Developing the Use of Wool Rope within Aquaculture—A Systematic Review

Abstract

:1. Introduction

1.1. Micro- and Macro-Plastic Pollution

1.2. Seaweed Industry in the UK and Northern Europe

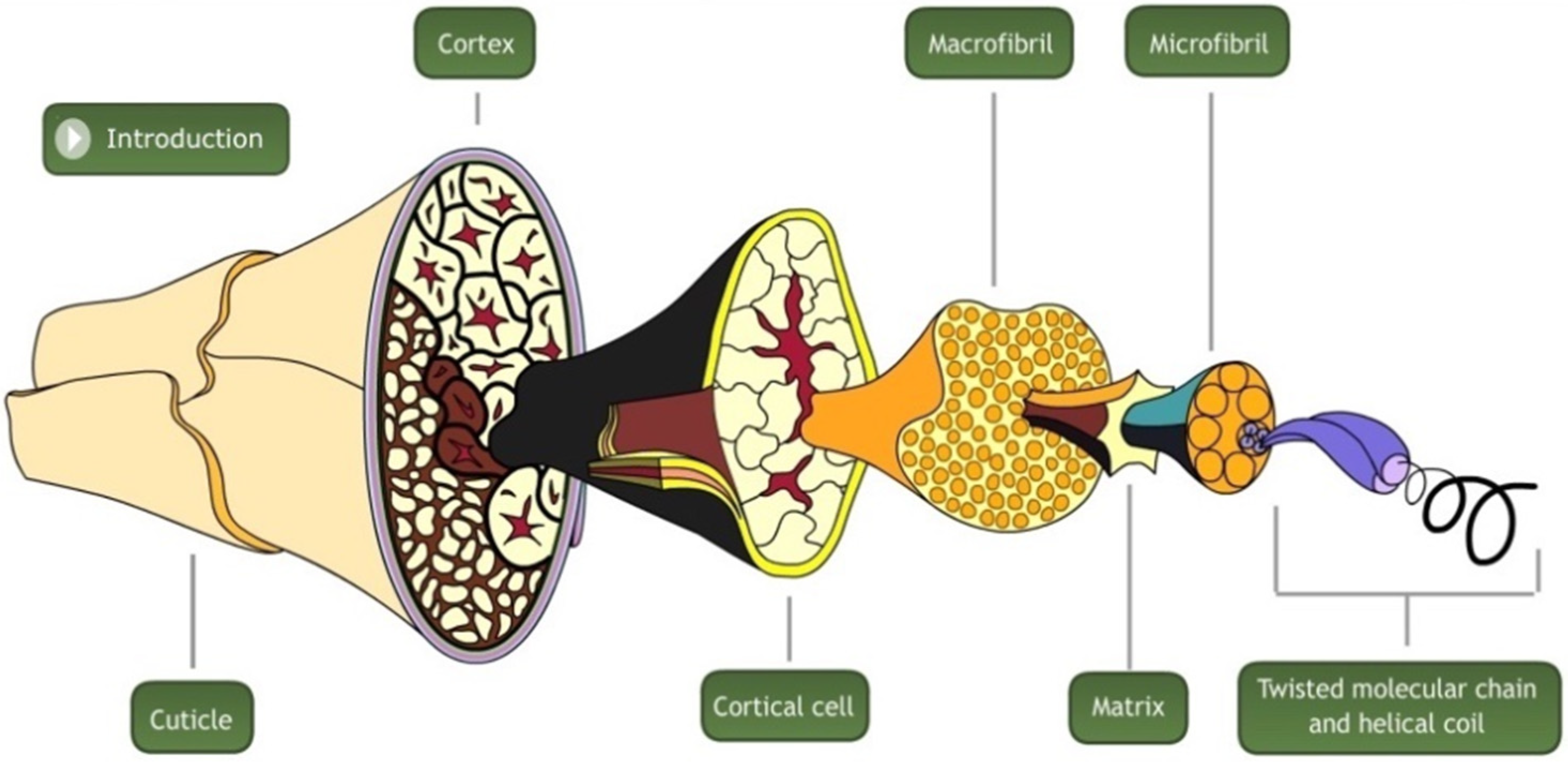

1.3. Wool Properties

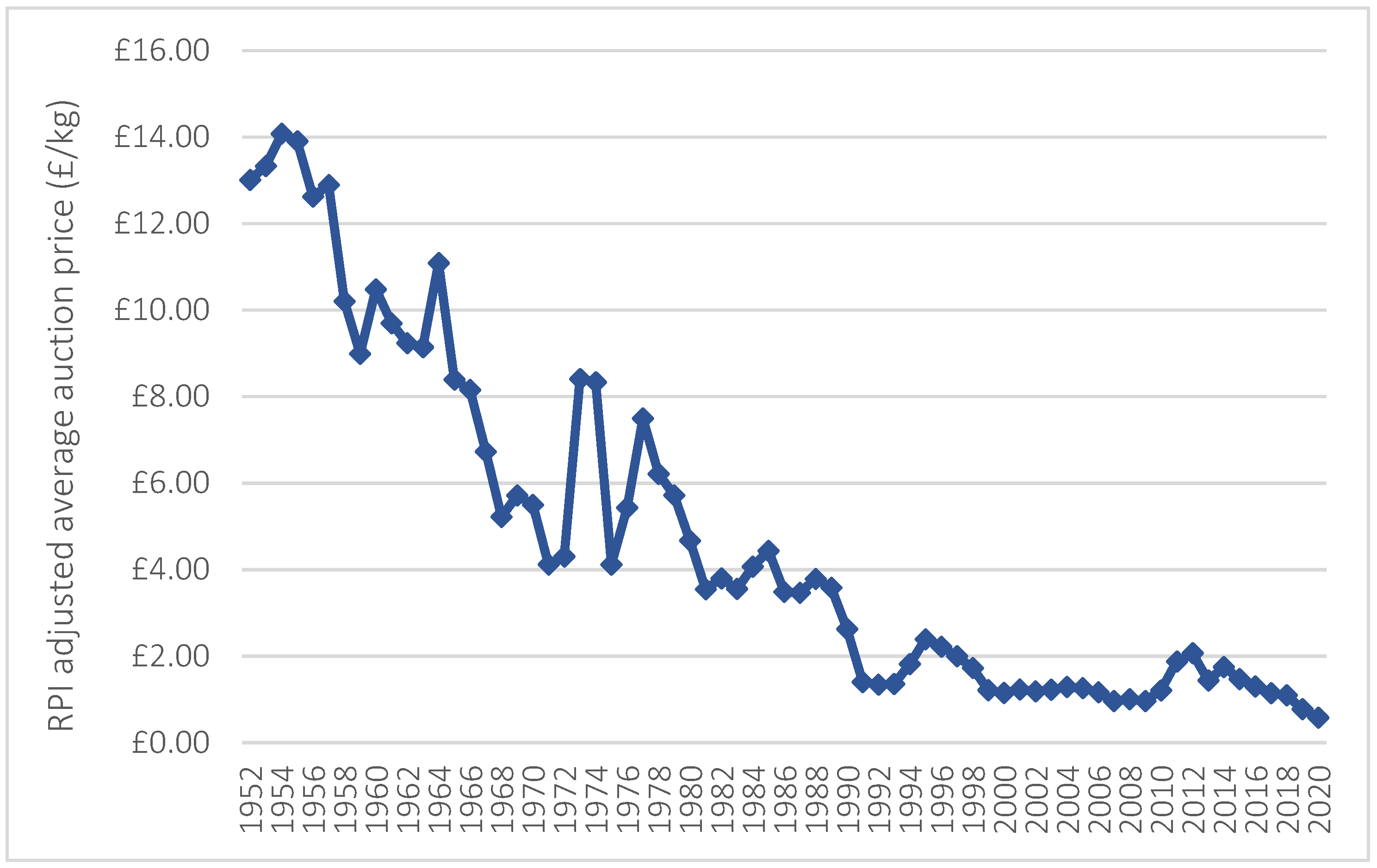

