A Novel Solution for Optimized Energy Management Systems Comprising an AC/DC Hybrid Microgrid System for Industries

Abstract

:1. Introduction

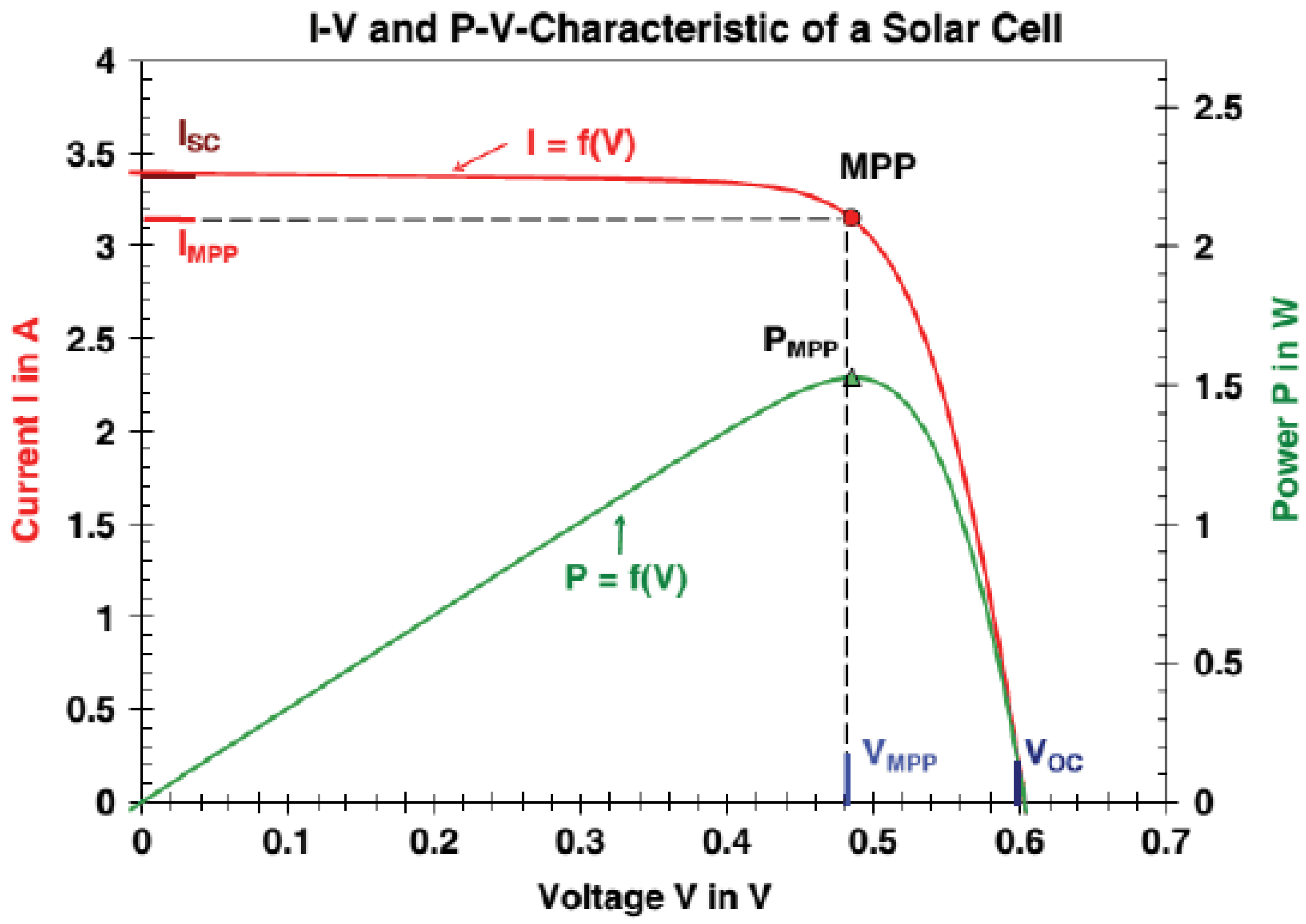

2. Proposed System Designing

2.1. Microgrid Architecture

2.2. Industrial Load

2.2.1. Shiftable Load

2.2.2. Non-Shiftable Load

2.2.3. Base Load

3. Problem Formulation and Proposed Optimization Techniques

