 MPa (normal strength concrete). High strength and ultra-high strength FRP confined concrete specimens were not considered in this database.

- The database comprises specimens with a height to diameter ratio of up to three. The specimens with a height to diameter greater than three were excluded from the database.

- The database included only specimens of circular cross-sections. Specimens of rectangular and square cross-sections were excluded from the database.

- The concrete specimens confined with the continuous FRP wrap were included. Specimens confined with intermittent FRP wraps were not considered in the database.

- Only externally FRP confined concrete specimens were included in the database. Specimens reinforced with longitudinal and transverse steel and FRP reinforcements were excluded from the database.

- The datasets from existing studies with incomplete material and physical properties were not included in the database.

4.2. Development of Strength Enhancement Coefficient

4.2.1. Comparison of Experimental and Computed FRP Confined Concrete Strength

4.2.2. Comparison of Experimental Confined Concrete Strengths with Existing Models

4.2.3. Cost-Effectiveness of GFRP-R and GFRP-MS

4.2.4. Environmental Assessment

5. Conclusions

- The single layer of CFRP confined concrete, GFRP-R confined concrete, and GFRP-MS confined concrete strengths were 1.76, 1.17, and 1.09 times higher, respectively, than the unconfined concrete strengths. The CFRP confined concrete specimens exhibited 1.51 times and 1.62 times higher confined concrete strength, respectively, than the GFRP-R confined concrete and GFRP-MS confined concrete specimens. The CFRP confined concrete specimens exhibited about 2.1 times higher confined concrete strain at the peak axial stress than GFRP-R and GFRP-MS confined concrete specimens. The GFRP-R confined concrete specimens exhibited 1.5 times higher confined concrete strain at peak axial stress than GFRP-MS confined concrete specimens.

- Mix-B having unconfined concrete strength of 24.3 MPa exhibited about 19.3% larger confined concrete strengths than Mix-A having unconfined concrete strength of 29.3 MPa. However, Mix B showed about 24% lower confined concrete strain at peak axial stress than Mix-A.

- Locally available low-cost two layers of GFRP-R wrap and four layers of GFRP-MS wrap can give similar confined concrete strength as a single layer of CFRP with 12 times and 6 times lower costs, respectively.

- A regression model based on FRP confined concrete database comprising experimental results of 140 specimens was proposed to predict the strength enhancement coefficient (). This study proposes of 3.20 for FRP confined concrete. The experimental and predicted CFRP confined concrete strengths matched well. However, the GFRP-R and GFRP-MS confined concrete strengths were underestimated by about 14.5% and 5%, respectively, by the proposed model.

- The GFRP-R confined concrete exhibited CI of 0.76 times CFRP confined concrete, 0.87 times of GFRP-MS confined concrete, and 1.43 times of unconfined concrete. Moreover, GFRP-R confined concrete exhibited CSI of 0.66 times CFRP confined concrete, 1.07 times of GFRP-MS confined concrete, and 1.17 times of unconfined concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hadi, M.N.S.; Khan, Q.S.; Sheikh, M.N. Axial and flexural behavior of circular concrete filled FRP tube (CFFT) columns with and without FRP reinforcing bars. Constr. Build. Mater. 2016, 122, 43–53. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Axial and flexural interactions of GFRP-CFFT columns with and without reinforcing GFRP bars. J. Compos. Constr. 2017, 21, 3. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Experimental results of circular FRP tube confined concrete (CFFT) and comparison with analytical models. J. Build. Eng. 2020, 29, 101157. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Axial compressive behavior of circular CFFT: Experimental database and design-oriented model. Steel Compos. Struct. Int. J. 2016, 21, 921–947. [Google Scholar] [CrossRef]

- Raza, S.; Khan, M.K.I.; Menegon, S.I.; Tsang, H.; Wilson, J.L. Strengthening and repair of reinforced concrete columns by jacketing: State of the Art. Sustainability 2019, 11, 3208. [Google Scholar] [CrossRef]

- Sánchez, M.; Faria, P.; Ferrara, L.; Horszczaruk, E.; Jonkers, H.M.; Kwiecień, A.; Mosa, J.; Peled, A.; Pereira, A.S.; Snoeck, D.; et al. External treatments for the preventive repair of existing constructions: A review. Constr. Build. Mater. 2018, 193, 435–452. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Algburi, A.H.M.; Neaz, M.S.; Carrigan, A.T. Axial and flexural behavior of circular reinforced concrete columns strengthened with reactive powder concrete jacket and fiber reinforced polymer wrapping. Constr. Build. Mater. 2018, 172, 717–727. [Google Scholar] [CrossRef]

