Abstract

The traditional production system is mainly concerned with economic growth. However, with growing pollution and the rapid depletion of natural resources, there is an urgent need to adopt environmentally conscious manufacturing (ECM) to prioritize the environment alongside society and business. Therefore, it is crucial to identify the barriers that prevent the sustainable implementation of ECM to overcome them better. This research uses interpretive structural modeling to identify and comprehend the contextual interrelationships between barriers to ECM. The identified barriers are categorized and modeled based on their interdependence and driving powers. The findings show that management’s lack of understanding of ECM is an essential barrier that leads to a communication gap. Both lead to barriers, such as a less qualified workforce, high taxation, poor policy framing and implementation, poor financial support, and lack of technological upgrades. Thereby, this leads to the poor adoption of remanufacturing, higher costs of sustainable products, and in turn, overconsumption of natural resources. Overcoming these barriers will improve the poor acceptance of ECM, the inadequate legislative framework, and the lack of its implementation. The resulting model provides a deeper understanding of the barriers and enables the better design of coping strategies toward a more sustainable implementation of ECM to its fullest potential.

1. Introduction

Today’s society has shorter product life cycles and a higher rate of product waste due to the exponential growth of technological innovation, in which manufacturers strive for economic growth, and consumers often desire to purchase newer product versions for many reasons. Examples of such products are new releases of electronics, gadgets, and equipment, to mention a few. Consequently, landfills and the Earth’s natural resources are approaching a tipping point, which is the case in developing countries, where technology manufacturers usually base their manufacturing facilities. In response to such an unsustainable practice, when a technological product reaches the end of its useful life or is simply outdated, manufacturing firms repossess the products they previously produced to comply with imposed regulations and increase customer awareness of the consequent environmental issues. Therefore, tech product manufacturers usually build “end-of-life” (EOL) facilities for product recovery to reduce the waste going to landfills.

Disassembly is the most critical activity in product recovery because it permits extracting valuable components, subassemblies, and materials from EOL products. The disassembly of EOL products may be achieved in several ways. The disassembly could be accomplished at a single workstation, cell, or disassembly line. Even though single workstations and disassembly cells are more adaptable, the disassembly line is the most productive and yields the most output [1,2]. Product disassembly is the primary step in remanufacturing, recycling, refurbishing, and disposing of outdated components. Disassembly is the reduction in non-destructive, semi-destructive, or destructive impacts on a system’s physical components. The rationale for disassembling these EOL products is to assist the recovery process in achieving its primary objective of lowering the use of natural resources. However, uncertainty over the quality of the recovered product’s components is the primary challenge to its recovery. This issue is due to failing to determine the condition of the parts before disassembly. After disassembly, testing each component is the logical next step. However, product disassembly harms the profit margins of remanufacturers. Thus, when figuring out whether or not to start the process of EOL product recovery, the cost of doing the relevant and necessary testing of the product as a whole and the amount of time it takes to do so are two key decision factors. Thus, the concept of environmentally conscious manufacturing (ECM) has emerged to help the manufacturing industry prioritize the environment alongside business and society beyond economic growth. However, due to the issues above, manufacturers encounter barriers to ECM adoption and implementation.

Therefore, it is crucial to identify the barriers that prevent the adoption and implementation of ECM to its fullest extent through a deeper understanding of the network of interrelationships between them. This research study uses interpretive structural modeling (ISM) to discover and comprehend the interrelationships between barriers to ECM. Based on their interdependence and driving powers, the identified barriers will be categorized into an interpretative network, providing a deeper understanding of the barriers and enabling the design of better targeted coping strategies. This is through prioritizing the barriers to practically overcome them and moving towards the successful and sustainable implementation of ECM. Following this is an overview of the ECM literature and the materials and methods used to achieve the study’s objective.

2. Literature Review

The present study focuses on identifying challenges to successful and sustainable ECM implementation and modeling contextual interrelationships between them using interpretive structural modeling (ISM). Next is an overview of the relevant literature on ECM and product recovery, barriers to its implementation, and the use of ISM to model contextual interrelationships among them.

2.1. Environmentally Conscious Manufacturing and Product Recovery (ECMPRO)

In recent years, numerous research studies have been conducted on environmentally conscious manufacturing and product recovery (ECMPRO) due to emerging challenges of its implementation [3,4,5,6]. Environmental concerns, public demand, and government regulation all play a role in signifying the importance of ECMPRO for the consumer and society. Commercial activities in ECMPRO have grown significantly because of the potential for considerable earnings from reverse logistics and the determination of companies to promote product recycling [7,8]. In light of environmental concerns, manufacturers have implemented stronger ecological regulations and created facilities to recycle materials and components from obsolete goods [1,9].