3.1. Problem Formulation

3.2. Electricity Consumption without a Microgrid

3.3. Electricity Consumption with a Microgrid

3.4. Proposed Optimization Technique

3.4.1. Cuckoo Search Algorithm (CSA)

3.4.2. Strawberry Algorithm (SA)

4. Results and Discussion

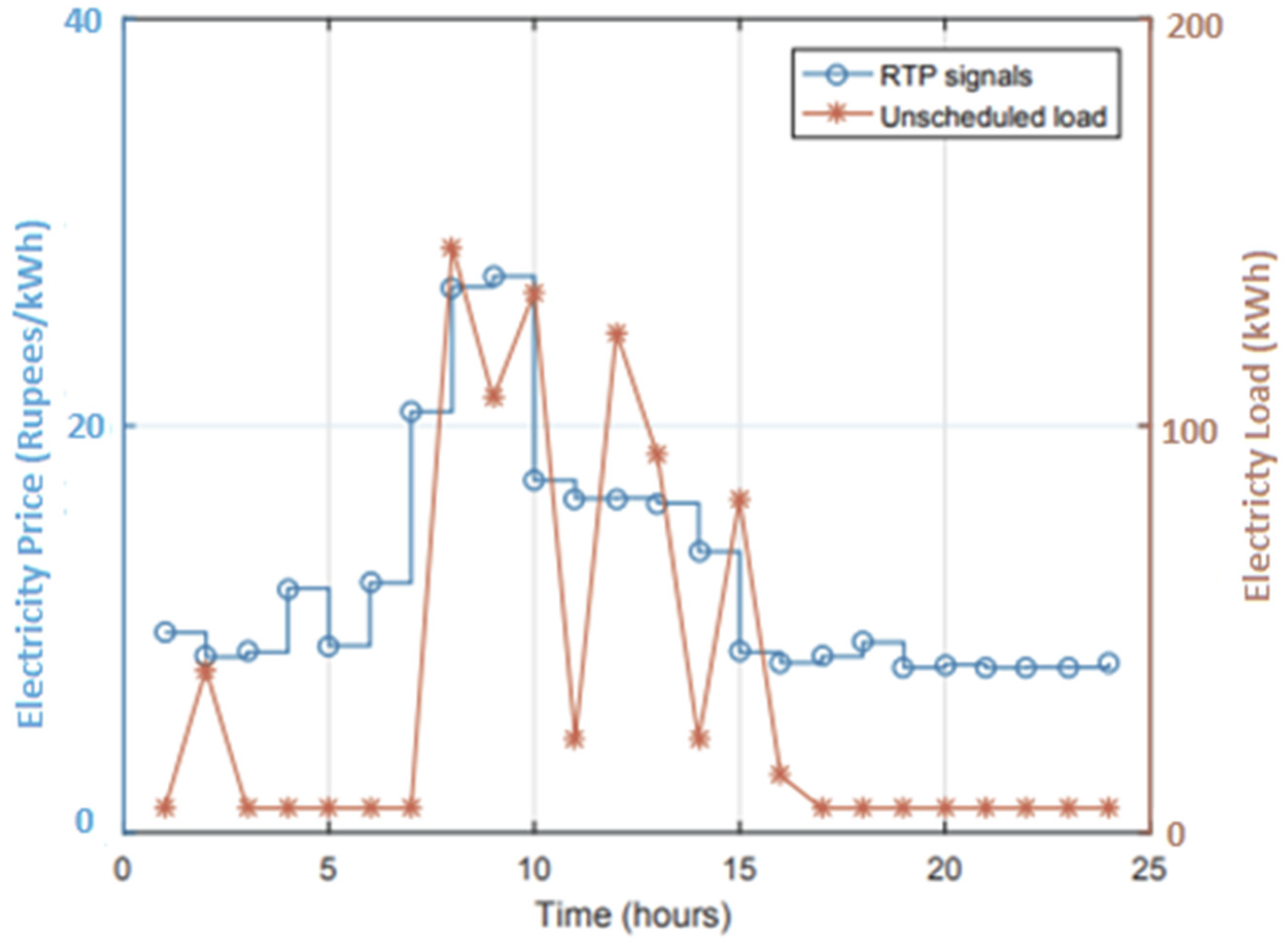

4.1. Industrial Energy Management with Power Trading, Real Time Pricing, and Weather Forecasting