- Yazici, V.; Hadi, M. Axial Load-Bending Moment Diagrams of carbon FRP wrapped hollow core reinforced concrete columns. J. Compos. Constr. 2009, 13, 262–268. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Tepfers, R. Comparative study of models on confinement of concrete cylinders with Fiber-Reinforced Polymer composites. J. Compos. Constr. 2003, 7, 219–237. [Google Scholar] [CrossRef]

- Pham, T.; Hadi, M. Stress prediction model for FRP confined rectangular concrete columns with rounded corners. J. Compos. Constr. 2014, 18, 04013019. [Google Scholar] [CrossRef]

- Attari, N.; Amziane, S.; Chemrouk, M. Flexural strengthening of concrete beams using CFRP, GFRP and hybrid FRP sheets. Constr. Build. Mater. 2012, 37, 746–757. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Concrete Filled Carbon FRP Tube (CFRP-CFFT) columns with and without CFRP reinforcing bars: Axial-flexural interactions. Compos. Part B Eng. 2018, 133, 42–52. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Experimental and analytical investigations of CFFT columns with and without FRP bars under concentric compression. Steel Compos. Struct. Int. J. 2019, 30, 591–601. [Google Scholar]

- Rizkalla, S.; Hasan, T.; Nahla, H. Design recommendations for the use of FRP for reinforcement and strengthening of concrete structures. Prog. Struct. Eng. Mater. 2003, 5, 16–28. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Predicting strength and strain enhancement ratios of circular fiber-reinforced polymer tube confined concrete under axial compression using artificial neural networks. Adv. Struct. Eng. 2019, 22, 1426–1443. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N.S. Tensile testing of carbon FRP (CFRP) and Glass FRP (GFRP) bars: An experimental study. ASTM J. Test. Eval. 2021, 49, 20180660. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C. Axial compressive behavior of FRP-confined concrete: Experimental test database and a new design-oriented model. Compos. Part B Eng. 2013, 55, 607–634. [Google Scholar] [CrossRef]

- Siddhwartha, M.; Andrew, H.; Amir, F. Influence of concrete strength on confinement effectiveness of fiber-reinforced polymer circular jackets. ACI Struct. J. 2005, 102, 383. [Google Scholar]

- Cui, C.; Sheikh, S.A. Experimental study of normal-and high-strength concrete confined with fiber-reinforced polymers. J. Compos. Constr. 2010, 14, 553–561. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Akin, E. Behavior of FRP-confined normal-and high-strength concrete under cyclic axial compression. J. Compos. Constr. 2011, 16, 451–463. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkaloglu, T. Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete. Constr. Build. Mater. 2013, 47, 814–826. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkloglu, T. Compressive behavior of prestressed high-strength concrete-filled Aramid FRP tube columns: Experimental observations. J. Compos. Constr. 2015, 19, 04015003. [Google Scholar] [CrossRef]

- Aire, C.; Gettu, R.; Casas, J.R.; Marques, S.; Marques, D. Estudio experimental y modelo teórico del hormigón confinado lateralmente con polímeros reforzados con fibras (FRP). Mater. Constr. 2010, 60, 19–31. [Google Scholar] [CrossRef]

- Chikh, N.; Gahmous, M.; Benzaid, R. Structural performance of high strength concrete columns confined with CFRP sheets. In Proceedings of the World Congress on Engineering, London, UK, 4–6 July 2012. [Google Scholar]

- Harajli, M.H. Axial stress—Strain relationship for FRP confined circular and rectangular concrete columns. Cem. Concr. Compos. 2006, 28, 938–948. [Google Scholar] [CrossRef]

- Pham, T.M.; Hadi, M.N.S. Confinement model for FRP confined normal- and high-strength concrete circular columns. Constr. Build. Mater. 2014, 69, 83–90. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress—Strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Berthet, J.F.; Ferrier, E.; Hamelin, P. Compressive behavior of concrete externally confined by composite jackets. Constr. Build. Mater. 2006, 20, 338–347. [Google Scholar] [CrossRef]

- Wu, G.; Lü, Z.T.; Wu, Z.S. Strength and ductility of concrete cylinders confined with FRP composites. Constr. Build. Mater. 2006, 20, 134–148. [Google Scholar] [CrossRef]

