Environmental and Economic Implication of Implementation Scale of Sewage Sludge Recycling Systems Considering Carbon Trading Price

Abstract

:1. Introduction

2. Materials and Methods

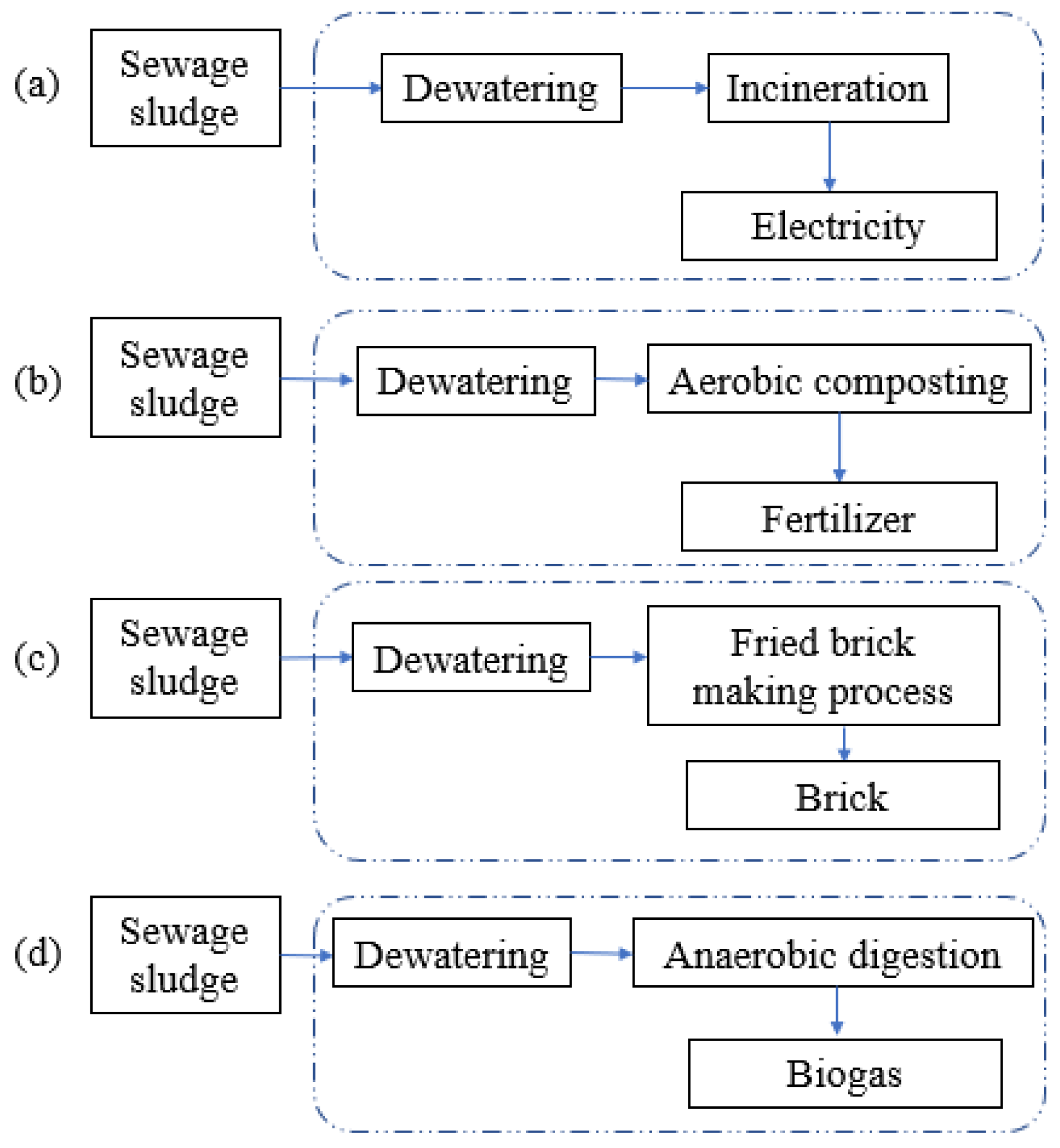

2.1. Comparison Cases

- (1)

- The GHG emissions of the construction phase were not examined as they did not exceed 5% of the total impact [19].

- (2)

- Energy and by-products recovered in the SRTS were sold completely, regardless of market demand.

- (3)

- The energy consumed by SRTS during the dewatering and treatment processes was derived from fossil fuels.

- (4)

- The nitrogen content in the fertilizer generated by sewage sludge was 8%, which compared with the conventional fertilizer [38].