4.1.1. Traditional Industry Operation without a Microgrid and EMS

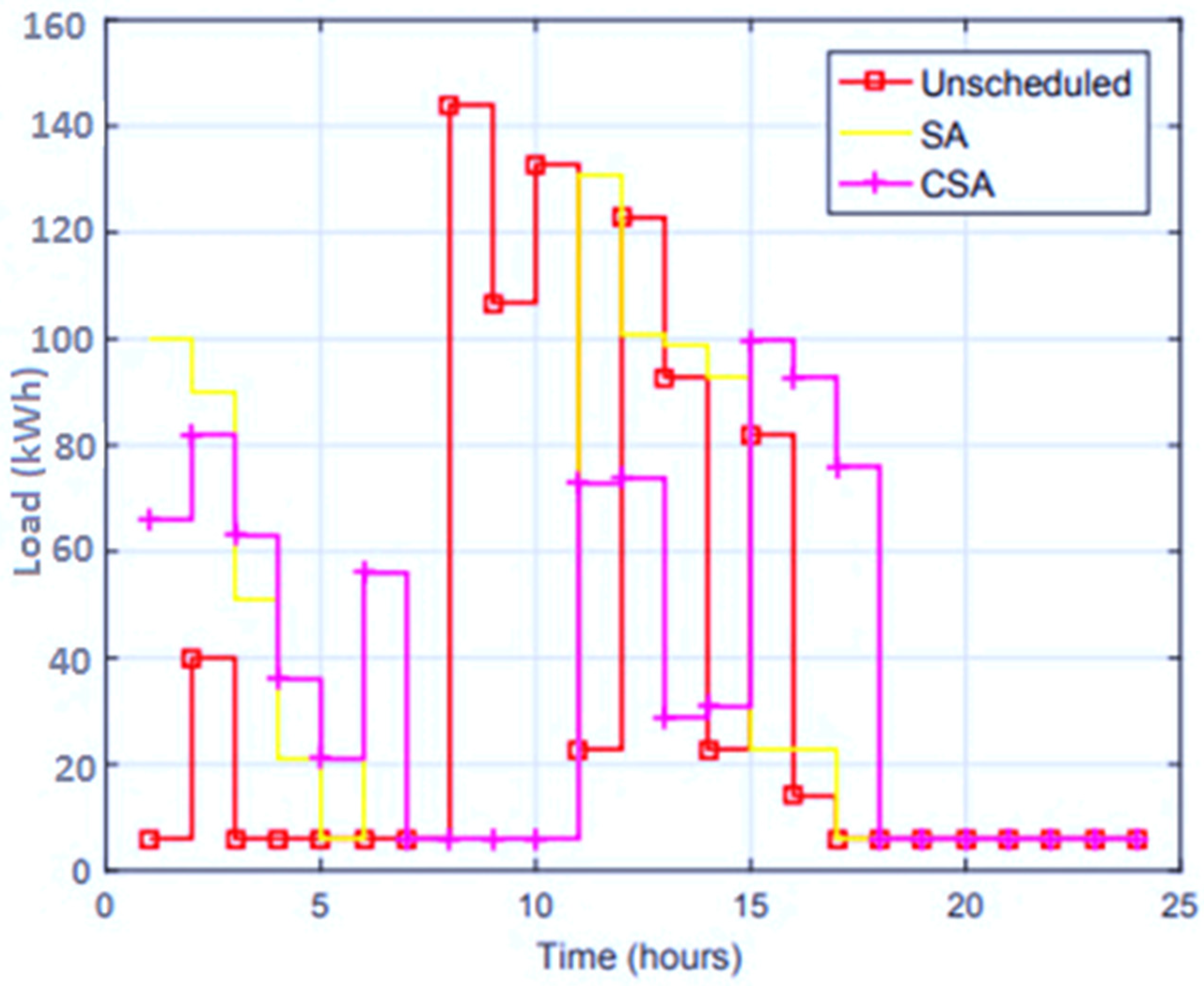

4.1.2. Industry Operation with EMS and without a Microgrid

4.1.3. Industry Operation with EMS and Microgrid Integration

4.2. Comparative Studies

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Algorithm A1 Basic working of the cuckoo search 7algorithm. |