When prioritizing practices responsible for the environment, researchers have focused on the logistical issues encountered during manufacturing products. As a direct consequence, researchers have reported overviews of the many challenges that ECMPRO presents [10,11,12,13,14]. ECMPRO has been the focus of the remanufacturing research discourse due to its vital role in the recovery process. Therefore, several researchers have provided in-depth analyses of the different components that make up the disassembly process [15,16,17].

A recent study explored the ECM innovation challenges encountered by manufacturing enterprises in Pakistan. They found that environmental innovation is hindered due to a lack of organizational resources and willingness to change, corporate traditions, and technological challenges [18]. This is the case when environmentally friendly manufacturing technologies and techniques are out of reach for many businesses, mainly small- and medium-sized enterprises (SMEs). Therefore, in a recent study, an integrated methodology for estimating the challenges encountered by SMEs was developed [19]. They used a hybrid multi-criteria decision-making (MCDM) framework in a fuzzy setting to rank and examine the interrelationships of the identified barriers. Further, another research study was conducted on facilities in nine developing countries and different industrial subsectors to reveal factors impacting the use of environmentally friendly technologies [20].

Exploring what enables a sustainable ECM was also the focus of many researchers. For instance, the enablers of an ECM strategy in a manufacturing company were investigated to assess the practicability and effectiveness of a recommended approach [21]. It was found that other facilitators of an ECM strategy, such as “environmental protection equipment” and “environmental design technology,” could affect the “corporate social responsibility motivation,” which has been acknowledged as an essential facilitator for the example company in adopting an ECM strategy [21]. Another study examined success criteria for sustainable supply chain management (SSCM) and found the most critical success criteria for SSCM deployment are financial gains and supplier environmental consciousness [22]. Additionally, another study identified the most important success criteria for sustainable supply chain management strategies in the oil and gas industry [23].

Other studies investigated barriers to ECM. For instance, thirty-nine barriers to sustainable manufacturing were identified using the best worst method (BWM) in one of India’s manufacturing firms [24]. Moreover, another comparative study reported drivers and barriers to ECM in Indian and German firms and emerging economies to help companies strategically focus their efforts on reaching greater competitiveness [25]. Furthermore, barriers to ECM were explored using structural equation modeling (SEM), which revealed that they could be classified as internal, policy, economic, and social barriers [26]. Additionally, in another study, a model was built using the fuzzy TOPSIS technique for ranking ECM barriers, and it was indicated that government and industry leaders who must deal with these issues could benefit from ranking the barriers from various perspectives [27].

2.2. Interpretive Structural Modeling (ISM) and Barriers to Environmentally Conscious Manufacturing (ECM)

ISM could be used to find and explain correlations between specific components that define a problem, rank the variables according to their relevance, and provide inferences and, in turn, knowledge to address the issue in various ways. For the analysis of raw data and uncertain settings, researchers in multiple topics have used ISM. ISM facilitates system representations that are vague or poorly articulated cognitively to be transformed and synthesized into observable and well-defined models. Such models could be used in various ways [28]. Thus, some studies used ISM to investigate the barriers to ECM.

A study used ISM to evaluate ECM challenges and identified eleven barriers as dependent, driving, and linking variables [29]. Another study also used ISM to model the links between the barriers that prevent the implementation of green supply chain management (GSCM) in the Indian automotive sector [30]. Furthermore, a study of the hierarchy of barriers to ECM adoption also examined the interaction of barriers [31]. They indicated that policymakers in government and business could better understand the interconnectedness of ECM challenges. They also organized the barriers into a five-tiered hierarchy to demonstrate the links between the driver and the dependent barriers. They found that internal, economic, and legal barriers are the three subcategories of these five levels. Moreover, the ISM and the Cross-Impact Matrix Multiplication Applied to Classification (MICMAC) technique were also used to discover and assess the relationships between factors that inhibit Pakistani manufacturing from adopting reverse logistics [32].

According to the ISM and MICMAC studies, there were a variety of interrelated barriers that hampered progress to ECM deployment. There are many reasons why companies are not recovering their products. The most common reasons are government policy incentives, inability to respond to reverse logistics, lack of enforced laws on product return, changes in regulations due to political shifts, and a lack of environmental law awareness. After a review of the literature, the critical barriers to ECM implementation are gathered and listed with their associated references in Table 1.

Table 1.

Barriers to the Sustainable Implementation of Environmentally Conscious Manufacturing (ECM).

Even though ECM seems to be a highly viable business model for manufacturing corporations in the long term, few research studies, in specific contexts, have used the ISM technique to investigate barriers to its implementation. The primary factor contributing to this inefficiency is the lack of disclosure of relationships between various groups of enablers and barriers. Using ISM, this work identifies general barriers to sustainable ECM and product recovery and puts forward a contextual model that prioritizes the interconnections between them. The materials and methods employed in this research investigation are described in the next section.