1.4. Wool Market

2. Materials and Methods

2.1. Approach

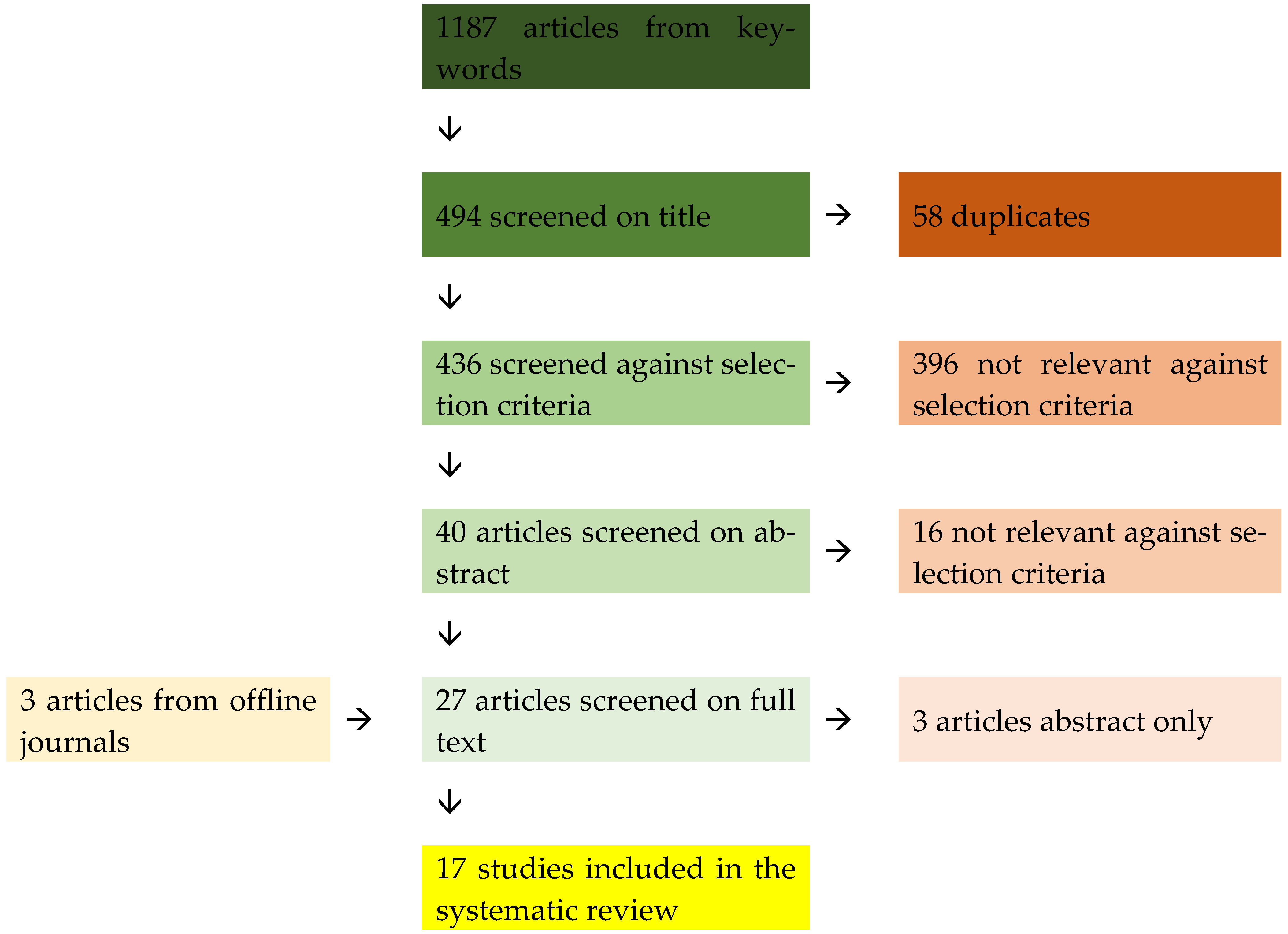

2.2. Search Strategy and Selection of Literature

3. Results

3.1. Findings

3.2. Analysis

3.3. Review of Findings

4. Synthesis

4.1. Natural Fibres

4.2. Wool Degradation