| Objective function Initial a population of n host nests While (t<MaxGeneration) or (stop criterion); Get a cuckoo (say i) randomly by Lévy flights; Evaluate its quality/fitness Choose a nest among n (say j) randomly; Replace j by the new solution; end Abandon a fraction ( of worse nests [and build new ones at new locations via Lévy flights]; Keep the best solutions (or nests with quality solutions); Rank the solutions and find the current best; end while postprocess results and visualization; |

References

- Bölük, G.; Mert, M. Fossil & renewable energy consumption, GHGs (greenhouse gases) and economic growth: Evidence from a panel of EU (European Union) countries. Energy 2014, 74, 439–446. [Google Scholar] [CrossRef]

- Gungor, V.C.; Sahin Kocak, D.; Ergut, S.; Buccella, C.; Cecati, C.; Hancke, G.P. Smart grid and smart homes: Key players and pilot projects. IEEE Ind. Electron. Mag. 2012, 6, 18–34. [Google Scholar] [CrossRef]

- Evangelisti, S.; Lettieri, P.; Clift, R.; Borello, D. Distributed Generation by Energy from Waste Technology: A Life Cycle Perspective. Process Saf. Environ. Prot. 2015, 93, 161–172. [Google Scholar] [CrossRef]

- Wu, J.; Yan, J.; Jia, H.; Hatziargyriou, N.; Djilali, N.; Sun, H. Integrated Energy Systems. Appl. Energy 2016, 167, 155–157. [Google Scholar] [CrossRef]

- Hu, H.; Xie, N.; Fang, D.; Zhang, X. The role of renewable energy consumption and commercial services trade in carbon dioxide reduction: Evidence from 25 developing countries. Appl. Energy 2018, 211, 1229–1244. [Google Scholar] [CrossRef]

- Akram, F.; Asghar, F.; Majeed, M.A.; Amjad, W.; Manzoor, M.O.; Munir, A. Techno-economic optimization analysis of stand-alone renewable energy system for remote areas. Sustain. Energy Technol. Assess. 2020, 38, 100673. [Google Scholar] [CrossRef]

- Asghar, F.; Talha, M.; Kim, S.H. Fuzzy logic-based intelligent frequency and voltage stability control system for standalone microgrid. Int. Trans. Electr. Energy Syst. 2017, 28, e2510. [Google Scholar] [CrossRef]

- Lujano, R.; Análisis, J.M. Gestión Óptima de la Demanda en Sistemas Eléctricos Conectados a la red y en Sistemas Aislados Basados en Fuentes Renovables. Ph.D. Thesis, Univesity of Zaragoza, Zaragoza, Spain, 2012. [Google Scholar]

- Cristóbal, M.; Dufo, I.R.; López, R. Optimization of photovoltaic-diesel-battery stand-alone systems minimizing system weight. Energy Convers. Manag. 2016, 119, 279–288. [Google Scholar] [CrossRef]

- Thirugnanam, K.; Kerk, S.K.; Yuen, C.; Liu, N.; Zhang, M. Energy Management for Renewable Microgrid in Reducing Diesel Generators Usage with Multiple Types of Battery. IEEE Trans. Ind. Electron. 2018, 65, 6772–6786. [Google Scholar] [CrossRef]

- Asghar, F.; Talha, M.; Kim, S.H. Robust Frequency and Voltage Stability Control Strategy for Standalone AC/DC Hybrid Microgrid. Energies 2017, 10, 760. [Google Scholar] [CrossRef] [Green Version]

- Majeed, M.A.; Asghar, F.; Hussain, M.I.; Amjad, W.; Munir, A.; Armghan, H.; Kim, J.T. Adaptive Dynamic Control Based Optimization of Renewable Energy Resources for Grid-Tied Microgrids. Sustainability 2022, 14, 1877. [Google Scholar] [CrossRef]