3. Materials and Methods

A review of the literature was conducted to determine the barriers to the sustainable implementation of ECM. This needed a methodical approach to the literature review in order to extract the barriers from previously published scientific datasets. The identified barriers to ECM were then investigated using the ISM approach, and their interdependencies and driving forces were discovered via modeling. This was accomplished by enlisting a panel of twenty-five specialists (Table A1 in Appendix A) to gather information on these barriers. Targeted specialists participated in evaluating the collected ECM barriers and provided informative and usable comparisons to supplement the modeling process while uncovering the contextual links between the barriers. Individual specialists included academics specializing in ECM and any closely connected subject areas, such as remanufacturing, reverse logistics, closed-loop supply chains, and product recovery, as well as practitioners who have successfully managed ECM systems. The specialists who participated in this research study attended academic and/or social events related to ECM. Each expert was tasked with determining if each extracted barrier impacted another barrier and in which direction until all available barrier pair combinations had been exhausted.

The seven ISM procedures were implemented [45,46,47,48]. As shown in Table 1, a list of ECM barriers was compiled after a review of existing studies. Second, the contextual connections between pairs of ECM barriers were identified using the data gathered from the 25 specialists who participated in the research through a questionnaire. Then, using the obtained data and the rules described in Table 2, the structural self-interaction matrix (SSIM) is established. The initial reachability matrix (IRM) is generated as the fourth step. Fifth, using the IRM, the final reachability matrix (FRM) was determined after a transitivity test was performed between ECM barriers based on Warshall’s algorithm [49]. Then, barrier levels were determined using the partitioning matrix (PM). Sixth, based on their dependency and driving capacities, ECM barriers were classified as linking, dependent, driver, or autonomous barriers using MICMAC. The seventh step was to configure the final ISM network of ECM barriers. The outcomes of applying the seven stages are reported in the following section.

Table 2.

Rules for constructing the structural self-interaction matrix (SSIM) and the initial reachability matrix (IRM).

4. Results

The seven procedure stages of the ISM application mentioned above were used to meet the study’s objectives. First, a list of barriers was compiled from the literature review process, as shown in Table 1. Second, a group of ECM experts was involved in determining the contextual links of influence directions between barriers. In the third stage, in order to model interactions among barriers using ISM, the SSIM (Table 3) was built using the rules presented in Table 2, demonstrating the pair-wise contextual linkages between the studied barriers based on the directions of the relationships.

Table 3.

Structural self-interaction matrix (SSIM) of barriers to the sustainable implementation of environmentally conscious manufacturing (ECM).

The entry code V in the resulting SSIM in Table 3 indicates that a barrier influences or leads to another barrier. Moreover, entry code A indicates that a barrier is influenced or led to by another barrier. Furthermore, the entry code X indicates that a pair of barriers influence or lead to each other. Lastly, the entry code O indicates no influence between a pair of barriers.

Fourth, the IRM was created as indicated in Table 4 utilizing the SSIM (Table 3) and the replacement rules presented in Table 2. Row and column sums of 0 and 1 entries in the IRM show the initial (i.e., only direct interrelationships without considering transitivity) driving and dependence powers, respectively. The results presented in Table 4 demonstrated that the barrier (ECM-B7: Ignorance of management towards ECM) received the highest initial driving power with a sum value of 10. Then, it was followed by the barrier (ECM-B3: Communication gap) with a sum value of 8, the barriers (ECM-B4: Heavy taxes) and (ECM-B5: Poor policy framing and lack of implementation) with values of 7, the barriers (ECM-B2: Less-skilled workforce) and (ECM-B8: Poor financial support) with values of 6, the barrier (ECM-B9: lack of technological up-gradation) with a value of 5, the barriers (ECM-B1: Poor adoption of remanufacturing and reusing) and (ECM-B6: Higher cost of sustainable products) with values of 3, and lastly the barrier (ECM-B10: Overconsumption of natural resources), which received the lowest initial driving power value of 1. In contrast, the results presented in Table 4 demonstrated that the barrier (ECM-B10: Overconsumption of natural resources) received the highest initial dependence power with a sum value of 10. Then, it was followed by the barriers (ECM-B1: Poor adoption of remanufacturing and reusing) and (ECM-B6: Higher cost of sustainable products) with values of 9, and the barrier (ECM-B9: lack of technological up-gradation) with a value of 7, the barriers (ECM-B2: Less-skilled workforce) and (ECM-B8: Poor financial support) with values of 5, the barriers (ECM-B4: Heavy taxes) and (ECM-B5: Poor policy framing and lack of implementation) with values of 4, the barrier (ECM-B3: Communication gap) with a value of 2, and lastly the barrier (ECM-B7: Ignorance of management towards ECM), which received the lowest initial dependence power value of 1.

Table 4.

Initial reachability matrix (IRM) of barriers to the sustainable implementation of environmentally conscious manufacturing (ECM).