2.2. GHG Emission of Sewage Sludge Recycling System

= EFm,treatment × Qtreatment + EFi,energy × Qenergy + EFn,chemicals × Qchemical

2.3. Total Cost of Sewage Sludge Recycling System

Costoperation = Costenergy + Costchemical + Costcarbon

Costcarbon = GHG × Pcarbon

CostCEQ = GHGavoided × Pcarbon

3. Results

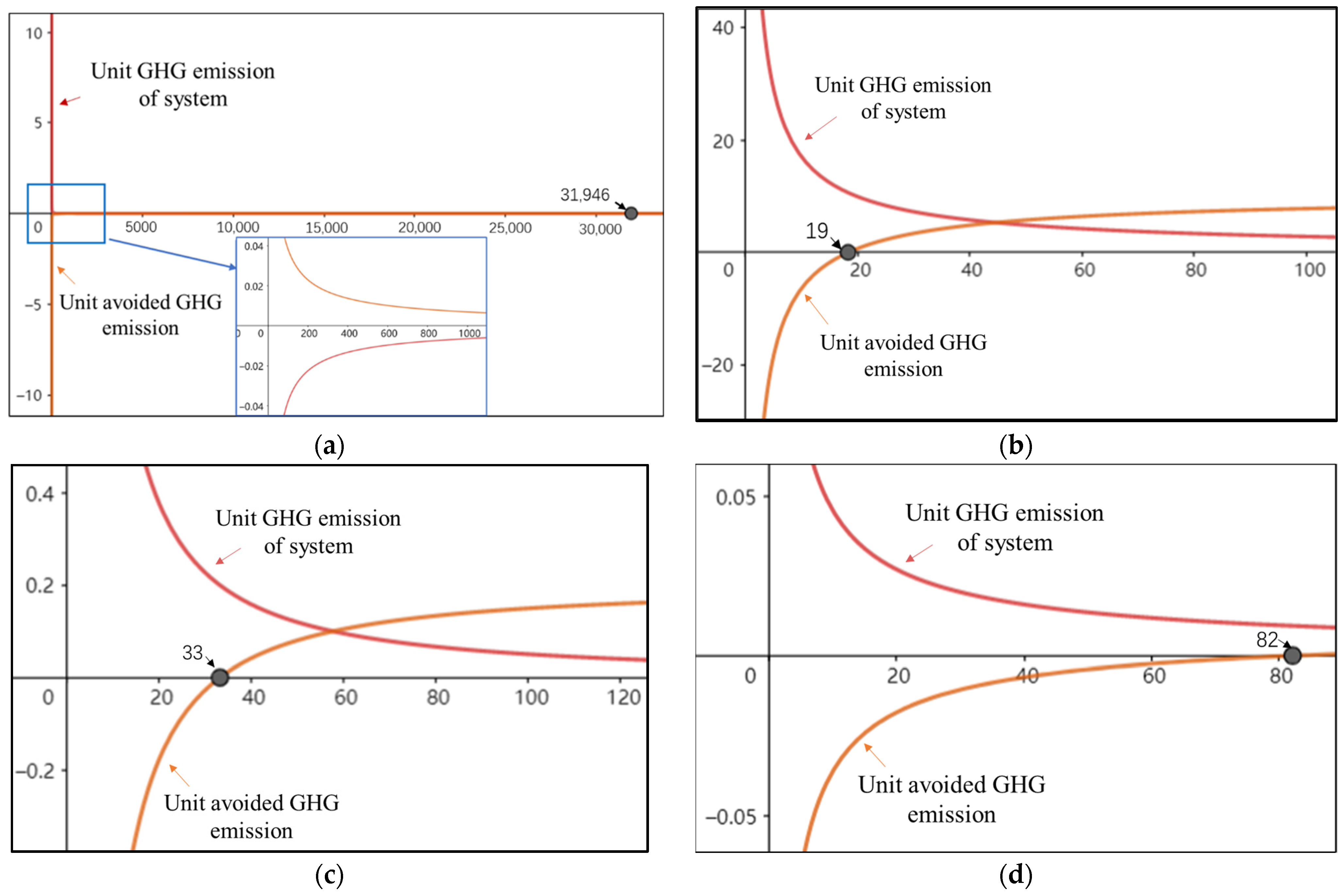

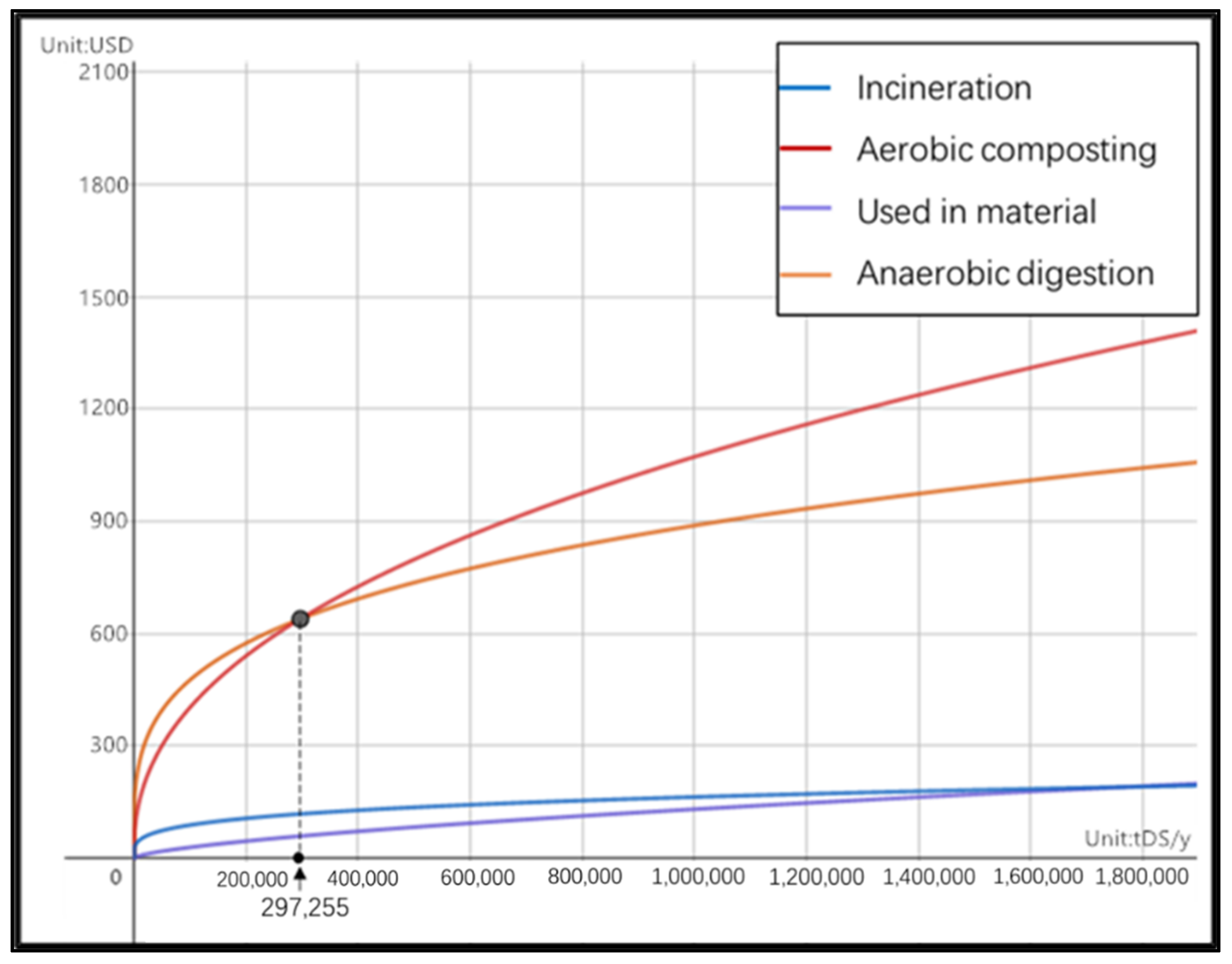

3.1. Impact of Scale on GHG Emission of System

3.2. Impact of Scale on Cost and Benefit of System

3.2.1. The Unit Initial Cost

3.2.2. The Unit Cost of Energy Consumption

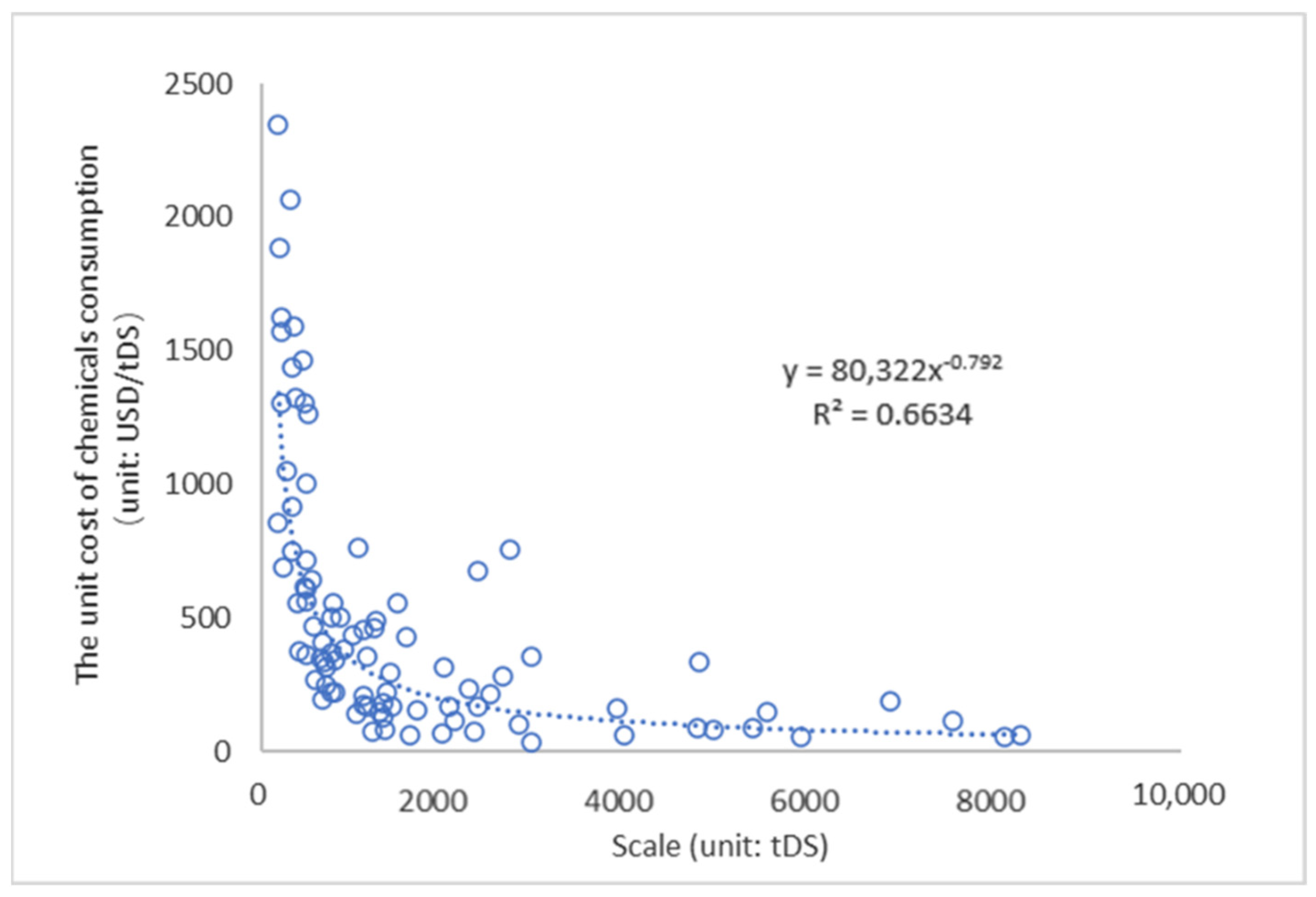

3.2.3. The Unit Cost of Chemical