- Shi, W.; Lee, E.K.; Yao, D.; Huang, R.; Chu, C.C.; Gadh, R. Evaluating microgrid management and control with an implementable energy management system. In Proceedings of the 2014 IEEE International Conference on Smart Grid Communications, Venice, Italy, 15 January 2015. [Google Scholar]

- Shi, W.; Li, N.; Chu, C.C.; Gadh, R. Real-Time Energy Management in Microgrids. IEEE Trans. Smart Grid 2015, 8, 228–238. [Google Scholar] [CrossRef]

- Majeed, M.A.; Khan, M.G.; Asghar, F. Nonlinear control of hybrid energy storage system for hybrid electric vehicles. Int. Trans. Electr. Energy Syst. 2019, 30, e12268. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Chandorkar, M.; Lee, T.L.; Loh, P.C. Advanced Control Architectures for Intelligent Microgrids—Part I: Decentralized and Hierarchical Control. IEEE Trans. Ind. Electron. 2013, 60, 1254–1262. [Google Scholar] [CrossRef] [Green Version]

- Velik, R.; Nicolay, P. Grid-price-dependent energy management in microgrids using a modified simulated annealing triple-optimizer. Appl. Energy 2014, 130, 384–395. [Google Scholar] [CrossRef]

- Jin, M.; Feng, W.; Liu, P.; Marnay, C.; Spanos, C. MOD-DR: Microgrid optimal dispatch with demand response. Appl. Energy 2017, 187, 758–776. [Google Scholar] [CrossRef] [Green Version]

- Zame, K.K.; Brehm, C.A.; Nitica, A.T.; Richard, C.L.; Iii, G.D.S. Smart grid and energy storage: Policy recommendations. Renew. Sustain. Energy Rev. 2018, 82, 1646–1654. [Google Scholar] [CrossRef]

- Johnson, M. Controlling and optimizing resilient distributed energy resources and microgrids with a demand-side operation platform. Electr. J. 2017, 30, 12–15. [Google Scholar] [CrossRef]

- Golmohamadi, H.; Keypour, R.; Bak-Jensen, B.; Pillai, J.R. A multi-agent based optimization of residential and industrial demand response aggregators. Int. J. Electr. Power Energy Syst. 2018, 107, 472–485. [Google Scholar] [CrossRef]

- Karfopoulos, E.; Tena, L.; Torres, A.; Salas, P.; Gil Jorda, J.; Dimeas, A.; Hatziargyriou, N. A multi-agent system providing demand response services from residential consumers. Electr. Power Syst. Res. 2015, 120, 163–176. [Google Scholar] [CrossRef]

- Mocci, S.; Natale, N.; Pilo, F.; Ruggeri, S. Demand side integration in LV smart grids with multi-agent control system. Electr. Power Syst. Res. 2015, 125, 23–33. [Google Scholar] [CrossRef]

- Li, W.; Logenthiran, T.; Phan, V.T.; Woo, W.L. Intelligent Multi-Agent System for Power Grid Communication. In Proceedings of the IEEE Region 10 Conference, Singapore, 22–25 November 2016; pp. 3386–3389. [Google Scholar]

- Wang, Y.; Wu, J.; Mao, X. Research on intelligent dispatching strategy of power grid using multi-agent and knowledge discovery algorithm. J. Eng. 2018, 2018, 1503–1508. [Google Scholar] [CrossRef]

- Luna, A.C.; Diaz, N.L.; Graells, M.; Vasquez, J.C.; Guerrero, J.M. Mixed integer linear programming-based energy management system for hybrid PV-wind-battery microgrids: Modeling, design, and experimental verification. IEEE Trans. Power Electron. 2016, 32, 2769–2783. [Google Scholar] [CrossRef] [Green Version]

- Akhil, A.A.; Huff, G.; Currier, A.H.; Kaun, B.C.; Rastler, D.M.; Chen, S.B.; Cotter, A.L.; Bradshaw, D.T.; Gauntlett, W.T. DOE/EPRI Electricity Storage Handbook in Collaboration with NRECA; Sandia National Laboratories: Albuquerque, NM, USA, 2015. [Google Scholar]

- Nemati, M.; Braun, M.; Tenbohlen, S. Optimization of unit commitment and economic dispatch in microgrids based on genetic algorithm and mixed integer linear programming. Appl. Energy 2018, 210, 944–963. [Google Scholar] [CrossRef]