4.3. Rope Specification within the Seaweed Industry

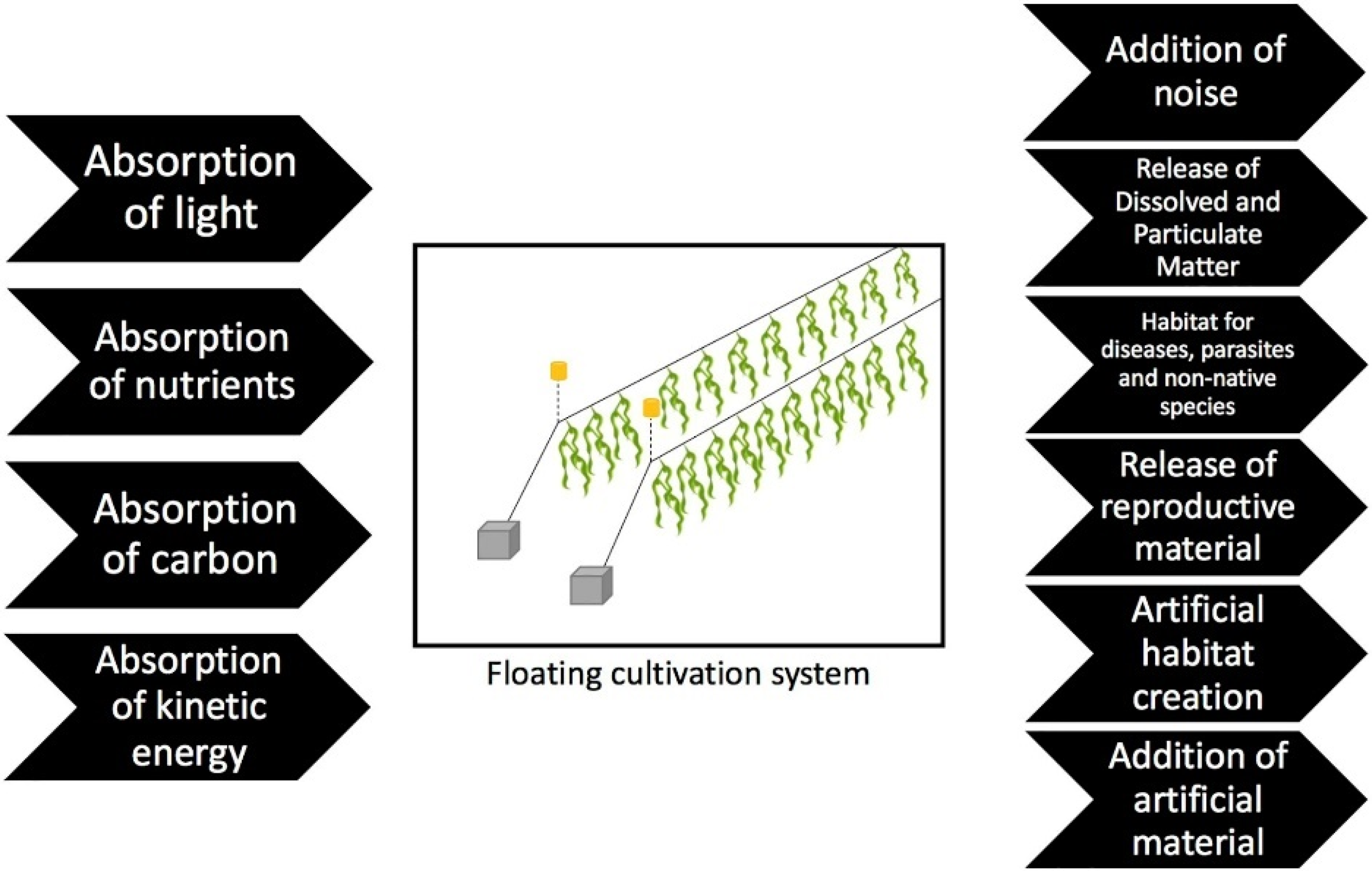

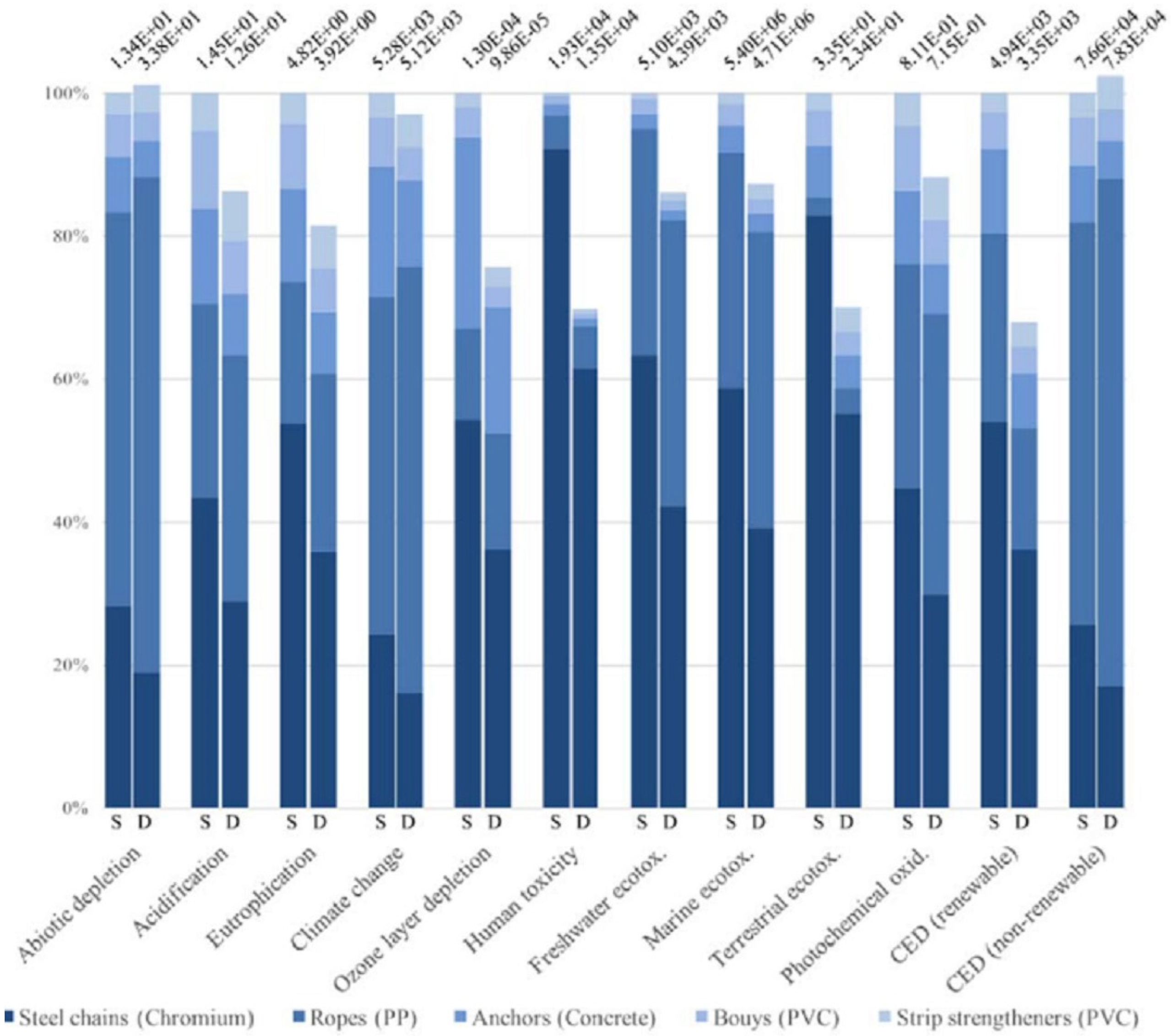

4.4. Environmental Impact of the Seaweed Industry

4.5. Rope Microplastic Pollution

4.6. Wool in the Marine Environment

4.7. Rope Innovation within the Seaweed Industry

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Scottish Government. Potential Scale of Scottish Seaweed-Based Industry Research Paper. 2022. Available online: www.gov.scot/publications/understanding-potential-scale-seaweed-based-industries-scotland/ (accessed on 25 May 2022).