- Teng, J.G.; Jiang, T.; Lam, L.; Luo, Y.Z. Refinement of a design-oriented stress—Strain model for FRP-confined concrete. J. Compos. Constr. 2009, 13, 269–278. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, Y. Unified stress—Strain model of concrete for FRP-confined columns. Constr. Build. Mater. 2012, 26, 381–392. [Google Scholar] [CrossRef]

- Fardis, M.N.; Khalili, H.H. FRP-encased concrete as a structural material. Mag. Concr. Res. 1982, 34, 191–202. [Google Scholar] [CrossRef]

- Ahmad, S.M.; Khaloo, A.R.; Irshad, A. Behavior of concrete spirally confined by fiberglass filaments. Mag. Concr. Res. 1991, 43, 143–148. [Google Scholar] [CrossRef]

- Howie, I.; Karbhari, V.M. Effect of Tow sheet composite wrap architecture on strengthening of concrete due to confinement: I—Experimental Studies. J. Reinf. Plast. Compos. 1995, 14, 1008–1030. [Google Scholar] [CrossRef]

- Owen, L.M. Stress—Strain Behavior of Concrete Confined by Carbon Fiber Jacketing; University of Washington: Seattle, WA, USA, 1998. [Google Scholar]

- Matthys, S.; Toutanji, H.; Taerawe, L. Stress—Strain Behavior of Large-Scale Circular Columns Confined with FRP Composites. J. Struct. Eng. 2006, 132, 123–133. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Analysis-oriented stress—Strain models for FRP—Confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- ASTM C192/C192M-14 (ASTM 2014); Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2014.

- Imporient Chemicals. Imporient Chemicals Lahore, Pakistan. 2020. Available online: https://imporientgroup.com (accessed on 21 January 2022).

- ASTM D3039-17 (ASTM 2017); International Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C39-18 (ASTM 2018); International Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018.

- Richart, F.E.; Anton, B.; Lenoi, B.R. A study of the Failure of Concrete under Combined Compressive Stresses; University of Illinois: Champaign, IL, USA, 1928. [Google Scholar]

- Lea, G.; Elie, A.; George, S.; Helmi, K.; Mounir, M. Concrete columns wrapped with Hemp fiber reinforced polymer—An Experimental Study. Procedia Eng. 2017, 200, 440–447. [Google Scholar]

- Vincent, T.; Ozbakkaloglu, T. Influence of concrete strength and confinement method on axial compressive behavior of FRP confined high- and ultra high-strength concrete. Compos. Part B Eng. 2013, 50, 413–428. [Google Scholar] [CrossRef]

- Tara, S.; Ashim, P. Confining concrete with sisal and jute FRP as alternatives for CFRP and GFRP. Int. J. Sustain. Built Environ. 2015, 4, 248–264. [Google Scholar]

- Jalal, M.; Ramezanianpour, A.A. Strength enhancement modeling of concrete cylinders confined with CFRP composites using artificial neural networks. Compos. Part B Eng. 2012, 43, 2990–3000. [Google Scholar] [CrossRef]

- Akogbe, K.; Meng, L.; Zhi-Min, W. Size effect of axial compressive strength of CFRP confined concrete cylinders. Int. J. Concr. Struct. Mater. 2011, 5, 49–55. [Google Scholar] [CrossRef]

- Dai, J.; Yu-Lei, B.; Teng, J.G. Behavior and modeling of concrete confined with FRP composites of large deformability. J. Compos. Constr. 2011, 15, 963–973. [Google Scholar] [CrossRef]

- Eid, R.; Roy, N.; Paultre, P. Normal-and high-strength concrete circular elements wrapped with FRP composites. J. Compos. Constr. 2009, 13, 113–124. [Google Scholar] [CrossRef]

- Almusallam, T.H. Behavior of normal and high-strength concrete cylinders confined with E-glass/epoxy composite laminates. Compos. Part B Eng. 2007, 38, 629–639. [Google Scholar] [CrossRef]

- Valdmanis, V.; De Lorenzis, L.; Theodoros, R.; Tepfers, R. Behavior and capacity of CFRP-confined concrete cylinders subjected to monotonic and cyclic axial compressive load. Struct. Concr. Lond. Thomas Telford Ltd. 2007, 8, 187. [Google Scholar]

- Wu, Y.; Wang, L. Unified strength model for square and circular concrete columns confined by external jacket. J. Struct. Eng. 2009, 135, 253–261. [Google Scholar] [CrossRef]