3.2.4. The Unit Cost of Carbon Emission

3.2.5. Revenue of By-Products

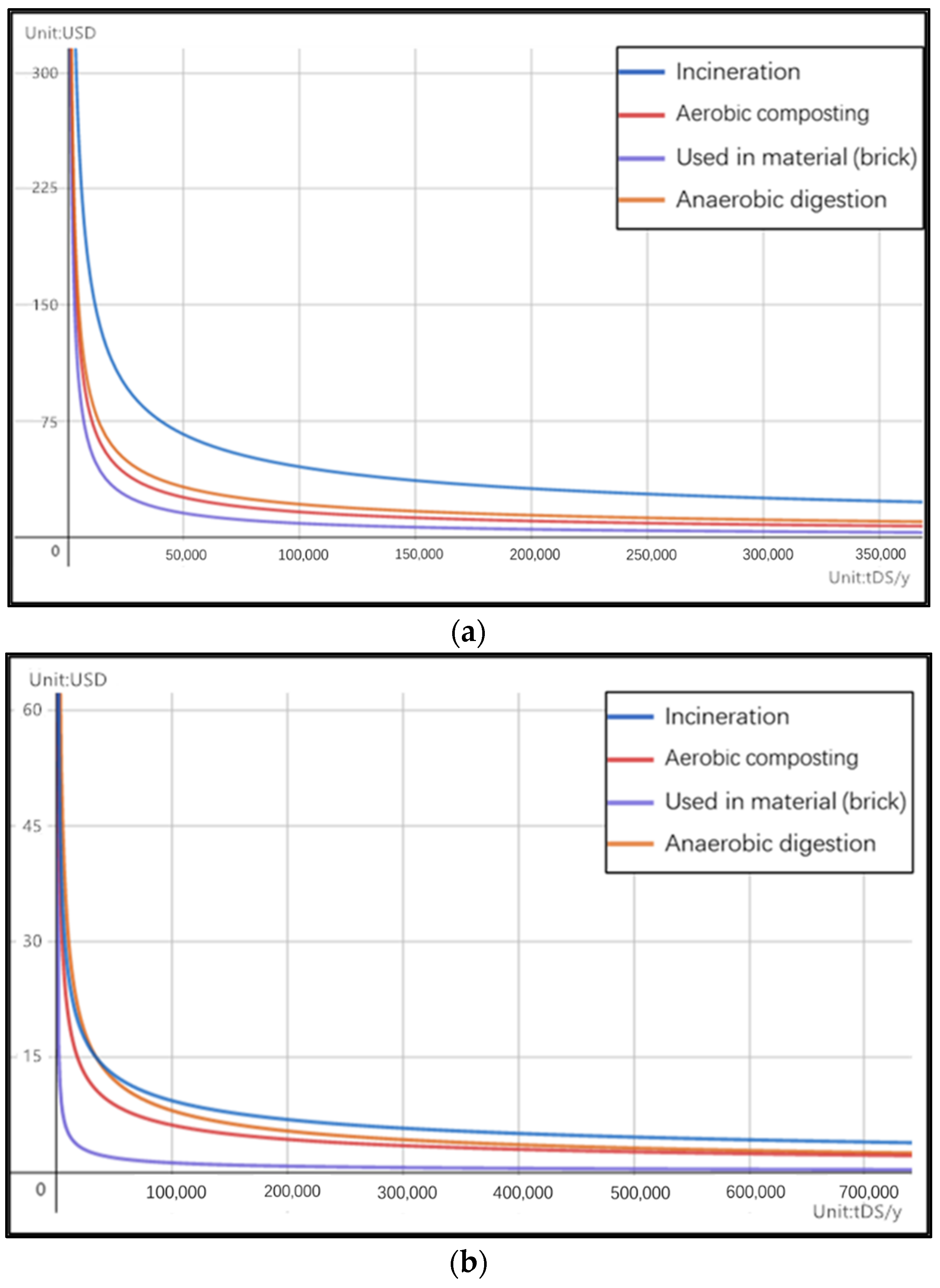

3.2.6. The Total Cost

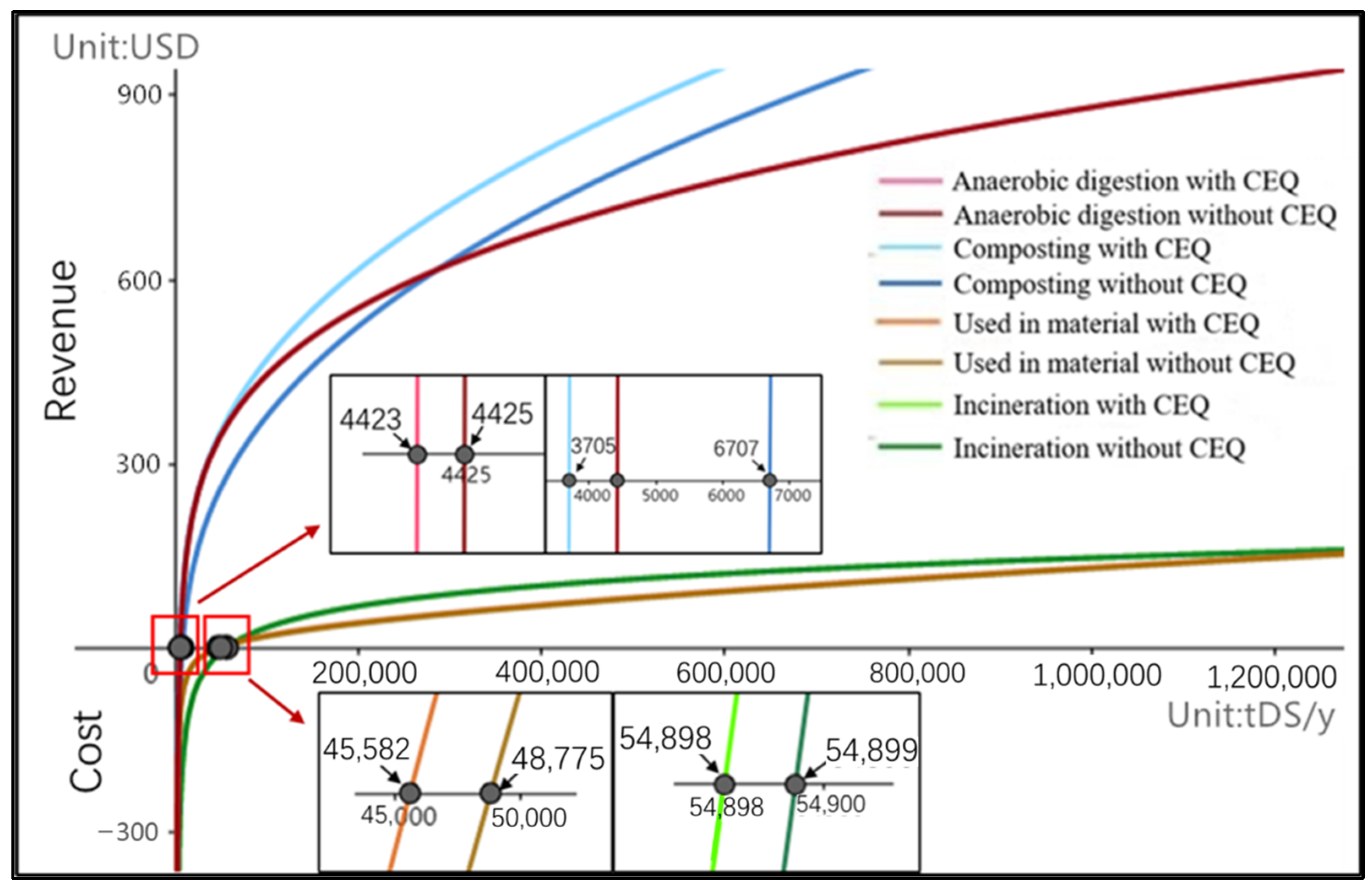

3.3. The Break-Even Implantation of Scale

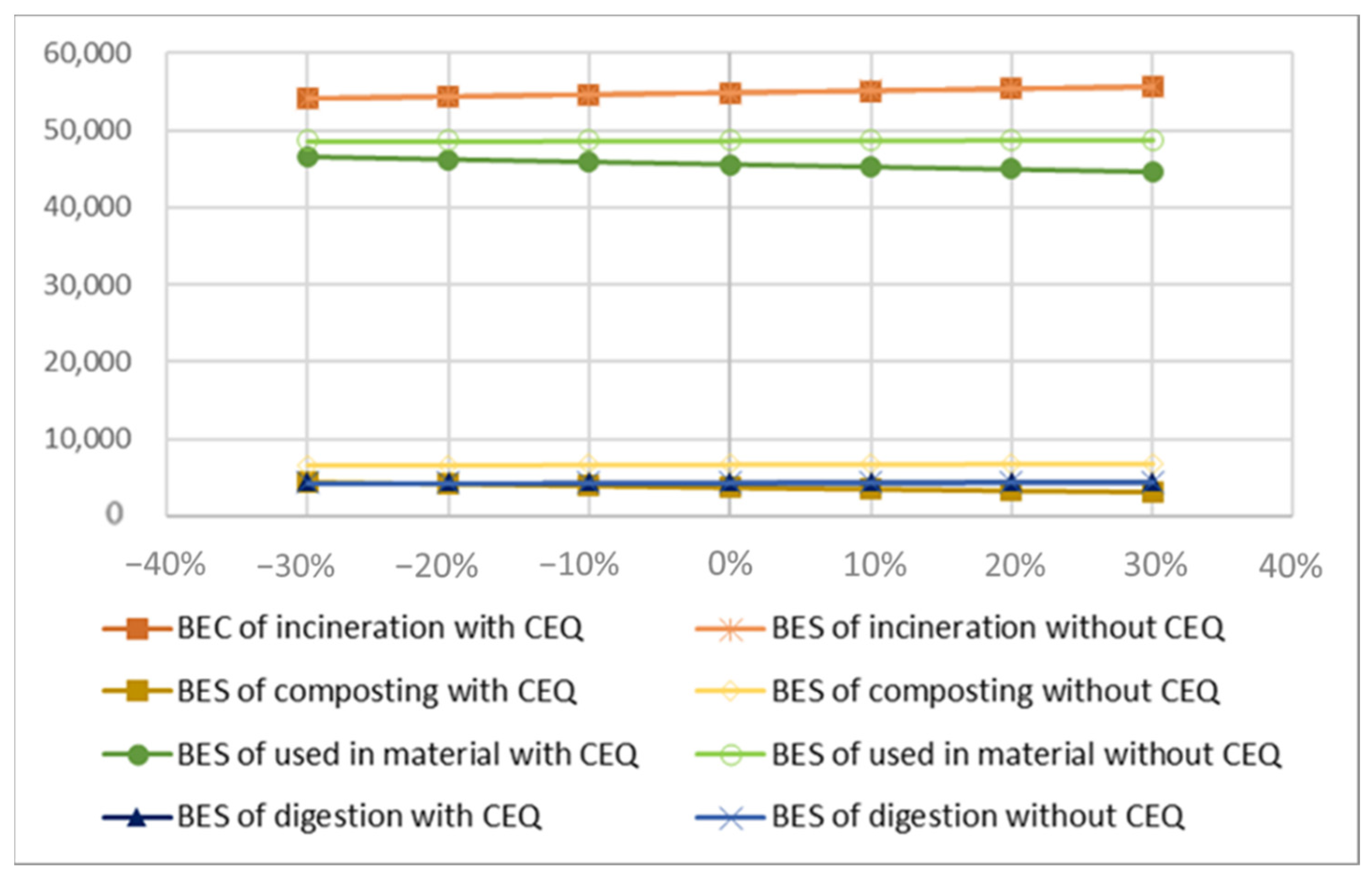

3.4. Sensitivity Analysis

4. Conclusions

- (1)

- The small implementation scale of the GHG emission balance was determined by considering the substitution of energy and resources. The small implementation scales of incineration, aerobic composting, use in building materials (bricks), and anaerobic digestion were 31,946, 19, 33, and 82 t-DS/y, respectively.