- Naylor, R.L.; Hardy, R.W.; Buschmann, A.H.; Bush, S.R.; Cao, L.; Klinger, D.H.; Little, D.C.; Lubchenco, J.; Shumway, S.E.; Troell, M. A 20-year retrospective review of global aquaculture. Nature 2021, 591, 551–563. [Google Scholar] [CrossRef] [PubMed]

- Napper, I.E.; Thompson, R.C. Plastic debris in the marine environment: History and future challenges. Glob. Chall. 2020, 4, 1900081. [Google Scholar] [CrossRef] [PubMed]

- Arthur, C.; Baker, J.; Bamford, H. In Proceedings of the International Research Workshop on the Occurrence, Effects, and Fate of Microplastic Marine Debris, Tacoma, WA, USA, 9–11 September 2008.

- Debris. Stop Ghost Gear. Report WWF. 2020. Available online: https://wwfint.awsassets.panda.org/downloads/wwfintl_ghost_gear_report_1.pdf (accessed on 25 May 2022).

- Gestoso, I.; Cacabelos, E.; Ramalhosa, P.; Canning-Clode, J. Plasticrusts: A new potential threat in the Anthropocene’s rocky shores. Sci. Total Environ. 2019, 687, 413–415. [Google Scholar] [CrossRef] [PubMed]

- Ehlers, S.M.; Ellrich, J.A.; Gestoso, I. Plasticrusts derive from maritime ropes scouring across raspy rocks. Mar. Pollut. Bull. 2021, 172, 112841. [Google Scholar] [CrossRef]

- Ogunola, O.S.; Onada, O.A.; Falaye, A.E. Mitigation measures to avert the impacts of plastics and microplastics in the marine environment (a review). Environ. Sci. Pollut. Res. 2018, 25, 9293–9310. [Google Scholar] [CrossRef]

- Napper, I.E.; Wright, L.S.; Barrett, A.C.; Parker-Jurd, F.N.F.; Thompson, R.C. Potential microplastic release from the maritime industry: Abrasion of rope. Sci. Total Environ. 2022, 804, 150155. [Google Scholar] [CrossRef]

- Kerrison, P.D.; Stanley, M.S.; Edwards, M.D.; Black, K.D.; Hughes, A.D. The cultivation of European kelp for bioenergy: Site and species selection. Biomass Bioenergy 2015, 80, 229–242. [Google Scholar] [CrossRef]

- Van Den Burg, S.W.K.; Dagevos, H.; Helmes, R.J.K. Towards sustainable European seaweed value chains: A triple P perspective. Ices J. Mar. Sci. 2021, 78, 443–450. [Google Scholar] [CrossRef] [Green Version]

- van Oirschot, R.; Thomas, J.B.E.; Grondahl, F.; Fortuin, K.P.J.; Brandenburg, W.; Potting, J. Explorative environmental life cycle assessment for system design of seaweed cultivation and drying. Algal Res.-Biomass Biofuels Bioprod. 2017, 27, 43–54. [Google Scholar] [CrossRef]

- Stanley, M.S.; Kerrison, P.K.; Macleod, A.M.; Rolin, C.; Farley, I.; Parker, A.; Billing, S.L.; Burrows, M.; Allen, C. Seaweed Farming Feasibility Study for Argyll & Bute. A report by SRSL for Argyll & Bute Council. 2019. Available online: https://www.argyll-bute.gov.uk/sites/default/files/seaweed_farming_feasibility_study_for_argyll_and_bute_report_december_2019.pdf (accessed on 25 May 2022).

- Reith, E.H.; Deurwaarder, E.P.; Hemmes, K.; Curvers, A.P.W.M.; Kamermans, P.; Brandenburg, W.A.; Lettings, G. Bio-Offshore: Grootschalige Teelt van Zeewieren in Combinatie Met Offshore Windparken in de Noordzee; ECN. 2005. Available online: https://library.wur.nl/WebQuery/wurpubs/reports/347698 (accessed on 25 May 2022).

- Kim, J.K.; Kraemer, G.P.; Yarish, C. Field scale evaluation of seaweed aquaculture as a nutrient bioextraction strategy in Long Island Sound and the Bronx River Estuary. Aquaculture 2014, 433, 148–156. [Google Scholar] [CrossRef]

- Campbell, I.; Macleod, A.; Sahlmann, C.; Neves, L.; Funderud, J.; Øverland, M.; Hughes, A.D.; Stanley, M. The Environmental Risks Associated with the Development of Seaweed Farming in Europe—Prioritizing Key Knowledge Gaps. Front. Mar. Sci. 2019, 6, 107. [Google Scholar] [CrossRef]

- Sheavly, S.B.; Register, K.M. Marine debris & plastics: Environmental concerns, sources, impacts and solutions. J. Polym. Environ. 2007, 15, 301–305. [Google Scholar] [CrossRef]

- Oceans 2050. 2022. Available online: https://www.oceans2050.com (accessed on 25 May 2022).