- Picher, F. Confinement de Cylinders en Béton Par Des Composites Carbone-éPoxy Unidirectionnels. Master’s Thesis, University of Sherbrooke, Sherbrooke, QC, Canada, 1995. [Google Scholar]

- Tamuzs, V.; Tepfers, R.; Chi-Sang, Y.; Rousakis, T.; Repelis, I.; Skruls, V.; Vilks, U. Behavior of concrete cylinders confined by carbon-composite tapes and prestressed yarns 1. Experimental data. Mech. Compos. Mater. 2006, 42, 13–32. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G.; Cheung, C.H.; Xiao, Y. FRP-confined concrete under axial cyclic compression. Cem. Concr. Compos. 2006, 28, 949–958. [Google Scholar] [CrossRef]

- Campione, G. Influence of FRP wrapping techniques on the compressive behavior of concrete prisms. Cem. Concr. Compos. 2006, 28, 497–505. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Ultimate condition of fiber reinforced polymer-confined concrete. J. Compos. Constr. 2004, 8, 539–548. [Google Scholar] [CrossRef]

- Theriault, M.; Neale, K.W.; Claude, S. Fiber-reinforced polymer-confined circular concrete columns: Investigation of size and slenderness effects. J. Compos. Constr. 2004, 8, 323–331. [Google Scholar] [CrossRef]

- Harries, K.A.; Carey, S.A. Shape and “gap” effects on the behavior of variably confined concrete. Cem. Concr. Res. 2003, 33, 881–890. [Google Scholar] [CrossRef]

- Ibrahim, S.A.E.M.; Luiz, C.A.V.; Lidia, S.C.D. Strength of short concrete columns confined with CFRP sheets. Mater. Struct. 2002, 35, 50–58. [Google Scholar]

- Rousakis, T.; Tepfers, R. Experimental investigation of concrete cylinders confined by carbon FRP sheets, under monotonic and cyclic axial compressive load. Res. Rep. 2001, 1–10. [Google Scholar]

- Shahawy, M.; Mirmiran, A.; Beitelman, T. Tests and modeling of carbon-wrapped concrete columns. Compos. Part B Eng. 2000, 31, 471–480. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Compressive behavior of concrete confined by carbon fiber composite jackets. J. Mater. Civ. Eng. 2000, 12, 139–146. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Gao, Y. Composite jacketed concrete under uniaxial compression—Verification of simple design equations. J. Mater. Civ. Eng. 1997, 9, 185–193. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y. Unified strength model based on Hoek-Brown failure criterion for circular and square concrete columns confined by FRP. J. Compos. Constr. 2010, 14, 175–184. [Google Scholar] [CrossRef]

- Pour, A.F.; Ozbakkaloglu, T.; Vincent, T. Simplified design-oriented axial stress-strain model for FRP-confined normal- and high-strength concrete. Eng. Struct. 2018, 175, 501–516. [Google Scholar] [CrossRef]

- Park, S.; Wu, S.; Lu, Z.; Pyo, S. The role of supplementary cementitious materials (SCMs) in ultra-high performance concrete (UHPC): A review. Materials 2021, 14, 1472. [Google Scholar] [CrossRef] [PubMed]

- Mara, V.; Hoghani, R.; Harryson, P. Bridge decks of fiber reinforced polymer (FRP): A sustainable solution. Constr. Build. Mater. 2014, 50, 190–199. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y. Axial strength of eccentrically loaded FRP confined short concrete columns. Polymers 2020, 12, 1261. [Google Scholar] [CrossRef]

| FRP Type | Modulus of Elasticity (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Thickness (mm) |

|---|---|---|---|---|

| GFRP-MS | 2480 | 134 | 5.4 | 1.90 |

| GFRP-R | 5520 | 276 | 5.0 | 1.75 |

| CFRP | 54,000 | 810 | 1.5 | 1.40 |

| Mix/ Concrete Mix Proportion | No. of Specimens | |||

|---|---|---|---|---|

| Control Specimen (Unconfined) | GFRP-MS Confined | GFRP-R Confined | CFRP Confined | |

| A | 2 | 2 | 2 | 2 |

| B | 2 | 2 | 2 | 2 |

| Mix ID. | Unconfined Concrete Strength (MPa) | GFRP-MS Confined Concrete Strength (MPa) | Strength Enhancement Ratio | GFRP-R Confined Concrete Strength (MPa) | Strength Enhancement Ratio | CFRP Confined Concrete Strength (MPa) | Strength Enhancement Ratio |