- (2)

- When considering the subsidy and substitution of energy and resources, the break-even scales of incineration, aerobic composting, use in building materials (bricks), and anaerobic digestion were 54,899, 6707, 48,775, and 4425 t-DS/y, respectively. The break-even scale was reduced by introducing a carbon trading system into the sewage sludge recycling system.

- (3)

- The optimal technology for different implementation scales was determined. Aerobic composting was a prior technology used when the implementation scale was larger than 285,345 t-DS/y. Anaerobic digestion was prioritized when the implementation scale was between 4425 t-DS/y and 285,345 t-DS/y.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, L.; Zhu, F.; Li, Q.; Xue, C.; Xia, X.; Yu, H.; Zhao, Q.; Jiang, J.; Bai, S. Development, current state and future trends of sludge management in China: Based on exploratory data and CO2-equivaient emissions analysis. Environ. Int. 2020, 144, 106093. [Google Scholar] [CrossRef]

- Luo, H.; Cheng, F.; Yu, B.; Hu, L.; Zhang, J.; Qu, X.; Yang, H.; Luo, Z. Full-scale municipal sludge pyrolysis in China: Design fundamentals, environmental and economic assessments, and future perspectives. Sci. Total Environ. 2021, 795, 148832. [Google Scholar] [CrossRef] [PubMed]

- Elmi, A.; Al-Khaldy, A.; AlOlayan, M. Sewage sludge land application: Balancing act between agronomic benefits and environmental concerns. J. Clean. Prod. 2020, 250, 119512. [Google Scholar] [CrossRef]

- Hospido, A.; Carballa, M.; Moreira, M.; Omil, F.; Lema, J.M.; Feijoo, G. Environmental assessment of anaerobically digested sludge reuse in agriculture: Potential impacts of emerging micropollutants. Water Res. 2010, 44, 3225–3233. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Xu, D.; Feng, P.; Hao, B.; Guo, Y.; Wang, S. Municipal sewage sludge incineration and its air pollution control. J. Clean. Prod. 2021, 295, 126456. [Google Scholar] [CrossRef]

- Chu, L.; He, W. Toxic metals in soil due to the land application of sewage sludge in China: Spatiotemporal variations and influencing factors. Sci. Total Environ. 2021, 757, 143813. [Google Scholar] [CrossRef] [PubMed]

- Rulkens, W. Sewage sludge as a biomass resource for the production of energy: Overview and assessment of the various options. Energy Fuels 2008, 22, 9–15. [Google Scholar] [CrossRef]

- Ding, A.; Zhang, R.; Ngo, H.H.; He, X.; Ma, J.; Nan, J.; Li, G. Life cycle assessment of sewage sludge treatment and disposal based on nutrient and energy recovery: A review. Sci. Total Environ. 2021, 769, 144451. [Google Scholar] [CrossRef]

- Xiao, L.; Lin, T.; Wang, Y.; Ye, Z.; Liao, J. Comparative life cycle assessment of sludge management: A case study of Xiamen, China. J. Clean. Prod. 2018, 192, 354–363. [Google Scholar]

- Hong, J.; Hong, J.M.; Otaki, M.; Jolliet, O. Environmental and economic life cycle assessment for sewage sludge treatment processes in Japan. Waste Manag. 2009, 29, 696–703. [Google Scholar] [CrossRef]

- Cydzik-Kwiatkowska, A.; Bernat, K.; Zielinska, M.; Gusiatin, M.Z.; Wojnowska-Baryla, I.; Kulikowska, D. Valorization of full-scale waste aerobic granular sludge for biogas production and the characteristics of the digestate. Chemosphere 2022, 303 Pt 2, 135167. [Google Scholar] [CrossRef] [PubMed]

- Li, L. “Green” effects of hybrid actors through carbon trading: Cases in Beijing. Glob. Transit. Proc. 2020, 1, 13–22. [Google Scholar] [CrossRef]

- Huang, Q.; Xu, J. Bi-level multi-objective programming approach for carbon emission quota allocation towards co-combustion of coal and sewage sludge. Energy 2020, 211, 118729. [Google Scholar] [CrossRef]

- Chen, W.; Liu, J.; Zhu, B.; Shi, M.; Zhao, S.; He, M.; Yan, P.; Fang, F.; Guo, J.; Li, W.; et al. The GHG mitigation opportunity of sludge management in China. Environ. Res. 2022, 212 Pt C, 113284. [Google Scholar] [CrossRef]

- Wang, K.; Nakakubo, T. Strategy for introducing sewage sludge energy utilization systems at sewage treatment plants in large cities in Japan: A comparative assessment. J. Clean. Prod. 2021, 316, 128282. [Google Scholar] [CrossRef]

- Kumar, L.R.; Yellapu, S.K.; Tyagi, R.D.; Drogui, P. Cost, energy and GHG emission assessment for microbial biodiesel production through valorization of municipal sludge and crude glycerol. Bioresour. Technol. 2020, 297, 122404. [Google Scholar] [CrossRef]