- Aslam, S.; Javaid, N.; Khan, F.A.; Alamri, A.; Almogren, A.; Abdul, W. Towards Efficient Energy Management and Power Trading in a Residential Area via Integrating a Grid-Connected Microgrid. Sustainability 2018, 10, 1245. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.S.; Deb, S. Cuckoo Search via Levy Flights. In Proceedings of the World Congress on Nature and Biologically Inspired Computing, Coimbatore, India, 9–11 December 2009. [Google Scholar]

- Merrikh-Bayat, F. A numerical optimization algorithm inspired by the strawberry plant. arXiv 2014, arXiv:1407.7399. [Google Scholar]

| Load | Machine Type (Load) | Rating (Motor) | Motors Quantity | Total (kW) | TOU/ h | Total kWh | Starter Type |

|---|---|---|---|---|---|---|---|

| Shiftable Load | Singging Machine | 02 HP | 1 | 1.49 | 2.3 | 3.427 | |

| Jet Type Machine | 03 HP | 9 | 20.14 | 3.94 | 79.35 | ||

| Standard Machine | 04 HP (heat sucking from exhaust) | 3 | 8.95 | 4.65 | 41.61 | 2.2 kW Inverter | |

| 7.5 HP (Gas Burner) | 3 | 16.78 | 5 | 83.9 | 7.5–15 kW Inverter |

| Shiftable Load | Calendar Machine | 05 HP | 4 | 14.92 | 2.1 | 31.33 | 2.2–5 kW Inverter |

| Comfort Machine | 04 HP | 2 | 5.9 | 3 | 17.7 | - |

| Shiftable Load | Care Machine | 03 HP | 8 | 23.87 | 4.1 | 97.68 | DOL |

| Dryer | 03 HP | 2 | 4.476 | 3.6 | 16.11 | DOL | |

| Boozer Machine | 01 HP | 6 | 4.476 | 4 | 17.904 | 2.2 kW Inverter | |

| Ager Machine | 02 HP | 1 | 1.492 | 4 | 5.968 | 2.2 kW Inverter | |

| Marsrise Machine | 2.94 HP | 1 | 2.2 | 6.3 | 13.86 | DOL | |

| 03 HP | 1 | 2.238 | 4.9 | 10.96 | DOL | ||

| Rotary Machine | 03 HP | 8 | 6.714 | 5.34 | 35.85 | DOL | |

| Pre-Printing Process Machine | 02 HP | 1 | 1.492 | 5.8 | 8.65 | 2.2 kW Inverter | |

| 1.5 HP | 8 | 11.19 | 5.23 | 58.52 | 2.2 kW Inverter |

| Load | Machine Type (Load) | Rating (Motor) | Motors Quantity | Total (kW) | TOU/ h | Total kWh | Starter Type |

|---|---|---|---|---|---|---|---|

| Non-shift-able Load | Singging Machine | 10 HP | 2 | 14.9 | 8 | 119.36 | 7.5–15 kW Inverter |

| Jet Machine | 05 HP | 9 | 33.5 | 8 | 268.56 | - | |

| Standard Type Machine | 10 HP | 3 | 22.38 | 8 | 179.04 | 7.5–15 kW Inverter | |

| 15 HP | 3 | 33.57 | 8 | 268.5 | 15–25 kW Inverter |

| Non-Shift-able Load | Calendar Machine | 40 HP | 4 | 119.36 | 8 | 954.8 | 45–55 kW Inverter |

| Comfort Machine | 07 HP | 2 | 10.4 | 8 | 83.55 | 7.5–15 kW Inverter |

| Non-Shift-able Load | Care Machine | 15 HP | 2 | 22.38 | 8 | 179.4 | Star/Delta |

| Dryer | 15 HP | 2 | 22.38 | 8 | 179.04 | 15 kW Inverter | |

| Washing Machine | 20 HP | 4 | 59.68 | 08 to 10 | 477.44/596.8 | 7.5–15 kW Inverter | |