|---|---|---|---|---|---|---|---|

| Mix A | 24.3 | 26.3 | 1.08 | 28.2 | 1.16 | 44.1 | 1.81 |

| Mix B | 29.3 | 32.0 | 1.09 | 34.4 | 1.17 | 50.2 | 1.71 |

| Mix ID | Confinement Type | Peak Confined Concrete Stress (MPa) | Axial Strain at Peak Axial Stress (%) | Lateral Strain at Peak Axial Stress (%) |

|---|---|---|---|---|

| Mix A | GFRP-MS | 26.3 | 0.19 | 0.23 |

| Mix B | 32.0 | 0.21 | 0.25 | |

| Mix A | GFRP-R | 28.2 | 0.43 | 0.33 |

| Mix B | 34.4 | 0.19 | 0.29 | |

| Mix A | CFRP | 44.1 | 0.61 | 0.64 |

| Mix B | 50.2 | 0.45 | 0.71 |

| References | (mm) | (mm) | (MPa) | k1 | |

|---|---|---|---|---|---|

| Lea et al. [43] | 200 | 400 | 18.91 | 1.09 | 2.3 |

| Vincent and Ozbakkaloglu [44] | 152 | 305 | 44.8 | 1.61–1.67 | 2.05 |

| Tara and Ashim [45] | 103 | 200 | 20 | 0.67–1.08 | 2.3 |

| Vincent and Ozbakkaloglu [22] | 152 | 305 | 35.5 | 1.24 | 2.06 |

| Ozbakkaloglu and Lim [17] | 100 | 200 | 49.4 | 1.23 | 2.15 |

| Jalal and Ramezanianpour [46] | 132 | 294 | 17.4–39.7 | 1.8–1.95 | 2.1–2.3 |

| Akogbe et al. [47] | 100 | 200 | 25.2–28.1 | 2.36–2.55 | 2.21–2.25 |

| Dai et al. [48] | 152 | 305 | 32.5–39.2 | 1.19–1.6 | 2.17–4.19 |

| Aire et al. [23] | 150 | 300 | 42 | 0.97–1.1 | 2.05 |

| Cui and Sheikh [19] | 150 | 300 | 45.7–48.1 | 1.23–1.8 | 1.5–3.58 |

| Eid et al. [49] | 152 | 300 | 32.1–48 | 1.04–1.09 | 3.6–3.9 |

| Almusallam [50] | 150 | 300 | 47.7–50.8 | 1.0–1.18 | 2.66–2.99 |

| Valdmanis et al. [51] | 150 | 300 | 20–40 | 1.64–2.4 | 3.54–3.93 |

| Wu and Wang [52] | 150 | 300 | 31.2–32.3 | 1.01–1.4 | 3.7–3.8 |

| Jiang and Teng [37] | 152 | 305 | 44.2–45.9 | 1.0–1.4 | 3.01–3.03 |

| Picher F. [53] | 152 | 305 | 39.7 | 1.41 | 2.3 |

| Tamuzs et al. [54] | 150 | 300 | 20.5–51.8 | 1.2–1.4 | 3.44–3.93 |

| Lam et al. [55] | 152 | 305 | 41.1 | 1.27 | 3.3 |

| Campione G. [56] | 100 | 200 | 20 | 2.47 | 4.08 |

| Matthys et al. [36] | 150 | 300 | 34.9 | 1.3 | 2.32 |

| Lam and Teng [57] | 152 | 305 | 35.9 | 1.4 | 3.3 |

| Theriault et al. [58] | 51 | 102 | 37 | 1.7–1.89 | 3.77 |

| Harries and Carey [59] | 152 | 305 | 32.1 | 1.03–1.15 | 3.45–3.90 |

| Ibrahim et al. [60] | 150 | 300 | 25.6–29.8 | 1.7–1.9 | 4.12 |

| Rousakis and Tepfers [61] | 152 | 305 | 25.8-49.1 | 1.49–1.61 | 4.09 |

| Shahawy et al. [62] | 152.5 | 305 | 19.4-49 | 1.21–1.74 | 3.6–4.02 |

| Xiao and Wu [63] | 152 | 305 | 33.7-55 | 1.05–1.45 | 4.13 |

| Owen L. [35] | 152 | 305 | 47.5 | 1.37 | 2.66 |

| Owen L. [35] | 102 | 203 | 53 | 1.33 | 2.8 |