- Mydland, Ø.; Haugom, E.; Lien, G. Economies of scale in Norwegian electricity distribution: A quantile regression approach. Appl. Econ. 2018, 50, 4360–4372. [Google Scholar] [CrossRef]

- Fragkias, M.; Lobo, J.; Strumsky, D.; Seto, K.C. Does Size Matter? Scaling of CO2 Emissions and U.S. Urban Areas. PLoS ONE 2013, 8, e64727. [Google Scholar] [CrossRef]

- Liu, B.B.; Wei, Q.; Zhang, B.; Bi, J. Life cycle GHG emissions of sewage sludge treatment and disposal options in Tai Lake Watershed, China. Sci. Total Environ. 2013, 447, 361–369. [Google Scholar] [CrossRef]

- Lanko, I.; Laura, F.; Marianna, G.; Vladimir, T.; John, A.P.; Pavel, J.; Ivet, F. Life Cycle Assessment of the Mesophilic, Thermophilic, and Temperature-Phased Anaerobic Digestion of Sewage Sludge. Water 2020, 12, 3140. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Li, S.; Bai, Z.; Ma, L. Advanced composting technologies promotes environmental benefits and eco-efficiency: A life cycle assessment. Bioresour. Technol. 2022, 346, 126576. [Google Scholar] [CrossRef] [PubMed]

- Alyaseri, I.; Zhou, J. Towards better environmental performance of wastewater sludge treatment using endpoint approach in LCA methodology. Heliyon 2017, 3, e00268. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rand, T.; Haukohl, J.; Marxen, U. Municipal Solid Waste Incineration: A Decision Maker’s Guide (English); World Bank Group: Washington, DC, USA, 2000; Available online: http://documents.worldbank.org/curated/en/206371468740203078/Municipal-solid-waste-incineration-a-decision-makers-guide (accessed on 4 July 2022).

- Burnett, S. The comparative economics of incineration. J. Waste Manag. Resour. Recovery 1994, 1, 19–24. [Google Scholar]

- Liu, Y.; Lin, R.; Ren, J. Developing a life cycle composite footprint index for sustainability prioritization of sludge-to-energy alternatives. J. Clean. Prod. 2021, 281, 124885. [Google Scholar] [CrossRef]

- Su, D.; Wang, X.; Liu, Y. Three typical processes of electricity generation by sewage sludge. Environ. Prot. Sci. 2009, 35, 54–57. [Google Scholar]

- Economopoulos, A. Technoeconomic aspects of alternative municipal solid wastes treatment methods. Waste Manag. 2010, 30, 707–715. [Google Scholar] [CrossRef]

- Pandyaswargo, A.; Premakumara, D. Financial sustainability of modern composting: The economically optimal scale for municipal waste composting plant in developing Asia. Int. J. Recycl. Org. Waste Agric. 2014, 3, 4. [Google Scholar] [CrossRef] [Green Version]

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Seleiman, M.F.; Santanen, A.; Mäkelä, P.S.A. Recycling sludge on cropland as fertilizer—Advantages and risks. Resour. Conserv. Recycl. 2020, 155, 104647. [Google Scholar] [CrossRef]

- Subrahmanya, M.H.B. Energy intensity and economic performance in small scale bricks and foundry clusters in India: Does energy intensity matter? Energy Policy 2006, 34, 489–497. [Google Scholar] [CrossRef]

- Weng, C.-H.; Lin, D.-F.; Chiang, P.-C. Utilization of sludge as brick materials. Adv. Environ. Res. 2003, 7, 679–685. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Recycled wastewater treatment plant sludge as a construction material additive to ecological lightweight earth bricks. Clean. Eng. Technol. 2021, 2, 100050. [Google Scholar] [CrossRef]

- Okuno, N.; Ishikawa, Y.; Shimizu, A.; Yoshida, M. Utilization of sludge in building material. Water Sci. Technol. 2004, 49, 225–232. [Google Scholar] [CrossRef]

- Rapport, J.; Zhang, R.; Williams, R.; Jenkins, B.M. Anaerobic Digestion technologies for the treatment of Municipal Solid Waste. Int. J. Environ. Waste Manag. 2011, 9, 100–122. [Google Scholar] [CrossRef]

- Amigun, B.; von Blottnitz, H. Capacity-cost and location-cost analyses for biogas plants in Africa. Resour. Conserv. Recycl. 2010, 55, 63–73. [Google Scholar] [CrossRef]

- Di Capua, F.; Spasiano, D.; Giordano, A.; Adani, F.; Fratino, U.; Pirozzi, F.; Esposito, G. High-solid anaerobic digestion of sewage sludge: Challenges and opportunities. Appl. Energy 2020, 278, 115608. [Google Scholar] [CrossRef]

- Song, D.; Hou, S.; Wang, X.; Liang, G.; Zhou, W. Nutrient resource quantity of crop straw and its potential of substituting. J. Plant Nutr. Fertil. 2018, 24, 1–21. (In Chinese) [Google Scholar]

- Kainou, K. Evaluation and Verification of CO2 Emissions Originating from Limestone Using Input-Output Tables and Mining and Industry Statistics. (In Japanese). Available online: https://www.rieti.go.jp/jp/publications/dp/10j026.pdf (accessed on 4 July 2022).

- Ministry of the Environment of Japan (MINE). Global Warming Countermeasure Manual for Sewerage. (In Japanese). Available online: https://www.env.go.jp/earth/ondanka/gel/ghg-guideline/files/manual_sewer_201803.pdf (accessed on 4 July 2022).