| Boozer Machine | Magnet (56 V, 0.8 A) | 32 | 1.436 | 4 | 5.744 | - | |

| 7.5 HP | 1 | 5.595 | 4 | 22.38 | 7.5 kW Inverter | ||

| Marsrise Machine | 10 HP | 8 | 74.6 | 8 | 596.8 | 7.5–15 kW Inverter | |

| 15 HP | 3 | 33.57 | 8 | 268.56 | Star/Delta | ||

| Rotary Machine | 25 HP. D.C Motor | 1 | 18.65 | 8 | 149.2 | D.C Starter | |

| 7.5 HP | 1 | 5.595 | 8 | 44.76 | D.C Starter | ||

| 20 HP | 4 | 59.68 | 8 | 477.44 | 22 kW Inverter | ||

| Pre-Printing Process Machine | 14.74 HP | 2 | 22 | 8 | 176 | Operated withServo Drive | |

| 1 kW Heater Rod | 10 | 10 | 8 | 80 | - | ||

| 7.5 HP | 4 | 22.38 | 8 | 179.04 | DOL | ||

| 7.0 HP | 1 | 5.222 | 1 | 5.222 | DOL | ||

| Agar Machine | 4 HP | 1 | 2.984 | 4 | 11.936 | 7 kW inverter | |

| 7.5 HP | 1 | 5.595 | 4 | 22.38 | 7 kW inverter | ||

| Super Machine | 7.5 HP | 3 | 16.785 | 4 | 67.14 | - | |

| 5 HP | 1 | 3.73 | 4 | 14.92 | 7.5 kW Inverter | ||

| 15 HP | 1 | 11.19 | 4 | 44.76 | 2.2 kW Inverter |

| Sr. No. | Parameters | Values |

|---|---|---|

| 1 | Discovery Rate | 0.30 |

| 2 | Host Nest | 60 |

| 3 | Iteration | 1800 |

| 4 | Number of Eggs (n) | 13 |

| Sr. No. | Parameters | Values |

|---|---|---|

| 1 | Population Size | 115 |

| 2 | Runner | 55 |

| 3 | Root | 12 |

| 4 | Iteration | 1800 |

| 5 | N | 13 |

| Sr. No. | Parameters | Values |

|---|---|---|

| 1 | 50 kW | |

| 2 | 150 kW | |

| 3 | 5 m/s | |

| 4 | 25 m/s | |

| 5 | 100 kW | |

| 6 | 95% | |

| 7 | SOC | 90% |

| Parameters | First Type | Second Type | Third Type | ||

|---|---|---|---|---|---|

| Techniques | Unscheduled | SA | CSA | SA | CSA |

| Electricity Purchase Cost (Millions/PKR) | 1.2 | 0.983 | 0.785 | 0.659 | 0.432 |

| PAR | 3.82 | 3.39 | 2.98 | 3.09 | 2.43 |

| Cost Saving by EMS/Microgrid | 0 | 18.08% | 34.583% | 45.08% | 64% |

| Earnings (millions/PKR) | 0 | 0 | 0 | 0.170 | 0.987 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asghar, F.; Zahid, A.; Hussain, M.I.; Asghar, F.; Amjad, W.; Kim, J.-T. A Novel Solution for Optimized Energy Management Systems Comprising an AC/DC Hybrid Microgrid System for Industries. Sustainability 2022, 14, 8788. https://doi.org/10.3390/su14148788

Asghar F, Zahid A, Hussain MI, Asghar F, Amjad W, Kim J-T. A Novel Solution for Optimized Energy Management Systems Comprising an AC/DC Hybrid Microgrid System for Industries. Sustainability. 2022; 14(14):8788. https://doi.org/10.3390/su14148788

Chicago/Turabian StyleAsghar, Faran, Adnan Zahid, Muhammad Imtiaz Hussain, Furqan Asghar, Waseem Amjad, and Jun-Tae Kim. 2022. "A Novel Solution for Optimized Energy Management Systems Comprising an AC/DC Hybrid Microgrid System for Industries" Sustainability 14, no. 14: 8788. https://doi.org/10.3390/su14148788

APA StyleAsghar, F., Zahid, A., Hussain, M. I., Asghar, F., Amjad, W., & Kim, J.-T. (2022). A Novel Solution for Optimized Energy Management Systems Comprising an AC/DC Hybrid Microgrid System for Industries. Sustainability, 14(14), 8788. https://doi.org/10.3390/su14148788