In the fifth stage of ISM, the transitivity test was applied to the IRM (Table 4) to validate all IRM’s entries, and transitive relationships are indicated by (1*), resulting in the FRM shown in Table 5. The transitivity rule is used to check for indirect relationships of higher order with other barriers beyond the direct relationships of barrier pairs and was checked until all barriers were exhausted. As shown in Table 5, the sums of the entries in the FRM’s rows and columns represent each barrier’s driving and dependence powers (ECM-B1– ECM-B10), respectively. The results presented in Table 5 demonstrated that after checking for transitive relationships, the final driving power of the barrier (ECM-B3: Communication gap) increased to a sum value of 9. Additionally, the final driving powers of the barriers (ECM-B2: Less-skilled workforce), (ECM-B4: Heavy taxes), (ECM-B5: Poor policy framing and lack of implementation), (ECM-B8: Poor financial support), and (ECM-B9: lack of technological up-gradation) have increased to sum values of 8. In contrast, the final dependence powers of the barriers (ECM-B2: Less-skilled workforce), (ECM-B4: Heavy taxes), (ECM-B5: Poor policy framing and lack of implementation), and (ECM-B8: Poor financial support) have increased to sum values of 7. The resulting FRM in Table 5 will be used for the remainder of the analysis because it considers all transitive and indirect relationships of higher order among the studied barriers.

Table 5.

Final reachability matrix (FRM) of barriers to the sustainable implementation of environmentally conscious manufacturing (ECM).

Consequently, to define the levels of all barriers (ECM-B1–ECM-B10) in the structural model, they were partitioned into three primary sets to create a PM. The first set is the reachability set, which shows all the barriers that a barrier can reach. The second set is the antecedent set, which represents the set of barriers that have already passed through that barrier. The third set is the intersection set, which depicts the set of barriers that overlap between the reachability and antecedent sets, suggesting that they may be eliminated, and a level can be assigned to the barrier based on this. The elimination and level assignment process were used in the PM in iterations until all barriers were depleted and the levels were identified. Table 6 shows the implementation of this process, which resulted in five iterations (Iteration 1–Iteration 5) and categorized the ten ECM barriers into five levels (Level I–Level V).

Table 6.

Partitioning matrix (PM) of barriers to the sustainable implementation of environmentally conscious manufacturing (ECM).

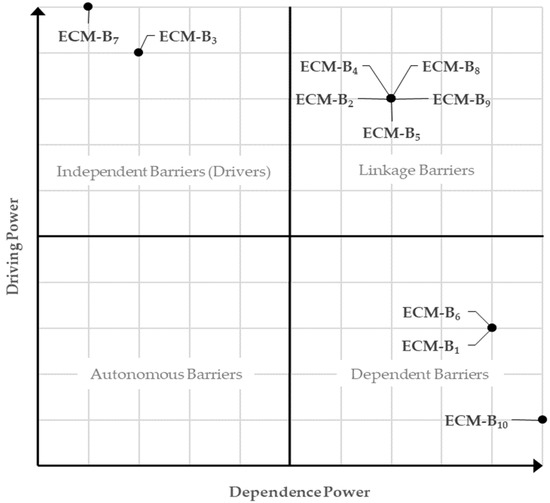

In the sixth stage of ISM, all ten barriers (ECM-B1–ECM-B10) were clustered into four categories using MICMAC using the calculated dependence and driving powers presented in the FRM (Table 4) as (x, y) coordinates. As shown in Figure 1, these barriers are charted into a quadrant chart and classified as autonomous, dependent, linkage, and independent or driver barriers. The resulting MICMAC presented in Figure 1 shows that none of the barriers are found to be classified as autonomous. In contrast, (ECM-B7: Ignorance of management towards ECM) and (ECM-B3: Communication gap) are classified as independent or driving barriers. Moreover, (ECM-B2: Less-skilled workforce), (ECM-B4: Heavy taxes), (ECM-B5: Poor policy framing and lack of implementation), (ECM-B8: Poor financial support), and (ECM-B9: lack of technological up-gradation) are all classified as linkage barriers. Finally, (ECM-B1: Poor adoption of remanufacturing and reusing), (ECM-B6: Higher cost of sustainable products), and (ECM-B10: Overconsumption of natural resources) are classified as dependent barriers.

Figure 1.

Cross-Impact Matrix Multiplication Applied to Classification (MICMAC) of the barriers to the sustainable implementation of environmentally conscious manufacturing (ECM). Note: ECM-B stands for Environmentally Conscious Manufacturing Barrier, and subscripts indicate the barrier number.