- Chinese Academy of Environmental Plan (CAEP). China Products Carbon Footprint Factors Database. (In Chinese). Available online: http://www.caep.org.cn/sy/tdftzhyjzx/zxdt/202201/t20220105_966202.shtml (accessed on 4 July 2022).

- Piippo, S.; Lauronen, M.; Postila, H. Greenhouse gas emissions from different sewage sludge treatment methods in north. J. Clean. Prod. 2018, 177, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Song, C.; Yuan, R. CO2 emissions from electricity generation in China during 1997–2040: The roles of energy transition and thermal power generation efficiency. Sci. Total Environ. 2021, 773, 145026. [Google Scholar] [CrossRef]

- Peng, X.; Tao, X.; Zhang, H.; Chen, J.; Feng, K. CO2 emissions from the electricity sector during China’s economic transition: From the production to the consumption perspective. Sustain. Prod. Consum. 2021, 27, 1010–1020. [Google Scholar] [CrossRef]

- Da Cunha, A.P.; Cammarota, M.; Volschan Jr, I. Anaerobic co-digestion of sewage sludge and food waste: Effect of pre-fermentation of food waste in bench- and pilot-scale digesters. Bioresour. Technol. Rep. 2021, 15, 100707. [Google Scholar] [CrossRef]

- Deng, L.; Liu, Y.; Zheng, D.; Wang, L.; Pu, X.; Song, L.; Wang, Z.; Lei, Y.; Chen, Z.; Long, Y. Application and development of biogas technology for the treatment of waste in China. Renew. Sustain. Energy Rev. 2017, 70, 845–851. [Google Scholar] [CrossRef]

- Han, W.; Jin, P.; Chen, D.; Liu, X.; Jin, H.; Wang, R.; Liu, Y. Resource reclamation of municipal sewage sludge based on local conditions: A case study in Xi’an, China. J. Clean. Prod. 2021, 316, 128189. [Google Scholar] [CrossRef]

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| Energy 2 | |||||

| Heavy oil | tCO2eq/kL | 2.71 | LPG | tCO2eq/kL | 3 |

| Coal oil | tCO2eq/kL | 2.49 | Disel | tCO2eq/kL | 2.58 |

| Gasoline | tCO2eq/kL | 2.32 | Coal | tCO2eq/t | 2.33 |

| Electricity | tCO2eq/kwh | 0.000433 | Natural gas | tCO2eq/103Nm3 | 2.62 |

| Chemicals 1,2 | |||||

| Ferrous chloride | tCO2eq/t | 0.32 | Poly-ferrous sulfate | tCO2eq/t | 0.0308 |

| Ca(OH)2 | tCO2eq/t | 0.45 | CaO | tCO2eq/t | 0.75 |

| PAM | tCO2eq/t | 6.5 | Poly-aluminum chloride | tCO2eq/t | 0.41 |

| H2O2 | tCO2eq/t | 0.39 | |||

| Sludge 2 | |||||

| Incineration | tCH4/wet-t | 0.0000097 | Composting | tCH4/wet-t | 0.004 |

| tN2O/wet-t | 0.0003 | tN2O/wet-t | 0.0006042 | ||

| Production 3 | |||||

| Electricity | kgCO2eq/kwh | 0.53 | Nitrogen Fertilizer | tCO2eq/t | 10.63 |

| Clay Brick | tCO2eq/t | 0.2 | Biogas | kgCO2eq/t | 9.35 |

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| Energy | |||||

| Heavy oil | USD/L | 0.71 | LPG | USD/m3 | 1.87 |

| Coal oil | USD/L | 0.42 | Disel | USD/L | 1.03 |

| Gasoline | USD/L | 1.05 | Coal | USD/t | 253.23 |

| Electricity | USD/kwh | 0.095 | Natural gas | USD/m3 | 0.39 |

| Chemicals | |||||

| Ferrous chloride | USD/t | 74.63 | Poly-ferrous sulfate | USD/t | 134.33 |

| Ca(OH)2 | USD/t | 74.63 | CaO | USD/t | 67.16 |

| Polymer flocculant (PAM) | USD/t | 895.52 | Poly-aluminum chloride | USD/t | 179.10 |

| H2O2 | USD/t | 111.94 | CaCO3 | USD/t | 59.70 |

| NaOH | USD/t | 223.88 | |||

| By-production | |||||

| Clay Brick | USD/piece | 0.075 | Fertilizer | USD/t | 344.78 |

| Electricity | USD/kwh | 0.097 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liang, Z.; Matsumoto, T.; Zhang, T. Environmental and Economic Implication of Implementation Scale of Sewage Sludge Recycling Systems Considering Carbon Trading Price. Sustainability 2022, 14, 8684. https://doi.org/10.3390/su14148684

Zhang J, Liang Z, Matsumoto T, Zhang T. Environmental and Economic Implication of Implementation Scale of Sewage Sludge Recycling Systems Considering Carbon Trading Price. Sustainability. 2022; 14(14):8684. https://doi.org/10.3390/su14148684

Chicago/Turabian StyleZhang, Jiawen, Zhiyi Liang, Toru Matsumoto, and Tiejia Zhang. 2022. "Environmental and Economic Implication of Implementation Scale of Sewage Sludge Recycling Systems Considering Carbon Trading Price" Sustainability 14, no. 14: 8684. https://doi.org/10.3390/su14148684

APA StyleZhang, J., Liang, Z., Matsumoto, T., & Zhang, T. (2022). Environmental and Economic Implication of Implementation Scale of Sewage Sludge Recycling Systems Considering Carbon Trading Price. Sustainability, 14(14), 8684. https://doi.org/10.3390/su14148684