| Karbhari and Gao [64] | 152 | 305 | 38.38 | 1.16 | 2.33 |

| Howie and Karbhari [34] | 152.4 | 304.8 | 42.49 | 1.05 | 2.38 |

| References | (mm) | (mm) | k1 | ||

|---|---|---|---|---|---|

| Lea et al. [43] | 200 | 400 | 18.91 | 1.09 | 2.31 |

| 200 | 400 | 18.91 | 1.09 | 2.31 | |

| 200 | 400 | 18.91 | 1.09 | 2.31 | |

| Tara and Ashim [45] | 103 | 200 | 20 | 1.08 | 2.3 |

| 103 | 200 | 20 | 0.93 | 2.3 | |

| 103 | 200 | 20 | 0.87 | 2.3 | |

| 103 | 200 | 20 | 0.67 | 2.3 | |

| Ozbakkaloglu and Lim [17] | 152 | 305 | 35.5 | 1.24 | 2.15 |

| 152 | 305 | 35.5 | 1.24 | 2.15 | |

| 152 | 305 | 35.5 | 1.21 | 2.15 | |

| Vincent and Ozbakkaloglu [22,44] | 152 | 305 | 44.8 | 1.61 | 2.05 |

| 152 | 305 | 44.8 | 1.67 | 2.05 | |

| 100 | 200 | 49.4 | 2.21 | 2.06 | |

| 100 | 200 | 49.4 | 2.09 | 2.06 | |

| 100 | 200 | 49.4 | 2.13 | 2.06 | |

| 100 | 200 | 49.4 | 2.18 | 2.06 | |

| 100 | 200 | 49.4 | 2.10 | 2.06 | |

| 100 | 200 | 49.4 | 2.23 | 2.06 | |

| Jalal and Ramezanianpour [46] | 132 | 294 | 39.68 | 1.95 | 2.1 |

| 132 | 294 | 17.39 | 1.80 | 2.3 | |

| Akogbe et al. [47] | 100 | 200 | 25.2 | 2.55 | 2.25 |

| 100 | 200 | 25.9 | 2.43 | 2.25 | |

| 100 | 200 | 28.1 | 2.36 | 2.21 | |

| 100 | 200 | 26.8 | 2.42 | 2.23 | |

| Dai et al. [48] | 152 | 305 | 39.2 | 1.57 | 4.19 |

| 152 | 305 | 39.2 | 1.60 | 4.19 | |

| 152 | 305 | 39.2 | 1.42 | 4.19 | |

| 152 | 305 | 39.2 | 1.40 | 4.19 | |

| 152 | 305 | 39.2 | 1.34 | 4.19 | |

| 152 | 305 | 39.2 | 1.29 | 4.19 | |

| 152 | 305 | 39.2 | 1.20 | 4.19 | |

| 152 | 305 | 39.2 | 1.36 | 4.19 | |

| 152 | 305 | 39.2 | 1.11 | 2.17 | |

| 152 | 305 | 32.5 | 1.28 | 2.17 | |

| 152 | 305 | 32.5 | 1.28 | 2.17 | |

| 152 | 305 | 32.5 | 1.30 | 2.17 | |

| Aire et al. [23] | 150 | 300 | 42 | 0.98 | 2.05 |

| 150 | 300 | 42 | 1.10 | 2.05 | |

| 150 | 300 | 42 | 0.98 | 2.05 | |

| Cui and Sheikh [19] | 150 | 300 | 48.1 | 1.68 | 2.95 |

| 150 | 300 | 48.1 | 1.80 | 3.46 | |

| 150 | 300 | 48.1 | 1.75 | 3.25 | |

| 150 | 300 | 48.1 | 1.83 | 3.58 | |

| 150 | 300 | 47.76 | 1.24 | 1.5 | |

| 150 | 300 | 47.76 | 1.25 | 1.59 | |

| 150 | 300 | 47.76 | 1.33 | 2.69 | |

| 150 | 300 | 47.76 | 1.31 | 2.03 | |

| 150 | 300 | 45.6 | 1.27 | 2.28 | |

| 150 | 300 | 45.6 | 1.21 | 1.85 | |

| 150 | 300 | 45.6 | 1.23 | 2.02 | |

| 150 | 300 | 45.6 | 1.29 | 2.48 | |

| 150 | 300 | 45.7 | 1.48 | 3.07 | |

| 150 | 300 | 45.7 | 1.40 | 2.59 | |

| 150 | 300 | 45.7 | 1.44 | 2.84 | |

| 150 | 300 | 45.7 | 1.44 | 2.85 | |

| Eid et al. [49] | 152 | 300 | 32.1 | 1.10 | 3.69 |