- Duarte, C.M.; Agusti, S.; Barbier, E.; Britten, G.L.; Castilla, J.C.; Gattuso, J.-P.; Fulweiler, R.W.; Hughes, T.P.; Knowlton, N.; Lovelock, C.E.; et al. Rebuilding marine life. Nature 2020, 580, 39–51. [Google Scholar] [CrossRef] [PubMed]

- University of Waikato. Science Learning Hub—Pokapu Akoranga Putaiao, University of Waikato. 2010. Available online: www.sciencelearn.org.nz (accessed on 25 May 2022).

- British Wool. British Sheep and Wool; British Wool Marketing Board: Bradford, UK, 2010. [Google Scholar]

- British Wool. Annual Report and Accounts. Available online: https://www.britishwool.org.uk/annual-report (accessed on 7 July 2022).

- Cook, J.G. Handbook of Textile Fibres: Man-Made Fibres; Elsevier: Amsterdam, The Netherlands, 1984. [Google Scholar]

- DEFRA. Review of the British Wool Marketing Board. In Livestock and Livestock Products; Department for Environment, Food and Rural Affairs: London, UK, 2008. [Google Scholar]

- Bowman, R.A. The Structure of the United Kingdom Wool Textile Industry. Q. Rev. Rural Econ. 1970, 23, 35. [Google Scholar]

- Gilbert, K. Thebes, A History of Technology; Singer, C., Hall, A., Eds.; Clarendon Press: Oxford, UK, 1954; Volume 1, pp. 452–455. [Google Scholar]

- McKenna, H.A.; Hearle, J.W.; O’Hear, N. Handbook of Fibre Rope Technology; Woodhead Publishing: Cambridge, UK, 2004; Volume 34. [Google Scholar]

- Boland, A.; Cherry, M.G.; Dickson, R. Doing a Systematic Review: A Student’S Guide; Sage Publications: London, UK, 2017. [Google Scholar]

- Astbury, W.T. Lecture on “How the Wool Molecule Works, and its Further Significance in Biology and Medicine”; Wool Education Society. Department of Education of the International Wool Secretariat: London, UK, 1951. [Google Scholar]

- Ciba-Geigy. Review 1975 the Sphere of Dye and Chemical Application in the Textile Industry; Ciba-Geigy: Ardsley, NY, USA, 1975. [Google Scholar]

- Broda, J.; Przybyło, S.; Kobiela-Mendrek, K.; Biniaś, D.; Rom, M.; Grzybowska-Pietras, J.; Laszczak, R. Biodegradation of sheep wool geotextiles. Int. Biodeterior. Biodegrad. 2016, 115, 31–38. [Google Scholar] [CrossRef]

- Brown, R.M. The Microbial Degradation of Wool in the Marine Environment; University of Canterbury: Christchurch, New Zealand, 1994. [Google Scholar] [CrossRef]

- Cassie, A. Natural fibres versus man-made fibres. Natural Fibres. J. Text. Inst. Proc. 1946, 37, 556–561. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Jiang, Y. Discussion on the Natural Fiber Degradation Index. In Proceedings of the 12th International Wool Research Conference (IWRC 2010), Shanghai, China, 19–22 October 2010; Volumes I and II. [Google Scholar]

- Chou, R.; Volpenhein, K.; Mozsgai, G. Synthetic lines for marine and other applications: Rope design, selection and best practice. In Proceedings of the OCEANS 2016, Shanghai, China, 10–13 April 2016. [Google Scholar] [CrossRef]

- Collie, S.; Ranford, S.; Fowler, I.; Brorens, P. Microfibre pollution—What’s the story for wool. In Proceedings of the AUTEX2019–19th World Textile Conference on Textiles at the Crossroads, Ghent, Belgium, 11–15 June 2019. [Google Scholar]

- Collins, N.; Mediboyina, M.K.; Cerca, M.; Vance, C.; Murphy, F. Economic and environmental sustainability analysis of seaweed farming: Monetizing carbon offsets of a brown algae cultivation system in Ireland. Bioresour. Technol. 2022, 346, 126637. [Google Scholar] [CrossRef]

- Endresen, P.C.; Norvik, C.; Kristiansen, D.; Birkevold, J.; Volent, Z.; ASME. Current induced drag forces on cultivated sugar kelp. In Proceedings of the 38th ASME International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2019), Glasgow, UK, 9–14 June 2019; Volume 6. [Google Scholar] [CrossRef]

- Grosvenor, A.; Morton, J.; Dyer, J. Protein Primary Level Degradation in Wool. In Proceedings of the 12th International Wool Research Conference (IWRC 2010), Shanghai, China, 19–22 October 2010; Volumes I and II. [Google Scholar]

- Kozłowski, R.M.; Mackiewicz-Talarczyk, M. Introduction to natural textile fibres. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–13. [Google Scholar] [CrossRef]

- Prakash, R.V.; Viswanath, V.; ASME. Effect of Sea-Water Environment on the Tensile and Fatigue Properties of Synthetic Yarns. In Volume 12: Advanced Materials: Design, Processing, Characterization, and Applications, Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2019, Salt Lake City, Utah, USA, 11–14 November 2019; ASME: New York, NY, USA, 2019. [Google Scholar] [CrossRef]