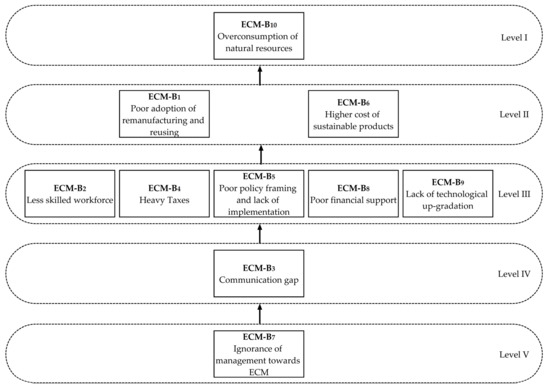

The resulting five levels from the PM (Table 6) and the MICMAC categorization of the ten ECM barriers (Figure 1) were used to develop the final ISM model illustrated in Figure 2. The final ISM model in Figure 2 shows that (ECM-B7: Ignorance of management towards ECM) in level V leads to (ECM-B3: Communication gap) in level IV. Furthermore, both lead (ECM-B2: Less-skilled workforce), (ECM-B4: Heavy taxes), (ECM-B5: Poor policy framing and lack of implementation), (ECM-B8: Poor financial support), and (ECM-B9: lack of technological up-gradation) in level III, thereby leading to (ECM-B1: Poor adoption of remanufacturing and reusing) and (ECM-B6: Higher cost of sustainable products) in level II. Finally, in level I, both lead to (ECM-B10: Overconsumption of natural resources).

Figure 2.

Final interpretive structural modeling (ISM) diagraph of barriers to the sustainable implementation of environmentally conscious manufacturing (ECM).

5. Discussion

The developed model revealed that management’s lack of understanding of ECM is an essential barrier that leads to a communication gap. This result indicates the vital leadership and communication roles expected from top management in the manufacturing industry and the up-down enforcement direction for a more sustainable implementation of ECM. Moreover, the resulting model reveals that both, if not addressed, lead to barriers such as a less qualified workforce, high taxation, poor policy framing and implementation, poor financial support, and lack of technological upgrades, which thereby consequently results in poor adoption of remanufacturing higher costs of sustainable products, and overconsumption of natural resources. Thus, using the developed model in this study as a roadmap toward enabling sustainable ECM implementation and saving the environment by addressing each barrier is recommended. It is possible for policymakers in government and business to strategically harness their resources by following the ISM model’s established hierarchy and interrelationships. More individuals within and outside of the company could benefit from improved change management using visual models of ECM. Prioritizing ECM adoption tactics will be easier with this information at hand. To assist industry managers in explaining ECM adoption to senior management, make workers understand their role during ECM adoption, and express the reasons for ECM adoption, this model is also believed to be useful in this regard. In contrast to some quality and productivity improvement programs, the internal enforcement of ECM adoption should be driven by top management’s awareness and conviction. Otherwise, as a result of external laws or supply chain stakeholders’ forceful actions, senior management’s commitment to ECM adoption may also be externally imposed. Therefore, the proactive adoption of ECM is recommended to produce cost savings and competitiveness rather than adopting it as a reaction to external variables.

Although previous studies concerning ECM used other methods, such as AHP and PROMETHEE [50], or the DEMATEL method [51], the current study revealed the general direction of barriers in terms of driving and dependence powers, which is consistent with the studies mentioned above. This indicates the priority of overcoming such barriers to realize ECM benefits in business environments.

Finally, human progress is inextricably related to environmental degradation. ECM is a unique idea that, by severing the relationship between economic growth and environmental deterioration, is intended to bring about eco-economic decoupling in both emerging and industrialized civilizations. ECM includes high-risk commercial operations since the strategic decisions in this area must assure financial sustainability and environmental benevolence. The execution of the idea of ECM is hampered further by the widespread misconception that any consideration for environmental preservation in a business strategy incurs expenditures and hence reduces predicted earnings. In this context, the study’s findings regarding the identified barriers to sustainable ECM implementation and their modeled linkages will help to change green-thinking misperceptions.

6. Conclusions

The purpose of this study is to explore barriers to the sustainable implementation of ECM. A systematic procedure fulfilled this goal based on the ISM technique. A literature review compiled a set of ten barriers to ECM. An expert panel of ECM specialists was involved in the study to confirm the extracted barriers and provide insightful comparisons to feed into the modeling process of linkages between them. The data gathered were utilized to assess the contextual links between the barriers and prioritize them for building the model.

Key findings of this study revealed that management’s lack of understanding of ECM is an essential barrier that leads to a communication gap. Both lead to barriers such as a less qualified workforce, high taxation, poor policy framing and implementation, poor financial support, and lack of technological upgrades, which thereby lead to the poor adoption of remanufacturing, higher costs of sustainable products, and in turn, the overconsumption of natural resources. It is recommended to use the method outlined in this study to allow sustained ECM adoption and protect the environment by removing each barrier. Using the ISM model’s hierarchy and interrelationships as a guide, government and business authorities may deploy their resources wisely. Visual ECM models facilitate internal and external change management. This information assists in prioritizing ECM adoption strategies. This technique may assist industry managers in explaining ECM adoption to senior management, informing personnel of their position during it, and elucidating its justification. The internal enforcement of ECM adoption should be driven by the awareness and conviction of top management, in contrast to some quality and productivity improvement efforts. External restrictions or parties in the supply chain may compel top management to adopt ECM. Proactively adopting ECM instead of responding to external influences would result in cost savings and increased competitiveness.