| 152 | 300 | 32.1 | 1.10 | 3.69 | |

| 152 | 300 | 32.1 | 1.10 | 3.69 | |

| 152 | 300 | 48 | 1.04 | 3.92 | |

| 152 | 300 | 48 | 1.04 | 3.92 | |

| 152 | 300 | 48 | 1.04 | 3.92 | |

| Almusallam [50] | 150 | 300 | 47.7 | 1.19 | 2.66 |

| 150 | 300 | 47.7 | 1.19 | 2.66 | |

| 150 | 300 | 47.7 | 1.19 | 2.66 | |

| 150 | 300 | 50.8 | 1.09 | 2.99 | |

| 150 | 300 | 50.8 | 1.09 | 2.99 | |

| 150 | 300 | 50.8 | 1.09 | 2.99 | |

| Valdmanis et al. [51] | 150 | 300 | 20 | 2.06 | 3.54 |

| 150 | 300 | 20 | 2.43 | 3.54 | |

| 150 | 300 | 40 | 1.65 | 3.93 | |

| 150 | 300 | 40 | 1.64 | 3.93 | |

| Wu and Wang [52] | 150 | 300 | 31.4 | 1.02 | 3.79 |

| 150 | 300 | 31.2 | 1.03 | 3.79 | |

| 150 | 300 | 32.3 | 1.01 | 3.81 | |

| 150 | 300 | 31.7 | 1.02 | 3.8 | |

| Jiang and Teng [37] | 152 | 305 | 45.9 | 1.05 | 3.03 |

| 152 | 305 | 45.9 | 1.00 | 3.03 | |

| 152 | 305 | 45.9 | 1.20 | 3.03 | |

| 152 | 305 | 44.2 | 1.09 | 3.01 | |

| 152 | 305 | 44.2 | 1.42 | 3.01 | |

| Picher F. [53] | 152 | 305 | 39.7 | 1.41 | 2.3 |

| 152 | 305 | 39.7 | 1.40 | 2.3 | |

| 152 | 305 | 39.7 | 1.41 | 2.3 | |

| Tamuzs et al. [54] | 150 | 300 | 25.2 | 1.40 | 3.55 |

| 150 | 300 | 47.4 | 1.37 | 3.9 | |

| 150 | 300 | 51.8 | 1.20 | 3.95 | |

| 150 | 300 | 20.5 | 1.40 | 3.44 | |

| 150 | 300 | 40.7 | 1.35 | 3.81 | |

| 150 | 300 | 44.3 | 1.28 | 3.86 | |

| 150 | 300 | 49.7 | 1.40 | 3.93 | |

| Lam et al. [55] | 152 | 305 | 41.1 | 1.28 | 3.3 |

| 152 | 305 | 41.1 | 1.28 | 3.3 | |

| 152 | 305 | 41.1 | 1.28 | 3.3 | |

| Campione G. [56] | 100 | 200 | 20.05 | 2.47 | 4.08 |

| 100 | 200 | 20.00 | 2.45 | 4.08 | |

| 100 | 200 | 20.05 | 2.47 | 4.08 | |

| Matthys et al. [36] | 150 | 300 | 34.9 | 1.32 | 2.32 |

| 150 | 300 | 34.9 | 1.31 | 2.32 | |

| 150 | 300 | 34.9 | 1.31 | 2.32 | |

| Lam and Teng [57] | 152 | 305 | 35.9 | 1.40 | 3.3 |

| 152 | 305 | 35.9 | 1.40 | 3.3 | |

| 152 | 305 | 35.9 | 1.40 | 3.3 | |

| Theriault et al. [58] | 51 | 102 | 37 | 1.89 | 3.77 |

| 51 | 102 | 37 | 1.89 | 3.77 | |

| 51 | 102 | 37 | 1.89 | 3.77 | |

| 51 | 102 | 37 | 1.73 | 3.77 | |

| 51 | 102 | 37 | 1.73 | 3.77 | |

| 51 | 102 | 37 | 1.73 | 3.77 | |

| Harries and Carey [59] | 152 | 305 | 32.1 | 1.03 | 3.45 |

| 152 | 305 | 32.1 | 1.15 | 3.9 | |

| 152 | 305 | 32.1 | 1.10 | 3.7 | |

| Ibrahim et al. [60] | 150 | 300 | 25.6 | 1.71 | 4.12 |

| 150 | 300 | 29.8 | 1.91 | 4.12 | |

| 150 | 300 | 29.0 | 1.80 | 4.12 | |

| Rousakis and Tepfer [61] | 152 | 305 | 25.8 | 1.61 | 4.09 |