- Ryszard, M.K.; Maria, M.T.; Malgorzata, M.; Jorge, B.B. Future of natural fibers, their coexistence and competition with man-made fibers in 21st century. Mol. Cryst. Liquid Cryst. 2012, 556, 200–222. [Google Scholar] [CrossRef]

- Sebok, S.; Brockhagen, B.; Storck, J.L.; Post, I.B.; Bache, T.; Korchev, R.; Bottjer, R.; Grothe, T.; Ehrmann, A. Growth of marine macroalgae Ectocarpus sp. on various textile substrates. Environ. Technol. 2022, 43, 1340–1351. [Google Scholar] [CrossRef]

- Sørensen, L.; Groven, A.S.; Hovsbakken, I.A.; Del Puerto, O.; Krause, D.F.; Sarno, A.; Booth, A.M. UV degradation of natural and synthetic microfibers causes fragmentation and release of polymer degradation products and chemical additives. Sci. Total Environ. 2021, 755, 143170. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, J.; Ni, A.Q.; Bi, Y.Y.; Yu, W.D. Study on biodegradability of wool and PLA fibers in natural soil and aqueous medium. Adv. Mater. Res. 2013, 641, 82–86. [Google Scholar] [CrossRef]

- Zheng, S.; Bawazir, M.; Dhall, A.; Kim, H.-E.; He, L.; Heo, J.; Hwang, G. Implication of Surface Properties, Bacterial Motility, and Hydrodynamic Conditions on Bacterial Surface Sensing and Their Initial Adhesion. Front. Bioeng. Biotechnol. 2021, 9, 643722. [Google Scholar] [CrossRef] [PubMed]

- Černá, M. Seaweed proteins and amino acids as nutraceuticals. Adv. Food Nutr. Res. 2011, 64, 297–312. [Google Scholar] [CrossRef] [PubMed]

| Keywords and Search Terms |

|---|

| Systematic review of wool |

| Systematic review of the environmental impact of sustainable fibres |

| Wool |

| Wool rope |

| Wool rope characteristics |

| Wool rope properties |

| Wool marine environment |

| Wool AND degradation |

| Natural AND degradation AND wool |

| Wool AND degradation AND Sea water |

| Environmental impact of sustainable fibres |

| Sustainable fibres for rope |

| Availability wool rope |

| Availability of production of wool rope |

| Supply chain wool rope |

| Viable alternatives for polypropylene rope |

| Environmental AND impact AND sustainable AND rope |

| Man-made vs natural fibre |

| Seaweed rope |

| Seaweed farming rope requirements |

| Marine AND industry AND rope |

| Sustainable rope in seaweed production |

| Sustainable rope in seaweed farming |

| Wool AND Rope AND seaweed |

| Financial margins for seaweed production in the UK |

| Inclusion and Exclusion Criteria | ||

|---|---|---|

| Area | Include | Exclude |

| 1. Locality | No location, UK, Europe and Scandinavia | Southern hemisphere, Outside of Europe |

| 2. Applications | Rope for seaweed farming. | All other applications |

| 3. Fish-farming rope requirements. | Seaweed—its environment and requirements of the rope. | All others |

| 4. Characteristics: Incl. strength, durability, degradation, stretch, buoyancy | Wool rope, polypropylene rope | Aesthetic look, cellulosic fibres, non-protein, re-engineered fibres |

| 5. Application methods of rope in seaweed farming | UK, inshore and outshore | Rest of the world. |

| 6. Economics and accessibility wool | Common breeds to UK | All others including Merino |

| 7. Study design | All | None |

| Author | Year | Reference | Title | Journal | Keywords: | |

|---|---|---|---|---|---|---|

| 1 | Broda et al. | 2016 | [31] | Biodegradation of sheep wool geotextiles. | International Biodeterioration & Biodegradation, 115, 31–38. | Wool rope characteristics and degradation |

| 2 | Brown, R.M. | 1994 | [32] | The microbial degradation of wool in the marine environment. | Thesis—University of Canterbury, New Zealand | Degradation in a marine environment |

| 3 | Cassie, A. | 1946 | [33] | Natural fibres versus man-made fibres. Natural Fibres. | Journal of the Textile Institute Proceedings, 37(12), P556–P561. | Characteristics of natural and man-made fibre |

| 4 | Cheng et al. | 2010 | [34] | Discussion on the Natural Fiber Degradation Index. | Proceedings of the 12th international wool research conference, vols i and ii. 12th International Wool Research Conference (IWRC 2010), Shanghai, PEOPLES R CHINA. | Degradation |

| 5 | Chou et al. | 2016 | [35] | Synthetic lines for marine and other applications: Rope design, selection and best practice. | OCEANS 2016-Shanghai, | Rope characteristics and requirements |

| 6 | Collie et al. | 2019 | [36] | Microfibre pollution–what’s the story for wool. | Proceedings of the AUTEX2019–19th World Textile Conference on Textiles at the Crossroads | Wool degradation |