A limitation of this work is that the barriers are quantitatively examined and modeled based on data from a small group of experts using the ISM. Thus, a larger sample that enables a statistical correlation analysis and modeling between ECM barriers might validate the developed model and provide more insights. Furthermore, conducting studies based on statistical approaches and validating the dimensionality of ECM barriers in different manufacturing contexts is an essential future research direction to better understand the barriers to ECM in specific contexts. Another limitation of the established model in this study is that it is confined to representing the views and experiences of the involved experts in this study. Therefore, reconducting the study with another group of specialists in the field is a potential future research path to confirm the barriers and the modeled contextual linkages among them. Finally, the developed model in this study prioritizes barriers to ECM implementation; however, methods and procedures to overcome them in specific contexts are future research directions.

Author Contributions

Conceptualization, A.Y.A. and A.A.M.; methodology, A.Y.A. and A.A.M.; software, A.Y.A. and A.A.M.; validation, A.Y.A. and A.A.M.; formal analysis, A.Y.A. and A.A.M.; investigation, A.Y.A. and A.A.M.; resources, A.Y.A. and A.A.M.; data curation, A.Y.A.; writing—original draft preparation, A.Y.A. and A.A.M.; writing—review and editing, A.Y.A. and A.A.M.; visualization, A.Y.A. and A.A.M.; supervision, A.Y.A. and A.A.M.; project administration, A.Y.A. and A.A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy and ethical restrictions.

Acknowledgments

The authors acknowledge and thank all the questionnaire respondents in this research study.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Specialists’ profile.

Table A1.

Specialists’ profile.

| Expert Number | Qualification | Occupation | Years of Experience | Country |

|---|---|---|---|---|

| 1 | Ph.D. | Academic | 28 | USA |

| 2 | Ph.D. | Academic | 24 | UK |

| 3 | Ph.D. | Academic | 22 | Denmark |

| 4 | Ph.D. | Academic | 20 | Sweden |

| 5 | Ph.D. | Environment Expert | 19 | USA |

| 6 | Ph.D. | Environment Expert | 18 | USA |

| 7 | Ph.D. | Manufacturing Expert | 16 | USA |

| 8 | Ph.D. | Environment Expert | 15 | USA |

| 9 | Ph.D. | Manufacturing Expert | 15 | USA |

| 10 | Ph.D. | Environment Expert | 15 | USA |

| 11 | Ph.D. | Environment Expert | 15 | Japan |

| 12 | Ph.D. | Manufacturing Expert | 15 | China |

| 13 | M.Sc. | Manufacturing Expert | 14 | China |

| 14 | M.Sc. | Manufacturing Expert | 14 | China |

| 15 | M.Sc. | Environment Expert | 14 | Korea |

| 16 | M.Sc. | Academic | 14 | Japan |

| 17 | M.Sc. | Academic | 14 | Korea |

| 18 | M.Sc. | Academic | 14 | UK |

| 19 | M.Sc. | Academic | 14 | Japan |

| 20 | M.Sc. | Manufacturing Expert | 13 | UK |

| 21 | M.Sc. | Environment Expert | 13 | China |

| 22 | M.Sc. | Academic | 13 | Australia |

| 23 | B.Sc. | Academic | 13 | India |

| 24 | B.Sc. | Environment Expert | 9 | India |

| 25 | B.Sc. | Environment Expert | 8 | India |

References

- Güngör, A.; Gupta, S.M. Disassembly line in product recovery. Int. J. Prod. Res. 2002, 40, 2569–2589. [Google Scholar] [CrossRef]

- Laili, Y.; Wang, Y.; Fang, Y.; Pham, D.T. Robotic Disassembly for Remanufacturing. In Optimisation of Robotic Disassembly for Remanufacturing; Springer: Cham, Switzerland, 2022; pp. 7–25. [Google Scholar]

- Gungor, A.; Gupta, S.M. Issues in environmentally conscious manufacturing and product recovery: A survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Gupta, S.M.; Lambert, A.F. Environment Conscious Manufacturing; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhao, Q.; Zhao, X.; Tang, L. On the introduction of green product to a market with environmentally conscious consumers. Comput. Ind. Eng. 2020, 139, 106190. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Remanufacturing Modeling and Analysis; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Wang, Z.; Wang, Y.; Liu, Z.; Cheng, J.; Chen, X. Strategic management of product recovery and its environmental impact. Int. J. Prod. Res. 2021, 59, 6104–6124. [Google Scholar] [CrossRef]

- Alvial-Hein, G.; Mahandra, H.; Ghahreman, A. Separation and recovery of cobalt and nickel from end of life products via solvent extraction technique: A review. J. Clean. Prod. 2021, 297, 126592. [Google Scholar] [CrossRef]