| 152 | 305 | 25.8 | 1.50 | 4.09 | |

| 152 | 305 | 49.1 | 1.60 | 4.09 | |

| 152 | 305 | 48.8 | 1.49 | 4.09 | |

| Shahawy et al. [62] | 152.5 | 305 | 19.4 | 1.74 | 3.6 |

| 152.5 | 305 | 19.4 | 1.74 | 3.6 | |

| 152.5 | 305 | 19.4 | 1.74 | 3.6 | |

| 152.5 | 305 | 19.4 | 1.74 | 3.6 | |

| 152.5 | 305 | 19.4 | 1.74 | 3.6 | |

| 152.5 | 305 | 49 | 1.21 | 4.02 | |

| 152.5 | 305 | 49 | 1.21 | 4.02 | |

| 152.5 | 305 | 49 | 1.21 | 4.02 | |

| 152.5 | 305 | 49 | 1.21 | 4.02 | |

| 152.5 | 305 | 49 | 1.21 | 4.02 | |

| Xiao and Wu [63] | 152 | 305 | 33.7 | 1.05 | 4.13 |

| 152 | 305 | 33.7 | 1.05 | 4.13 | |

| 152 | 305 | 33.7 | 1.05 | 4.13 | |

| 152 | 305 | 55.2 | 2.83 | 4.13 | |

| 152 | 305 | 55.2 | 2.83 | 4.13 | |

| 152 | 305 | 55.2 | 2.83 | 4.13 | |

| 152 | 305 | 33.7 | 1.45 | 4.13 | |

| 152 | 305 | 33.7 | 1.45 | 4.13 | |

| 152 | 305 | 33.7 | 1.45 | 4.13 | |

| 152 | 305 | 43.8 | 1.10 | 4.13 | |

| 152 | 305 | 43.8 | 1.10 | 4.13 | |

| 152 | 305 | 43.8 | 1.10 | 4.13 | |

| Owen L. [35] | 152 | 305 | 47.5 | 1.38 | 2.66 |

| 102 | 203 | 53 | 1.33 | 2.8 | |

| Karbari and Gao [64] | 152 | 305 | 38.38 | 1.17 | 2.33 |

| Howie and Karbhari [34] | 152.4 | 304.8 | 42.49 | 1.06 | 2.38 |

| Confinement Type | Concrete Mix ID | Percentage Differences between Experimental and Analytical Compressive Strength of FRP-Confined Concrete (%) | |||

|---|---|---|---|---|---|

| Lam and Teng [27] | Wu and Zhou [65] | Pham and Hadi [26] | Pour et al. [66] | ||

| CFRP | Mix A | −3 | 16 | 6 | 12 |

| Mix B | −1 | 16 | 10 | 13 | |

| GFRP-MS | Mix A | 1 | 1 | −14 | 2 |

| Mix B | 9 | 8 | −4 | 9 | |

| GFRP-R | Mix A | 11 | 12 | −9 | 12 |

| Mix B | 17 | 17 | 5 | 14 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qazi, A.U.; Khan, Q.S.; Ahmad, H.A.; Pham, T.M. Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps. Sustainability 2022, 14, 9989. https://doi.org/10.3390/su14169989

Qazi AU, Khan QS, Ahmad HA, Pham TM. Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps. Sustainability. 2022; 14(16):9989. https://doi.org/10.3390/su14169989

Chicago/Turabian StyleQazi, Asad U., Qasim S. Khan, H. Abrar Ahmad, and Thong M. Pham. 2022. "Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps" Sustainability 14, no. 16: 9989. https://doi.org/10.3390/su14169989

APA StyleQazi, A. U., Khan, Q. S., Ahmad, H. A., & Pham, T. M. (2022). Axial Behavior of FRP Confined Concrete Using Locally Available Low-Cost Wraps. Sustainability, 14(16), 9989. https://doi.org/10.3390/su14169989