| 7 | Collins et al. | 2022 | [37] | Economic and environmental sustainability analysis of seaweed farming: Monetizing carbon offsets of a brown algae cultivation system in Ireland. | Bioresource Technology, 346, 126637. | Life-cycle assessment and application in seaweed farming |

| 8 | Endresen et al. | 2019 | [38] | Current induced drag forces on cultivated sugar kelp | Proceedings of the ASME 38th International Conference on Ocean Offshore and Arctic Engineering, Univ Strathclyde, Glasgow, Scotland | Rope requirements and application in seaweed farming |

| 9 | Grosvenor et al. | 2010 | [39] | Protein Primary Level Degradation in Wool. | [Proceedings of the 12th international wool research conference, vols i and ii]. 12th International Wool Research Conference (IWRC 2010), Shanghai, PEOPLES R CHINA. | Degradation |

| 10 | Kozłowski, R.M. and Mackiewicz-Talarczyk, M. | 2020 | [40] | Introduction to natural textile fibres. | Handbook of Natural Fibres (pp. 1–13). Elsevier. | UV degradation. Economics and accessibility |

| 11 | Napper E. et al. | 2022 | [9] | Potential microplastic release from the maritime industry: Abrasion of rope. | Science of The Total Environment, 804, Article 150155. | Rope abrasion, age and maintenance |

| 12 | Prakash et al. | 2019 | [41] | Effect of Sea-water environment on the tensile and fatigue properties of synthetic yarn | Proceedings of the ASME International Mechanical Engineering Congress and Exposition | Rope requirements and construction in sea water. Degradation |

| 13 | Ryszard et al. | 2012 | [42] | Future of natural fibers, their coexistence and competition with man-made fibers in 21st century. | Molecular Crystals and Liquid Crystals, 556(1), 200–222. | Characteristics of wool. Economics and accessibility |

| 14 | Sebok et al. | 2020 | [43] | Growth of marine macroalgae Ectocarpus sp on various textile substrates. | Environmental Technology, 12. | Rope design |

| 15 | Sørensen et al. | 2021 | [44] | UV degradation of natural and synthetic microfibers causes fragmentation and release of polymer degradation products and chemical additives. | Science of The Total Environment, 755, 143170. | UV degradation |

| 16 | Sun et al. | 2013 | [45] | Study on biodegradability of wool and PLA fibers in natural soil and aqueous medium. | Advanced Materials Research, | Degradation |

| 17 | van Oirschot et al. | 2017 | [12] | Explorative environmental life cycle assessment for system design of seaweed cultivation and drying. | Algal Research-Biomass Biofuels and Bioproducts, | Rope requirements and application in seaweed farming |

| Study | Year | Country | Funding |

|---|---|---|---|

| Fibres—Natural and Synthetic | |||

| Cassie, A. [33] | 1946 | UK | Textile Institute |

| Cheng et al. [34] | 2010 | China | International Wool Research |

| Ryszard et al. [42] | 2012 | Poland | Ins. Of Natural Fibres & Medical Plants |

| Wool degradation | |||

| Broda et al. [31] | 2016 | Poland | University of Bielsko-Biaol, Poland |

| Grosvenor et al. [39] | 2010 | China | International Wool Research |

| Kozłowski et al. [40] | 2020 | Poland | Ins. Of Natural Fibres & Medical Plants |

| Sørensen et al. [44] | 2021 | Norway | SINTEF Ocean AS |

| Sun et al. [45] | 2013 | China | Ministry of Education, PRofC |

| Rope consideration in a marine environment | |||

| Chou et al. [35] | 2016 | USA | Samson Rope Technologies |

| Collins et al. [37] | 2022 | Ireland | University College, Dublin |

| Endresen et al. [38] | 2019 | Norway | ASME Int Conf. OMAE |

| Napper et al. [9] | 2022 | UK | University of Plymouth |

| Prakash et al. [41] | 2019 | USA | ASME Int Mechanical Engineer CE |

| Sebok et al. [43] | 2020 | Germany | Uni of Applied Sciences, Bielefeld |

| van Oirschot et al. [12] | 2017 | Netherlands | Wageningen University, Netherlands |

| Wool in the marine environment | |||

| Brown, R.M. [32] | 1994 | New Zealand | Wool Research of NZ |

| Collie et al. [36] | 2019 | New Zealand | Ag Research Ltd., New Zealand |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Drury, K.E.; Crotty, F.V. Developing the Use of Wool Rope within Aquaculture—A Systematic Review. Sustainability 2022, 14, 9011. https://doi.org/10.3390/su14159011

Drury KE, Crotty FV. Developing the Use of Wool Rope within Aquaculture—A Systematic Review. Sustainability. 2022; 14(15):9011. https://doi.org/10.3390/su14159011

Chicago/Turabian StyleDrury, Katherine Elizabeth, and Felicity Victoria Crotty. 2022. "Developing the Use of Wool Rope within Aquaculture—A Systematic Review" Sustainability 14, no. 15: 9011. https://doi.org/10.3390/su14159011

APA StyleDrury, K. E., & Crotty, F. V. (2022). Developing the Use of Wool Rope within Aquaculture—A Systematic Review. Sustainability, 14(15), 9011. https://doi.org/10.3390/su14159011