- Moyer, L.K.; Gupta, S.M. Environmental concerns and recycling/disassembly efforts in the electronics industry. J. Electron. Manuf. 1997, 7, 1–22. [Google Scholar] [CrossRef]

- Gupta, S.M. Reverse Supply Chains: Issues and Analysis; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ilgin, M.A.; Gupta, S.M.; Battaïa, O. Use of MCDM techniques in environmentally conscious manufacturing and product recovery: State of the art. J. Manuf. Syst. 2015, 37, 746–758. [Google Scholar] [CrossRef]

- Santos, A.G.; de Albuquerque, T.L.; Ribeiro, B.D.; Coelho, M.A.Z. In situ product recovery techniques aiming to obtain biotechnological products: A glance to current knowledge. Biotechnol. Appl. Biochem. 2021, 68, 1044–1057. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.N.R.; Ang, W.L.; Teow, Y.H.; Mohammad, A.W.; Hilal, N. Nanofiltration membrane processes for water recycling, reuse and product recovery within various industries: A review. J. Water Process Eng. 2022, 45, 102478. [Google Scholar] [CrossRef]

- Lambert, A.F.; Gupta, S.M. Disassembly Modeling for Assembly, Maintenance, Reuse and Recycling; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Okorie, O.; Obi, M.; Russell, J.; Charnley, F.; Salonitis, K. A triple bottom line examination of product cannibalisation and remanufacturing: A review and research agenda. Sustain. Prod. Consum. 2021, 27, 958–974. [Google Scholar] [CrossRef]

- Nwankpa, C.; Eze, S.; Ijomah, W.; Gachagan, A.; Marshall, S. Achieving remanufacturing inspection using deep learning. J. Remanuf. 2021, 11, 89–105. [Google Scholar] [CrossRef]

- Akbar, K.; Jin, Y.; Salam, S. Barriers to environmentally-conscious manufacturing innovation. Hum. Syst. Manag. 2018, 37, 453–462. [Google Scholar] [CrossRef]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M.; Chowdhury, P.; Paul, S.K. An integrated approach to modeling the barriers in implementing green manufacturing practices in SMEs. J. Clean. Prod. 2020, 265, 121737. [Google Scholar] [CrossRef]

- Luken, R.; Van Rompaey, F. Drivers for and barriers to environmentally sound technology adoption by manufacturing plants in nine developing countries. J. Clean. Prod. 2008, 16, S67–S77. [Google Scholar] [CrossRef]

- Ma, L.; Song, W.; Zhou, Y. Modeling enablers of environmentally conscious manufacturing strategy: An integrated method. Sustainability 2018, 10, 2284. [Google Scholar] [CrossRef]

- Yang, M.; Movahedipour, M.; Zeng, J.; Xiaoguang, Z.; Wang, L. Analysis of success factors to implement sustainable supply chain management using interpretive structural modeling technique: A real case perspective. Math. Probl. Eng. 2017, 2017, 7274565. [Google Scholar] [CrossRef]

- Raut, R.D.; Narkhede, B.; Gardas, B.B. To identify the critical success factors of sustainable supply chain management practices in the context of oil and gas industries: ISM approach. Renew. Sustain. Energy Rev. 2017, 68, 33–47. [Google Scholar] [CrossRef]

- Malek, J.; Desai, T.N. Prioritization of sustainable manufacturing barriers using Best Worst Method. J. Clean. Prod. 2019, 226, 589–600. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S.; Herrmann, C.; Egede, P.; Wulbusch, C. Drivers and barriers of environmentally conscious manufacturing: A comparative study of Indian and German organizations. In Leveraging Technology for A Sustainable World; Springer: Berlin/Heidelberg, Germany, 2012; pp. 97–102. [Google Scholar]

- Mittal, V.K.; Sangwan, K.S. Development of a model of barriers to environmentally conscious manufacturing implementation. Int. J. Prod. Res. 2014, 52, 584–594. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Fuzzy TOPSIS method for ranking barriers to environmentally conscious manufacturing implementation: Government, industry and expert perspectives. Int. J. Environ. Technol. Manag. 2014, 17, 57–82. [Google Scholar] [CrossRef]

- Sushil, S. Interpreting the interpretive structural model. Glob. J. Flex. Syst. Manag. 2012, 13, 87–106. [Google Scholar] [CrossRef]

- Sarkis, J.; Hasan, M.A.; Shankar, R. Evaluating environmentally conscious manufacturing barriers with interpretive structural modeling. In Proceedings of the Environmentally Conscious Manufacturing VI, Boston, MA, USA, 11 October 2006; pp. 68–76. [Google Scholar]

- Luthra, S.; Kumar, V.; Kumar, S.; Haleem, A. Barriers to implement green supply chain management in automobile industry using interpretive structural modeling technique: An Indian perspective. J. Ind. Eng. Manag. 2011, 4, 231–257. [Google Scholar] [CrossRef]

- Mittal, V.K.; Sangwan, K.S. Assessment of hierarchy and inter-relationships of barriers to environmentally conscious manufacturing adoption. World J. Sci. Technol. Sustain. Dev. 2013, 10, 297–307. [Google Scholar] [CrossRef]

- Waqas, M.; Qianli, D.; Ahmad, N.; Zhu, Y.; Nadeem, M. Modeling reverse logistics barriers in manufacturing industry of Pakistan: An ISM and MICMAC approach. J. Adv. Manuf. Syst. 2020, 19, 309–341. [Google Scholar] [CrossRef]

- Singhal, D.; Tripathy, S.; Jena, S.K. Sustainability through remanufacturing of e-waste: Examination of critical factors in the Indian context. Sustain. Prod. Consum. 2019, 20, 128–139. [Google Scholar] [CrossRef]

- Sawhney, A. Striving towards a circular economy: Climate policy and renewable energy in India. Clean Technol. Environ. Policy 2021, 23, 491–499. [Google Scholar] [CrossRef]

- Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of drivers for integrated lean-green manufacturing for Indian manufacturing SMEs. J. Clean. Prod. 2018, 171, 675–689. [Google Scholar] [CrossRef]

- Dhull, S.; Narwal, M. Prioritizing the drivers of green supply chain management in Indian manufacturing industries using fuzzy TOPSIS method: Government, industry, environment, and public perspectives. Process Integr. Optim. Sustain. 2018, 2, 47–60. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, Y.; Lin, X.; Li, L.; Ke, Y. Identifying and analyzing barriers to offshore wind power development in China using the grey decision-making trial and evaluation laboratory approach. J. Clean. Prod. 2018, 189, 853–863. [Google Scholar] [CrossRef]

- Al-Maskari, A.; Al-Maskari, M.; Alqanoobi, M.; Kunjumuhammed, S. Internal and external obstacles facing medium and large enterprises in Rusayl Industrial Estates in the Sultanate of Oman. J. Glob. Entrep. Res. 2019, 9, 1. [Google Scholar] [CrossRef]

- Jones, P.; Hillier, D.; Comfort, D. Shopping for tomorrow: Promoting sustainable consumption within food stores. Br. Food J. 2011, 113, 935–948. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Critical success factors of green supply chain management for achieving sustainability in Indian automobile industry. Prod. Plan. Control 2015, 26, 339–362. [Google Scholar]

- Luthra, S.; Mangla, S.K.; Yadav, G. An analysis of causal relationships among challenges impeding redistributed manufacturing in emerging economies. J. Clean. Prod. 2019, 225, 949–962. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Srivastava, R.K. Analysis of external barriers to remanufacturing using grey-DEMATEL approach: An Indian perspective. Resour. Conserv. Recycl. 2018, 136, 79–87. [Google Scholar] [CrossRef]

- Schmidt, K.; Matthies, E. Where to start fighting the food waste problem? Identifying most promising entry points for intervention programs to reduce household food waste and overconsumption of food. Resour. Conserv. Recycl. 2018, 139, 1–14. [Google Scholar] [CrossRef]

- Shah, I.A.; Amjed, S.; Alkathiri, N.A. The economics of paper consumption in offices. J. Bus. Econ. Manag. 2019, 20, 43–62. [Google Scholar] [CrossRef]

- Kannan, G.; Haq, A.N.; Sasikumar, P.; Arunachalam, S. Analysis and selection of green suppliers using interpretative structural modelling and analytic hierarchy process. Int. J. Manag. Decis. Mak. 2008, 9, 163–182. [Google Scholar] [CrossRef]

- Mandal, A.; Deshmukh, S. Vendor selection using interpretive structural modelling (ISM). Int. J. Oper. Prod. Manag. 1994, 14, 52–59. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Makki, A.A.; Alidrisi, H.; Iqbal, A.; Al-Sasi, B.O. Barriers to green entrepreneurship: An ISM-based investigation. J. Risk Financ. Manag. 2020, 13, 249. [Google Scholar] [CrossRef]

- Warshall, S. A theorem on boolean matrices. J. ACM 1962, 9, 11–12. [Google Scholar] [CrossRef]

- Kataria, K.K.; Goyal, S.; Luthra, S.; Sharma, M. Analysing The Barriers and Solutions to Promote Environmentally Conscious Manufacturing Using Ahppromethee Hybrid Framework. Ind. Eng. J. 2021, 14, 12–18. [Google Scholar]

- Pinto, M.M.A.; Kovaleski, J.L.; Yoshino, R.T.; Pagani, R.N. Knowledge and technology transfer influencing the process of innovation in green supply chain management: A multicriteria model based on the DEMATEL Method. Sustainability 2019, 11, 3485. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).